Abstract

Meat is the main protein source of the human diet in many cultures. Because of the increasing population growth and welfare, the conventional meat industry cannot follow consumer demands worldwide. Besides, some of the environmental, sustainability-related, and ethical concerns associated with the traditional meat industry have directed scientists to develop new strategies to tackle these negative effects. Culturing meat from cell culture is an emerging bioprocess that will revolutionize the industrial animal agriculture. Many tissue engineering techniques can be utilized for this rising field, although its further development faces important cell culture challenges as well as scale-up limitations. The invention of innovative tools for large-scale in vitro meat production will concurrently advance the technology for biomedical and therapeutic applications. This review highlights vital factors and fundamental cell biology parameters for designing a bioprocess to produce an environmentally friendly meat product that will be accepted by consumers. New applications of current biomedical products and concepts will form the groundwork for future academic research and novel designs enabling large-scale production of cultured meat.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Meat is an essential part of the human diet in many cultures, and because of the increasing population growth and welfare, the meat industry cannot follow consumer demands worldwide. Additionally, limited land resources and several adverse effects of conventional meat production (e.g., the poor nutritional value of meat, foodborne diseases, extensive use of antibiotics, and greenhouse gas emissions) have compelled scientists to develop innovative techniques that will tackle the negative consequences of traditional meat production through livestock [6, 70, 104]. The meat industry also results in substantially increased land and water use, as livestock farming also requires farmland to produce animal feed (e.g., corn and soy). To further illustrate (Fig. 1), according to research from Bard College, production of beef (per calorie) requires 160 times more land than potatoes, wheat, and rice [126]. Aside from that, the production of popular protein sources results in the formation of about 11 times more greenhouse gases than the production of rice. Having the above-mentioned in mind, a switch to cultured or engineered meat, referred to also as lab-grown or clean meat, from its “traditional” production, would lessen or even detain the effects of global warming. Furthermore, since this technology does not rely on the “sacrifice” of animals to produce food, it would also be more acceptable from the ethical point of view for the well-being of animals.

Nutritional and environmental consequences associated with feed-to-food conversion between meat production and plant-based alternatives. Livestock takes up about 77% of global agriculture land yet produces 17% of the world’s supply of calories. Crops occupy less than 25% of global agriculture land for production of 83% global food caloric supply. Farm-based meat production contributes 4 times more to the total greenhouse gas emissions than plant-based food

Many of the crucial technologies for the realization of large-scale cultured meat production are the same as those that have been pioneered for other large-scale cell culture applications (e.g., antibody therapeutics, cell-based therapy, regenerative medicine) [118, 130]. For the most part, edible animal meat is derived from skeletal muscle tissue; in vitro cultured meat production relies on techniques and strategies developed in skeletal muscle tissue engineering. Research conducted in the mentioned field has elucidated multiple fundamental mechanisms of skeletal muscle repair and identified various types of cells and regulatory factors, which play a crucial role in muscle regeneration [109]. Those findings can also be applied for creating artificially engineered meat in vitro. Proof of concept for the feasibility to grow meat in vitro (beef patty) was provided in 2013 [105]. However, it was not a consumer-available product. Although the science behind skeletal muscle tissue engineering is steadily increasing [17, 69, 102], the technology behind the production of cultured meat is still in its infancy [4, 104, 130]. Several technical challenges are facing its industrial-scale production before it can be introduced into the market in an appreciable quality and quantity and at a reasonable price [4, 29, 36, 130, 131].

Skeletal Muscle Tissue Engineering for Meat Production

The process of growing tissue-engineered meat starts with the acquisition of desired cell or tissue types. Because mature skeletal muscle cells lack proliferation capability, stem cells (mesenchymal) are the most common primary source of myoprogenitors [102]. Despite exhibiting some limitations regarding their regeneration potential, which is restricted only to minor damages [119, 140, 144], the regenerative abilities of these stem cells (satellite cells) and their potential for proliferation and differentiation present important foundations for skeletal muscle tissue engineering.

Skeletal muscle tissue (Fig. 2) comprises aligned myofibers formed through myoblasts fused into elongated multinucleated myotubes. The centralized position of their nuclei characterizes newly formed myotubes. As the myotubes mature to shape myofibers, their nuclei settle on positions at the cell’s periphery. Each myofiber is surrounded by extracellular connective tissue, and numerous myofibers are assembled to form a skeletal muscle. Connective tissue provides a supportive framework that maintains muscle shape and enables synergic contraction of myofibers during movement. Specific alignment of myofibers dictates force generation, and on top of that, connective tissue helps maintain muscle shape and allows myofibers to contract synergically during movement [22, 109, 140].

Skeletal muscle tissue. Skeletal muscle consists of muscle fibers that are arranged in regular bundles enclosed by a dense connective tissue epimysium. From epimysium, a thin septum of connective tissue extends inward (i.e., perimysium), wrapping each fascicle of fibers. Individual muscle fibers (elongated multinuclear cells) is surrounded by a delicate connective tissue, the endomysium, composed of a basal lamina synthesized by the muscle fiber and reticular fibers and fibroblasts [56]

In general, the skeletal muscle can regenerate in response to damage by activating satellite cells, which repose beneath the basal lamina of adult skeletal muscles. As part of the normal physiological response to trauma and injury, satellite cells proliferate and differentiate into myoblasts, which subsequently fuse to form multinucleated myofibers. They usually remain quiescent in the basal lamina until various growth factors and signaling pathways activate them. These primary cells are identified through the expression of Pax7, a transcriptional factor responsible for the regulation of myogenic proliferation. They can be harvested from adult muscle and successfully grown in vitro. Myogenic differentiation is regulated by Myf5 and MyoD, which are transcription factors expressed by myoblasts (and thus, both are identification criteria for them); at this stage, the cell is “committed” to become a muscle fiber [119]. To use tissue engineering either for various applications in regenerative medicine or for cultured meat production, some requirements need to be met. A cell source that can proliferate indefinitely, while it simultaneously has the potential to differentiate into functional skeletal muscle tissue, needs to be embedded (and precisely positioned, as well as oriented) in a three-dimensional (3D) matrix. The latter must allow muscle growth while, at the same time, facilitates the delivery of oxygen and nutrients, as well as enables cell waste removal. To obtain mature, functional muscle fibers, muscle cells need to be cultured in a bioreactor that provides constant (and appropriate) biochemical and biophysical stimuli [7, 70].

The most straightforward in vitro tissue engineering approach to generate mature and contractile muscle constructs is to culture cells on a biomaterial substrate until they have evolved into a functional tissue. However, this approach faces several critical obstacles: (1) fabricating a large muscle construct while maintaining high myofiber packing density and alignment, (2) providing sufficient vascularization to maintain cellular viability in such a large construct for longer periods, and (3) fabricating engineered tissues that can generate physiologically relevant contraction forces. Even though the cells may be the protagonist for skeletal muscle tissue engineering, the important role of biomaterials should not be neglected. By combining various features, like the choice of biomaterials, scaffolds’ 3D architecture, chemical composition, surface functionalization, and bioactivity modulation of cell behavior can be achieved [109].

Cell Sources

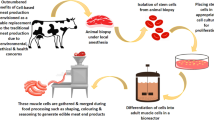

As outlined above, a vital component of skeletal muscle tissue engineering is myoprogenitor cells that can directly or indirectly re-form muscle tissue. The stem cell technology utilized for the production of engineered meat (which, as aforementioned, is a skeletal muscle) requires the following steps: (1) harvesting stem cells, (2) expansion of stem cell numbers, (3) their differentiation into myoblasts and myofibers, and (4) assembly into the final meat product. Each cell type comes with advantages over others; sourcing considerations, cost, and degree of characterization of the cell type are all relevant factors to contemplate. Since mature muscle fibers do not possess any proliferation potential, they cannot be used as a cell source for tissue-engineered constructs. Precursor cells and native regenerative cells are reliant upon numerous external factors to promote adhesion, proliferation, differentiation, and maintenance of the desired phenotype [104, 119].

One of the main objectives of bringing cultured meat to a consumer market is the long-term cultivation of cell lines. The strains utilized for fermentation in brewing will likely be used as sample guidelines for these cell lines: Cultures can be used continuously for some number of passages, but periodically they are re-seeded from frozen stocks to avoid genetic drift [130]. Numerous strategies have been introduced to maintain stemness in continuous cultures. These, among others, include the exposure of cells to hypoxic conditions [8] and modulating parameters like scaffold stiffness [79].

Cell Lines

There are two possible cell sources for the production of in vitro meat, namely, primary cells isolated from the original tissue, or established cell lines that are derived directly from native tumor tissue or artificially generated from primary cells in vitro [114, 115, 131]. The latter can be achieved in two ways. A typical strategy involves genetic or chemical induction, which reprograms the cells to proliferate indefinitely [114, 115]. Another method is to select cells that went through a spontaneous transformation and became immortal and then further culture only the selected sub-clones [131]. These immortalized cells (i.e., continuous cell lines) have already proven to be a useful alternative source for fresh tissue samples, and they could be valuable tools to increase the speed of proliferation and differentiation [115, 131].

Nevertheless, since they have undergone significant mutations to become immortal, potential implications of these processes need to be evaluated with extreme care. Besides, these cells can change genetically over multiple passages, leading to phenotypic differences among isolates and potentially misidentification. One general limitation may also be that they are not always representative of primary cells. For example, they may exhibit different growth rates; hence, cell data should be interpreted cautiously [131].

Once cell lines for in vitro meat production have been established, best practices of cell banking, derived from the use of stem cells in biomedical applications, can be utilized to enhance the stability, reproducibility, and long-term maintenance of cell stocks for cultured meat [130].

Stem Cells

Stem cells are considered the most promising cell source since they have characteristic capabilities to retain themselves in the undifferentiated form for a specific number of population doublings. Different types of stem cells can be used to create in vitro meat and meat products [6, 29, 70]. Two favorable options among them are embryonic stem cells and satellite (i.e., myosatellite) cells from native muscle tissue.

In theory, after the embryonic stem cell line is set up, its unlimited regenerative ability eliminates the need to harvest more cells from embryos. Despite their high proliferation and differentiation capacity, these cells must be specifically stimulated to differentiate into myoblasts and may inaccurately restate myogenesis. Moreover, the cell yields from harvests are usually meager [29, 36]. For embryonic stem cells to become muscle fibers, the first requirement is their differentiation into myogenic progenitor cells. One of the major challenges at this stage is achieving direct differentiation into myoprogenitor cells without the development of any other lineages. It seems that inducing myogenesis in embryonic stem cells in vitro is a tougher nut to crack than the in vivo counterpart. Zheng and colleagues demonstrated that myogenic precursor progeny from human embryonic stem cells effortlessly form myofibers when transplanted in vivo in mice after muscle damage [152].

On the other hand, in vitro formation of myofibers from the cells has proven to be strenuous. Authors presumed that in vitro system lack some important in vivo niche elements [152]. Apart from the risk of uncontrolled proliferation and differentiation, an additional issue with using embryonic stem cells as a cell source for cultured meat production is the ethical concerns [70].

The most promising and practical cell types for skeletal muscle tissue engineering, as well as for in vitro meat production, are (myo)satellite cells. However, having the drawback of being a rare muscle cell type (they make up < 5% of the total nuclei in the skeletal muscle fiber of adult rodents and humans), they are the main contributors to muscle repair and regeneration; they recapitulate myogenesis (Fig. 3) more closely than the immortal myogenic cell lines. In the event of muscle damage and subsequent transmission of biochemical signals, activated satellite cells migrate to the injured site, proliferate, undergo myogenic differentiation, and fuse to form myotubes [109]. It has been shown in vivo that satellite cell fusion causes remodeling in adult fibers. Subsequently, their competence to proliferate and fuse with adjacent fibers in uninjured muscle has been revealed, providing a mechanism for the addition of nuclei to growing fibers. The inclusion of new nuclei to growing fibers alleviates further growth in fibers’ length and perimeter [11]. On the other hand, numerous studies have demonstrated that the expansion and culturing of satellite cells in vitro, even for a few days, can significantly limit their proliferative properties. Usually, the satellite cell proliferation rate decreases with each passage until a stage, known as proliferative senescence, is reached. At this point, the cells cease to divide, plausible because of the loss of telomeric DNA that occurs with each cell division [117]. A related key finding has been made by Gilbert et al., who showed that satellite cells could maintain their in vivo-like self-renewal properties when cultured on elastic substrates [46]. Namely, when these primary cells are cultured on appropriate biomaterials (with Young’s elasticity modulus of 12 kPa), they retain their characteristic proliferative and regenerative features.

Myogenesis. a The development of skeletal muscle tissue begins when myoblasts align and fuse to make longer multinucleated myotubes. Myotubes continue differentiating and synthesize proteins to form functional myofilaments, where the nuclei are displaced against the sarcolemma. Part of the myoblast population does not fuse and differentiate but remains as a satellite cell located on an external surface of muscle fibers. Satellite cells proliferate and produce new muscle fibers following muscle injury. b Example of mouse-tissue derived myotubes [1]

Satellite cells have been until now successfully isolated and characterized from the skeletal muscle tissue of cattle [31], chickens [147], fish [107], lambs [33], pigs [13, 143], and turkeys [84]. Cells from respective animal species’ have their benefits and limitations. Thus, satellite cells isolated from different muscles have different capabilities to proliferate, differentiate, or be regulated by growth modifiers that mimic the extracellular matrix (ECM) environment encircling muscle cells (e.g., proteoglycans, growth factors, and steroid hormones) [20, 29].

Adult Stem Cells

Myosatellite or satellite cells are one of the representatives of an adult stem cell type with multilineage potential. Adult stem cells, also known as progenitor cells, are preferred sources for cultured meat production, independent of their in vivo origin. They have been obtained from pigs [68, 149] and cattle [67]. Alas, at present, the proliferative ability of adult stem cells does not match that of embryonic stem cells, mainly because they tend to differentiate spontaneously in vitro [6, 70].

Adipose Tissue-Derived Adult Stem Cells

Another cell type, relevant to in vitro meat engineering, are adipose tissue-derived adult stem cells. As the name suggests, this unique population of multipotent cells is located in adipose tissue. These highly expandable cells can be relatively non-invasively obtained from subcutaneous fat and further transdifferentiated to myogenic, osteogenic, chondrogenic, or adipogenic cell lineages [65]. The most significant worry regarding their usage remains their proneness to the malignant transformation in long-term cultures. Adipose tissue-derived adult stem cells can be immortalized at high frequency and can undergo a rapid transformation in long-term culturing; however, to date, researchers have been unable to reproduce some of the reported spontaneous transformation events [121]. For in vitro meat production, re-harvesting of adult stem cells might be necessary to minimize the risk of spontaneous transformation. Thus, harvesting adipose tissue-derived adult stem cells from subcutaneous fat is far less invasive than collecting satellite cells from muscle tissue via biopsy. More importantly, from the ethical point of view, these samples can be obtained from certain animals without causing considerable harm [29].

Mesenchymal Stem Cells

Another cell type being deemed ever more usable for skeletal muscle tissue engineering is mesenchymal stem cells (MSCs). These are multipotent cells, which possess the ability to differentiate into osteogenic, chondrogenic, and adipogenic lineages. Also, MSCs can undergo myogenic differentiation, provoking the formation of myotubes that can contribute to muscle growth. It has been reported that this cell source can be differentiated towards the myogenic lineage by expressing muscle-specific markers, regardless of their limited myogenic potential. However, it is still unclear how reproducible the transformation of MSCs into skeletal myoblasts is, especially having in mind their multipotency combined with the uncertainty of collecting them from different sources such as bone marrow, adipose tissue, synovial membrane, and umbilical cord blood [109, 144]. One of the main disadvantages of using MSCs is the decline in their regenerative properties over time, which is further compromised with in vitro expansion [109]. Although myogenic differentiation of MSCs alone might not be satisfactory, they can still represent a promising cell source for co-cultivation with myoblasts; they can fuse myoblasts and therefore play a part in the muscle regeneration process. Moreover, it is known that MSCs secrete several growth factors involved in the muscle regeneration process, as well as stimulate myoblast migration, proliferation, differentiation, and cell survival upon co-cultivation [144].

Co-cultures

The simplest approach for the production of a cultured meat system is to use a single myogenic cell line from an animal or co-culture it with other cells that are beneficial for the whole system. Once primary cells are differentiated into myoblasts, these cells, among producing some components of the extracellular matrix (ECM), are specialized in synthesizing contractile proteins. The ECM is the non-cellular part present within all tissues and organs which fills the space around the cells, and it is arranged in a unique 3D organization. Its precise composition and structure vary from tissue to tissue, depending on its particular functional need. Therefore, the ECM not only provides a mere structural scaffold for cells, but it is also one of the key regulators of cellular activities. Its active role involves modulation of many cellular functions in different ways. Moreover, through varying the degree of stiffness of the matrix components, it acts as a mechanical stimulator and thus directly influences cell differentiation [42].

To engineer functional skeletal muscle, it is necessary to combine different cell types. This is experimentally and technically challenging because the number of culture parameters that need to be carefully considered exponentially increases with an increasing number of different cell types. Furthermore, cell types are very specific in their nutritional and stimuli needs [102]. Co-culturing myoblasts with another (lone) cell population (e.g., fibroblasts, mesenchymal stromal or endothelial cells) has been shown to influence myoblast differentiation and proliferation capability, as well as alignment. Within a muscle, the main “factory” of EMC is fibroblasts. One of the concerns regarding co-culturing fibroblasts and myoblasts involves the risk of fibroblasts overgrowing the myoblasts, due to the difference in growth rate [11, 23, 70]. Previous studies in monolayer cultures revealed that stromal cells positively impact the expansion of myoblasts; an enhanced proliferation of myoblasts was present in the first 24 h of contact co-culture and then gradually decreased and became negligible after 72 h [123]. These findings in two-dimensional (2D) co-cultures have been partially reproduced in 3D systems. Co-culture with stromal vascular fraction (SVF) cells (i.e., non-expanded MSCs from adipose tissue) promoted proliferation and differentiation of myoblasts, resulting in muscle-like constructs. Besides, SVF cells deposited an increased amount of ECM and formed organized endothelial cell-structures [23].

The skeletal muscle has an abundant blood vessel supply, so one of the major challenges in engineering thick, complex tissues like muscle, is to vascularize the construct in vitro. The introduction of vascular networks in vitro could aid in maintaining cell viability during tissue growth and induce structural organization. Levenberg et al. hypothesized that embryonic endothelial cells in the appropriate 3D environment could be employed to promote the formation of endothelial vessel networks in in vitro engineered skeletal muscle tissue [74]. When both myoblasts and endothelial cells were cultured on scaffolds, the endothelial cells organized into tubular structures amid myoblasts and throughout the structure, assembling vessel networks within the cultured muscle tissue in vitro. The inclusion of embryonic fibroblasts under appropriate culture conditions into the mentioned co-cultures strongly advanced vascularization of the engineered muscle; their addition promoted stabilization of vessel organization over time. Their study highlights the importance of multi-cell cultures in providing relevant signals for vascular structure development in skeletal muscle tissue. Furthermore, co-cultures with endothelial cells may also be important to prompt differentiation of engineered tissues, because embryonic endothelial cells are pivotal for the earliest stages of organogenesis of muscle tissue [74]. Namely, the formation of microvascular networks is essential to generate suitable conditions for adipogenesis and to affect the maturation of nearby ECM secreting cells [10]. Recent studies have demonstrated that bovine stromal vascular cells (SVC) can promote both angiogenesis and adipogenesis in vitro, owing to their heterogeneity [10, 80]. Albeit vascularization is one of the crucial factors in functional muscle tissue development, production of the cultured meat of lower cell plurality can be achieved without them, as blood vessels may be a negligible component of meat taste and texture [10].

Scaffolds

Myoblasts are attachment-dependent cells, capable of spontaneous contraction. For proliferation and differentiation of myoblasts to take place, they require an appropriate substratum or scaffolds. Scaffolds made from biocompatible materials present an effective tool to control and guide tissue development locally. Scaffolds can play an essential role in providing a suitable environment also for myogenesis; they can act as a mimicked ECM for cells and can provide desired mechanical, as well as biochemical stimuli to the cells [109, 119]. An ideal scaffold would have a large surface area for attachment and growth, be flexible to enable contractions, maximize media diffusion, and be easily removed from the meat culture. Besides, scaffold and its by-products must be non-toxic or even edible, if they are not removed after cell culturing and may be of non-animal origin [29, 36]. The best choice would be a scaffold that closely mimics in vivo conditions in the skeletal muscle. It has been reported that myotubes best differentiate on the substrates with tissue-like stiffness [38]. Moreover, to achieve the optimal in vivo cell niche, a 3D muscle construct that leads to uniform cell alignment and reproducible architecture is needed. The advantage of 3D matrices with tubular pores over patterned 2D substrates is that large quantities of cells can be concentrated into a small scaffold volume and can be simultaneously stimulated to form myotubes. Furthermore, physiologically relevant 3D models permit longer culture times and more significant developmental maturation. In a 3D setting, the scaffolds’ material mechanical properties, forces generated by cells and constructs mechanical behavior (e.g., deformation), also seem to have an impact on cell survival, organization, and differentiation [63, 70, 109]. Cutting-edge micro- and nanofabrication techniques have facilitated the development of novel biomaterial substrates and 3D scaffolds that can, through their unique architecture, promote alignment and fusion of myoblasts in vitro. An example of such a model that is being developed in our laboratories is shown in Fig. 4.

Myofiber Alignment

Myofiber alignment is one of the specific requirements of muscle cells and thus should be investigated in scaffold design. Native muscle fibers are either aligned along the longitudinal axis or are oriented at an angle to the axis (i.e., pennation angle). The texturized surface of scaffolds can contribute to myotube alignment. Despite numerous strategies to recreate skeletal muscle tissue, the reality in the majority of cases is that myoblasts were embedded in bulk hydrogels where they assembled in a “chaotic-like” 3D lattice [91]. Without surface markers or patterns, myotubes cannot align. Therefore, they create a branched network. As a result, misaligned networks may generate contractile forces in opposing directions, contrary to those in native muscle fibers, reducing the overall contractility of the construct, and hence hinder the desired continuous protein production. In the absence of surface stimulation, external electrical and mechanical cues (including applied passive tension) can boost alignment. Furthermore, it has been shown that increased fiber alignment is associated with enhanced differentiation as well as upregulation of contractile proteins and the presence of advanced sarcomeric structures. Myoblast elongation and alignment are generally encouraged by utilizing a micropatterned surface [119]. Findings from various studies have shown that scaffold topology has a significant impact on the organization of aligned myofibers. By slight modifications of parameters, the degree of alignment can be altered [24]. Myofiber organization dictates the functional characteristics of muscle and therefore also the texture properties of meat [29].

Mechanical Properties

To imitate native muscle tissue mechanical characteristics, an ideal scaffold should possess similar elasticity and mechanical stiffness as its native counterpart. The muscle is an elastic tissue (Young’s modulus of ~ 12 kPa) [38, 46]. Therefore, a suitable scaffold elasticity is a prerequisite to resemble the contraction and relaxation abilities of native muscle fascicles. An improper elasticity can reduce force transmission, which eventually leads to motion hindering. In tissue engineering, unsuitable stiffness of a construct can cause a mechanical mismatch between the construct and native tissue, resulting in the formation of stress concentrations [119]. Mechanical loading of the tissue construct has a beneficial influence on cell alignment, elongation, proliferation, and fusion [136]. Additional cyclic mechanical stretching can even increase protein synthesis and hypertrophy of in vitro engineered muscle [135]. Two main characteristics govern cell phenotyping, namely, elasticity and stiffness. Cells receive mechanical cues from their surrounding that can either promote or inhibit both proliferation and differentiation. Under proper conditions, such cues can be applied in vitro as a means to amend and accelerate myogenic differentiation [5, 46, 76]. The most straightforward and scalable format to obtain “self-anchored” muscle fiber is letting them grow in a ring around a central column of elastic material. Using this strategy, the maturation period of a muscle fiber takes about 3 weeks [101]. As described above, Gilbert et al. showed that when cultured on soft polyethylene glycol hydrogels with an elasticity of 12 kPa, skeletal muscle stem cells exhibit in vivo-like self-regenerative properties [46]. Another research group reported that alginate hydrogels with an elasticity between 10 and 16 kPa displayed the highest potential for myogenic differentiation as evidenced by upregulation of myogenic genes (myogenin, MyoD, and Myf5) [5]. While static mechanical stimulation is largely associated with induction of myogenic differentiation, there have been inconsistencies concerning the role of cyclic mechanical strain on signaling and myogenic marker expression [50]. In early stages of myogenesis, uniaxial passive tension is superior to cyclic strain as it more closely reflects the natural situation in muscle development and growth [50, 136]. However, cyclic tension might play a role as an upregulatory stimulus for muscle hypertrophy and maturation of myotubes at later stages of myogenesis [88, 106]. The continuous static strain on skeletal muscle, caused by bone growth and elongation during embryogenesis and neonatal development, affects muscle weight, muscle length, and myofilament organization. Bone growth can be simulated by using ramp stretch. The mixed outcomes with beneficial [137] and negative effects [15] of combined stretch protocols from various studies are likely linked to the amount of stretch that the myotubes undergo [63].

Electrical Stimulation (Contraction)

Neural stimulation (i.e., regular contraction) presents an essential environmental signalization during embryogenesis in adult muscle since it promotes differentiation and healthy myofiber morphology. In a prolonged absence of it, muscle is subjected to atrophy [29, 45]. Muscles in vivo are innervated, which enables regular and controlled contraction. It was found that subjecting scaffolds to mechanical stretching can fulfill the requirement of providing contraction. However, this approach is less effective than electrical stimulation for optimal skeletal muscle development [29]. Incorporation of external electrical cues induces contraction internally and, under in vitro culture conditions, can be used to simulate part of the in vivo niche in the muscle [17]. Living cells create electrical forces in the form of membrane (i.e., action) potentials. Studies have shown that aside from the impact on muscle cell phenotype [35], myosin expression [94, 142], and contractile sarcomere assembly [41], electrical stimulation can also modulate fiber-type switch [98], as well as induce contractility in differentiated myotubes [58]. By incorporating electroactive materials directly into scaffolds, an alternative strategy can be used to imitate the natural cellular microenvironment. Inclusion of electrically conductive polymers (e.g., polyaniline, polypyrrole, polythiophene) [18, 47, 116], coupled with externally applied electrical stimuli, can promote tissue development (as evident by increased alignment and differentiation) on account of the delivery of electrical signals to cells via conductive polymers. According to literature, external electrical cues can trigger the action potential in in vitro cultures due to the difference in electrical resistance between culture media and intracellular fluid [148]. Consequently, calcium ions are released from the sarcoplasmic reticulum, and myotube contraction is triggered. On the contrary, when the applied electrical forces are too strong, they can cause membrane damage, decrease force generation, and prevent the increase in force generation after electrical induced contraction [63]. Boonen et al. have observed a complex interaction between electrical stimulation, surface protein coating, and substrate stiffness [16]. The response of muscle progenitor cells to electrical stimulation was most efficient on substrates with an elasticity of 21 kPa, which is close to the physiological stiffness of differentiated myoblasts [16, 27]. In another study, they showed that electrical induced contractions of cells on different coatings could activate different pathways of maturation [17]. These effects were also reproduced in a 3D culture system, in which myotube maturation was even faster [69]. The authors confirmed the advantages of cell cultures grown in a 3D construct through histological analysis, which showed that the myotubes were organized in the direction of stress. Uniform alignment of myotubes is important for the final construction of engineered muscle tissue, as it supports a maximal force generation upon contraction. However, the strength and duration of the electric stimulus require careful fine-tuning to result in active contractions of the myotubes [69]. Electrical stimulation has been successfully applied for the expansion of myogenic progenitor cells in 3D scaffolds without loss of myogenic potential. This is a useful method, especially for expanding satellite cells, which are known for their loss of regenerative potential after expansion in “standard” cell cultures [124].

Culture Conditions and Growth Media Composition

Despite recent advances in tissue engineering and consequent rapid development of novel-engineered muscle models, with each new model utilizing a diverse range of culture conditions, there is still no established “gold standard” for growing muscle cells in vitro [63]. In the process of building engineered muscle tissue, which could be used in regenerative medicine and cultured meat production, it is necessary to develop a native-like tissue architecture that possesses the ability of active force generation. Regardless of the efforts and breakthroughs in this field, it remains a challenge to overcome muscle cell’s inability to fully mature within engineered muscle constructs. Biochemical cues have the main role in the initial differentiation process, whereas (bio)physical stimuli have been proven to be pivotal in maturation towards fully functional and mature engineered tissue [70]. Moreover, to replicate the biological processes of the muscle tissue formation at an industrial scale raises several technical issues [54, 141]. Due to the complexity of the development of a mature muscle fiber, the step-wise production of a meat tissue will encompass the critical decision points [141].

“Base” Growth Media

To compete with the conventional meat industry, large-scale production of cultured meat would need to employ a low-cost media system. Aside from affordability, such media should contain essential nutrients, which are readily available (mostly through diffusion) for the cultured myoblasts and associated cells. Refinements in the composition of commercially available cell culture media have improved the cultivation of various types of animal cells [36]. For culturing mammalian cells in vitro on an industrial scale, serum-free media is a more realistic option, because it reduces both operating costs and process variability while lessening the potential source of infectious agents. Serum-free media have been developed for culturing satellite cells from turkey, sheep, and pig. Variations among different serum-free media outline the fact that satellite cells, derived from different animal origins, have different requirements and also respond variously to certain additives [32]. The animal serum is usually added to primary media formulations to supply an undefined assortment of growth factors, hormones, and other additives that promote cell survival, proliferation, and differentiation. The proportion of serum supplementation is one of the key parameters to induce myogenesis [48] as it guides skeletal myoblasts either towards proliferation or differentiation. In general, fetal bovine serum (FBS) is added in high levels (10–20% of final concentration) into media to encourage proliferation [6, 23, 63]. Based on previous studies, myogenic differentiation can be achieved in vitro by using lower levels (2–10%) of serum content in culture media [23, 25, 63, 71, 72]. Reduced concentrations of serum are needed for cell cycle withdrawal, which is a key factor for the onset of differentiation [71]. When using animal-derived serums, lot-to-lot variations and serum origin need to be considered as both were shown to significantly affect spontaneous contractility and force production (up to 3-fold), as well as influence growing muscle cell phenotype [61]. To develop commercially available serum substitutes that will replace FBS, some research groups have already designed animal-free serums. In their attempt to create an in vitro and edible muscle protein production system, Benjaminson et al. noticed that mushroom extracts were comparable with animal-derived serum in promoting explant surface area expansion [11]. Aside from chitin, cellulose, and melanin, mushrooms yield high-quality amino acids that can be applied as a rich serum supplement for an in vitro meat production. Plant-derived serum surrogates seem to be the ideal solution. However, their potential allergenicity should be considered [29].

Antibiotics

Extensive use of antibiotics in traditional livestock farming is an important risk factor for cultivating resistant bacteria (e.g., Salmonella, Campylobacter, Listeria, and Escherichia coli), which could be eliminated in cell culture conditions in a strictly controlled industrial environment. In this context, it is expected that cultured meat production will reduce the incidence of animal-borne infections (i.e., zoonosis) and other emerging diseases [29]. In particular, the high degree of environmental control will likely prevent problems associated with foodborne diseases by reducing the risk of foodborne pathogens and consequently improve food safety [10, 141]. In general, antibiotics are added into growth media as prophylaxis to prevent microbial contamination of cultured cells. Typically, used antibiotics in cell culture are penicillin and streptomycin. Streptomycin has a negative impact on skeletal muscle culture; it decreases protein synthesis and developmental maturation of myotubes due to inhibition of spontaneous contractility. In static cultured muscle tissue, the addition of streptomycin resulted in a 3- to a 4-fold reduction of force generation and a decline in frequency and intensity of spontaneous contractions [62]. Based on these trends, it has been advised to eliminate streptomycin from culture media to minimize variability and maximize maturation and functionality of in vitro skeletal muscle and rather increase the concentration of penicillin instead (to 100 IU/ml) [63]. As an alternative, sodium benzoate could be added to growth media to protect cells from yeast and fungus infection [141]. Sodium benzoate does not pose an additional risk to consumer health since it is generally used as a preservative in processed meat products [53]. Even though cultured meat is produced under sterile culture conditions with the possible use of antibiotic-free media, it is mandatory to investigate the magnitude of their use in-depth. Promoters of cultured meat production advocate that the process can be achieved with a notable lower level of antibiotics compared with the current use in the conventional meat industry [10, 130] or even without their use [134, 141]. At this point, providing the required sterile environment during production represents a great financial burden and is very difficult on a larger scale. Since the sterile environment can be difficult to conserve long term at lab level, there is a liability for the addition of chemicals and antimicrobials in the production process. However, it remains unknown whether antibiotics, antimicrobials, or chemicals will be routinely or occasionally requisite during muscle cell culture. On the contrary, the benefits of establishing the cultured meat production will reduce the exposure to noxious chemicals (e.g., pesticides and fungicides) in a traditional animal-agriculture industry [141].

Regulatory Biological/Growth Factors

Stimulation with different supplements, such as growth factors, potentiates myoblast proliferation and differentiation capacity. To ensure high rates of cell growth, the formulation of the growth media needs to contain not only the appropriate level of nutrients but also the appropriate level of the myogenic regulatory growth factors and hormones [141]. In addition to promoting myoblast proliferation and differentiation, different members of the transforming growth factor-β (TGF-β) superfamily, basic fibroblast growth factor (bFGF), hepatocyte growth factor (HGF), and insulin-like growth factor 1 (IGF-1) also stimulate migration and cell survival upon co-cultivation [81, 144]. Both TGF-β and bFGF reduce myoblast recruitment and differentiation (under independent mechanisms) by increasing myoblast proliferation, with the difference being that bFGF is more stimulatory in its action [49, 70]. Myostatin, a member of the TGF-β superfamily that is highly expressed in skeletal muscle, is a negative regulator of skeletal muscle growth. Loss of myostatin function is associated with an increase in muscle mass in mice, cows, and humans [10, 37, 55, 64]. Similar action is prescribed to TGF-β1, another member of the TGF-β superfamily, which inhibits the proliferation of myogenic cells [59]. The isoform TGF-β1 promotes ECM preservation by enhancing matrix protein synthesis and, at the same time, suppressing the activity of ECM degradation proteins, resulting in an increased overall quantity of the ECM (i.e., connective tissue) in muscle cross-section [55]. In the case of the bFGF role, Guthridge et al. [49] proposed a model whereby intracellularly produced bFGFs regulate myogenesis by autocrine and paracrine action. The complex mechanisms involving both paracrine and autocrine regulation dictate the proliferation capability of myoblasts. A bFGF positive feedback loop, which is initiated by an exogenous factor, maintains myoblast proliferation. Disruption of the auto-stimulatory loop by inhibition of FGF synthesis or by inhibition of FGF export leads to the terminal differentiation of myoblasts [49]. In other words, when a sufficient level of bFGF is present in growth media surrounding cells, most myoblast will proliferate. When the growth factor in growth media is depleted, the myoblasts cease division and fuse into multinucleated myotubes. It is well known that HGF primarily induces the proliferation of satellite cells by binding to the c-met tyrosine receptor and stimulates different downstream targets. The majority of circulating IGF-1 is bound to specific IGF-binding proteins (IGFBPs), and its function, among many others, is to activate proliferation as well as differentiation of satellite cells. Although stimulation with HGF and IGF-1 induces upregulation of different myogenic markers, it was discovered by Witt and colleagues that it is probably not essential for myogenic differentiation. IGFBPs participate during myogenic differentiation, differing among culture and stimulation conditions [144]. It is important to note that the specific selection of suitable extrinsic regulatory factors must be based according to the chosen cell type and animal species, as they respond differently to the same regulatory factors [20]. Besides, increasing the number of cells (i.e., proliferation) is feasible only at the satellite cell stage and the myoblasts’ stage [141]. Regarding a serum supplement ratio in growth media, it is very likely that the combination of growth factors should be changed over the course of culturing; one particular combination of growth factors may be beneficial for the proliferation period, whereas the differentiation and maturation period may require a different mixture [29].

Bioreactors

Animal cell culture has its roots in cell-based therapy, which has become viable on a commercial level and thus provides important guidelines for the transfer of cultured meat technologies to the industrial scale [130]. It is generally believed that a sufficiently advanced tissue bioreactor system will enable the development, growth, and maintenance of mature living muscle [30]. For the most part, some basic functions are common to many tissue engineering bioreactors: (1) maintaining an aseptic environment; (2) controlling environmental parameters such as temperature and pH; (3) controlling nutrient delivery; and (4) offering controlled experimental interventions, including online sensors. In addition, a system intended for developing skeletal muscle tissue generally requires mechanical and/or electrical stimuli that mimic the in vivo environment. However, the complete process from single-cell proliferation and differentiation to the maturation of large and well-defined structured cuts of meat probably requires several stages taking place under different conditions. Thus, the construction of a technological blueprint for a muscle bioreactor system is a complex engineering endeavor [4, 30], let alone the scaling up to an industrial level, which will require a substantial effort to achieve sustainable and cost-effective large-scale production of cultured meat [14, 141, 150]. Also, decisions related to the type, size, and the number of bioreactor units are influenced by several factors, such as seeding density, final cell number or density, and passaging steps. The obtained cell density will differ for suspension systems that use microcarriers for anchorage-dependent cells compared with single-cell suspension systems. Importantly, when designing a bioreactor, engineers should note the fact that the “working volume” of a bioreactor does not dictate the process of media requirements. Due to cell metabolic requirements over the entire duration of the culture period, the media requirements will be much greater than the bioreactor working volumes [4].

Bioreactor System

Companies currently working on scalable cultured meat products do not disclose information about their bioprocess design. However, a theoretical model of a bioreactor system, which could fulfill all of the criteria mentioned above, was presented in the work of [130, 29], as shown in Fig. 5. In essence, tissue development would take place into two stages: (a) for cell proliferation (e.g., in a stirred tank bioreactor) to provide a sufficient amount and density of cells and (b) for tissue development (e.g., on a porous scaffold in a perfusion bioreactor) where a structured and large-scale cut of meat would grow and mature [103, 130, 29]. Ideally, both stages should allow precise control over the bio-physicochemical parameters of the culture, continuous production, and efficient medium recycling. Although the production of cultured meat from self-replicating satellite cells derived from a biopsy is a simple concept, one of the main problems to overcome is its scalability [14, 141]. Satellite cells are anchorage-dependent, meaning that they need a surface for attachment, as well as have to be expanded in vitro, to obtain large cell numbers. When the required cell density is reached, the differentiation process is initiated, resulting in the formation of myotubes and the expression of proteins characteristic to functional myocytes [14].

Overview of a possible scaffold-based preparation of cultured meat. It starts with the isolation of myosatellite cells from muscle and their proliferation. The sequence of the following steps includes: 1) A formulated media is kept in the feed tank before being deposited 2) into a bioreactor with a scaffolding system. Media perfusion enables expanded cells to be seeded 3) onto a scaffold within a bioreactor. During the culturing process, media is being constantly replenished and oxygenated in an external fluid loop 4). After the culturing process is completed, media can be recycled 5), while the scaffold and cultured tissue are removed from the bioreactor system 6). Further processing includes tissue removal from the scaffold [29]

Proliferation and Differentiation Stage

Present conventional planar cell culture systems have notable limitations related to their low surface-to-volume ratio, the lack of pH, gas, and metabolite concentration control, offering to produce up to 1011 cells [14, 120]. To meet the demands for large-scale production, generation of a significantly higher amount of cells (in comparison 1012–1013 cells, correspond approximately to 10–100 kg of meat) is favored while using limited space, time, and amount of resources and requiring minimal handling [14, 89]. Stirred tank bioreactors remain the most prevalent type of bioreactors in the biotechnology industry. However, possible cell damage due to the shear forces caused by the impeller, alternatives such as airlift bioreactors, is approaching the market [95]. Due to the increased production efficiency and consequently lower requirements of volume per output, the biopharmaceutical sector has recently also begun adopting single-use bioreactors (SUBs), which eliminate the need for cleaning and validation while preventing cross-contamination [95]. With the advent of smaller culture vessels, new approaches to agitation can be deployed. Thus, SUBs can be adapted to several stirring mechanisms, such as orbitally shaken or wave bioreactors [95]. The described approaches provide new possibilities for process optimization in the experimental phase of cellular agriculture. For continuous production on an industrial level, perpetual supply of nutrients, and biological regulators (e.g., growth factors, hormones), as well as a supply of oxygen and removal of waste products, is integral in the culture media [141]. Therefore, the development of cultured meat can be seen as a finite-state machine (Fig. 5), meaning that every development stage is a stable condition that depends on its previous condition and the present values of its inputs. At each development stage, the growing muscle tissue (i.e., meat) will require a variety of inputs to reach the next level of development. Important development stages encompass (1) terminal differentiation of myoblasts to myocytes, (2) fusion of myoblasts to form primary (weak and low excitability) myotubes, (3) growth of secondary (stronger, more excitable) myotubes, (4) expression of adult muscle proteins, and (5) formation of the target product [30]. Alongside the units for proliferation and differentiation, a muscle bioreactor system should incorporate additional components such as media storage tanks, media heat exchangers, and suitable controllers to maintain a constant temperature within the system. In addition, an advanced bioreactor should also include units for automatic and frequent monitoring of muscle tissue development without affecting it, thus aiding in assessing suitable quantity and duration of applied stimuli to the tissue in real-time [4, 30].

Maturation Stage—Final Product Development

At the development stage of the final product, the bioreactor system should provide conditions for maturation and maintain the engineered muscle tissue. To facilitate the development of a large and structured “cut of meat,” scaffolds are likely to be included in the process to provide the cells with a well-defined 3D growth substrate, along with which the tissue will develop. Successful nutrient supply and removal of waste products inside large 3D structures is currently a major limiting factor in the scalability of cultured meat. Within the scope of realizing a highly structured product that mimics large cuts of meat (e.g., steak, chops, tenderloin), several research groups endorse the use of a perfusion-based bioreactor system with a 3D engineered tissue construct as the most suitable technique for the production of cultured meat [150]. To enable continued growth and long-term sustainability of viable 3D engineered tissue constructs, homogeneous and adequate oxygen supply is paramount to avoid a necrotic nucleus. Albeit, owing to the microporous structure of the scaffold material, media flow can only be laminar, restricting the heat and mass transfer efficiency. To maintain the optimal, replenishing rate across scales, it is vital that the flow rate increases linearly with the scale of the structure. This, in turn, contributes to high shear stress and a considerable pressure drop. To subdue such problems, a typical approach encompasses enlarging the pore size of 3D engineered construct to improve permeability [150]. However, this could limit control over the texture and consistency of the final product. Various approaches to sustaining continuous medium perfusion through the scaffold have been proposed, including stirred tank, rotating vessel, or direct perfusion bioreactors (Fig. 6). While a high mass transfer of medium flow is required, it is accompanied by a significant increase in shear stress, therefore determining that a suitable flow rate is critical for successful and effective growth [29, 82]. Direct perfusion bioreactors provide this type of bioreactor which is mainly intended for scaffold-based myocyte cultivation and high-density, uniform myocyte seeding [110]. Cerino et al. [23] demonstrated a one-step (proliferation and maturation) platform by the use of SVF co-culture and a 3D perfusion bioreactor, creating a complex biological model for engineering functional 3D uniform muscle tissue that resembles its native multi-cellular environment [23]. However, at this point, the proposed system is only suitable for small sample sizes with limited scalability. Despite the accomplishments in tissue engineering, in its current form, such a perfusion-based bioprocess system is unsuitable for upscaling the cultured meat production [150]. To ensure controlled tissue production, monitoring of its development is crucial. Biomarkers that can be used to evaluate the developmental stage of the muscle harmlessly are contractility (force and rate of contraction and relaxation), excitability (energy required to achieve stimulation), and metabolism, which can be, among other methods, determined by oxygen consumption [30]. Besides, several technologies for in-line, real-time monitoring of systems performance, culture conditions, and cell viability have been validated [151], alongside with Raman-based strategies for in situ monitoring of chemical composition [85]. For all bioprocessing systems, three main sensor parameters, in particular, pH, dissolved oxygen, and temperature, are prerequisites. Cell culture media normally contains buffer agents and sodium bicarbonate to maintain pH values within optimal working conditions. The optimal pH of cell media alters throughout the bioprocess; therefore, it must be carefully monitored at each stage of the process. Namely, even a (rather) small change of 0.1 pH units from the optimum can greatly affect cell viability and concentration [95]. Dissolved oxygen is another critical parameter that must be closely monitored and optimized. This is crucial for the survival of aerobic cell types. However, high levels of dissolved oxygen levels can lead to the production of super-oxides or peroxides, which have a damaging effect on the cell membranes or even cause DNA breakdown. To ensure optimal cell viabilities and high product yields during bioprocessing, the temperature inside a bioreactor must be accurately measured. For the production of mammalian cells, the optimal temperature has been widely established for many years to be around 37 °C (like body temperature). Though recent studies demonstrated that at lower temperatures, in the range of 30–35 °C, the high production of some proteins can be achieved. Thus, depending on the desired product, the temperature sensors must operate accurately in the range of 30–40 °C as the process temperature will vary over time. Moreover, they must be highly sensitive in temperature variations to prevent loss in cell viability. The bioreactor’s monitoring system can be further implemented for continuous measurements of the substrate and product concentrations (viable), cell density, and metabolites [95].

Commonly used bioreactors for the production of 3D tissue-engineered constructs: a spinner flask, b rotating wall vessel, and c perfusion bioreactor [100]

Microcarriers

Owing to a large surface-to-volume ratio, microcarriers (MCs) are the most promising candidates for large-scale implementation. The suspended MCs provide a 3D environment, but the cells still grow on a 2D surface, although the strong curvature of the bead surface affects cell attachment and proliferation. Since the microenvironment of the cells remains unchanged, the translation from the traditional monolayer culture to a suspension one is smoother. Moreover, depending on their buoyancy and density, they can be used in various types of vessels (e.g., stirred tank, fluidized bed, packed bed, bubble column bioreactor) that are generally employed for scaling up chemical and bioprocesses. As opposed to fixed-bed bioreactor cultures, such as hollow fiber or microplate, MC-based bioprocesses are easier to control and monitor, resulting in the quality and consistency of the products. A significant advantage of MCs is that the cell growth surface can be increased simply by adding new MCs to the culture. This is feasible due to a phenomenon referred as “bead to bead transfer,” which describes the cell migration from bead to bead, and the population of newly added MCs [14, 52, 66, 97, 112, 113, 138, 150]. Introducing a new surface area into satellite cell culture also is beneficial to avoid aggregation of MCs [14, 138]. The use of MCs has long been instituted in the cell-based therapy industry and vaccine production for expansion of cells producing a molecule of interest (e.g., monoclonal antibodies, proteins, vaccines) [99, 150]. Verbruggen et al. [138] provided a proof-of-concept experimental work of using MCs-based bioprocess for cultured beef production. The materials for such MCs should comply with food regulations (following good manufacturing practice, GMP, hazard and critical points, HACCP, and standards). MCs can be designed to serve as a temporary substrate for cell attachment and proliferation, or they can be embedded in the final product, and ergo need to be edible. Using edible materials can obviate the need for dissociation/degradation/separation steps and limit the risk of non-edible residues. Besides, they can be even tailored to enhance the sensorial and nutritional qualities if embedded in the final product. Towards that end, abundant, edible polymers, such as alginates, pectins, and chitosan, that are prevalent in the food industry, such as stabilizers, thickeners, coatings, and emulsifiers [3, 14, 127], seem to be promising candidates for upscaling the process.

Oxygen Carriers

Cell viability and density positively correlate with oxygen gradient in statically grown tissue cultures [111]. To overcome limitations in oxygen diffusion in tissue cultures and to maintain the high oxygen concentration in the bioreactor, oxygen carriers can be added into growth media. They can be divided into two varieties: hemoglobin-based oxygen carriers (HBOCs), which are mostly modified hemoglobin versions, and chemically inert, artificially produced perfluorocarbons (PFCs). Even though PFCs dissolve large amounts of oxygen and can perform the same functions as hemoglobin, they are extremely potent greenhouse gases on a per molecule basis [29].

Recycling

Technical experiences from the established biotechnology industries (e.g., brewery, pharmaceutical, and recombinant/therapeutic protein industries) pose good parallels for upscaling the bioprocess of cultured meat manufacture. Downstream units require recycling operation with cell debris removal, media refinement, cell harvesting, and product formulation [4]. The management of metabolic waste by recycling (as well as by disposal or upgrading) must satisfy the requirements of the HACCAP procedure [141]. If recycling is put into operation, the emissions from excess nutrients in the wastewater could be comparable with, or lower than, a poultry operation [83, 141]. One approach for media refinement is through the replenishment of utilized nutrients (e.g., glucose and glutamine) and removal of waste by-products such as lactate and ammonia, which, even in small quantities, are known to inhibit cell growth. One strategy for media replenishment is by perfusion mode, in which fresh media is continuously pumped at a given perfusion rate together with the removal of used media at the same rate. At the same time, the cells are retained in the bioreactor. This implantation of continuous perfusion processes has gained prevalence in the biopharmaceutical industry for large-scale production, as constant media refinement and removal of toxic by-products ensure high productivity and product quality. Moreover, for industry related to cell therapy, maintaining the concentration of essential nutrients and metabolic products at optimal levels may be crucial in the regulation of cell growth, differentiation, and other vital attributes [2]. It might be favorable to reuse a part of supplements in growth media (e.g., growth factors, cytokines) that were either added or produced by cells and therefore stimulate further cell growth [89]. Nath et al. [93] established a culture media refinement method using a dialysis for the expansion of human-induced pluripotent stem cells (hiPSCs) in suspension culture. By exchanging fresh media only once, following the refinement of media with the proposed dialysis system, they removed toxic metabolites. At the same time, essential macromolecules of media (e.g., growth and autocrine factors) were recycled efficiently [93]. Recovery of purified water is also feasible by using downstream separation units that comprise one or more of the following processes: membrane filtration, (electro)dialysis, precipitation, solvent extraction, and absorption systems [4].

Production and Supply at the Regional Level

As cultured meat production is generally believed to be most feasible at an industrial level, some companies like FM Technologies propose two conceivable scenarios where cultured meat production could proceed at (1) a small business or (2) an individual consumer scale [141]. FM Technologies (https://www.future-meat.com/) portrays this as a “distributive approach to sustainable manufacturing.” Their proposed model system centralizes stores of stem cells, which are periodically delivered to local communities. The latter would have small-scale bioreactors with the capacity to feed small villages or regions, and a central point will give the technological know-how. Models of the distributive approach present are purely theoretical and remain to translate into practice [141].

Nutritional and Sensorial Aspects

The reasoning behind cultured meat is that “traditional” consumers expect meat, which is as readily accessible and comparable (if not superior in nutritional value) with native meat and not a meat substitute with perceived lower quality (from the start). The resemblance should be guided not only by sensory factors (e.g., color, flavor, tenderness) but also by nutritional and health values. In other words, the biochemical and structural composition of engineered meat needs to be like the natural counterpart. The key factors that govern cell and tissue cultures on the way to becoming a desired product are culture conditions, as well as the external dynamic environment (mechanical and electrical cues). With existing technology, all these conditions can be controlled and further optimized, with a focus on flavor (taste and aroma), texture, nutritional value, and food safety [10, 101, 102]. However, some differences will still be present; some nutrients that are not produced by myoblasts nor adipocytes, such as vitamin B12, are absorbed from the environment (in vivo from blood). The requirements of these “environmental” nutrients can be easily fulfilled by supplementing the growth media. For efficiency and safety reasons, future studies will guide the selection of nutrients, which are essential for the development of cultured meat and at the same time harmless for consumers [4]. Although alternatives to farm-grown meat (i.e., plant-based protein and cultured meat) have received considerable attention within academia and the popular press, the consumers’ willingness to adopt cultured meat is unclear even if it tastes the same. Nevertheless, the current market is less optimistic about a lab-grown version. It is important to note that consumers’ preferences are amenable and can be changed by new information govern by marketing campaigns or social norms [9, 129]. The abundance of vegetarian meat substitutes may “prepare the ground” for acceptances of cultured meat in the form of burgers and sausages, as well as the possibility to prepare meat variations from animals that are considered a delicacy [129].

Protein Composition

The highly complex meat composition, which includes a wide variety of proteins, carbohydrates, fatty acids, and aromatic compounds, is the main contributor to its flavor [90]. Muscle tissue is rich in proteins as it contains up to 6500 types of proteins with an extremely wide expression range of several orders of magnitude [96]. The most abundant proteins are myosin, actin, and titin, which together make up 75% of cytoskeletal proteins of myoblast cells and represent between 40 and 60% of the total amount of protein in muscle fibers (total percentage depends on the type of muscle fiber) [92]. It is hypothesized that highly aligned and tightly co-expressed myosin and actin molecules have the most significant contribution to the meat’s texture. Nutritional value, taste, and mouthfeel are co-determined by the amount and composition of the most abundant proteins (e.g., actin and myosin, respectively) in myoblasts. Therefore, the muscle proteome presents the foundation for the creation of meat tissue that consumers “perceive as meat.” Optimizing protein composition focuses primarily on the proteins actin and myosin. However, it is also likely that scarcer proteins, such as heme-containing proteins (e.g., hemoglobin and myoglobin) possess specific components contributing disproportionally to taste and appearance [101].

The culture conditions that will lead to these improvements are well-known in medical tissue engineering but will need to be implemented in a scalable process for meat production. Current culturing methods are suitable for creating fully mature muscle tissue with typical cross-striation that indicates the development of sarcomeres [16, 17, 69]. The overall protein content is 20%, which is comparable with native muscle fibers [101]. On the other hand, the previously mentioned electrical stimulation has not yet proven to be a resource-efficient method, and alternative ways for stimulating the muscles to produce higher amounts of relevant proteins will need to be developed (explored) to achieve the same result. Similarly, stimulation of myoglobin expression has been described and confirmed in many other muscle cells of vertebrates. It can be easily used in ways that are compatible with scalable production methods. For example, by reducing oxygen concentration during cell culturing, myoblasts started to show a 5-fold increase in myoglobin expression [51, 60]. Sufficient myoglobin is important for color, nutritional value (heme iron), and taste of meat (serum-like taste and metallic mouthfeel of red meat) [87].

Fat Composition

To achieve complete meat flavor, ensure its expected nutritional value, and mimic its natural texture, it is mandatory to add adipose tissue to the final meat product. It appears that a large number of small peptides are jointly responsible for taste [26], while an equal amount of aromatics (originating mostly from adipose tissue) co-determine the flavor [125]. Intramuscular fat (IMF) accounts for about 80% of the muscle fat, while the remaining 20% is stored as lipid droplets within myofibers. Its amount and fatty acid composition are accounted for meat quality (e.g., juiciness, flavor, tenderness, and nutritional value). IMF is created via adipogenesis, in which stem cells differentiate into adipocytes, and lipogenesis, in which triglycerides are accumulated inside the adipocytes [10, 77]. Between muscle types, the phospholipids coverage is relatively constant, while the muscle triglyceride content is highly variable among the species [77]. Adipose tissue can be cultured from MSCs, from adipose-derived stem cells, or from myosatellite cells that entered an alternative differentiation pathway (resulting in the formation of intermuscular adipose tissue (IMAT)) [73, 139]. Adipogenic differentiation involves activation of several transcriptional factors including a peroxisome proliferator-activated receptor-γ (PPAR-γ) that is a dominant regulator of white-adipocyte differentiation [21], and for which free fatty acids (FFAs) present natural ligands. In addition to their function as an energy source, some of those FFAs have been proven to induce adipogenesis in stem cells with mild and natural stimulation (e.g., cultivation in FFA-supplemented media) [86]. Maturation of adipose tissue into characteristic white adipose tissue takes approximately 2–3 months, whereas maturation of muscle tissue takes around 3 weeks. Despite the longer maturation period, the formation of fat tissue presents a less challenging process compared with the preparation of mature muscle fibers in vitro. The interactions between differentiating adipocytes, which are the basis to formation of a similar structure to the native tissue, are not as significant and complex as in the case of muscle fibers. Although the fat fraction is one of the main components of meats taste and texture, it may also be associated with cardiovascular diseases due to high content of saturated fatty acids and low levels of polyunsaturated fatty acids (PUFAs). In cultured meat, PUFA levels can be controlled with adjusting the composition of fat tissue culture media [145, 146]. In the interest of “not compromising” the taste of the engineered meat, the optimal amount of PUFAs will need to be derived from a combination of biochemical and sensory evaluations [101].

Tenderness

To mimic livestock derived meat in the majority of sensory aspects, the procedure of recreating conventional meat in vitro should also involve the usual aging process after native tissue’s “death.” Many studies have shown the complexity of meat tenderization. It is based on the extent of proteolysis of vital target cytoskeleton proteins within muscle fibers and the alteration of muscle structure due to the sequential actions of enzymes. After slaughtering the farm animals, muscle fibers undergo postmortem rigidity (rigor mortis) due to protein contractions, resulting in muscle toughness. The extent and mechanism behind rigor mortis are still rather poorly understood and likely vary for different harvesting conditions of the muscle. However, it is expected that mimicking only ischemic conditions in engineered meat cannot produce the same comparable effects on muscles as a sequence of death-related events in vivo (i.e., preslaughter stress and postmortem muscle metabolism), such as the release of catecholamines, increase in blood lactate, and cortisol concentration [28, 34, 102]. In the case of farm animals, the aging process is accompanied by a decline in aerobic metabolism due to decreasing oxygen supply. Subsequently, glycogen is converted into lactic acid, which induces a decrease in pH to 5.4–5.8 [102], activating enzymes responsible for tenderization and formation of aroma precursors [40]. The aging period depends on the meat; for example, in beef that has a low amount of proteases, aging takes approximately 14 days. Aside from pH, temperature also has an impact on the palatability of meat. Hence, both factors should decrease within a precise timeframe [132]. The involvement of different groups of muscle peptidases that are responsible for the postmortem protein breakdown during cadaver storage is still a controversial topic. Among these peptidases, the calpain system accompanied by its inhibitors (e.g., calpastatin) was considered to be the predominant system accountable for meat tenderization [75]. The extent to which proteolytic enzymes act is strongly influenced by the microenvironment conditions (e.g., pH, ionic strength, cellular oxidative, and nitrosylation status) [78]. Hence, mechanisms that are responsible for postmortem degradation of structural proteins are under the scope of various studies, which aim to elucidate the underlying processes. Likely, intracellular conditions in cultured meat might overall differ from conventional meat, which would affect the rate and extent of tenderization and flavor development [40]. Considering this, further insights into the phenomena of postmortem degradation would enable a better prediction of the quality and resemblance to the conventional meat. Isoforms of actin and myosin in cultured muscle tissue were found to be rather neonatal or embryonic than adult [40, 133]. This could affect the postmortem protein breakdown, resulting in altered postmortem transformations. In the case of their absence, the engineered muscle tissue is not transformed into the meat and, consequently, biochemically dissimilar [29].

Moreover, particularly in cattle, connective tissue influences meat tenderness by its composition and structure, whereby collagen is seen as a major determinant of the shear force. However, there exist substantial differences between raw and cooked meat that are, in the case of raw meat, highly correlated with the collagen content. On the other hand, in cooked meat, the level of the relationship between the content, thermal solubility, or cross-linked level of collagen and meat shear force varies according to muscle type and cooking conditions [77]. All mentioned will aid the newly emerging industry of cultured meat to create a product that is as close an imitation of livestock meat as possible [4].

Color

As mentioned above, the myoglobin, which contains heme, is “the main culprit” for the red color of meat, specifically its chemical state [40, 77, 102]. In deep muscles and meat stored under vacuum, myoglobin is in a reduced state, which gives the meat the purple red color. In an oxygenated form (i.e., when exposed to oxygen conditions) such as oxymyoglobin, it exhibits an attractive red color. During the meat storage and cooking process, oxymyoglobin is further oxidized into metmyoglobin that is displayed as a darker brown-red color. Muscles that are rich in myoglobin (e.g., from cattle, sheep, horses) are apt to metmyoglobin formation and decreased color stability [77, 128]. Due to the suppressed myoglobin expression at ambient aerobic conditions and, therefore, the absence of myoglobin, the engineered muscle tissues have a pale color [40, 44, 102]. Thus, several strategies have been proposed to improve the myoglobin load of cultured meat. Briefly mentioned in the previous subsection (“Protein Composition”), the first approach involves culturing myofibers under hypoxic conditions [51, 60, 102]. However, deeper insight is needed to determine whether a low amount of oxygen is sufficient enough, as well as any potential impact on culturing efficiency [89]. Namely, this can lead to media acidification, which is harmful to cell viability [29, 40, 57]. Supplementation of culture media with additives, such as lipids and acetic acid, could also stimulate myoglobin expression [89]. Only myoglobin protein synthesis is not enough for color development; the presence of a sufficient amount of iron in the cell is also of great importance. In general, cell culture media contain no iron (e.g., IMDM) or only low amounts of it in the form of ferric nitrate nonahydrate (e.g., DMEM 0.1 mg/L) or ferrous sulfate heptahydrate (Ham’s media 0.8 mg/L). The addition of extra iron into culture media increases the iron content in the cultured cells. However, only part of the iron is uptaken. This indicates that while media can be formulated to affect nutritional coverage, there is a limit to the amount of this microelement the cells can incorporate [122]. Since the iron uptake is dependent on transferrin, a protein that binds iron and mediates transport in the cell [57, 89], further investigations are necessary to determine the extent to which iron is then incorporate into heme (for good iron bio-accessibility) and myoglobin (for red color development) [40, 102].