Abstract

The aims of the present work were: (1) to determine both mycobiota in raw materials and finisher poultry feed, as well as the ability to produce aflatoxin B1 by A. flavus strains, and (2) to evaluate the natural co-occurrence of aflatoxins (AFs), fumonisins (FBs), gliotoxin, diacetoxyscirpenol (DAS), HT-2 toxin, and T-2 toxin in poultry feed by LC-MS/MS. Nineteen percent of raw materials and 79% of finisher poultry feed samples exceeded the maximum allowed total fungal count (1 × 104 CFU g−1) to ensure hygienic quality. Aspergillus flavus was the only species belonging to section Flavi which was isolated while Fusarium verticilliodes was the prevalent species. Forty-seven percent of A. flavus strains were aflatoxin B1 producers and the highest frequency of aflatoxigenic strains was isolated from finisher poultry feeds. Principal component analysis showed that corn grains are closely related with total fungal and Fusarium counts. This positive relationship suggests that total fungal and Fusarium spp. counts in poultry feed might come mainly from corn grains. Regarding poultry feeds, in ground finisher type, Aspergillus spp. counts increased as water activity (aw) diminished. A positive relationship among aw, total fungal and Fusarium spp. counts was observed in both ground finisher and ground starter feed. Several mycotoxins were monitored in feeds by applying the LC MS/MS technique. One hundred percent of poultry samples were contaminated with FB1, and the highest levels were detected in pelleted finisher poultry. AFB1, gliotoxin, DAS, HT-2 toxin, and T-2 toxin were not detected in any poultry feed. The scarcity of available mycotoxicological studies from Argentinean poultry feed using a multitoxin analysis technique enhances the contribution of the findings of this report.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Argentinian poultry production has been growing considerably in the recent past and is expected to continue expanding in the near future. Poultry feed is one of the most important components in the modern systems of production (Secretaría de Agricultura Ganadería y Pesca 2007). Their composition includes mixtures of different raw materials such as home-grown cereals, mainly corn grains and soybeans, plus other additives. The toxigenic fungal contamination of the raw materials occurs during the pre-harvest and/or the post-harvest periods, and the finished feeds are also exposed during production, processing, transportation, and storage. Temperature and humidity play an important role not only in the development of fungi but also in mycotoxin production (Magan and Aldred 2007). The occurrence of Aspergillus spp. and Fusarium spp. is widespread in tropical countries, and they have also been observed in feeds from Argentina (Okoli et al. 2006; Magnoli et al. 2002, 2005). In particular, they have been associated with cereals and animal feed-based cereals, and comprise several species which are mycotoxin producers and therefore have adverse effects on human and animals, resulting in illness and economic losses (Hussein and Brasel 2001).

Aflatoxins (AFs) are by far the most studied group of mycotoxins and their production is attributed to Aspergillus flavus and A. parasiticus. Aflatoxin B1 (AFB1) is the most potent natural carcinogen known and is classified by the International Agency of Research on Cancer as a Group 1 carcinogen (International Agency for Research on Cancer 1993). In poultry, AFs produce hepatic and kidney disorders, suppress immune function, and decrease productive parameters. Pale, enlarged, friable, and fatty livers are characteristic of acute aflatoxicosis in poultry (Council of Agriculture, Science and Technology 2003).

Fumonisins (FBs) are mycotoxins produced mainly by Fusarium verticillioides and F. proliferatum. Among the naturally occurring FBs, fumonisin B1 (FB1) is usually the most abundant and represents about 70% of the total concentration in corn and feeds. The studies of the effects of this toxin in poultry began in the last decade. Its occurrence in corn and poultry feeds has been associated with poor feed conversion, hepatotoxicity, impaired disease immunity, diarrhea, increase in organ weight, total body weight decrease, and increased susceptibility to environmental and microbial agents (Fandohan et al. 2003).

Several species of Fusarium are aggressive plant pathogens and have found to be trichothecenes producers. Among them, F. sporotrichioides and F. poae are the most frequent producers of T-2 toxin and diacetoxyscirpenol (DAS), whereas F. crookwellense, F. culmorum, F. graminearum, and F. sambucinum produce DAS and deoxynivalenol (DON or vomitoxin). Oral lesions in poultry are the primary means of diagnosing trichothecenes toxicoses in the field. In addition, asthenia and diarrhea decrease of the growth rate as well as egg production, and immunotoxicity has also been observed (Bennett and Klich 2003; Eriksen and Pettersson 2004; Iheshiulor et al. 2011). The most prevalent mycotoxins of the trichothecene group detected in agricultural products contaminated with Fusarium species were T-2 toxin and DON (Labuda et al. 2005; Lincy et al. 2008). Diacetoxyscirpenol was reported as a co-occurring mycotoxin though in trace amounts (Labuda et al. 2005).

Several studies have shown the prevalence of toxigenic mycobiota in poultry feeds from many countries and AFs and FBs as the most frequent mycotoxins (Shetty and Bhat 1997; Siame et al. 1998; Ali et al. 1998; Scudamore et al. 1998; Accensi et al. 2004; Oliveira et al. 2006; Rosa et al. 2006, Osho et al. 2007). On the other hand, previous studies reported that A. flavus and F. verticillioides isolated from poultry feeds were the main AFs and FBs producers in Argentina, and AFs, FBs, zearalenone (ZEA), DON, and ochratoxin A (OTA) were the prevalent mycotoxins (Dalcero et al. 1997, 1998, 2002; Magnoli et al. 2002, 2005).

In recent years, LC-MS/MS multi-analyte methods have been applied as useful tools to monitor the range of mycotoxins potentially occurring in moldy food and feed products. This technique provides an easy assessment of the risk that these compounds pose to human and animal health. Therefore, the aims of the present work were: (1) to determine the mycobiota present in raw materials and finished poultry feed, as well as the ability of A. flavus isolated strains to produce aflatoxin B1, and (2) to evaluate the natural co-occurrence of AFB1, FB1, gliotoxin, DAS, HT-2 toxin, and T-2 toxin in poultry feed by LC-MS/MS over a sampling period of 12 months

Materials and methods

Sampling

Samples were collected in a feed-processing plant located in Río Cuarto, Cordoba Province, Argentina. A total of 148 samples including poultry feed (108 samples of different types of feeds: starter and finisher, either ground or pelleted) and corresponding raw materials (10 samples of each of the following feedstock: corn grains, soy pellets, soybean off and meat meal) were analyzed. Soybean off refers to soybeans that have been treated to deactivate anti-nutritional factors. Poultry feed samples were collected at random every month during a year between August 2008 and July 2009, and raw materials were collected from October 2008 to July 2009

Sampling was performed manually from the silos in transects at three levels (upper, middle and low). At each site, two sub-samples of 2 kg each were collected. In the laboratory, samples were homogenized and quartered to obtain 1-kg primary samples. These samples were finely ground, immediately analyzed for moisture content and fungal contamination, and then stored at 4°C for mycotoxin analyses.

Moisture content of samples

Water activity (aw) determinations of the samples were carried out with AQUALAB CX2 (Decagon Devices, Pullman, WA, USA) and calibration was performed before sample measurements. Before calibrating, Aqua Lab was located in an area with a stable ambient temperature and the reference humidity standards were at room temperature. New sample cups for the reference humidity standards were used. Sodium chloride (NaCl) which has 0.760 aw was used as humidity standard and its aw was compared with the table in the operator’s manual. Readings of the humidity standard were within the stated ranges, and duplicate readings of distilled water were made.

Mycobiota isolation and identification

Quantitative enumeration of fungal propagules was done on solid media using the surface spread method by blending 10 g of each sample with 90 ml of 0.1% peptone water solution for 30 min. Serial dilutions from 10−1 to 10−3 concentrations were made and 0.1-ml aliquots were inoculated in triplicate on two culture media: Dichloran Rose Bengal Chloranphenicol Agar (DRBC) and Dichloran 18% Glycerol Agar (DG18) (Pitt and Hocking 1997). The plates were incubated in darkness at 25°C for 7 days. On the last day of incubation, only plates containing 10–100 colonies were used for counting, and the results were expressed as colony-forming units (CFU) per gram of sample (King 1992). Each colony of Aspergillus section Flavi and Fusarium genus was transferred on Malt Extract Agar (MEA) and Carnation Leaf Agar (CLA), respectively. Taxonomic identification of Aspergillus section Flavi species was achieved through macroscopic and microscopic studies following the schemes proposed by Klich (2002). In the case of Fusarium species the identification was performed according to Nelson et al. (1983) and Leslie and Summerell (2006). The results were expressed as fungal counts and frequency (percentage of samples in which each species was present).

Aflatoxin production by Aspergillus flavus strains

Ninety-seven A. flavus strains (37 isolated from raw materials and 60 from poultry feeds) were evaluated for their ability to produce AFs following the methodology described by Geisen (1996). This technique was done by screening of aflatoxigenic capacity of the isolated strains. The strains were grown in MEA at 25°C for 7 days in darkness, after which mycelium and conidia were collected from the agar surface with a sterile brush and transferred to microtubes. Aflatoxins were extracted with chloroform (500 μl) and centrifuged at 896g for 10 min. The chloroform phase was transferred to a clean microtube, evaporated to dryness, and stored until AFs analysis. The chloroformic extracts were spotted together with standard solutions of AFB1, aflatoxin B2 (AFB2), aflatoxin G1 (AFG1), and aflatoxin G2 (AFG2) (Sigma Chemical, St. Louis, MO, USA) and screened by thin layer chromatography (TLC). Silica gel plates without fluorescent indicator (0.25 mm, G60; Merck, Buenos Aires, Argentina), and chloroform:acetone (9:1, v/v) as developing solvent were used. Plates were then examined under long-wave UV light (365 nm) and AFs concentrations were determined throughout visual comparison with standard solutions. The detection limit of the analytical method was 1 μg g−1.

Assay of spiking and recovery of mycotoxins from poultry feed

The mycotoxins AFB1, FB1, gliotoxin, DAS, HT-2 toxin, and T-2 toxin were obtained from Sigma-Aldrich Chemical (Dorset, UK). Stock and working solutions were prepared in acetonitrile.

In order to determine the efficacy of the analytical method, recovery studies were performed as follows: poultry feeds samples (0.5 g) were fortified at two spiking levels with 1 mL of a combined mycotoxins working solution. Each spiking level was conducted by triplicate. The samples were subsequently stored for 3 days at 40°C to allow equilibration between the analytes and the matrix and also solvent evaporation. After this period of time, mycotoxin extraction was performed. Matrix blank extraction was also included for comparison

Extraction and detection of mycotoxins from poultry feed

Mycotoxin extraction and detection were performed according to Sulyok et al. (2007). Briefly, 2 mL of extraction solvent (acetonitrile/water/acetic acid 79:20:1, v/v/v) was added to the samples and extracted for 90 min using a GFL 3017 rotary shaker (Vicking model DUBNOFF). Samples were subsequently centrifuged for 2 min at 1,512g (Rolco SRL). The extracts (1 mL) were transferred into glass vials using Pasteur pipettes and were diluted with the same volume of dilution solvent (acetonitrile/water/acetic acid 20:79:1, v/v/v). After appropriate mixing, 50 μL of the diluted extracts were injected into the LC-MS/MS system without further treatment. Results were not corrected by recovery. Table 1 shows calibration curve data, contamination and recovery levels, and detection and quantification limits of each mycotoxin.

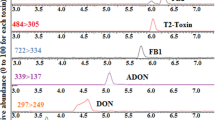

All LC-MS/MS analyses were performed using a Waters 2695 Alliance HPLC (Waters, Milford, MA, USA) equipped with a Waters Alliance 2685 pump, a Waters Alliance 2695 autosampler, and a diode array detector Waters 2996 PDA interfaced to a Quattro Ultima Platinum tandem quadrupole mass spectrometer with electrospray ionization (ESI) source. An XBridge™ C18 (3.5 μm, 2.1 × 150 mm) column with a guard column was used. The mobile phase of the chromatographic procedure was a gradient of aqueous 1% acetic acid/5 mM ammonium acetate (solvent A) and 0.1% methanol/1% acetic acid/5 mM ammonium acetate (solvent B). The program gradient is shown in Table 2. The flow rate was 0.2 mL/min. The temperature of column was kept at 22°C. For the sake of sensitivity, the most abundant trace in the multiple reaction monitoring (MRM) mode was used for quantitative analysis. Retention time differences lower than 0.05 min relative to toxin standards together with two precursor/product ion transitions were considered for qualification. The interfaces were operated in a positive ion mode. Nitrogen gas was used for both nebulization and desolvation heated to 150 and 200°C, respectively. The capillary voltage was 3.00 kV. The nitrogen flow was adjusted to 104 and 678 L/h for cone and desolvation gases, respectively. The MRM transitions and experimental conditions are shown in Table 3. Dwell time was set at 0.1 ms for all transitions. Data acquisition and processing were performed using Mass Lynx V.4.1 software (Waters).

Statistical analyses

Data were analyzed with analysis of variance. Means were compared using a linear mixed model and Fisher’s protected least significant difference (LSD) test to determine the significant differences among means of water activities, fungal counts, percentage of samples contaminated by A. flavus, Fusarium species, and presence of mycotoxins in raw materials and poultry feeds (p < 0.05). Principal component analysis (PCA) of the data was carried out in order to determine the relationships among water activities, fungal counts, and mycotoxin levels in raw materials and different types of terminated poultry feeds (Quinn and Keough 2002). The analysis was conducted using software InfoStat (2008 version; group InfoStat, National University of Córdoba, Argentina).

Results

Mycobiota contamination

Water activity of the samples throughout the sampling period ranged from 0.534 to 0.694 in raw materials and from 0.541 to 0.637 in poultry feeds, respectively. Statistical analyses demonstrated that lowest levels of aw (mean 0.550) were obtained from meat meal and pelleted finisher poultry feed samples. No significant differences were observed among the rest of the raw materials and poultry feeds (p < 0.05) (data not shown).

Analysis of total fungal counts from raw materials and poultry feed samples did not show significant differences between media. The means of fungal total counts of raw materials ranged from 2 × 103 to 2 × 106 CFU g−1. Highest fungal total counts were observed in corn samples (in the order of 106 CFU g−1). No statistical significant differences were observed between meat meal and soy pellets (p < 0.05). The lowest counts were found in soybean off (in the order of 104 CFU g−1) (Fig. 1a). The fungal total counts in poultry feeds varied depending on month of sampling and the special feed type, and the means varied from 103 to 107 CFU g−1. In general, ground starter poultry feed samples showed higher counts than those observed in finisher feed samples either ground or pelleted. All feeds, except finisher pelleted type collected in August, December and February, exceeded the values of 1 × 104 CFU g−1(Fig. 1b–d).

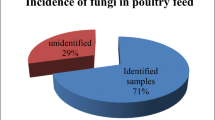

Aspergillus flavus was the only species belonging to section Flavi isolated from raw materials and terminated poultry feeds. Three Fusarium species were found: F. verticilliodes was the prevalent in all samples, followed by F. proliferatum (33.3%) and F. subglutinans (16.6%). The last two species were only isolated from poultry feeds. Figure 2 shows the frequency of A. flavus and F. verticillioides in raw materials. The frequency of A. flavus varied from 40 to 100% depending on culture medium. The highest frequencies were found in meat meal and soy pellet samples. From the Fusarium genus, F. verticillioides was isolated in 100% of the meat meal samples (in DG18), and in corn grains and soy pellets (in both media), while lower frequencies were observed in soybean off samples (25 and 50%).

With regard to finisher feeds, A. flavus was isolated only in some months of sampling from starter and finisher ground poultry and the frequency of contaminated samples varied from 20 to 100% and 40 to 100%, respectively. On the contrary, this species was isolated all months of sampling, except to November (2008), June and July (2009), from pelleted finisher poultry; and the frequency of contaminated samples was 100% from December (2008) to May (2009) (Fig. 3).

From the Fusarium genus, F. verticillioides was isolated from 100% from all poultry feed samples, except in some months of sampling. In August, this species was isolated in 80–90% of the samples in both media from all feeds. In February, the percentages of contaminated samples were 90 and 50% from ground starter and pelleted finisher poultry, respectively. While in July, only 33% of pelleted finisher samples contained this species (data not shown).

Aflatoxin production by Aspergillus flavus strains

Table 4 shows the potential aflatoxigenic of A. flavus strains in raw materials and poultry feeds. The distribution of AFs producer strains varied according to the type of feed. From 97 tested strains, 46 (47%) were AFB1 producers with levels ranged from <1.0 to 20.6 μg g−1. The highest frequency of aflatoxigenic strains was isolated from poultry feed samples.

Mycotoxins determination

Clean chromatograms of each mycotoxin naturally contaminated poultry feed samples were obtained. One hundred percent of poultry feed samples were contaminated with FB1, in levels ranging from 26.30 to 859.18, 37.4 to 825.2, and 41.6 to 217.2 μg kg−1 from ground starter, ground finisher, and pelleted finisher feed, respectively. The highest levels of FB1 were detected in pelleted finisher feed samples (p < 0.05). Aflatoxin B1, gliotoxin, DAS, HT-2 toxin, and T-2 toxin were not detected in any poultry feed sample; see limit of detection (LOD) of the particular technique in Table 1.

Multivariate statistical analysis

Figure 4 shows the bi-plot for principal component analysis (PCA) in order to determine the influence of type of raw materials or poultry feed on aw, total fungal counts, A. flavus and F. verticillioides counts, and FB1 levels. As can be observed, corn grains (C) are closely related to total fungal and Fusarium counts. This positive relationship suggests that total fungal and Fusarium spp. counts in finisher feed samples might come mainly from corn grains. Regarding meat meal (MM) at high aw, a closely relationship is then observed between this raw material and Aspergillus counts. A defined behavior pattern among the variables assayed in soy pellets and soybean off was not observed (Fig. 4a). Regarding poultry feeds, in both ground starter and finisher poultry (GSP and GFP), the variable aw diminished as Aspergillus spp. counts increased, and a positive relationship between aw, total fungal and Fusarium spp. counts was observed (Fig. 4b). In contrast, in pelleted finisher poultry (PFP) samples, a negative relationship between aw and Aspergillus spp. counts was observed.

Biplot graph with principal component analysis (PCA) for the variables in this study (aw, total fungal, A. flavus and F. verticillioides counts, and FB1 levels) in relation to feed type. C corn grains, MM meat meal, SO soybean off, SP soy pellets, GFP ground finisher poultry feed, PFP pelleted finisher poultry feed, GSP ground starter poultry feed, (a) raw materials, (b) poultry feeds

Discussion

This study shows the presence of toxigenic species belonging to Aspergillus section Flavi and Fusarium species in raw materials and finisher poultry feeds. It has been demonstrated that fungal propagules are helpful indicators of the hygienic quality of feeds. The latest regulations for feeds establish a maximum value of 1 × 104 CFU g−1 to assure a good hygienic quality of the product (Good Manufacturing Practices 2008). In this study, 19% of raw materials and a quite high percentage of finisher poultry feed samples (79%) exceeded the maximum allowed. These results suggest a high fungal activity which could affect both the organoleptic properties and nutritive quality of the feed. These results are similar to those obtained earlier from the same substrate (Accensi et al. 2004; Dalcero et al. 1998; Magnoli et al. 2005; Rosa et al. 2006; Krnjaja et al. 2008; Shareef 2010; Astoreca et al. 2011). In these reports, some counts were higher than 105 CFU g−1. However, Magnoli et al. (2002), Oliveira et al. (2006), Fraga et al. (2007), and Lincy et al. (2008) found moderate values ranging from 103 to 104 CFU g−1 in all samples. No significant differences in fungal counts were observed between the general DRBC medium which reflects the total fungal count and DG18 which showed high counts of moderately xerophilic fungi such as Aspergillus spp. Similar data were observed by Fraga et al. (2007) from samples of maize and poultry feeds.

Poultry feeds undergo a pelleting process during their fabrication (usually 115°C, 60 min). The fungal counts and frequency of Fusarium and Aspergillus species suggest a fungal resistance to the manufacturing practices and/or the potential contamination after feed elaboration, packing, or storage of finisher product. In this study, the total fungal counts detected in pelleted finisher poultry were significantly lower than those observed in other feeds not subject to the pelleting process (ground starter and finisher poultry). This finding agrees with previous studies (Chelkowski 1991; Dalcero et al. 2002) which reported that fungal counts decreased significantly when the pelleting process was carried out. In contrast with the present results, Fraga et al. (2007) reported that any Brazilian poultry feed samples collected after this process showed fungal contamination, and the counts were below 100 CFU g−1. In the present work, a high frequency of A. flavus has been observed in pelleted finisher poultry. In agreement with these results, in previous work, this species has also been isolated in commercial pet feeds after this process (Fernández-Juri et al. 2009; Campos et al. 2009). In addition, F. verticillioides was the most frequent species isolated, followed by A. flavus during this sampling period, both in corn and finisher feeds, suggesting that this species also tolerates the pelleting process. In contrast, A. flavus was reported as the prevalent species followed by F. verticilliodes (Rosa et al. 2006; Labuda and Tančinová 2006; Oliveira et al. 2006; Saleemi et al. 2010). F. verticillioides and F. proliferatum are commonly isolated from maize throughout the world, and are also recognized by their capacity to produce FBs (Fandohan et al. 2003; Glenn 2007). Fusarium is one of the major fungal genera associated with maize in Argentina. In previous years, F. verticillioides, F. proliferatum, and FB1 were mainly detected in corn grain (Ramirez et al. 1996; Solovey et al. 1999; González et al. 1999; Torres et al. 2001; Pacin et al. 2009). With respect to other species isolated in the present work, F. subglutinans has not been recognized as a producer of high levels of FBs, but in recent years, its capacity to produce other mycotoxins such as moniliformin and beauvericin has been demonstrated (Jestoi 2011). The presence of F. subglutinans in poultry feeds leads to the possibility of finding samples contaminated with these toxins.

In the present study, 47% of the A. flavus strains were AFB1 producers. The incidence of aflatoxigenic strains found in the present study is similar to that reported in previous work in Argentina and Brazil (Magnoli et al. 1999; Fraga et al. 2007), and the levels produced are relatively lower than those reported by other authors in poultry feeds (Saleemi et al. 2010; Astoreca et al. 2011). The presence of aflatoxigenic strains suggests the potential risk of AFs production in raw materials or feeds if storage conditions are inadequate.

The prevalent species isolated in this study, A. flavus and F. verticillioides, produce mycotoxins of greater concern for poultry health. In general, relatively low water content present in stored products is most often related with Aspergillus spp. growth (Krnjaja et al. 2008), while F. verticillioides and F. proliferatum presence in substrates such as corn grains are related to high water content (Samapundo et al. 2005). In the present study, a positive relationship between F. verticillioides and FB1 has not been detected. However, positive relationships between high aw level and Fusarium spp. counts and low aw levels and Aspergillus counts have been found in some samples.

Regarding the mycotoxin contamination, FB1 was present in all poultry feed samples, while AFB1, gliotoxin, DAS, HT-2 toxin, and T-2 toxin were not detected. In previous sampling in Argentina, the presence of AFB1, ZEA, DON, OTA, and FBs were reported in this substrate, and FB1 levels were lower than those detected in the present work (Dalcero et al. 1997, 1998, 2002; Magnoli et al. 2002). In any sample, the FBs levels exceeded the maximum tolerable limit (20 mg FB1 + FB2 kg−1) established for avian feeds by the European Commission (UE 2007). The presence of FB1 in finished feeds may be explained by considering that FBs in processed corn products for poultry consumption vary depending on cultivar growth conditions, and then are also influenced by environmental factors such as temperature, humidity, and rainfall during pre-harvest and harvest periods. Then, while in storage, these mycotoxins can be produced when the air humidity is appropriate (Bacon and Nelson 1994).

Recently, Astoreca et al. (2011) reported the co-occurrence of AFB1 and cyclopiazonic acid in 16% of poultry feed samples. A few surveys have reported the natural occurrence of trichothecenes such as T-2 toxin, HT-2 toxin, and DAS in poultry feeds. Labuda et al. (2005) reported the presence of ZEA and trichothecenes in Slovakia. The most frequent mycotoxin detected was T-2, which was found in 90% of the samples in relatively low concentrations (1–130 μg/kg), followed by ZEA that was found in 88%. Lower frequencies were observed with HT-2 and DON (76 and 56%, respectively) with contamination levels ranging from 2 to 173 μg/kg and 64 to 1,230 μg/kg, respectively. A combination of four simultaneously co-occurring mycotoxins, i.e. T-2, HT-2, ZEA, and DON, was found in 44% of the samples. In another study from India, T-2 toxin and trichothecenes producing Fusarium were detected only in just 1 sample out of 40, by PCR assays from poultry feed (Lincy et al. 2008). A small number of poultry feed samples from Croatia contained T-2 toxin and DAS. Positive samples were correlated with evident clinical symptoms of toxicosis in poultry (Sokolovic and Simpraga 2006). In contrast, in the present sampling period, trichothecenes and Fusarium producer species were not detected, although F. graminearum and DON have been previously detected in Argentinean poultry feeds (Dalcero et al. 1997, 1998).

Previous surveys have shown that mycotoxin contamination depends on the location and the particular year (Dalcero et al. 1997, 1998, 2002; Magnoli et al. 2002). Marked differences in terms of FBs contamination were observed for the same maize variety between two consecutive growing seasons in Argentina (Hennigen et al. 2000). Differences in environmental conditions from one season to another might be responsible for mycotoxin contamination of poultry feed. According to the Argentina Meteorological Service reports, the period from August 2008 to July 2009 were extremely dry and warm (Servicio Meteorológico Nacional 2007). Therefore, the lack of trichothecenes in the sampling period could be explained because their production is favored at low temperatures and high air humidity.

Although each mycotoxin is produced under specific environmental conditions, during the storage the available water and the temperature play a key role in controlling mycotoxin production. In general, due to their composition, feeds are, at high moisture (>12%) and temperature, an excellent substrate for the growth of fungi.

Taking into account that mycotoxicoses affect health and production efficiency and cause economic losses, this survey shows that Aspergillus and Fusarium species represent a potential toxicological risk and should be regarded as a potential source of mycotoxins. Because there is a wide range of different mycotoxins with different chemical structures that can sporadically occur in agricultural-based feeds, a regular monitoring of toxigenic mycobiota and the application of methodologies for detecting multiple mycotoxins is becoming an essential pre-requisite for the development of strategies to control or prevent mycotoxin exposure in the ploutry industry. The scarcity of available mycotoxicological studies from Argentinean poultry feed using a multitoxin analysis technique enhances the contribution of the findings of this report.

References

Accensi F, Abarca ML, Cabañes FJ (2004) Occurrence of Aspergillus species in mixed feeds and component raw materials and their ability to produce ochratoxin A. Food Microbiol 21:623–627

Ali N, Sardjono S, Yamashita A, Yoshizawa T (1998) Natural co-occurrence of aflatoxins and Fusarium mycotoxins (fumonisins, deoxynivalenol, nivalenol and zearalenone in corn from Indonesia. Food Addit Contam 15:377–384

Astoreca AL, Dalcero AM, Fernández Pinto V, Vaamonde G (2011) A survey on distribution and toxigenicity of Aspergillus section Flavi in poultry feeds. Int J Food Microbiol 146:38–43

Bacon CW, Nelson PE (1994) Fumonisin production in corn by toxigenic strains of Fusarium moniliforme and F. proliferatum. J Food Prot 57:915–917

Bennett JW, Klich M (2003) Mycotoxins. Clin Microbiol Rev 16:497–516

Campos A, Da Costa G, Coelho AV, Fevereiro P (2009) Identification of bacterial protein markers and enolase as a plant response protein in the infection of Olea europaea subsp. europaea by Pseudomonas savastanoi pv. Savastanoi. Eur J Plant Pathol 125:603–616

Chelkowski J (1991) Mycological quality of mixed feeds and ingredients. In: Chelkowski J (ed) Cereal grain, mycotoxins, fungi and quality in drying and storage. Developments in food science. Elsevier, Amsterdam, pp 217–228

Council of Agriculture, Science and Technology (2003) Mycotoxins: risks in plant, animal, and human systems. Council of Agriculture, Science and Technology, Ames, IA

Dalcero AM, Magnoli C, Chiacchiera S, Palacios G, Reynoso M (1997) Mycoflora and incidence of aflatoxin B1, zearalenone and deoxynivalenol in poultry feeds in Argentina. Mycopathologia 137:179–184

Dalcero AM, Magnoli C, Luna M, Ancasi G, Reynoso M, Chiacchiera S, Miazzo R, Palacios G (1998) Mycoflora and naturally ocurring mycotoxins in poultry feeds in Argentina. Mycopathologia 141:37–43

Dalcero A, Magnoli C, Hallak C, Chiacchiera SM, Palacio G, Da Rocha Rosa CA (2002) Detection of ochratoxin A in animal feeds and capacity to produce this mycotoxin by Aspergillus section Nigri in Argentina. Food Addit Contam 19:1065–1072

Eriksen GS, Pettersson H (2004) Toxicological evaluation of trichothecenes in animal feed. Anim Feed Sci Technol 114:205–239

Fandohan P, Hell K, Marasas WFO, Wingfield MJ (2003) Infection of maize by Fusarium species and contamination with fumonisin in Africa. Afr J Biotechnol 2:570–579

Fernández-Juri MG, Bressán F, Astoreca AL, Barberis CL, Campos Gaspar S, Cavaglieri LR, Dalcero AM, Magnoli CE (2009) Mycotoxicological quality of different commercial extruded dog food in Argentina. Rev Bras Med Vet 31:272–281

Fraga ME, Curvello F, Gatti MJ, Cavaglieri LR, Dalcero AM, Rosa CAR (2007) Potential aflatoxins and ochratoxin A production by Aspergillus species in poultry feed processing. Vet Res Comm 31:343–353

Geisen R (1996) Multiplex polymerase chain reaction for the detection of potential aflatoxin and sterigmatocystin producing fungi. Syst Appl Microbiol 19:388–392

Glenn AE (2007) Mycotoxigenic Fusarium species in animal feed. Anim Feed Sci Technol 137:213–240

Good Manufacturing Practices (2008) Certification Scheme Animal Feed Sector, 2006. Appendix 1: Product standards (including residue standards). Productschap Diervoeder, The Hague, pp 1–39

González HH, Martínez EJ, Pacin AM, Resnik SL, Sydenham EW (1999) Natural co-occurrence of fumonisins, deoxynivalenol, zearalenone and aflatoxins in field trial corn in Argentina. Food Addit Contam 16:565–569

Hennigen MR, Valente Soares LM, Sanchez S, Di Benedetto NM, Longhi A, Eyhérabide G, Torroba J, Zanelli M (2000) Fumonisin in corn hybrids grown in Argentina for two consecutive seasons. In: De Koe WJ, Samson RA, van Egmond HP, Gilbert J, Sabino M (eds) Proceeding of the Xth international IUPAC symposium on mycotoxins and phycotoxins. 21–25, May 2000. Guaruja, Brazil, pp 331–339

Hussein SH, Brasel MJ (2001) Toxicity, metabolism and impact of mycotoxins on humans and animals. Toxicology 167:101–134

Iheshiulor OOM, Esonu BO, Chuwuka OK, Omede AA, Okoli IC, Ogbuewe IP (2011) Effects of mycotoxins in animal nutrition: A review. Asian J Anim Sci 5:19–33

International Agency for Research on Cancer (1993) Evaluation of carcinogenic risks of chemical to humans. Some naturally-occurring substances: Food Items and Constituents. Heterocyclic aromatic amines and mycotoxins. IARC Monographs, vol. 56. Lyon, pp 359–362

Jestoi M (2011) Emerging Fusarium mycotoxins fusaproliferin, beauvericin, enniatins, and moniliformin -a review. Crit Rev Food Sci Nut 48:21–49

King AD (1992) Methodology for routine mycological examination of food. In: Samson RA, Hocking AD, Pitt JI, King AD (eds) Modern methods in food mycology. Developments in food science. Elsevier, Amsterdam, pp 11–20

Klich MA (2002) Identification of common Aspergillus species. Centraalbureau voor Schimmelcultures, Utrecht

Krnjaja V, Stojanović Lj, Cmiljanić R, Trenkovski S, Tomašević D (2008) The presence of potentially toxigenic fungi in poultry feed. Biotechnol Anim Husband 24:87–93

Labuda R, Parich A, Berthiller F, Tancinová D (2005) Incidence of trichothecenes and zearalenone in poultry feed mixtures from Slovakia. Int J Food Microbiol 105:19–25

Labuda R, Tančinová D (2006) Fungi recovered from Slovakian poultry feed mixtures and their toxinogenity. Ann Agric Environ Med 13:193–200

Leslie J, Summerell B (2006) The Fusarium laboratory manual. Blackwell, USA

Lincy SV, Latha R, Chandrashekar A, Manonmani HK (2008) Detection of toxigenic fungi and quantification of type A trichothecene levels in some food and feed materials from India. Food Cont 19:962–966

Magan N, Aldred D (2007) Post-harvest control strategies: Minimizing mycotoxins in the food chain. Int J Food Microbiol 119:131–139

Magnoli C, Saenz M, Chiacchiera S, Dalcero A (1999) Natural occurrence of Fusarium species and fumonisin-production by toxigenic strains isolated from poultry feeds in Argentina. Mycopathologia 145:35–41

Magnoli C, Chiacchiera S, Miazzo R, Palacio G, Angeletti A, Hallak C, Dalcero A (2002) The mycoflora and toxicity of feedstuffs from a production plant in Córdoba, Argentina. Mycotoxin Res 18:7–22

Magnoli C, Hallak C, Astoreca A, Ponsone L, Chiacchiera SM, Palacio G, Dalcero A (2005) Surveillance of toxigenic fungi and ochratoxin A in feedstuffs from Córdoba province, Argentina. Vet Res Comm 29:431–445

Nelson PE, Toussoun TA, Marasas WFO (1983) Fusarium species. An illustrated manual for identification. Pennsylvania State University Press, University Park, PA

Okoli IC, Nweke CU, Okoli CG, Opara MN (2006) Assessment of the mycoflora of commercial poultry feeds sold in the humid tropical environment of Imo State, Nigeria. Int J Environ Sci Tech 3:9–14

Oliveira GR, Ribeiro JM, Fraga ME, Cavaglieri LR, Direito GM, Keller KM, Dalcero AM, Rosa CA (2006) Mycobiota in poultry feeds and natural occurrence of aflatoxins, fumonisins and zearalenone in the Rio de Janeiro State, Brazil. Mycopathologia 162:355–362

Osho IB, Awoniyi TAM, Adebayo AI (2007) Mycological investigation of compounded poultry feeds used in poultry farms in southwest Nigeria. Afr J Biotechnol 6:1833–1836

Pacin AM, Ciancio Bovier E, González HH, Whitechurch EM, Martínez EJ, Resnik SL (2009) Fungal and fumonisins contamination in Argentine maize (Zea mays L.) silo bags. J Agric Food Chem 57:2778–2781

Pitt JI, Hocking AD (1997) Fungi and food spoilage, vol II. Blackie, London

Quinn GP, Keough MJ (2002) Experimental design data analysis for biologists. Cambridge University Press, Cambridge

Ramirez ML, Pascale M, Chulze S, Reynoso MM, March G, Visconti A (1996) Natural occurrence of fumonisins and their correlation to Fusarium contamination in commercial corn hybrids growth in Argentina. Mycopathologia 135:29–34

Rosa CAR, Ribeiro JMM, Fraga MJ, Gatti M, Cavaglieri LR, Magnoli CE, Dalcero AM, Lopes CWG (2006) Mycoflora of poultry feeds and ochratoxin-producing ability of isolated Aspergillus and Penicillium species. Vet Microbiol 113:89–96

Saleemi MK, Khan MZ, Khan A, Javed I (2010) Mycoflora of poultry feeds and mycotoxins producing potential of Aspergillus species. Pak J Bot 42:427–434

Samapundo S, Devliehgere F, De Meulenaer B, Debevere J (2005) Effect of water activity and temperature on growth and the relationship between fumonisin production and the radial growth of Fusarium verticillioides and Fusarium proliferatum on corn. J Food Prot 68:1054–1059

Scudamore KA, Nawaz S, Hetmanski MT (1998) Mycotoxins in ingredients of animal feeding stuffs: II determination of mycotoxins in maize and maize products. Food Addit Contam 15:30–55

Secretaría de Agricultura Ganadería y Pesca (2007) Perfiles productivos Sector Avícola Dirección Nacional de Alimentos. http://www.alimentosargentinos.gov.ar/revistas/cadenas/carnesproduccionavicola.htm. Accessed 28 May 2011

Servicio Meteorológico Nacional (2007) Informe sobre condiciones climáticas predominantes durante 2009 en las zonas afectadas por la falta de lluvias y altas temperaturas. http://www.smn.gov.ar. Accessed 28 May 2011

Shareef AM (2010) Molds and mycotoxins in poultry feeds from farms of potential mycotoxicosis Iraqi J Vet Sci 24:17–25

Shetty PH, Bhat RV (1997) Natural occurrence of fumonisin B1 and aflatoxin B1 in Indian sorghum, maize and poultry feeds. J Agric Food Chem 45:2170–2173

Siame BA, Mpuchane SE, Gashe BA, Allotey GF, Teffera G (1998) Occurrence of aflatoxins, fumonisin B1 and zearalenone in foods and feeds in Botswana. J Food Prot 61:1670–1673

Sokolovic M, Simpraga B (2006) Survey of trichothecene mycotoxins in grains and animal feed in Croatia by thin layer chromatography. Food Cont 17:733–740

Solovey MM, Somoza C, Cano G, Pacin A, Resnik S (1999) A survey of fumonisins, deoxynivalenol, zearalenone and aflatoxins contamination in corn-based food products in Argentina. Food Addit Contam 16:325–329

Sulyok M, Krska R, Schuhmacher R (2007) A liquid chromatography/tandem mass spectrometric multi-mycotoxin method for the quantification of 87 analytes and its application to semi-quantitative screening of moldy food samples. Anal Bioanal Chem 389:1505–1523

Torres AM, Reynoso MM, Rojo FG, Ramirez ML, Chulze SN (2001) Fusarium species (section Liseola) and its mycotoxins in maize harvested in northern Argentina. Food Addit Contam 18:836–843

UE (2007) Regulation (EC) No 1126/2007 of 28 September 2007 setting maximum levels for certain contaminants in foodstuffs as regards Fusarium toxins in maize and maize products. Official Journal of the European Union L 255 of 29/09/2007, pp 14–17

Acknowledgements

This work was carried out thanks to grants from CONICET, SECYT-UNRC, FONCYT-PICT (Argentina).

Conflict of Interest

None.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Monge, M., Magnoli, C.E. & Chiacchiera, S.M. Survey of Aspergillus and Fusarium species and their mycotoxins in raw materials and poultry feeds from Córdoba, Argentina. Mycotoxin Res 28, 111–122 (2012). https://doi.org/10.1007/s12550-011-0121-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12550-011-0121-8