Abstract

In this work, a route to synthesize bioadditives through H4SiW12O40-catalyzed levulinic acid esterification reactions with alcohols of short chain at room temperature was assessed. Among the Brønsted acids assessed (i.e., sulfuric, p-toluenesulfonic, silicotungstic, phosphomolybdic and phosphotungstic acids), H4SiW12O40 was the most active and selective catalyst. High conversions (ca. 90%) and selectivity (90–97%) for alkyl levulinates with carbon chain size ranging from C6 to C10 were obtained. The effect of main reaction parameters was studied, with a special focus on the reaction temperature, stoichiometry of reactants, concentration and nature of the catalyst. Insights on reaction mechanism were done and the activity of heteropoly catalysts was discussed based on acid strength and softness of the heteropolyanions. The use of renewable raw material, the mild reaction conditions (i.e., room temperature), and a recyclable solid catalyst are the some of the positive features of this process. The alkyl levulinates obtained are renewable origin bioadditives that can be blended either to gasoline or diesel.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

This work describes the synthesis of alkyl levulinates at room temperature using as catalyst the silicotungstic acid, an efficient and recyclable commercial catalyst. Heteropolyacid have been used as solid-supported catalysts, in reactions carried out at reflux temperature of alcohols. Herein, the soluble solid catalyst (H4SiW12O40) was very efficient in reactions carried out at room temperature. We developed a simple route to recovery through liquid–liquid extraction process, which was thus successfully reused without loss activity. In general, only solid-supported can be reused, however, it commonly requires a laborious synthesis to supporting the acid catalyst on high surface solid. In addition, solid supported catalysts suffer with deactivation due to the high polarity of reaction medium. All these drawbacks were circumvented herein.

Introduction

The inevitable depleting of the fossil fuels and the environmental impact generated by the increase of the greenhouse gases emission has motivated the chemical industries to develop processes where renewable raw materials can replace the petroleum-derived chemicals [1, 2]. In this sense, lignocellulosic biomass has been recognized as a renewable feedstock that can become an inexhaustible source of products for industrial application, reducing the consumption of the petrochemicals and arising a strategically important option from economic and environmental viewpoint [3, 4]. Feed crop residues, wood wastes, and other renewable biomass by-products are highly available raw materials that are a source of platform molecules for the future biorefinery [5,6,7].

The acid hydrolysis of lignocellulosic feedstock (i.e., carbohydrates such as glucose and fructose) has as one of the main products the levulinic acid, which is a versatile building block to synthesize various interesting chemicals for fragrance, food and pharmaceutical industries [8, 9]. Especially, alkyl levulinates are useful as fuel’s bioadditive because have low toxicity and improve some main properties such as flashpoint stability, lubricity, and the flow properties under low temperatures [10,11,12,13]. Indeed, alkyl levulinates are structurally like the biodiesel, they feature better oxidative stability and have less tendency to form undesirable gums [14]. Recently, several reviews have explored the potentiality of alkyl levulinates as raw material [14,15,16].

Conventionally, esterification reactions have been catalyzed by soluble mineral acid catalysts (i.e., sulfuric or hydrochloric acids) [17, 18]. Although these processes achieve high esters yield, they have great drawbacks such as the large generation of residues and neutralization effluents, the high corrosiveness, besides the great difficulty in handling and reuse the liquid acid catalysts [19].

Recyclable solid materials with strong acidity can potentially replace the conventional homogeneous acid catalysts. A common strategy is supporting the Brønsted acids over solids that have a high surface area [20]. Nevertheless, the main challenge is to obtain a stable catalyst that resists to the leaching caused by the high medium polarity. Different solids matrixes have been treated with sulfonic or sulfuric acids, resulting in catalysts that were used in levulinic acid esterification processes [21,22,23,24,25,26]. However, in addition to the leaching, the sulfonic groups of these catalysts can be alkylated and deactivated during the esterification reactions with the alcohols [27].

Notwithstanding these challenges, some sulfonated heterogeneous catalysts have been successfully developed. Guo et al. synthesized catalysts based on aryl sulfonic acid functionalized hollow mesoporous carbon spheres (named as ArSO3H-HMCSs) [28]. Those catalysts were assessed in the synthesis of alkyl levulinates from furfuryl alcohol and levulinic acid. They have found that ArSO3H-HMCSs were more active than solid or liquid commercial catalysts (i.e., Amberlyst-15 or sulfuric acid, respectively).

Lewis acid catalysts are also a viable alternative. Peng et al. developed an interesting strategy to synthesize ethyl levulinate by using the furfuryl alcohol as a substrate and AlCl3 as the catalyst [29]. This simple commercial catalyst was efficient and easily recovered and reused. Nevertheless, this route of synthesis has a disadvantage; the temperature required for the reaction of ring opening of the furfuryl alcohol is higher than that used to esterify the levulinic acid (i.e., 393 K and 333 K, respectively). Moreover, the ethyl levulinate synthesis was efficient only when a high molar ratio ethyl alcohol: furfuryl alcohol was used (ca. 170:1).

Keggin heteropolyacids (HPAs) have received a lot of attention due to their easy synthesis and strong Brønsted acidity, being widely used in several acid-catalyzed reactions [30,31,32]. However, they are solid with a low surface area (i.e., 1–5 m2/g) [33]. Aiming to circumvent this drawback, several groups have supported the HPAs over solid matrixes with higher surface area [34,35,36,37]. Nowadays, the design of stable solid-supported acid catalysts for biofuels production is still a great challenge [38, 39]. Baronetti et al. synthesized several silica-included Wells–Dawson HPAs and used they as catalysts to convert levulinic acid to ethyl levulinate. Although these catalysts had been repeatedly used without loss activity, a high molar ratio of alcohol to acid (ca. 1:64) was essential to achieve a high ester yield [40]. Guo et al. described the successful use of H4SiW12O40/bi-functionalized organosilica nanotubes ZrO2 in esterification of levulinic acid with different alcohols [41]. The laborious synthesis of this catalyst hampers its use at industrial scale.

In this study, we established a route to synthesize alkyl levulinates at room temperature using the H4SiW12O40 as a soluble and recyclable catalyst. A novel procedure allowed recovery and reuse the homogeneous catalyst. The activity of H4SiW12O40 was compared to the other soluble Keggin HPAs and liquid Brønsted acid catalysts. Alkyl levulinates with carbon chain size of gasoline (C6–C9) were efficiently synthesized at room temperature when H4SiW12O40 was the catalyst. The effects of the main reaction parameters were assessed. We paid a special emphasis on reuse and recycle of H4SiW12O40 catalyst, an aspect that distinguishes this homogeneous catalyst from the other ones.

Materials and Methods

Chemicals

All the chemicals and solvents were used as received. Heteropolyacids (i.e., H3PW12O40, H3PMo12O40, H4SiW12O40), and p-toluene sulfonic acid (99 wt%) were acquired from Sigma-Aldrich. Levulinic acid (97 wt%), alkyl (i.e., methyl, ethyl, propyl, isopropyl, butyl and benzyl) alcohols having purity between 99.5 and 99.8% wt%, were also purchased from Sigma-Aldrich. Sulfuric acid (98 wt%) were purchased from Dinamica.

Catalytic Runs

Catalytic tests were carried in a glass reactor (50 mL) fitted with a reflux condenser and sampling septum, under magnetic stirrer. Typically, Brønsted acid catalyst (ca. 1 mol% of H+ ions in relation to the levulinic acid) and an adequate amount of the alcohol (ca. 158.0 mmol) were dissolved, and the reactor temperature was adjusted to 298 K. Then, the reaction was started by adding of levulinic acid (ca. 8.8 mmol).

To monitoring the reactions, aliquots were collected at regular time intervals and analyzed by chromatography gas, in a Shimadzu 2014 plus gas chromatograph instrument fitted with FID and a CP-WAX capillary chromatographic column (25 m × 0.32 mm × 0.30 µm). Toluene was internal standard. The plotting of GC peak areas of the products or substrate in the calibrating curves allowed calculating the conversion and the checking the reaction mass balance.

The selectivity of the main products was calculated following the Eq. 1, where rf correspond to the response factor that was obtained from calibration curves built with the pure products.

The E-factor calculation for the reaction of levulinic acid esterification with ethanol was done in according with the Eq. 2:

The reaction products were identified by GC/MS analyses (Shimadzu MS-QP 2010 ultra, mass spectrometer, electronic impact mode at 70 eV, coupled to a Shimadzu 2010 plus, GC) and by comparison with the authentic samples.

Measurements of Acidity Strength

The catalysts acidity was measured by potentiometric titration, as describe by Pizzio et al. [42]. The electrode potential variation was measured with a potentiometer (i.e., Bel, model W3B). Typically, an acetonitrile solution containing the acid catalyst (ca. 100 mg) was titrated with n-butylamine solution in toluene (ca. 0.025 mol L−1).

Product Chromatographic Separation and Characterization

Reaction products were separated by column chromatography (silica) using mixtures of hexane and ethyl acetate at 1:3 volume proportion as the eluent, and then identified by GC/MS (Shimadzu MS-QP 2010 ultra mass spectrometer instrument operating at 70 eV coupled Shimadzu 2010 GC) by comparison with the authentic samples. Afterwards, they were characterized by 1H and 13C NMR analyses and FT-IR/ATR spectroscopy analyses. The main results are presented in the supplemental material (Figs. SM1–SM4).

The NMRs spectra were taken in CDCl3 solutions, using a Varian 300 spectrometer at 300.13 and 75.47 MHz, respectively. FT-IR/ATR spectroscopy analyses were recorded in Varian spectrometer. The chemical shifts were expressed as δ (ppm) relatively to tetramethyl silane (TMS) as an internal reference.

Recovery and Reuse of Catalyst

The catalyst recovery was performed through the liquid–liquid extraction process. After the end of the reaction, the remaining solution was concentrated in a rotatory evaporator; a mixture of dichloromethane-water was added (ca. 10 mL 1:1). The organic phase was three times washed with water (ca. 5 mL), and the aqueous phase containing the catalyst was vapored until dry, providing the solid catalyst, which was then reused in another catalytic run.

Results and Discussion

Effect of Catalyst Nature on the Levulinic Acid Esterification with Ethyl Alcohol

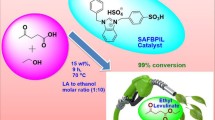

The levulinic acid (1) esterification with alcohols is a reversible reaction commonly carried out in the presence of liquid Brønsted acid catalysts such as hydrochloric, p-toluenesulfonic or sulfuric acids. Herein, we have assessed this reaction in the presence of silicotungstic acid and at room temperature (Scheme 1).

Besides the acidic strength, the softness of the anion present in the Brønsted acid plays a key role in the catalyst activity in esterification reactions. Therefore, we have assessed the activity of Brønsted acids with the same H+ concentration. Frequently, esterification reactions of (1) have been carried out at the reflux temperature of alcohol [39,40,41]. However, in a previous work, we have found that H3PW12O40 catalyst was highly active in esterification reactions of glycerol and fatty acids at room temperature [43, 44]. Therefore, this was the temperature selected herein. It is worth mentioning that reaction initial conditions (Fig. 1) were not optimized to provide the highest conversions.

The silicotungstic acid (i.e., H4SiW12O40) is a solid catalyst easier to handling than traditional liquid Bronsted acid catalysts. In addition, it was more active than sulfuric acid or even other Keggin heteropolyacids studied (Fig. 1).

The leveling effect of solvent makes all these catalysts equally stronger in water. However, this effect is absent herein, because even being used at the same H+ cations concentration, different conversions were achieved in esterification reactions of (1) (Fig. 1). The HPA catalysts were more efficient than sulfuric and p-toluene sulfonic acids. It can be attributed to the large radium of heteropolyanions, which have the highest softness due to their higher charge delocalization. Experimentally, we have found that the HPAs catalyst activity obeys the trends: H4SiW12O40 ≅ H3PW12O40 > H3PMo12O40. This result agrees with the literature that attributes higher pKa values for the tungsten HPA catalysts [45].

The site of protons is an important issue to understand this result. NMR experiments and DFT calculations demonstrated that the protons of the H3PW12O40 are placed on terminal oxygen atom; whereas, the protons of the H3PMo12O40 are located on the oxygen of µ2-oxo bridges [46]. These two different positions explain why the acid strength of W and Mo HPAs is different.

In Table 1, we briefly summarized the main results of solid or soluble catalysts reported in the literature related to the esterification reactions of (1).

In general, the solid acid-catalyzed levulinic acid esterification reactions described in the literature were performed at a temperature equal or higher than ethyl alcohol reflux temperature (ca. 351 K) (Table 1). Although HPAs are extensively used as solid-supported catalysts in LA esterification reactions, different sulfonic acid solid catalysts are also employed on these processes [49,50,51,52]. For instance, Vaccaro and coworkers on the use of organic polymer supported catalysts for the esterification of (1) [49].

The most of catalysts listed in Table 1 were solid-supported, requiring an extensive synthesis work up. Therefore, we realize that if the affordable commercially catalyst (H4SiW12O40) was the most active at room temperature (ca. 298 K), to optimize the reaction conditions to achieve higher yield could be an important improvement for the synthesis routes of alkyl levulinates.

Discussing the Activity and Acid Strength of Catalysts

The measurement of initial electrode potential (Ei) allows to classify the acidity strength of acid sites as; Ei > 100 mV (very strong sites), 0 < Ei < 100 mV (strong sites), − 100 < Ei < 0 (weak sites) and Ei < − 100 mV (very weak sites) [42]. The acidity strength of Brønsted acid catalysts was measured by potentiometric titration with n-butylamine (Fig. 2).

All the catalysts have very strong acid sites and had their protons totally titrated with n-butylamine. The trend of acid strength was as follow: H3PW12O40 > H3PMo12O40 > H4SiW12O40 > p-toluene sulfonic acid > H2SO4. The presence of two protons with different acid strength was confirmed by the profile of the titration curve of sulfuric acid that displayed two plateaus corresponding to the different endpoints. On the other hand, it was not possible to differentiate the acid strength of protons belonging to the same heteropolyacid (Fig. 2).

We verified that our results agree with the literature, which reports that with a decreasing of the anion charge (i.e., PW12O403− < SiW12O40−4) its basicity also decreases; therefore, the acidity of the catalyst also increases [54, 55]. It explains why the H3PW12O40 is an acid stronger than H4SiW12O40. Figure 1 shows that the tungsten heteropolyacids-catalyzed reactions accomplished higher conversion than that with H3PMo12O40. Timofeeva et al. verified the same trend (i.e., H3PW12O40 ≥ H4SiW12O40 > H3PMo12O40) in the acetic acid esterification with n-butyl alcohol [45].

Other authors have demonstrated that regardless of lower acid strength, silicotungstate can be more active than phosphotungstate due to the higher softness of SiW12O404− anion [47, 48]. With a higher softness, the negative charge of heteropolyanions is more efficiently dispersed. This ability depends on the double bond polarization M=Ot (i.e., W or Mo—terminal oxygen), which left less distributed the negative charge of the anion [20].

Thus, we can conclude that the silicotungstic acid was the most active due to higher softness of SiW12O404− anion, which stabilizes the protonated intermediate formed in the esterification reaction of levulinic acid (Scheme 2) [47, 48]. Consequently, even being a weaker acid than H3PW12O40, the H4SiW12O40 was the most efficient catalyst (Fig. 1).

H4SiW12O40-Catalyzed Levulinic Acid Esterification Reactions with C2H5OH: Effect of Catalyst Concentration

Although the catalyst concentration has no effect on reaction equilibrium, our goal was establishing which load should be used to achieve the highest conversion within the shortest time, regardless the equilibrium has been or not reached.

An increase of the catalyst concentration resulted in higher conversions (Fig. 3). Notwithstanding the catalyst concentration, the reactions achieved the maximum conversion within two first hours of reaction, undergoing only a slight increase after this time (Fig. 3a). The conversion remained almost constant after this period, probably due to the water formed in the reaction, which shifts the equilibrium toward reactants. To avoid this drawback, the water can be removed from the reaction by azeotropic distillation, using Dean–Stark apparatus, however, it is out of the scope of the present work.

Although the reaction conversion has been improved by increasing catalyst load, the ethyl levulinate (2a) selectivity remained always equal or higher than 90% (Fig. 3b). Therefore, no concurrent reaction has occurred when the catalyst load was increased.

The E-factor value (obtained from Eq. 2, see experimental section) was calculated for the catalytic run with 8 mol % of catalyst load was 0.53, considering ca. 95% recovery rate of alcohol excess. This very low result is an important feature, that in according with the literature suggest that our catalytic reaction is efficient at a (multi) gram scale [53].

Effect of Reactants Molar Ratio on H4SiW12O40-Catalyzed Levulinic Acid Esterification with Ethyl Alcohol

The efficiency of H4SiW12O40 catalyst in reactions with different reactants stoichiometry was assessed varying the proportion of acid to alcohol from 1:1 to 1:18. The kinetic curves are shown in Fig. 4.

The runs with bigger proportions between (2) and (1) achieved higher initial rate and reached the greater conversions. For the molar ratios greater than 1:15, a minimum beneficial effect was accomplished. Although 1:15 represent an excess of alcohol, it is important to note that this reactant can be easily distilled and reused. In addition, the literature describes that other routes to synthesize levulinate alkyl (i.e., starting from the furfuryl alcohol) requires proportions even higher than 1:15 (ca. 1: 64) [40].

Effect of the Alcohol Carbon Chain on the H4SiW12O40-Catalyzed Levulinic Acid Esterification

Esterification reactions may be affected by the nature of the alcohols. The steric hindrance on hydroxyl group of alcohol could hamper the attack on the carbonyl group of the acid that will result in lower formation of ester. To investigate this effect, the levulinic acid was esterified with different alcohols in the presence of H4SiW12O40 catalyst (Fig. 5).

It was observed that in the reactions with primary alcohols containing until four carbon atoms, conversion rates higher or equal to 90% were achieved (see Fig. 5a). This is an attractive result because these esters have carbon chain size appropriated for be an additive to the biogasoline.

Conversely, when secondary or tertiary alcohols were the substrates, the conversion to the respective esters was significant lower. This diminishing was more pronounced when comparing the conversion rate of butyl alcohols (i.e., 90 (5), 70 (6), and 14% (7), respectively, Fig. 5b). The role of catalyst consists in protonating the levulinic acid carbonyl group, generating a sp2-intermediate. When there is a large steric hindrance on the hydroxyl group of the alcohol, the attack of carbonylic carbon atom of protonated acid is probably less efficient, which reduce the ester yield.

Alkyl esters selectivity was also significantly lower when secondary or tertiary alcohols were the reactants. No byproducts were detected by GC analyses. However, it is possible that dehydration products of alcohols (i.e., volatile olefins) have been formed in the reaction, nonetheless, they were not detected by chromatography analysis. This low selectivity may be also attributed to the formation of oligomers from branched alcohols, which are equally undetectable by GC analysis.

In Table 2, we are comparing the theoretical conversions calculated from thermodynamic equilibrium and those experimentally determined on the H4SiW12O40-catalyzed reactions.

The thermodynamic data showed that excepted the tert-butyl alcohol (7) (Entry 7, Table 2), all the other alcohols should be efficiently esterified with levulinic acid at room temperature reaching high conversions (Table 2). Nonetheless, it was essentially confirmed only for the primary alcohols. We can conclude that in some cases, the time reaction it was unable to the equilibrium be reached (i.e., reactions with (8), Entry 8, Table 2). On the other hand, when the substrates were the secondary alcohols (i.e., entries 4 and 6, respectively; Table 2), the ester selectivity was considerably low, therefore, as the theoretical calculations considered only the esterification reaction, a direct comparison of conversions it is not adequate.

Reuse and Recycle of H4SiW12O40 Catalyst in Homogeneous Phase

The H4SiW12O40 heteropolyacid is a solid catalyst, but completely soluble in the reaction medium. However, we envisage that a simple procedure may be used to recovery and reuse the catalyst. A simple liquid–liquid extraction was performed; a water-dichloromethane mixture was added to the reaction solution providing a biphasic mixture where products (organic phase) and catalyst (aqueous phase) was separated. After the water vaporization, the solid catalyst was collected and reused. The results of recovery and reuse of the catalyst are shown in Fig. 6.

The high recovery rate suggests that procedure used to catalyst recovery was efficient. In addition, no typical absorption band of Keggin heteropolyacid anion was observed in the FT-IR spectra analyses of purified products. We have found that the procedure to recovering the catalyst do not compromised its performance; indeed, the H4SiW12O40 catalyst was successfully reused without activity loss (Fig. 6).

Alternatively, the use of dichloromethane was avoided following a procedure where after the end of reaction, the solvent alcohol was vapored, and ethyl acetate was added to the reaction solution, which was eluted in silica column to removal the catalyst from products and the substrate unreacted. The washing of silica with hot water provide a solution containing the catalyst, which after vaporization give the solid catalyst, already to be once more used. Similarly, as in the previous procedure, the catalyst was successfully recovered and reused without loss activity.

It is noteworthy that the procedure to recovery the homogenous catalyst should not be considered an additional step, because to separate and purify the products after finish of reactions are steps obligatory. Therefore, even though if a heterogeneous catalyst had been used, this procedure will continue to be required.

Finally, we would like to highlight that the performance of soluble H4SiW12O40 was equal or superior to the solid-supported acid catalysts, which generally works well only at reflux temperature of the alcohol.

Conclusion

An efficient process to convert levulinic acid to alkyl esters at room temperature was developed. Among the several Brønsted acids evaluated, Keggin heteropolyacid containing tungsten (i.e., H4SiW12O40) was the most active and selective catalyst. The activity of catalysts was discussed in terms of acid strength and softness of the anions. The effects of main reaction parameters were assessed. In the presence of catalytic amounts of H4SiW12O40 dissolved in alcoholic solutions at room temperature, the levulinic acid was converted to esters with high conversions (ca. 90%, C1–C4 primary alcohols) and selectivity (ca. 90%). These esters have adequate carbon chain size to be blended with gasoline (C6–C9). Although soluble, H4SiW12O40 catalyst was easily recovered through the liquid–liquid extraction process and was reused without activity loss.

References

Mukherjee, A., Dumont, M.-J., Raghavan, V.: Review: sustainable production of hydroxymethylfurfural and levulinic acid: challenges and opportunities. Biomass Bioenergy 72, 143–183 (2015)

Rackemann, D.W., Doherty, W.O.S.: The conversion of lignocellulosic to levulinic acid. Biofuel Bioprod. Bioref. 5, 198–214 (2011)

Badgujar, K.C., Bhanage, B.M.: The green metric evaluation and synthesis of diesel-blend compounds from biomass derived levulinic acid in supercritical carbon dioxide. Biomass Bioenergy 84, 12–21 (2016)

Kuwahara, Y., Kaburagi, W., Osada, Y., Fujitani, T., Yamashita, H.: Catalytic transfer hydrogenation of biomass-derived levulinic acid and its esters to γ-valerolactone over ZrO2 catalyst supported on SBA-15 silica. Catal. Today 281, 418–428 (2017)

Chen, S.S., Maneerung, T., Tsang, D.C.W., Ok, Y.S., Wang, C.-H.: Valorization of biomass to hydroxymethylfurfural, levulinic acid, and fatty acid. methyl ester by heterogeneous catalysts. Chem. Eng. J. 328, 246–273 (2017)

Tan, J., Liu, Q., Chen, L., Wang, T., Ma, L., Chen, G.: Efficient production of ethyl levulinate from cassava over Al2(SO4)3 catalyst in ethanol–water system. J. Energy Chem. 26, 115–120 (2017)

De, S., Saha, B., Saha, B., Luque, R.: Hydrodeoxygenation processes: advances on catalytic transformations of biomass-derived platform chemicals into hydrocarbon fuels. Bioresour. Technol. 178, 108–118 (2015)

Cirujano, F.G., Corma, A., Xamena, F.X.L.: Conversion of levulinic acid into chemicals: synthesis of biomass derived levulinate esters over Zr-containing MOFs. Chem. Eng. Sci. 124, 52–60 (2015)

Enumula, S.S., Gurram, V.R.B., Chada, R.R., Burri, D.R., Kamajaru, S.R.R.: Conversion of furfuryl alcohol to alkyl levulinate fuel additives over Al2O3/SBA-15 catalyst. J. Mol. Catal. A 426, 30–38 (2017)

Zhang, J., Chen, J.: Modified solid acids derived from biomass based cellulose for one-step conversion of carbohydrates into ethyl levulinate. J. Energy Chem. 25, 747–753 (2016)

Nandiwale, K.Y., Sonar, S.K., Niphadkar, P.S., Joshi, P.N., Deshpande, S.S., Patil, V.S., Bokade, V.V.: Catalytic upgrading of renewable levulinic acid to ethyl levulinate biodiesel using dodecatungstophosphoric acid supported on desilicated H-ZSM-S as catalyst. Appl. Catal. A 90, 460–461 (2013)

Pileidis, F.D., Titirici, M.M.: Levulinic acid biorefineries: new challenges for efficient utilization of biomass. ChemSusChem 9, 562–582 (2016)

Omoruyi, U., Page, S., Hallett, J., Miller, P.W.: Homogeneous Catalyzed reactions of levulinic acid: to γ-valerolactone and beyond. ChemSusChem 9(16), 2037–2047 (2016)

Tiong, Y.W., Yap, C.L., Gan, S., Yap, W.S.P.: Conversion of biomass and its derivatives to levulinic acid and levulinate esters via ionic liquids. Ind. Eng. Chem. Res. 57, 4749–4766 (2018)

Trombettoni, V., Lanari, D., Prinsen, P., Luque, R., Vaccaro, L.: Recent advances in sulfonated resin catalysts for efficient biodiesel and bio-derived additives production, Prog. Energy Comb. Sci. 65, 136–162 (2018)

Mika, L.T., Cséfalvay, E., Németh, Á: Catalytic conversion of carbohydrates to initial platform chemicals: chemistry and sustainability. Chem. Rev. 118(2), 505–613 (2018)

Windom, B.C., Lovestead, T.M., Mascal, M., Nikitin, E.B., Bruno, T.J.: Advanced distillation curve analysis on ethyl levulinate as a diesel fuel oxygenate and a hybrid biodiesel fuel. Energy Fuels 25, 1878–1889 (2011)

Choudhary, V., Pinar, A.B., Lobo, R.F., Vlachos, D.G., Sandler, S.I.: Comparison of homogeneous and heterogeneous catalysts for glucose-to-fructose isomerization in aqueous media. ChemSusChem 6, 2369–2376 (2013)

Liu, Y.J., Lotero, E., Goodwin Jr, J.G.: A comparison of the esterification of acetic acid with methanol using heterogeneous versus homogeneous acid catalysis. J. Catal. 242, 278–286 (2006)

Su, F., Guo, Y.: Advancements in solid acid catalysts for biodiesel production. Green Chem. 16, 2934–2957 (2014)

Reddy, B.M., Patil, M.K.: Organic syntheses and transformations. catalyzed by sulfated zirconia. Chem. Rev. 109, 2185–2208 (2009)

Alsalme, A.M., Wiper, P.V., Khimyak, Y.Z., Kozhevnikova, E.F., Kozhevikov, I.V.: Solid acid catalysts based on H3PW12O40 heteropoly acid: acid and catalytic properties at a gas-solid interface. J. Catal. 276, 181–189 (2010)

Zuo, D., Lane, J., Culy, D., Schultz, M., Pullar, A., Waxman, M.: Biodiesel production from jatropha curcas crude oil using Zno/SiO2 photocatalytic for free fatty acids esterification. Appl. Catal. B 129, 342–350 (2013)

Hara, M., Yoshida, T., Takagaki, A., Takata, T., Kondo, J.N., Domen, K., Hayashi, S.: A carbon material as a strong protonic acid. Angew. Chem. Int. Ed. 43, 2955–2958 (2004)

Nakajima, K., Hara, M.: Amorphous carbon with SO3H groups as a solid brønsted acid catalyst. ACS Catal. 2, 1296–1304 (2012)

Pileidis, F.D., Tabassum, M., Coutts, S., Titirici, M.M.: Esterification of levulinic acid into ethyl levulinate catalysed by sulfonated hydrothermal carbons. Chin. J. Catal. 35, 929–936 (2014)

Fraile, J.M., García-Bordejé, E., Roldán, L.: Deactivation of sulfonated hydrothermal carbons in the presence of alcohols: evidences for sulfonic esters formation. J. Catal. 289, 73–79 (2012)

Song, D., An, S., Lu, B., Guo, Y., Leng, J.: Arylsulfonic acid functionalized hollow mesoporous carbon spheres for efficient conversion of levulinic acid or furfuryl alcohol to ethyl levulinate. Appl. Catal. B 179, 445–457 (2015)

Peng, L., Gao, X., Chen, K.: Catalytic upgrading of renewable furfuryl alcohol to alkyl levulinates using AlCl3 as a facile, efficient, and reusable catalyst. Fuel 160, 123–131 (2015)

Bregeault, J.-M., Vennat, M., Salles, L., Piquemal, J.-Y., Mahha, Y., Briot, E., Bakala, P.C., Atlamsani, A., Thouvenot, R.: From polyoxometalates to polyoxoperoxometalates and back again; potential applications. J. Mol. Catal. A 250, 177–189 (2006)

Haber, J., Pamin, K., Matachowski, L., Mucha, D.: Catalytic performance of the dodecatungstophosphoric acid on different supports. Appl. Catal. A 256, 141–152 (2003)

Yadav, G.D.: Synergism of clay and heteropoly acids as nano-catalysts for the development of green processes with potential industrial applications. Catal. Surv. Asia 9(2), 117–137 (2005)

Sawant, D.P., Vinu, A., Justus, J., Srinivasu, P., Halligudi, S.B.: Catalytic performances of silicotungstic acid/zirconia supported SBA-15 in an esterification of benzyl alcohol with acetic acid. J. Mol. Catal. A 276, 150–157 (2007)

Avhad, M.R., Marchetti, J.M.: A review on recent advancement in catalytic materials for biodiesel production. Renew. Sustain. Energy Rev. 50, 696–718 (2015)

Sambeth, J., Romanelli, G., Autino, J.C., Thomas, J., Baronetti, G.: A theoretical experimental study of Wells-Dawson phospho-tungstic heteropolyacid: an explanation of the pseudo liquid or surface-type behavior. Appl. Catal. A 378, 114–118 (2010)

Narkhede, N., Singh, S., Patel, A.: Recent progress on supported polyoxometalates for biodiesel synthesis via esterification and transesterification. Green Chem. 17, 89–107 (2015)

Zhou, Y., Chen, G., Long, Z., Wang, J.: Recent advances in polyoxometalate-based heterogeneous catalytic material for liquid-phase organic transformations. RSC Adv. 4, 42092–42113 (2014)

Da Silva, M.J., Liberto, N.A.: Soluble and solid-supported Keggin heteropolyacids as catalysts in reactions for biodiesel production: challenges and recent advances. Curr. Org. Chem. 20, 1263–1283 (2015)

Yan, K., Wu, G., Wen, J., Chen, A.: One-step synthesis of mesoporous H4SiW12O40-SiO2 catalysts for the production of methyl and. ethyl levulinate biodiesel. Catal. Commun. 34, 58–63 (2013)

Pasquale, G., Vázquez, P., Romanelli, G., Baronetti, G.: Catalytic upgrading of levulinic acid to ethyl levulinate using reusable silica-included Wells–Dawson heteropolyacid as catalyst. Catal. Commun. 18, 115–120 (2012)

Song, D., An, S., Sun, Y., Guo, Y.: Efficient conversion of levulinic acid or furfuryl alcohol into alkyl levulinates catalyzed by heteropoly acid and ZrO2 bifunctionalized organosilica nanotubes. J. Catal. 333, 184–199 (2016)

Pizzio, L.R., Vásquez, P.G., Cáceres, C.V., Blanco, M.N.: Supported Keggin type heteropoly compounds for ecofriendly reactions. Appl. Catal. A 256, 125–139 (2003)

Silva, V.W.G., Laier, L.O., Da Silva, M.J.: Novel H3PW12O40: catalyzed esterification reactions of fatty acids at room temperatures for biodiesel production. Catal. Lett. 135, 207–211 (2010)

Da Silva, M.J., Julio, A.A., Dorigetto, F.C.S.: Solvent free heteropolyacid-catalyzed glycerol ketalization at room temperature. RSC Adv. 5, 44499–44506 (2015)

Timofeeva, M.N.: Acid catalysis by heteropoly acids. Appl. Catal. A 256, 19–35 (2003)

Micek-Ilnicka, A.: The role of water in the catalysis on solid heteropolyacids. J. Mol. Catal. A 308(1–2), 1–14 (2009)

Raveendra, G., Rajasekhar, A., Srinivas, M., Prasad, P.S., Lingaiah, N.: Selective etherification of hydroxymethylfurfural to biofuel additives over Cs containing silicotungstic acid catalysts. Appl. Catal. A 520, 105–113 (2016)

An, S., Song, D., Lu, B., Yang, X., Guo, Y.H.: Morphology tailoring of sulfonic acid functionalized organosilica nanohybrids for the synthesis of biomass-derived alkyl levulinates. Chem. Eur. J. 21, 10786–10798 (2015)

Tejero, M.A., Ramìrez, E., Fitè, C., Tejero, J., Cunill, F.: Esterification of levulinic acid with butanol over ion exchange resins. Appl. Catal. A 517, 55–56 (2016)

Trombettoni, V., Bianchi, L., Zupanic, A., Porciello, A., Cuomo, M., Piermatti, I.D.O., Marrocchi, A., Vaccaro, L.: Efficient catalytic upgrading of levulinic acid into alkyl levulinates by resin-supported acids and flow reactors. Catalysts 7(8), 235–249 (2017)

Su, F., Ma, L., Song, D., Zhang, X., Guo, Y.: Design of a highly ordered mesoporous H3PW12O40/ZrO2–Si(Ph)Si hybrid catalyst for methyl levulinate synthesis. Green Chem. 15, 885–890 (2013)

Izumi, Y., Urabe, K., Onaka, A.: Zeolite, Clay, and Heteropolyacids in Organic Reactions. Tokio-VCH, Kodansha, Weinheim (1992)

Ren, Y., Liu, B., Zhang, Z., Lin, J.: Silver-exchanged heteropolyacid catalyst (Ag1H2PW): an efficient heterogeneous catalyst for the synthesis of 5-ethoxymethylfurfural from 5-hydroxymethylfurfural and fructose. J. Ind. Eng. Chem. 21, 1127–1131 (2015)

Trombettoni, V., Sciosci, D., Bracciale, M.P., Campana, F., Santarelli, M.L., Marrocchi, A., Vaccaro, L.: Boosting biomass valorisation. Synergistic design of continuous flow reactors and water-tolerant polystyrene acid catalysts for a non-stop production of esters. Green Chem. 20, 3222–3396 (2018)

Timofeeva, M.N., Matrosova, M.M., Maksimov, G.M., Likholobov, V.A., Golovin, A.V., Maksimovskaya, R.I., Paukshtis, E.A.: Esterification of n-butanol with acetic acid in the presence of heteropoly acids with different structures and compositions. Kinet. Catal. 42, 868–871 (2001)

Acknowledgements

The authors are grateful for the financial support from CNPq and FAPEMIG (Brazil). This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - Brasil (CAPES) - Finance Code 001.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Vilanculo, C.B., de Andrade Leles, L.C. & da Silva, M.J. H4SiW12O40-Catalyzed Levulinic Acid Esterification at Room Temperature for Production of Fuel Bioadditives. Waste Biomass Valor 11, 1895–1904 (2020). https://doi.org/10.1007/s12649-018-00549-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-018-00549-x