Abstract

Almost unlimited reserves and low cost of sodium are accelerating the commercialization of sodium-ion batteries. However, serious safety and stability issues, arising mainly from organic liquid electrolytes, hinder further developments of sodium-ion batteries. Polymer electrolytes might be a solution to the safety and stability issues due to the better safety of polymers. Herein, an overview is provided on recent advances in polymer electrolytes for solid-state sodium batteries, including solid polymer electrolytes, composite polymer electrolytes and gel polymer electrolytes. Fundamental properties, ionic conduction mechanisms and promising applications of polymer electrolytes are discussed, and pending challenges and effective solutions are emphasized. Hopefully, this review will promote commercial applications of polymer electrolytes in energy storage systems.

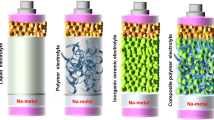

Graphical abstract

摘要

储量丰富、成本低廉的钠资源有助于钠离子电池的商业化。然而, 有机电解液引起的安全性和稳定性问题阻碍了钠离子电池的进一步发展. 聚合物基电解质具有良好的安全性, 是解决安全性和稳定性问题的最佳选择. 本文概述了用于固态钠电池的聚合物电解质的最新研究进展,包括固体聚合物电解质、复合聚合物电解质和凝胶聚合物电解质,讨论了聚合物电解质的基本性质、离子传导机制和有前景的应用, 并对聚合物电解质所面临的挑战提出了有效的解决方案. 最后, 对聚合物电解质在储能系统中的商业应用前景进行了分析和展望。

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

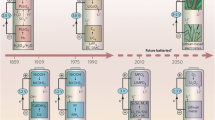

Sodium-ion batteries are an indispensable part of electrochemical energy storage systems owing to their competitive advantages of high sodium reserves and environmental benignity [1,2,3,4]. Unfortunately, the limited energy density restricts their applications in scenarios requiring compact but powerful energy storage like electric vehicles, defense and aviation [5, 6]. In addition, current liquid organic electrolytes suffer from serious challenges, including effumability, flammability and explosion, uncontrolled dendrite evolution and inevitable parasitic reactions, which cause severe safety problems in sodium-ion batteries [7,8,9]. Solid electrolytes are nonvolatile and flame-retardant, and utilization of solid electrolytes could effectively suppress dendrite growth and parasitic reactions. Therefore, solid-state batteries are expected to achieve enhanced safety and prolonged cycling lifespan [10,11,12].

Two categories of solid electrolytes, ceramics and polymers, are currently being developed [13,14,15]. Although ceramic electrolytes possess high ionic conductivity at ambient temperature, several issues like large interface impedance, poor interface compatibility and complex synthesis processes hamper their commercial applications [16, 17]. On the contrary, polymer electrolytes exhibit unique merits of good flexibility, enhanced interface compatibility and remarkable processability, therefore are regarded as the most promising electrolytes for solid-state sodium batteries (SSBs) [18,19,20]. However, limited ionic conductivity at room temperature and relatively poor electrochemical stability restrict their practical applications. Strategies of designing macromolecular structures, incorporating inorganic fillers and developing gel polymer electrolytes have been explored to overcome these limitations [21,22,23]. For instance, Ma and coworkers applied macromolecular design by grafting β-cyclodextrin with multiple oligo(methyl methacrylate)-block-oligo (ethylene glycol) methyl ether methacrylate short chains to obtain star-like hyperbranched structure [24]. When complexed with sodium trifluomethanesulfonate salt, the flexible polymer electrolyte demonstrated an enhanced ionic conductivity of 1.3 × 10−4 S·cm−1 at 60 °C and high anodic stability of 5.2 V. Coupling ferroelectrics with polymer could effectively elevate the interfacial ionic conduction. Lu and coworkers reported a polymer electrolyte composited with ferroelectric K0.5Na0.5NbO3 [25]. The aligned K0.5Na0.5NbO3 polarization formed a local electric field and weakened the potential gap at the interface, which facilitated interfacial ionic conduction and inhibited further growth of the solid electrolyte interphase (SEI). Niederberger and coworkers developed a biopolymer-based gel polymer electrolyte, achieving a high ionic conductivity of 2.32 × 10−3 S·cm−1 and Na-ion transference number of 0.637 [26]. Although polymer electrolytes for SSBs have made significant progress, they are still in their infancy. In pursuit of SSBs with superior performances, polymer electrolytes should possess sufficient ionic conductivity, high Na-ion transference number, high oxidation potential and superior mechanical/electrochemical stability [27, 28]. Hitherto, good-quality reviews on polymer electrolytes for SSBs are pretty rare.

This review provides a comprehensive discussion of polymer electrolytes for SSBs by summarizing recent advances in this field, including fundamental properties, ionic conduction mechanisms and promising applications. It aims to offer clear guidance to design excellent polymer electrolytes and provide practical solutions to critical issues of polymer electrolytes for SSBs. Moreover, perspectives of polymer electrolytes for the next-generation SSBs are also outlined.

2 Polymer electrolytes

In 1973, Wright et al. reported ionically conductive complexes with alkali metal salt dissolving in polyethylene oxide (PEO) [29]. Recently, investigations on polymer electrolytes for SSBs have been revitalized. Herein, mechanisms of Na-ion conduction in polymers and fundamental properties of solid polymer electrolytes, composite polymer electrolytes and gel polymer electrolytes are expounded.

2.1 Na-ion conduction in polymers

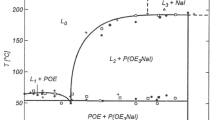

Polymers containing polar groups (−O− , C=O, C≡N) can dissolve Na salts to form polymer-salt complexes, and polymer hosts with high dielectric constant allow rapid charge separation of Na salts and generate movable Na ions. Ionic conductivity is determined by the concentration of mobile Na ions and their mobility. It is commonly recognized that the Na-ion conduction mainly occurs in amorphous phase of polymer hosts above their glass transition temperature, and the segmental-related mobility is responsible for the ionic mobility in polymers. Especially, the dissociation effect creates Na+ to coordinate with polar groups of polymers. These directional ion migrations are realized via constant coordinating and de-coordinating processes under the electric field, along with the segmental motions (Fig. 1). The above concept was challenged, since Bruce and coworkers investigated the ionic conductivity of crystalline complexes P(EO)6: LiXF6 (X = P, As, Sb) and found that ions could migrate rapidly along the aligned cylindrical tunnels in crystalline polymer electrolytes [30]. However, the conduction of Na-ions in crystalline polymers has rarely been reported and is difficult to be understood due to the lack of precise structure models.

A comprehensive physical description of the ion transport in polymer electrolytes cannot be easily obtained because of the large variety of systems involved and the lack of simple structure–property correlations. Generally, the conductivities of these systems can be interpreted in terms of Arrhenius or Vogel-Tammann-Fulcher (VTF) behaviors, or of a combination of both [31]. The Arrhenius behavior of the ionic conductivity (σ) is described by Eq. (1):

where the pre-exponential factor σ0 is related to the number of charge carriers, and k and T are the Boltzmann constant and temperature, and the activation energy for conductivity (Ea) may be computed from the linear best-fit of lgσ vs. 1/T plot. The Arrhenius behavior is generally related to the ion hopping mechanism decoupled from polymer chain breathing.

The VTF behavior, which is more relevant for polymer electrolytes, is described by Eq. (2):

where σ0 is the pre-exponential factor, B is the pseudo-activation energy for ions, and T0 is the equilibrium glass transition temperature (T0 = Tg \(-\) 50 K, where Tg is the glass transition temperature).

Although the migrations of both cations and anions contribute to the total ionic current, the useful fraction of the current that drives the redox reactions at electrodes in most electrochemical cells is carried by cations. The cation transference number characterizes this fraction, and maximizing this number is a key to increase the efficiency of battery operation since any potential used to drive anions is just wasting energy.

The cation transference number of polymer electrolytes (\(t_{\text{Na}^+ }\)) can be determined by means of the direct current (DC) polarization combined with the electrochemical impedance spectroscopy (EIS), and calculated according to Eq. (3), as proposed by Bruce et al. (alternating current (AC)/DC method) [32]:

where I0 and Iss are the initial and steady-state currents, ΔV is the applied dc potential, and R0 and Rss are the initial and steady-state resistances.

2.2 Solid polymer electrolytes

Solid polymer electrolytes (SPEs), consisting of polymer matrices and Na salts, are considered solvent-free systems [33]. Desirable polymer matrices for SPEs should meet some crucial criteria: (1) Good cation solvation capability to ensure that Na ions are solvated by polymer backbones, which facilitates the ionic moving/hopping from one coordinating position to an adjacent active position; (2) High rotation flexibility of bonds to promote the segmental motion of polymer chains; (3) excellent mechanical strength to suppress Na dendrites. Typical SPEs and their polymer structures are summarized in Table 1 and discussed in the following section.

West and coworkers [34] firstly reported relatively low ionic conductivity at room temperature for PEO-NaClO4 SPEs in 1988. A widely accepted principle for the ionic conduction in PEO is the segmental motion in the amorphous region. Thus, to enhance the ionic conductivity, one has to optimize Na salts to reduce the portion of crystalline phase; therefore, a series of PEO-Na salt systems were explored, like PEO-sodium bis(trifluoromethanesulfonyl)imide (NaTFSI) [35], PEO-sodium bis(fluorosulfonyl)imide (NaFSI) [36], PEO-sodium hexafluorophosphate (NaPF6) [37]. Although the ionic conductivity was significantly improved, NaTFSI and NaFSI seriously corroded the Al collector due to electrochemical reactions. Zhou and coworkers developed a novel (Na[(FSO2)(n-C4F9SO2)N], NaFNFSI)-PEO SPE by introducing –C4F9 groups to inhibit the Al corrosion (Fig. 2a) [38]; the SPE achieved a relatively high ionic conductivity (3.36 × 10−4 S·cm−1 at 80 °C) and excellent electrochemical stability up to 4.87 V.

Reproduced with permission from Ref. [38]. Copyright 2017, the Royal Society of Chemistry. b Chemical structures of NaFSI and PTMC; c Optical image of PTMC-NaFSI electrolyte membrane. Reproduced with permission from Ref. [41]. Copyright 2019, American Chemical Society. d Elemental mapping on fracture surface of PVC-SPE by means of energy dispersive spectroscopy (EDS). Reproduced with permission from Ref. [43]. Copyright 2019, American Chemical Society

Polyethylene oxide and polycarbonate-based solid polymer electrolytes. a Chemical structure of Na[(FSO2)(n-C4F9SO2)N].

As a new host for SPEs, aliphatic or cyclic polycarbonates have emerged and gained tremendous momentum now in academia and industry, owing to their low glass transition temperatures. Smith and coworkers synthesized poly(trimethylene carbonate) (PTMC) based SPE in 2003 [39]. Afterwards, a series of polycarbonate-based SPEs including poly(ethylene carbonate) (PEC), poly(propylene carbonate) (PPC), poly(vinylene carbonate) (PVCA) were explored. For example, PEC displayed desirable Na-ion mobility due to low-donor-concentration functional groups [40]. Mindemark and coworkers reported PTMC-based SPE for SSBs, a large amount of Na salt was dissolved in PTMC [41], the as-developed SPE membrane was transparent (Fig. 2b, c), and the PTMC-based SPE presented a decent ionic conductivity of 5 × 10−5 S·cm−1 at 25 °C and stable cycling of Na metal//Prussian blue battery. PVCA has massive polar groups and complexation sites. Cui and coworkers developed a PVCA-based SPE and achieved desirable ionic conductivity as well as high oxidation potential [42]. Despite numerous achievements gained in PVCA-based SPEs, insufficient flexibility still limits their applications. Chen et al. [43] fabricated PVCA-based SPE by employing poly(vinylidene fluoride-co-hexafluoropropylene) (PVDF-HFP) as porous support (PVC-SPE). Figure 2d shows the porous PVDF-HFP support completely filled with the polymer electrolyte, the obtained PVC-SPE delivered a high ionic conductivity of 1.2 × 10−4 S·cm−1 at 25 °C. Benefiting from the intimate contacts and elevated Na-ion transfer rate, this PVC-SPE achieved an excellent battery performance with a capacity retention of 86.8% over 250 cycles at 1.0C.

Polyesters have superior ionic conductivity and wide electrochemical stability window. For instance, poly(ε-caprolactone) (PCL) with flexible chains shows strong Na+-solvating capability and low glass transition temperature of − 60 °C. Fonseca et al. [44] firstly reported a SPE based on PCL in 2006. Unfortunately, due to the semi-crystallinity, their application required high temperatures. Introduction of other supporting polymers through copolymerization and cross-linking processes can effectively broaden the temperature range. Zhang et al. [45] designed a new triblock copolymer PCL-PPC-PCL as host for SPE, which achieved a decent ionic conductivity of 3 × 10−4 S·cm−1 at 30 °C and high resistance against electrochemical oxidation. Brandell et al. developed a PCL-PTMC SPE and revealed the effect of the composition of the PCL-PTMC system on the ionic conductivity and the glass transition temperature [46].

SPEs formed by dissolving Na salts in polymer hosts are dual-ion conductors, in which both Na+ cations and their counter anions are mobile. High anion conduction causes serious concentration polarization, which results in a substantial decay in conductivity, a time-dependent increase in cell impedance, and dendrite growth. A high ionic transference number close to unity is required for ideal polymer electrolytes. Therefore, single Na-ion conducting solid polymer electrolytes are highly desirable to overcome the challenges and drawbacks of dual-ion conducting SPEs. In single-ion conducting polymer electrolytes, anions are covalently bound to polymer chains, therefore, the migration of anions is limited, i.e. the anion transference number is close to zero, and only Na+ contributes to a permanent flow of charge [47, 48]. Yang et al. [49] reported a novel sodium-poly(tartaric acid)borate-based single-ion conducting polymer electrolyte (NaPTAB-SGPE) which achieved a Na-ion transference number of 0.91 and superior electrochemical performance when cycled at 60 °C, manifesting huge potential of this single-ion conducting polymer electrolyte for practical applications in SSBs.

SPEs are composed of polymer matrices and Na salts, forming macromolecular or supramolecular structures. The solubility and stability of Na salts effectively determine the Na+ concentration and the ionic conductivity, thus exploring appropriate Na salts plays a crucial role in achieving high ionic conductivity and good battery performances. However, due to the high crystallinity and strong intermolecular and intramolecular forces, polymer matrices with single functional groups (ether groups, carbonate groups and ester groups) can hardly meet the requirement for high ionic conductivity at room temperature. Applying multifunctional molecular design via blending, copolymerization or cross-linking to inhibit crystallization and balance the intermolecular and intramolecular interactions is a strategy to fundamentally enhance the ionic conductivity at room temperature.

2.3 Composite polymer electrolytes

Practical applications of SPEs are still hindered by inferior ionic conductivity at room temperature and relatively poor electrochemical stability at high voltages. Coupling inorganic fillers with SPEs to develop composite polymer electrolytes (CPEs) has been confirmed to be an efficient strategy to ameliorate the ionic conductivity and electrochemical properties. In 1982, Weston and Steele [50] reported a PEO-Al2O3 CPE with remarkable improvement in mechanical stability. Moreover, Wieczorek and coworkers [51] discovered that the ionic conductivity of PEO-based SPEs was significantly improved by the incorporation of Al2O3. Herein, CPEs composed of passive fillers and active fillers are summarized in Table 2 and discussed.

Though passive fillers like oxide ceramics do not have the ability to conduct ions, the resultant CPEs still present enhanced ionic conductivity and electrochemical/mechanical stability. Oxide ceramics, as solid plasticizers, reduce the crystallinity of polymer hosts. Additionally, the Lewis acid–base interaction theory reveals that anions can be adsorbed on the surfaces of oxide ceramics and elevate the dissociation of ion pairs, producing more movable Na ions [52]. Oxide ceramics like Al2O3, NaAlO2, TiO2 and SiO2 have been utilized to improve electrochemical/mechanical properties of SPEs. For example, Chen and coworkers fabricated a CPE based on poly(methacrylate) (PMA)-poly(ethylene glycol) (PEG)-Al2O3-NaClO4 [53]. Benefiting from the high-density acidic surface sites of Al2O3, the as-developed CPE delivered a desirable ionic conductivity (1.46 × 10−4 S·cm−1 at 70 °C). Mishra et al. employed a solution-casting method to prepare a free-standing flexible PEO-NaClO4-NaAlO2 CPE [54]. The addition of NaAlO2 significantly inhibited the crystallization of PEO, and the resultant CPE achieved an ionic conductivity of 7.5 × 10−5 S·cm−1 at 30 °C. Hwang and coworkers developed a TiO2-PEO-NaClO4 CPE [55] which achieved a high ionic conductivity of 2.62 × 10−4 S·cm−1 at 60 °C when 5 wt% TiO2 was introduced (Fig. 3a, b). However, it is difficult to further improve the ionic conductivity by dispersing ceramic fillers in polymer matrices, due to weak polymer-ceramic interactions. Strategies to enhance chemical interactions between oxide ceramics and polymer chains were proposed. Lin et al. [56] employed an in-situ growth method to prepare the monodispersed SiO2-PEO CPE. Benefiting from the strong chemical interactions between SiO2 and PEO chains, the degree of PEO crystallinity was suppressed, and the ionic conductivity was considerably enhanced.

Reproduced with permission from Ref. [55]. Copyright 2015, Elsevier. c Flexibility of NZSP-based CPE. Reproduced with permission from Ref. [61]. Copyright 2015, the Royal Society of Chemistry. d Na-ion transport model in CPEs. Reproduced with permission from Ref. [63]. Copyright 2020, Elsevier

TiO2 and NZSP-based composite polymer electrolytes. a Schematic illustration of Na+ conduction in TiO2-PEO-NaClO4, and b ionic conductivity plots.

As a typical active filler, Na superionic conductor (NASICON) with composition of Na1+xZr2SixP3−xO12 (0 ≤ x ≤ 3) presents high ionic conductivity and superior electrochemical stability [57,58,59,60]. Introducing NASICON electrolytes into flexible polymer matrices to develop CPEs can not only enhance the ionic conductivity of SPEs but also overcome the brittleness of NASICON electrolytes and improve the interfacial compatibility between electrolytes and electrodes. Kim et al. [61] fabricated a NASICON (Na3Zr2Si2PO12, NZSP) based CPE with favorable flexibility (Fig. 3c), the flexible CPE helped to construct better interfacial contacts with electrodes. When the flexible CPE was matched with hard carbon and NaFePO4, the flexible SSB delivered a high reversible capacity and long cycle lifespan at 0.2C with good capacity retention of 96% over 200 cycles. Yu et al. [62] synthesized a heterogeneous multilayered CPE composed of an anode-friendly PEO layer, an oxidation-resistance polyacrylonitrile (PAN) layer, and incorporated NZSP particles for the improvement of the Na-ion conductivity and the mechanical strength. With this design, the as-prepared CPE exhibited a high oxidation potential (4.8 V) and excellent Na-ion conductivity (1.36 × 10−4 S·cm−1 at 30 °C). Furthermore, to visualize the Na-ion transport process, a novel ion transport model in CPEs was put forward by Fan and coworkers [63]. As shown in Fig. 3d, there are three paths for the Na-ion diffusion in CPEs according to different contents of ionic conductors: PEO, polymer/ceramic interfaces and the ion hopping among the ceramic particles.

The addition of the NZSP particles not only reduced the crystallization degree of PEO but also provided extra channels for the Na-ion transport in CPEs. The addition of ceramic particles weakened the interactions between polymer chains and Na ions, and promoted the dissociation of Na salts and generates more movable Na ions. Ceramic fillers can also destroy the regularity of polymer chains, and increase the free volume of polymers and improve the movement ability of chain segments. However, aggregation of ceramic particles and poor interfacial compatibility between ceramic particles and polymer matrices greatly limited their practical applications. Surface modification to increase the adhesion of ceramic particles to polymer matrices and construction of continuous Na-ion transport pathways in polymer matrices like 3D interconnected ceramic frameworks can be employed to overcome these limitations.

2.4 Gel polymer electrolytes

Gel polymer electrolytes (GPEs) contain a portion of liquid ingredients, with which the problems of low ionic conductivity at room temperature and poor solid–solid contacts can be solved. Different from other electrolyte systems, GPEs achieve a performance balance in mechanical and electrochemical properties and are very promising for SSBs due to excellent interfacial stability between electrodes and electrolytes as well as marked ionic conductivity. More importantly, the liquid phase is trapped in the polymeric matrix, which reduces the risk of leakage and acquires better safety performance. In 1974, Feuillade and Perche [64] introduced propylene carbonate/NH4ClO4 salt solution into polymer matrix and laid the foundation of quasi-solid gel electrolytes. Up to now, various GPEs, along with individual components, have been systemically investigated [65]. Usually, PEO, PVCA and PVDF are served as polymer matrices, while ester solvents, ether solvents and ionic liquids are worked as liquid ingredients. In this section, GPEs prepared by physical methods and in-situ synthesis are summarized in Table 3 and discussed respectively.

Typically, two steps are required to prepare GPEs by physical methods: polymers are dissolved in uniform mixtures of organic solvents and additives, and then volatile solution is evaporated; the resultant porous membranes are then swelled with liquid electrolytes containing Na salts and plasticizers. Janakiraman and coworkers [66] prepared a GPE via soaking porous electrospun PVDF-HFP in the liquid electrolyte with 1 mol·L−1 NaClO4 solution (ethylene carbonate/diethyl carbonate, 1:1 in volume ratio). The obtained GPE presented a decent ionic conductivity (1.13 × 10−3 S·cm−1 at 30 °C) as well as a high oxidation potential of 4.8 V. Nevertheless, polymer matrices tend to be dissolved in liquid electrolytes under special conditions like high temperatures, which may cause solvent leakage and safety hazards.

In-situ synthesis of hyperbranched/cross-linked polymer networks by molecular design can improve thermal stability, and the liquid phase can be tightly encapsulated in the polymer matrix to prevent leakage. Specifically, the precursor solution consisting of polymerizable monomers, liquid electrolytes and initiators can be directly added into a battery system and then cured under specific circumstances (such as thermal, ultraviolet (UV) or electron beam radiation) to generate polymer networks, with the liquid phase being uniformly anchored on the polymer skeletons during curing. Furthermore, the precursor solution with a relatively low viscosity can readily wet the electrodes and the separator, to create ultra-conformal interfacial contacts between the electrodes and electrolyte. Guo and coworkers reported a 3D cross-linked GPE prepared by copolymerizing poly(ethylene glycol) diacrylate (PEGDA) and ethoxylated trimethylolpropane triacrylate (ETPTA) [67]. Thermogravimetric analysis showed that the weight loss of 3D cross-linked GPE could be neglected until temperature reached 280 °C, which confirmed its remarkable thermal stability. Additionally, the 3D cross-linked GPE presented a high ionic conductivity of 5.6 × 10−4 S·cm−1 at 25 °C and constructed a robust and conductive solid electrolyte interphase, which improved the contact between the anode and the electrolyte.

Facile and scalable in-situ polymerization methods mainly include thermal initiation, radiation initiation, and electrochemical initiation. Chen et al. [68] reported a branched GPE prepared by thermal curing poly(ethylene glycol methyl ether methacrylate) (PEGMA) at 80 °C for 3 h (Fig. 4a), the as-prepared GPE displayed a superior ionic conductivity (9.1 × 10−4 S·cm−1 at room temperature) and built stable interfaces to protect Na metal from corrosion. Wei et al. [69] prepared ionic membranes coated on the Na metal electrode via in-situ electro-initiated polymerization process (Fig. 4b), the resultant membranes protected the Na metal against parasitic reactions. Moreover, Bella et al. [70] prepared a GPE by UV-induced polymerization of bisphenol A ethoxylate dimethacrylate (BEMA) and PEGMA (Fig. 4c), the obtained GPE delivered a marked ionic conductivity of 5.1 × 10−3 S·cm−1 at 20 °C and high anodic stability of 4.8 V. Very importantly, the in-situ thermal curing process is compatible with the current production technology of batteries. However, several critical problems still need to be solved. For example, residual monomers or highly active initiators remain in the battery system, which may cause the deterioration of electrochemical properties [71]. Moreover, defects in GPEs caused by the solvent volatilization during curing lead to reduced ionic conductivity and significant polarization [72]. To optimize precursor solutions by means of adding initiators with high initiation efficiency and a certain number of monomers is a crucial step to develop in-situ formed GPEs.

Reproduced with permission from Ref. [68]. Copyright 2020, Elsevier. b Electro-polymerization process. Reproduced with permission from Ref. [69]. Copyright 2017, Wiley–VCH. c UV-polymerization process. Reproduced with permission from Ref. [70]. Copyright 2015, Wiley–VCH

Gel polymer electrolytes prepared by in-situ synthesis. Schematic illustration of a thermal-curing process.

Mechanisms of the Na-ion conduction in GPEs are not entirely clear. Generally, Na-ion transfer in solid polymer matrices or between the solid and liquid phase is kinetically sluggish, as compared with that in liquid solvents. The transport of Na ions mainly occurs in liquid solvents that play a major role in dissolving Na salts. Meanwhile, functional groups of polymer chains change the solvation structure of Na+ by strong interactions with small molecules or Na+ and influence the ionic conduction mode of Na+. Through rational utilization of the above interactions, GPEs with high ionic conductivity can be developed.

3 Applications of polymer electrolytes in solid-state sodium batteries

Interfacial stability between polymer electrolytes and electrodes determines the rate performance and cycle stability of SSBs. Desirable interfaces between electrolytes and electrodes should exhibit good compatibility and favorable mechanical strength as well as fast charge transfer. However, the rigid cathode/electrolyte interface via point-to-point contacts severely impedes the Na-ion conduction and mass transfer, and the unstable anode/electrolyte interface triggers a series of inevitable parasitic reactions and uncontrollable dendrite growth. In addition, interface destruction derived from the volume change of electrodes during the charge/discharge processes seriously damages the battery performance. Ideal interfaces between polymer electrolytes and electrodes are highly desirable. Li and coworkers reported a reactivity-guided formulation strategy to address the challenges associated with the interfacial compatibility and the electrochemical stability [73], a highly conductive interfacial-wetting layer was built on the Na anode through the unique reactivity between the Na anode and PPC, which significantly improved the interfacial conductivity. Yang and coworkers [74] reported a poly(butyl acrylate)-based polymer electrolyte developed by in-situ polymerization, the resultant stable interfaces could not only alleviate the volume changes of the electrodes but also modulate the deposition behavior of Na ions on the Na anode, thereby suppressing the evolution of Na dendrites.

A variety of polymer electrolytes have been applied in SSBs to achieve excellent battery performances. For example, Yao et al. [75] fabricated superior-performance SSBs by employing PEGDMA-NaFSI as the SPE. Benefiting from the high ionic conductivity and intimate interfacial contacts, the as-prepared pouch cell demonstrated outstanding cycling stability over 740 cycles and maintained 95% of initial discharge capacity. Ling et al. [76] reported a multilayer structured CPE prepared by the UV curing of an interpenetrating network of poly(ether-acrylate) in the Na3Zr2Si2PO12/PVDF-HFP porous skeleton. When the multilayer structured CPE was matched with Na3V2(PO4)3 (NVP), the as-synthesized SSBs displayed a highly reversible capacity of 85 mAh·g−1 over 100 cycles at 0.5C. Zheng et al. [77] designed a hybrid network-based SPE, which was prepared by cross-linking of octakis(3-glycidyloxypropyldimethylsiloxy) octasilsesquioxane and amine-terminated PEG. The resultant SPE showed outstanding electrochemical stability, enabling stable cycling of Na symmetric cells over 3550 h at 0.5 mA·cm−2. Generally, polymer electrolytes can meet basic requirements for SSBs. Specific applications should be considered for further developments of advanced polymer electrolytes, such as wide electrochemical window to match high-voltage cathodes, wide temperature range to enhance the safety.

Due to superior electro-oxidative resistance of polymers, polymer electrolytes present higher anodic stability, as compared with traditional organic liquid electrolytes, which enables the applications of polymer electrolytes in high-voltage SSBs. Wen et al. [78] fabricated an ethoxylated trimethylolpropane triacrylate-based quasi-solid-state electrolyte (ETPTA-NaClO4-QSSE) with a wide electrochemical window of 4.7 V (Fig. 5a). This quasi-solid-state electrolyte demonstrated their practicability in SSBs (Fig. 5b, c), the as-assembled NVP|ETPTA-NaClO4-QSSE|Na pouch cell maintained a high reversible capacity of 100 mAh·g−1 at 1.0C, whatever in the flatting state, the folding state or the reflating state. However, as a representative, PEO with ether groups demonstrates low oxidation potential, it begins to be oxidized when operating voltage exceeds 4 V [79]. Grafting terminal groups onto other supporting polymers to change the host structure or physically separating ether groups from the high reaction interface can effectively improve the antioxidant capacity. Ran et al. [80] fabricated a sandwich NASICON framework consisting of anti-oxidation PAN layer and anti-reduction PEO layer (Fig. 5d). The PEO layer was attached on the negative side to prevent oxidation, thus the resultant CPE showed wide electrochemical window up to 5.0 V (vs. Na/Na+) (Fig. 5e), and the CPE-based SSBs displayed an excellent rate performance (Fig. 5f) and long cycling lifespan.

Reproduced with permission from Ref. [78]. Copyright 2021, Wiley–VCH. d Schematic illustration of CPE; e CV curve of Na|CPE|stainless steel cell; f rate performance of CPE-based SSB. Reproduced with permission from Ref. [80]. Copyright 2021, Elsevier

Polymer electrolytes for high-voltage solid-state sodium batteries. a Cyclic voltammetry (CV) and linear sweep voltammetry (LSV) curves of ETPTA-NaClO4-QSSE; b, c Electrochemical performances of NVP|ETPTA-NaClO4-QSSE|Na pouch cell.

Battery systems that can operate over a wide temperature range are highly desirable, especially at high temperatures (> 100 °C) or low temperatures (< − 30 °C). Traditional organic liquid electrolytes based on ethylene carbonate cannot work over such a broad temperature range. However, polymer electrolytes with favorable flexibility and thermal stability are preferable for these battery systems. Du et al. [81] prepared a polymer electrolyte (perfluorosulfonic acid (PFSA)-Na membranes) through a simple ionic exchange process. As depicted in Fig. 6a, the resultant PFSA-Na membrane demonstrated a decent ionic conductivity over a wide temperature range and excellent low-temperature performance. Notably, the as-assembled SSB exhibited excellent cycling stability at − 35 °C (Fig. 6b, c), demonstrating great applicability in low-temperature SSBs. Xie et al. [82] prepared a flexible GPE consisting of PVDF-HFP and ionic liquid (Fig. 6d), the as-prepared GPE achieved superior thermal decomposition temperature over 450 °C (Fig. 6e). When the GPE was matched with Prussian blue, the as-prepared SSB obtained excellent electrochemical performance.

Reproduced with permission from Ref. [81]. Copyright 2020, Wiley–VCH. d Schematic illustration of fabrication of PVDF-HFP and PVDF-HFP/ionic liquid membranes, where DMAC is dimethylacetamide; e thermogravimetry (TG) curves; inset being differential scanning calorimetry (DSC) curves. Reproduced with permission from Ref. [82]. Copyright 2019, Wiley–VCH

Polymer electrolytes for solid-state sodium batteries with a wide working temperature range. a Arrhenius plots and corresponding AC impedance spectra of PFSA-Na electrolyte; b, c low-temperature cycling test of SSB.

The flame retardance of electrolytes determines the battery safety. Traditional organic liquid systems potentially have safety hazards of leakage or flammability. However, polymer electrolytes are much safer than organic liquid systems. Adding flame retardant to polymers or chemically bonding flame retardant to polymers are two facile methods to prepare flame retardant polymer electrolytes. Yang et al. [83] prepared a non-flammable quasi-solid polymer electrolyte with triethyl phosphate as a flame retardant (Fig. 7a). Figure 7b, c depicts the non-flammability of the quasi-solid polymer electrolyte which exhibited better flame retardancy than the NaClO4/propylene carbonate electrolyte. When assembled in NVP/Na metal batteries, this nonflammable quasi-solid polymer electrolyte delivered outstanding cycle performance with 84.4% capacity retention after 1000 cycles. The same strategy was employed by Wu’s group [68], they prepared a flexible poly(ethylene glycol methyl ether methacrylate) based GPE plasticized by nonflammable triethyl phosphate. Self-extinguishing time results verified that the addition of triethyl phosphate significantly improved the flame retardancy (Fig. 7d). However, these phosphides might be decomposed on the anode surface during electrochemical reactions. Chemically bonding flame retardant to the polymer matrix can suppress the decomposition of the flame retardant. Zheng et al. [84] designed a safer GPE by in-situ polymerization of phosphonate-containing monomers of di(2-methacryloyltrioxyethyl)phenylphosphonate (MATEPP) (Fig. 7e). As shown in Fig. 7f, this GPE demonstrated superior flame retardant effect when 7.5 wt% MATEPP was incorporated, and the GPE-based SSB presented excellent high-rate cycling stability at 5.0C over 10,000 cycles with 69.2% capacity retention. These flame-retardant polymer electrolytes hold great promise for highly-safe SSBs.

Reproduced with permission from Ref. [83]. Copyright 2019, Springer Nature. d Flammability tests of PPEGMA-based GPE. Reproduced with permission from Ref. [68]. Copyright 2020, Elsevier. e Synthesis of MATEPP-based GPE; f self-extinguishing time and linear flame propagation of electrolytes containing different contents of MATEPP. Reproduced with permission from Ref. [84]. Copyright 2018, the Royal Society of Chemistry

Nonflammable polymer electrolytes for solid-state sodium batteries. a Schematic illustration of preparation of flame-retardant poly(methyl vinyl ether-alt-maleic anhydride) P(MVE-alt-MA)/bacterial cellulose composite polymer electrolyte (FRPMM-CPE); b glass fiber saturated with 1.0 mol·L−1 NaClO4/propylene carbonate and c FRPMM-CPE.

4 Conclusions and perspectives

The current battery technology is evolving from liquid systems to solid-state with high energy density, superior safety and intelligent functions, which requires the development of innovative electrolytes. Polymer electrolytes, as a promising substitute to liquid electrolytes, can enable high energy density, enhanced safety and durable cyclability for SSBs. In this review, recent advances in polymer electrolytes and their potential applications in SSBs are discussed. However, polymer electrolytes for SSBs still face numerous challenges; potential solutions are elaborated in the followings:

-

(1)

Polymer electrolytes with intrinsic safety and high ionic conductivity. Polymer structural design via copolymerization, cross-linking and so on can be employed to enhance the flexibility of polymer chains to facilitate the ionic conduction, and thus achieving marked ionic conductivity. Furthermore, advanced in-situ polymerization technology will significantly improve the ionic conductivity. Meanwhile, the exploration of low-cost and high safe plasticizers is of great significance for exploiting advanced GPEs for SSBs.

-

(2)

Interface compatibility between polymer electrolytes and electrodes. Exploring efficient electrolyte additives to construct robust interfacial layers is a key to achieving high-performance SSBs.

-

(3)

Transport mechanisms of Na ions, including conduction process, migrating pathways and internal interactions. The conduction mechanisms of Na ions have not yet been fully understood; a good insight into the ionic conduction mechanisms is of scientific significance and can better guide the preparation of advanced electrolytes.

-

(4)

Innovative polymer electrolytes with intelligent functions. For example, the self-healing ability to automatically repair damages under mechanical strain, thermal-responsive ability that can protect battery system under high temperatures to prevent thermal runaway.

-

(5)

Advanced characterization techniques and theoretical calculations. Advanced in-situ characterization techniques are required to deepen the understanding of the Na+ conduction and the electrochemical reactions. In combination with theoretical calculations, it is able to elucidate interactions among polymer chains, small molecules and anions-cations in the system, which can provide guidance for the design of novel polymer electrolytes.

-

(6)

Preparing polymer electrolytes for SSBs at low cost. In situ polymerization of monomers in cells is scalable and cost-effective, and it should be further optimized.

References

Delmas C. Sodium and sodium-ion batteries: 50 years of research. Adv Energy Mater. 2018;8(17):1703137. https://doi.org/10.1002/aenm.201703137.

Li L, Zheng Y, Zhang S, Yang J, Shao Z, Guo Z. Recent progress on sodium ion batteries: potential high-performance anodes. Energ Environ Sci. 2018;11(9):2310. https://doi.org/10.1039/c8ee01023d.

Liu X, Wang M, Qin B, Zhang Y, Liu Z, Fan H. 2D–2D MXene/ReS2 hybrid from Ti3C2Tx MXene conductive layers supporting ultrathin ReS2 nanosheets for superior sodium storage. Chem Eng J. 2022;431:133796. https://doi.org/10.1016/j.cej.2021.133796.

Li Z, Peng Z, Sun R, Qin Z, Liu X, Wang C, Fan H, Lu S. Super Na+ half/full batteries and ultrafast Na+ diffusion kinetics of cobalt-nickel selenide from assembling Co0.5Ni0.5Se2@NC nanosheets into cross-stacked architecture. Chin J Chem. 2021;39(9):2599. https://doi.org/10.1002/cjoc.202100192.

Ma Q, Yue J, Fan M, Tan S, Zhang J, Wang W, Liu Y, Tian Y, Xu Q, Yin Y, You Y, Luo A, Xin S, Wu X, Guo YG. Formulating the electrolyte towards high-energy and safe rechargeable lithium-metal batteries. Angew Chem Int Ed Engl. 2021;60(30):16554. https://doi.org/10.1002/anie.202103850.

Li Z, Sun R, Qin Z, Liu X, Wang C, Fan H, Zhang Y, Lu S. Recent progress of nanostructured metal chalcogenides and their carbon-based hybrids for advanced potassium battery anodes. Mater Chem Front. 2021;5(12):4401. https://doi.org/10.1039/d1qm00085c.

Wang L, Xie R, Chen B, Yu X, Ma J, Li C, Hu Z, Sun X, Xu C, Dong S, Chan T, Luo J, Cui G, Chen L. In-situ visualization of the space-charge-layer effect on interfacial lithium-ion transport in all-solid-state batteries. Nat Commun. 2020;11(1):5889. https://doi.org/10.1038/s41467-020-19726-5.

Zhao Q, Liu X, Stalin S, Khan K, Archer LA. Solid-state polymer electrolytes with in-built fast interfacial transport for secondary lithium batteries. Nat Energy. 2019;4(5):365. https://doi.org/10.1038/s41560-019-0349-7.

Liu X, Xu F, Li Z, Liu Z, Yang W, Zhang Y, Fan H, Yang H. Design strategy for MXene and metal chalcogenides/oxides hybrids for supercapacitors, secondary batteries and electro/photocatalysis. Coord Chem Rev. 2022;464: 214544. https://doi.org/10.1016/j.ccr.2022.214544.

Xie HX, Fu Q, Li Z, Chen S, Wu J, Wei L, Guo X. Ultraviolet-cured semi-interpenetrating network polymer electrolytes for high-performance quasi-solid-state lithium metal batteries. Chemistry. 2021;27(28):7773. https://doi.org/10.1002/chem.202100380.

Li Z, Huang H, Zhu JK, Wu JF, Yang H, Wei L, Guo X. Ionic conduction in composite polymer electrolytes: case of PEO:Ga-LLZO composites. ACS Appl Mater Interfaces. 2019;11(1):784. https://doi.org/10.1021/acsami.8b17279.

Zhou Q, Xu B, Chien PH, Li Y, Huang B, Wu N, Xu H, Grundish NS, Hu YY, Goodenough JB. NASICON Li1.2Mg0.1Zr1.9(PO4)3 solid electrolyte for an all-solid-state Li-metal battery. Small Methods. 2020;4(12):2000764. https://doi.org/10.1002/smtd.202000764.

Li Z, Zhou X, Guo X. High-performance lithium metal batteries with ultraconformal interfacial contacts of quasi-solid electrolyte to electrodes. Energy Storage Mater. 2020;29:149. https://doi.org/10.1016/j.ensm.2020.04.015.

Xu B, Li X, Yang C, Li Y, Grundish NS, Chien PH, Dong K, Manke I, Fang R, Wu N, Xu H, Dolocan A, Goodenough JB. Interfacial chemistry enables stable cycling of all-solid-state Li metal batteries at high current densities. J Am Chem Soc. 2021;143(17):6542. https://doi.org/10.1021/jacs.1c00752.

Zhou X, Li X, Li Z, Xie H, Fu J, Wei L, Yang H, Guo X. Hybrid electrolytes with an ultrahigh Li-ion transference number for lithium-metal batteries with fast and stable charge/discharge capability. J Mater Chem A. 2021;9(34):18239. https://doi.org/10.1039/d1ta04631d.

Zhou X, Li X, Li Z, Fu J, Xu S, Zhou W, Gui S, Wei L, Yang H, Wu JF, Guo X. Ten micrometer thick polyethylene separator modified by α-LiAlO2@γ-Al2O3 nanosheets for simultaneous suppression of Li dendrite growth and polysulfide shuttling in Li-S batteries. Mater Today Energy. 2022;26:100990. https://doi.org/10.1016/j.mtener.2022.100990.

Wu JF, Zhang R, Fu Q, Zhang J, Zhou X, Gao P, Xu C, Liu J, Guo X. Inorganic solid electrolytes for all-solid-state sodium batteries: fundamentals and strategies for battery optimization. Adv Funct Mater. 2020;31(13):2008165. https://doi.org/10.1002/adfm.202008165.

Yang J, Zhang H, Zhou Q, Qu H, Dong T, Zhang M, Tang B, Zhang J, Cui G. Safety-enhanced polymer electrolytes for sodium batteries: recent progress and perspectives. ACS Appl Mater Interfaces. 2019;11(19):17109. https://doi.org/10.1021/acsami.9b01239.

Zhao C, Liu L, Qi X, Lu Y, Wu F, Zhao J, Yu Y, Hu YS, Chen L. Solid-state sodium batteries. Adv Energy Mater. 2018;8(17):1703012. https://doi.org/10.1002/aenm.201703012.

Li Z, Weng S, Fu J, Wang X, Zhou X, Zhang Q, Wang X, Wei L, Guo X. Nonflammable quasi-solid electrolyte for energy-dense and long-cycling lithium metal batteries with high-voltage Ni-rich layered cathodes. Energy Storage Mater. 2022;47:542. https://doi.org/10.1016/j.ensm.2022.02.045.

Meng N, Lian F, Cui G. Macromolecular design of lithium conductive polymer as electrolyte for solid-state lithium batteries. Small. 2021;17(3):e2005762. https://doi.org/10.1002/smll.202005762.

Banerjee A, Wang X, Fang C, Wu EA, Meng YS. Interfaces and interphases in all-solid-state batteries with inorganic solid electrolytes. Chem Rev. 2020;120(14):6878. https://doi.org/10.1021/acs.chemrev.0c00101.

Zhou D, Shanmukaraj D, Tkacheva A, Armand M, Wang G. Polymer electrolytes for lithium-based batteries: advances and prospects. Chem. 2019;5(9):2326. https://doi.org/10.1016/j.chempr.2019.05.009.

Chen S, Feng F, Yin Y, Che H, Liao XZ, Ma ZF. A solid polymer electrolyte based on star-like hyperbranched β-cyclodextrin for all-solid-state sodium batteries. J Power Sources. 2018;399:363. https://doi.org/10.1016/j.jpowsour.2018.07.096.

Wang Y, Wang Z, Zheng F, Sun J, Oh JAS, Wu T, Chen G, Huang Q, Kotobuki M, Zeng K, Lu L. Ferroelectric engineered electrode-composite polymer electrolyte interfaces for all-solid-state sodium metal battery. Adv Sci. 2022;3:e2105849. https://doi.org/10.1002/advs.202105849.

Mittal N, Tien S, Lizundia E, Niederberger M. Hierarchical nanocellulose-based gel polymer electrolytes for stable Na electrodeposition in sodium ion batteries. Small. 2022. https://doi.org/10.1002/smll.202107183.

Yin H, Han C, Liu Q, Wu F, Zhang F, Tang Y. Recent advances and perspectives on the polymer electrolytes for sodium/potassium-ion batteries. Small. 2021;17(31): e2006627. https://doi.org/10.1002/smll.202006627.

Tan SJ, Zeng XX, Ma Q, Wu XW, Guo YG. Recent advancements in polymer-based composite electrolytes for rechargeable lithium batteries. Electrochem Energy R. 2018;1(2):113. https://doi.org/10.1007/s41918-018-0011-2.

Fenton DE, Parker JM, Wright PV. Complexes of alkali metal ions with poly(ethylene oxide). Polymer. 1973;14(11):589. https://doi.org/10.1016/0032-3861(73)90146-8.

Gadjourova Z, Andreev YG, Tunstall DP, Bruce PG. Ionic conductivity in crystalline polymer electrolytes. Nature. 2001;412(6846):520. https://doi.org/10.1038/35087538.

Popovic J, Brandell D, Ohno S, Hatzell KB, Zheng J, Hu YY. Polymer-based hybrid battery electrolytes: theoretical insights, recent advances and challenges. J Mater Chem A. 2021;9(10):6050. https://doi.org/10.1039/d0ta11679c.

Bruce PG, Evans J, Vincent CA. Conductivity and transference number measurements on polymer electrolytes. Solid State Ionics. 1988;28:918. https://doi.org/10.1016/0167-2738(88)90304-9.

Long L, Wang S, Xiao M, Meng Y. Polymer electrolytes for lithium polymer batteries. J Mater Chem A. 2016;4(26):10038. https://doi.org/10.1039/c6ta02621d.

West K, Zachau B, Jacobsen T, Lorenzen E, Skaarup S. Poly(ethylene oxide)-sodium perchlorate electrolytes in solid-state sodium cells. British Polymer J. 1988;20:243. https://doi.org/10.1002/pi.4980200315.

Serra Moreno J, Armand M, Berman MB, Greenbaum SG, Scrosati B, Panero S. Composite PEOn: NaTFSI polymer electrolyte: preparation, thermal and electrochemical characterization. J Power Sources. 2014;248:695. https://doi.org/10.1016/j.jpowsour.2013.09.137.

Qi X, Ma Q, Liu L, Hu Y-S, Li H, Zhou Z, Huang X, Chen L. Sodium bis(fluorosulfonyl)imide/poly(ethylene oxide) polymer electrolytes for sodium-ion batteries. ChemElectroChem. 2016;3(11):1741. https://doi.org/10.1002/celc.201600221.

Zhang Q, Lu Y, Yu H, Yang G, Liu Q, Wang Z, Chen L, Hu YS. PEO-NaPF6 blended polymer electrolyte for solid state sodium battery. J Electrochem Soc. 2020;167(7): 070523. https://doi.org/10.1149/1945-7111/ab741b.

Ma Q, Liu J, Qi X, Rong X, Shao Y, Feng W, Nie J, Hu YS, Li H, Huang X, Chen L, Zhou Z. A new Na[(FSO2)(n-C4F9SO2)N]-based polymer electrolyte for solid-state sodium batteries. J Mater Chem A. 2017;5(17):7738. https://doi.org/10.1039/c7ta01820g.

Silva MM, Barros SC, Smith MJ, MacCallum JR. Characterization of solid polymer electrolytes based on poly(trimethylenecarbonate) and lithium tetrafluoroborate. Electrochim Acta. 2004;49(12):1887. https://doi.org/10.1016/j.electacta.2003.12.017.

Zhang J, Yang J, Dong T, Zhang M, Chai J, Dong S, Wu T, Zhou X, Cui G. Aliphatic polycarbonate-based solid-state polymer electrolytes for advanced lithium batteries: advances and perspective. Small. 2018;14(36):e1800821. https://doi.org/10.1002/smll.201800821.

Sångeland C, Mogensen R, Brandell D, Mindemark J. Stable cycling of sodium metal all-solid-state batteries with polycarbonate-based polymer electrolytes. ACS Appl Polym Mater. 2019;1(4):825. https://doi.org/10.1021/acsapm.9b00068.

Chai J, Liu Z, Ma J, Wang J, Liu X, Liu H, Zhang J, Cui G, Chen L. In situ generation of poly (vinylene carbonate) based solid electrolyte with interfacial stability for LiCoO2 lithium batteries. Adv Sci. 2017;4(2):1600377. https://doi.org/10.1002/advs.201600377.

Chen S, Che H, Feng F, Liao J, Wang H, Yin Y, Ma ZF. Poly(vinylene carbonate)-based composite polymer electrolyte with enhanced interfacial stability to realize high-performance room-temperature solid-state sodium batteries. ACS Appl Mater Interfaces. 2019;11(46):43056. https://doi.org/10.1021/acsami.9b11259.

Fonseca CP, Rosa DS, Gaboardi F, Neves S. Development of a biodegradable polymer electrolyte for rechargeable batteries. J Power Sources. 2006;155(2):381. https://doi.org/10.1016/j.jpowsour.2005.05.004.

Zhang B, Liu Y, Pan X, Liu J, Doyle-Davis K, Sun L, Liu J, Jiao X, Jie J, Xie H, Sun X. Dendrite-free lithium metal solid battery with a novel polyester based triblock copolymer solid-state electrolyte. Nano Energy. 2020;72:104690. https://doi.org/10.1016/j.nanoen.2020.104690.

Sångeland C, Younesi R, Mindemark J, Brandell D. Towards room temperature operation of all-solid-state Na-ion batteries through polyester-polycarbonate-based polymer electrolytes. Energy Storage Mater. 2019;19:31. https://doi.org/10.1016/j.ensm.2019.03.022.

Pan Q, Li Z, Zhang W, Zeng D, Sun Y, Cheng H. Single ion conducting sodium ion batteries enabled by a sodium ion exchanged poly(bis(4-carbonyl benzene sulfonyl)imide-co-2,5-diamino benzesulfonic acid) polymer electrolyte. Solid State Ionics. 2017;300:60. https://doi.org/10.1016/j.ssi.2016.12.001.

Wang P, Zhang H, Chai J, Liu T, Hu R, Zhang Z, Li G, Cui G. A novel single-ion conducting gel polymer electrolyte based on polymeric sodium tartaric acid borate for elevated-temperature sodium metal batteries. Solid State Ionics. 2019;337:140. https://doi.org/10.1016/j.ssi.2019.04.022.

Yang L, Jiang Y, Liang X, Lei Y, Yuan T, Lu H, Liu Z, Cao Y, Feng J. Novel sodium-poly(tartaric acid)borate-based single-ion conducting polymer electrolyte for sodium-metal batteries. ACS Appl Energ Mater. 2020;3(10):10053. https://doi.org/10.1021/acsaem.0c01756.

Weston JE, Steele B. Effects of inert fillers on the mechanical and electrochemical properties of lithium salt-poly(ethylene oxide) polymer electrolytes. Solid State Ionics. 1982;7(1):75. https://doi.org/10.1016/0167-2738(82)90072-8.

Wieczorek W, Such K, Wycislik H, Plocharski J. Modifications of crystalline structure of peo polymer electrolytes with ceramic additives. Solid State Ionics. 1989;36(3):255. https://doi.org/10.1016/0167-2738(89)90185-9.

Fu J, Li Z, Zhou X, Guo X. Ion transport in composite polymer electrolytes. Materials Advances. 2022;3(9):3809. https://doi.org/10.1039/d2ma00215a.

Zhang X, Wang X, Liu S, Tao Z, Chen J. A novel PMA/PEG-based composite polymer electrolyte for all-solid-state sodium ion batteries. Nano Res. 2018;11(12):6244. https://doi.org/10.1007/s12274-018-2144-3.

Chauhan AK, Mishra K, Kumar D, Singh A. Enhancing sodium ion transport in a PEO-based solid polymer electrolyte system with NaAlO2 active fillers. J Electron Mater. 2021;50(9):5122. https://doi.org/10.1007/s11664-021-09051-y.

Ni’mah YL, Cheng MY, Cheng JH, Rick J, Hwang BJ. Solid-state polymer nanocomposite electrolyte of TiO2/PEO/NaClO4 for sodium ion batteries. J Power Sources. 2015;278:375. https://doi.org/10.1016/j.jpowsour.2014.11.047.

Lin D, Liu W, Liu Y, Lee HR, Hsu PC, Liu K, Cui Y. High ionic conductivity of composite solid polymer electrolyte via in situ synthesis of monodispersed SiO2 nanospheres in poly(ethylene oxide). Nano Lett. 2016;16(1):459. https://doi.org/10.1021/acs.nanolett.5b04117.

Yang J, Liu G, Avdeev M, Wan HL, Han FD, Shen L, Zou ZY, Shi SQ, Hu YS, Wang CS, Yao XY. Ultrastable all-solid-state sodium rechargeable batteries. ACS Energy Lett. 2020;5(9):2835. https://doi.org/10.1021/acsenergylett.0c01432.

Kou ZY, Lu Y, Miao C, Li JQ, Liu CJ, Xiao W. High-performance sandwiched hybrid solid electrolytes by coating polymer layers for all-solid-state lithium-ion batteries. Rare Met. 2021;40(11):3175. https://doi.org/10.1007/s12598-020-01678-w.

Hong YP. Crystal structures and crystal chemistry in the system Na1+xZr2SixP3xO12. Mater Res Bull. 1976;11(2):173. https://doi.org/10.1016/0025-5408(76)90073-8.

Goodenough JB, Hong YP, Kafalas JA. Fast Na+-ion transport in skeleton structures. Mater Res Bull. 1976;11(2):203. https://doi.org/10.1016/0025-5408(76)90077-5.

Kim JK, Lim YJ, Kim H, Cho GB, Kim Y. A hybrid solid electrolyte for flexible solid-state sodium batteries. Energ Environ Sci. 2015;8(12):3589. https://doi.org/10.1039/c5ee01941a.

Yu X, Xue L, Goodenough JB, Manthiram A. Ambient-temperature all-solid-state sodium batteries with a laminated composite electrolyte. Adv Funct Mater. 2020;31(2):2002144. https://doi.org/10.1039/c5ee01941a.

Niu W, Chen L, Liu Y, Fan LZ. All-solid-state sodium batteries enabled by flexible composite electrolytes and plastic-crystal interphase. Chem Eng J. 2020;384:123233. https://doi.org/10.1016/j.cej.2019.123233.

Feuillade G, Perche P. Ion-conductive macromolecular gels and membranes for solid lithium cells. J Appl Electrochem. 1975;5(1):63. https://doi.org/10.1007/bf00625960.

Zhu M, Wu J, Wang Y, Song M, Long L, Siyal SH, Yang X, Sui G. Recent advances in gel polymer electrolyte for high-performance lithium batteries. J Energy Chem. 2019;37:126. https://doi.org/10.1016/j.jechem.2018.12.013.

Janakiraman S, Padmaraj O, Ghosh S, Venimadhav A. A porous poly (vinylidene fluoride-co-hexafluoropropylene) based separator-cum-gel polymer electrolyte for sodium-ion battery. J Electroanal Chem. 2018;826:142. https://doi.org/10.1016/j.jelechem.2018.08.032.

Fan W, Li NW, Zhang X, Zhao S, Cao R, Yin Y, Xing Y, Wang J, Guo YG, Li C. A dual-salt gel polymer electrolyte with 3D cross-linked polymer network for dendrite-free lithium metal batteries. Adv Sci. 2018;5(9):1800559. https://doi.org/10.1002/advs.201800559.

Chen G, Zhang K, Liu Y, Ye L, Gao Y, Lin W, Xu H, Wang X, Bai Y, Wu C. Flame-retardant gel polymer electrolyte and interface for quasi-solid-state sodium ion batteries. Chem Eng J. 2020;401:126065. https://doi.org/10.1016/j.cej.2020.126065.

Wei S, Choudhury S, Xu J, Nath P, Tu Z, Archer LA. Highly stable sodium batteries enabled by functional ionic polymer membranes. Adv Mater. 2017;29(12):1605512. https://doi.org/10.1002/adma.201605512.

Bella F, Colo F, Nair JR, Gerbaldi C. Photopolymer electrolytes for sustainable, upscalable, safe, and ambient-temperature sodium-ion secondary batteries. Chemsuschem. 2015;8(21):3668. https://doi.org/10.1002/cssc.201500873.

Lee KH, Lim HS, Wang JH. Effect of unreacted monomer on performance of lithium-ion polymer batteries based on polymer electrolytes prepared by free radical polymerization. J Power Sources. 2005;139(1):284. https://doi.org/10.1016/j.jpowsour.2004.07.007.

Zhou D, He YB, Cai Q, Qin X, Li B, Du H, Yang QH, Kang F. Investigation of cyano resin-based gel polymer electrolyte: in situ gelation mechanism and electrode-electrolyte interfacial fabrication in lithium-ion battery. J Mater Chem A. 2014;2(47):20059. https://doi.org/10.1039/c4ta04504a.

Matios E, Wang H, Luo J, Zhang Y, Wang C, Lu X, Hu X, Xu Y, Li W. Reactivity-guided formulation of composite solid polymer electrolytes for superior sodium metal batteries. J Mater Chem A. 2021;9(34):18632. https://doi.org/10.1039/d1ta05490b.

Zhang WC, Zhang J, Liu XC, Li H, Guo Y, Geng CN, Tao Y, Yang QH. In-situ polymerized gel polymer electrolytes with high room-temperature ionic conductivity and regulated Na+ solvation structure for sodium metal batteries. Adv Funct Mater. 2022;32:2201205. https://doi.org/10.1002/adfm.202201205.

Yao Y, Wei Z, Wang H, Huang H, Jiang Y, Wu X, Yao X, Wu ZS, Yu Y. Toward high energy density all solid-state sodium batteries with excellent flexibility. Adv Energy Mater. 2020;10(12):1903698. https://doi.org/10.1002/aenm.201903698.

Ling W, Fu N, Yue J, Zeng XX, Ma Q, Deng Q, Xiao Y, Wan LJ, Guo YG, Wu XW. A flexible solid electrolyte with multilayer structure for sodium metal batteries. Adv Energy Mater. 2020;10(9):1903966. https://doi.org/10.1002/aenm.201903966.

Zheng Y, Pan Q, Clites M, Byles BW, Pomerantseva E, Li CY. High-capacity all-solid-state sodium metal battery with hybrid polymer electrolytes. Adv Energy Mater. 2018;8(27):1801885. https://doi.org/10.1002/aenm.201801885.

Wen P, Lu P, Shi X, Yao Y, Shi H, Liu H, Yu Y, Wu ZS. Photopolymerized gel electrolyte with unprecedented room-temperature ionic conductivity for high-energy-density solid-state sodium metal batteries. Adv Energy Mater. 2020;11(6):2002930. https://doi.org/10.1002/aenm.202002930.

Dong T, Zhang J, Xu G, Chai J, Du H, Wang L, Wen H, Zang X, Du A, Jia Q, Zhou X, Cui G. A multifunctional polymer electrolyte enables ultra-long cycle-life in a high-voltage lithium metal battery. Energ Environ Sci. 2018;11(5):1197. https://doi.org/10.1039/c7ee03365f.

Ran L, Li M, Cooper E, Luo B, Gentle I, Wang L, Knibbe R. Enhanced safety and performance of high-voltage solid-state sodium battery through trilayer, multifunctional electrolyte design. Energy Storage Mater. 2021;41:8. https://doi.org/10.1016/j.ensm.2021.05.040.

Du G, Tao M, Li J, Yang T, Gao W, Deng J, Qi Y, Bao SJ, Xu M. Low-operating temperature, high-rate and durable solid-state sodium-ion battery based on polymer electrolyte and Prussian blue cathode. Adv Energy Mater. 2019;10(5):1903351. https://doi.org/10.1002/aenm.201903351.

Xie M, Li S, Huang Y, Wang Z, Jiang Y, Wang M, Wu F, Chen R. An ionic liquid/poly(vinylidene fluoride-co-hexafluoropropylene) gel-polymer electrolyte with a compatible interface for sodium-based batteries. ChemElectroChem. 2019;6(9):2423. https://doi.org/10.1002/celc.201900101.

Yang J, Zhang M, Chen Z, Du X, Huang S, Tang B, Dong T, Wu H, Yu Z, Zhang J, Cui G. Flame-retardant quasi-solid polymer electrolyte enabling sodium metal batteries with highly safe characteristic and superior cycling stability. Nano Res. 2019;12(9):2230. https://doi.org/10.1007/s12274-019-2369-9.

Zheng J, Zhao Y, Feng X, Chen W, Zhao Y. Novel safer phosphonate-based gel polymer electrolytes for sodium-ion batteries with excellent cycling performance. J Mater Chem A. 2018;6(15):6559. https://doi.org/10.1039/c8ta00530c.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China and the Israeli Science Foundation within the framework of the joint NSFC-ISF grant (No. 51961145302). This work was also supported by the China Postdoctoral Science Foundation Project (No. 2020M682403).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Li, ZY., Li, Z., Fu, JL. et al. Sodium-ion conducting polymer electrolytes. Rare Met. 42, 1–16 (2023). https://doi.org/10.1007/s12598-022-02132-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-022-02132-9