Abstract

Million tons of domestic wastewater treatment plant sludge is produced in each year. Since it increases the volume of the landfill area, the treatment of sludge with vermicomposting is an attractive approach. Vermicomposting of domestic wastewater treatment plant sludge with yard waste was carried out using Eisenia Fetida for 60 days. The effects of Bio-One™ (liquid microbial fertilizer), additives (different mature vermicomposts), recirculation and ventilation on decomposition rate of composting were investigated for composting mixtures. Temperature, moisture content (MC), organic matter (OM), pH, electrical conductivity (EC), total carbon (TOC) and total kjeldahl nitrogen (TKN) were monitored during the composting process. In addition, phototoxicity level and worm number changes of the mixtures were determined. C/N and OM value decreases ranged between 27.56–63.77% and 15.15–43.12%, respectively. It was concluded that vermicomposting process was faster than traditional composting process in terms of decomposition of organic matter. The result C/N ratio was more suitable to use it as soil remedial material in vermicomposting process. It has been shown that Bio-One™ addition has a positive effect on the acceleration of the process. It has been found that the process of recirculation some of the leachate formed during the vermicomposting process is an advantageous. It has been determined that mature vermicompost addition is an effective method. The final worm numbers were higher (except ventilation conditions) than the initial. The positive results of the plant growth tests on the final products in all cases may indicate that the products will not cause any toxic effect in the use as soil conditioning material.

Graphic Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

There are many studies on vermicomposting of sewage sludge. But, the effect of operating parameters on vermicomposting of sewage sludge has not been investigated before. Especially, the effects of Bio-One™ (liquid microbial fertilizer), additives (different mature vermicomposts), recirculation and ventilation on decomposition rate of composting were investigated for composting mixtures in this study.

Introduction

Among solid waste removal methods, probably composting is the most environmentally friendly one. Composting is a process of decomposition of organic matter by microorganisms, it is a biological recycling procedure. Liu et al. [1] reported that composting is a more acceptable and economical process in developing countries. Due to the physical properties and nutrient content, compost has various advantages. When compost is blended to soil, it is able to ventilate the soil, increase the water retention capacity, increase the organic substance and soil productivity [2].

Vermicomposting is a biological method used to convert organic compounds into humus-like products using worms [3]. Different worm species (Eisenia andrei, Eisenia fetida, Eudrilus eugeniae, Perionyx excavatus and Perionyx sansibaricus) are used in vermicomposting process according to the type of waste, the composting method and ambient conditions [4]. The profile of worm distribution varies with depth. For example, Perionyx excavatus while present in the bottom of the reactor, Eisenia fetida live in the top of reactor. Eisenia fetida is often preferred for vermicomposting since it can adapt to different environmental conditions.

Because worms are able to easily consume all compostable wastes (kitchen wastes, all kind of animal manure, garden wastes etc.), vermicomposting is a sustainable option for sewage sludge management [5]. Sewage sludge must be removed properly, in case of air, soil and water pollution threats [1]. There are a variety of sewage sludge disposal methods that can ensure soil amendment material [6]. When filter press sludge cake is used alone in vermicomposting, dense structure of sludge cake prevents aeration and worm movements. In such a case, bulking agents should be used to eliminate these constraints. Sawdust [7], spent mushroom compost [8], rock dust [9], fly ash [10], biochar [11], corn stalk [12], sugarcane trash [13] and much more organic or inorganic materials can be used as bulking agent. Another bulking agent used in vermicomposting are yard wastes [14,15,16]. Yard wastes can be easily available and also enhance the aeration efficiency and water retention time in the composting system. Garden wastes not only provide these advantages but also cause to increase organic matter and nitrogen content in the composting mixture.

Several operation conditions which affect the efficiency of vermicomposting process should be considered for sustainable application of vermicomposting. One of them is the aeration rate and it can be said it is the main factor influencing the composting process [12]. Productive worm activities is monitored in the composting systems which have effective air circulation and relatively porous media [17]. Another significant parameter is also the moisture content of composting material. Dominiguez and Edwards [18] reported that moisture content should be between 65 and 90% (optimum 85%) to continue microbial activity. While moisture is provided by natural environmental components (such as rain, dew and humidity of air) to compost pile in open space area, leachate recirculation or spray irrigation are used in closed area. Leachate recirculation also allows rapid degradation of the solid waste [19].

Compost additives (basically inoculants, activators or starters) accelerate the composting process. So, composting efficiency can be increased by using compost additives in vermicomposting. Animal manure generally is used as a compost additive to provide bulking agent and to set appropriate media for worm life. The most important advantages of the compost additives are to increase microbial community in the compost pile and seed effect for vermicomposting process. In addition, Hait and Tare [20, 21] emphasized that in case of using mature vermicompost as compost additive, there is no need for an external supplement.

The primarily aim of this study is focused on evaluating the effects of operation conditions in vermicomposting of municipal wastewater sewage sludge and yard wastes. Bio-One™ addition, leachate recirculation, mature vermicompost addition and ventilation of vermicompost reactors were selected as operation condition parameters. Effects of those parameters on vermicomposting performance were investigated in terms of C/N ratio, organic matter, pH, EC and phytotoxicity.

Materials and Methods

Composting Materials

Sewage sludge was taken from Denizli (Turkey) Municipal Wastewater Treatment Plant after thickening process. Kaushik and Garg [22] stated that treatment plant sludge should be dried using solar energy to reduce toxic volatile gases for composting microorganisms. So, before composting, sewage sludge was dried and mixed in an open area for 15 days. Yard waste containing grass clippings, leaves and branches were obtained from Denizli Municipal Composting Plant. The chemical characteristics of sludge and yard wastes are given in Table 1.

Due to their high growth and reproduction rate, Eisenia fetida earthworms were used in the experimental study [23]. E. fetida earthworms were purchased from a commercial supplier and saved in the laboratory for adaptation and acclimation to composting material. E. fetida earthworms normally were cultivated in cow dung in the commercial supplier plant. For adaptation of E. fetida earthworms were fed with yard waste, cow dung and sludge. E. fetida earthworms adopted by these types of compost material were used in the experimental study.

Lab-Scale Composting Reactors

During the experimental study, nine composting reactors were used. The bottom of the reactors that have approximately 1.5 L volume, were drilled from 50 points (3 mm diameter) to collect leachate as shown in Fig. 1. The leachate collected in a vessel at the bottom of reactor was recirculated over the compost pile.

Operating Procedure

Earthworms must have a bedding material to survive when unsuitable conditions (for example high temperature and/or high nitrogen concentrations) occur in the compost reactor [24]. For this reason, the bedding material prepared from waste paper and negligible quantity of soil was put on the ground of the reactors as a thin layer. 50 acclimated mature earthworms were placed in each bedding material. After pretreatment, sewage sludge and yard wastes were mixed with the same ratio (w/w) in the reactor and vermicomposting process was started. Temperature values were checked every 2 days and sufficient amount of chlorine free water was added to keep the water content between 70 and 80%, during the process. Top of the reactor was closed with veil such a way as to intake air, to prevent insect and fly problems. Reactor systems were established at a suitable air current environment and ambient temperature was between 18 and 26 °C. Samples were collected from the reactor on the first, 15th, 30th, 45th and 60th operation days.

The experimental setups are shown in Table 2. Control 1 and control 2 reactors represent traditional composting and vermicomposting of sludge and yard waste mixtures, respectively. Bio-One™ was added to the run 1 reactor as a compost additive. Bio-One™ was diluted with water 1/40 ratio. Leachate recirculation was carried out in run 2 and run 3 at different recirculation flow rate by pouring the accumulated water into the reactor. All and half of the collected water was poured to reactor in run 2 and run 3, respectively. The mature vermicompost that was produced in our previous studies was added to run 4 and run 5. Mature vermicompost produced from sludge (MVS) and cow dunk (MVD) was used in run 4 and run 5, respectively. Run 6 and run 7 reactors were aerated with excess air by an air pump (Resun LP-40).

Analytical Procedures

The pH was measured using digital pH meter (WTW pH 720) in 1/10 (w/v) aqueous solution (deionized water). Electrical conductivity (EC) measurement was also done in 1/10 (w/v) aqueous solution using EC meter (WTW Con 730). Moisture content was determined by oven drying at 105 °C. Organic matter (OM) content was determined according to test method of TMECC 05.07-A by the loss on burning of dried samples at 550 °C for 4 h. Total organic carbon (TOC) was determined by combustion of dried samples using a TRL instrument TOC device. Total Kjeldahl nitrogen (TKN) was measured by micro Kjeldahl method [25]. C/N ratio was calculated from the measured value of TOC and TKN.

Phytotoxicity Test

One way to measure compost stability is to determine its effect on plants. Phytotoxicity refers to the presence of substances that are toxic to plants and may contain acids or alcohols that may cause immature or anaerobic compost, seedlings or vulnerable plants [26].

The sample was first sieved through a 10 mm diameter sieve. For the phytotoxicity test, 25% and 50% compost mixtures were used. 25% compost means 25% by weight of compost or final product and 75% by soil. Soil mixture was accepted as a control and cress seed was added to those mixtures. After 4–5 days, cress plants were harvested and weighed. Germination percentage calculated with following equation (Eq. 1):

GP(%25, %50) means germination percentage of seeds in 25% and 50% compost mixtures. CW%25, %50 means cress weight grow in 25% and 50% compost mixtures (g) and CWsoil means cress weight grow in soil (g) [27].

It is possible to make a classification between compost stability and phytotoxicity to evaluate the toxicity of the compost sample [28]. This classification is given in Tables 3.

Results and Discussion

Physical–Chemical Properties of Vermicompost

Effect of Bio-One™ Addition

In this part of the study, effect of Bio-One™ addition on physical–chemical properties of run 1 reactor was investigated. The results of physical–chemical properties of the reactors according to operation days is shown in Table 4. Table 4 presents pH, EC, C, N, C/N, ratio and OM values of each reactor on first, 30th and 60th days.

The initial pH values of the control 1, control 2 and run 1 reactors were 7.70, 7.70 and 7.80, respectively. During the operation period, pH values increased approximately 1.2 unit in all reactors. Munroe [17] reported that residual organic nitrogen released to water dissolves as ammonia is increased in vermicomposting reactors. As a result the pH increases and this type of trend in pH values is consistent with the study of Arumugam et al. [29]. But, slightly decreased pH values of vermicomposting reactors were monitored in the study realized by Najjari and Ghasemi [7]. The reason of pH differentiation among those studies is using different types of organic wastes. While sludge is used as a composting material in our study, convert sawdust amended with blood powder were used by Najjari and Ghasemi [7].

EC shows the variation of salt and mineral ion concentrations. So, this parameter is used to check whether vermicompost is safely carried out in agricultural purposes [29]. EC values in all compost reactors increased according to time, like pH values. The highest increasing in EC was measured in run 1 reactor. This situation showed that Bio-One™ addition accelerated biodegradation of organic matter in vermicomposting reactor. The last EC value of the run 1 was 2870 µs/cm (Table 4). Lazcano et al. [30] reported that if the EC value of the stabile compost is lesser than 3 ds/m, it can be applied to the soil. All the EC results in our study were lesser than this reference value.

Amount of carbon decreases with the microbial conversion of C to CO2 by respiration. In our study C was measured as TOC (%). Because organic C degradation, our TOC concentrations decreased to 23.77%, 20.32% and 21.12% from 24.92%, 24.92% and 26.99% in control 1, control 2 and run 1 reactors, respectively (Table 4). As can be seen in this table, highest TOC decreasing was realized in run 1 reactor (22%). This result shows that Bio-One™ addition accelerated organic carbon degradation and supplied faster composting process according to traditional (control 1) and classic vermicomposting (control 2). In addition, decreasing of TOC in vermicomposting reactor faster than without worm reactor (control 1). In the study done by Kaur et al. [31], toxic pulp and paper industry sludge was composted with or without worms (Eisenia fetida). The results of this study showed that the last TOC values of the vermicompost reactor is smaller than traditional composting reactor. While reduction of the TOC in the presence of E. fetida reactor was about 44%, in the absence of E. fetida reactor was it only 13%.

The low amount of TKN contents of all runs decreased in the first few operation days (data not shown in Table 4). The reason for this decreasing, nitrogen might have escaped as N2O or NH3 from the composting reactors. As can be seen in Table 4, the TKN percentages in control 1, control 2, and run 1 increased from 0.81%, 0.81% and 0.88% to 1.18%, 1.24% and 1.49%, respectively. The variation of initial and ultimate TKN percentages in the vermicomposting reactors is consistent to literature which are related to vermicomposing [32,33,34].

Mucus originated from earthworms and worm excreta including nitrogen mixed with composting material cause increasing in TKN contents in the vermicomposting process. Najjari and Ghasemi [7] reported that nitrogen can be released from earthworms’ metabolic products like dead tissues and hormones. Comparing the vermicomposting reactors (control 2 and run 1) the ultimate TKN contents of run 1 was higher than control 2 which might be due to the presence of Azotobacter vinelandi in run 1 reactor. It’s known that, these types of bacteria fix nitrogen from air as organic nitrogen. In addition to vermicomposting reactors, the TKN content of our traditional composting reactor (control 1) increased during operation period (except first few days). Similar results were found by Kebibeche et al. [35] and Meng et al. [36].

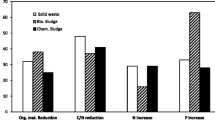

C/N ratio is used as a measure of quality of composted material. Decreasing this ratio indicates near completion of degradation of solid waste [37]. The variation of C/N ratio for control 1, control 2 and run 1 according to time is shown in Table 4 and Fig. 2.

As can be seen in this table, the initial C/N ratio in all reactors was about 30. The C/N ratios with or without earthworm composting reactors decreased during operation period. Senesi [38] reported that decreasing C/N ratio shows high stabilization of organic matter. Final C/N ratios of the control 1, control 2 and run 1 reactors were measured as 20.14, 16.39 and 14.17, respectively (Table 4). Percentage of C/N ratio declining in the vermicomposting reactors (47–53%) were higher than traditional composting reactor (36%). In a comparative study using industrial sludge as composting material with or without vermiculture, the ultimate C/N ratio of the vermicomposting reactor was lower than traditional composting reactor [39]. In addition, Gupta and Garg [40] indicated about 58–85% decreasing in C/N was measured in vermicomposting reactors using E. fetida as earthworm and sewage sludge as composting material for 105 operation days while our results (decrease in C/N ratio) were slightly lower than Gupta and Garg’s [40] study. But, the operation period in our study was only 60 days. Meanwhile, the final C/N ratio was 14.17 in vermicomposting reactor using Bio-One™ as an additive (run 1). Morais and Queda [41] informed that if the final C/N ratio is below 20, mature compost is good and if this ratio is 15 or lower, this compost can be used preferably in agriculture. The reason of low final C/N ratio of the run 1 can be bacterial culture in Bio-One™. Nitrogenous bacteria in this additive fix atmospherical nitrogen and transfer to compost material as ammonium. At the end of this process nitrogen content rises and it consequently C/N ratio declines. Similarly, Mupambwa et al. [42] found low final C/N ratio in vermicomposting reactors that contain effective microorganisms. Another study realized by Arumugam et al. [29] promotes positively effect of microbial consortia on vermicomposting. Our results show that Bio-One™ addition accelerates the vermicomposting process.

The variation of organic matter content in composting reactors is shown in Fig. 3. It was shown that there is no significant difference between control 2 (vermicomposting) and run 1 reactors related to OM. Either control 2 or run 1 reactors have the same OM decreasing (31%) at the end of the operation period. But, OM content of the run 1 sharply declined according to control 2 (Fig. 3). It can be said that Bio-One™ addition has no significant advantage in terms of OM reduction in vermicomposting reactors.

Effect of Leachate Recirculation

Leachate recirculation is an effective method in landfills. It is known that, organic compounds in the leachate can be reduced by physical, chemical and biological activity in landfill areas with leachate recirculation. Especially organic acids in leachate can be removed by converting them into CH4 and CO2 in the landfill area [19]. Studies have shown that when vermicompost leachate (named compost tea) applied to soil increases the product yield. In order to understand the effect of leachate recirculation in vermicomposting, run 2 and run 3 reactors were monitored. The results of physical–chemical properties of the reactors according to operation days are shown in Table 5.

According to Table 5, the pH of the vermicomposted material was higher than the initial values in all reactors. The initial pH values of control 1, control 2, run 2 and run 3 were 7.70 and final pH values ranged between 9.09 and 9.38. It was observed that the leachate recirculation had no significant effect on pH change. After microbial degradation, excess nitrogen in the compost mixtures dissolves in water in the formation of ammonium salts and it could be lead increasing of pH [43]. Releasing of H+ by evaporation of N-NH4 is caused to increase of pH [44]. Similar results related to pH increasing are found the studies realized by Negi and Suthar [43], Vig et al. [45] and Gong et al. [46]. EC level in the final vermicompost was significantly increased. The initial EC value was 755 µs/cm in four reactors. The maximum final EC value was observed in run 3 reactor as 2560 µs/cm. The final EC values of control 1, control 2 and run 2 were 2270 µs/cm, 1910 µs/cm and 2140 µs/cm, respectively.

Final TOC values were 23.77%, 20.32%, 19.80% and 17.39% for control 1, control 2, run 2 and run 3, respectively. The maximum decrease in TOC was observed in run 3 with 30%. The amount of TOC reduction of run 2, control 2 and control 1 were determined as 20%, 18% and 5%, respectively. There was significant difference in TOC reduction between recirculation runs and control reactors. So, it can be said that there is a positive effect of leachate recirculation on organic C degradation. Yadav and Garg [47] studied about co-vermicomposting of bakery industry sludge and cow dung to produce valuable product. They found that TOC values decreased between 26.1 and 42.8% in different vermicomposting bins. TOC decreases ranged between 13.3 and 16.6% in different ratios of distillery sludge with tea leaf residue combinations after 45 days of operation period [48].

TKN values of the reactors increased continuously. It was found that TKN values of reactors run 2(88.8%) and run 3(83.6%) increased more than control 1(45.7%) and control 2(53.1%). The high increase of TKN values in run 2 and run 3 was because of the nitrogen in the recirculating leachate.

The maximum reduction in C/N ratio was observed in reactor run 3 as 63%. The minimum decrease was 35% in the control 1 reactor (Fig. 4). Leachate recirculation (run 2, run 3) caused a better decrease in C/N ratio. The rapid decrease in C/N ratio indicates that leachate recirculation is effective in vermicomposting and this was agreement with the observation of Sponza and Aǧdaǧ [19] in anaerobic storage areas. Final values of C/N of this study were closer to what was reported by Mahaly et al. [48]. In that study, the final C/N ratios were varied between 17 and 25.

OM amounts tend to decrease as shown in Fig. 5. The initial amount of OM was 68.72% but reduced to 39.09% and 44.18% in run 2 and run 3, respectively. The variation in OM values of the reactors is similar to the change in TOC values. It was seen that the partial leachate recirculation reactor is more advantageous for both parameters.

Effect of Mature Vermicompost Addition

The results of physical–chemical properties of the reactors according to operation days is shown in Table 6. At the beginning, vermicompost mixtures control 1, control 2, run 4 and run 5 were neutral (pH 7.7–7.9). After vermicomposting, the pH values of all runs increased to alkaline values basic condition (pH 8.1–9.14). While initial EC values were 755 µs/cm in control runs, this value decreased to 500 µs/cm with the addition of mature vermicompost. After vermicomposting period, EC values increased approximately two times in all runs. The reason of this change in electrical conductivity can be explained by the mass loss during the decomposition of organic matter and the release of some salt minerals as phosphate, ammonium, potassium, etc. [49].

The presence of mature vermicompost produced from sludge in run 4 decreased the initial C/N ratio from 30.85 to 26.5, while the presence of mature vermicompost produced from cow dung in run 5 reduced the initial C/N to 19.7. In this case, it has been found that the addition of MVD pushed the required C/N ratio condition to a certain extent. In Fig. 6, the change in C/N ratio of run 4 and run 5 over time is clearly seen. While the C/N ratio decreased by 63.8% in run 4, it was observed that there was a 23.6% decrease in run 5. Considering the decrease in C/N ratio, it can be said that MVS addition is more advantageous.

The variation of the amount of OM of reactors control 1, control 2, run 4 and run 5 are given in Fig. 7. As it can be seen the OM amounts of the runs with mature vermicompost addition were less in the initial. It was determined that the amount of OM decreased by 15% in run 4 and 17% in run 5 during 60 days composting period.

Effect of Aeration Flow Rate

In order to investigate the effect of different aeration flow rates in vermicomposting, air was provided to run 6 and run 7 at flow rates of 2000 and 500 ml/min, respectively. The results of physical–chemical properties of the reactors according to operation days is shown in Table 7.

pH and EC values were increased in all reactors. Final pH values ranged between 9.04 and 9.14, final EC values ranged between 1910 and 3550 µs/cm. TOC in vermicomposted material was in the ranges of 19.96–23.77%. The maximum TOC reduction was in run 7 (19.90%) followed by run 6 (18.54%), Control 2 (18.45%) and control 1 (4.61%).

TKN content in all raw vermicomposting material was 0.81%. After composting and vermicomposting process TKN content significantly increased in control 1(45.67%), control 2(53.08%), run 6(62.97%), run 7(72.83%) and the final values were 1.18%, 1.24%, 1.32% and 1.4%, respectively. Those runs’ final C/N ratio were closer control 1 than the other runs. This may be explained by ventilation caused over-drying on vermicompost materials and deaths of worms. Figure 8 shows the change in C/N ratio of run 6 and run 7 with time. It was calculated that 50% decrease in run 6 and 53% decrease in run 7 was obtained. The change in the C/N ratio of the reactors was found to be close to the decrease in the C/N ratio (46%) of the control 2 reactor.

It can be seen that aeration positively effected the OM decrease (Fig. 9). The decrease in OM amount was the most in run 6 and at least in run 7. The intermediate and final values of the reactors control 2 and run 6 and control 1 and run 7 were similar. The decrease in the amount of OM in the Control 2 reactor was found to be 30.99%, 39.24% in run 6 and 24.00% in run 7.

Evaluation of Phytotoxicity

The phytotoxicity test results of the compost samples are given in Table 8. According to the phytotoxicity test results, values of 25% compost mixtures were 100%. For 50% compost mixtures determined as 83.2% and the average value was 95.9% (Table 8). According to Table 8, all of the compost samples were in the range of 81–100% so in the low, nontoxic class. From the toxicity point of view, it can be said that these end products will not be a problem in using as an auxiliary to soil enrichment. However, different tests should be applied to evaluate different toxic conditions of the product.

In a study investigating different test methods for determining compost stability and maturity, it was stated that according to German Standards, those ratios should be between 90 and 80% according to Austrian Standards and between 80 and 90% according to Swedish Standards [50]. In a report prepared by Brinton [51], the mature compost’s plant compliance percentage should be more than 90% according to plant growth performance standards. In a similar study, phytotoxicity test was applied to the final products of nine different compost samples and two different anaerobic reactors and respectively the average values in 25% mixtures were found to be 80%, 93% and 94% and in 50% mixture 75%, 78% and 62% [27]. In a similar study using sewage sludge and urban litter, germination index was found to be between 57.5 and 95% [52].

Variation of Number of Worms in Reactor

Table 9 shows initial and final adult worm number for all runs. Considering the amount of nutrients in the reactors, 50 adult worms were used for all runs. The maximum growth rate was in run 4 using mature vermicompost produced from the treatment sludge. It is known that growth of E. fetida is influenced by EC and salt content [53]. Run 4 has the lowest final EC value (1910 µs/cm). Therefore, it may have contributed to the increase in the number of worms.

The highest death rate was observed in run 6 with high flow rate aeration. The average number of final worms was about 49. The average number of final worms was found about 37 in our other study, using the market waste in the same period. In that study, the highest number of worms were in the reactor using the mature vermicompost produced from market wastes and again the least number of worms were in the reactor with high flow rate ventilation. High flow rate ventilation caused drying of the reactors much earlier than the irrigation time and death of worms. The number of cocoon and juvenile was higher in market wastes used reactor but worm weights were observed approximately twice in sludge used reactors. These results showed that organic matter was more easily available and consumed more quickly in market wastes during the same period studies. Therefore, after organic matter was consumed, the worms had a shortage of nutrients, resulting in a competition under stress, resulting in the development of cocoon production and the death of mature worms.

In a study, investigating earthworm growth during vermicomposting of sugar industry sludge and cow manure, 50 young non-clitellated E. fetida worms were initially used and the values varied between 71 and 79 in the end [54]. In Deys study worm number increased from 6 to 30 at the end of 60 days vermicomposting [55].

Conclusion

Co-vermicomposting of MWTP sludge and yard wastes on different operation condition parameters (Bio-One™ addition, leachate recirculation, mature vermicompost addition and ventilation) was performed. When vermicomposting compared with traditional composting, it was found that vermicomposting gave better results in terms of consumption of organic matter and increase of TKN. Also in traditional composting, the reactors have to be mixed at certain intervals, while in vermicomposting this role is assumed by worms.

The addition of Bio-One™ as a compost additive accelerated the degradation process of the organic material by increasing the microbial community in the composting reactor and positively effected the composting process. The leachate recirculation accelerated the aerobic process and effected the compost quality positively. Partial recirculation has been found to be effective whereas high recirculating leachate recirculation did not significantly affect the composting mechanism. For this reason, the recirculation volume of the leachate needs to be well adjusted. It has been shown that mature compost addition has a positive contribution to organic matter consumption.

It was found that atmospheric O2 is sufficient for the composting process especially in small volume reactors in vermicomposting. Additional water must be added because the pump reduces the water content suddenly causing drying in the compost mass. The low airflow rate accelerates the aerobic process, thus accelerating the removal of organic matter and shortening the composting period. However, this should be done in larger reactor volumes. The positive result of plant growth tests on compost products of reactors in all cases may mean that the products will not cause any toxic effect on the plants when used as soil conditioning material.

References

Liu, W., Huo, R., Xu, J., Liang, S., Li, J., Zhao, T., Wang, S.: Effects of biochar on nitrogen transformation and heavy metals in sludge composting. Bioresour. Technol. 235, 43–49 (2017)

Muscolo, A., Papalia, T., Settineri, G., Mallamaci, C., Jeske-Kaczanowska, A.: Are raw materials or composting conditions and time that most influence the maturity and/or quality of composts? Comparison of obtained composts on soil properties. J. Clean. Prod. 195, 93–101 (2018)

Sinha, R.K., Agarwal, S., Chauhan, K., Chandran, V., Soni, B.K.: Vermiculture technology: reviving the dreams of Sir Charles Darwin for scientific use of earthworms in sustainable development programs. Technol. Invest. 01, 155–172 (2010)

Suthar, S.: Vermicomposting potential of Perionyx sansibaricus (Perrier) in different waste materials. Bioresour. Technol. 98, 1231–1237 (2007)

Khwairakpam, M., Bhargava, R.: Vermitechnology for sewage sludge recycling. J. Hazard. Mater. 161, 948–954 (2009)

Mowla, D., Tran, H.N., Allen, D.G.: A review of the properties of biosludge and its relevance to enhanced dewatering processes. Biomass Bioenerg. 58, 365–378 (2013)

Najjari, F., Ghasemi, S.: Changes in chemical properties of sawdust and blood powder mixture during vermicomposting and the effects on the growth and chemical composition of cucumber. Sci. Hortic. 232, 250–255 (2018)

Azizi, A.B., Lim, M.P.M., Noor, Z.M., Abdullah, N.: Vermiremoval of heavy metal in sewage sludge by utilising Lumbricus rubellus. Ecotoxicol. Environ. Saf. 90, 13–20 (2013)

Rodrigues, A.S.L., Mesak, C., Silva, M.L.G., Silva, G.S., Leandro, W.M., Malafaia, G.: Organic waste vermicomposting through the addition of rock dust inoculated with domestic sewage wastewater. J. Environ. Manag. 196, 651–658 (2017)

Wang, L., Zhang, Y., Lian, J., Chao, J., Gao, Y., Yang, F., Zhang, L.: Impact of fly ash and phosphatic rock on metal stabilization and bioavailability during sewage sludge vermicomposting. Bioresour. Technol. 136, 281–287 (2013)

Malińska, K., Golańska, M., Caceres, R., Rorat, A., Weisser, P., Ślęzak, E.: Biochar amendment for integrated composting and vermicomposting of sewage sludge—The effect of biochar on the activity of Eisenia fetida and the obtained vermicompost. Bioresour. Technol. 225, 206–214 (2017)

Li, S., Li, D., Li, J., Li, G., Zhang, B.: Evaluation of humic substances during co-composting of sewage sludge and corn stalk under different aeration rates. Bioresour. Technol. 245, 1299–1302 (2017)

Suthar, S.: Vermistabilization of municipal sewage sludge amended with sugarcane trash using epigeic Eisenia fetida (Oligochaeta). J. Hazard. Mater. 163, 199–206 (2009)

Soobhany, N.: Remediation potential of metalliferous soil by using extracts of composts and vermicomposts from Municipal Solid Waste. Process Saf. Environ. Prot. 118, 285–295 (2018)

Soobhany, N.: Preliminary evaluation of pathogenic bacteria loading on organic municipal solid waste compost and vermicompost. J. Environ. Manag. 206, 763–767 (2018)

Suleiman, H., Rorat, A., Grobelak, A., Grosser, A., Milczarek, M., Płytycz, B., Kacprzak, M., Vandenbulcke, F.: Determination of the performance of vermicomposting process applied to sewage sludge by monitoring of the compost quality and immune responses in three earthworm species: Eisenia fetida, Eisenia andrei and Dendrobaena veneta. Bioresour. Technol. 241, 103–112 (2017)

Munroe, G.: Manual of on-farm vermicomposting and vermiculture. Org. Agric. Centre Canada 39, 40 (2007)

Dominiguez, J., Edwards, C.A.: Effects of stocking rate and moisture content on the growth and maturation of Eisenia andrei (Oligochaeta) in pig manure. Soil Biol. Biochem. 29, 743–746 (1997)

Sponza, D.T., Aǧdaǧ, O.N.: Impact of leachate recirculation and recirculation volume on stabilization of municipal solid wastes in simulated anaerobic bioreactors. Process Biochem. 39, 2157–2165 (2004)

Hait, S., Tare, V.: Optimizing vermistabilization of waste activated sludge using vermicompost as bulking material. Waste Manag. 31, 502–511 (2011)

Hait, S., Tare, V.: Vermistabilization of primary sewage sludge. Bioresour. Technol. 102, 2812–2820 (2011)

Kaushik, P., Garg, V.K.: Vermicomposting of mixed solid textile mill sludge and cow dung with the epigeic earthworm Eisenia foetida. Bioresour. Technol. 90, 311–316 (2003)

Malińska, K., Zabochnicka-Światek, M., Cáceres, R., Marfà, O.: The effect of precomposted sewage sludge mixture amended with biochar on the growth and reproduction of Eisenia fetida during laboratory vermicomposting. Ecol. Eng. 90, 35–41 (2016)

Lalander, C.H., Komakech, A.J., Vinnerås, B.: Vermicomposting as manure management strategy for urban small-holder animal farms—Kampala case study. Waste Manag. 39, 96–103 (2015)

Jackson, M.L.: Soil Chemical Analysis. Prentice Hall of India Private Limited, New Delhi (1973)

Rynk, R.: On-farm composting handbook. NRAES-54 Natural Resource Agriculture and Engineering Service, New York (1992)

Varank, G.: Aerobik Olarak Stabilize Edilmiş Kati Atiklar ile Kompost Ürününün Karşilaştirilmasi (2006)

Graves, R.E., Hattemer, G.M.: Chapter 2 Composting. In: Pierce, W. (ed.) Part 637 Environmental Engineering National Engineering Handbook. United States Department of Agriculture Natural Resources Conservation Service, Washington (2010)

Arumugam, K., Renganathan, S., Babalola, O.O., Muthunarayanan, V.: Investigation on paper cup waste degradation by bacterial consortium and Eudrillus eugeinea through vermicomposting. Waste Manag. 74, 185–193 (2018)

Lazcano, C., Gómez-Brandón, M., Domínguez, J.: Comparison of the effectiveness of composting and vermicomposting for the biological stabilization of cattle manure. Chemosphere 72, 1013–1019 (2008)

Kaur, A., Singh, J., Vig, A.P., Dhaliwal, S.S., Rup, P.J.: Cocomposting with and without eisenia fetida for conversion of toxic paper mill sludge to a soil conditioner. Bioresour. Technol. 101, 8192–8198 (2010)

Molina, M.J., Soriano, M.D., Ingelmo, F., Llinares, J.: Stabilisation of sewage sludge and vinasse bio-wastes by vermicomposting with rabbit manure using Eisenia fetida. Bioresour. Technol. 137, 88–97 (2013)

Kougias, P.G., Kotsopoulos, T.A., Martzopoulos, G.G.: Effect of feedstock composition and organic loading rate during the mesophilic co-digestion of olive mill wastewater and swine manure. Renew. Energy 69, 202–207 (2014)

Suthar, S., Mutiyar, P.K., Singh, S.: Vermicomposting of milk processing industry sludge spiked with plant wastes. Bioresour. Technol. 116, 214–219 (2012)

Kebibeche, H., Khelil, O., Kacem, M., Kaid Harche, M.: Addition of wood sawdust during the co-composting of sewage sludge and wheat straw influences seeds germination. Ecotoxicol. Environ. Saf. 168, 423–430 (2019)

Meng, L., Zhang, S., Gong, H., Zhang, X., Wu, C., Li, W.: Improving sewage sludge composting by addition of spent mushroom substrate and sucrose. Bioresour. Technol. 253, 197–203 (2018)

Garcia, C., Hernández, T., Costa, F., Ayuso, M.: Evaluation of the maturity of municipal waste compost using simple chemical parameters. Commun. Soil Sci. Plant Anal. 23, 1501–1512 (1992)

Senesi, N.: Composted materials as organic fertilizers. Sci. Total Environ. 81–82, 521–542 (1989)

Sangwan, P., Kaushik, C.P., Garg, V.K.: Vermiconversion of industrial sludge for recycling the nutrients. Bioresour. Technol. 99, 8699–8704 (2008)

Gupta, R., Garg, V.K.: Stabilization of primary sewage sludge during vermicomposting. J. Hazard. Mater. 153, 1023–1030 (2008)

Morais, F.M.C., Queda, C.A.C.: Study of storage influence on evolution of stability and maturity properties of MSW composts. In: Proceedings of the fourth International Conference of ORBIT association on Biological Processing of Organics: Advances for a sustainable Society Part II, Perth, Australia (2003)

Mupambwa, H.A., Ravindran, B., Mnkeni, P.N.S.: Potential of effective micro-organisms and Eisenia fetida in enhancing vermi-degradation and nutrient release of fly ash incorporated into cow dung-paper waste mixture. Waste Manag. 48, 165–173 (2016)

Negi, R., Suthar, S.: Degradation of paper mill wastewater sludge and cow dung by brown-rot fungi Oligoporus placenta and earthworm (Eisenia fetida) during vermicomposting. J. Clean. Prod. 201, 842–852 (2018)

Eklind, Y., Kirchmann, H.: Composting and storage of organic household waste with different litter amendments. II: nitrogen turnover and losses. Bioresour. Technol. 74(2), 125–133 (2000)

Vig, A.P., Singh, J., Wani, S.H., Dhaliwal, S.S.: Vermicomposting of tannery sludge mixed with cattle dung into valuable manure using earthworm Eisenia fetida (Savigny). Bioresour. Technol. 102, 7941–7945 (2011)

Gong, X., Li, S., Carson, M.A., Chang, S.X., Wu, Q., Wang, L., An, Z., Sun, X.: Spent mushroom substrate and cattle manure amendments enhance the transformation of garden waste into vermicomposts using the earthworm Eisenia fetida. J. Environ. Manag. 248, 109263 (2019)

Yadav, A., Garg, V.K.: Biotransformation of bakery industry sludge into valuable product using vermicomposting. Bioresour. Technol. 274, 512–517 (2019)

Mahaly, M., Senthilkumar, A.K., Arumugam, S., Kaliyaperumal, C., Karupannan, N.: Vermicomposting of distillery sludge waste with tea leaf residues. Sustain. Environ. Res. 28(5), 223–227 (2018)

Taeporamaysamai, O., Ratanatamskul, C.: Co-composting of various organic substrates from municipal solid waste using an on-site prototype vermicomposting reactor. Int. Biodeterior. Biodegrad. 113, 357–366 (2016)

ADAS: Assessment of options and requirements for stability and maturity testing of composts. The Waste and Resources Action Programme, Banbury (2005)

Brinton, W.F.: Compost quality standards & guidelines. (2000)

Wu, D., Yu, X., Chu, S., Jacobs, D.F., Wei, X., Wang, C., Long, F., Chen, X., Zeng, S.: Alleviation of heavy metal phytotoxicity in sewage sludge by vermicomposting with additive urban plant litter. Sci. Total Environ. 633, 71–80 (2018)

Alavi, N., Daneshpajou, M., Shirmardi, M., Goudarzi, G., Neisi, A., Babaei, A.A.: Investigating the efficiency of co-composting and vermicomposting of vinasse with the mixture of cow manure wastes, bagasse, and natural zeolite. Waste Manag. 69, 117–126 (2017)

Bhat, S.A., Singh, J., Vig, A.P.: Effect on growth of earthworm and chemical parameters during vermicomposting of pressmud sludge mixed with cattle dung mixture. Proced. Environ. Sci. 35, 425–434 (2016)

Dey, M.D., Das, S., Kumar, R., Doley, R., Bhattacharya, S.S., Mukhopadhyay, R.: Vermiremoval of methylene blue using Eisenia fetida: A potential strategy for bioremediation of synthetic dye-containing effluents. Ecol. Eng. 1006, 200–208 (2017)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yilmaz Cincin, R.G., Agdag, O.N. Co-vermicomposting of Wastewater Treatment Plant Sludge and Yard Waste: Investigation of Operation Parameters. Waste Biomass Valor 11, 6211–6222 (2020). https://doi.org/10.1007/s12649-019-00900-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-019-00900-w