Abstract

Water inrush greatly endangers the safety of coal mining above aquifers. To quantify and evaluate the reduction in disaster risk and ensure the safety of coal mining above aquifers, a fuzzy analytic hierarchy process model based on the fuzzy theory and hierarchy structure was established to assess the risk of water inrush with grouting reinforcement. Four first-grade indices and 14 second-grade indices were chosen to define the fuzzy evaluation system based on a case study of the Chengjiao Coal Mine, China. The grouting effect and the fault complexity were quantified by the grouting amount and fractal dimension, respectively. A weighting set was derived by the hierarchical structure for the evaluation factors. Applying the principle of fuzzy relational synthesis from multiple factors, the evaluation vector was obtained by calculating the risk degree using the fuzzy operator based on the average membership degree of each index. A comparative analysis showed a close agreement between the grouting coefficient and water inrush coefficient and the low risk obtained from the fuzzy evaluation, proving that the grouting reinforcement effectively reduced the risk of water inrushes. The successful actual project has well verified that this method is scientific and rational, which fully takes the advantages from qualitative to quantitative and of high accuracy and universal application.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Water inrush greatly endangers the safety of coal mining above aquifers (Wang and Park 2003). Most of the coal mines located in the Permo-Carboniferous coalfields in China are seriously threatened by the presence of limestone aquifers under the coal seams (Zhang 2005; Lu and Wang 2015). The limestone aquifers are relatively close to the coal seam and contain a large volume of water with high hydraulic pressure (Zhang 2005; Zhu et al. 2008). While coal mining is conducted above aquifers, especially in karst terrains, some preexisting geological structures, such as faults, cavities, and sinkholes, may form channels for water inrush (Demiroglu 2016; Tang et al. 2011; Li et al. 2013). Moreover, the floor strata may be broken by both hydraulic and mining-induced pressure, and the addition of induced fractures in the strata enhances the hydraulic conductivity and eventually leads to large uncontrolled water inrushes (Demiroglu 2016; Yuan et al. 2016). Hundreds of water inrushes have occurred in coal mines in China since the 1950s, deeply affecting the safety of coal mine workers and production of coal; among such events, karst water inrush is the most serious (Meng et al. 2012; Gui et al. 2017). However, grouting has been widely used to reinforce aquifers to reduce the risk of water inrushes (Yang et al. 2017). Therefore, it is essential to accurately predict and assess the risk of water inrush through a coal seam floor to ensure the safety of coal mining above aquifers via grouting.

Varied methods and methodologies have been proposed to evaluate the risk of water inrush in coal mines, and corresponding geological and hydrogeological models (Bukowski 2011; Hu et al. 2019) and mathematical methods considering nonlinear theory (Wu et al. 2014; Wang et al. 2016) were established. A vulnerability index evaluation system combining analytic hierarchy process (AHP) and ANN with GIS was comprehensively established and successfully applied in the risk assessment of water inrush from aquifers overlaying individual coal seams and even multiple coal seams (Wu et al. 2008; Wu et al. 2011). Zhang et al. (2019) presented a mathematical assessment method for coal-floor water-inrush risk by integrating the hierarchy-variable-weight model (HVWM) with collaboration-competition theory (CCT), which is more reasonable than the VWM model. Li et al. (2013) proposed an attribute synthetic evaluation system to assess the risk of water inrush in karst tunnels and quantitatively classified the risk degree into 4 grades. Then, an improved attribute recognition model combined with the entropy weight method was established based on attribute mathematic theory via software to evaluate the risk of water inrush in a tunnel (Wang et al. 2019a). Moreover, fault tree analysis was adopted to analyze resource risk, which is of guiding significance in the prevention of water inrush in the process of coal production via scientific measures (Chen and Yang 2011). The multistage decision support framework and integrated decision support model have also been significantly investigated to effectively evaluate the risk degree in industrial regions and new energy resources (Nie et al. 2018; Peng et al. 2019).

With the development of a data network, the neural network and decision tree algorithms were studied by Liu et al. (2011) to build a prediction system for water inrush events through coal seam floors based on data mining classification techniques. GP analysis was also employed to optimize and predict the strength of rocks (Karakus 2011). Additionally, the fuzzy theory is widely used in the decision-making process for unknown and uncertain issues, such as risk assessment and performance evaluation (Tian et al. 2018). Karakus and Tutmez (2006) constructed the Mamdani fuzzy algorithm to predict the UCS of intact rock samples using a data-driven fuzzy model. A hybrid fuzzy multicriteria decision-making framework based on fuzzy image information to quantify the risk indices of energy performance contracting projects was formulated by Wang et al. (2018). Wang et al. (2012) constructed a secondary fuzzy comprehensive evaluation system including 4 first-grade indices and 13 second-grade indices based on fuzzy mathematics to evaluate the risk of floor water inrush in coal mines. Yang et al. (2017) developed a systematic method using GIS and fuzzy set theory combined with the entropy weight method to evaluate the risk of water inrush through a coal seam floor. A nonlinear fuzzy interval method combining AHP, consisting of a multi-index evaluation system and a computational model, was established for risk assessment of floor water inrush in coal mines by Wang et al. (2019b).

However, water inrush is significantly affected by various factors, such as the geological structures, mechanical properties, and permeability of floor strata and the thickness of the impermeable strata separating the coal seam from the confined aquifer, which mainly control and influence the occurrences of water inrush (Zhang 2005). Moreover, mining factors include the length and rate of the mining advance and the length of the mining face in the longwall mining system, which also significantly influence the stability of, in situ stress state of, and hydraulic pressure in the confined aquifer (Wang and Park 2003). Thus, the direct current resistivity method was widely used for the routine detection, advanced detection, and real-time monitoring of early-warning information for water inrush (Li et al. 2015), and the transparent soil method was widely applied to modeling the rock and soil structure (Yuan et al. 2019a, b). Considering the uncertainty in these influential factors, Chen et al. (2014) proposed a new assessment approach to evaluate coal mine safety by discriminatory weight. (Tian et al. 2018; Tian et al. 2019) established a consensus-based mathematical programming model to calculate the weights of decision-makers. Jin et al. (2011) proposed a warning criterion that includes stress, water temperature, and water pressure to predict water inrush through coal seam floors, and engineering practice has successfully verified this early warning technique. However, the geological conditions in China are extremely complex; in particular, faults are distributed widely and significantly affect underground activities (Li et al. 2019). Mining leads to the reactivation of faults and further enhances the permeability of the fault zone, potentially inducing water inrush disasters (Hu et al. 2014). Based on catastrophe theory, a mathematical model of the catastrophe fuzzy subordinate function was established via fuzzy mathematics, a multilayer contradiction decomposition of evaluation targets, to assess the water inrush risk induced by fault activation (Hua et al. 2011).

Generally, water inrushes from underlying aquifers are influenced by complex hydrogeological and mining conditions. In particular, the Chengjiao Coal Mine in China has experienced 2 water inrush accidents from underlying limestone aquifers in the Taiyuan Formation due to complex hydrogeological conditions. Both of these water inrushes were induced by faults in the mining panel and resulted in great economic losses. With the increase in the mining depth, the factors influencing the risk of water inrush become increasingly complex and uncertain, especially the high water pressure of the limestone aquifer and the amplification of a mining disturbance. Although grouting has been widely used to prevent this disaster, evaluating the grouting effect on the risk of water inrush during a continued mining operation is a challenge that ultimately restricts mine safety and efficient production. Therefore, it is urgent that the risk of water inrush from the underlying limestone aquifer after grouting reinforcement in the Chengjiao Coal Mine is quantitatively and accurately predicted and assessed. Previous studies simplified the influencing conditions or factors and failed to profoundly reveal the quantitative relation between water inrush and its affecting indices, while other studies exhibit some limitations despite their uniqueness approaches to managing the problem of water inrush.

In this study, a fuzzy hierarchy process model based on the theory of fuzzy mathematics and AHP was proposed to assess the water inrush disaster risk reduction due to grouting; this model fully takes into consideration the main indices affecting water inrush, produces quantitative and highly accurate results, and is universally applicable. Then, the weight of each index was calculated by the analytic hierarchy process (AHP). A fuzzy calculation was conducted to determine the risk degree of water inrush due to coal mining above aquifers in the Chengjiao Coal Mine. Finally, decision-making was achieved to assess the risk reduction due to grouting reinforcement in the Chengjiao Coal Mine, China. The comparative analysis of the grouting coefficient and water inrush coefficient effectively verified the efficiency and significance of the fuzzy comprehensive evaluation.

Method

Coal mining above aquifers is seriously threatened by water inrush, which is mainly controlled by the geological and hydrogeological conditions and mining activity. Then, a quantitative evaluation model for the risk of water inrush due to coal mining above aquifers with grouting reinforcement was established using the comprehensive fuzzy evaluation method combined with the AHP. Applying the principle of fuzzy relational synthesis of multiple factors, the comprehensive fuzzy evaluation method is characterized by a unique evaluation value for the judged object; this value is not affected by the set of judgment objects and can be used for quantitatively judging each indicator. Then, the weight of each impact indicator can be quantitatively calculated by the analytic hierarchy process (AHP). Finally, decision-making can be achieved using the fuzzy evaluation for the risk assessment of water inrush due to coal mining above aquifers in the Chengjiao Coal Mine. The evaluation steps are as follows.

- (1)

Establishing the set of evaluation factors

The evaluation factor set comprises various factors affecting the risk of water inrush and is defined as the first-grade set: U = {u1, u2,..., un}. Then, the first-grade set is divided into the second-grade set as ui = {F1, F2,..., Fn} and Fi = {f1, f2..., fn}, where U and F are the criteria and subcriteria evaluation indices, respectively.

- (2)

Defining the comment set for comprehensive evaluation

A comment set shows the possible outcomes for various indicators, which is defined as C = {c1, c2, c3,..., cn}, where C is the evaluation grade that characterizes the state in which each factor is located and n is the number of comments. Generally, the evaluation grade is divided into 3 to 5 levels. In this paper, the comment set is defined as C = {very low (I), low (II), mediate (III), high (IV), very high (V)} to determine the risk degree of disaster reduction.

- (3)

Calculating the weight vector of each factor

In the evaluation process, the weight is a measure of the relative importance of the factors. If the weight cannot be determined objectively, the evaluation result may be seriously distorted and may even lead to the incorrect judgment of the evaluator. This study uses the AHP method to quantitatively determine the weight of the evaluation factors through expertise judgment.

The AHP was first proposed by Saaty (1980) to select priorities. The AHP divides various factors of complex problems into interrelated and orderly levels and then organizes these levels. Additionally, this approach can directly and effectively combine the expert opinions and objective judgment results of an analyst based on a subjective evaluation structure and quantitatively describe the importance of every two elements at the same level. Then, the weights that reflect the relative importance order of the elements of each level are calculated using mathematical methods, and the relative weights of all the elements are calculated and sorted by the overall order among all the levels. The specific steps are as follows.

The first step is to establish a multilevel hierarchy structure, which divides the decision-making system into several hierarchical levels according to different goals and functional realizations. As mentioned in the fuzzy evaluation model, the evaluation factor set is essential to evaluate the influence degree of each factor on water inrush due to coal mining above aquifers. Specifically, the criteria and subcriteria influencing the water inrush are identified in this study.

In the second step, the correlation degree between adjacent hierarchical elements in the hierarchical structure must be determined by constructing a pairwise comparison evaluation matrix. According to Saaty’s scale (1987), the 9-point ratio describes the relative advantages and disadvantages of each evaluation index sequence, and then, the comparison matrices at each hierarchical level are established based on the expertise judgment. However, the consistency of such a matrix must be tested to ensure that it reaches a threshold level. The consistency index (CI) is calculated by Eq. (1).

where λmax is the largest principal eigenvalue of the matrix. If CI = 0, the consistency is uniform; otherwise, the larger CI is, the more serious the deviation in the consistency. Then, the consistency ratio (CR) values for comparison are calculated by Eq. (2), where RI is the random matrix listed in Table 1. Generally, if CR ≤ 0.1, the matrix can satisfy the consistency; otherwise, the comparison matrix should be reexamined.

The final step is to calculate the weights of each subcriterion and criterion at different hierarchical structures and determine the local ratings to the alternatives. Then, the total sorting is achieved by calculating the composite weights to determine the importance level of the total goal.

Then, the weight set of each factor, i.e., the weight vector, is represented by V = (v1, v2, v3, ..., vi), where vi >> 0, and ∑vi = 1, which reflects a trade-off for the factors.

- (1)

Fuzzy evaluation of a single factor and establishing the evaluation matrix

The single factor Fi (i = 1, 2, 3, ..., n) is first evaluated. The membership degree of the factor Fi to the evaluation level Cj is Dij, and then, the single factor of the ith factor Fi can be obtained as Di = (Di1, Di2, ..., Din). In this process, the determination of the membership degree is very important. This study uses the triangular fuzzy membership function to calculate the membership degree of the factors. Finally, a total evaluation matrix D is constructed from the evaluation set of n factors. That is, each of the judged objects determines the fuzzy relation matrix D from F to C, as expressed as:

-

(2)

Fuzzy synthesis and evaluation

A fuzzy subset G on the evaluation set C is introduced, that is, G = (g1, g2, g3, ..., gn). Let G = V*D, where “*” is the operator symbol of the fuzzy comprehensive evaluation model. Then, the risk degree is determined according to the maximum membership of the evaluated process, which is defined as:

Case study

The Chengjiao Coal Mine

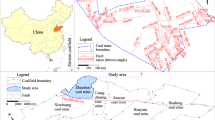

The Chengjiao Coal Mine is located in the eastern part of Yongcheng City in Henan Province, China (Fig. 1). The II2 coal seam is the primary mineable seam, with an average thickness of 2.84 m, and provides a production capacity of 5.0 Mt/a for the mine. Geologically, the elevation of the main mining seam ranges from − 400 to − 800 m in the lower Permian system of the Shanxi Formation. The general structural features are mainly gentle folds with fault structures, most of which are concentrated on the synclinal sides with an obvious performance. The stratum in the southeastern part of the minefield tends to be north-north-eastward trending, with a dip angle of 8~15°.

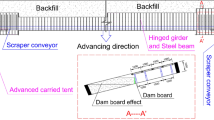

Panel 21403 is located in the 14th mining area. The average elevations of the ground surface and the panel are + 29.6~+ 33.4 m and − 416.7~− 478.8 m, respectively. The fully mechanized mining method was adopted to mine the II2 coal seam with dip angles between 1 and 10°. The lithology in the study area consists of a thin mudstone directly underlying the coal seam with an average thickness of 2.16 m, overlain by a fine-grained sandstone with an average thickness of 11.32 m, as shown in Fig. 2.

Specifically, two regional limestone aquifers, Carboniferous and Ordovician, occur under the coal seam, both of which have a high water pressure. The limestone aquifers in the Carboniferous Taiyuan Formation consist of 4 levels of aquifers named L11, L10, L9, and L8, from top to bottom. In particular, the L11 and L10 limestones occur 49.89 m and 60.33 m below the coal seam; these are the aquifers threatening the mining process, with average thicknesses of 1.42 m and 4.27 m and water pressures of 1.8 MPa and 1.91 MPa, respectively. According to water injection testing, the unit water inflow of these aquifers varies from 0.14 to 0.32 L/(s m), which indicates a moderate water abundance according to the “Detailed Rules for Coal Mine Water Prevention” (State Administration of Coal Mine Safety 2018). Fortunately, the Ordovician aquifer is 200 m from the coal seam floor; data from hydrological observation holes suggest a weak hydraulic connection with the overlying aquifer.

However, 2 water inrushes have occurred from the Carboniferous aquifers since the mine was built, and the maximum water inrush has reached 300 m3/h, which seriously threatens the mining process. Moreover, complex geological structures, such as faults, not only constitute the channels for water inrush, but also reduce the water-blocking capacity of the strata and strengthen the hydraulic connection between the aquifers. Twenty-seven faults have been exposed during the excavation process, with the maximum and minimum throws of 6.0 m and 0.5 m, respectively, as listed in Table 2. The strata have developed a sloping monoclinic structure. Thus, the occurrence of faults will have a certain impact on the mining process; this impact should be quantitatively evaluated.

Therefore, the risk of water inrush may be increased when mining is carried out in the structure-controlled region. Thus, the grouting method was carried out to reinforce the L11 and L10 aquifers and the fractures in the sandy mudstone, which can cut off the recharge from aquifers L9 and L8. A total of 25 pairs of holes were drilled, including 220 boreholes for grouting (Fig. 3). Then, the water yield and grouting amount in L11 and L10 were determined after drilling. The total grouting amount achieved 14,103.3 t, with an average value of 64.11 t per hole, of which the maximum value reached 634 t per hole. The specific situation of the grouting process is shown in Table 3.

Defining factor set for synthetic evaluation index system

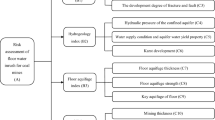

The risk of water inrush due to coal mining above aquifers is significantly affected by various factors, such as the geological structure, the hydrogeological conditions, the mining activity, and various engineering phenomena. Various index systems have been established to evaluate and predict such a disaster. According to the actual mining conditions, the limestone aquifers of L11 and L10 underlie the exploitable II2 coal seam and present a hazard for the mining operations. A hierarchical structure is constructed according to the experience gained during the multiple years of mining in each mining area. The first-grade factors that influence the safe mining above aquifers are selected as U = {geological structures, aquifers, aquifuge, mining conditions}. The second-grade indices are F = {fractal dimensions of faults, fluctuation of the coal seam floor, thickness, water yield, and pressure of aquifers under the coal seam; thickness of aquifuge under the coal seam, amount of grout; thickness and depth of the mined coal, incline length of the panel, dip angle of the coal seam}, as shown in Fig. 4.

Geological structures mainly include the fractal dimensions of the faults and the fluctuation in the coal seam floor.

Aquifers include the thickness, water yield, and pressure of aquifers L11 and L10.

Aquifuge include the distance between the II2 coal seam and L11 and L9 aquifers and the grouting amount.

Mining conditions include mining thickness and depth, incline length of the panel, and dip angle of the coal seam.

Then, the evaluation factor set is represented as F = (F1, F2, F3, F4, F5, F6, F7, F8, F9, F10, F11, F12, F13, F14), as shown in Fig. 4. The value of each factor is listed in Table 4. The factors are standardized according to the following equations.

where fij is the nondimensional data and eij is the original data.

Evaluation of single index and derivation membership functions of indices

Fractal dimension of faults in panel 21403

Fractal analysis was proposed by Mandelbrot (1979) and is widely used to characterize the similarity of objects. Fractal theory is becoming increasingly advantageous in evaluating the complexity of faults and can describe not only the number and patterns of the faults but also the unevenness and distribution of the faults. Therefore, this paper adopts the fractal dimension evaluation method to characterize the complexity of faults in panel 21403.

These faults have obvious self-similarity features that can be defined as the fractal dimension and can be calculated by the following equation.

where Ds is the similarity dimension, r is the diameter of the divided zone, and N(d) is the number of zones that can be covered.

Panel 21403 was divided into 92 zones with a side length of 100 m (Fig. 5). The values of the other lengths are r = 100, 50, 25, 12.5, and 6.25, respectively. Then, the fractal dimension was calculated by Eq. (6). The results of each zone are listed in Table 5. Figure 6 shows the fitted curves of the fractal dimensions of the faults.

Membership function of each index of hierarchical structure in panel 21403

The single factor Fi (i = 1, 2, 3, ..., n) is first evaluated. The membership degree of the factor Fi to the evaluation level Cj is Dij, and then, the single factor of the ith factor Fi can be obtained as Di = (Di1, Di2, ..., Din). In this process, the determination of membership degree is very important. This study uses the triangular fuzzy membership function to calculate the membership degree of the factors. Finally, a total evaluation matrix D is constructed from the evaluation set of n factors. That is, each of the judged objects determines the fuzzy relation matrix D from F to C; i.e., the fractal dimension is expressed as the following equations. The other indices are described in Fig. 7.

According to the measured data from the boreholes in panel 21403, the membership degree of each index with interval values was calculated as DFij. Then, the final values were determined based on the average calculations, as shown in Eq. (12).

Therefore, the first-grade and second-grade fuzzy judgment matrices are listed as follows:

where \( {D}_{F_{ij}} \) is the membership degree of each index from multiple measured data points, i is the number of second-grade indices, and j is the number of measured data points.

Finally, the fuzzy judgment matrices corresponding to the risk degree of water inrush from the aquifers underlying the coal seam are established based on the membership degree of each index, as listed in Eq. (14).

Calculation of weight of index by AHP

According to the hierarchical layer, the evaluation matrix of the first-grade index was first constructed and expressed as follows.

The evaluation matrices of the second-grade index U1, U2, U3, and U4 are defined as the following sets.

Then, the weights of the first-grade (VU) and second-grade (VUi) indices are calculated as follows.

The total weight of the second-grade index is calculated by Eq. (25). The final weight set of the evaluation index is calculated by Eq. (26).

where “*” is the operator for the matrix.

Table 6 lists the results of the weight of each index.

Results and discussions

Fuzzy comprehensive evaluation

According to the weight set of the evaluation index, fuzzy operators of the weighted average are adopted to determine the final evaluation for the risk degree of water inrush from aquifers under coal seams in panel 21403, as shown in Eq. (27).

The maximum membership degree is 0.2903 for the low comment, followed by 0.2300 for the moderate comment. Thus, the risk degree of water inrush is low after grouting reinforcement of panel 21403 in the Chengjiao Coal Mine, China, on the basis of the maximum membership principal. The successful actual project has verified this result.

Evaluation of grouting coefficient

The statistical analysis of the field investigation results from each grouting borehole shows that the water yield is mainly attributed to the limestone aquifer. A total of 225 water inflow events occurred during the grouting process, including 4 inflows with a water yield larger than 50 m3/h, which accounted for 1.82% of the total number of water inflows. Moreover, 104 inflows with a water yield of less than 10 m3/h occurred, accounting for 47.3% of the total water inflows, as shown in Fig. 8. Additionally, grouting amounts greater than 300 t were used in 4 boreholes, which accounted for 1.82% and 14.02% of the total number of grouting holes and grouting amounts, respectively. Ninety-four boreholes were grouted with less than 20 t, accounting for 42.73% and 3.52% of the total number of grouting holes and grouting amounts, respectively, as shown in Fig. 8.

Thus, the grouting coefficient K is used to quantify the risk of water inrush after grouting and is calculated by Eq. (28).

where Q and Z are the water yield and grouting amount of each borehole, m3/h and t, respectively; n is the number of grouting boreholes.

The design requirements show that K must generally range between 0.6 and 28.3 and be no less than 0.5. Considering the 225 grouting boreholes, the water yield of each borehole ranges between 1 and 60 m3/h, and the grouting amount of each borehole reached 634 t. Then, the final K was calculated as 0.9~12.1, with an average value of 4.36, which is greater than 0.5; therefore, the grouting reinforcement project satisfied the engineering requirement, verified the results of the fuzzy comprehensive evaluation, and can effectively reduce the risk degree of water inrush.

Evaluation of water inrush coefficient

Furthermore, the water inrush coefficient T is always used to evaluate the risk degree of water inrush and is usually calculated by:

where P is the water pressure of the aquifer under the coal seam (MPa) and M is the thickness of the aquifuge (m).

The maximum water pressure of the L10 limestone aquifer is 1.91 MPa according to the measured borehole data. Moreover, the thin sandstone of the coal seam floor and the L11 and L10 limestone aquifers were transformed into an aquifuge via the grouting reinforcement, which confirmed that the thickness of the aquifuge reached up to 70.4 m. Then, K was calculated as 0.027 MPa/m, which is lower than 0.06 MPa/m, which indicates a low risk of water inrush according to the “Detailed Rules for Coal Mine Water Prevention” (State Administration of Coal Mine Safety 2018) and closely agrees with that obtained from the fuzzy comprehensive evaluation.

Conclusions

In this study, a fuzzy analytic hierarchy process model was established to assess the risk degree of water inrush from aquifers underlying a coal seam after grouting reinforcement based on a case study of the Chengjiao Coal Mine in China. The evaluation index system was first defined considering the main indices affecting water inrush, including 4 first-grade indices and 14 second-grade indices according to the hierarchical structure. The grouting effect and the fault complexity were quantified by the grouting amount and fractal dimension, respectively. Then, a single index was graded and fuzzy evaluated to achieve a fuzzy judgment matrix based on the average membership degree of the data of each index obtained from the borehole investigation. Next, the weight of each influential factor was quantified by the analytic hierarchy process (AHP) to derive a weighting set for the evaluation factors. Finally, the evaluation vector was obtained by calculating the risk degree using the fuzzy operator. A comparative analysis shows a close agreement between the grouting coefficient and water inrush coefficient and the low risk obtained from the fuzzy evaluation.

The results of the fuzzy comprehensive evaluation indicate that the risk degree of water inrush is low, 0.2903, due to the grouting reinforcement according to the maximum membership principle. In a comparison of the water yield and the grouting amount, the grouting coefficient was calculated to be 4.36, and the water inrush coefficient was calculated to be 0.027 MPa/m, both of which proved that the grouting reinforcement effectively reduced the risk of water inrush from the aquifers underlying the coal seam and verified the results achieved via analytic hierarchy fuzzy evaluation. The success of the actual project has verified this result.

All of the results indicate that the analytic hierarchy fuzzy evaluation model is scientific and rational and can be used to evaluate the risk degree of water inrush from aquifers underlying a coal seam with grouting reinforcement; this model fully takes into consideration the main indices affecting water inrush, produces quantitative and highly accurate results, and is universally applicable. This evaluation model is effective and advantageous, can be applied in coal mining safety assessment and management, and can improve the safety of coal mining in China. However, factors affecting the grouting process, such as the grouting pressure, grouting depth, and grouting material properties, should be considered in future studies.

References

Bukowski P (2011) Water hazard assessment in active shafts in Upper Silesian Coal Basin mines. Mine Water Environ 30:302–311. https://doi.org/10.1007/s10230-011-0148-2

Chen J, Yang R (2011) Analysis of mine water inrush accident based on FTA. Procedia Environ Sci 11:1550–1554. https://doi.org/10.1016/j.proenv.2011.12.233

Chen J, Ma L, Wang C, Zhang H, Ha M (2014) Comprehensive evaluation model for coal mine safety based on uncertain random variables. Saf Sci 68:146–152. https://doi.org/10.1016/j.ssci.2014.03.013

Demiroglu M (2016) Classification of karst springs for flash-flood-prone areas in western Turkey. Nat Hazards Earth Syst Sci 16(6):1473–1486. https://doi.org/10.5194/nhess-16-1473-2016

Gui H, Song X, Lin M (2017) Water-inrush mechanism research mining above karst confined aquifer and applications in North China coal mines. Arab J Geosci 10:180–189. https://doi.org/10.1007/s12517-017-2965-5

Hu X, Wang L, Lu Y, Yu M (2014) Analysis of insidious fault activation and water inrush from the mining floor. Int J Min Sci Technol 24:477–483. https://doi.org/10.1016/j.ijmst.2014.05.010

Hu Y, Li W, Wang Q, Liu S, Wang Z (2019) Evaluation of water inrush risk from coal seam floors with an AHP–EWM algorithm and GIS. Environ Earth Sci 78:1–15. https://doi.org/10.1007/s12665-019-8301-5

Hua X, Zhang W, Jiao D (2011) Assessment method of water-inrush risk induced by fault activation and its application research. Process Eng 26:441–448. https://doi.org/10.1016/j.proeng.2011.11.2190

Jin D, Zheng G, Liu Z, Liu Y, Pang X (2011) Real-time monitoring and early warning techniques of water inrush through coal floor. Proc Earth Planet Sci 3:37–46. https://doi.org/10.1016/j.proeps.2011.09.063

Karakus M (2011) Function identification for the intrinsic strength and elastic properties of granitic rocks via genetic programming (GP). Comput Geosci 37(9):1318–1323. https://doi.org/10.1016/j.cageo.2010.09.002

Karakus M, Tutmez B (2006) Fuzzy and multiple regression modelling for evaluation of intact rock strength based on point load, Schmidt hammer and sonic velocity. Rock Mech Rock Eng 39(1):45–57. https://doi.org/10.1007/s00603-005-0050-y

Li S, Zhou Z, Li L, Xu Z, Zhang Q, Shi S (2013) Risk assessment of water inrush in karst tunnels based on attribute synthetic evaluation system. Tunn Undergr Space Technol 38:50–58. https://doi.org/10.1016/j.tust.2013.05.001

Li S, Liu B, Nie L, Liu Z, Tian M, Wang S et al (2015) Detecting and monitoring of water inrush in tunnels and coal mines using direct current resistivity method: a review. J Rock Mech Geotech Eng 7:469–478. https://doi.org/10.1016/j.jrmge.2015.06.004

Li S, Wu J, Xu Z, Yang W (2019) Mechanics criterion of water inrush from the coal floor under influence of fault and its engineering application. Int J Geomech 19:04019022. https://doi.org/10.1061/(asce)gm.1943-5622.0001387

Liu Z, Jin D, Liu Q (2011) Prediction of water inrush through coal floors based on data mining classification technique. Proc Earth Planet Sci 3:166–174. https://doi.org/10.1016/j.proeps.2011.09.079

Lu Y, Wang L (2015) Numerical simulation of mining-induced fracture evolution and water flow in coal seam floor above a confined aquifer. Comput Geotech 67:157–171. https://doi.org/10.1016/j.compgeo.2015.03.007

Mandelbrot BB (1979) Fractals: form, chance and dimension. WH Freeman, San Francisco

Meng Z, Li G, Xie X (2012) A geological assessment method of floor water inrush risk and its application. Eng Geol 143–144:51–60. https://doi.org/10.1016/j.enggeo.2012.06.004

Nie R, Tian Z, Wang J et al (2018) Water security sustainability evaluation: applying a multistage decision support framework in industrial region. J Clean Prod 196:1681–1704. https://doi.org/10.1016/j.jclepro.2018.06.144

Peng H, Shen K, He S, Zhang H, Wang J (2019) Investment risk evaluation for new energy resources: an integrated decision support model based on regret theory and ELECTRE III. Energy Convers Manag 183:332–348. https://doi.org/10.1016/j.enconman.2019.01.015

Saaty T L (1980) The analytic hierarchy process: planning, priority setting, resource allocation. McGraw-Hill The analytic hierarchy process: planning, priority setting, resource allocation

Saaty RW (1987) The analytic hierarchy process—what it is and how it is used. Math Model 9(3–5):161–176

State Administration of Coal Mine Safety (2018) Detailed rules for coal mine water prevention. Coal industry press, Beijing (in Chinese)

Tang J, Bai H, Yao B, Wu Y (2011) Theoretical analysis on water-inrush mechanism of concealed collapse pillars in floor. Min Sci Technol 21:57–60. https://doi.org/10.1016/j.mstc.2010.12.005

Tian Z, Wang J, Wang J, Zhang HY (2018) A multi-phase QFD-based hybrid fuzzy MCDM approach for performance evaluation: a case of smart bike-sharing programs in Changsha. J Clean Prod 171:1068–1083. https://doi.org/10.1016/j.jclepro.2017.10.098

Tian Z, Nie R, Wang J, Li L (2019) Group multigranular linguistic QFD for prioritizing service designs with combined weighting method. Expert Syst 4:e12419. https://doi.org/10.1111/exsy.12419

Wang J, Park HD (2003) Coal mining above a confined aquifer. Int J Rock Mech Min Sci 40:537–551. https://doi.org/10.1016/S1365-1609(03)00029-7

Wang Y, Yang W, Li M, Liu X (2012) Risk assessment of floor water inrush in coal mines based on secondary fuzzy comprehensive evaluation. Int J Rock Mech Min Sci 52:50–55. https://doi.org/10.1016/j.ijrmms.2012.03.006

Wang Q, Wang H, Qi Z (2016) An application of nonlinear fuzzy analytic hierarchy process in safety evaluation of coal mine. Saf Sci 86:78–87. https://doi.org/10.1016/j.ssci.2016.02.012

Wang L, Peng J, Wang J (2018) A multi-criteria decision-making framework for risk ranking of energy performance contracting project under picture fuzzy environment. J Clean Prod 191:105–118. https://doi.org/10.1016/j.jclepro.2018.04.169

Wang J, Li S, Li L, Lin P, Xu Z, Gao C (2019a) Attribute recognition model for risk assessment of water inrush. Bull Eng Geol Environ 78:1057–1071. https://doi.org/10.1007/s10064-017-1159-4

Wang X, Li S, Xu Z, Lin P, Hu J, Wang W (2019b) Analysis of factors influencing floor water inrush in coal mines: a nonlinear fuzzy interval assessment method. Mine Water Environ 38:81–92. https://doi.org/10.1007/s10230-018-00578-x

Wu Q, Xu H, Pang W (2008) GIS and ANN coupling model: an innovative approach to evaluate vulnerability of karst water inrush in coal mines of north China. Environ Geol 54:937–943. https://doi.org/10.1007/s00254-007-0887-3

Wu Q, Liu Y, Liu D, Zhou W (2011) Prediction of floor water inrush: the application of GIS-based AHP vulnerable index method to Donghuantuo coal mine, China. Rock Mech Rock Eng 44:591–600. https://doi.org/10.1007/s00603-011-0146-5

Wu Q, Fan Z, Zhang Z, Zhou W (2014) Evaluation and zoning of groundwater hazards in Pingshuo no. 1 underground coal mine, Shanxi Province, China. Hydrogeol J 22:1693–1705. https://doi.org/10.1007/s10040-014-1138-9

Yang B, Sui W, Duan L (2017) Risk assessment of water inrush in an underground coal mine based on GIS and fuzzy set theory. Mine Water Environ 36:617–627. https://doi.org/10.1007/s10230-017-0457-1

Yuan B, Xu K, Wang Y, Chen R, Luo Q (2016) Investigation of deflection of a laterally loaded pile and soil deformation using the PIV technique. Int J Geomech 17(6):04016138. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000842

Yuan B, Sun M, Xiong L, Luo Q et al (2019a) Investigation of 3D deformation of transparent soil around a laterally loaded pile based on a hydraulic gradient model test. J Build Eng 28:1–9. https://doi.org/10.1016/j.jobe.2019.101024

Yuan B, Xiong L, Zhai L et al (2019b) Transparent synthetic soil and its application in modeling of soil-structure interaction using optical system. Front Earth Sci 7:276. https://doi.org/10.3389/feart.2019.00276

Zhang J (2005) Investigations of water inrushes from aquifers under coal seams. Int J Rock Mech Min Sci 42:350–360. https://doi.org/10.1016/j.ijrmms.2004.11.010

Zhang J, Wu Q, Mu W, Du Y, Tu K (2019) Integrating the hierarchy-variable-weight model with collaboration-competition theory for assessing coal-floor water-inrush risk. Environ Earth Sci 78:1–13. https://doi.org/10.1007/s12665-019-8217-0

Zhu Q, Feng M, Mao X (2008) Numerical analysis of water inrush from working-face floor during mining. J China Univ Min Technol 18:159–163. https://doi.org/10.1016/S1006-1266(08)60034-6

Acknowledgments

The authors would like to thank the Yongcheng Coal and Electricity Holding Group Co., Ltd., for providing data support.

Funding

The authors receive financial support from Henan scientific and technical projects (182102310746).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Murat Karakus

Rights and permissions

About this article

Cite this article

Liu, J., Yang, B., Yuan, S. et al. A fuzzy analytic hierarchy process model to assess the risk of disaster reduction due to grouting in coal mining. Arab J Geosci 13, 227 (2020). https://doi.org/10.1007/s12517-020-5130-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-020-5130-5