Abstract

The aim of the research was to compare the content of tobacco smoke obtained from five cigarette brands, 3R4F reference cigarette, and emission derived from IQOS tobacco heating system (Technical regulations of Customs Union “Technical regulations for tobacco products” (TP TC 035/2014) http://www.eurasiancommission.org/ru/act/texnreg/deptexreg/tr/Pages/tabac.aspx Accessed 5 August 2021). Constituents of the IQOS tobacco heating system stick aerosol, mainstream smoke of five commercial cigarettes, and 3R4F reference cigarette smoke were tested. The list of toxicants that are relevant to human health risks and appear on lists of priority toxicants in cigarette smoke was selected. Nicotine, carbon monoxide, 1,3-butadiene, benzene, and benzo[a]pyrene contents were measured using gas chromatography/mass spectrometry methods. Most of the analyzed compounds were detected in the IQOS mainstream aerosol at a significantly lower level than in smoke of the 3R4F reference cigarette and commercial cigarettes. The nicotine content decreased in IQOS mainstream aerosol by 33.7–40.3% compared to 3R4F reference cigarettes and by 42.7% compared to cigarette brands. The yields per puff were similar to the data published by the PMI tobacco company (Schaller et al. in Regul Toxicol Pharmacol 81:S27-S47, 11) and independent laboratories (Li et al. in Nicotine Tob Res 21:111–118, 12; Mallock et al. in Arch Toxicol 92: 2145, 13). Our results showed that the content of priority toxic compounds indicated in the WHO/FDA and Health Canada lists (carbon monoxide, 1,3-butadiene, benzene, and benzo[a]pyrene) and nicotine was significantly lower in case of IQOS tobacco stick aerosol than in the smoke of the 3R4F reference and commercial cigarettes. So our study represents one of the few independent studies on THS products showing similar data on aerosol emissions to those showed by the tobacco industry.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Cigarette smoking possesses a severe world heath challenge due to its ability to cause serious diseases including oncological, cardiovascular, and bronchopulmonary diseases. Although smoking prevalence has declined over the last decade, tobacco products continue to be consumed on a global scale. The actual worldwide strategy of tobacco harm reduction represents the necessity in less harmful products available to smokers who would otherwise continue smoking.

Innovative products which introduce alternative to conventional smoking methods for nicotine consumption are now becoming widespread throughout the world. These products differ from traditional smoking products (cigarettes, cigars, etc.) by the way of aerosol formation, as they are heated without combustion process.

Different types of nicotine-containing products are widely available on the market. To separate them as a special category, the following principles can be utilized:

-

Presence of nicotine

-

Consumer inhales nicotine-containing aerosol

-

Absence of combustion

-

Novel nicotine delivery system

Corresponding to the WHO Framework Convention on Tobacco Control, products that heat rather than burn products are claimed to be less harmful than traditional cigarettes, although these claims of risk reduction are based on industry-funded studies. Independent studies should be conducted to investigate these claims. All new and emerging tobacco products should be regulated under the WHO FCTC. This should include all novel devices which can be used for tobacco consumption and are not classified as electronic cigarettes. When regulation under the WHO FCTC is not feasible, novel products should be monitored to determine their health effects [1].

Tobacco heating system (THS) is the device that electrically heats a tobacco stick to deliver nicotine-containing aerosol.

THS is composed of three distinct components: a tobacco-containing product called tobacco stick (later in text “tobacco stick” or “stick”); a holder, which heats the tobacco to produce the aerosol; and a charger that is used to recharge the holder.

The chemical composition of tobacco stick aerosol represents reduced average of harmful and potentially harmful constituents (HPHCs) compared to 3R4F reference cigarette [2] smoke.

The aim of this study was to measure the level of nicotine and some other toxic compounds in THS aerosol, in 3R4F reference cigarette smoke, and in smoke of five best-selling cigarette brands in the Russian Federation. All tobacco samples were consumed using a smoking machine under ISO intense smoking protocols. The results were calculated per one piece of product.

2 Materials and Methods

2.1 Test Product Samples

Tobacco heating system (THS) is the device that electrically heats a tobacco stick that contains corrugated reconstituted tobacco. To operate the THS product, the customer inserts the tobacco stick into the holder and turns the device on. This initiates the heating process of a special blade inserted into the tobacco.

Due to absence of combustion, the composition represents the reduced average of HPHCs.

A tobacco stick (Fig. 1) is composed of:

-

Tobacco filler: reconstituted tobacco, glycerol, water, fibers, guar gum, propylene glycol, ethanol, and flavorings.

-

Acetate tube

-

Filter from corrugated film

-

Filter-mouthpiece

-

Filter plug wrap

-

Tipping paper

-

Binding compounds

-

Flavorings

The data about tested samples is collected in Table 1.

Reference cigarettes are produced according to international standard ISO 16,055–2012 [3]. Utilizing this standard, state standard GOST 31,629–2012 was elaborated at FGBNU VNIITTI [2].

Reference cigarettes were manufactured from thoroughly mixed tobacco of one type without addition of expanded stem, reconstituted tobacco, humectants, and flavorings. Manufactured batch is produced under strict manufacturing control, and batch quantity should be sufficient for at least 2 years. Non-tobacco materials such as cigarette paper, acetate fiber, and tipping paper utilized for reference cigarette production are also taken from one batch.

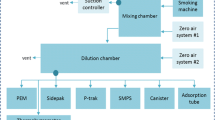

2.2 Smoke and Aerosol Collection

Standard methods were used for nicotine and carbon monoxide maintenance measurements in cigarettes’ smoke [4].

Conditioning of test samples was performed according to [5] for 48 h under 22 ± 1 °C and relative humidity 60 ± 3%. THS aerosol and cigarette smoke were generated using the 20-channel linear Cerulean SM450 (UK) smoking machine under the following conditions: temperature of 22 ± 2 °C, relative humidity of 60% ± 5, and air flow in the smoking zone of the machine 200 ± 50 mm/s. Two smoking regimens (ISO and ISO intense) were applied. Detailed parameters of each regime are presented in the Table 3.

The holder was charged by a charger before consuming the tobacco stick. After charging the holders, part of the tobacco stick was then inserted into holders. Before the experiment, special fiberglass filters (ISO 3308) had been conditioned for not less than 12 h and weighted to an accuracy of 0.1 mg. Holders with sticks and cigarettes were inserted into fiberglass filter holders (ISO 4387/ISO 3308) until the filter end reached the disk with a hole which was located inside the fiberglass filter holder (for 9 mm depth) as shown in Fig. 2. Due to water absorption by fiberglass filter and solvents, each smoking cycle was carried out with one not smoked fiberglass filter holder.

The holder was switched on 2 s before starting. The visual indicator of the holder started flashing green light, informing about starting of stick heating process to optimal temperature. When green indicator light became permanent, the aerosol collecting began and lasted approximately for 6 min (about 11–12 puffs). Orange visual indicator informed about the end of smoking process.

2.3 Smoke and Aerosol Analysis

At the end of the process, the holder was disconnected from fiberglass filter holder and its front and back holes were secured with special caps. Then, the fiberglass filter holder was weighted to an accuracy of 0.1 mg. The back side of each fiberglass filter was checked for absence of spots and water in order to exclude the overload or defective fiberglass filters. In case of presence of spots or water, the filter was disposed and smoking procedure was repeated.

Collecting gaseous benzene and 1,3-butadiene was carried utilizing two special bubblers with 10 ml of methanol each arranged in series and immersed into Dewar flasks. The first flask contained ice and water and the second, a mix of dry ice and isopropanol (temperature, − 70 °C).

Measurements of nicotine and water content in condensate were carried out using gas chromatography Agilent 7890 B system (USA) with thermal conduction and flame-ionization detectors [6,7,8]. Carbon monoxide determination was carried on non-particulate infrared gas analyzer built-in smoking machine. Measurements of benzene, 1,3-butadiene, and 3,4-benzo[a]pyrene content were carried out using gas chromatography with mass spectrometry Shimadzu GCMS-QPUltraNCI (Japan) [9, 10].

2.4 Statistical Analysis

Results of the analytes’ quantification are expressed per piece of product.

For all the analytes, the arithmetic mean and the standard deviation (95% confidence interval) are provided.

Statistical analysis was performed using Microsoft Office Excel Software (2011).

3 Results

3.1 Measurement of Nicotine, Total Particulate Matter (TPM), Carbon Monoxide, Benzo[a]pyrene, Benzene, and 1,3-Butadiene Concentration in THS Aerosol, 3R4F Reference Cigarette Smoke, and Smoke of Five Best-selling Cigarette Brands in Russian Federation

In this study, we analyzed the composition of tobacco stick aerosol compared to aerosol of 3R4F reference cigarettes and five commercial cigarettes. A quantitative comparison of carbon monoxide, nicotine, 1,3-butadiene, benzene, and benzo[a]pyrene contents in tobacco stick aerosols, 3R4F reference cigarettes, and five commercial cigarettes smoked under ISO intense smoking protocols and calculated per piece of product is presented below.

Carbon monoxide content decreased by 96–98% in the case of tobacco stick aerosol compared to 3R4F reference cigarettes and most popular cigarette brands in the Russian Federation (Fig. 3).

Nicotine content decreased by 33.7–40.3% in the case of tobacco stick aerosol compared to 3R4F reference cigarettes and by 42.7% compared to the most popular cigarette brands in the Russian Federation (Fig. 4).

1,3-Butadiene content decreased in the case of tobacco sticks aerosol by more than 99% comparing to 3R4F reference cigarettes and most popular cigarette brands in the Russian Federation (Fig. 5).

Benzene content decreased by more than 99% in case of tobacco sticks aerosol comparing to 3R4F reference cigarettes and most popular cigarette brands in the Russian Federation (Fig. 6).

Benzo[a]pyrene content decreased by 90–94% in case of tobacco sticks aerosol compared to 3R4F reference cigarettes and the most popular cigarette brands in the Russian Federation (Fig. 7).

Extremely low concentrations of carbon monoxide (0.5–0.7 mg per piece of product or 2% from 3R4F reference cigarette concentration) and other compounds generated after pyrolysis reactions confirm the absence of burning process in the case of tobacco stick. Numerical data for each experiment is presented in Supplementary Data (STab.1).

4 Discussion

Heated tobacco products significantly differ from traditional tobacco products since they do not undergo combustion process and do not produce smoke. Instead, if a smoke customer inhales a nicotine-containing aerosol, it was claimed by the manufacturers to contain significantly lower levels of harmful and potentially harmful constituents.

This reduction was confirmed by several independent laboratories for selected compounds. Carbon monoxide, nicotine, 1,3-butadiene, benzene, and benzo[a]pyrene production found in the present study are in line with the results of studies performed by tobacco companies [11] and independent laboratories [12, 13].

We have observed substantial reductions of yields of the analyzed compounds in heating tobacco product aerosol as compared to 3R4F cigarette smoke and five best-selling cigarette brands in the Russian Federation.

5 Conclusion

The chemical composition of aerosol of novel tobacco- and nicotine-containing products requires a systematic study, being a starting point in assessing the level of risk to consumers. Carbon monoxide, benzene, and benzo[a]pyrene,1,3-butadiene are included in the lists of priority tobacco smoke toxicants by the WHO and various public health organizations, so their quantification in aerosols of novel products is an important step in determining both the absolute and relative (compared to cigarette smoking) product risks, taking into account the mode of consumption and design features of these products [1].

The results of the present study demonstrate that the levels of carbon monoxide, benzene, and benzo[a]pyrene,1,3-butadiene in the aerosol of the tested samples of heated tobacco product are significantly (by 90–99%) lower than those in 3R4F cigarette smoke, as well as compared to commercially available cigarettes. Nicotine content decreased by 33.7–40.3% compared to reference cigarettes 3R4F and by 42.7% compared to conventional cigarettes.

The applied analytical methods demonstrated good intra-laboratory reproducibility, and the obtained results are in line with findings from the studies conducted by product manufacturers and independent laboratories.

Availability of data and material (data transparency)

None.

Code availability (software application or custom code)

None.

References

Conference of the Parties to the WHO Framework Convention on Tobacco Control: Further development of the partial guidelines for implementation of Articles 9 and 10 of the WHO FCTC; FCTC/COP/7/9 12 July 2016.

GOST 31629–2012 (ISO 16055:2003) "Tobacco and tobacco products. Reference sample. Demands and utilization”.

Piade, J. J., Wajrock, S., Jaccard, G., & Janeke, G. (2013). Formation of mainstream cigarette smoke constituents prioritized by the World Health Organization – yield patterns observed in market surveys, clustering and inverse correlations. Food and Chemical Toxicology, 55, 329–347. https://doi.org/10.1016/j.fct.2013.01.016

GOST ISO 3308–2015 “Laboratory machine for smoking cigarettes (smoking machine). Definitions and standard conditions”;

GOST ISO 3402–2003 “Tobacco and tobacco products. Ambient air for conditioning and testing”

GOST 30571–2003 (ISO 4387:2000) “Cigarettes. Determination of TPM and NFDPM (tar) in cigarette smoke with laboratory smoking machine”;

GOST 30570–2015 (ISO 10315:2013) “Cigarettes. Determination of nicotine in smoke condensate. Method of gas chromatography”;

GOST 30622.1–2003 (ISO 10362–1:99), “Cigarettes. Determination of water content in smoke condensate. Method of gas chromatography”;

Methods and protocols “Analysis of volatiles and semi-volatiles in Platform 1 aerosol” https://www.pmiscience.com/library/publication/analysis-of-volatiles-and-semi-volatiles-in-platform-1-aerosol Accessed 5 August 2021

Methods and protocols “Analysis of 12 polycyclic aromatic hydrocarbons in Platform 1 aerosol” https://www.pmiscience.com/library/publication/analysis-of-12-polycyclic-aromatic-hydrocarbons-in-ths-aerosol Accessed 5 August 2021

Schaller, J. P., Keller, D., Poget, L., et al. (2016). Evaluation of the tobacco heating system 2.2 Part 2: chemical composition,genotoxicity,cytotoxicity, and physical properties of the aerosol. Regul Toxicol Pharmacol, 81(S2), S27–S47. https://doi.org/10.1016/j.yrtph.2016.10.001

Li, X., Luo, Y., Jiang, X., et al. (2019). Chemical analysis and simulated pyrolysis of tobacco heating system 22. compared to conventional cigarettes. Nicotine Tob Res, 21(1), 111–118. https://doi.org/10.1093/ntr/nty005

Mallock, N., Boss, L., Burk, R., et al. (2018). Levels of selected analytes in the emissions of “heat not burn” tobacco products that are relevant to assess human health risks. Archives of Toxicology, 92, 2145. https://doi.org/10.1007/s00204-018-2215-y

Author information

Authors and Affiliations

Contributions

None.

Corresponding author

Ethics declarations

Ethics approval (include appropriate approvals or waivers)

None.

Consent to participate (include appropriate statements)

None.

Consent for publication (include appropriate statements)

None.

Conflict of Interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Informed Consent

None.

Financial interests

• The authors have no relevant financial or non-financial interests to disclose.

• All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

• The authors have no financial or proprietary interests in any material discussed in this article.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Perezhogina, T.A., Gnuchikh, E.V., Faizullin, R.I. et al. Investigation of Volatile Organic Compounds and Benzo[a]pyrene Contents in the Aerosols of Cigarettes and IQOS Tobacco Heating System Using High-Performance Gas Chromatography/Mass Spectrometry. BioNanoSci. 11, 939–945 (2021). https://doi.org/10.1007/s12668-021-00898-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12668-021-00898-3