Abstract

Purpose

Present study aims to use oil palm frond (OPF) hydrolysate obtained from enzymatic hydrolysis as feedstock for ethanol production.

Methods

Pretreated OPF was used in this study. Optimization of ethanol production was performed using central composite design of response surface methodology. TAPPI Standard Methods were used to analyze the chemical composition of the pretreated OPF.

Results

The results obtained indicated that the biomass contains 63.68% of cellulose, 21.92% of hemicellulose and 14.4% of lignin content. Enzymatic hydrolysis of pretreated OPF showed that the highest reducing sugar of 2444.6 µg/g was obtained when the biomass was hydrolysed using cellulase (40 U/g) and hemicellulase (10 U/g) for 150 min at 50 °C. The kinetic study indicated that the specific growth rate of S. cerevisiae HC10 during ethanol production was 0.034 h−1 with about 20.39 h of doubling time. The biomass yield coefficient and ethanol yield coefficient obtained were 0.1623 g cell/g sugar and 0.1191 g ethanol/g sugar, respectively. The highest ethanol yield was 79.4%. Fermentation profile for ethanol production demonstrated that the highest ethanol (7.23 g/L) was detected at 24 h of fermentation process. Under optimized conditions of inoculum, 30 mL; hydrolysate, 78.85 mL; pH, 4.50; and incubation time, 94.01 h, the highest ethanol yield was 13.79 g/L.

Conclusions

The results obtained from this study proved that OPF hydrolysate obtained from enzymes hydrolysis has high potential to be used as feedstock for ethanol production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fluctuations of oil prices, gradual depletion of fossil fuel sources and increased greenhouse gas emissions have stimulated global efforts in finding a sustainable alternatives way to replace fossil fuels in order to satisfy the ever-growing energy requirement [1]. The conversion of plant biomass/products into biofuels and biochemical has gained attentions due to the feasible alternative processes available to convert the complex biomass into biofuels and biomaterials [2]. There were a variety of materials that have been used for the biofuel production previously whereby each group of materials were categorized from ‘first generation’ biofuel to the ‘fourth generation’ biofuel.

The ‘first generation’ bioethanol are produced using raw materials containing simple sugars or starches which are mainly come from consumable [3]. On the other hand, ‘second generation’ bioethanol are those that are mainly produced using non-consumable sources such as lignocellulosic [3]. Another category of bioethanol is known as the ‘third generation’ bioethanol. These bioethanol are produced from algal biomass, which has a very distinctive growth yield as compared with the second generation bioethanol [4]. Finally, the ‘fourth generation’ biofuels are identified as photobiological solar fuels and electro-fuels [5]. The principle behind this infant-staged idea is that through synthetic biology, solar energy will be directly converted into fuel [5].

Lignocellulosic biomass was chosen as one of the preferred materials to be used for bioethanol production in Malaysia because of the country’s global-scale palm oil plantation industry. With huge oil palm plantation area, comes a high generation of wastes or by-products. The palm oil mill waste (POMW) can be divided into two categories; liquid-based waste and solid-based (biomass) waste [6]. Palm oil mill effluent (POME) is the liquid-based waste [6] while others, such as empty fruit bunches (EFB), palm pressed fibers (PPF), oil palm trunk (OPT), oil palm frond (OPF) and shells are biomass wastes. Around 51% of these wastes are come from oil palm frond (OPF) [7]. The disposals of OPF are either done by natural decaying process or by on-site burning. The distinctive drawback is that the natural decaying process consumes time and does not effectively decompose the whole OPF. In addition, on-site burning of the OPF is a clear violation of environmental law. Thus, alternative ways to utilize and/or dispose of OPF are needed.

A Huge amount of OPF waste has attracted researcher’s attention for utilizing the source as feedstock for bioethanol production [8]. Only a few studies have focused on utilizing the lignocellulosic components of OPF [9]. Almost all plant material is composed of cellulose, hemicelluloses and lignin. Both cellulose and hemicellulose are the sugars polymers that can be hydrolyzed into simple sugars for bioethanol fermentation. On the other hand, lignin is a complex, aromatic polymer [10] that does not possess any fermentative value. Generally, lignin is responsible for the overall protection of the plant cell in such a way that it provides mechanical strength, resistance toward water permeation across the cell, and protection against pathogen attack [10]. Due to its protective nature of the plant cell, lignin somehow prevents the hydrolysis of sugars. Therefore, some pretreatment steps are needed in order to degrade lignin. There are a wide range of pretreatment techniques that can be used, such as physical, chemical, physicochemical and biological pretreatment. In biological pretreatment method, white-rot fungus (WRF) is preferred since the fungus contains ligninolytic enzymes that are effective for lignin degradation. Next, specific enzymes such as cellulase and hemicellulase are often used to enhance the hydrolysis of simple sugars for fermentation.

Fermentation can be divided into two types according to the state of the media used for the fermentation, which are solid state fermentation (SSF) and submerged fermentation (SmF) [11]. Generally, in SSF system fungi are often used during biological pretreatment process for bioethanol production. Meanwhile, in SmF system yeast or bacteria are used. Hydrolysate, which is the liquid derived from enzymatic treatment can be fermented by microbiological agents such as yeast and bacteria. Yeast such as Saccharomyces cerevisiae, is notable for its application in bioethanol fermentation due to its robustness and rapid rates of ethanol production [12, 13].

Thus, in this project OPF substrate which is previously treated with white rot fungus (Phanerochaete chrysosporium CK1) was subjected to enzymatic hydrolysis using commercial enzyme such as Cellulase A “Amano” 3 and Hemicellulase “Amano” 90 (Amano, Japan) either individually or in combination. The fermentable sugars released in the hydrolysate were used as feedstock in bioethanol production process using yeast (S. cerevisiae HC 10). Factors which affect biological pretreatment of OPF using P. chrysosporium CK1 (fermentation time and inoculum size) have been examined by previous researchers [14]. On top of that, factors which affect enzymatic hydrolysis of pretreated OPF (cellulase, hemicellulase and combination, enzyme loading and incubation time) were determined. Finally, the efficiency of bioethanol production using hydrolysate as feedstock were determined and optimized.

Materials and Methods

Source and Preparation of Pretreated Oil Palm Frond

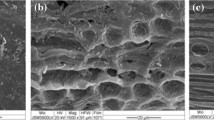

Fresh OPF were obtained from Federal Land Consolidation and Rehabilitation Authority (FELCRA) Plantations in Balik Pulau, Penang. The leaves of the OPF were cut off and discarded. The fronds (center part) were cleaned and dried under the room temperature to remove excess water. The skin of the clean OPF was peeled off and cut into smaller size. Then, OPF was pressed using sugarcane pressing machine and the OPF juice was collected for other uses. The OPF biomass was dried in an oven at 70 °C for 48 h to prevent any microbial growth. The dried OPF was ground into a smaller size and sieved using 1.5 mm sieve. The sample was kept at room temperature for further usage. P. Chrysosporium CK 1 obtained from School of Industrial Technology, USM was used to pretreat the OPF. Under the optimized conditions of inoculum size of 0.5 × 107 spore/mL and incubated at room temperature for 3 weeks using The Japan Industries Standard (JIS) broth medium, the highest percentage of lignin removal was about 51%, which are significantly different (P < 0.05) compared with untreated OPF. Analysis using TAPPI Standard Test Methods shows that cellulose, hemicellulose and lignin content of OPF after P. Chrysosporium CK 1 treatment were 63.68%, 21.92% and 14.4%, respectively [14].

Enzymatic Hydrolysis of Pretreated OPF Using Commercial Enzyme

The commercial enzymes used in this study were Cellulase A “Amano” 3 and Hemicellulase “Amano” 90 which were obtained from Amano Pharmaceutical Co., LTD (Nagoya, Japan). The enzymes used were either individually or in combination during hydrolysis of pretreated OPF. Three grams of pretreated OPF were mixed with 50 mL of Citric-NaOH buffer (50mM, pH 5) in an Erlemenyer flask. The sample was pre-incubated at 50 °C for 5 min before the appropriate concentration of enzyme was added. The sample was mixed well and the flask was continued incubated for another 60 min. After incubation, the supernatant was separated using Whatman No.1 filter paper to remove the debris. The reducing sugars content was determined using 3,5-dinitrosalicylic acid (DNS) method and the samples were measured spectrophotometrically at 540 nm using sugar (glucose or xylose) as standard [15]. For samples obtained from enzymes combination, the reducing sugars were measured using phenol–sulfuric method. Factors which affect enzymatic hydrolysis of pretreated OPF such as enzyme loading (10, 20, 30, 40, 50 U/g) and incubation time (30, 60, 90, 120, 150 min) were examined.

Bioethanol Production Process

Yeast Strain and Inoculum Preparation

Saccharomyces cerevisiae HC 10 which was obtained from School of Industrial Technology, USM was used in this study for bioethanol production. Yeast strain previously grown on agar slant was diluted with sterile distilled water to obtain a standardized inoculum with optical density (OD) of about 0.8 at 600 nm. Nutrient broth (98 mL) was prepared and the pH of the medium was adjusted to 4.5 prior to autoclaving at 121 °C for 15 min. The sterile medium was inoculated with 2 mL of standardized inoculum and incubated at 30 °C for 24 h and agitated at 150 rpm. This medium was used as inoculum in fermentation process for bioethanol production.

Growth Profile of S. Cerevisiae HC 10 and Fermentation Process for Bioethanol Production

Inoculum (2%, v/v) was transferred into 200 mL sterilized nutrient broth containing 30 ml of hydrolysate from enzymatic hydrolysis of pretreated OPF. The sample was incubated at 30 °C for 60 h and agitated at 150 rpm. Sample (10 mL) was taken out every 6 h interval for 60 h and immediately stored at −20 °C until further analysis. Kinetic studies of the fermentation process were performed in order to further understand the fermentation process.

Optimization of Bioethanol Production Process

Optimization of the fermentation process for bioethanol production was performed using central composite design (CCD) of response surface methodology (RSM) from Design-Expert® version 7 program. The experiments were conducted using Erlenmeyer flask system and 30 experimental runs with different conditions proposed by the CCD model were performed. Factors taken into consideration in these studies included inoculum size (mL), Hydrolysate (%), initials medium pH and Incubation time (h). The sample volume (nutrient broth + hydrolysate) was kept in constant (100 mL) for each run. After fermentation, the sample was analyzed for yeast biomass, sugar residual, and ethanol production. For optimization, the fermentation process was performed according to the best combination condition suggested by the by the Design-Expert® program. An experimental run was performed in order to verify the suggested best condition.

Analysis

Determination of Reducing Sugar

The supernatant of the sample was prepared by separating the debris and slurry. For sample obtained from individual enzyme hydrolysis, the reducing sugar (glucose or xylose) produced was determined according to DNS method [15]. While for the sample obtained from a combination of enzymes hydrolysis, the reducing sugar produced was determined using phenol–sulfuric method [16].

Determination of Yeast Biomass

The yeast biomass was determined by measuring the cell dry weight. The cell suspension was vacuum-filtered through 0.45 μm filter paper and rinsed 2 times with distilled water. The filtered papers were dried in an oven at 65 °C for 2 days until a constant weight was obtained. The cell dry weight was obtained by weighing the dried filter papers using an analytical balance [17].

Determination of Bioethanol

Ethanol produced was analyzed using gas chromatography (GC) equipped with Flame Ionization Detector (FID). Helium (He) was used as a carrier gas and the column used was Rt-Q-BOND column (30 m length × 0.25 µm film thickness × 0.32 mm inner diameter). The temperature of the column, injector, and detector was set at 200 °C. The flow rate and operating pressure used were 21.9 mL/min and 71.1 KPa, respectively. Five min holding time was used for each sample [18].

Statistical Analysis

Statistical analysis was performed using Statistical Package for the Social Science, SPSS version 20. The significant difference between each test variable was determined using one-way ANOVA analysis and Least Significance Test. All the tests were carried out in triplicates with a confidence interval of 95%.

Results and Discussions

Effect of Enzyme Loading on Hydrolysis Pretreated OPF

Five different enzyme loadings (10, 20, 30, 40, 50 U/g) were used in this study. The pretreated OPF was hydrolyzed by cellulase for 60 min. The results obtained indicated that with an increase in cellulase loading from 10 U/g to 50 U/g, the glucose produced was significantly increased (P < 0.05) from 1385 µg/g (10 U/g) and reaching maximum value of 2317 µg/g (50 U/g) (Fig. 1). On the other hand, the result obtained was within expectation because the rate of OPF hydrolysis to generate glucose increased with increasing the enzyme concentration used.

For hemicellulase hydrolysis of pretreated OPF for xylose production, the results obtained showed a similar pattern compared with cellulase hydrolysis (Fig. 1). In addition, with an increase in hemicellulase loading for OPF hydrolysis, xylose produced was increased from 1041 µg/g (10 U/g) to 1756 (50 U/g). Statistical analysis indicated that xylose released by hemicellulase hydrolysis was significantly different (P < 0.05) compared with other enzyme loading used except 40 U/g. On top of that, when compared with glucose content (cellulase hydrolysis), xylose produced (hemicellulase hydrolysis) was lower. This is due to the cellulose content (63.68%) in pretreated OPF was much higher compared with xylan content (21.92%) [14].

The reducing sugars produced from by combining cellulase and hemicellulase to obtain an enzyme loading of 50 U/g are shown in Fig. 2. As shown in Fig. 2, cellulase plays a major role in reducing sugar released since the amount of reducing sugars registered increased when increasing of cellulase loading. For example, about 2351 µg/g of reducing sugar was generated from 40 U/g of cellulase and 10 U/g of hemicellulase hydrolysis compared with 2066 µg/g when 10 U/g of cellulase and 40 U/g of hemicellulase was used. In addition, statistical analysis also indicated that these differences are significant (P < 0.05). The conditions that gave the lowest reducing sugar content was 50 U/g of hemicellulase loading. This can be explained by cellulose accounting for a much larger portion in lignocellulosic biomass as compared to hemicellulose [14, 19]. In addition, Sun and Cheng [20] reported that the used of cellulase mixture from different microbes or a mixture of cellulase with other enzymes exhibited a significant increase in cellulose conversion in lignocellulosic materials. In addition, Lin et al. [21] also reported that the used of xylanase and cellulase mixture can increase the hydrolysis efficiency by 160%. In conclusions, cellulase alone hydrolysis produced higher reducing sugar compared to hemicellulase alone hydrolysis. In order to study the effect of enzyme hydrolysis time on reducing sugar production a combination of 40 U/g of cellulase and 10 U/g of hemicellulase were selected because it gave the highest reducing sugars content.

Effect of Hydrolysis Time on Pretreated OPF

Five different hydrolysis times (30–150 min with 30 min intervals) on pretreated OPF was carried out in this studies. The results obtained showed that there are an increasing trend of glucose and xylose produced with an increase in hydrolysis time (Fig. 3) and reaching maximum at 150 min (2421 µg/g). Thus, more cellulose was converted to glucose. No significant different (P > 0.05) on glucose produced at 90 min when compared to 120 and 150 min. On the other hand, the result obtained was in an agreement with Tye et al. [22] who recorded that the enzymatic hydrolysis of water pretreated kapok fiber incubated for 60 min gave a better yield than those incubated for 45 min. No significant increase (P > 0.05) in glucose content after 90 min hydrolysis may probably due to end production inhibition, in which when the glucose (end product) concentration is high enough in a reaction mixture; it will become an inhibitor for cellulase.

Hemicellulase hydrolysis of pretreated OPF showed a similar increasing pattern with cellulase hydrolysis (Fig. 3). The xylose released reaching maximum level of 2418 µg/g at 150 min hydrolysis which was closed to cellulase alone hydrolysis (2421 µg/g). Statistical analysis showed no significant different (P > 0.05) for xylose obtained at 120 and 150 min of hydrolysis. Xylan content in pretreated OPF was lower compared with cellulose content. Thus, the reducing sugar produced from hemicellulase hydrolysis was lower compared with cellulase hydrolysis. But, the xylose produced from hemicellulase hydrolysis was kept on increasing throughout the experiment. This showed that no end product inhibition occurred during hemicellulase hydrolysis. In addition, as shown in Fig. 2, the xylose produced from hemicellulase hydrolysis is marginally increased from 30 min up to 150 min of hydrolysis. But, no drastically increased in glucose was detected for cellulase hydrolysis.

The combination of cellulase and hemicellulase hydrolysis of pretreated OPF at different hydrolysis time also showed an increasing trend from 30 min (2109 µg/g) to 150 min (2445 µg/g) (Fig. 4). However, statistical analysis showed no significant different (P > 0.05) for all the different hydrolysis time used except for 30 min. The result obtained was in an agreement with the previous researcher who stated that the sugars yield was little change when the pretreatment time was too long and higher yield was only obtained at the early stage of pretreatment. In addition, prolonging of pretreatment time will increase the cost and loss of feedstock. Therefore, it is crucial to make a balance between the pretreatment time and fermentable sugar yield [23].

Fermentation Process for Bioethanol Production

Profile of Yeast Biomass, Ethanol Production, and Sugars Consumption

No lag phase was observed in the growth profile because the same medium was used for inoculum preparation and the fermentation process. Thus, yeast strain had good adaptation when transferred into the fermentation medium (Fig. 5). From 1 to 22 h of fermentation period, the growth of yeast was exponential and the consumption of sugars was high during this period. During this period the yeast was undergone active metabolism to produce components needed for growth. The growth profile of yeast entered deceleration phase from 22 to 24 h, in which 24 h was the end of the exponential phase and the beginning of the stationary phase. The growth rate becomes slower starting from 24 h and at the same time, the rate of sugars consumption was also slowed down. While, from 24 to 36 h of fermentation time, the growth of yeast was slowed down and the biomass concentration started to reduce. This may due to a number of new (or viable) cells are less than the number of dead cells. This occurred may due to the high concentration of ethanol produced that will either inhibit the growth or harmful to the yeast [24]. From 36 h until the end of the fermentation process (60 h), the biomass concentration remained constant.

Ethanol production profile showed that the ethanol production continued increased from the beginning of fermentation and reaching the maximum value (7.23 g/L) after 24 h (Fig. 5). Beyond 24 h, ethanol concentration started to decrease and reach a minimum of 3.04 g/L at the end of fermentation. Reduction in ethanol was due to microbial stress factor such as high ethanol concentration in the fermentation medium that starts to take place [25]. On top of that, decreased in ethanol concentration until the end of the fermentation may due to low sugar residual in the medium and also ethanol being used up as an alternative carbon source to sustain the yeast growth. In addition, ethanol may lose on evaporation during the fermentation process. Previous researcher also using oil palm frond juice as feedstock for bioethanol production and the highest ethanol obtained was 6.81 g/L, which was lower than in this study. This likely due to the total free sugars used in the fermentation medium was lower [26].

Kinetic Study of S. cerevisiae HC10 Fermentation for Bioethanol Production

A better understanding of fermentation process for bioethanol production can be achieved via kinetic study. The specific growth rate (µ) and double time obtained from this study were 0.034 h−1 and 20.63 h−1, respectively (Table 1). However, the specific growth rate obtained from this study was lower compared to Lee and Abdul Halim [26] (0.037 h−1) and Maya Emira [27] (0.1 h−1). Although the specific growth rate obtained from this study was low, but according to Boender et al. [28], µ value in the range of 0.03–0.40 h−1 is considered relevant and suitable for being used in industrial application. On the other hand, previous researcher obtained a specific growth rate of 0.38 h−1 [29] and 0.47 h−1 [30] in their studies through a fermentation process. Thus, this showed that in cell growth, the specific growth rate is depends on environmental conditions and most of the specific growth rate achieved is still relevant for industrial application. In term of double time, although the value obtained from this work is considered high and represented a faster growth in the natural environment because in natural environments the double time of cells are much higher due to cell growth was constrained by the limited amount of growth-limiting nutrients [31].

Throughout the fermentation process, about 12.57 g/L of sugars have been consumed by S. cerevisiae HC 10 for growth and ethanol production. For every gram of sugar consumed, 0.1623 g of biomass and 0.1191 g of bioethanol were produced. Biomass yield coefficient obtained from this study was slightly higher than those reported by Estela-Escalante [32] but lower when compared to Lee and Abdul Halim [26]. On the other hand, Lee and Abdul Halim [29] recorded ethanol yield coefficient (Yp/s) of 0.4 g ethanol/g sugar which was about 0.28 g ethanol/g sugar higher than the value obtained from present study. A study of ethanol production using batch fermentation showed that the ethanol yield coefficient (Y p/s) was 0.06 g of ethanol per g of glucose which was lower than in this study [33]. This likely may due to the higher glucose concentration present in the fermentation process [26] since the ethanol production is directly correlated with the concentration of sugar present in the fermentation medium. On the other hand, ethanol yield obtained from present study was 79.4% which was lower compared to ethanol yield recorded by Lee and Abdul Halim [26] and Maya Emira [26] of 80 and 82%, respectively. In addition, Chen et al. [34] obtained about 90% of ethanol yield from the study. This was due to the used of concentrated tropical maize syrup in the fermentation process.

Optimization of Bioethanol Production Process Using Shake Flask System

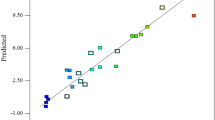

Response surface methods (RSM) is commonly used to investigate the interactions between variables and to find the optimum conditions for the multi-variable system. The Design-Expert software had suggested 30 combination of experimental run for determination of the best combination conditions for optimization of bioethanol production. Optimization using CCD design was suitable because the result obtained was most fit to quadratic model. But there is a considerable probability of having a significant lack of fit.

Table 2 indicated the fit summary analysis of sequential model sum of squares and model summary statistics. The suggested model is quadratic with insignificant sequential model sum of squares. The Model Summary Statistics gave an acceptable standard deviation of 2.36 (Table 3). In addition, the fitness of the model was expressed by the R2. From Table 3, a value of 0.7054 was obtained which indicated 70.54% of the response variability in bioethanol production. The closer the R2 to 1, the stronger the model and the better the response prediction.

The statistical significance of respective model equation was checked using F-test analysis of variance (ANOVA) (Table 4). The report implies that the model was significant (F-value: 2.57) with P-value obtained was significant (P < 0.05). In addition, only inoculum, hydrolysis time and interaction between hydrolysis time and pH factors bring significant effect (P < 0.05) in ethanol production. The normal plot of residuals shows approximately linear thus no transformation correction is needed. Numerical optimization was carried out in order to determine the conditions which gave the highest ethanol production. The optimization for bioethanol production was carried out by setting the inoculum “within” the range of 10 to 30 mL. The hydrolysate was set in the range of 40 to 80 mL. The pH was targeted at 4.50. The hydrolysis time was set in the range of 48 to 96 h. The response of this experiment, bioethanol production were set to maximum.

An experiment was conducted according to the suggested conditions (inoculum, 30 mL; hydrolysate, 78.85 mL; pH, 4.50; and hydrolysis time, 94.01 h) to validate the suggested combination. The results obtained demonstrated that ethanol production was 14.21 g/L, which was closed to the suggested value of 13.79 g/L. In addition, the difference was only 3%, which is in the acceptable range of 5%. This percentage error value was calculated from the validation experiment which proved that the optimization process by CCD was dependable and capable of ethanol production from OPFJ using S. cerevisiae HC10.

Conclusions

In this study, combinations of cellulase and hemicellulase enzymes for the hydrolysis of pretreated OPF produced higher reducing sugar release as compared to cellulase or hemicellulase used individually. The ethanol fermentation profile indicated that the highest ethanol yield was 79.4%. Besides, under optimized fermentation conditions, the highest ethanol concentration obtained was 13.79 g/L. The results obtained from this present study demonstrated that OPF hydrolysates obtained from combination cellulase and hemicellulase hydrolysis have a potential to be used as a feedstock for ethanol production.

References

Fasahati, P., Woo, H.C., Liu, J.J.: Industrial-scale bioethanol production from brown algae: effects of pretreatment processes on plant economics. Appl. Energy 139, 175–187 (2015)

Chaturvedi, V., Verma, P.: An overview of key pretreatment process employed for bioconversion of lignocellulosic biomass into biofuels and value-added products. Biotech 3, 415–431 (2013)

Lee, R.A., Lavoie, J.M.: From first- to third-generation biofuels: challenges of producing a commodity from a biomass of increasing complexity. Anim. Front. 3, 6–11 (2013)

Brennan, L., Owende, P.: Biofuels from microalgae—a review of technologies for production, processing, and extractions of biofuels and co-products. Renew. Sustain. Energy Rev. 14, 557–577 (2010)

Aro E.-M.: From first-generation biofuels to advanced solar biofuels. Ambio, 45 (Suppl. 1), 24–31 (2016)

Lorestani, A.A.Z.: Biological treatment of palm oil effluent (POME) using an up-flow anaerobic sludge fixed film (UASFF) bioreactor. Doctoral dissertation, Universiti Sains Malaysia (2006)

Abdullah, N., Sulaiman, F.: The oil palm wastes in Malaysia. In: Matovic, M.D. (ed.) Biomass Now-sustainable Growth and Use. Science, Technology, and Medicine open access publisher (2013)

Jamaludin, N.F.M.: Study on bioethanol production from oil palm trunk (OPT) sap by using Saccharomyces Cerevisiae Kyokai No.7 (ATCC 26422). Bachelor of Chemical Engineering (Biotechnology), Universiti Malaysia Pahang (2010)

Lim, S.H., Ibrahim, D., Che Omar, I.: Oil palm frond for the production of bioethanol. Int. J. Biochem. Biotechnol. 1, 007–011 (2012)

Crawford, Don, L., Ronald, L.: Crawford.: Microbial degradation of lignocellulose: the Lignin Component. Appl. Environ. Microbiol. 31(5), 714–717 (1976)

Subramaniyam, R., Vimala, R.: Solid State and submerged fermentation for the production of bioactive substances: a comparative study. Int. J. Sci. Nat. 3, 480–486 (2012)

Dombek, K.M., Ingram, L.O.: Ethanol production during batch fermentation with Saccharomyces cerevisiae: changes in glycolytic enzymes and internal pH. Appl. Environ. Microbiol. 53(6), 1286–1291 (1987)

Stanbury, P.F.: Principles of Fermentation Technology, Pergamon Press, UK Ch.1 (1984)

Mukhtar, Z.: Biological pretreatment of oil palm frond (OPF) for a better yield of fermentable sugar. Undergraduate Dissertation, Universiti Sains Malaysia (2015)

Dubois, M., Gilles, K.A., Hamilton, J.K., Rebers, P.A., Smith, F.: Colorimetric method for determination of sugars and related substances. Anal. Chem. 28, 350–356 (1956)

Miller, G.L.: Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31, 426–428 (1959)

Maurice, M.L.: Factors effecting ethanol fermentation via simultaneous saccharification and fermentation. Doctoral dissertation, Shanghai Jiao Tong University (2011)

Abdul Halim, F.A.: Oil palm frond juice: potential feedstock for bioethanol production. Undergraduate Dissertation, Universiti Sains Malaysia (2014)

Behera, S.S., Ray, R.C.: Solid state fermentation for production of microbial cellulases: recent advances and improvement strategies. Int. J. Biol. Macromol. 86, 656–669 (2016)

Sun, Y., Cheng, J.Y.: Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour. Technol. 83, 1–11 (2002)

Lin, Z.X., Huang, H., Zhang, H.M., Zhang, L., Yan, L.S., Chen, J.W.: Ball milling pretreatment of corn stover for enhancing the efficiency of enzymatic hydrolysis. Appl. Biochem. Biotechnol. 162, 1872–1880 (2010)

Tye, Y.Y., Lee, K.T., Wan Abdullah, W.N., Leh C.P.: Potential of Ceiba pentandra (L.) Gaertn. (kapok fiber) as a resource for second generation bioethanol: effect of various simple pretreatment methods on sugar production. Bioresour. Technol. 116, 536–539 (2012)

Zhang, X.Y., Yu, H.B., Huang, H.Y., Liu, Y.X.: Evaluation of biological pretreatment with white rot fungi for the enzymatic hydrolysis of bamboo culms. Int. Biodeterior. Biodegrad. 60, 159–164 (2007)

Winkelhausen, E., Velickova, E., Amartey, S. A., Kuzmanova, S.: Ethanol production using immobilized Saccharomyces cerevisiae in lyophilized cellulose gel. Appl. Biochem. Biotechnol. 162, 2214–2220 (2010)

Gibson, B.R, Lawrence, S.J., Leclaire, J.P, Powell, C.D., Smart, K.A.: Yeast responses to stresses associated with industrial brewery handling. FEMS Microbiol. Rev. 31, 535–569 (2007)

Lee, C.K., Abdul Halim, F.A.: Oil palm frond juice: a potential feedstock for bioethanol production. Int. J. Sci. Res. Publ. 4(12), 520–526 (2014)

Maya Emira, M.S.: Production of bioethanol by Saccharomyces cerevisiae HC10 using oil palm frond juice (OPFJ). Undergraduate Dissertation, Universiti Sains Malaysia (2015)

Boender, L.G., De Hulster, E.A., Van Maris, A.J., Daran-Lapujade, P.A., Pronk, J.T.: Quantitative physiology of Saccharomyces cerevisiae at near-zero specific growth rates. Appl. Environ. Microbiol. 75, 5607–5614 (2009)

Kartawiria, I.S., Syamsub, K., Noorb, E., Sa’idb, E.: Sorghum talk Juice pre-treatment method for bioethanol fermentation process. Energy Proc. 65, 140–145 (2015)

Paredes-López, O., Camargo-Rubio, E., Ornelas-Vale, A.: Influence of specific growth rate on biomass yield, productivity, and composition of Candida utilis in batch and continuous culture. Appl Environ Microbiol. 31(4), 487–491 (1976)

Brock, T.D.: Microbial growth rates in nature. Bacteriol. Rev. 35(1), 39–58 (1971)

Estela-Escalante, W.R.M., Melzoch, K., Hatta-Sakoda, B.: Effect of aeration on the fermentative activity of Saccharomyces cerevisiae cultured in apple juice. Revista Mexicana de Ingeniería Química. 11, 211–226 (2012)

Cheng, N.G., Hasan, M., Kumoro, A.C.: Production of ethanol by fed-batch fermentation. J Sci. Technol. 17, 399–408 (2009)

Chen, M.H., Kaur, P., Dien, B., Below, F., Vincent, M.L., Singh, V.: Use of tropical maize for bioethanol production. World J. Microbiol. Biotechnol. 29, 1509–1515 (2013)

Acknowledgements

The authors would like to thank Universiti Sains Malaysia for providing short-term grant (304/PTEKIND/6312113). Special thanks to staffs of School of Industrial Technology, especially the laboratory assistant namely Mr. Azmaizan Yaakob and Mrs. Najmah Hamid. They have been very helpful in giving equipment assistance and providing for all my laboratory needs.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Farah Amani, A.H., Toh, S.M., Tan, J.S. et al. The Efficiency of Using Oil Palm Frond Hydrolysate from Enzymatic Hydrolysis in Bioethanol Production. Waste Biomass Valor 9, 539–548 (2018). https://doi.org/10.1007/s12649-017-0005-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-017-0005-z