Abstract

Biofilms may contain pathogenic and spoilage bacteria and can become a recurring problem in the dairy sector, with a negative impact on product quality and consumer health. Peracetic acid (PAA) is one of the disinfectants most frequently used to control biofilm formation and persistence. Though effective, it cannot be used at high concentrations due to its corrosive effect on certain materials and because of toxicity concerns. The aim of this study was to test the possibility of PAA remaining bactericidal at lower concentrations by using it in conjunction with reuterin (3-hydroxypropionaldehyde). We evaluated the efficacy of PAA in pure form or as BioDestroy®, a PAA-based commercial disinfectant, on three-species biofilms formed by dairy-derived bacteria, namely Pseudomonas azotoformans PFlA1, Serratia liquefaciens Sl-LJJ01, and Bacillus licheniformis Bl-LJJ01. Minimum inhibitory concentrations of the three agents were determined for each bacterial species and the fractional inhibitory concentrations were then calculated using the checkerboard assay. The minimal biofilm eradication concentration (MBEC) of each antibacterial combination was then calculated against mixed-species biofilm. PAA, BioDestroy®, and reuterin showed antibiofilm activity against all bacteria within the mixed biofilm at respectively 760 ppm, 450 ppm, and 95.6 mM. The MBEC was lowered significantly to 456 ppm, 337.5 ppm, and 71.7 mM, when exposed to reuterin for 16 h followed by contact with disinfectant. Combining reuterin with chemical disinfection shows promise in controlling biofilm on food contact surfaces, especially for harsh or extended treatments. Furthermore, systems with reuterin encapsulation and nanotechnologies could be developed for sustainable antimicrobial efficacy without manufacturing disruptions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

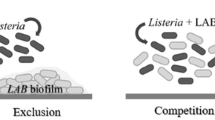

Dairy processing plants frequently face the challenge of eradicating biofilms, which are a potential source of contamination by spoilage and/or pathogenic microorganisms [1, 2]. Biofilms can form and spread easily on equipment surfaces because of the ability of some bacteria to attach thereto, aggregate, and produce a matrix of extracellular polymeric substances (EPS) [3]. The structure and composition of EPS matrix allow them to act as a physical barrier that reinforces bacterial defenses against physical and chemical attacks including cleaning and disinfection treatments [4, 5].

Despite the variety of means available to control biofilms, such as ultrasound, ozonation, and ultraviolet irradiation [6,7,8,9], the chemical approach remains the most commonly adopted in the dairy industry. This is mainly because the chemical agents ensure reliable and high hygiene standards, in addition to providing effective, scalable, cost-efficient, and time-saving solutions to the dairy sector. This method relies on a range of cleaning solutions and sanitizers, which are often used in high concentrations to maximize their biofilm removal potential [10].

Peracetic acid (PAA) is one of the most widely used disinfectants in cleaning procedures because of its strong oxidizing properties, short time of action, and broad antimicrobial spectrum covering all microbial groups, including viruses, Gram-positive and Gram-negative bacteria, yeasts, and molds [2, 11,12,13,14,15,16,17]. It is recognized also for its high compatibility with stainless steel, the most common material used in dairy processing equipment [18]. Unlike many other disinfectants, peracetic acid retains its antimicrobial activity even in the presence of organic matter. This partly explains its effectiveness as an antibiofilm agent due to its ability to penetrate the EPS matrix [19,20,21]. Although it decomposes to two non-toxic compounds, namely acetic acid and hydrogen peroxide, at the high concentrations used during sanitation operations, it may cause discomfort to workers, for example, irritation of skin and mucous membranes [22].

Reuterin (3-hydroxypropionaldehyde or 3-HPA) is a natural antimicrobial molecule produced by Lactobacillus reuteri during the anaerobic fermentation of glycerol [23]. This compound displays strong oxidizing properties and is active against Gram-positive bacteria including Staphylococcus, Streptococcus, Clostridium, Bacillus, Leuconostoc, and Lactobacillus; Gram-negative including Escherichia, Shigella, Salmonella, Proteus, and Pseudomonas; and Saccharomyces cerevisiae, Penicillium roqueforti, and possibly other yeasts and molds [23,24,25]. Its efficacy at eliminating planktonic bacteria, alone or in combination with other antimicrobial compounds such as organic acids and bacteriocins, has been proven [26] but no studies have been focused on the antimicrobial activity of the reuterin-peracetic acid combination. Furthermore, limited investigations have been conducted to determine its effectiveness against biofilms [27, 28], especially in the dairy sector, and, to date, the synergistic effect between reuterin and peracetic acid on multispecies biofilms has not been examined. The aim of this study was to evaluate the efficacy of reuterin alone and in combination with an industrial disinfectant, namely peracetic acid or a peracetic-acid-based commercial disinfectant (BioDestroy®) on biofilms composed of three dairy biofilm producer species; Pseudomonas azotoformans PFlA1, Serratia liquefaciens Sl-LJJ01, and Bacillus licheniformis Bl-LJJ01.

Materials and Methods

Bacterial Species

Three bacteria were selected to produce multi-species biofilms. Pseudomonas azotoformans PFlA1 was collected from a Canadian dairy plant [29]. Serratia liquefaciens Sl-LJJ01 and Bacillus licheniformis Bl-LJJ01 were isolated from biofilms generated in the laboratory at 4 °C from raw milk using the CDC Biofilm reactor and identified by matrix-assisted laser desorption ionization-time of flight (MALDI-TOF) spectroscopy (Faculty of Veterinary Medicine, Université de Montréal, Quebec, Canada).

Biofilm-Forming Capacity

The ability of bacteria to form biofilms was measured using the following two methods.

Crystal Violet Method

Single-species biofilm was grown in 96-well microtiter plates as detailed by Goetz et al. [29]. Briefly, pre-inoculum was prepared by adding 20 µL of bacterial strain to 10 mL of Bacto™ tryptic soy broth (BD Canada, Mississauga, Ontario) and incubated at 30 °C for 24 h (with shaking at 160 rpm for Ps. azotoformans PFlA1 only). The culture was diluted in tryptic soy broth at 1/1000 (Ser. liquefaciens Sl-LJJ01), 1/100 (Ps. azotoformans), or 1/10 (B. licheniformis Bl-LJJ01) to a count of 6 log cfu mL−1, and microtiter plates (Corning Incorporated, 3595, Kennebunk, ME, USA) were loaded with these suspensions (200 µL per well, in triplicate for each species). After 24 h of incubation, biofilm was quantified, the cut-off OD (ODc) was defined, and the bacterial species was rated as non-adherent (OD ≤ ODC), weakly (ODC < OD ≤ 2 × ODC), moderately (2 × ODC < OD ≤ 4 × ODC), or strongly adherent (4 × ODC < OD), as proposed by Stepanović et al. [30].

Colony-Forming Units (cfu) Method

After biofilm formation, planktonic cells were discarded by removing the bacterial suspensions and the microtiter plate wells were rinsed three times with PBS. Then, 200 µL of PBS was added to each well and the microtiter plate was sonicated at 40 kHz for 30 min using a Branson CPX2800H ultrasonic water bath (Branson Ultrasonics Corporation, Brookfield, CT, USA) at a power of 110 W. The bacterial suspensions thus obtained were diluted serially tenfold in a sterile 96-well microtiter plate, and the number of viable cells was determined by spot plating 10 µL on BD Difco™ tryptic soy agar (BD, Mississauga, Canada). After 24 h of incubation at 30 °C, the biofilm bacterial density was calculated as follows:

where N is the number of colony-forming units and D is the dilution factor.

Multi-species Biofilm Formation

The cross-streak method was used to ensure that no antagonistic action due to antimicrobial compound production existed between the bacteria in the multi-species biofilm. As described by Balouiri et al. [31], each bacterial species was streaked centrally on tryptic soy agar in a Petri plate. After 24 h of incubation at 30 °C, the other two species were added as a single streak perpendicular to the first. Antagonistic activity was revealed if an inhibition zone appeared at the junctions after 24 h of incubation at 30 °C.

The multi-species biofilms were formed according to the ASTM standard test method [32] with modifications. Briefly, the culture of each species was adjusted to 6 log cfu mL−1 as described above and then added (50 µL each) to an MBEC Assay® Biofilm Inoculator plate (Innovotech, Edmonton, AB, Canada) in triplicate and the plate was then incubated at 30 °C for 24 h. Once formed, multi-species biofilm was first rinsed by placing the MBEC plate lid for 10 s in a 96-well microplate containing 200 µL of PBS, and then transferred onto another plate containing the same volume of PBS for 30 min of sonication. After tenfold serial dilution, 10 µL of the biofilm suspension obtained was spotted on selective media and incubated as shown in Table 1. The bacterial density of each species within the biofilm was calculated as follows:

where X is the number of cfu counted in the spot, B is the volume plated (0.01 mL), V is the well volume (0.20 mL), A is the peg surface area (46.63 mm2), and D is the dilution.

Multi-species Biofilm Structure

To assess visually bacteria viability in mixed biofilms and their appearance, scanning electron microscopy (SEM) and confocal laser scanning microscopy (CLSM) were performed.

SEM

Biofilm grown on MBEC microplate pegs was fixed in a mixture of 5% glutaraldehyde and 0.1 M cacodylate buffer then kept at 4 °C for 24 h (MBEC assay® procedural manual, version 2.1, Innovotech). The fixative solution was then discarded, and the pegs were air-dried under a laminar flow hood for 72 h, then mounted on aluminum stubs, metalized with gold (EMS 350 × Sputter Coater, Hatfield, PA), and observed at × 500, × 2000, and × 10,000 magnifications using a JEOL 6360LV scanning electron microscope (JEOL Inc., Tokyo, Japan) at 15 kV on SEI mode.

CLSM

Biofilm grown on the MBEC pegs was stained with Syto 9 and propidium iodide using the Filmtracer™ LIVE/DEAD™ Biofilm Viability Kit (Catalog no. L10316). Viable and dead cells were observed using an inverted Leica TCS SP8 confocal laser scanning microscope (Leica Microsystems CMS, Mannheim, Germany) with fluorescence excitation at 488 nm and 552 nm, respectively, for Syto 9 and propidium iodide. The 3D images were obtained from the analysis of a z-stack of 50 images scanned with 0.533 µm spacing using a 40X/0.85 dry objective and Leica Application Suite X software (LAS X, Leica Microsystems). Biofilm average thickness was calculated from 21 z-stack images observed on different pegs using a custom macro https://github.com/alexandrebastien/ImageJ-Script-Collection/tree/master/Clients/Julie%20Jean/Biofilm%20Thickness for Fiji/ImageJ [37].

Antimicrobial Compounds

Peracetic acid was generated by mixing acetic acid (Sigma-Aldrich, 27,225-1L-R, St. Louis, MO, USA) and 30% hydrogen peroxide (Sigma-Aldrich, 216,763, St. Louis, MO, USA) at a volume ratio of 1.5: 1, adding 10 M sulfuric acid (Fisher Scientific, 351,297–212, Ontario, Canada) at 1% w/w and holding at 30 °C in a water bath for 48 h [38]. The peracetic-acid-based commercial disinfectant BioDestroy® was provided by Sani Marc (Sani Marc Inc., Québec, Canada). The peracetic acid concentration in these two disinfectants was measured before each experiment using a method described elsewhere [39].

Reuterin at a concentration of 258 mM reuterin was produced according to Vimont et al. [25] and supplied by Dr. Ismail Fliss (Université Laval, Québec, Canada) and Laboratoire Innodal (Québec, Canada).

Antibacterial Activity

Agar Well Diffusion Assay

The antibacterial activity of the disinfectants and reuterin against biofilm bacteria was evaluated by the agar diffusion method as described by [40]. Tryptic soy broth (25 mL) containing 0.75% agar was inoculated with 1% of the bacterial culture obtained after 24 h of growth as described above and poured into Petri dishes. Wells 5 mm in diameter were made in the solidified medium, to which 80 µL of 0.5% peracetic acid, 0.05% BioDestroy®, 258 mM reuterin, and PBS 1X (negative control) were added. Growth inhibition zones were observed and measured after 18 h of incubation at 30 °C.

Minimum Inhibitory Concentration (MIC) and Minimum Bactericidal Concentration (MBC)

MICs for peracetic acid, BioDestroy®, and reuterin were determined for Ps. azotoformans PFlA1, Ser. liquefaciens Sl-LJJ01, and B. licheniformis Bl-LJJ01 using the broth microdilution method [41] in 96-well microplates (Corning Incorporated, Kennebunk, ME, USA). Briefly, three wells in a column were filled with 125 µL of antimicrobial agent by performing two-fold successive dilutions in TSB. Fifty microliters of each 24 h bacterial suspension diluted as described above was added. Wells containing 125 µL of medium inoculated with 50 µL of the corresponding strain and others containing only 175 µL of medium were used as positive and negative controls. The microplates were incubated at 30 °C for 18 h and OD was measured at 595 nm using a microplate reader. The lowest concentration of microbial agent that prevented turbidity was noted as the MIC. To determine the MBC, 10 µL of bacterial suspension was sampled from wells displaying no turbidity and spotted on TSA. After 24 h of incubation, the lowest concentration of antimicrobial substance allowing no bacterial growth was called the MBC.

Synergistic Effects Between Antimicrobial Combinations

The checkerboard assay was carried out to determine possible interactions between disinfectants and reuterin in combination against biofilm and to calculate their fractional inhibitory concentration (FIC) as it has been described previously [26]. Peracetic acid and BioDestroy® were diluted serially in tryptic soy broth in a 96-well plate, starting at 16× MIC. Reuterin was diluted likewise on another plate starting at 8× MIC, and 50 µL of each of these dilutions was transferred to the corresponding wells containing 50 µL of peracetic acid or BioDestroy®. All wells except the negative control were then inoculated with 50 µL of bacterial culture (6 log cfu mL−1). After 18 h of incubation at 30 °C, bacterial growth or inhibition was assessed by measuring OD at 595 nm in each well. Interactions between antimicrobial agents were defined as synergistic, additive, or antagonistic based on the fractional inhibitory concentration index (FICI) calculated as follows:

where A and B are the MIC of each disinfectant combined with reuterin (in wells without turbidity), and MICA and MICB are the MICs of each antibacterial agent alone.

FICI ≤ 0.5 indicates synergy, 0.5 < FICI ≤ 1 is additive, 1 < FICI ≤ 4 is indifferent, and FICI > 4 is antagonistic.

Only the combinations for which FICI ≤ 1 were retained, and the FICs of the two antimicrobial agents (peracetic acid/reuterin and BioDestroy®/reuterin) involved in these associations were used in the next step of the study.

Antibiofilm Activity

Initially, biofilms were grown in triplicate using MBEC microplates as described above. They were rinsed by placing the MBEC plate lid for 10 s on a 96-well microplate containing 200 µL of PBS per well, and then treated with the disinfectants alone, reuterin alone, and each disinfectant/reuterin combination. Based on previous calculations of FIC, concentrations corresponding to 2 × , 4 × , 6 × , 8 × , and 10 × the FIC for peracetic acid and reuterin in combination (PAA/reuterin) and to 5 × , 10 × , 15 × , 20 × and 25 × FIC for BioDestroy® and reuterin (BioDestroy®/reuterin) were used. The disinfectants and reuterin were used at these concentrations separately and in association with biofilm experiments.

MBEC plate lid was placed for 5 min (recommended by the manufacturer) on a microplate containing 200 µL of peracetic acid or BioDestroy® per well at their respective five concentrations (listed above) at room temperature. The disinfectants were then neutralized by immersing the MBEC pegs in microplate wells containing 200 µL of Dey-Engley neutralizing broth (D3435, Sigma-Aldrich, St. Louis, MO, USA) and sonicating for 30 min at 40 kHz and 110 W in the ultrasonic water bath [32]. The effect of reuterin alone on biofilms was tested at all concentrations (2, 4, 5, 6, 8, 10, 15, 20, and 25 times the FIC, 200 µL per well) after rinsing and incubating at room temperature for 16 h. The pegs were rinsed twice in PBS solution and the remaining biofilm bacteria were recovered in PBS by sonication in a sterile 96-well plate (200 µL per well). Combined treatments involved exposure to disinfectant for 5 min and then to reuterin for 16 h at the concentrations mentioned above. The pegs were rinsed twice with PBS to remove all remaining traces of neutralizer before contact with reuterin. Biofilm cells were recovered in PBS by sonicating the MBEC plate. The resulting suspension was diluted serially six times (tenfold) then spotted on a selective medium and incubated under the growth conditions for each strain as shown in Table 1. The bacterial counts of the three strains were calculated for each antimicrobial used alone and in combination using Eq. 2. The viable count reductions obtained for each treatment and bacterial species were calculated as follows:

Statistical Analysis

All experiments were performed three times. Inhibition of bacterial or biofilm growth was analyzed by two-way ANOVA and compared using the Tukey test with GraphPad Prism 9.2.0 software (GraphPad Software, San Diego, CA, USA). Data were expressed as mean ± standard deviation (SD), and p < 0.05 was considered statistically significant.

Results

Biofilm-Forming Capacity

Based on measuring the OD of biofilms formed on 96-well plates, Ps. azotoformans PFlA1 and Ser. liquefaciens Sl-LJJ01 are moderate producers of biofilm, whereas B. licheniformis Bl-LJJ01 is a strong producer (OD = 1.27 ± 0.76, 0.97 ± 0.35, and 2.87 ± 0.36, respectively, Fig. 1a). The bacterial densities were considerable (Fig. 1b), but contrary to what was expected, significantly lower (p < 0.0001) in biofilms formed by B. licheniformis Bl-LJJ01 (4.77 ± 0.19 log10 cfu mL−1) than in those of Ps. azotoformans PFlA1 (7.72 ± 0.44 log10 cfu mL−1) and Ser. liquefaciens Sl-LJJ01 (7.57 ± 0.56 log10 cfu mL−1).

Evaluation of biofilm formation by Ps. azotoformans PFlA1, Ser. liquefaciens Sl-LJJ01, and B. licheniformis Bl-LJJ01 using crystal violet (a) and colony counting (b). OD ≤ 0.46 indicates a non-producer of biofilm, 0.46 < OD ≤ 0.92 a weak producer, 0.92 < OD ≤ 1.84 a moderate producer, and 1.84 < OD a strong producer. Values are mean ± SD (n = 3)

Multi-species Biofilm Formation and Structure

As shown in Fig. 2, none of these bacterial species appears to have any antagonistic effect on either of the other two, and the three therefore can be propagated together.

The bacterial density of each species comprising the mixed-species biofilm is shown in Fig. 3. B. licheniformis Bl-LJJ01 reached a significantly lower count, at 3.77 log cfu/mm2 versus 5.18 and 4.88 log cfu/mm2, respectively, for Ser. liquefaciens Sl-LJJ01 and Ps. azotoformans PFlA1.

Scanning electron microscopy revealed that 24-h mixed biofilms formed on MBEC microplates were dense and contained practically confluent cell growth with a 3D structure (Fig. 4). At low magnification (× 500) holes and cracks are apparent, which are probably pores and water channels (white arrows in images a1 and a2). At higher magnification (× 2000), some areas appeared smooth (top and bottom of image a3) compared to others, reflecting the presence of a large production of matrix. The bacteria showed a likely tenacious multilayer of cells bonded together by the EPS matrix (black arrows in image a4). CLSM images show a heterogeneous structure (Fig. 4b1 and b2). Fluorochrome staining with Syto 9 and propidium iodide revealed that most cells were alive (green colored), with some presumed to be dead (red colored) in uneven distribution. The average thicknesses ranged from 4.76 to 29.76 µm (Figure S1 and Table S1 in supplementary material). Some examples are shown in Figs. 4b3, b4, and b5.

SEM (a) and CLSM (b) micrographs of mixed species biofilm (Ps. azotoformans PFlA1, Ser. liquefaciens Sl-LJJ01, and B. licheniformis Bl-LJJ01) grown for 24 h on MBEC microplate pegs. White arrows point to typical holes and cracks appearing on the biofilm surface (a1). The black rectangle in a2 is shown magnified at × 2000 in a3 and at × 10,000 in a4. Black arrows indicate bacteria glued to each other with EPS matrix. CLSM magnifications are × 10 (b1) and × 40 (b2). Biofilms were stained with LIVE/DEAD™ Biofilm Viability Kit. Live cells are colored green and dead cells are colored red. Z-stack 3D images represent biofilm at thicknesses of 20 µm (b3), 25 µm (b4), and 18 μm (b5)

Antibacterial Activity

Agar Well Diffusion Assay

Both disinfectants and reuterin exhibited an effective antibacterial effect against the three species tested, as shown in Fig. 5. Inhibition zones of 22.5–34.0 mm and 27.5–35 mm in diameter were obtained with respectively 5000 ppm peracetic acid and 500 ppm BioDestroy® whereas smaller zones of inhibition were observed with 258 mM reuterin (Table 2). Ps. azotoformans PFlA1 appeared to be less sensitive to reuterin (16 mm) compared to 25 mm for Ser. liquefaciens Sl-LJJ01 and 19 mm for B. licheniformis Bl-LJJ01.

MIC and MBC Determination

The MIC and MBC of disinfectants and reuterin against Ps. azotoformans PFlA1, Ser. liquefaciens Sl-LJJ01, and B. licheniformis Bl-LJJ01 are reported in Table 3. The MIC of peracetic acid was the same for all bacteria and was half the MBC. BioDestroy® had a stronger antibacterial effect than peracetic acid and this was most notable for Ps. azotoformans PFlA1 followed by B. licheniformis Bl-LJJ01. In contrast, Ser. liquefaciens Sl-LJJ01 was the most susceptible of these three species to reuterin. However, the bactericidal effect of reuterin was the same for all three.

Synergistic Effects Between Antimicrobial Combinations

The checkerboard test was carried out and FICI values are reported in Table 4. Ps. azotoformans PFlA1 was chosen for the tests on the peracetic acid/reuterin combination, while Ser. liquefaciens Sl-LJJ01 was used for the BioDestroy®/reuterin. As shown in Table 4, both combinations were additive. The MICs of peracetic acid, BioDestroy®, and reuterin through these combinations were thus lowered from 152 ppm, 45 ppm, and 19.1 mM to 76 ppm, 22.5 ppm, and 4.78 mM, respectively.

Antibiofilm Activity

Treating the 24-h three-species biofilms developed on MBEC microtiter plate with peracetic acid, BioDestroy®, or reuterin alone and with combinations of both disinfectants with reuterin at different concentrations gave the log reductions of viable count shown in Fig. 6. At 760 ppm of peracetic acid alone (10 times the FIC), Ps. azotoformans PFlA1 and Ser. liquefaciens Sl-LJJ01 were eliminated (4.84 and 4.72 log reductions of cfu/mm2) whereas B. licheniformis Bl-LJJ01 was (3.93 log reduction of cfu/mm2) at 608 ppm (8 times the FIC). Using reuterin alone at 47.8 mM (10 times the FIC) resulted in smaller reductions of Ps. azotoformans PFlA1 (2.26 log cfu/mm2) and Ser. liquefaciens Sl-LJJ01 (0.86 log cfu/mm2), whereas B. licheniformis Bl-LJJ01 was effectively eliminated (4.15 log cfu/mm2) at this concentration (p < 0.0001 for both comparisons). It is notable that the peracetic acid/reuterin combination halted growth of Ps. azotoformans PFlA1 and Ser. liquefaciens Sl-LJJ01 in the biofilm at concentrations no higher than 6 times the FIC of these antibacterial agents (456 ppm and 28.68 mM, p < 0.0001) and growth of B. licheniformis Bl-LJJ01 at only twice the FIC (p < 0.0001, Fig. 6a). Results reported that BioDestroy® concentrations providing the eradication of the three bacteria within the biofilms were lower than those of PAA. Therefore, the MBEC values of BioDestroy® when used singly against the mixed biofilms were 450 ppm (20 × FIC) for Ps. azotoformans PFlA1 and Ser. liquefaciens Sl-LJJ01 and corresponded to 337.5 ppm (15 × FIC) for B. licheniformis Bl-LJJ01, achieving reductions of respectively 4.94, 4.72, and 3.93 log cfu/mm2). Furthermore, findings have demonstrated that reuterin alone had exerted an antibiofilm activity against all three species in biofilm, albeit at different concentrations (47.8 mM, 71.7 mM, and 95.6 mM, respectively, for B. licheniformis Bl-LJJ01, Ps. azotoformans PFlA1, and Ser. liquefaciens Sl-LJJ01 with reductions of 4.15, 4.94, and 5.17 log cfu/mm2). Reuterin made BioDestroy® more effective at eradicating biofilm than both used separately as similar removal rates were attained with more reduced concentrations of the two components for B. licheniformis Bl-LJJ01 (at 112.5 ppm and 9.56 mM), Ps. azotoformans PFlA1 (at 225 ppm and 47.8 mM), and Ser. liquefaciens Sl-LJJ01 (at 337.5 ppm and 71.7 mM, p < 0.0001, Fig. 6b).

Antibiofilm activity of a peracetic acid (PAA) or b peracetic-acid-based disinfectant in the presence or absence of reuterin against Ps. azotoformans PFlA1, Ser. liquefaciens Sl-LJJ01, and B. licheniformis Bl-LJJ01 in mixed-species biofilm grown on MBEC microplate pegs. Biofilms were contacted with peracetic acid (pure or as a disinfectant) for 5 min then with reuterin for 16 h or not, or only with reuterin for 16 h. Peracetic acid concentrations start at 152 ppm (2 × FIC). Disinfectant concentrations start at 112.5 ppm (5 × FIC). Reuterin concentrations start at 9.56 mM (2 × FIC). Values plotted are mean ± SD (n = 3 independent experiments)

Discussion

Biofilms exist naturally as multi-species populations, even in regularly sanitized food processing facilities [42, 43]. They are inherently more difficult to remove than planktonic cells [44] and are more resistant to disinfectants [45,46,47,48], making tougher control strategies necessary. In this study, we examined reuterin in combination with peracetic acid in pure form and in a commercial disinfectant to see if synergism could allow the use of these agents at reduced concentrations against multi-species biofilms containing one pathogen (Ser. liquefaciens Sl-LJJ01) and two spoilage bacteria (Ps. azotoformans PFlA1 and B. licheniformis Bl-LJJ01) commonly found in dairy processing plants. Our findings show that these species are moderate to strong formers of biofilm when grown alone under static conditions. When grown together, they readily formed dense, multilayered biofilms with 3D structures viewable by SEM and CLSM. In addition to pores and water channels which are indicative of mature structures [49], the biofilm surface features include smooth areas suggesting the presence of considerable amounts of matrix material [50]. However, we find that bacterial densities are substantially lower within this mixed structure compared with the corresponding single-species biofilms, with predominance of Ps. azotoformans PFlA1 and Ser. liquefaciens Sl-LJJ01. Dead cells are present in the multi-species biofilm, as revealed by CSLM. The reduced bacterial densities after 24 h of growth are not likely due to antagonism between the species, but could be due to depletion of nutrients [51] or to differences in growth rate. B. licheniformis Bl-LJJ01 was apparently less dense in terms of cell concentration because it is not a fast-growing species compared to the other two but produces EPS in large amounts as revealed by the mucoid colony appearance (supplementary material) and OD measurement. Overproduction of EPS likely contributes to matrix formation, which is the cornerstone of biofilm development and structural stability [52, 53]. Dairy species of Bacillus species, notably B. licheniformis, have been characterized as having the ability to form mucoid and robust biofilms that reduce susceptibility to disinfectants [54,55,56].

Peracetic acid is the most widely used antimicrobial agent in dairy processing plants, thanks to its recognized bactericidal activity against Gram-positive and Gram-negative bacteria and its sporicidal action [57]. This was fully corroborated in this study since all tested bacterial strains were found equally sensitive to this disinfectant. BioDestroy® was shown to be more effective with lower MIC values. This product contains other ingredients that may act synergistically with peracetic acid, including about 14% hydrogen peroxide, and was shown to be more bactericidal than pure peracetic acid. The effectiveness of peracetic acid against other bacterial species is known, such as Pseudomonas aeruginosa (160–1000 ppm), Staphylococcus aureus (160–4620 ppm), or Escherichia coli (160–2310 ppm) [58].

The antibiofilm properties of peracetic acid and BioDestroy® were also demonstrated in the present study. The MBEC values were significantly superior to the bactericidal concentrations for all three species. For instance, concentrations up to 7.5 and 10 times higher were required to eliminate B. licheniformis Bl-LJJ01 and Ps. azotoformans PFlA1 in biofilm than in free suspension. This is likely due at least in part to the presence of the EPS matrix, which should hinder direct access of the chemical agent to the bacteria cells. In previous studies of the effectiveness of peracetic acid in prepared solutions or commercial products at different concentrations and contact times, it has been confirmed that this compound is fast-acting against biofilm and more effective than quaternary ammonium compounds, chlorine, chlorine dioxide, sodium dichloroisocyanurate, hydrogen peroxide, ortho-phthalaldehyde, and alkaline-buffered glutaraldehyde [12, 21, 59]. It has been shown microscopically that peracetic acid acts by disturbing the biofilm structure, breaking down matrix components, reducing bacterial aggregation, and triggering changes in cell morphology due to major structural alterations. However, the concentrations found to eradicate biofilms vary from one study to another. In some cases, concentrations as low as 160 ppm were sufficient to eliminate or substantially reduce biofilms [60,61,62,63,64], while in others, concentrations up to 300 times higher were needed to achieve similar effects [65,66,67,68]. Based on these studies, the discrepancies in disinfectant tolerance could be attributable to the main biofilm bacterial species involved, the composition of the EPS matrix, the age of the biofilm, the hydrodynamic conditions of biofilm growth, and the overall microbial composition. In addition, it has been shown that higher concentrations are needed to eradicate biofilms comprising more than one bacterial species because of the protective role that some members of the biofilm may exert on the whole community [69, 70]. We have observed this more recently [29] where the MBEC of peracetic acid against Ps. azotoformans PFl1A mono-species biofilm grown under similar conditions corresponded to 500 ppm, and was lower than the concentration found in the present work (760 ppm).

Although the antibiofilm properties of peracetic acid have been proven, its use is still limited to situations where high concentrations and extended exposure times (> 5 min according to the manufacturer’s recommendations) may be used to achieve the desired effects.

In this study, we have demonstrated that reuterin could have antibiofilm properties. Reuterin was shown to eliminate B. licheniformis Bl-LJJ01, Ps. azotoformans PFlA1, and Ser. liquefaciens Sl-LJJ01 in a multi-species biofilm. We also found that combining reuterin with peracetic acid alone or as the main active component of a commercial disinfectant allows the reductions obtained with the single agents to be reached at considerably lower concentrations, for all three bacteria. Lower MBECs were obtained especially for B. licheniformis Bl-LJJ01, which was eliminated by peracetic acid or BioDestroy® at concentrations 4 and 3 times lower than those of each agent alone. Preliminary tests (data not shown) indicated that the simultaneous application of reuterin with disinfectant did not increase their efficacy, whereas the FICI calculated for both combinations suggested additive effects. However, treating mixed-species biofilm initially with peracetic acid or BioDestroy® respectively at 456 ppm and 337.5 ppm followed by 16 h of contact with reuterin eliminated all bacteria. This suggests that reuterin requires more time to be effective, compared to peracetic acid, which is a fast-acting antibiofilm agent. A recent study of the antibiofilm properties of reuterin [28] suggests that this compound at concentrations of 0.34 to 1.35 mM is effective within 24 h against a dual-species biofilm of Porphyromonas gingivalis and Treponema denticola. It has been reported that 24 h of exposure to 8 mM reuterin alone or 2 mM reuterin in combination with catechin decreased by 29.9% and 33.5% biofilm formation by Streptococcus mutans [71] and that prolonging this exposure could further reduce or eliminate the biofilm. This could be related to the mechanism of antimicrobial action of reuterin, which relies on the aldehyde moiety depleting free sulfhydryl groups such as glutathione and on proteins and enzymes, causing oxidative damage and loss of vital cell functions [72, 73]. Despite a thorough study of this mechanism, it is still unclear how reuterin acts on bacterial cells embedded in a protective matrix. In a study investigating on P. aeruginosa biofilm inactivation by glutaraldehyde (a disinfectant having two aldehyde groups), it was demonstrated that biofilm exposure to 50 mg/L for 10 h resulted in the same 2-log reduction obtained for planktonic cells exposed for 20 min [74]. These results suggest that like glutaraldehyde, reuterin has a slow diffusion into biofilm and that matrix and its constituents must significantly delay penetration to reach the target bacteria, probably because of its size or constituent moieties. Further research is needed to decipher the behavior of reuterin within biofilms. Application of reuterin after peracetic acid may be expected to enhance the antibiofilm action of the latter but may also be involved in preventing bacterial regrowth by inhibiting biofilm formation, as shown in a study where reuterin at 4.3 mM prevented Clostridium perfringens (Cp 13124) from forming biofilms by affecting the expression of specific genes involved in cell adherence [75]. Furthermore, the prolonged action of reuterin could add value to peracetic acid sanitation by preventing the recolonization of freshly disinfected biofilms by bacteria able to use residual EPS to form secondary biofilms, or by inhibiting the establishment of other biofilm-forming microorganisms such as yeasts on the treated surfaces [76, 77].

Peracetic acid is considered a food-grade sanitizer [78], whereas reuterin currently is not even GRAS, unlike certain bacteriocins such as nisin and pediocin, although several studies have suggested its suitability for use in the dairy sector [79,80,81,82,83] and in the meat and fish industries [24, 84,85,86,87]. Other studies demonstrated that no relevant quality-related modifications like acidity and pH variations occur and affect dairy product quality when reuterin is added to inhibit bacterial growth and extend shelf-life [88, 89]. Otherwise, studies conducted to assess the cytotoxicity of this antimicrobial agent showed that no skin sensitization was observed at 40 mg mL−1 (540 mM) nor was hemolytic activity or damage to gastrointestinal tract cells at concentrations below 270 mM and as high as 1080 mM respectively [90, 91]. A number of advantages owing to the physicochemical properties of reuterin make it particularly valuable as an antibiofilm agent in the food industry. In addition to its water solubility [92], its stability over a wide range of pH (3–9) and at high concentrations of NaCl and milk fat (0.5–3%) and its increased effectiveness as the temperature rises (10–30 °C) have been shown [81, 82, 93,94,95,96].

Conclusion

The results of the present study demonstrate an antibiofilm activity of reuterin against three species in a mixed biofilm and that its association with peracetic acid or with a commercial disinfectant containing peracetic acid effectively lowers the effective concentrations of both active agents. The peracetic acid and BioDestroy® concentrations thus lowered by virtue of this combination meet the approved regulatory concentrations for sanitizing product contact surfaces in processing plants [97]. Introducing this natural antimicrobial agent into disinfectant formulations for suppressing biofilm growth would be advantageous by reducing the input of chemicals which, at high concentrations and over the long term, can be damaging to surfaces, exposed workers, and the environment. However, these conclusions are based on laboratory tests and further studies are needed to validate these results on a larger scale. Other research should be carried out to optimize the use of reuterin and to validate its effectiveness and practicality in an industrial setting. In this context, it is worth considering the integration of advanced technologies, such as the application of encapsulation systems and nanotechnologies on reuterin for the development of active ingredient disinfectant or new sanitizing approaches. This could present a promising prospect for the future, being able to ensure lasting antimicrobial action with minimal disruption to production processes.

Data availability

All data supporting the findings of this study are available within the paper and its Supplementary Information. Procedure for measuring biofilm thickness is available in the following link: https://github.com/alexandrebastien/ImageJ-Script-Collection/tree/master/Clients/Julie%20Jean/Biofilm%20Thickness. Biofilm thickness values and the CLSM micrographs used to perform the measurements in this study are provided in Supplementary Table 1 and Supplementary Fig. 1. Bacterial colony morphology of the strains composing the multi-species biofilms in this study is shown in Supplementary Fig. 2.

References

Flint S, Bremer P, Brooks J, Palmer J, Sadiq FA, Seale B, Teh KH, Wu S, Md Zain SN (2020) Bacterial fouling in dairy processing. Int Dairy J 101:104593. https://doi.org/10.1016/j.idairyj.2019.104593

Perez Alonso VP, de Campos FRC, Alonso Cotta M, Kabuki DY (2022) Influence of milk proteins on the adhesion and formation of Bacillus sporothermodurans biofilms: implications for dairy industrial processing. Food Control 134:108743. https://doi.org/10.1016/j.foodcont.2021.108743

Bhosale S, Brahmane P, Kubade A, Desale R (2021) Biofilm in the dairy industry: detection and common process for control biofilms. Pharma Innovation J 10(8):809–817

Carpentier B, Cerf O (1993) Biofilms and their consequences, with particular reference to hygiene in the food industry. J Appl Bacteriol 75(6):499–511. https://doi.org/10.1111/j.1365-2672.1993.tb01587.x

Mosteller TM, Bishop JR (1993) Sanitizer efficacy against attached bacteria in a milk biofilm. J Food Prot 56(1):34–41. https://doi.org/10.4315/0362-028X-56.1.34

Baumann RR, Martin SE, Feng H (2009) Removal of Listeria monocytogenes biofilms from stainless steel by use of ultrasound and ozone. J Food Protect 72(6):1306–1309. https://doi.org/10.4315/0362-028x-72.6.1306

Dosti B, Guzel-Seydim Z, Greene AK (2005) Effectiveness of ozone, heat and chlorine for destroying common food spoilage bacteria in synthetic media and biofilms. Int J Dairy Technol 58(1):19–24. https://doi.org/10.1111/j.1471-0307.2005.00176.x

Feng H, Barbosa-Cánovas GV, Weiss J (2011) Ultrasound technologies for food and bioprocessing. Springer, New York

Tachikawa M, Yamanaka K, Nakamuro K (2009) Studies on the disinfection and removal of biofilms by ozone water using an artificial microbial biofilm system. Ozone Sci Eng 31(1):3–9. https://doi.org/10.1080/01919510802586566

Norwood DE, Gilmour A (2000) The growth and resistance to sodium hypochlorite of Listeria monocytogenes in a steady-state multispecies biofilm. Appl Microbiol 88:512–520. https://doi.org/10.1046/j.1365-2672.2000.00990.x

Čapla J, Zajác P, Bajzík P, Zeleňáková L, Golian J, Vietoris V (2012) Sanitation process optimalization in relation to the microbial biofilm of Pseudomonas fluorescens. J Microbiol Biotechnol Food Sci 1:733–741. https://api.semanticscholar.org/CorpusID:100665254

Chino T, Nukui Y, Morishita Y, Moriya K (2017) Morphological bactericidal fast-acting effects of peracetic acid, a high-level disinfectant, against Staphylococcus aureus and Pseudomonas aeruginosa biofilms in tubing. Antimicrob Resist Infect Control 6:122. https://doi.org/10.1186/s13756-017-0281-1

Gawande HM, Dhotre AV, Shendurse AM, Khodwe NM (2013) Peroxyacetic acid: a potent food industry sanitizer. Indian Food Industry Mag 32:26–30

Srey S, Kabir Jahid I, Ha SD (2013) Biofilm formation in food industries: a food safety concern. Food Control 31(2):572–585. https://doi.org/10.1016/j.foodcont.2012.12.001

Tomičić R, Tomičić Z, Nićetin M, Knežević V, Kocić-Tanackov S, Raspor P (2023) Food grade disinfectants based on hydrogen peroxide/peracetic acid and sodium hypochlorite interfere with the adhesion of Escherichia coli, Pseudomonas aeruginosa, Staphylococcus aureus and Listeria monocytogenes to stainless steel of differing surface roughness. Biofouling 39(9–10):990–1003. https://doi.org/10.1080/08927014.2023.2288886

Yuan L, Wang N, Sadiq FA, He G (2020) Interspecies interactions in dual-species biofilms formed by psychrotrophic bacteria and the tolerance of sessile communities to disinfectants. JFP 83(6):951–958. https://doi.org/10.4315/0362-028X.JFP-19-396

Tadielo LE, dos Santos EAR, Possebon FS, Schmiedt JA, Juliano LCB, Cerqueira-Cézar CK, de Oliveira JP, Sampaio ANdCE, Melo PRL, Caron EFF, Pinto JPdAN, Bersot LdS, Pereira JG (2023) Characterization of microbial ecology, Listeria monocytogenes, and Salmonella sp. on equipment and utensil surfaces in Brazilian poultry, pork, and dairy industries. Int Food Res 173:113422. https://doi.org/10.1016/j.foodres.2023.113422

Frank JF, Ehlers J, Wicker L (2003) Removal of Listeria monocytogenes and poultry soil-containing biofilms using chemical cleaning and sanitizing agents under static conditions. Food Protection Trends 23:654–663. https://eurekamag.com/research/003/914/003914376.php

Bridier A, Dubois-Brissonnet F, Greub G, Thomas V, Briandet R (2011) Dynamics of the action of biocides in Pseudomonas aeruginosa biofilms. Antimicrob Agents Chemother 55(6):2648–2654. https://doi.org/10.1128/AAC.01760-10

da Silva FM, Coelho Alvares AC, Martins Manoel JG, Ramires Esper LM, Kabuki DY, Kuaye AY (2017) Formation of multi-species biofilms by Enterococcus faecium, Enterococcus faecalis, and Bacillus cereus isolated from ricotta processing and effectiveness of chemical sanitation procedures. Int Dairy J 72:23–28. https://doi.org/10.1016/j.idairyj.2017.03.016

Marques SC, Silva BC, Rezende J, das GOS, Alves E, Abreu LR de, Alves LA de F, Piccoli RH, (2007) Formation of biofilms by Staphylococcus aureus on stainless steel and glass surfaces and its resistance to some selected chemical sanitizers. Braz J Microbiol 38(3):538–543. https://doi.org/10.1590/S1517-83822007000300029

National Research Council (2010) Acute exposure guideline levels for selected airborne chemicals. Volume 8, pp 464. Washington, DC: The National Academies Press. https://doi.org/10.17226/12770. Accessed 02 Aug 2023

Vollenweider S, Lacroix C (2004) 3-hydroxypropionaldehyde: applications and perspectives of biotechnological production. Appl Microbiol Biotechnol 64(1):16–27. https://doi.org/10.1007/s00253-003-1497-y

Dobrogosz WJ, Lindgren SE (1995) Antibiotic reuterin. United States Patent No. 5,413,960. Washington, DC: U.S. Patent and Trademark Office

Vimont A, Fernandez B, Ahmed G, Fortin HP, Fliss I (2019) Quantitative antifungal activity of reuterin against food isolates of yeasts and moulds and its potential application in yogurt. Int J Food Microbiol 289:182–188. https://doi.org/10.1016/j.ijfoodmicro.2018.09.005

Soltani S, Biron E, Ben Said L, Subirade M, Fliss I (2022) Bacteriocin-based synergetic consortia: a promising strategy to enhance antimicrobial activity and broaden the spectrum of inhibition. Microbiol Spectr 10(1):e00406-00421. https://doi.org/10.1128/spectrum.00406-21

Widyarman AS, Theodorea CF (2019) Effect of reuterin on dual-species biofilm in vitro of Streptococcus mutans and Veillonella parvula. J Int Dent Medical Res 12(1):77–83. https://api.semanticscholar.org/CorpusID:150376988

Widyarman AS, Theodorea CF (2022) Novel indigenous probiotic Lactobacillus reuteri strain produces anti-biofilm reuterin against pathogenic periodontal bacteria. Eur J Dent 16(1):96–101. https://doi.org/10.1055/s-0041-1731591

Goetz C, Larouche J, Velez Aristizabal M, Niboucha N, Jean J (2022) Efficacy of organic peroxyacids for eliminating biofilm preformed by microorganisms isolated from dairy processing plants. Appl Environ Microbiol 88(4):e01889-e1921. https://doi.org/10.1128/aem.01889-21

Stepanović S, Vuković D, Dakić I, Savić B, Švabić-Vlahović M (2000) A modified microtiter-plate test for quantification of staphylococcal biofilm formation. J Microbiol Methods 40(2):175–179. https://doi.org/10.1016/S0167-7012(00)00122-6

Balouiri M, Sadiki M, Ibnsouda SK (2016) Methods for in vitro evaluating antimicrobial activity: a review. J Pharm Anal 6(2):71–79. https://doi.org/10.1016/j.jpha.2015.11.005

ASTM. (2017). ASTM E2799–12 Standard test method for testing disinfectant efficacy against Pseudomonas aeruginosa biofilm using the MBEC assay. West Conshohocken, PA: ASTM International

MacFaddin JF (1985) Media for isolation-cultivation-identification-maintenance of medical bacteria. Williams & Wilkins, Baltimore, MD

Truong TV, Twist A, Zaytsev A, Marrs ECL, Perry A, Turnbull G, Orenga S, Stanforth SP, Perry JD (2022) Evaluation of a novel chromogenic medium for the detection of Pseudomonas aeruginosa in respiratory samples from patients with cystic fibrosis. Microorganisms 10(5):1004. https://doi.org/10.3390/microorganisms10051004

Stanbridge LH, Board RG (1994) A modification of the Pseudomonas selective medium, CFC, that allows differentiation between meat pseudomonads and Enterobacteriaceae. Lett Appl Microbiol 18(6):327–328. https://doi.org/10.1111/j.1472-765X.1994.tb00880.x

Miri M, Bergayou H, Belmouden A, Moukrim A, Baazizi H, Boumhandi N (2021) Medium optimization for exopolysaccharides production by Bacillus zhangzhouensis BZ 16 strain isolated from Khnifiss Lagoon. E3S Web Conf 234:00099. https://doi.org/10.1051/e3sconf/202123400099

Schindelin J, Arganda-Carreras I, Frise E, Kaynig V, Longair M, Pietzsch T, Preibisch S, Rueden C, Saalfeld S, Schmid B, Tinevez JY, White DJ, Hartenstein V, Eliceiri K, Tomancak P, Cardona A (2012) Fiji: an open-source platform for biological-image analysis. Nat Methods 9(7):676–682. https://doi.org/10.1038/nmeth.2019

Vimont A, Fliss I, Jean J (2015) Study of the virucidal potential of organic peroxyacids against norovirus on food-contact surfaces. Food Environ Virol 7(1):49–57. https://doi.org/10.1007/s12560-014-9174-0

Greenspan FP, MacKellar DG (1948) Analysis of aliphatic per acids. Anal Chem 20:1061–1063. https://doi.org/10.1021/ac60023a020

Naimi S, Zirah S, Hammami R, Fernandez B, Rebuffat S, Fliss I (2018) Fate and biological activity of the antimicrobial lasso peptide microcin J25 under gastrointestinal tract conditions. Front Microbiol 9:1764. https://doi.org/10.3389/fmicb.2018.01764

Suresh G, Pakdel H, Rouissi T, Brar SK, Fliss I, Roy C (2019) In vitro evaluation of antimicrobial efficacy of pyroligneous acid from softwood mixture. BIORI 3(1):47–53. https://doi.org/10.1016/j.biori.2019.02.004

Elias S, Banin E (2012) Multi-species biofilms: living with friendly neighbors. FEMS Microbiol Rev 36(5):990–1004. https://doi.org/10.1111/j.1574-6976.2012.00325.x

Oliveira GS, Lopes DRG, Andre C, Silva CC, Bagliniere F, Vanetti MCD (2019) Multispecies biofilm formation by the contaminating microbiota in raw milk. Biofouling 35(8):819–831. https://doi.org/10.1080/08927014.2019.1666267

Akinbobola AB, Sherry L, MacKay WG, Ramage G, Williams C (2017) Tolerance of Pseudomonas aeruginosa in in-vitro biofilms to high-level peracetic acid disinfection. J Hosp Infect 97(2):162–168. https://doi.org/10.1016/j.jhin.2017.06.024

Langsrud S, Moen B, Møretrø T, Løype M, Heir E (2016) Microbial dynamics in mixed culture biofilms of bacteria surviving sanitation of conveyor belts in salmon-processing plants. J Appl Microbiol 120(2):366–378. https://doi.org/10.1111/jam.13013

Pang XY, Yang YS, Yuk HG (2017) Biofilm formation and disinfectant resistance of Salmonella sp. in mono- and dual-species with Pseudomonas aeruginosa. J Appl Microbiol 123(3):651–660. https://doi.org/10.1111/jam.13521

Schwering M, Song J, Louie M, Turner RJ, Ceri H (2013) Multi-species biofilms defined from drinking water microorganisms provide increased protection against chlorine disinfection. Biofouling 29(8):917–928. https://doi.org/10.1038/nmeth.2019

van der Veen S, Abee T (2011) Mixed species biofilms of Listeria monocytogenes and Lactobacillus plantarum show enhanced resistance to benzalkonium chloride and peracetic acid. Int J Food Microbiol 144(3):421–431. https://doi.org/10.1016/j.ijfoodmicro.2010.10.029

Guzmán-Soto I, McTiernan C, Gonzalez-Gomez M, Ross A, Gupta K, Suuronen EJ, Mah TF, Griffith M, Alarcon EI (2021) Mimicking biofilm formation and development: recent progress in in vitro and in vivo biofilm models. iScience 24(5):102443. https://doi.org/10.1016/j.isci.2021.102443

Gagné-Thivierge C, Barbeau J, Levesque RC, Charette SJ (2018) A new approach to study attached biofilms and floating communities from Pseudomonas aeruginosa strains of various origins reveals diverse effects of divalent ions. FEMS Microbiol Lett. https://doi.org/10.1093/femsle/fny155

Ripolles-Avila C, Garcia-Hernandez N, Cervantes-Huaman BH, Mazaheri T, Rodriguez-Jerez JJ (2019) Quantitative and compositional study of monospecies biofilms of spoilage microorganisms in the meat industry and their interaction in the development of multispecies biofilms. Microorganisms. https://doi.org/10.3390/microorganisms7120655

Danese PN, Pratt LA, Kolter R (2000) Exopolysaccharide production is required for development of Escherichia coli K-12 biofilm architecture. J Bacteriol 182:3593–3596. https://doi.org/10.1128/JB.182.12.3593-3596.2000

Flemming HC, Wingender J (2010) The biofilm matrix. Nature 8(9):623–633. https://doi.org/10.1038/nrmicro2415

Ostrov I, Paz T, Shemesh M (2019) Robust biofilm-forming Bacillus isolates from the dairy environment demonstrate an enhanced resistance to cleaning-in-place procedures. Foods 8(4):134. https://doi.org/10.3390/foods8040134

Ostrov I, Sela N, Belausov E, Steinberg D, Shemesh M (2019) Adaptation of Bacillus species to dairy associated environment facilitates their biofilm forming ability. Food Microbiol 82:316–324. https://doi.org/10.1016/j.fm.2019.02.015

Ostrov I, Sela N, Freed M, Khateb N, Kott-Gutkowski M, Inbar D, Shemesh M (2015) Draft genome sequence of Bacillus licheniformis S127, isolated from a sheep udder clinical infection. Genome Announc. https://doi.org/10.1128/genomeA.00971-15

André S, Hédin S, Remize F, Zuber F (2012) Evaluation of peracetic acid sanitizers efficiency against spores isolated from spoiled cans in suspension and on stainless steel surfaces. J Food Protect 75(2):371–375. https://doi.org/10.4315/0362-028X.JFP-11-329

Kampf G (2018) Peracetic acid. In: Kampf G (ed) Antiseptic stewardship: biocide resistance and clinical implications,1st edn. Springer Cham. Switzerland AG, pp 63–98. https://doi.org/10.1007/978-3-319-98785-9

Hua Z, Korany AM, El-Shinawy SH, Zhu MJ (2019) Comparative evaluation of different sanitizers against Listeria monocytogenes biofilms on major food-contact surfaces. Front Microbiol 10:2462. https://doi.org/10.3389/fmicb.2019.02462

Cruz CD, Fletcher GC (2012) Assessing manufacturers’ recommended concentrations of commercial sanitizers on inactivation of Listeria monocytogenes. Food Control 26(1):194–199. https://doi.org/10.1016/j.foodcont.2012.01.041

Kostaki M, Chorianopoulos N, Braxou E, Nychas GJ, Giaouris E (2012) Differential biofilm formation and chemical disinfection resistance of sessile cells of Listeria monocytogenes strains under monospecies and dual-species (with Salmonella enterica) conditions. Appl Environ Microbiol 78(8):2586–2595. https://doi.org/10.1128/AEM.07099-11

Mariscal A, Lopez-Gigosos RM, Carnero-Varo M, Fernandez-Crehuet J (2009) Fluorescent assay based on resazurin for detection of activity of disinfectants against bacterial biofilm. Appl Microbiol Biotechnol 82(4):773–783. https://doi.org/10.1007/s00253-009-1879-x

Stopforth JD, Samelis J, Sofos JN, Kendall PA, Smith GC (2003) Influence of extended acid stressing in fresh beef decontamination runoff fluids on sanitizer resistance of acid-adapted Escherichia coli O157:H7 in biofilms. J Food Prot 66(12):2258–2266. https://doi.org/10.4315/0362-028x-66.12.2258

Yuan L, Wang N, Sadiq FA, He G (2020) Interspecies interactions in dual-species biofilms formed by psychrotrophic bacteria and the tolerance of sessile communities to disinfectants. J Food Prot 83(6):951–958. https://doi.org/10.4315/0362-028X.JFP-19-396

Belessi CEA, Gounadaki AS, Psomas AN, Skandamis PN (2011) Efficiency of different sanitation methods on Listeria monocytogenes biofilms formed under various environmental conditions. Int J Food Microbiol 145:S46–S52. https://doi.org/10.1016/j.ijfoodmicro.2010.10.020

Konrat K, Schwebke I, Laue M, Dittmann C, Levin K, Andrich R, Arvand M, Schaudinn C (2016) The bead assay for biofilms: a quick, easy and robust method for testing disinfectants. PLoS ONE 11(6):e0157663. https://doi.org/10.1371/journal.pone.0157663

Melo RT, Mendonça EP, Monteiro GP, Siqueira MC, Pereira CB, Peres PABM, Fernandez H, Rossi DA (2017) Intrinsic and extrinsic aspects on Campylobacter jejuni biofilms. Front Microbiol. https://doi.org/10.3389/fmicb.2017.01332

Vázquez-Sánchez D, Cabo ML, Ibusquiza PS, Rodríguez-Herrera JJ (2014) Biofilm-forming ability and resistance to industrial disinfectants of Staphylococcus aureus isolated from fishery products. Food Control 39:8–16. https://doi.org/10.1016/j.foodcont.2013.09.029

Bridier A, Sanchez-Vizuete MP, Le Coq D, Aymerich S, Meylheuc T, Maillard JY, Thomas V, Dubois-Brissonnet F, Briandet R (2012) Biofilms of a Bacillus subtilis hospital isolate protect Staphylococcus aureus from biocide action. PLoS ONE 7(9):e44506. https://doi.org/10.1371/journal.pone.0044506

Oxaran V, Dittmann KK, Lee SHI, Chaul LT, Fernandes de Oliveira CA, Corassin CH, Alves VF, De Martinis ECP, Gram L (2018) Behavior of foodborne pathogens Listeria monocytogenes and Staphylococcus aureus in mixed-species biofilms exposed to biocides. Appl Environ Microbiol. https://doi.org/10.1128/aem.02038-18

Zhang G, Tan Y, Yu T, Wang S, Liu L, Li C (2021) Synergistic antibacterial effects of reuterin and catechin against Streptococcus mutans. Lwt. https://doi.org/10.1016/j.lwt.2020.110527

Sun M-C, Hu Z-Y, Li D-D, Chen Y-X, Xi J-H, Zhao C-H (2022) Application of the reuterin system as food preservative or health-promoting agent: a critical review. Foods 11(24):4000. Retrieved from https://www.mdpi.com/2304-8158/11/24/4000

Vollenweider S, Evers S, Zurbriggen K, Lacroix C (2010) Unraveling the hydroxypropionaldehyde (HPA) system: an active antimicrobial agent against human pathogens. J Agric Food Chem 58:10315–10322. https://doi.org/10.1021/jf1010897

Grobe KJ, Stewart PS (2000) Characterization of glutaradehyde efficacy against bacterial biofilm. Paper presented at the CORROSION 2000, Orlando, Florida, 26–31 Mar 2000

Xu Y, Wang Y, Ding X, Wang J, Xiuan Zhan X (2022) Inhibitory effects of reuterin on biofilm formation, quorum sensing and virulence genes of Clostridium perfringens. Lwt 162:113421. https://doi.org/10.1016/j.lwt.2022.113421

Akinbobola AB, Amaeze NJ, Mackay WG, Ramage G, Williams C (2021) Secondary biofilms could cause failure of peracetic acid high-level disinfection of endoscopes. J Hosp Infect 107:67–75. https://doi.org/10.1016/j.jhin.2020.09.028

Riad AM, Widyarman AS (2021) The Effect of parabiotic reuterin on the expression of genes involved in Candida albicans biofilm formation: an ex vivo study. J. Dent. Indones. 28:163–170. https://doi.org/10.14693/jdi.v28i3.1276

U. S. Food and Drug Administration. Department of health and human services (2023). https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/cfrsearch.cfm?fr=178.1010. Accessed 21Aug 2023

Arques JL, Rodriguez E, Nunez M, Medina M (2008) Antimicrobial activity of nisin, reuterin, and the lactoperoxidase system on Listeria monocytogenes and Staphylococcus aureus in cuajada, a semisolid dairy product manufactured in Spain. J Dairy Sci 91(1):70–75. https://doi.org/10.3168/jds.2007-0133

Avila M, Gómez-Torres N, Hernández M, Garde S (2014) Inhibitory activity of reuterin, nisin, lysozyme and nitrite against vegetative cells and spores of dairy-related Clostridium species. Int J Food Microbiol 172:70–75. https://doi.org/10.1016/j.ijfoodmicro.2013.12.002

El-Ziney MG, Debevere JM (1998) The effect of reuterin on Listeria monocytogenes and Escherichia coli O157:H7 in milk and cottage cheese. J Food Prot 61(10):1275–1280. https://doi.org/10.4315/0362-028X-61.10.1275

Langa S, Martin-Cabrejas I, Montiel R, Landete JM, Medina M, Arques JL (2014) Short communication: combined antimicrobial activity of reuterin and diacetyl against foodborne pathogens. J Dairy Sci 97(10):6116–6121. https://doi.org/10.3168/jds.2014-8306

Pilote-Fortin H, Ben Said L, Cashman-Kadri S, St-Gelais D, Fliss I (2021) Stability, bioavailability and antifungal activity of reuterin during manufacturing and storage of stirred yoghurt. Int Dairy J 121:105141. https://doi.org/10.1016/j.idairyj.2021.105141

Angiolillo L, Conte A, Del Nobile MA (2018) A new method to bio-preserve sea bass fillets. Int J Food Microbiol 271:60–66. https://doi.org/10.1016/j.ijfoodmicro.2018.01.010

Montiel R, Martín-Cabrejas I, Medina M (2015) Reuterin, lactoperoxidase, lactoferrin and high hydrostatic pressure on the inactivation of food-borne pathogens in cooked ham. Food Control 51:122–128. https://doi.org/10.1016/j.foodcont.2014.11.010

Zhang L, Ben Said L, Diarra MS, Fliss I (2021) Inhibitory activity of natural synergetic antimicrobial consortia against Salmonella enterica on broiler chicken carcasses. Front Microbiol 12:656956. https://doi.org/10.3389/fmicb.2021.656956

Zhang L, Ben Said L, Diarra MS, Fliss I (2022) Effects of bacterial-derived antimicrobial solutions on shelf-life, microbiota and sensory attributes of raw chicken legs under refrigerated storage condition. Int J Food Microbiol 383:109958. https://doi.org/10.1016/j.ijfoodmicro.2022.109958

Kumar N, Kumar V, Waheed SM, Pradhan D (2020) Efficacy of reuterin and bacteriocins nisin and pediocin in the preservation of raw milk from dairy farms. Food Technol Biotechnol 58(4):359–369. https://doi.org/10.17113/ftb.58.04.20.6728

Ortiz-Rivera Y, Sanchez-Vega R, Gutierrez-Mendez N, Leon-Felix J, Acosta-Muniz C, Sepulveda DR (2017) Production of reuterin in a fermented milk product by Lactobacillus reuteri: inhibition of pathogens, spoilage microorganisms, and lactic acid bacteria. J Dairy Sci 100(6):4258–4268. https://doi.org/10.3168/jds.2016-11534

Soltani S, Couture F, Boutin Y, Ben Said L, Cashman-Kadri S, Subirade M, Biron E, Fliss I (2021) In vitro investigation of gastrointestinal stability and toxicity of 3-hydroxypropionaldehyde (reuterin) produced by Lactobacillus reuteri. Toxicol Rep 8:740–746. https://doi.org/10.1016/j.toxrep.2021.03.025

Soltani S, Boutin Y, Couture F, Biron É, Subirade M, Fliss I (2022) In vitro assessment of skin sensitization, irritability and toxicity of bacteriocins and reuterin for possible topical applications. Sci Rep 12:4570. https://doi.org/10.1038/s41598-022-08441-4

El-Ziney MG, van den Tempel T, Debevere J, Jakobsen M (1999) Application of reuterin produced by Lactobacillus reuteri 12002 for meat decontamination and preservation. J Food Prot 62(3):257–261. https://doi.org/10.4315/0362-028x-62.3.257

Axelsson LT, Chung TC, Dobrogosz WJ, Lindgren SE (1989) Production of a broad spectrum antimicrobial substance by Lactobacillus reuteri. Microb Ecol Health D 2(2):131–136. https://doi.org/10.3109/08910608909140210

Rasch M (2002) The influence of temperature, salt and pH on the inhibitory effect of reuterin on Escherichia coli. Int J Food Microbiol 72(3):225–231. https://doi.org/10.1016/S0168-1605(01)00637-7

Rasch M, Métris A, Baranyi J, Bjørn Budde B (2007) The effect of reuterin on the lag time of single cells of Listeria innocua grown on a solid agar surface at different pH and NaCl concentrations. Int J Food Microbiol 113(1):35–40. https://doi.org/10.1016/j.ijfoodmicro.2006.07.012

Silva M, Jacobus NV, Deneke C, Gorbach SL (1987) Antimicrobial substance from a human Lactobacillus strain. Antimicrob Agents Chemother 31(8):1231–1233. https://doi.org/10.1128/aac.31.8.1231

Environmental Protection Agency (2000) Peroxyacetic acid; exemption from the requirement of a tolerance. https://www.federalregister.gov/documents/2000/12/01/00-30679/peroxyacetic-acid-exemption-from-the-requirement-of-a-tolerance. Accessed 01 Sep 2023

Acknowledgements

The authors acknowledge Sani Marc for providing BioDestroy® and Dr. Patrick Marchand for technical support and are grateful to Dr. Lyia Zhang and Dr. Samira Soltani (Department of food sciences, Université Laval) for their technical support and advice. They gratefully thank Dr. Alexandre Bastien (Institute of integrative biology and systems, Université Laval) for technical assistance with SEM and CLSM analysis and helpful suggestions for designing the biofilm thickness calculation script. Thanks are due to Teresa Paniconi, Laurie Sanschagrin and Jules Larouche for laboratory assistance. Authors are grateful to Valérie Goulet-Beaulieu and Steven Davids for proofreading the manuscript.

Funding

This project was sponsored by Consortium de Recherche et Innovations en Bioprocédés Industriels au Québec (CRIBIQ, grant 2016–049-C22), Groupe Sani Marc, and the Natural Sciences and Engineering Research Council of Canada (NSERC grant RDCPJ516460-17). N.N. received research grants from the Canadian Dairy Commission (administered in Quebec by Novalait) and the FRQNT Op + Lait Strategic Cluster. C.G. was a recipient of postdoctoral fellowships from Fonds de Recherche Québécois–Nature et Technologie (FRQNT), the FRQNT Op + Lait Strategic Cluster and Fonds d’Enseignement et de Recherche Germain Brisson from the Faculté des Sciences de l’Agriculture et de l’Alimentation, and of an additional postdoctoral fellowship from the Institut sur la Nutrition et les Aliments (INAF).

Author information

Authors and Affiliations

Contributions

NN conducted the experiments and wrote the manuscript. ÉJ and CG provided scientific advice. LP and AC took part in some experiments. NN, ÉJ, CG, IF, SL, and JJ designed the study and reviewed the manuscript. JJ supervised the project. All authors have read and approved the submitted version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Niboucha, N., Jubinville, É., Péloquin, L. et al. Reuterin Enhances the Efficacy of Peracetic Acid Against Multi-species Dairy Biofilm. Probiotics & Antimicro. Prot. (2024). https://doi.org/10.1007/s12602-024-10351-y

Accepted:

Published:

DOI: https://doi.org/10.1007/s12602-024-10351-y