Abstract

Benzene is one of the most hazardous pollutants listed in National Ambient Air Quality Standard parameters. Indigenously prepared, accurate and traceable metrological standard of benzene is required for the calibration of instruments used for monitoring of benzene in ambient air. Four calibration gas mixtures of benzene in nitrogen were prepared gravimetrically following ISO 6142-1. Three gas mixtures of benzene in nitrogen in the range of 4–15 µmol/mol were prepared independently from pure benzene. One cylinder was diluted gravimetrically from one of the premixture of benzene in nitrogen. Verification of all the four gas mixture was done as per ISO 6143 by using the gas chromatography-flame ionization detector technique. A linear relationship with regression coefficient > 0.999 was observed between detector response and gravimetric amount fraction for all prepared gas mixtures. Uncertainty estimation of these prepared gas mixtures was done by using the bottom-up approach of “ISO Guide to the Expression of Uncertainty in Measurement” (ISO/GUM). The prepared gas mixtures are traceable to SI unit of amount-of-substance ‘mol’ through mass and estimated gravimetric uncertainty achieved in amount fractions is < 1% relative and the analytical uncertainty is 2–4% relative at k = 2. All prepared gas mixtures are found to show linear detector response over one-year study and are found to be stable for one and half year at laboratory ambient conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Benzene is one of the most hazardous among VOC (volatile organic compound) pollutants present in ambient air. It has been listed in 12 National Ambient Air Quality Standard (NAAQS) parameters notified by central pollution control board (CPCB) in 2009 [1]. The annual prescribed limit for benzene is 5 µg/m3 [1] which is 1.56 nmol/mol at NTP (Normal Temperature and Pressure) [2], and there is no short-term standard listed for ambient monitoring. Hazardous nature of benzene is due to its adverse effect on human health, including cancer, blood disorders, neurological damage, etc. [3]. This neuro-toxic organic pollutant is introduced into the atmosphere through natural activities like volcanoes and forest fires. The anthropogenic sources of benzene are emissions from vehicular exhaust, cigarette smoke, fuel refineries, paints, chemical solvents & industrial emissions [4, 5]. Carcinogenic nature of benzene is well known and classified as a group I carcinogen (carcinogenic to humans) by International Agency for Research on Cancer (IARC) and US Environmental Protection Agency (EPA) [6, 7]. So, there is a requirement to quantify it accurately with traceability to the International System of Units (SI). Accurate measurements of the amount fraction of gases are required to apply regulatory strategies for control of emissions into the atmosphere. Gas chromatography-based analysers and adsorption and desorption followed by gas analysis are the notified method of measurements for benzene [1, 8, 9]. All the instrumental methods required the use of certified reference material for the accurate and reliable measurement data. CSIR-NPL (NPLI) and National Metrology Institutes (NMIs) of India have been working towards the developing calibration gas mixtures also known as primary reference gas mixtures (PRGMs) following ISO 6142-1 [10,11,12,13]. Benzene in nitrogen gas mixture standards is required to be produced in nmol/mol (ppb) amount fractions and in µmol/mol (ppm) amount fractions to underpin calibration of environmental ambient and emission monitoring instruments, respectively. Also, gas cylinders with different cylinder materials and internal treatments are used for the preparation of different VOCs gas mixture standards. Aluminium cylinders with internal passivation or chemical treatments are used for the preparation of benzene, n-hexane, and propane gas mixtures and are considered to be quite stable among VOCs [14].

In the present work, we report the preparation of four gas mixtures of benzene in nitrogen in the range of 2–14 µmol/mol according to ISO 6142-1 [13] in aluminium cylinders without chemical treatment or passivation. A known amount of nitrogen is transferred in the aluminium cylinder before introducing pure benzene to the cylinder. It will prevent the chances of adhering of benzene molecule on the cylinder surface during transferring of benzene with rest of the diluent nitrogen gas. The target mass of benzene required for the preparation of nmol/mol amount fractions of benzene in nitrogen gas mixtures is very small and accurate weighing of small amount of VOC in syringe is very challenging. Hence, gas mixture standards in the amount fraction of nmol/mol can be easily prepared from these higher amount fraction of gas mixtures which are also known as premixtures. Verification of the prepared gas mixtures was done following ISO 6143 [15], and stability of all the prepared gas mixture has been reported after one-year measurement study.

2 Materials & Method

2.1 Reagents

Liquid benzene was purchased from Sigma-Aldrich with ≥ 99.9% purity with certificate. The diluent nitrogen gas, with a specified purity of > 5.5 N, was obtained from a commercial supplier. Aluminium cylinders (Luxfer, UK) of 10 L water capacity were purchased for the preparation of the gas mixture. The diluent gas, nitrogen, was measured for impurities by using cavity ring down spectroscopy (CRDS) technique. Impurities of total hydrocarbon in pure nitrogen were measured by GC-FID analyser.

2.2 Preparation

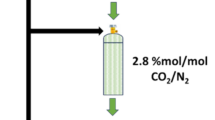

Mixtures of benzene in nitrogen were prepared in a 10-L aluminium cylinder (Luxfur, UK) with double spindle valve with IS 3224 specifications. Figure 1 depicts the preparation scheme of benzene in nitrogen gas mixtures. The cylinders were evacuated using Vacuum system (Make; Zinke, Germany) which include oil free backing pump and Pfeiffer turbo molecular pump. Cylinder was evacuated up to 10–3 mbar with simultaneously heating at (70 ± 5) °C. High-purity nitrogen gas is filled and kept overnight and again evacuated. The procedure is repeated three times, and then after final evacuation, the empty cylinder is weighed with respect to reference cylinder on double pan balance. An equal arm double pan balance (Raymer HCE-25G) of 25 kg with 1 mg sensitivity was used for matrix gas weighing. All balances and mass piece used for weighing were calibrated from CSIR–NPL. The target mass of benzene and nitrogen for the required amount fraction is calculated as per equation given in ISO 6142-1 [12, 13]. The weighing procedure using equal arm double pan balance and calculations are explained in recent published literature [12]. The amount-of-substance fraction (mole fraction) of the benzene/nitrogen gas mixture is calculated from the mass of the pure liquid benzene and the mass of the nitrogen transferred in the cylinder following ISO 6142-1 [13]. Then 1/3rd amount of target nitrogen mass is filled in the cylinder and weighed on double pan balance with reference cylinder. Nitrogen will cover the surface of the cylinder, and there is least chance of contact of benzene at the cylinder surface. This will also remove the chances of the formation of monolayer of benzene at surface of aluminium cylinder.

Syringe method described in ISO 6142-1 was used for the introduction of pure benzene in nitrogen line. Gas tight Hamilton syringe (100 µL) was used to weigh the mass of benzene. A Sartorius balance of 200 g with 0.1 mg readability was used for the syringe weighing. The syringe is weighed after filling it with pure benzene and again weighed after transferring benzene in nitrogen transfer line. The transfer line made from 1/8″-diameter high-pressure Swagelok tubing specially dedicated for benzene transfer through gas tight Hamilton syringe is connected to high-pressure filling system on one side and the aluminium cylinder on other side. The difference in weighing gave the mass of benzene transferred in the line. The liquid was introduced in line through ball valve which is closed off during pressurizing with nitrogen gas. During transferring of liquid benzene approx. 60 °C temperature provided to the fitting by using heating coil so that all liquid completely convert to vapour form and transferred along with rest of the pure nitrogen (2/3rd of amount of target mass of nitrogen). A gas filling system (Make: Zinke, Germany) was used for filling high-purity nitrogen. Figure 2 represents the schematic diagram for transfer of vaporize benzene component with high-pressure nitrogen. Calibration gas mixtures prepared are traceable to SI unit of amount-of-substance ‘mol’ through mass. Three gas mixtures were prepared independently from pure benzene, and one gas mixture was prepared from one of the three premixtures.

2.3 Verification Analysis

After homogenization, the gravimetric amount fraction of the gas mixtures produced was calculated and verification was done as per ISO 6143 using gas chromatography. Analyses of all the prepared benzene gas mixtures were done using GC-FID (6890N, Agilent Technologies, USA). The column fitted in the GC was 30 m long HP-5 (5% Phenyl methyl Siloxane) capillary column with 0.25 μm inner diameter. Ultrapure nitrogen gas was used as the carrier gas at 1.5 mL min−1 flow. Air and hydrogen flow was 400 mL min−1 and 60 mL min−1, respectively. A gas tight syringe was used for injecting the 0.5 mL sample with split ratio 10:1. The injector and detector temperatures were 200 °C and 250 °C, respectively. The oven temperature of GC was programmed for 50 °C and held for 1 min, raised to 80 °C at a rate of 20 °C min−1 and again held for 1 min. The FID detector response (µV) of four prepared calibration gas mixture (CGMs) is plotted vs benzene mole fraction and is given in Fig. 3. The detector response and benzene mole fraction linear correlation coefficient is one. Chromatogram of all the four gas mixture showing peak of benzene at retention time of 2.67 min is shown in Fig. 4.

2.4 Stability Testing

Prepared gas mixture cylinders were placed on wooden surface all the time and stored in the laboratory condition (25 ± 2) °C with relative humidity of (45 ± 10) %. After six months of preparation of gas mixtures, stability study has been done for a period of approximate one year by doing monthly analysis of all prepared gas mixtures (From October 2021 to August 2022).

3 Results and Discussion

Three benzene gas mixtures prepared in aluminium (Luxfer, UK) cylinders from pure benzene after transferring a weighed amount of nitrogen and one gas mixture were diluted by mass from 13.64 µmol/mol amount fraction of benzene in nitrogen. Conversion of mass of every component in mole fraction has been done as per the standard method reported in the literature [12, 13, 16]. Amount-of-substance fraction of benzene is calculated as per Eq. (1) given below:

where mB is mass of benzene, mN is mass of nitrogen, MB is molar mass of benzene (78.11 g mol−1), and MN is molar mass of nitrogen (28.0135 g mol−1).

Mass and number of moles of both the components in benzene/nitrogen gas mixtures are given in Table 1. Uncertainty in mole fraction of benzene has been estimated by following bottom-up approach of ISO/GUM and by following EURACHEM Guidelines [17, 18]. Detailed estimation of gravimetric preparation uncertainty for two component mixture are given in the recently published literature [12]. Following this approach, u(xgrav) is estimated for benzene mole fraction. Gravimetric uncertainty for benzene mole fraction, i.e. u(xgrav), is ≤ 0.5% relative (at k = 1) to all the prepared gas mixtures as shown in Table 1.

Verification of these gas mixtures was done using GC-FID following ISO 6143 [13], and consistency in the verification results has been found with the gravimetric values in the uncertainty ranges. Figure 5 shows the verification results of all the four gas mixtures. Analytical uncertainty (at k = 1) bar overlaps the gravimetric range, indicating the consistency in the both values.

Analytical value was calculated by multipoint calibration method using straight line equation of linear regression fit. Uncertainty in the verification analysis u(xver) included the uncertainty due to linear regression, uregression, and uncertainty in measurement precision, u(xprecision), as Type A uncertainty and was calculated as given in Eq. (2).

Gravimetric and analytical uncertainty has been combined as given in Eq. (3). The values are given in Table 2 for all prepared benzene/nitrogen gas mixtures.

The following verification Eq. (4) applied on each cylinder measurement results as per ISO 6142-1.

The verification results and uncertainties are given in Table 2, and it can be evident from the data that all the prepared gas mixtures follow Eq. (4).

The stability of all the four cylinders is represented by verification data. The deviation from the initial amount fraction (µmol/mol) of each gas mixture cylinder is plotted versus elapsed time (in months) and is represented in Fig. 6a, b and c. Other NMIs used the internal treated cylinders for preparation of different VOCs premixtures and further lower amount fractions and reported their stability [19]. Internationally, benzene in nitrogen gas mixture with nominal concentration of 1–10 ppb with 2–3% relative uncertainty is available with NPL-UK [20]. No calibration gas mixture of benzene in nitrogen is available in India.

Stability of benzene in nitrogen gas mixtures at a 13.64 µmol/mol, b 7.25 µmol/mol, c 3.38 µmol/mol and 2.79 µmol/mol contained in Luxfer Al-cylinder with no treatment. Error bars represent uanal at k = 1. Black solid line represents respective gravimetric value with dotted lines representing their respective uncertainty; ugrav at k = 1. Stability measurements were made over a period of 300 days after six months from the date of preparation & verification

4 Conclusion

We report the status of preparation of benzene in nitrogen gas mixture standards and its stability estimates at CSIR-NPL. A total of four gas mixture standards are prepared gravimetrically, three independently from pure benzene and one by gravimetric dilution from the premixture of highest amount fraction. The addition of 1/3rd of the target mass of nitrogen gas is done to the evacuated cylinder to prevent the direct contact of pure benzene vapours with evacuated cylinder surface. All gas mixtures are verified as per ISO 6143 for their gravimetric amount fractions using GC-FID, and good correlation and linearity are achieved. The traceability to the SI is established through mass. Stability of all four cylinders is checked by verification analysis till one year after preparation, and deviation in mole fraction from the initial gravimetric values is found in the range of preparation uncertainty. The stability study further supports the preparation method in which nitrogen gas is added before addition of benzene component to avoid the chances of adhering of benzene molecule with cylinder surface. This method is less expensive as no treatment or passivation of cylinder surface is done before preparation which has been reported in earlier literature [14, 19]. These gas mixtures can be used for further dilution in nmol/mol range for calibration of analysers used for the ambient benzene measurement. Now in future we are looking forward for an opportunity for inter comparison/bilateral comparison of these cylinder with similar standards of different NMIs.

References

https://cpcb.nic.in/uploads/National_Ambient_Air_Quality_Standards.pdf.

Agency for toxic substances and disease registry (ATSDR). Toxicological Profile for Benzene. U.S. Public Health Service, U.S. Department of Health and Human Services, Atlanta, GA. (2007).

B.H. Lv, S. Song, Z. Zhang, Z.Y. Mei and F.L. Ye, Urinary s-phenylmercapturic acid as a key biomarker for measuring occupational exposure to low concentrations of benzene in Chinese workers: a pilot study. J. Occup. Environ. Med., 56 (2014) 319–325.

A.A. Melikian, Q. Qu, R. Shore, G. Li, H. Li, X. Jin and Y. Wang, Personal exposure to different levels of benzene and its relationships to the urinary metabolites S-phenylmercapturic acid and trans, trans-muconic acid. J. Chromatography B Anal. Technol. Biomed. Life Sci., 778 (2002) 211–221.

IRIS. Benzene integrated risk information system, U.S. Environmental Protection Agency, Washington, DC, (2007).

F. Lyon, Some industrial chemicals. IARC Monographs Eval. Carcinog. Risks Hum., 60 (1994) 389–433.

G.C. Rhoderick and J.H. Yen, Development of a NIST Standard Reference Material containing thirty volatile organic compounds at 5 nmol/mol in nitrogen. Anal. Chem., 78 (2006) 3125–3132. https://doi.org/10.1021/ac052136r.

W.R. Miller and G.C. Rhoderick, Stability of compressed gas mixtures containing low level volatile organic compounds in aluminum cylinders. Fresen. J., 86 (1995) 2580–2589. https://doi.org/10.1021/ac403761u.

K. Hong, B.M. Kim, H.K. Bae, S. Lee, J. Tshilongo, D. Mogale, P. Seemane, T. Mphamo, H.A. Kadir, M.F. Ahmad, N.H.A. Nasir, N. Baharom, D. Soni, K. Singh, S. Bhat, S.G. Aggarwal, and P. Johri, Final report of supplementary comparison for APMP.QM-S7.1: Methane in nitrogen at 2000 μmol/mol, Metrologia, 57, 1A (2020).

J. Lee, J. Lee, J. Lim, D. Moon, S.G. Aggarwal, P. Johri, D. Soni, L. Hui, K.F. Ming, R. Sinweeruthai, S. Rattanasombat, O. Zuas, H. Budiman5 , Muhammad Rizky Mulyana and Vladimir Alexandrov,Final report for supplementary comparison APMP.QM-S15: Carbon dioxide in nitrogen at 1000μmol/mol, Metrologia, 58, 1A (2021).

D. Soni, P. Kumari, K. Singh and S.G. Aggarwal, A practical approach of measurement uncertainty evaluation for gravimetrically prepared binary component calibration gas mixture. MAPAN-J. Metrol. Soc. India, 37 (2022) 653–664. https://doi.org/10.1007/s12647-022-00600-2.

ISO 6142-1, Gas analysis-Preparation of calibration gas mixtures - Part 1: Gravimetric method for Class 1 mixtures (2015).

G.C. Rhoderick, C.E. Cecelski, W.R. Miller, D.R. Worton, S. Moreno, P.J. Brewer, J. Viallon, F. Idrees, P. Moussay, Y.D. Kim, D. Kim, S. Lee, A. Baldan and J. Li, Stability of gaseous volatile organic compounds contained in gas cylinders with different internal wall treatments. Elem. Sci. Anth., 7 (2019) 28. https://doi.org/10.1525/elementa.366.

ISO 6143:2001-Gas analysis—Comparison methods for determining and checking the composition of calibration gas mixtures (2001).

M.J.T. Milton, G.M. Vargha and A.S. Brown, Gravimetric methods for the preparation of standard gas mixtures. Metrologia, 48 (2011) 1–9.

JCGM 100:2008, Evaluation of measurement data-Guide to the expression of uncertainty in measurement, GUM 1995 with minor corrections, Published by International Bureau of Weights and Measures (BIPM), France(2008).

EURACHEM/CITAC Guide CG4, Quantifying uncertainty in analytical measurement, 3rd Ed.; QUAM, (2012).

R.J.P. Grenfell, M.J.T. Milton, A.M. Harling, G.M. Vargha, C. Brookes, P.G. Quincey and P.T. Woods, Standard mixtures of ambient volatile organic compounds in synthetic and whole air with stable reference values. J. Geophys. Res., 115 (2010) D14302. https://doi.org/10.1029/2009JD012933.

https://www.npl.co.uk/products-services/gas/primary-reference-gas-materials

Acknowledgements

Poonam Kumari is thankful to Council of Scientific and Industrial Research (CSIR) for providing the fellowship under CSIR-SRF scheme (P-81-101) for her Ph.D work. Authors thank the Director, CSIR-NPL, for providing a platform to carry out experimental work and for providing research facilities. Authors are also thankful to head of ESBM Division (CSIR-NPL) for encouragement and support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumari, P., Soni, D., Singh, K. et al. Preparation, Verification and Stability of Calibration Gas Mixture of Benzene in Nitrogen. MAPAN 38, 707–713 (2023). https://doi.org/10.1007/s12647-023-00659-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12647-023-00659-5