Abstract

The combination of anaerobic digestion and composting is examined as an integrated valorization process of the livestock waste generated in rural areas. Both biogas and high quality compost may be produced by such a combined process. Six different kinds of waste (pig manure, cow manure, cattle manure, poultry manure, sheep manure and whey) were mixed considering the annual waste production of Metsovo region, Greece, in a representative way. The feed was subjected to a solids/liquid separation step. The bioreactor was operated in different phases with different organic loadings of the liquid fraction of the waste. During phase #1, the Periodic Anaerobic Baffled Reactor (PABR) was fed with a hydraulic retention time (HRT) of 10.65 days, (an organic loading rate of 0.83 g-COD Lreactor−1 day−1) and the biogas production rate was 0.2 Lbiogas Lreactor−1 day−1. During phase #2, the organic loading rate was increased to 1.9 g-COD Lreactor−1 day−1. The biogas production rate was 0.41 Lbiogas Lreactor−1 day−1. During phase #3, the organic loading rate was increased to 2.69 g-COD Lreactor−1 day−1 by decreasing the HRT to 6 days, resulting in the kinetic limitation of the process. The biogas production rate increased to 0.68 Lbiogas Lreactor−1 day−1 with an average methane composition of 65%. The experimental results obtained were used as a basis for the development of an ADM1 model (Batstone et al. in Anaerobic digestion model no. 1 (ADM1). IWA Task Group for Mathematical Modelling of Anaerobic Digestion Processes Report no 1, vol 1(1), 2002) that was able to adequately simulate the operation of the bioreactor. The solid fraction of the pretreatment step was mixed with sawdust and fed to a closed-vessel composter. The highest temperature (56.2 °C) was reached in 2 days. The germination index (GI) of the compost produced was 77.8%, meaning that it was free of phytotoxic substances.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Animal by-products and whey are the by-products of livestock farming, which is a significant agricultural activity with high social and economic impact on rural regions [1]. The properties of livestock waste include its -by nature- high content in anaerobic bacteria, high moisture levels (96–98% in slurry) and good digestibility without requiring the addition of micronutrients.

There are, however, several factors that render the design of an anaerobic digester at an individual farm level, quite expensive, unprofitable and susceptible to unpredictable failures. A possible solution to this problem is the anaerobic co-digestion of multiple waste types, as far as origin, composition and seasonality of livestock waste are concerned in a central unit, capable of handling large and diverse amounts of waste. A combined anaerobic digestion followed by composting process may be the most effective and beneficial valorization of the animal by-products [2]. A standard CSTR-type digester may be used for the production of biogas, while the digestate may be subsequently composted. Such an approach would generally require rather large retention times for the digester, implying high construction costs. On the other hand, separation of the solid and the liquid fraction of the waste, would allow the use of a high-rate digester for biogas production, operated at much smaller hydraulic retention times (less than 10 days), while the solid fraction is suitable for composting to produce high quality fertilizer [3]. Such a scheme would not exploit of course all the methane potential of the organic matter, but it would lead to an economically viable and robust valorization scheme.

Solid/liquid separation and production of biogas from the liquid fraction have been proposed before. For example, in Italy swine manure has been processed by a sequencing anaerobic digestion batch reactor (SBR) at large scale [4]. The high proportion of solids in the manure (60%) led to a higher gas production per digester volume than the one that could be achieved by liquid manure alone [5] or by conventional anaerobic fermentation [6].

The combined treatment of the liquid (anaerobic) and the solid to produce fertilizer is examined and highly recommended by many research projects and experts in the field [7,8,9] and has also been applied in some cases such as in the Hengelo, Netherlands plant where a continuous plug-flow anaerobic digester is integrated into a larger composting operation [10] and in Järna/Sweden where a prototype on-farm biogas plant produces biogas and subsequently a solid manure compost [11]. A similar combined process of anaerobic digestion and co-composting has been also employed in Italy, for municipal solid waste [12].

In the present study, a mixture of livestock waste and whey collected from the mountainous region of Metsovo, Greece, was subjected to a liquid/solid separation stage. The liquid fraction (extract) was fed to a pilot-scale Periodic Anaerobic Baffled Reactor for the production of biogas and the solid fraction was led to a lab-scale composter for the production of fertilizer.

The periodic anaerobic baffled reactor (PABR) is a novel high-rate bioreactor, designed to operate at high organic loading rates. The PABR resembles a simple anaerobic baffled reactor (ABR) with the compartments configured circularly. Due to the compartmentalized structure of the PABR, the biomass is not required to be in the form of granules to be retained in the interior of the bioreactor (in contrast to the UASB reactors), although granules may be formed with time. Variation of the switching frequency [or equivalently the switching period (T), i.e. the time for switching the feed to all compartments] allows flexibility in the operation of the PABR. The PABR can be operated as a simple ABR, if the switching frequency is set to zero, and, in the extreme case of very high switching frequency, as a single-compartment upflow bioreactor [13, 14]. As a high-rate bioreactor, the PABR optimally operates with a feedstock of less than 5% TS (w/w) [15]. For a given switching frequency, despite the fact that the influent and effluent flow rates to the reactor may be constant, a stable periodic state is established in the reactor, with the concentrations of all species undergoing a continual oscillation with amplitudes that depend on the switching frequency. Thus, concentrations in the PABR compartments and the reactor effluent generally exhibit larger standard deviations than is the case for a CSTR.

The scope of the current study was to develop a novel method for the integrated utilization of animal by-products and whey. More specifically, the potential to use a combined anaerobic digestion and composting process to produce biogas and high-quality fertilizer was investigated. To achieve this, a pretreatment step was developed aiming to separate the liquid and the solid fractions of the waste. The pretreatment step was necessary since as mentioned, the PABR, as a high-rate bioreactor cannot treat high in solids wastewater. The liquid fraction of the pretreatment step was used as a feedstock in the pilot-scale PABR and the solid fraction in the composting process.

The experimental results of the PABR were used as a basis to develop a model that will be able to adequately simulate the operation of this novel bioreactor. The Anaerobic Digestion Model No 1 (ADM1) [16] ,which is the most widely accepted is used as a modeling framework, in order to assess its applicability for describing the behavior of the PABR, something that has not been attempted before.

Materials and Methods

Experimental Procedure

The livestock waste and the cheese whey used in this study were collected from local farms from the region of Metsovo, Greece. The sampling methodology used was based on the US EPA Soil Sampling methodology [17]. Animal manure from five different points was collected. Cheese whey was collected in 5 consecutive days, to ensure that the collected waste is representative.

The feedstock used for the period in which the experiments took place (the whole quantity of feedstock used was taken once) was preserved at 4 °C. The physicochemical characteristics of each type of waste are presented in Table 1 [15].

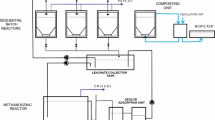

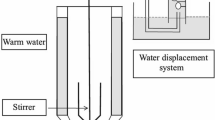

The different types of livestock waste and whey were mixed in different ratios. The mixture produced, was diluted in water at 60 °C and was vigorously stirred for 30 min. Then the slurry was filtered under pressure using a cloth filter. The liquid phase (extract) retained an average of ~ 50% of the organic content of the mixture and was fed with different organic loading rates (OLR) to a pilot scale PABR (Fig. 1), for the production of biogas through anaerobic co-digestion. The organic content of the liquid phase was suitable for feeding the PABR (8–21 g-COD/L) depending on the dilution ratio. The solid fraction of the pretreatment step was mixed with sawdust as a bulking agent (5:2 w/w) and the mixture was fed to a lab-scale composter with a total useful volume of 28 L (Fig. 2) for the production of compost.

The Periodic Anaerobic Baffled Reactor

The operating volume of the pilot scale four-compartment PABR was 77 L. It was equipped with sampling valves in every compartment placed in the middle-height of the compartment. There were also four biogas vents on the top of the reactor. The PABR consists of two concentric cylinders of which the interior is full of water maintained at 35 °C through temperature control. Feeding was performed via a peristaltic pump controlled by an on/off time controller. Details of the PABR description can be found in Skiadas and Lyberatos [14].

The Composter

The composter used in the experimental procedure was a horizontal cylinder made of stainless steel and had 30 cm diameter and 40 cm length. The operating volume of the composter was 28 L. For insulation of the composter, polyurethane foam was used, covered by aluminum foil. At the bottom of the reactor, a sieve tray allowed effective air diffusion through the mixture. At the same time, the holes of the tray allowed the leachate of the mixture to be collected through a valve at the bottom of the reactor. The composter was equipped with a mechanical stirring system, which was activated every 24 h for the homogenization of the substrate and a temperature sensor, continuously monitoring and recording the temperature of the composting mixture. The composter design allowed condensate collection and sampling.

Anaerobic Co-digestion

During the experimental phase #1, the HRT was set to 10.65 days and the average influent COD was 8.81 g/L. After 78 days of operation, the OLR was increased (average influent COD of 20.31 g/L), while maintaining the HRT at 10.65 days and the switching period at 2 days (phase #2). The PABR operated under these conditions for 59 days and then the HRT was decreased to 6 days (phase #3) with an average influent COD of 16.15 g/L. The operating period of phase #3 was 65 days. In Table 2, the proportions of the livestock waste in the feedstock mixture regarding each experimental phase are presented.

The operating parameters of each experimental phase are presented in Table 3.

During the experiments, gas and liquid samples were taken at regular intervals and biogas production, composition in CH4, total suspended solids (TSS), volatile suspended solids (VSS), pH, alkalinity, soluble and total COD, VFAs concentration were determined.

Co-composting

The composter was thus fed with a 6 kg mixture of sawdust and the solid fraction of the waste produced in the pretreatment step of experimental phase #3 (2:5 w/w sawdust per waste solid fraction). This proportion was chosen for a minimum C/N ratio of 25/1 and 56% moisture to be achieved in the initial feedstock. Animal manure is considered to be of high N-concentration [18,19,20]. The sawdust addition gave also the advantage of a high initial Free Air Space (F.A.S.) of 30.5%, therefore securing aerobic conditions. The initial feedstock mixture characteristics are presented in Table 4.

The mechanical stirring system was activated once every 24 h for 2 min and the rotational speed was adjusted to 30 rpm. The aeration system was constantly activated and provided 220 L/day of air to the composter. Sampling was performed once a day, right after the turning of the mixture in order to obtain a representative sample. The temperature was recorded continuously.

At experimental day 33, 10 ml of distilled water were added to 10 compost samples on filter paper in Petri dishes and 10 seeds of cress (Lepidum sativum) were then placed on the filter paper. Also, 10 control Petri dishes containing 10 ml of distilled water and 10 seeds of cress each were made. All experiments were run in duplicate. The Petri dishes were sealed with tape to minimize water loss while allowing air penetration and then were incubated in the dark for 48 h at room temperature. The root lengths of the plants were measured after 8 days. The germination index (GI), calculated as a percentage of seed germination and root growth, was used to indicate the presence of phytotoxicity. The percentages of seed germination, root growth and germination index (GI) were calculated according to Zucconi et al. [21].

Aquasim Modeling with ADM1

The ADM1 describes the processes that take place during the anaerobic digestion of organic material to produce methane, CO2 and other by-products. ADM1 describes the following steps of the anaerobic digestion process: disintegration, hydrolysis, acidogenesis, acetogenesis and methanogenesis.

As IWA highlights, the modeling of disintegration, hydrolysis and microbial decay are based on first order kinetics [16]. Monod kinetics are used to describe the biochemical reactions that describe substrate consumption with microbial growth. ADM1, also, describes the basic physicochemical processes in anaerobic digestion, ion association and dissociation, and gas–liquid transfer. In total, ADM1 includes 32 dynamic concentration state variables, 26 dynamic state concentration variables and 8 implicit algebraic equations.

In order to describe biomass retaining in the PABR, a parameter named tres_x is being used. The specific parameter corresponds to the difference between the Solid Retention Time and the Hydraulic Retention Time [22].

In the present study, AQUASIM 2.0 [23] was used to model the anaerobic digestion in the PABR. Phase 3 was selected for model development because it was the phase in which kinetic limitation was observed. After estimating the kinetic parameters, the experimental results of the phase 2 were used to validate the developed model.

Analytical Methods

Determinations of total chemical oxygen demand (tCOD), soluble chemical oxygen demand (sCOD), total suspended solids (TSS), volatile suspended solids (VSS), volatile solids (VS) and alkalinity were carried out according to standard methods [24]. The total organic carbon was measured in an analytical SHIMADZU TOC-VCSH instrument and total nitrogen according to ISO-11261_1995. For the quantification of Volatile Fatty Acids (VFAs), 1 ml of sample acidified with 30 μL of 20% H2SO4 was analyzed on a gas chromatograph (SHIMADZU GC-2010 plus) equipped with a flame ionization detector and a capillary column (Agilent technologies HP-FFAP, 30 m × 0.53 mm ID × 1 μm film) and an autosampler (SHIMADZU AOC-20 s). The oven was programmed from 105 to 160 °C at a rate of 15 oC/min and subsequently to 225 °C (held for 3 min) at a rate of 20 °C/min. Helium was used for as the carrier gas at 30 ml/min, the injector temperature was set at 230 °C and the detector at 230 °C. The methane content of biogas was quantified indirectly using an experimental set-up in which CO2 was absorbed by NaOH [25, 26]. The biogas production rate was measured using an oil displacement technique [27]. The phytotoxicity and germination index (GI) of the final compost were measured with an in-lab method [21, 28,29,30].

Results and Discussion

Anaerobic Co-digestion

During phase #1, the PABR responded effectively to a low HRT of 10.65 days. The average total alkalinity in all four compartments of the reactor was 2900 ± 80 mgCaCO3 L−1 and the pH was 7.5. The volatile suspended solids concentration in the compartments of the reactor was 0.9 g/L, except for a slight temporary increase in compartment #4, which was caused by operating issues (temporarily blocked effluent pipeline). The average acetic acid and propionic acid concentrations inside the reactor were 35.2 ± 15 and 13.8 ± 5.2 mg/L respectively, while the concentration of higher volatile fatty acids (VFAs) was below detection levels. The biogas production rate was 0.2 ± 0.05 Lbiogas/Lreactor/day with an average methane content of 65%.

After a stable periodic state was reached, the influent total COD concentration was increased to 20.31 g/L and the other operating parameters were maintained the same (phase #2). The increase of the influent COD concentration resulted in an increase of the organic loading rate to 1.91 g-COD Lreactor−1 day−1. The PABR responded well to the change. The biogas production rate increased to 0.41 ± 0.07 Lbiogas/Lreactor/day with an average methane content of 67.5%. The pH increased temporarily to approximately 8.0 in all four compartments, possibly due to the high total nitrogen concentration levels of poultry manure (73.82% of the new feedstock mixture) [31, 32], but soon stabilized. The average acetic acid and propionic acid concentrations increased to 217 ± 149 and 76.8 ± 45.6 mg/L respectively, while the concentration of higher VFAs remained below detection levels. VSS concentrations slightly increased in all four compartments, but remained in the range 1–1.5 g/L throughout phase #2.

Subsequently, the OLR was increased, this time by lowering the HRT to 6 days (phase #3). The reduced HRT resulted in the reduction of the average tCOD removal rate (68.8%). The kinetic limitation of the system is also noted by the increase of the VFA levels in the reactor. The average acetic acid concentration in the four compartments of the PABR was 360.4 ± 97.6 mg/L, the average propionic acid concentration was 101 ± 97.6 mg/L, while the concentrations of iso-butyric, butyric, iso-valeric and valeric acid were 26.4 ± 9, 39.9 ± 14.3, 14.6 ± 9.3 and 2.6 ± 2 mg/L respectively. The increase of the OLR to 2.69 g-COD Lreactor−1 day−1, resulted in a slight increase of the average TSS and VSS concentration in all four compartments of the reactor to 2 and 1.3 g/L respectively. During the stable periodic state of phase #3, the biogas production rate was 0.68 ± 0.2 Lbiogas/Lreactor/day with an average methane content of 65%. The results of the 3 experimental phases in comparison with the operating parameters of each phase are summarized in Table 5.

Aquasim Modeling with ADM1

The PABR operated with great stability despite the low HRT and the kinetic limitation during phase #3. During the stable periodic state, the biogas productivity was 34 Lbiogas kgfeedstock mixture−1. Based on the experimental results obtained during phase #3, a modified ADM1 model was developed for the simulation of the process. Measured and simulated values of the pH, VSS, COD, VFAs and biogas productivity regarding phase #3, are presented in Figs. 3, 4, 5, 6, 7, 8, 9 and 10. The experimental data of the pH, sCOD and VFAs presented are average values of the four compartments of the reactor at particular points in time, while the experimental data of tCOD and VSS represent the values measured in the effluent of the PABR. It should be mentioned that based on the model assumptions, soluble components at the effluent are equal to those inside the reactor, whereas particulate components at the effluent are significantly lower than those in the reactor, because of the difference between hydraulic and solid retention times. Parameter estimation was conducted based on the results of phase #3, as suggested by Batstone et al. [16].

The model simulates the average values of the pH and VFAs inside the four compartments of the reactor (Figs. 3, 5, 6, 7 respectively) and the VSS concentration in the outflow of the PABR (Fig. 4) quite well. It also provides a satisfactory simulation of the tCOD and sCOD removal efficiency of the reactor, as shown in Figs. 9 and 10 respectively. The experimental data do not show oscillations (as a result of the periodic switching of the influent and effluent compartment) despite the fact that a stable periodic state is reached. This occurs because the data correspond to samples taken from the reactor at different time points during the process. The relatively large standard deviation in some of the measured parameters is of course a consequence of the fact that measurements were not taken necessarily at the same time within a switching period. On the other hand, the model simulates the behavior of the reactor based on the assumption that the hydraulic behavior of the PABR is equivalent to the behavior of a CSTR, based on the retaining factor concept [13] and consequently predicts average concentrations in the reactor and at the effluent. Thus, no oscillations are predicted by the model. The value of the tres_x parameter as estimated by the model was equal to 18.9 days, meaning that the Solids Retention Time was equal to 24.9 days (HRT = 6 days). This probably explains the observed gradual increase in the biogas productivity during the experimental process (Fig. 8). However, the model simulates the biogas productivity during the latter HRTs of phase #3 in a satisfactory manner. It should be mentioned that the experimental data in Fig. 8 are based on measurements of the total biogas generated on a daily basis.

Subsequently, the ADM1 model developed based on the experimental data of phase #3 was validated through simulation of phase #2. The initial conditions and the tres_x parameter were the only fitted parameters. Measured and model -predicted values for phase #2, are presented in Figs. 11, 12, 13, 14, 15, 16, 17 and 18. The experimental data of the pH, sCOD and VFAs presented are the average values of the four compartments of the reactor, while the experimental data of tCOD and VSS represent the values measured in the effluent of the PABR.

The model’s prediction of the pH, VFAs and VSS levels is quite satisfactory in comparison with the experimental data of phase #2 (Figs. 11, 12, 13, 14, 15). As far as the reactor’s COD removal efficiency and biogas productivity is concerned (Figs. 17, 18, 16 respectively), the model can also predict the experimental data accurately. The value of the tres_x parameter as estimated by the model was equal to 104.7 days, thus meaning that the Solids Retention Time was equal to 115.35 days (HRT = 10.65 days).

Co-composting

The solid fraction from the solids/liquid separation (pretreatment) step, along with sawdust as a bulking agent (5:2 w/w wet basis) was fed to the lab-scale composter for the production of compost. The performance of the composter is presented in Figs. 19, 20, 21, 22 and 23.

As presented in Fig. 19, the highest temperature was reached in 2 days (~ 56.2 °C). The volatile solids on a dry base, declined from 94.44 to 75.2% (Fig. 22) during the process as the biodegradable substances were consumed by the microorganisms [18].

The moisture levels of the compost marginally increased, from 56.0 to 60.0% (Fig. 20), as water was produced by the metabolism of the microorganisms in the compost. A possible cause that prevented the moisture decrease is the closed-vessel reactor that was used, which did not allow water vapor to escape during the process. Constant aeration and daily stirring may have prevented further increase in the moisture of the compost.

The initial C/N ratio was 23.6:1, marginally below the optimal area of 25:1 to 35:1 [33], but it remained between the optimal values during the process (Fig. 20). The C/N ratio defines mainly the nutritional balance of the microorganisms.

The pH levels were initially above the optimal range of 5.5–8.0 [34, 35], and remained high during the composting. Usually the pH is not a key factor for composting since most materials are within this pH range. However, this factor is very relevant for controlling N-losses by ammonia volatilisation, which can be particularly high at pH > 7.5 [18, 36]. As shown in Fig. 21, as the composting proceeds, the compost tends towards a neutral pH (7.0) [37].

Generally, the compost is considered mature when the germination index is higher than 60%, compared to the control with distilled water [28]. As far as the seed germination is concerned, the compost is non-toxic when the germination rate is more than 85% [21, 28, 30, 38]. Therefore, the results (Table 6) indicate a free-of-toxins, mature final product.

Conclusions

The aim of the present study was to develop a novel approach for the integrated utilization of animal by-products and whey, through the combination of high-rate anaerobic co-digestion and co-composting. The feedstock mixture was subjected to a solids/liquid separation step and the liquid fraction (extract) was fed to a novel pilot-scale PABR at different Organic Loading Rates. The pilot reactor exhibited great stability during all three phases of the experiment. During the experimental phase #3 (HRT = 6 days, OLR = 2.69 g-COD Lreactor−1 day−1) the system was kinetically limited. The data obtained from phase#3 were used for the development of a modified ADM1 model. The model was able to adequately simulate the operation. The model was subsequently validated on the experimental data of a different experimental phase (phase #2), proving that it can predict the behavior of the reactor, taking into account the higher Solids Retention Time compared with the HRT. The solids fraction of the feedstock pretreatment, mixed with sawdust, was composted at lab-scale for the production of compost. During the process, the closed-vessel composter reached a high temperature of 56.2 °C and the germination index of the compost produced was 77.8% indicating a mature, free of phytotoxic substances final product.

Abbreviations

- ADM1:

-

Anaerobic Digestion Model No 1

- COD:

-

Chemical oxygen demand

- FAS:

-

Free air space

- GI:

-

Germination index

- HRT:

-

Hydraulic retention time

- IWA:

-

International water association

- OLR:

-

Organic loading rate

- PABR:

-

Periodic anaerobic baffled reactor

- sCOD:

-

Soluble chemical oxygen demand

- SRT:

-

Solid retention time

- T:

-

Switching period

- tCOD:

-

Total chemical oxygen demand

- TOC:

-

Total organic carbon

- TSS:

-

Total suspended solids

- UASB:

-

Upflow anaerobic sludge blanket

- US EPA:

-

United States Environmental Protection Agency

- VFAs:

-

Volatile fatty acids

- VS:

-

Volatile solids

- VSS:

-

Volatile suspended solids

References

Blika, P., Stamatelataou, K., Kornaros, M., Lyberatos, G.: Anaerobic digestion of olive mill wastewater in a periodic anaerobic baffled reactor (PABR). Global NEST 11(3), 364–372 (2009)

Tambone, F., Scaglia, B., D’ Imporzano, G., Schievano, A., Salati, S., Adani, F.: Assessing amendment and fertilizing properties of digestates from anaerobic digestion through a comparative study with digested sludge and compost. Chemosphere 8(5), 577–583 (2010)

Braun, R., Wellinger, A.: Potential of co-digestion. IEA Bioenergy (2002)

Bortone, G.: Integrated anaerobic/aerobic biological treatment for intensive swine production. Bioresour. Technol. 100, 5424–5430 (2009)

Møller, H.B., Nielsen, A.M., Nakakubo, R., Olsen, H.J.: Process performance of biogas digesters incorporating pre-separated manure. Livest. Sci. 112(3), 217–223 (2007)

Hill, D.T., Bolte, J.P.: Methane production from low solid concentration liquid swine waste using conventional anaerobic fermentation. Bioresour. Technol. 74(3), 241–247 (2000)

Burton, C.H., Turner, C.: Manure management—treatment strategies for sustainable agriculture, 2nd edn. Silsoe Research Institute, Wrest Park (2003)

Holm-Nielsen, J.B., Al Seadi, T., Oleskowicz-Popiel, P.: The future of anaerobic digestion and biogas utilization. Bioresour. Technol. 100(33), 5478–5484 (2009)

Jones, A., Pimbert, M., Jiggins, J.: Virtuous circles: values, systems and sustainability. IIED and IUCN CEESP, London (2011)

Kraemer, T., Gamble, S.: Integrating anaerobic digestion with composting. BioCycle 55(10), 32 (2014)

Schäfer, W., Lehto, M.: Solid compost from biogas plant digestion residues—a new product. http://orgprints.org/10631/1/fnytt306.pdf (2006). Accessed 20 Aug 2017

de Bertoldi, M., Vallini, G., Pera, A.: Co-composting for managing effluent from thermophilic anaerobic digestion of municipal solid waste. Environ. Technol. 12(12), 1137–1145 (1991)

Skiadas, I.V., Gavala, H.N., Lyberatos, G.: Modelling of the periodic anaerobic baffled reactor (PABR) based on the retaining factor concept. Water Res. 34(15), 3725–3736 (2000)

Skiadas, I.V., Lyberatos, G.: The periodic anaerobic baffled reactor. Water Sci. Technol. 38(8–9), 401–408 (1998)

Michalopoulos, I., Chatzikonstantinou, D., Mathioudakis, D., Vaiopoulos, I., Tremouli, A., Georgiopoulou, M., Papadopoulou, K., Lyberatos, G.: Valorization of the liquid fraction of a mixture of livestock waste and cheese whey for biogas production through high-rate anaerobic co-digestion and for electricity production in a microbial fuel cell (MFC). Waste Biomass Valoriz. 8(5), 1759–1769 (2017)

Batstone, D., Keller, J., Angelidaki, I., Kalyuzhnyi, S.V., Pavlostathis, S.G., Rozzi, A., Sanders, W.T.M., Siegrist, H., Vavilin, V.A.: Anaerobic digestion model no. 1 (ADM1). IWA Task Group for Mathematical Modelling of Anaerobic Digestion Processes Report No. 1, vol. 1(1) (2002)

Simmons, K., Deatrick, J.: Soil sampling. U.S. Environmental Protection Agency, Science and Ecosystem Support Division, Athens (2014)

Bernal, M.P., Alburquerue, J.A., Moral, R.: Composting of animal manures and chemical criteria for compost maturity assessment: a review. Bioresour. Technol. 100(22), 5444–5453 (2009)

Amon, B., Kryvoruchko, V., Moitzi, G., Amon, T., Zechmeister-Boltenstern, S.: Methane, nitrous oxide and ammonia emissions during storage and after application of dairy cattle slurry and influence of slurry treatment. Agric. Ecosyst. Environ. 112, 153–162 (2006)

Barrington, S., Choinière, D., Triqui, M., Knight, W.: Compost convective airflow under passive aeration. Bioresour. Technol. 86(3), 259–266 (2003)

Zucconi, F., Forte, M., Monaco, A.D.E., De Bertoldi, M.: Biological evaluation of compost maturity. BioCycle 22(2), 27–29 (1982)

Antonopoulou, G., Gavala, H.N., Skiadas, I.V., Lyberatos, G.: Modeling of fermentative hydrogen production from sweet sorghum extract based on modified ADM1. Int. J. Hydrog. Energy 37(1), 191–208 (2012)

Reicher, P.: AQUASIM 2.0—user manual. Technical report, Swiss Federal Institute for Environmental Science and Technology (EAWAG), CH-8600 Dubendorf, Switzerland (1998)

APHA, AWWA, WEF: Standard methods for the examination of water and wastewater. American Public Health Association, Washington, DC (1995)

Soto, M., Mendez, R., Lema, J.M.: Methanogenic and non-methanogenic activity tests theoretical basis and experimental set up. Water Res. 27(8), 1361–1376 (1993)

Valcke D., Verstraete W.: A practical method to estimate the acetoclastic methanogenic biomass in anaerobic sludges. Wat. Pollut. Control Fed. 55(9), 1191–1195 (1983)

Angelidaki, I., Ellegaard, L., Ahring, B.K.: Compact automated displacement gas metering system for measurement of low gas rates from laboratory fermentors. Biotechnol. Bioeng. 39(3), 351–353 (1992)

Selim, S.M., Zayed, M.S., Atta, H.M.: Evaluation of phytotoxicity of compost during composting process. Nat. Sci. 10(2), 69–77 (2012)

Tiquia, S.M., Tam, N.F.Y.: Elimination of phytotoxicity during co-composting of spent pig-manure sawdust litter and pig sludge. Bioresour. Technol. 65(1–2), 43–49 (1998)

Erhart, E., Burian, K.: Evaluating quality and suppressiveness of Austrian biowaste composts. Compost Sci. Util. 5(3), 15–24 (1997)

Anjum, R., Grohmann, E.: Anaerobic digestion of nitrogen rich poultry manure: impact of thermophilic biogas process on metal release and microbial resistances. Chemosphere 168, 1637–1647 (2017)

Borowski, S., Domański, J., Weatherley, L.: Anaerobic digestion of swine and poultry manure with municipal sewage sludge. Waste Manag. 34(2), 513–521 (2014)

Bishop, P.L., Godfrey, C.: Nitrogen transformation during sludge composting. BioCycle 24, 34–39 (1983)

de Bertoldi, M., Vallini, G., Pera, A.: The biology of composting: a review. Waste Manag. Res. 1(2), 157–176 (1983)

Miller, F.C.: Composting as a process based on the control of ecologically selective factors. In: Metting, F.B. (ed.) Soil Microbial Ecology: Applications in Agricultural and Environmental Management. Marcel Dekker Inc, New York (1992)

Mari, I., Ehaliotis, C., Kotsou, M., Chatzipavlidis, I., Georgakakis, D.: Use of sulfur to control pH in composts derived from olive processing by-products. Compost Sci. Util. 13, 281–287 (2005)

Tiquia, S.M., Wan, J.H.C., Tam, N.F.Y.: Extracellular enzyme profiles during co-composting of poultry manure and yard trimmings. Process Biochem. 36(8–9), 813–820 (2001)

Wong, J.W., Mak, K.F., Chan, N.W., Lam, A., Fang, M., Zhou, L.X., Wu, Q.T., Liao, X.D.: Co-composting of soybean residues and leaves in Hong Kong. Bioresour. Technol. 76(2), 99–106 (2001)

Acknowledgements

This research has been financed by the project “Development of a multiparametric model for optimizing energy planning on mountainous areas”, funded by the European Regional Development Fund (ERDF) and implemented by the National Technical University of Athens (NTUA).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Michalopoulos, I., Mathioudakis, D., Premetis, I. et al. Anaerobic Co-digestion in a Pilot-Scale Periodic Anaerobic Baffled Reactor (PABR) and Composting of Animal By-Products and Whey. Waste Biomass Valor 10, 1469–1479 (2019). https://doi.org/10.1007/s12649-017-0155-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-017-0155-z