Abstract

The selective catalytic reduction of NOx with NH3 (NH3-SCR) is a very effective technology to control the emission of NOx, and the thermal stability of NH3-SCR catalyst is very important for removal of NOx from diesel engines. In this work, V2O5/WO3–TiO2 (VWT) and SiO2-doped V2O5/WO3–TiO2 (VWTSi10) catalysts were prepared by impregnation method and characterized by Brunauer–Emmett–Teller (BET), X-ray diffraction (XRD), Raman, temperature programmed reduction by hydrogen (H2-TPR), X-ray photoelectron spectroscopy (XPS) and temperature programmed desorption by ammonia (NH3-TPD). The doping of SiO2 promotes the thermal stability of V2O5/WO3–TiO2 for NH3-SCR significantly. After calcination at 650 °C for 50 h, the operation window of 10% SiO2-doped V2O5/WO3–TiO2 is 220–480 °C, while the maximum NOx conversion on V2O5/WO3–TiO2 is about 77%. The presence of SiO2 obviously blocks the transformation of TiO2 from anatase to rutile and stabilizes the dispersion of VOx and WO3 on the surface. It is available for the existence of V4+ and the amount of surface acid sites increases, which inhabits the NH3 oxidation at the high temperature range and promotes NH3-SCR activity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Diesel engines have been widely used due to their high fuel efficiency and power output. However, the removal of NOx from diesel engine exhaust is a major challenge in environmental catalysis and air pollution control [1]. The selective catalytic reduction of NOx with NH3 (NH3-SCR) is one of the best available technologies to control the emission of NOx [2].

Among the current commercial SCR catalysts, V2O5/WO3–TiO2 has also been used successfully since 2005 in European on-road mobile applications [3]. There are still some problems for the V2O5/WO3–TiO2 catalyst [4,5,6], such as the thermal deactivation in high temperature exhaust gas [7]. When the diesel exhaust temperature exceeds 600 °C, it will lead to TiO2 sintering with crystal phase transforming from anatase to rutile and accompanying loss of surface area, which causes aggregation or even volatilization of vanadium species [8, 9].

Casanova et al. [4, 5, 7] found that the presence of rare earths elements (Tb, Er) could lead to the formation of rare earth vanadates which hinder phase structure transformation of TiO2 and surface area loss. The composite supports were also used to improve high temperature activity and stability, such as TiO2–Al2O3, TiO2–ZrO2 and TiO2–SiO2 [10,11,12]. Among them, SiO2 is widely used due to its large specific surface area and excellent thermal stability. Kobayashi et al. [13] reported that V2O5/TiO2–SiO2 behaved better SCR activity and higher N2 selectivity than V2O5/TiO2 due to the remarkably stronger acidity, higher BET surface area and a lower crystallite sizes of TiO2, resulting in a good thermal stability and a higher vanadia dispersion. Pan et al. [14] reported that SiO2 doping could keep Lewis acid unchanged and significantly increased Brönsted acid, which had been proven to be beneficial for the low temperature activity. In addition, it could easily generate V4+. Zhao et al. [15] found that co-introduction of SiO2 and Al2O3 into TiO2 greatly increased Brunauer–Emmett–Teller (BET) surface area and the amount of surface acid sites, which promoted SCR activity. Therefore, the Si-doped V2O5/WO3–TiO2 catalyst may not only improve the high temperature activity but also improve the thermal stability under harsh conditions.

In this work, the SiO2-doped V2O5/WO3–TiO2 were prepared and the effects of silica on structure, surface properties and catalytic performance of V2O5/WO3–TiO2 catalysts were investigated.

2 Experimental

2.1 Catalysts preparation

SiO2-doped WO3–TiO2 was prepared by impregnation TiO2–WO3 powder (90 wt%TiO2–10 wt%WO3, Kailong Lanfeng New Material Technology Co., Ltd) with tetraethyl orthosilicate [16], which was denoted as WTSix (where x is the content of SiO2 respect to WO3–TiO2). The catalysts were prepared by conventional incipient impregnation method and the oxalic acid solution of NH4VO3 was used as precursor. After impregnation, the samples were dried overnight at 100 °C and calcination at 550 or 650 °C for 6 h to obtain the fresh catalysts, which were assigned to VWT-550 °C and VWTSix-650 °C. After further calcination at 550 or 650 °C for 50 h, the VWT-550 °C-50 h and VWTSix-650 °C-50 h were obtained. The V2O5 loadings in all catalysts were 3 wt%.

2.2 Activity test

The steady-state NH3-SCR activities of catalysts were tested in a fixed-bed reactor at atmospheric pressure with 0.3 ml catalysts (250–380 μm). The feed gas containing 500 × 10−6 NO, 500 × 10−6 NH3, 5 vol% O2, 2 vol% H2O (when used), 100 × 10−6 SO2 (when used) and balanced argon passed through the catalytic bed at a flow rate of 300 ml·min−1. The NOx concentration of outlet gas was detected from 100 to 550 °C by an online Chemiluminescence NO–NO2–NOx analyzer (Thermal-Scientific Model 42i-HL). The steady NOx conversion was obtained after keeping at each set temperature for 30 min. The temperature range corresponding to more than 80% NOx conversion was defined as the operation window.

The NH3 oxidation activities were measured by a Nicolet 6700 (Thermo Scientific) with gas analysis cell (2 m optical path) with 500 min−1 NH3 and 5 vol% O2 in argon as a feed from 100 to 550 °C. The catalysts were kept at each set temperature for 30 min to obtain a stable conversion.

2.3 Catalyst characterization

The powder X-ray diffraction (XRD) patterns were recorded on a BrukerD8 Focus X-ray diffractometer with Cu Kα radiation, the mean crystallite sizes of TiO2 were calculated based on Scherer equation. The surface areas of samples were measured on a Micromeritics ASAP 2400 instrument by N2 adsorption–desorption at − 196 °C. The Raman spectra of the catalysts were obtained on a confocal micro-Raman apparatus (IDSpec Aurora, China) using Ar+ laser with a charged coupled device (CCD) detector, the wavelength of laser was 632.8 nm and the exposure time was 20 s.

Temperature programmed reduction by hydrogen (H2-TPR) was performed on a commercial temperature-programming system. 100 mg catalyst was heated in 5 vol% H2/N2 (40 ml·min−1) from 100 to 800 °C at the rate of 10 °C·min−1 after pretreated at 500 °C for 1 h in a flow of 40 ml·min−1 N2. Temperature programmed desorption by ammonia (NH3-TPD) experiment was performed using the same apparatus. 100 mg catalyst was pretreated at 500 °C for 1 h in N2 (50 ml·min−1) and cooled down to 120 °C, then 10 vol% NH3/N2 (50 ml·min−1) passed through catalyst bed for 1 h to obtain saturation. After purging with N2 for 1 h, the temperature was raised up to 700 °C at the rate of 10 °C·min−1.

X-ray photoelectron spectroscopy (XPS) spectra were obtained on a Thermo ESCALAB 250 spectrometer with a monochromatized Al Kα X-ray source. All binding energies were calibrated by the deposit C 1s at 284.6 eV.

3 Results and discussion

3.1 NH3-SCR activity

The activities of SiO2-doped V2O5/WO3–TiO2 catalysts for NH3-SCR reaction are shown in Fig. 1a. The operation window was 185–470 °C on VWT-550 °C catalyst. The doping of SiO2 slightly decreases the light-off activity, but the activity in the high temperature range is enhanced significantly, which broadens the operation window. Among them, VWTSi10-550 °C behaves the optimum performance with the operation window of 205–520 °C. When the content of SiO2 exceeds 10%, the high temperature activity decreases gradually with the increase of SiO2 content.

After calcination at 650 °C, the light-off curve of VWT-650 °C obviously shifts to higher temperature, and NOx conversion at the high temperature range also decreases significantly, resulting in a narrow operation window of 235–390 °C (Fig. 1b). For VWT-650 °C-50 h, the maximum NOx conversion is about 77%. However, VWTSi10-650 °C shows nearly same SCR activity as VWTSi10-550 °C. Furthermore, the light-off property and high temperature activity slightly decrease with the calcination time extending to 50 h, and operation window still is 220–480 °C, indicating that the deposition of SiO2 dramatically improves the thermal stability of VWT catalyst.

As shown in Fig. 1c, d, VWTSi10-550 °C behaves lower activity for NH3 oxidation than VWT-550 °C. After calcination at 650 °C for 6 and 50 h, the NH3 oxidation activities of all catalysts increase. However, the increasing extent of VWTSi10 is obviously smaller than that of VWT, which indicates that the doping of SiO2 suppresses NH3 oxidation and results in higher SCR activity in higher temperature range.

The activities of SiO2-doped V2O5/WO3–TiO2 catalysts for NH3-SCR reaction on the condition of existing H2O and SO2 are shown in Fig. 1e. The operation window is 220–450 °C on VWT-650 °C catalyst. The doping of SiO2 slightly increases the light-off activity, and the activity in the high temperature range is also enhanced significantly, which broadens the operation window. After extending the calcination time to 50 h, the catalytic activities decrease significantly. However, the catalytic activity of VWTSi10-650 °C-50 h is higher than that of VWT-650 °C-50 h, and it shows the temperature operation window in the range of 240–440 °C. Hence, the doping of SiO2 could improve the high catalytic activity and enhance the stability of resisting H2O and SO2.

3.2 BET surface and XRD

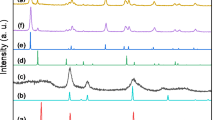

XRD patterns are shown in Fig. 2, and the average crystallite sizes of TiO2 are calculated and listed in Table 1. For VWT-550 °C, only anatase-TiO2 phases are detected, and the peaks corresponding to V2O5 and WO3 are not observed, suggesting that V2O5 and WO3 are highly dispersed on TiO2. After calcination at 650 °C, the diffraction peaks corresponding to WO3 are detected on VWT-650 °C. When the calcination time increases to 50 h, the peak intensities of WO3 greatly enhance, and significant rutile-TiO2 could also be detected. Meanwhile, the surface area of VWT-650 °C catalyst decreases to 7.1 m2·g−1, accompanying the significant increase of crystallite sizes of TiO2 from 45.2 to 61.0 nm.

There is no observable difference between the structure of VWT-550 °C and VWTSi10-550 °C, but the deposition of SiO2 decreases the crystallite sizes of TiO2 and increases the surface area significantly. After the calcination at 650 °C for 6 h, the surface area of VWTSi10-650 °C decreases by about 41% but is much higher than that of VWT-650 °C, while the crystallite size of TiO2 also slightly increases from 17 to 19.8 nm. Further extending the calcination time to 50 h, only anatase-TiO2 is detected on VWTSi10-650 °C-50 h, and the surface area of VWTSi10-650 °C-50 h and crystallite sizes of TiO2 are about 4.6 and 0.41 times that of VWT-650 °C-50 h, respectively. Combing BET and XRD results, it could be concluded that the doping of SiO2 improves the surface area and thermal stability of VWT significantly.

3.3 Raman

The Raman spectra of VWT and VWTSi10 catalysts calcined at different temperature are shown in Fig. 3. All catalysts show the characteristic bands of anatase TiO2 at 145, 197, 396, 515 and 635 cm−1 [17], and the band intensities increase with the increase of calcination temperature and time.

For VWT-550 °C, a weak band assigned to the stretching vibration of W=O could be at 803 cm−1 [18], which is enhanced significantly after calcination at 650 °C for 6 h. The new bands of crystalline WO3 are observed at 270, 324 and 713 cm−1 on VWT-650 °C, corresponding to the W–O–W deformation and the bending vibrations of W=O, respectively. Meanwhile, the bands assigned to the bending vibration of the bridging V–O–V, V=O and the stretching vibration of V=O are detected at 285, 303 and 994 cm−1, respectively [19,20,21]. For VWT-650 °C-50 h, the Raman spectrum is similar with that of VWT-650 °C, except that the bands of TiO2, WO3 and V2O5 are strengthened. These results show the agglomeration of W and V species on the VWT.

For VWTSi10-550 °C, only the characteristic bands of TiO2 are detected, and the peak intensities are much weaker than those of VWT-550 °C, which coincides with the results of XRD, the doping of SiO2 induces the structural distortion and decreases the crystallite size of TiO2. A weak band of V2O5 is detected at 994 cm−1 on VWTSi10-650 °C. After further calcination at 650 °C for 50 h, the bands corresponding to WO3 and V2O5 are observed at 803 and 994 cm−1, respectively, but their intensities are significantly weaker than those of VWT-650 °C and VWT-650 °C-50 h, indicating that the modification of SiO2 could improve the dispersion and thermal stability of V and W species significantly.

3.4 H2-TPR

H2-TPR profiles of VWT and VWTSi10 catalysts calcined at different temperatures are shown in Fig. 4. For VWT-550 °C, the overlapping reduction peak at 300–650 °C could be assigned to the co-reduction of monomeric/polymeric surface vanadia species (V5+/V4+) to V3+ and W6+→W4+ [22,23,24]. The reduction peak centered at around 800 °C could be ascribed to the reduction of W4+ to W0 [24, 25]. The doping of SiO2 slightly decreases the reduction ability of VWT, and all reduction peaks shift to higher temperature, which agrees with the little lower SCR catalytic activity in the low temperature range, as shown in Fig. 1b.

Compared with those on VWT-550 °C and VWTSi10-550 °C, the co-reduction peaks of V and W species on VWT-650 °C and VWTSi10-650 °C distinctly shift to high temperature and the peak intensity decreases, indicating the reducibility decrease of surface V and W species. Meanwhile, a new reduction peak generated at around 600–750 °C could be assigned to the reduction of W6+ to W4+ of bulk phase WO3 [22, 26]. Combined with XRD and Raman results, the decreased reduction ability of VWT-650 °C and VWTSi10-650 °C in the low temperature range may be induced by the agglomeration and separation of V and W species.

By increasing calcination time to 50 h, the reduction peak intensity in the temperature range of 300–600 °C further decreases. The presence of SiO2 suppresses the decrease of reduction peak, and the reduction peak area of VWTSi10-650 °C-50 h is still larger than that of VWT-650 °C, implying that the V and W species could keep stable on VWTSi10-650 °C-50 h and the reduction ability is maintained. Combined with the results of Fig. 1b, the doping of SiO2 could enhance the thermal stability of VWT catalyst, and VWTSi10-650 °C-50 h shows much higher activity than VWT-650 °C and VWT-650 °C-50 h through the stabilization of V and W species on the surface.

3.5 XPS analysis

The V 2p XPS spectra are shown in Fig. 5. Compared with the catalysts calcined at 550 °C, the peaks of V 2p shift to higher binding energy after calcination at 650 °C for 6 and 50 h, which indicates the increase of oxidation state of V species. The ratio of V5+ listed in Table 1 which is obtained by the fitting of V 2p spectra according to the Ref. [27] also confirms that the ratio of V5+ increases with the increase of calcination temperature and time. It is suggested to be induced by the increase of crystalline V species on the surface of catalyst [28], which coincides with results of Raman and XRD.

The results in Table 1 also show that the doping of SiO2 obviously decreases the surface concentration of V, which may be induced by the larger surface area of catalysts containing SiO2. Meanwhile, the surface ratio of V5+ on VWTSi10 is obviously less than that of VWT calcined at the same condition, indicating that the presence of SiO2 improves the dispersion of V species on the surface and the stability of V4+. Kobayashi et al. [13] reported that the modification of SiO2 was available for the existence of V4+ on V2O5/TiO2. Lee et al. [29] reported that VOx (x < 2.5) could improve the reduction and/or re-oxidation properties of catalysts. H2-TPR result (Fig. 4) confirms that the reduction peak of V species shifts to higher temperature after calcination at 650 °C.

3.6 NH3-TPD

NH3-TPD profiles of different catalysts are shown in Fig. 6. A wide NH3 desorption peak and a relative weak shoulder peak are observed on VWT-550 °C at the temperature range of 100–300 °C (α peak) and 300–500 °C, corresponding to the Brönsted and Lewis acid sites, respectively [15, 20, 30]. The desorption peak area of VWTSi10-550 °C is much larger than that of VWT-550 °C, which indicates that the presence of SiO2 improves the amount surface acid sites significantly. After calcination at 650 °C, α peak decreases significantly on VWT-650 °C, which could be ignored on VWT-650 °C-50 h. However, α peak is maintained on VWTSi10-650 °C, and has a slight decrease even on VWTSi10-650 °C, indicating that the doping of SiO2 enhances the stability of surface acid sites significantly.

In addition, two strong desorption peaks are observed on the catalysts calcined at 650 °C at the range of 250–500 °C. Busca et al. reported that VOx and WOx could generate both strong Brönsted and Lewis acid sites [1]. He et al. [31] reported that oligomeric surface V species could produce more acid sites than isolated V species. Combined with Raman results, it could be drawn that isolated or highly dispersed VOx behaves relatively weak Brönsted acid, and the aggregation of VOx and/or WOx would produce new strong acid sites after calcination at 650 °C.

As mentioned above, the doping of SiO2 not only improves surface area of catalyst, but also stabilizes the structure of TiO2, which could stabilize and improve the dispersion of VOx and WO3 species on the surface. The isolated or highly dispersed VOx species is available for the existence of V4+ and increases the amount of surface acid sites, which could inhabit NH3 oxidation at the high temperature range and promote NH3-SCR activity [32] even after calcination at 650 °C.

4 Conclusion

The SiO2-doped 3 wt% V2O5/WO3–TiO2 catalysts were prepared and the catalytic performances for NH3-SCR were investigated. Among them, VWTSi10-550 °C behaves the maximum operation window of 205–520 °C, which still maintains at the temperature range of 220–480 °C even after calcination at 650 °C for 50 h, while the maximum NOx conversion is about 77% on VWT-650 °C. The characterization results show that the doping of SiO2 obviously increases the surface area of catalysts and blocks the transformation of TiO2 from anatase to rutile after calcination at 650 °C, which could stabilize and improve the dispersion of VOx and WO3 species on the surface. The existence of V4+ and stabilized surface acid sites would inhabit the NH3 oxidation at the high temperature range and promote NH3-SCR activity.

References

Baldi M, Finocchio E, Milella F, Busca G. Catalytic combustion of C3 hydrocarbons and oxygenates over Mn3O4. Appl Catal B Environ. 1998;16(1):41.

Li J, Chang H, Ma L, Hao J, Yang RT. Low-temperature selective catalytic reduction of NOx with NH3 over metal oxide and zeolite catalysts. A review. Catal Today. 2011;175(1):147.

Roy S, Hegde MS, Madras G. Catalysis for NOx abatement. Appl Energy. 2009;86(11):2283.

Wang HY, Shao XZ, Wang L, Zhan WC, Guo Y, Lu GZ. Catalytic activity of SiO2 doped V2O5/WO3–TiO2 for selective catalytic reduction of NOx by NH3. Chin J Rare Met. 2018;42(1):53.

Casanova M, Schermanz K, Llorca J, Trovarelli A. Improved high temperature stability of NH3-SCR catalysts based on rare earth vanadates supported on TiO2–WO3–SiO2. Catal Today. 2012;184(1):227.

Heon PH, Soon HJ, Jun YL, Sung HH. Study on SCR De NOx mechanism through in situ electrical conductivity measurements on V2O5–WO3/TiO2 catalysts. Rare Met. 2006;25(6):77.

Vargas MAL, Casanova M, Trovarelli A, Busca G. An IR study of thermally stable V2O5–WO3–TiO2 SCR catalysts modified with silica and rare-earths (Ce, Tb, Er). Appl Catal B Environ. 2007;75(3–4):303.

Madia G, Elsener M, Koebel M, Raimondi F, Wokaun A. Thermal stability of vanadia–tungsta–titania catalysts in the SCR process. Appl Catal B Environ. 2002;39(2):181.

Nova I, Acqua LD, Lietti L, Giamello E, Forzatti P. Study of thermal deactivation of a de-NOx commercial V2O5–WO3/TiO2 catalyst. Appl Catal B Environ. 2001;35(1):31.

Reddy BM, Ganesh I, Chowdhury B. Design of stable and reactive vanadium oxide catalysts supported on binary oxides. Catal Today. 1999;49(1–3):115.

Shi AJ, Wang XQ, Yu T, Shen MQ. The effect of zirconia additive on the activity and structure stability of V2O5/WO3–TiO2 ammonia SCR catalysts. Appl Catal B Environ. 2011;106(3):359.

Reddy BM, Mehdi S, Reddy EP. Dispersion and thermal stability of vanadium oxide catalysts supported on titania-alumina binary oxide. Catal Lett. 1996;36(3):187.

Kobayashi M, Kuma R, Masaki S, Sugishima N. TiO2–SiO2 and V2O5/TiO2–SiO2 catalyst: physico-chemical characteristics and catalytic behavior in selective catalytic reduction of NO by NH3. Appl Catal B Environ. 2005;60(3–4):173.

Pan Y, Zhao W, Zhong Q, Cai W, Li H. Promotional effect of Si-doped V2O5/TiO2 for selective catalytic reduction of NOx by NH3. J Environ Sci. 2013;25(8):1703.

Zhao W, Tang Y, Wan Y, Li L, Yao S, Li X, Gu J, Li Y, Shi J. Promotion effects of SiO2 or/and Al2O3 doped CeO2/TiO2 catalysts for selective catalytic reduction of NO by NH3. J Hazard Mater. 2014;278(1):350.

Chapman DM, Fu G, Augustine S, Watson M, Crouse J, Zavalij L, Banks DP. New titania materials with improved stability and activity for vanadia-based selective catalytic reduction of NOx. SAE Int J Fuels Lubr. 2010;3(1):643.

Cheng K, Liu J, Zhang T, Li J, Zhao Z, Wei Y, Jiang G, Duan A. Effect of Ce doping of TiO2 support on NH3-SCR activity over V2O5–WO3/CeO2–TiO2 catalyst. J Environ Sci. 2014;26(10):2106.

Ross-Medgaarden EI, Wachs IE, Knowles WV, Burrows A, Kiely CJ, Wong MS. Tuning the electronic and molecular structures of catalytic active sites with titania nanoligands. J Am Chem Soc. 2009;131(2):680.

Wang J, Yan Z, Liu L, Chen Y, Zhang Z, Wang X. In situ DRIFTS investigation on the SCR of NO with NH3 over V2O5 catalyst supported by activated semi-coke. Appl Surf Sci. 2014;313(13):660.

Putluru SSR, Schill L, Godiksen A, Poreddy R, Mossin S, Jensen AD, Fehrmann R. Promoted V2O5/TiO2 catalysts for selective catalytic reduction of NO with NH3 at low temperatures. Appl Catal B Environ. 2016;183(1):282.

Wachs IE, Roberts CA. Monitoring surface metal oxide catalytic active sites with Raman spectroscopy. Chem Soc Rev. 2010;39(12):5002.

Liu X, Wu X, Xu T, Weng D, Si Z, Ran R. Effects of silica additive on the NH3-SCR activity and thermal stability of a V2O5/WO3–TiO2 catalyst. Chin J Catal. 2016;37(8):1340.

Yu W, Wu X, Si Z, Weng D. Influences of impregnation procedure on the SCR activity and alkali resistance of V2O5–WO3/TiO2 catalyst. Appl Surf Sci. 2013;283(20):209.

Wu X, Yu W, Si Z, Weng D. Chemical deactivation of V2O5–WO3/TiO2 SCR catalyst by combined effect of potassium and chloride. Front Environ Sci Eng. 2013;7(3):420.

Chen L, Li J, Ge M. The poisoning effect of alkali metals doping over nano V2O5–WO3/TiO2 catalysts on selective catalytic reduction of NOx by NH3. Chem Eng J. 2011;170(2–3):531.

Wang C, Yang S, Chang H, Peng Y, Li J. Dispersion of tungsten oxide on SCR performance of V2O5WO3/TiO2: acidity, surface species and catalytic activity. Chem Eng J. 2013;225(6):520.

Guo XY, Bartholomew C, Hecker W, Baxter LL. Effects of sulfate species on V2O5/TiO2 SCR catalysts in coal and biomass-fired systems. Appl Catal B Environ. 2009;92(1–2):30.

Reddy BM, Ganesh I, Reddy EP. Study of dispersion and thermal stability of V2O5/TiO2–SiO2 catalysts by XPS and other techniques. J Phys Chem B. 1997;101(10):1769.

Lee JY, Hong SH, Cho SP, Hong SC. The study of deNO(x) catalyst in low temperature using nano-sized supports. Curr Appl Phys. 2006;6(6):996.

Zhang QM, Song CL, Lv G, Bin F, Pang HT, Song J. Effect of metal oxide partial substitution of V2O5 in V2O5–WO3/TiO2 on selective catalytic reduction of NO with NH3. J Ind Eng Chem. 2015;24(1):79.

He YY, Ford ME, Zhu MH, Liu QC, Tumuluri U, Wu ZL, Wachs IE. Influence of catalyst synthesis method on selective catalytic reduction (SCR) of NO by NH3 with V2O5–WO3/TiO2 catalysts. Appl Catal B Environ. 2016;193(1):141.

Boningari T, Koirala R, Smirniotis PG. β-Bi2O3 and Er3+ doped β-Bi2O3 single crystalline nanosheets with exposed reactive {001} facets and enhanced photocatalytic performance. Appl Catal B Environ. 2013;140–141(8):289.

Acknowledgements

This project was financially supported by the National Key Research and Development Program of China (No. 2016YFC0204300), the National High Technology Research and Development Program of China (No. 2015AA034603), and the National Natural Science Foundation of China (Nos. 21333003 and 21571061), the “Shu Guang” Project of the Shanghai Municipal Education Commission (No. 12SG29) and the Commission of Science and Technology of Shanghai Municipality (No. 15DZ1205305).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shao, XZ., Wang, HY., Yuan, ML. et al. Thermal stability of Si-doped V2O5/WO3–TiO2 for selective catalytic reduction of NOx by NH3. Rare Met. 38, 292–298 (2019). https://doi.org/10.1007/s12598-018-1176-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-018-1176-x