Abstract

To evaluate the supplementation of the sugarcane bagasse and straw hemicellulosic hydrolysate with sugarcane syrup, which is a sucrose-rich co-product, for xylitol production by Candida guilliermondii FTI 20037. Recently, we demonstrated that sucrose supplementation to sugarcane straw hemicellulosic hydrolysate favoured this bioprocess. A mixture 1:1 of sugarcane bagasse and straw was submitted to dilute-acid hydrolysis with H2SO4 to obtain the hemicellulosic hydrolysate, which was concentrated, detoxified and autoclaved. Three sugarcane syrup concentrations (0.83, 2.50 and 3.33% v/v) were added to the hemicellulosic hydrolysate, which was also supplemented with rice bran extract, (NH4)2SO4, CaCl2·2H2O. Next, a full factorial design was performed to assess the replacement of conventional nutrients by sugarcane syrup. Fermentations were performed in 125 mL Erlenmeyer flasks containing 50 mL of fermentation medium, for 48 h at 30 °C and 200 rpm. Improvements of 16.85% and 12.24% in xylose uptake rate (1.04 ± 0.01 g L−1 h−1) and xylitol volumetric productivity (0.55 ± 0.02 g L−1 h−1), respectively, were achieved with syrup supplementation (2.50% v/v), which led to a final xylitol titer of 26.19 ± 0.02 g L−1. Conventionally employed nutrients (rice bran extract, (NH4)2SO4 and CaCl2·2H2O) did not have significant influence on xylitol production when sugarcane syrup was added to the fermentation medium. Sugarcane syrup as a nutritional supplement improved xylitol production from a mixture of bagasse and straw, becoming an alternative to reduce costs in the formulation of the fermentation medium and contributing to the integration of this bioprocess in a sugarcane biorefinery.

Graphic Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

A mixture of the sugarcane lignocellulosic by-products bagasse and straw was employed as raw material for xylitol bioproduction. Sugarcane syrup was evaluated as nutritional supplementation of the hemicellulosic hydrolysate based on its content of sucrose, nitrogenous compounds, vitamins and minerals, aiming to the possibility of replacing nutrients conventionally employed. To the best of our knowledge, this is the first time that these streams derived from sugarcane processing were used for formulation of the fermentation medium for xylitol bioproduction. This strategy can contribute to improve the feasibility of this bioprocess because of the potential reduction of costs associated to the fermentation medium and the possibility of integrating it in a sugarcane biorefinery.

Introduction

The bio-based economy is an alternative to reduce the dependence on the non-sustainable exploitation of fossil resources. This emerging economy uses vegetal biomasses as input for bioenergy and high added-value chemicals production in integrated facilities known as biorefineries [1, 2]. The sugarcane agroindustry, based in one of the most important and traditional crops in Brazil [3], has an enormous potential to diversify and valorize its portfolio of products in the context of a biorefinery. Sugarcane juice and the lignocellulosic by-product bagasse are currently used as feedstock to obtain sugar, ethanol and energy, whereas the other by-product, straw, is partially kept in the field or used along with bagasse [3, 4]. Bagasse and straw, all together, correspond to two thirds of the total energy content and to approximately 28% of the harvested sugarcane mass (dry basis) [3,4,5], which is estimated in 647.6 million tons for 2017/2018 season in Brazil [6]. Innovative processes focused on the complete bagasse and straw conversion into high added-value chemicals can be integrated to the sugarcane value chain.

According to Werpy and Peterson [7], xylitol is one of the high added-value chemicals capable of economically and technically supporting the low-value biofuel production in integrated biorefineries. This sugar alcohol has applications in food and pharmaceutical industries and a growing market [8, 9]. Xylitol commercial production is based on the chemical hydrogenation of xylose purified from hemicellulosic hydrolysates, which is an expensive and inefficient process [9, 10]. Biotechnological production is an alternative for chemical processes based on xylose biochemical conversion into xylitol by a NADPH-dependent Xylose Reductase (XR) by pentose-assimilating yeasts [11, 12].

Xylitol efficiency and productivity in this bioprocess are highly dependent on oxygen availability during fermentation, since oxygen supply restriction leads to xylitol accumulation due to NAD+-dependent xylitol dehydrogenase (XDH) activity decrease, enzyme that catalyzes the xylitol oxidation into xylulose [12]. Nonetheless, the carbon flow through the central metabolic pathway decreases as consequence of limited XDH activity. Such process impairs cell growth, energy formation and NADPH regeneration, which is an important challenge for xylitol production by yeasts whose XR is exclusively dependent on NADPH, such as Candida guilliermondii [12], affecting mainly the volumetric productivity.

Utilization of a co-substrate that can be simultaneously metabolized with xylose is a strategy to overcome the limitation on the regeneration of NADPH, as well as to meet the demand for energy and carbon intermediates, under limited oxygen availability [13, 14]. Although hemicellulosic hydrolysates counts on carbon sources other than xylose, mainly on glucose and arabinose, these other sources may not be suitable co-substrates, because glucose can cause catabolic repression in xylose metabolism [13, 14] and poor arabinose assimilation [15]. Thus, supplementation of an additional carbon source as co-substrate can become a sustainable strategy, because agro-industrial by-products or co-products can be used and they may supply other nutrients that replace conventional nutritional sources [14].

In this regard, we recently showed that supplementation of sucrose as a co-substrate to sugarcane straw hemicellulosic hydrolysate favored xylitol production by C. guilliermondii FTI 20037 [16]. This result leads to the possibility of using complex sources of sucrose, such as sugarcane molasses or syrup that are obtained during the sugar and ethanol production processes, as nutritional supplementation of the fermentation medium, which can benefit the yeast performance and the process feasibility by replacing more expensive nutrients. Thus, the effect of supplementation of sugarcane syrup to the sugarcane bagasse and straw hemicellulosic hydrolysate on xylose-to-xylitol bioconversion by Candida guilliermondii FTI 20037 was studied in the present work, aiming to the integration of xylitol production in a sugarcane biorefinery.

Methods

Materials

Sugarcane bagasse and straw were kindly provided by Usina Iracema—Grupo São Martinho, Iracemápolis, SP, Brazil. Sugarcane straw was mechanically ground. Both biomasses were dried until reaching approximately 10% moisture content. Sugarcane syrup was kindly donated by the microbrewery at Escola de Engenharia de Lorena—Universidade de São Paulo (EEL-USP). Concentrations of the measured carbohydrates in the sugarcane syrup were (g L−1): sucrose (446.53), glucose (248.76) and fructose (230.26). All chemicals were analytical grade and were provided by Sigma-Aldrich, Brazil.

Hemicellulosic hydrolysate preparation

A sugarcane bagasse and straw mixture 1:1 (w/w) was subjected to dilute-acid hydrolysis in a jacketed 40 L AISI316 stainless steel reactor under the following conditions: 1% (w/v) H2SO4, 1:10 solid:liquid ratio, for 20 min at 121 °C. The liquid fraction, which corresponded to the sugarcane bagasse and straw hemicellulosic hydrolysate (BSHH), was separated from the solid fraction through filtration and preserved at 4 °C. BSHH was concentrated at vacuum (70 °C) in order to achieve threefold xylose concentration based on Rodrigues et al. [17]. Subsequently, it was detoxified through pH adjustment in two stages: first, pH adjustment to 7.0 by using CaO and to 2.5 by using H3PO4. The procedure was followed by the adsorption treatment with 1.0% (w/v) activated charcoal, at 60 °C and 100 rpm for 30 min [18]. The precipitates deriving from the detoxification procedure were separated through vacuum filtration. BSHH was autoclaved at 111 °C for 15 min in order to be used as fermentation medium, which was stored at 4 °C.

Microorganism and Inoculum Preparation

Candida guilliermondii FTI 20037 was preserved at 4 °C in malt extract agar slants and used for inoculum preparation in a semi-defined medium containing (g L−1): xylose (30.0), rice bran extract solution (20.0), (NH4)2SO4 (2.0) and CaCl2·2H2O (0.1). A loopful of grown cells was transferred to 125 mL Erlenmeyer flasks filled with cultivation medium (50 mL). The full flasks were incubated in rotary shaker (New Brunswick Scientific Inc., Edison, NJ, USA) for 24 h at 30 °C and 200 rpm. Cells were retrieved by centrifugation (2000×g) for 20 min, rinsed twice with sterile distilled water and re-suspended in an adequate volume of sterile distilled water in order to be used as inoculum at initial concentration 1 gDCW L−1.

Xylitol Production from Sugarcane Bagasse and Straw Hemicellulosic Hydrolysate Supplemented with Sugarcane Syrup

The study about the effect of BSHH supplementation with sugarcane syrup on xylitol production was divided in two stages. First, three sugarcane syrup concentrations (% v/v) were used to supplement the fermentation medium: 0.83, 2.50 and 3.33. The fermentation medium corresponded to the BSHH supplemented with nutrients conventionally employed in previous studies (rice bran extract, (NH4)2SO4, CaCl2·2H2O) [15, 16, 19] at the same concentrations used for inoculum preparation. An experiment without sugarcane syrup addition was utilized as a control. Second, a 23 full factorial design with three repetitions at the center point was performed to assess the complete or partial replacement of conventional nutrients by sugarcane syrup in the concentration determined in the first stage. Assessed variables and levels are shown in Table 1. The initial pH in all experiments was adjusted to 5.5 by using NaOH and was not controlled during the experiments. Batch fermentations were carried out in 125-mL Erlenmeyer flasks containing 50 mL of fermentation medium. The full flasks were incubated in rotary shaker for 48 h at 30 °C and 200 rpm.

Analytical methods

Xylose, glucose, arabinose, xylitol, ethanol, glycerol and acetic acid concentrations were measured through high-performance liquid chromatography (HPLC) (Agilent 1200, Kyoto, Japan). The device was equipped with a refractive index detector and used a Bio-Rad Aminex HPX-87H column (Hercules, CA, USA), as well as 0.01 N H2SO4 as eluent, at 45 °C and flow rate 0.6 mL min−1. Sucrose and fructose concentrations were quantified through HPLC in the same equipment, but at this time, deionized water was the eluent at 60 °C and flow rate 0.4 mL min−1. Samples were prepared through filtration in Sep-Pak C18 cartridges.

Furfural and 5-HMF concentrations were also set through HPLC by using RP-18 column (Hewlett-Packard, Palo Alto, CA, USA) and ultraviolet light detector (SPD-10A UV–Vis, Waters Corp., Milford, MA, USA) with acetonitrile:water (1:8) and 10% acetic acid as eluent at 25 °C and flow rate 0.8 mL min−1.Aliquots of 5 mL of the samples were diluted in 200 mL of distilled water in order to determine the concentration of phenolic compounds. The pH of the samples was adjusted to 12; absorbance was measured at 280 nm (DU 640B spectrophotometer, Beckman Coulter, Brea, CA, USA) and concentration was determined based on the methodology by Gouveia et al. [20]. Cell concentration was determined by measuring the absorbance at 600 nm (DU 640B spectrophotometer, Beckman Coulter, Brea, CA, USA) and calculated based on the calibration curve between absorbance and cell dry weight. Viable cell counts were estimated through the methylene blue staining technique by using the Neubauer cell counter chamber.

Results and Discussion

Effect of Different Sugarcane Syrup Concentrations Used to Supplement Sugarcane Bagasse and Straw Hemicellulosic Hydrolysate (BSHH) on Xylitol Production by C. guilliermondii FTI 20037

Sugarcane bagasse and straw hemicellulosic hydrolysate (BSHH) was supplemented with different sugarcane syrup concentrations (0.87%, 2.50% and 3.33% v/v). The effect of such process on xylose-to-xylitol bioconversion by C. guilliermondii FTI 20037 was herein studied. Carbohydrate and toxic compound (acetic acid, phenolic compounds, furfural and 5-HMF) composition in the fermentation media is presented in Table 2. This table shows that BSHH supplementation with sugarcane syrup increased the carbohydrate content of the fermentation media in comparison to the control medium, since this co-product is rich in sucrose, glucose and fructose. Sugarcane addition to BSSH resulted also in increase of total phenolic compound concentrations (Table 2). Such outcome can be explained by the content of phenolic compounds in the sugarcane syrup, as already reported by Duarte-Almeida et al. [21]. Total phenolic compound concentration increase could indicate a more challenging fermentation medium for the yeast performance, since these compounds can inhibit yeast growth, and metabolism, depending on their concentration [22]. Cortez and Roberto [23] showed that vanillin (2 g L−1) and syringaldehyde (2 g L−1) mixtures completely inhibited cell growth by C. guilliermondii FTI 20037, when it was grown in a medium in which xylose was the main carbon source.

Profiles of xylose, glucose and sucrose consumption by C. guilliermondii FTI 20037 in BSHH supplemented with different sugarcane syrup concentrations are presented in Fig. 1. Two xylose consumption stages were identified, both in experiments with and without sugarcane syrup supplementation. The first stage concerned the accelerated xylose consumption in the first 8 h of fermentation, which corresponds to approximate xylose uptake rate 2.1 g L−1 h−1. The second stage regards slow and constant xylose consumption from 8 h until the end of the fermentation process. The accelerated xylose consumption evidenced at the beginning of the fermentation was simultaneous with glucose consumption, which was completely exhausted in this period (Fig. 1), regardless of its concentration in the fermentation media (Table 2).

Despite simultaneous consumption of xylose and glucose has been observed in various studies of xylitol production by yeasts, xylose was assimilated in slower rates than those found after glucose depletion [15, 24, 25]. On the other hand, studies have evidenced sequential consumption of glucose and xylose [14, 19, 26,27,28]. This behavior has been related to the competition for transportation systems between glucose and xylose and the inhibition that glucose exerts on the induction of the enzymatic machinery for xylose metabolism [26, 29, 30]. The profiles of xylose and glucose consumption by C. guilliermondii FTI 20037 at the beginning of fermentation recorded in the present study (Fig. 1) contrast with the conventional results in studies of xylitol production from xylose and glucose mixtures media. Further experiments are necessary in order to better understand the causes of the accelerated xylose consumption at the beginning of the fermentation. It cannot be related to the supplementation with sugarcane syrup, because this result was recorded also for the fermentation medium without syrup addition.

Regarding the second stage of xylose consumption, hemicellulosic hydrolysate supplementation with sugarcane syrup led to an increase in the xylose uptake rate in comparison to the absence of syrup [from 0.89 ± 0.00 to 1.04 ± 0.01 g L−1 h−1 with 2.50% (v/v) syrup], which represent 16.85% increase. Improvement in xylose uptake rate here evidenced can be associated to the consumption of sucrose, which was constituent of the sugarcane syrup added to the fermentation media (Table 2). Sucrose exhaustion was evidenced after 8 h when the lowest sugarcane syrup concentration (0.83% v/v) was used, and after 24 h at concentrations 2.50% and 3.33% (v/v) (Fig. 1). As can be observed in this figure, sucrose was simultaneously consumed with xylose, regardless the different concentrations of this disaccharide in the composition of the fermentation media (Table 2). Simultaneous consumption of xylose and sucrose was also evidenced in our previous work, in which we studied the effect of sucrose supplementation at different concentrations to the hemicellulosic hydrolysate obtained only from sugarcane straw [16]. Furthermore, according to the aforementioned study, sucrose addition (10 g L−1) led to 8.88% increase in the xylose uptake rate (1.11 g L−1 h−1) in comparison to the sucrose-free medium (1.02 g L−1 h−1) [16].

Sucrose positive effect on xylose assimilation is related to its utility as co-substrate during xylitol production bioprocess. Breakdown of this disaccharide supplies glucose and fructose, which may be used as carbon and energy sources to meet the unsatisfied demand caused by the xylose incomplete metabolism under oxygen-restricted conditions. These hexoses derived from sucrose consumption can improve NAPDH regeneration through Pentoses Phosphate Pathway [31], favoring XR activity, and increase cell biomass formation, improving consequently the xylitol formation rate [13, 14, 25, 32]. Particularly, in the case of glucose, these positive effects on xylose-to-xylitol bioconversion have been demonstrated by studies in which glucose was added to the fermentation media or this hexose was constituent of the hemicellulosic hydrolysate [13, 15, 25, 33, 34]. It is noteworthy that in those cases the positive effects of glucose depend closely on the glucose:xylose ratio [15, 25, 32,33,34] and/or on the mode of addition of this hexose to the fermentation media [13, 33], since glucose can also cause catabolic repression to xylose assimilation, as discussed previously. In this context, simultaneous sucrose and xylose consumption observed in the present study becomes an important feature for the use of this disaccharide as co-substrate. Based on our results, glucose and fructose released from sucrose hydrolysis did not impair xylose assimilation, which can be related to the transportation and hydrolysis system that may be involved on sucrose assimilation.

According to the review of Flores et al. [35], in Saccharomyces cerevisiae and some non-Saccharomyces yeasts sucrose is hydrolyzed extracellularly and the monosaccharides released are transported to the interior of the cell. If this was the case for C. guilliermondii FTI 20037, extracellular release of hexoses did not affect xylose assimilation, probably because the activities of the hydrolytic enzyme (similar to invertase), the transport system and the intracellular enzymatic machinery were strictly regulated and coordinated, avoiding extracellular or intracellular accumulation of hexoses. On the other hand, it is also possible that the sucrose breakdown occurred intracellularly after be transported, or even in the periplasmatic space [35], case in which extracellular accumulation of hexoses was not possible, and intracellular sucrose hydrolysis and hexoses metabolism were tightly regulated avoiding hexoses accumulation. In this regard, Williamson et al. [36] demonstrated a existence of a sucrose/H+ symport transportation system and α-glucosidase for sucrose assimilation in Candida albicans. A similar mechanism was proposed by Tamburini et al. [14] for maltose assimilation by C. tropicalis, in which maltose is transported by a symport system, hydrolyzed by a maltase and the glucose released regulates these steps, keeping low intracellular levels of this hexoses and avoiding negative effects on the induction of XR and XDH. Lee et al. [26] also demonstrated that cellobiose did not interfere on xylose assimilation by C. guilliermondii FTI 20037 and that this disaccharide did not inhibit XR or XDH induction.

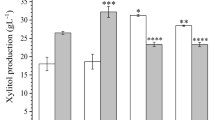

Profiles of xylitol production and cell growth by C. guilliermondii FTI 20037 in BSHH supplemented with different sugarcane syrup concentrations are presented in Fig. 2, which also shows the ethanol concentration profiles. Ethanol is a by-product of the xylitol production bioprocess. Table 3 summarizes the main results of the effect of BSHH supplementation with sugarcane syrup at different proportions on xylitol production by C. guilliermondii FTI 20037.

Sugarcane-syrup concentration increase up to 2.50% (v/v) was related to the increased final xylitol concentration and volumetric productivity. The highest final xylitol concentration and volumetric productivity values were obtained in the fermentation medium with 2.50% (v/v) sugarcane syrup concentration, which represented increases of 11.63% and 12.24%, respectively, in comparison to the syrup-free medium (Table 3). The increments on final xylitol concentration and volumetric productivity were coherent with the improvement of xylose assimilation associated with the simultaneous sucrose consumption, as discussed previously. Furthermore, other compounds besides sucrose found in sugarcane syrup, such as nitrogenous compounds or minerals, could also have beneficial effect on yeast performance [37].

BSHH supplementation with the highest sugarcane syrup concentration evaluated in the present study (3.33% v/v) resulted in 9.32% and 10.90% reduction in xylitol production and volumetric productivity in comparison to experiments with lower syrup concentrations; however, values were similar to those recorded in the absence of this co-product (Table 3). The xylitol production reduction observed for the highest sugarcane syrup concentration may result from the xylose consumption restriction also observed in this experiment (Fig. 1). These results can be related to the higher content of hexoses and sucrose when syrup was supplemented at the highest concentration in comparison to the other media. Silva and Felipe [15] reported that glucose:xylose ratios higher than 1:5 were related to reductions on xylose consumption and xylitol production by C. guilliermondii FTI 20037. Although we did not evidence the catabolic repression of xylose consumption, the glucose:xylose ratio in the medium with the highest syrup concentration (1:3.7) was higher than 1:5.

To the best of our knowledge, our study is pioneer in addressing the influence of hemicellulosic hydrolysates supplementation with sugarcane syrup on xylitol biotechnological production. Nevertheless, the herein recorded results can be compared to those reported in our recent study, which aimed at assessing the effect of sugarcane straw hemicellulosic hydrolysate supplementation with sucrose as co-substrate on xylitol production by C. guilliermondii FTI 20037 [16]. Results in the aforementioned study showed that sucrose addition (10 g L−1) to the fermentation medium led to significant improvement (12.88% and 8.69%) in the final xylitol concentration (36.11 g L−1) and volumetric productivity (0.75 g L−1 h−1), respectively, in comparison to the control medium (31.99 g L−1 and 0.69 g L−1 h−1, respectively). These improvements are similar to the ones recorded in the present study (11.63% and 12.24% in xylitol concentration and volumetric productivity), despite the differences between the values of these parameters in the previous and the present studies.

BSHH supplementation with sugarcane syrup was also related to increased cell growth (Fig. 2). The highest net cell biomass was obtained in the fermentation medium with the highest sugarcane syrup concentration (3.33% v/v), which represented 110.27% increase in comparison to the absence of this co-product. The complex sugarcane syrup composition explains such outcome, since sugarcane syrup can be a source of sugars, mainly of sucrose (45%), glucose (25%) and fructose (23%), as verified in the present study and reported in literature [38, 39], but also a source of minerals, nitrogenous compounds, among others [37]. These compounds can favor yeast growth and turn sugarcane syrup t into a potential nutritional supplement for fermentation media.

Cell growth improvement promoted by BSHH supplementation with sugarcane syrup could have both positive and negative effects on xylitol production. Firstly, the increased cell growth possibly favored xylitol production and volumetric productivity, since higher cell biomass concentrations could be related to higher xylose consumption and xylitol formation rates (Figs. 1 and 2). On the other hand, higher cell growth could also be the evidence of higher proportions of carbon derived from xylose assimilation used for cell growth. Such process affects xylitol accumulation and, consequently, bioconversion efficiency, which was actually lower or barely similar to the efficiency observed without sugarcane syrup (Table 3). Similar considerations were made by Tochampa et al. [32] when studied the effect of glucose as co-substrate on xylitol production by Candida mogii in a defined medium.

Similar to the cell growth results, supplementation of BSHH with higher sugarcane syrup concentrations was related to increased ethanol production (Fig. 2). The highest ethanol production (15.28 ± 2.09 g L−1) was reached in the fermentation medium with the highest sugarcane syrup concentration (3.33% v/v), which corresponded to 232.90% increase in comparison to the control (4.59 ± 0.33 g L−1). Ethanol production increase due to supplementation with sugarcane syrup resulted from the increment in hexoses and sucrose contents in the fermentation medium. Ethanol is not only a by-product of xylose metabolism but also a major fermentation product from hexoses metabolism under the micro-aerobic conditions adopted in the present study [40,41,42].

Ethanol concentrations reached in the experiment using the highest sugarcane syrup concentration (Fig. 2) were higher than those evidenced in previous studies on xylitol production by C. guilliermondii FTI 20037 from hemicellulosic hydrolysates without the supplementation with hexoses-rich nutrients [41, 43]. The high hexose-fermenting ability and ethanol production (approximately 90 g L−1) of this yeast were recently demonstrated in a defined medium [42]. Nevertheless, native xylose-fermenting yeasts have already shown low tolerance to ethanol [42, 44]. Based on our results, the recorded ethanol concentrations could have negative effect on the performance of C. guilliermondii FTI 20037. Such assumption is evidenced by the lower xylitol production in the experiment with the highest syrup addition in comparison to the other experiments (Fig. 2). Similar results were recorded by Kim et al. [13] and Walther et al. [27], which studied the effect of glucose on xylitol production by C. tropicalis on defined fermentation media. Glycerol is also a by-product of xylose metabolism, and its formation was observed in all experiments, although there was no difference between the assessed conditions (data not shown).

Replacement of the Conventional Nutritional Supplementation with Sugarcane Syrup Addition

Bagasse and straw hemicellulosic hydrolysate supplementation with sugarcane syrup at concentration 2.50% (v/v) favored xylose consumption and xylitol production by C. guilliermondii FTI 20037. The partial or complete replacement of conventional nutrients used for fermentation medium formulation [rice bran extract, (NH4)2SO4 and CaCl2·2H2O] with the supplementation with sugarcane syrup was investigated. Experiments were performed based on a 23 full factorial design with three repetitions at the center point. Table 4 summarizes the xylose consumption, bioconversion efficiency and xylitol volumetric productivity results.

The highest bioconversion efficiency (60.74%) and xylitol volumetric productivity (0.54 g L−1 h−1) values, and one of the highest xylose consumptions (98.51%), were recorded in experiment 3, in which the rice bran extract solution was not used to supplement the fermentation medium. Similar results were recorded for the center point experiments (Table 4), in which all nutrients were employed half of the concentration conventionally used in the supplementation [15, 16, 19]. Nevertheless, based on the statistical analysis of the collected data, all studied variables had non-significant effects on the xylitol volumetric productivity and bioconversion efficiency (p > 0.05) responses; only the variable (NH4)2SO4 had main significant and positive effect on xylose consumption (p < 0.05).

According to the recorded results, the use of sugarcane syrup as nutritional supplement in xylitol production from the hemicellulosic hydrolysate of the bagasse and straw mixture allowed replacing the nutrients conventionally adopted for this bioprocess: rice bran extract, (NH4)2SO4 and CaCl2·2H2O. Such outcome can be explained by the fact that sugarcane syrup is a source of several nutrients since its complex composition includes nitrogenous compounds, minerals and vitamins [37, 45]. Actually, sugarcane syrup has been already used as substrate in the production of many products such as ethanol, hydrogen, methane and levan [37, 46, 47].

Conclusion

Sugarcane syrup, which is a co-product from sugar and alcohol processes, can be used as nutritional supplementation for xylitol production by C. guilliermondii FTI 20037 from bagasse and straw hemicellulosic hydrolysate. Xylose consumption and xylitol volumetric productivity were improved by the hemicellulosic hydrolysate supplementation with sugarcane syrup at concentration 2.50% v/v, which was associated with the potential positive effects of simultaneous consumption of xylose and sucrose as co-substrate. Sugarcane syrup concentration increase to 3.33% (v/v) reduced xylitol production but favored cell growth and ethanol formation as a by-product from this bioprocess. When hemicellulosic hydrolysate was supplemented with sugarcane syrup (2.50% v/v), the nutrients conventionally adopted [rice bran extract, (NH4)2SO4 and CaCl2·2H2O] in studies on xylitol production from lignocellulosic biomasses had no significant effects on this bioprocess. Therefore, sugarcane syrup can replace these nutrients, which in consequence, may contribute for xylitol production cost reduction and for its integration to sugarcane biorefineries.

References

Cherubini, F.: The biorefinery concept: using biomass instead of oil for producing energy and chemicals. Energ. Convers. Manage. 51, 1412–1421 (2010)

Budzianowski, M.: High-value low-volume bioproducts coupled to bioenergies with potential to enhance business development of sustainable biorefineries. Renew. Sustain Energy Rev. 70, 793–804 (2017)

Renó, M.L.G., Olmo, O.A., Palacio, J.C.E., Lorea, E.E.S., Venturini, O.J.: Sugarcane biorefineries: case studies applied to the Brazilian sugar-alcohol industry. Energ. Convers. Manage. 86, 981–991 (2014)

Pippo, W., Luengo, C.A., Alberteris, L.A.M., Garzone, P., Cornacchia, G.: Energy recovery from sugarcane-trash in the light of 2nd generation biofuels. Part 1: current situation and environmental aspects. Waste Biomass Valor. 2, 1–16 (2011)

Long, S.P., Karp, A., Buckeridge, M.S., Davis, S.C., Jaiswal, D., Moore, P.H., Moose, S.P., Murphy, D.J., Onwona-Agyeman, S., Vonshak, A.: Feedstocks for fuels and bioenergy. In: Souza, G.M., Victoria, R.L., Joly, C.A., Verdade, L.M. (eds.) SCOPE Bioenergy and Sustainability: Bringing the Gaps, pp. 314–318. SCOPE, SCOPE (2015)

Companhia Nacional de Abasteciomento – CONAB: Acompanhamento da Safra Brasileira: Cana-de-açúcar. Primeiro levantamento. Brasilia (2017)

Werpy, T., Peterson, G.: Top value added chemicals from biomass. Volume I: Results of Screening for Potential Candidates from Sugars and Synthesis Gas. U.S. Department of Energy, Energy Efficiency and Renewable Energy. http://www1.eere.energy.gov/bioenergy/ (2004). Accessed 16 June 2014

Silva, S.S., Chandel, A.K.: d-Xylitol. Fermentative Production, Application and Commercialization. Springer, Berlin (2012)

Rueda, C., Calvo, P.A., Moncalián, G., Ruiz, G., Coz, A.: Biorefinery options to valorize the spent liquor from sulfite pulping. J. Chem. Technol. Biot. 90, 2218–2226 (2015)

Hou-Rui, Z.: Key drivers influencing the large scale production of xylitol. In: Silva, S.S., Chandel, A.K. (eds.) d-Xylitol. Fermentative Production, Application and Commercialization, pp. 267–290. Springer, Berlin (2012)

Sene, L., Vitolo, M., Felipe, M.G.A., Silva, S.S.: Effects of environmental conditions on xylose reductase and xylitol dehydrogenase production by Candida guilliermondii. Appl. Biochem. Biotechnol. 84–86, 371–380 (2000)

Granström, T., Izumori, K., Leisola, M.: A rare sugar xylitol. Part I: The biochemistry and biosynthesis of xylitol. Appl. Microbiol. Biotechnol. 74, 227–281 (2007)

Kim, J., Ryu, Y., Seo, J.: Analysis and optimization of a two-substrate fermentation for xylitol production using Candida tropicalis. J. Ind. Microbiol. Biot. 22, 181–186 (1999)

Tamburini, E., Bianchinib, E., Brunia, A., Forlani, G.: Cosubstrate effect on xylose reductase and xylitol dehydrogenase activity levels, and its consequence on xylitol production by Candida tropicalis. Enzyme Microb. Technol. 46, 352–359 (2010)

Silva, D.D.V., Felipe, M.G.A.: Effect of glucose:xylose ratio on xylose reductase and xylitol dehydrogenase activities from Candida guilliermondii in sugarcane bagasse hydrolyzate. J. Chem. Technol. Biot. 81, 1294–1300 (2006)

Hernández-Pérez, A.F., Costa, I.A.L., Silva, D.D.V., Dussán, K.J., Villela, T.R., Canettieri, E.V., Carvalho Jr., J.A., Soares Neto, T.G., Felipe, M.G.A.: Biochemical conversion of sugarcane straw hemicellulosic hydrolyzate supplemented with co-substrates for xylitol production. Bioresour. Technol. 200, 1085–1088 (2016)

Rodrigues, R.C.L.B., Felipe, M.G.A., Silva, J.B.A., Vitolo, M.: Response surface methodology for xylitol production from sugarcane bagasse hemicellulosic hydrolysate using controlled vacuum evaporation process variables. Process. Biochem. 38, 1231–1237 (2003)

Marton, J.M., Felipe, M.G.A., Silva, J.B.A., Pessoa Jr., A.: Evaluation of the activated charcoals and adsorption conditions used in the treatment of sugarcane bagasse hydrolyzate for xylitol production. Braz. J. Chem. Eng. 23, 9–21 (2006)

Arruda, P.V., Santos, J.C., Rodrigues, R.C.L.B., Silva, D.D.V., Yamakawa, C.K., Rocha, G.J.M., Junior, J.N., Pradella, J.G.C., Rossell, C.E.V., Felipe, M.G.A.: Scale up of xylitol production from sugarcane bagasse hemicellulosic hydrolysate by Candida guilliermondii FTI 20037. J. Ind. Eng. Chem. 47, 297–302 (2017)

Gouveia, E.R., Nascimento, R.T., Souto-Maior, A.M., Rocha, G.J.M.: Validação de metodologia para a caracterização química do bagaço de cana-de-açúcar. Quím Nova. 32, 1500–1503 (2009)

Duarte-Almeida, J.M., Salatino, A., Genovese, M.I., Lajolo, F.M.: Phenolic composition and antioxidant activity of culms and sugarcane (Saccharum officinarum L.) products. Food Chem. 125, 660–664 (2011)

Rao, L.V., Goli, J.K., Gentela, J., Koti, S.: Bioconversion of lignocellulosic biomass to xylitol: an overview. Bioresour. Technol. 213, 299–310 (2016)

Cortez, D.V., Roberto, I.C.: Individual and interaction effects of vanillin and syringaldehyde on the xylitol formation by Candida guilliermondii. Bioresour. Technol. 101, 1858–1865 (2010)

Preziosi-Belloy, L., Nolleau, V., Navarro, J.M.: Fermentation of hemicellulosic sugars and sugar mixture to xylitol by Candida parapsilosis. Enzyme Microb. Technol. 21, 124–129 (1997)

Wannawilai, S., Lee, W.C., Sirisansaneeyakul, S.: Furfural and glucose can enhance conversion of xylose to xylitol by Candida magnoliae TISTR 5663. J. Biotechnol. 241, 147–157 (2017)

Lee, H., Sopher, C.R., Yau, K.Y.F.: Induction of xvlose reductase and xvlitol dehydrogenase activities on mixed sugars in Candida guilliermondii. J. Chem. Technol. Biotechnol. 66, 375–379 (1996)

Walther, T., Hensirisak, P., Agblevor, F.A.: The influence of aeration and hemicellulosic sugars on xylitol production by Candida tropicalis. Bioresour. Technol. 76, 213–220 (2001)

Hernández-Pérez, A.F., Arruda, P.V., Felipe, M.G.A.: Sugarcane straw as feedstock for xylitol production by Candida guilliermondii FTI 20037. Braz. J. Microbiol. 47, 489–496 (2016)

Zhang, G.C., Liu, J.J., Kong, I.L., Kwak, S., Jin, Y.S.: Combining C6 and C5 sugar metabolism for enhancing microbial bioconversion. Curr. Opin. Chem. Biol. 29, 49–57 (2015)

Hou, J., Qiu, C., Shen, Y., Li, H., Bao, X.: Engineering of Saccharomyces cerevisiae for the efficient co-utilization of glucose and xylose. FEMS Yeast Res. 17 (2017)

Bruinenberg, P.M., Van Dikjen, J.P., Scheffers, A.: An enzymic analysis of nadph production and consumption in Candida utilis. J. Gen. Microbiol. 129, 965–971 (1983)

Tochampa, W., Sirisansaneeyakul, S., Vanichsriratana, W., Srinophakun, P., Bakker, H.H.C., Chisti, Y.: A model of xylitol production by the yeast Candida mogii. Bioprocess Biosyst. Eng. 28, 175–183 (2005)

Oh, D.K., Kim, S.Y.: Increase of xylitol yield by feeding xylose and glucose in Candida tropicalis. Appl. Microbiol. Biotechnol. 50, 419–425 (1998)

Tavares, J.M., Duarte, L.C., Collaço-Amaral, M.T., Gírio, F.M.: The influence of hexoses addition on the fermentation of d-xylose in Debaryomyces hansenii under continuous cultivation. Enzyme Microb. Technol. 26, 743–747 (2000)

Flores, C.L., Rodríguez, C., Petit, T., Gancedo, C.: Carbohydrate and energy-yielding metabolism in non-conventional yeasts. FEMS Microbiol. Rev. 24, 507–529 (2000)

Williamson, P.R., Huber, M.A., Bennett, J.E.: Role of maltase in the utilization of sucrose by Candida albicans. Biochem. J. 291, 765–771 (1993)

Oliveira, M.R., Silva, R.S.S.F., Buzato, J.B., Celligoi, M.A.P.C.: Study of levan production by Zymomonas mobilis using regional low-cost carbohydrate sources. Biochem. Eng. J. 37, 177–183 (2007)

Laksameethanasan, P., Somla, N., Janprem, S., Phochuen, N.: Clarification of sugarcane juice for syrup production. Procedia Eng. 32, 141–147 (2012)

Pimpakan, P., Yongmanitchai, W., Limtong, S.: Bioethanol production from sugar cane syrup by thermo-tolerant yeast, Kluyveromyces marxianus DMKU3-1042, using fed-batch and repeated-batch fermentation in a nonsterile system. Kasetsart. Nat. Sci. 46, 582–591 (2012)

Granström, T., Ojamo, H., Leisola, M.: Chemostat study of xylitol production by Candida guilliermondii. Appl. Microbiol. Biotechnol. 55, 36–42 (2001)

Rodrigues, R.C.L.B., Sene, L., Matos, G.S., Roberto, I.C., Pessoa Jr., A., Felipe, M.G.A.: Enhanced xylitol production by precultivation of Candida guilliermondii cells in sugarcane bagasse hemicellulosic hydrolysate. Curr. Microbiol. 53, 53–59 (2006)

Wen, X., Sidhu, S., Horemans, S.K.C., Sooksawat, N., Harner, N.K., Bajwa, P.K., Yuan, Z., Lee, H.: Exceptional hexose-fermenting ability of the xylitol-producing yeast Candida guilliermondii FTI 20037. J. Biosci. Bioeng. 121, 631–637 (2016)

Rodrigues, R.C.L.B., Felipe, M.G.A., Roberto, I.C., Vitolo, M.: Batch xylitol production by Candida guilliermondii FTI 20037 from sugarcane bagasse hemicellulosic hydrolyzate at controlled pH values. Bioprocess Biosyst. Eng. 26, 103–107 (2003)

Hahn-Hägerdal, B., Jeppsson, H., Skoog, K., Prior, B.A.: Biochemistry and physiology of xylose fermentation by yeasts. Enzyme Microb. Technol. 16, 933–943 (1994)

Prati, P., Camargo, G.A.: Características do caldo de cana e sua influência na estabilidade da bebida. BioEng 2, 037–044 (2008)

Doelle, H.W., Kennedy, L.D., Doelle, M.B.: Scale-up of ethanol production from sugarcane using Zymomonas mobilis. Biotechnol. Lett. 13, 131–136 (1991)

Nualsri, C., Reungsang, A., Plangklang, P.: Biochemical hydrogen and methane potential of sugarcane syrup using two-stage anaerobic fermentation process. Ind. Crop. Prod. 82, 88–99 (2016)

Acknowledgement

This work was supported by the São Paulo Research Foundation (FAPESP) (Process 2016/22179-0 and Scholarship 2016/05971-2) and CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico, Brazil).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hernández-Pérez, A.F., Chaves-Villamil, A.C., de Arruda, P.V. et al. Sugarcane Syrup Improves Xylitol Bioproduction from Sugarcane Bagasse and Straw Hemicellulosic Hydrolysate. Waste Biomass Valor 11, 4215–4224 (2020). https://doi.org/10.1007/s12649-019-00742-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-019-00742-6