Abstract

Transfer-matrix method (TMM) in optics serves as a robust mathematical formalism for determining the transmittance of electromagnetic waves through a slab, thin film, or multi-layered structure. A plane electromagnetic (PEM) wave impinges at an angle to the normal of a slab or multi-layered structure and interacts with the material. A portion of this light passes through the first interface and then propagates in the material. Finally, it leaves the second interface of the material and carries information about the material. This formalism models the experimental transmittance spectra of \(WO_3\) thin film prepared by a thermal evaporation method. The spectral variations of the transmission coefficient and refractive index of \(WO_3\) are derived using the TMM approach, demonstrating concordance with the experimental data.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Tungsten trioxide \(WO_3\) has long been considered a good choice for new and innovative applications, such as a photo-catalyst [1, 2], photo-electrodes [3, 4], gas sensors [5, 6] and electrochromic devices [5,6,7,8,9]. Some researchers who studied thin films transmission and reflection spectra have established advanced numerical and analytical methods [10]. They take into account both the absorbance of distinct areas and the angles of incidence on the sample. Similarly, researchers established the Transfer Matrix Method as a robust analytical tool in optics. The researchers can use the TMM to study the propagation of electromagnetic waves, acoustic waves, optical wave structures [11], and elastic waves through a material. This method is especially effective for studying transmission and reflection phenomena in multilayered systems [12]. Recent explorations extend the application of TMM to study the optical properties of thin films [13] complex dynamical systems, such as in plasma physics, revealing fractional soliton solutions [14], and offering comparative analyses of nonlinear phenomena like those described in the Vakhnenko-Parkes and Schrödinger equations [15, 16]. This work presents a TMM-based model for calculating the spectrum of the transmission coefficient, reflection coefficient, and refractive index of tungsten trioxide thin film coated on a glass substrate.

Section 2 discusses the experimental details of the preparation of tungsten trioxide. Section 3 defines the transfer matrix method for a thin film deposited on a glass slab, which helps us calculate the optical parameters such as transmission coefficient, reflection coefficients, and refractive index. Then in Sect. 4, the results obtained by using the TMM technique are discussed, and lastly, in Sect. 5 the conclusion is presented.

2 Experimental deailts

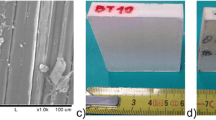

We purchased the tungsten trioxide \((WO_3)\) powder with a purity of \(99.98 \%\) from Sigma Aldrich to use as a starting material for thin film deposition. Before deposition, we cleaned the glass substrate using acetone and deionized water. We then placed two grams of tungsten oxide powder on a molybdenum boat and initiated the vacuum system to achieve the optimal pressure. Upon reaching a base pressure of \(5.4 \times 10^{-5}\) mbar, we passed a current of (50–60)A through the molybdenum boat. The resistive heating caused the tungsten oxide powder to evaporate and deposit onto the glass substrate positioned on the substrate holder, approximately 535 cm away from the source material. The deposition process lasted for 15 min. We used a surface profilometer to measure the thickness of the film, which was nearly \(8.56\times 10^{-7}\) m. We also estimated the thin film’s thickness using the maxima and minima values of the transmittance. We calculated the optical thickness using the following relation:

Here, l is the optical thickness of the thin film. Whereas \(\lambda _{\min }\) and \(\lambda _{\max }\) represent the wavelengths corresponding to the adjacent minimum and maximum in the transmittance spectrum of Fig. 2. The \(n_f\) is the refractive index of the glass corresponding to the \(\lambda _{\min }\).

3 The transfer matrix method (TMM) formulism

The transfer matrix (TM) \(M^{1\rightarrow 2}\) is derived for a single interface between two media based on the requirements of the continuity of tangential components of electric \(\vec {E}\) and magnetic \(\vec {H}\) fields. The TM elements give the magnitude of transmission amplitudes and reflection for electric and magnetic fields. The tangential components of the field vectors \(\vec {E}\) and \(\vec { H }\) have the same boundary conditions on both sides of the contact. We have the relationship between the electric field components across the interface given by:

Here, the matrix \(M^{1\rightarrow 2}\) is a TM of order \(2\times 2\) related to a single interface’s electric field components. Where the term \(k_{iz}\) is a component of wave vector normal to the interface, for the case of normal incidence \(k_{iz}=n_i(\frac{\omega }{c}) Cos(\theta _1)\) becomes \(k_{iz}=n_i(\frac{\omega }{c})\). The following are the amplitudes of transmission and reflection:

The Eq. (3). presents the Fresnel equations for a single interface. This formalism can be easily extended to the multi-layered system as well. For example, a system of thin film coated on a substrate is presented in Fig. 1, Where the PEM wave is represented by its electric field vector \(\vec {E}\) components, and the magnetic field \(\vec {H}\) components, along with its propagation vector \(\vec {k}\), indicating the direction of propagation. A plus sign "+" next to \(\vec {E}\), \(\vec {H}\), and \(\vec {k}\) indicates components of forward-moving waves propagating to the right, while a minus sign "-" denotes components of backward-moving waves propagating to the left.

\(\vec {E}\) Components denoted by "\(\times\)" illustrate the direction and amplitude of the electric field. \(\vec {H}\) Components are represented by blue arrows, showing the direction and amplitude of the magnetic field perpendicular to \(\vec {E}\). The propagation vector \(\vec {k}\) is shown as red arrows, demonstrating the waves’ travel direction through and reflection from the material interfaces. The interaction at each interface between the materials results in a partial reflection and a transmission illustrated by \(\vec {k}\) vectors. The above system requires five matrices that relate the electric field components of the PEM wave across the whole system. The three are the transfer matrices \(M^{1\rightarrow 2}\), \(M^{2\rightarrow 3}\) and \(M^{3\rightarrow 4}\) for 1st 2nd and 3rd interfaces, respectively. For the other two, a new matrix termed propagation matrix \(M^{p}\) must be introduced to account for wave propagation inside the thin film and substrate.

However, we are interested in the transfer matrix of the entire structure, which is given by simple multiplication of the individual matrices

The matrices \(M^{i \rightarrow j}\) are given in Eq. (2), and the diagonal matrices \(M^{pj}\) are given in Eq. (4). We may write the above Eq. (5) as:

Here, \(M^{system}\) is the transfer matrix for the entire structure. We can calculate the transmission and reflection amplitudes, which are provided by Eq. (3), as follows:

The transmission and reflection coefficients are calculated using the matrix \((M^{\hbox {system}})\) as follows.

4 Results and discussion

The TMM is applied to find out the transmission spectra, reflection spectra, and the refractive index of tungsten trioxide thin-film of thickness \(8.56\times 10^{-7}\) m coated on a glass substrate. The permeability of this thin film is \(\mu _2=1\), and the permittivity is frequency-dependent, given by

The refractive index for tungsten trioxide is also wavelength-dependent and is given as

Here \(\omega\) represents angular frequency, \(\varepsilon _\infty\) is permittivity at a very high frequency, \(\varepsilon _{st}\) is the permittivity at a very low frequency, and the resonance frequency is \(\omega _0\) for weakly interacting materials \(\gamma \approx 0\). The substrate is a glass of thickness \(l_2=3\) mm with a refractive index \(n_3=1.51\), the permeability and permittivity are \(\mu _3=1\) and \(\epsilon _3={n_3}^2\) respectively. The initial and final media are taken as air having the refractive indices \(n_1=n_4=1\). The values of permeability and permittivity for these media are \(\epsilon _1=\epsilon _4=\mu _1=\mu _4=1\).

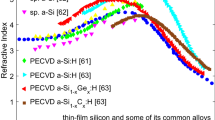

The transmission spectra of the thin film were simulated using the relation Eq.(8) for transmission coefficient, and the Lorentz Model i.e. Equation(9) is used for dielectrics. We simulated the Transmission Spectra numerically. Figure 2 shows the transmission coefficient of \(WO_3\) thin film coated on a glass substrate where the red line is for our experimental results and the black line is by using the TMM approach. Both our theoretical and experimental results agreed well with each other. There is no transmission for the wavelengths of ultraviolet radiation as the glass absorbs the UV spectrum of PEM waves. The transmission starts at the wavelength 340 nm. Before this wavelength, there was no transmission. Figure 3 is the Reflectance versus Wavelength of the thin film of \(WO_3\) using the TMM approach. Furthermore, we have also calculated the refractive index of the sample \(WO_3\) versus Wavelength using the TMM approach; these results are shown in Fig. 4. As the theoretical results presented in this paper agree with the experimental results, this method, TMM, is a powerful and convenient method to study the optical characteristics of different optical materials.

5 Conclusion

Using the Transfer Matrix Method (TMM), we successfully simulated the transmittance of tungsten trioxide \(WO_3\) thin films coated on glass substrates. The theoretical results show a high degree of agreement with experimental observations, underscoring the accuracy of the TMM in modeling such systems. We have also calculated reflectance and refractive indices across different wavelengths. Despite these promising results, future work could explore the impact of varying film thickness and substrate materials and include the absorption factor to validate further and expand the TMM’s applicability. These findings enhance our understanding of the optical properties of \(WO_3\) films and pave the way for optimized designs in photonic applications.

References

S Yao, F Qu, G Wang and X Wu J. Alloys Compd. 724 695 (2017).

G Jeevitha, R Abhinayaa, D Mangalaraj and N Ponpandian J. Phys. Chem. Solids 116 137 (2018).

V Chakrapani, J Thangala and M K Sunkara Int. J. Hydrogen Energy 34 9050 (2009).

J Zhou, S Lin, Y Chen and A M Gaskov Appl. Surface Sci. 403 274 (2017).

M Horprathum, K Limwichean et al Sens. Actuators, B Chem. 176 685 (2013).

B Matović, J Luković et al Process. Appl. Ceramics 14 282 (2020).

S Adhikari and D Sarkar Electrochim. Acta 138 115 (2014).

E Khoo, P S Lee and J Ma J. Eur. Ceramic Soc. 30 1139 (2010).

K Wang, P Zeng and J Zhai Electrochem. Commun. 26 5 (2013).

A Penzkofer, E Drotleff and W Holzer Opt. Commun. 158 221 (1998).

J Muhammad, M B Riaz et al Arab J. Basic Appl. Sci. 31 242 (2024).

A Farmani, M Miri and M H Sheikhi Opt. Commun. 391 68 (2017).

M Asif, A Afaq et al Mater. Today Commun. 37 106966 (2023).

W A Faridi, M Iqbal, M B Riaz, S A AlQahtani and A-M Wazwaz Alex. Eng. J. 95 247 (2024).

S Arshed, G Akram et al Opt. Quant. Electron. 56 1072 (2024).

M B Riaz, A Atangana, A Jahngeer, F Jarad and J Awrejcewicz Results Phys. 37 105471 (2022).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Adnan, M., Jamil, M.I., Ramzan, B. et al. Determination of the optical properties of tungsten trioxide thin film using the transfer matrix method. Indian J Phys (2024). https://doi.org/10.1007/s12648-024-03401-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12648-024-03401-2