Abstract

Different methods of sugar beet seed threshing have been used to improve the seed cultivation value. Two types of processing are common, including ordinary processing (seed size of 3.00–4.75 mm round sieve, coating with Gaucho insecticide) and special processing (seed size of 4.00–4.5 mm round sieve, and above 2.2 mm long sieve, coating with Cruiser insecticide). The present study was conducted to evaluate the effects of seed processing and plant density on quantitative and qualitative traits of sugar beet as a factorial experiment in a randomized complete block design with four replications in the crop year 2017–2018 in two regions of Karaj and Kermanshah. The first factor included the processing methods were ‘Shokoufa’ seeds with ordinary threshing and coating with Gaucho (a1) and Cruiser (a2), ‘Shokoufa’ seeds with special threshing and coating with Gaucho (a3) and Cruiser (a4) and seeds of cultivar F20909, and the second factor included the final plant density including 7, 10, and 13 plants per m2. The highest contents of impure (16.99%) and white sugar (8.23 t ha−1) and extraction coefficient of sugar (82.43%), and the lowest amounts of molasses (2.30%), harmful nitrogen (2.34 meq 100 g−1 beet), and potassium (4.97 meq 100 g−1 beet) were observed in F20909. Root yield, impure sugar yield, and white sugar significantly increased with increasing plant density. Regarding different areas of sugar beet cultivation, it was found that plants grown in Karaj had higher root yield (69.19 t ha−1), impure sugar (10.28 t ha−1), white sugar (7.58 t ha−1), harmful nitrogen (3.45 meq 100 g−1 beet), potassium (6.32 meq 100 g−1 beet), sodium (3.24 meq 100 g−1 beet), and molasses sugar (3.30%), while plants grown in Kermanshah had higher white and impure sugar content (16.55 and 14.14%), alkalinity (3.29), and extraction coefficient of sugar (84.84%).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The sugar beet (Beta vulgaris L.) is one of the most important sources of sugar worldwide. It produces approximately 253 million tons of roots annually in an area of about 5 million hectares and contains nearly 20% of the world’s sugar (Rašovský et al. 2022). In 2017, sugar beet with a cultivated area of 126 thousand hectares, 1.28% of the total area of cultivated crops, with 6.6 million tons of root crops, accounted for 9.83% of the total production of crops in Iran (Anonymous 2017). One of the problems of sugar beet cultivation in Iran is the lack of achieving the desired plant density per unit area, which while reducing the efficiency of consumption of agricultural inputs, reduces crop yield. In the field studies, about 61% of sugar beet production fields face the problem of improper plant density per unit area (Taleghani et al. 2006). One of the effective ways to increase plant stability in the field is to use seeds with good quality in terms of germination and stability. The importance of this issue has become more important with the production and planting of monogram seeds. In addition, the application of polishing techniques and the use of a small range of seed sizes contribute to the proper and uniform germination of seeds. Moreover, the use of fungicides, insecticides, nutrients, moisture-absorbing materials, and suitable colors and coatings are some of the techniques that increase the quality of seeds and, consequently, increase the stability of plants on the field surface (Taleghani et al. 2006; Finch-Savage and Bassel 2016; Kimmelshue et al. 2022).

One of the ways to improve and increase seed efficiency is to coat it with chemical compounds, which regulate and improve germination (Copeland and McDonald 2012; Paravar et al. 2023). Seed coating technologies date back several decades (Paravar et al. 2023). The main reasons for seed coating include insect control, control of pathogenic fungi, and the addition of beneficial microorganisms to the seed composition, germination improvement, and seedling stability (Kimmelshue et al. 2022; Paravar et al. 2023) and so on. Farmers need the right seeds to get the most yield, and the goal of seed coating is to achieve this potential (Rocha et al. 2019; Paravar et al. 2023). Seed coating is one of the methods of seed strengthening with different purposes such as increasing the speed and rate of germination, preventing pests and diseases, facilitating seeding operations, uniform distribution of seeds, maintaining moisture around seeds using moisture-absorbing materials, increasing the performance of delayed germination, preventing seeds from being eaten by animals, increasing the speed and ability of plant stability (Sohail et al. 2022; Zhang et al. 2022). Therefore, it is necessary to use different techniques to increase seed efficiency, increase the power and speed of germination, uniformity of germination, and increase the stability of the sugar beet plant. In addition, disinfection (with chemical toxins) and coating of sugar beet seeds are becoming more common day by day (Salimi and Boelt 2019).

Proper seed preparation, including seed processing before sowing, is one way to improve seed power and thus crop yield (Marinković et al. 2008). The main reason for the uneven and weak germination of sugar beet is attributed to the presence of seedless fruits as well as seeds with undeveloped embryos, and threshing as one of the seed processing methods includes the separation of hollow seeds, weed seeds, and foreign materials (such as sand, gravel, and brushwood) as well as the grading of seeds based on their diameter, which is done in the sugar beet seed processing plant (Chegini et al. 2015). The study by (Rochalska and Orzeszko-Rywka 2008) showed that in different stages of sugar beet seed threshing, seed abrasion significantly increased seed germination power and stability of sugar beet. This could be effective in the quantitative and qualitative characteristics of the product in the next steps. Seed disinfection is usually performed in the seed production system after harvest and threshing. In recent years, the use of various pesticides and fungicides to control seed-borne pathogens has increased (Tavakoli and Beheshti 2010). Olsson (2012) showed that treatment of sugar beet seeds with different types of pesticides significantly prevented damage caused by harmful insects at the beginning of the season. This resulted in significant improvements in the growth characteristics and sugar yield. Due to the possibility of performing additional threshing steps (removal of hollow seeds with incomplete embryos and seeds with thick shells) in seed coating technology, the power and speed of germination and the stability of the plant in the main ground are increased and make it possible to achieve the desired plant density in the field. Furthermore, processing treatments often have a positive effect on sugar beet yield by maximizing germination rate as well as increasing germination capacity and uniformity and seedling stability in the field (Lukaszewska et al. 2012). From the point of view of the effect of plant density changes on sugar beet quality characteristics, some studies indicate a reduction in root impurities (sodium and potassium) following an increase in plant density from 60 to 120 thousand plants per hectare (Jafarnia et al. 2013). In a recent study, the highest sugar yield and the lowest root impurities were obtained at a density of 90,000 plants per hectare. Another study showed an increase in plant density from 87.5 to 100 thousand plants per hectare. This resulted in a significant increase in sugar content, purity, white sugar content, and sugar yield (Masri 2008). In another study, Ismail and Allam (2007) reported that plant density between 70 and 105 thousand per hectare caused the highest yield and quality traits.

The main purpose of this study is to provide a sufficient number of plants per unit area by focusing on the effects of seed processing including threshing (ordinary and special) and coating with chemical toxins (Gaucho and Cruiser). Although the use of these treatments is often applied during the production and planting process of sugar beet seeds, there is little information about how these factors simultaneously affect and the reaction of Iranian and foreign cultivars in terms of quantitative and qualitative traits in seeds obtained from threshing (ordinary and special) as well as a difference in final yield between seeds from processing relative to different planting densities. According to the above, the present study was conducted to evaluate the effect of seed processing and plant density on some quantitative and qualitative characteristics of sugar beet in Karaj and Kermanshah regions.

Materials and Methods

To evaluate the effects of seed processing, including threshing (ordinary and special) and coating with chemical toxins (Gaucho and Cruiser) to provide a sufficient number of plants per unit area, this research was conducted as a factorial experiment in a randomized complete block design with four replications in the crop year 2017–2018 in two places, including Motahhari research station (Kamalabad, Karaj) with geographical coordinates of 35°50′ north latitude and 50°6′ east longitude with an altitude of 1244 m above sea level and Mahidasht research station in Kermanshah with geographical coordinates of 15°34′ north latitude and 46°48′ east longitude with an altitude of 1362 m above sea level.

The studied factors were the ‘Shokoufa cultivar’ with four different seed sizes and disinfection: (a1) ‘Shokoufa’ seeds with ordinary threshing (seed size equivalent to 3.00–4.75 mm round sieve + coating with Gaucho and carboxin-thiram fungicide with 90% potency); (a2) ‘Shokoufa’ seeds with ordinal threshing (seed size equivalent to 3.00–4.75 mm round sieve + coating with Cruiser and carboxin-thiram fungicide with 95% potency); (a3) ‘Shokoufa’ seeds with special threshing (seed size equivalent to 4.00–4.50 mm round sieve and above 2.2 long sieve + coating with Gaucho and carboxin-thiram fungicide with 90% potency); (a4) ‘Shokoufa’ seeds with special threshing (seed size equivalent to 4.0–4.5 mm round sieve and above 2.2 long sieve + coating with Cruiser and carboxin-thiram fungicide with 95% potency), and (a5) F20909, KWS cultivar with the size of 3.25–4.75. Plant density factors with three levels including (b1) seven; (b2) ten, and (b3) thirteen plants per square meter were planted with a fixed row spacing of 50 cm and were created by changing the distance between the plants.

Seeds with the same density were planted by a manual seeder (Kermanshah) and Oyord (Karaj) and in the thinning stage, plant density treatments were applied. Each plot consisted of six planting rows a length of eight meters. At the time of harvest, the length of the harvest line was considered equal to 6 m. The experiment was carried out in the 2nd decade of May by planting and a drip-tape irrigation system. Moreover, the most important meteorological components of the two regions during the experiment are shown in (Figs. 1 and 2).

To experiment, after tillage and leveling operations and before planting, a composite soil sample was taken from a depth of 0–30 cm to measure the physical and chemical characteristics and after chemical analysis of the soil, the test site in each area was recorded separately. For Mahidasht station (Kermanshah), soil reaction (pH), electrical conductivity, organic carbon, available phosphorus, available potassium were equal to 8.11, 0.50 dS m−1, 0.83%, 8.00 ppm, 600 ppm, respectively, and the type of soil texture was silty-clay. For Motahhari station (Kamalabad, Karaj), soil reaction (pH), electrical conductivity, organic carbon, available phosphorus, available potassium were equal to 7.80, 1.72 dS m−1, 1.33%, 20.83 ppm, 620 ppm, respectively, and the soil texture was loamy.

Measurement of Seed Germination Characteristics and Plant Stability

To determine the standard germination percentage of seed treatments, 100 seeds were divided into four parts of 25 using a divider and then, in a randomized complete plot design with four replications according to the International Seed Testing Association (ISTA 2013), was planted in accordion-folded filter papers and placed in a germinator at a temperature of 20 °C and relative humidity of 85%. The standard germination percentage (according to (ISTA 2013)) in each treatment after two weeks was counted and recorded. Simultaneously with counting the number of normal seedlings based on radicle growth of 2 mm, plumule and radicle length were measured by digital caliper, and radicle and plumule dry weight obtained using the tube-planting method was also determined by placing them in an oven at 70 °C for 24 h.

To evaluate the stability of processed sugar beet seeds under field conditions, an experiment was conducted in a randomized complete block design with four replications at two research stations Karaj and Kermanshah. Each plot consisted of a planting line four meters long and 50 cm wide. In each plot (with an area of 2 square meters), 100 seeds were planted manually at a distance of 5 cm from each other. After the first irrigation using the drip-tape method in the late week of May, for 21 days, every 3 days, the number of seeds that reached the cotyledon stage up to two true leaves was counted, recorded, and placed on a wooden stick next to the counted plants. The counting of plants continued until the number of plants was fixed.

At the time of harvest, after washing the roots in the laboratory by VENEMA apparatus (G2), the root pulp was prepared and 26 g of it was mixed with 177 ml of lead subacetate to prepare a clear extract. The filtered extract was poured into special glasses and sucked into the machine by the sucker of qualitative analysis machine of sugar beet and its sugar percentage was determined. The sugar content (SC) was measured by polarimetry, sodium and potassium by flame photometry, and harmful nitrogen (α-amino) by spectrophotometry. By determining the above values, other quality characteristics such as alkalinity (ALC), molasses sugar (MS), white sugar content (WSC), extraction coefficient of sugar (ECS), sugar yield (SY), and and white sugar yield (WSY) were calculated using Eqs. 1, 2, 3, 4, 5 and 6, respectively (Abdollahian-Noghabi et al. 2005):

In the above equations, ALC was alkalinity (without units) and Na, K, and α-amino-N were sodium, potassium, and harmful nitrogen (milliequivalents per 100 g fresh root weight), respectively, and MS was molasses sugar (percent).

In the above equations, WSC is white sugar content (percent); SC is sugar content of the root (percent); ECS is extraction coefficient of sugar (percent); SY is sugar yield (t ha−1); RY is root yield (t ha−1), and WSY is white sugar yield (t ha−1).

Statistical Analyzes

SAS software (Ver. 9.1 2002–2003, SAS Institute, Cary, NC) was used for the analysis of variance. It should be noted that in the combined analysis of variance, the location factor was considered as a constant factor and the calculations were based on mathematical expectations. Mean traits were compared using Duncan’s method at a 5% level.

Results

Germination Percentage

The results showed that the germination percentage was significantly (P < 0.01) affected by sugar beet seed processing (Table 1). Comparisons of the mean data also indicated that the highest germination percentage at 97.5% was related to the KWS cultivar (Table 2). Furthermore, the treatments of Normal ‘Shokoufa’ + Gaucho and Normal ‘Shokoufa’ + Cruiser at 85.0 and 88.5%, respectively, had the lowest germination percentage. According to the national standard of sugar beet seed germination (87%), the seeds of the ‘Shokoufa’ cultivar with normal processing lacked the necessary standard, which can be concluded that special processing caused a significant increase in germination percentage.

Seed Vigor

The results showed that the effect of type of sugar beet seed processing on seed vigor was significant at a 5% level (Table 1). Based on the comparison of the mean data, it was found that KWS cultivar (93.0%), ‘Super Shokoufa’ cultivar + Cruiser (88%), and ‘Super Shokoufa’ cultivar + Gaucho had the highest seed vigor among other treatments (Table 2). The lowest seed vigor was observed for Normal ‘Shokoufa’ + Gaucho (85.5%) and Normal ‘Shokoufa’ + Cruiser (86.0%). Another indicator that determines seed quality is the seed vigor index, which is effective in seed quality through the percentage of germination percentage and seedling length. Seeds that have strong vigor, have a high ability to withstand environmental stress factors, have a high percentage of germination, and can produce strong and normal seedlings. Strong seeds, which the conditions are more favorable for them, can produce normal and vigorous seedlings at germination.

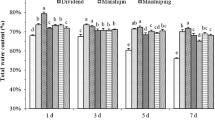

Plant Stability

The results of this study showed that the simple effects of location and sampling as well as the interaction of location × sampling on the stability of the sugar beet plant were significant at a 1% level (Table 3). Figure 3 shows plant stability in the Kermanshah region (45.07%) was significantly higher than in the Karaj region (24.85). In Kermanshah region, the rate of sugar beet plant stability in the early stages increased significantly nine days after planting and reached a maximum of 45.07% on the 12 day after planting, but then showed a gradual decrease (Fig. 3A). In Karaj region, it was found that the rate of decrease in plant stability occurred with a lower slope compared to Kermanshah region (24.9%), but at the same time at all stages of measuring this slope was increasing. In Fig. 3B, the effect of seed processing on the stability of sugar beet in Karaj region showed that the cultivars of Super ‘Shokoufa’ (34.7%) and Normal ‘Shokoufa’ (35.41%) processed with Cruiser had more suitable stability than other treatments, while according to Fig. 3C, in Kermanshah region, the highest percentage of plant stability was related to KWS (38.03%).

Root Yield, Sugar Yield and White Sugar Yield

The results of analysis of variance showed that the interaction of location × seed processing was significant at a 1% level on root yield and sugar yield as well as at a 5% level on white sugar yield in sugar beet (Table 4). Comparison of the mean interaction of location × seed processing also showed that the highest root yield was related to the treatments of Normal ‘Shokoufa’ + Cruiser (75.15 t ha−1), Super ‘Shokoufa’ + Cruiser (72.22 t ha−1), and Normal ‘Shokoufa’ + Gaucho (68.36 t ha−1) in Karaj region. In Kermanshah region, seed processing had no significant effect on the root yield, but in Karaj region, the seed treatment with Cruiser under both threshing conditions and the seed treatment with Gaucho only in the ordinary processing method produced the highest root yield (68.37–75.16 t ha−1) (Table 5).

In Karaj region, the highest sugar yield was related to Normal ‘Shokoufa’ + Cruiser at 11.02 t ha−1, and the lowest sugar yield was observed for Super ‘Shokoufa’ + Gaucho at 9.70 t ha−1. In Kermanshah region, the highest sugar yield was related to the KWS cultivar at 9.53 t ha−1, and the lowest sugar yield was observed for Super ‘Shokoufa’ + Cruiser at 6.18 t ha−1 (Table 5).

The highest white sugar yield in Karaj region was related to the KWS cultivar at 8.17 t ha−1, and the lowest white sugar yield was observed for Super ‘Shokoufa’ + Gaucho 7 t ha−1 (Table 5). The highest white sugar yield in Kermanshah region was related to the KWS cultivar at 8.28 t ha−1, and the lowest white sugar yield was observed for Super ‘Shokoufa’ + Cruiser cultivar at 5.27 t ha−1 (Table 5). According to Table 5, unlike Kermanshah region, seed processing in Karaj region caused the white sugar yield of other treatments with the KWS cultivar to be in the same statistical group.

Planting density factor was significant at a 5% level for all three traits of root yield, sugar yield, and white sugar yield of sugar beet, while none of the interactions of density × processing, location × density, and location × processing × density were significant for these traits (Table 4). By increasing planting density, root yield, sugar yield, and white sugar yield significantly increased. The root yield increased from 52.82 t ha−1 at a density of seven plants per square meter to 59.27 t ha−1at a density of 13 plants per square meter (about 11%). The sugar yield and white sugar yield of sugar beet at a density of 13 plants per square meter increased by about 10% compared to the density of seven plants per square meter, while planting densities of 10 and 13 plants per square meter were in the same statistical group (Table 6).

Sugar Content

The results of the analysis of variance showed that only the simple effect of location (at a 1% level) and seed processing (at a 5% level) on impure sugar content was significant (Table 4). According to Table 6, it was found that Kermanshah region (16.55%) at 1.64 units compared to Karaj region (14.91%) had the highest root sugar content (Table 6). Furthermore, regarding the effect of seed processing type, the KWS cultivar at 16.99% had the highest sugar content among the studied treatments (Table 6).

According to Table 4, it was found that the root white sugar content was affected by the simple effects of location and seed processing at a 1% level. Kermanshah region (14.14%) compared to Karaj region (11.01%) had about 3.13 more units of pure sugar content (Table 6). Among treatments related to seed processing, the KWS cultivar at 14.09% had the highest white sugar content of the sugar beet root.

Root Impurities

The results of the analysis of variance (Table 4) showed that the simple effect of location on the levels of harmful nitrogen and potassium in sugar beet was significant at a 1% level. The simple effect of processing on the sodium and molasses sugar content of sugar beet was significant at 5% and 1% levels, respectively. Comparison of the mean simple effects showed that Karaj region (3.45 meq 100 g−1 of pulp) had 49% more harmful nitrogen than Kermanshah region (1.75 meq 100 g−1 of pulp). The level of potassium in Karaj region (6.33 meq/100 g) was 27% higher than in Kermanshah region (4.61 meq 100 g−1 of pulp). In seed processing treatments, the KWS cultivar at 2.34 meq/100 g of pulp had less harmful nitrogen than other seed processing treatments. Moreover, the KWS cultivar at 4.97 meq 100 g−1g had the lowest level of potassium compared to other seed processing treatments (Table 6).

According to Table 4, it was found that the interaction of location × seed processing on sodium and molasses sugar content of sugar beet were significant at a 1% level. Comparison of the mean interactions of location × seed processing indicated that the highest level of sodium was related to Karaj region and the treatments of Super ‘Shokoufa’ + Cruiser (3.56 meq/100 g) and Super ‘Shokoufa’ + Gaucho (3.50 meq 100 g−1), and the lowest molasses sugar was observed for Karaj region and the KWS cultivar (2.87%), which was significantly different from other seed processing treatments (Table 6).

Extraction Coefficient

The extraction coefficient at a 1% level was affected only by the simple effects of location and seed processing (Table 4). According to Table 6, the highest extraction coefficient was related to Kermanshah region (84.84%), which in comparison with Karaj region (73.70%) increased by 13.13%. Regarding seed processing treatment, the results showed that the KWS cultivar at 82.43% had the highest extraction coefficient compared to other cultivars (Table 6).

Discussion

Processing technologies are widely used to enhance the physical, chemical, and quality properties of seeds and fruits (Steinbrecher and Leubner-Metzger 2017). In this study, the effect of seed processing treatments on sugar beet yield and quality was confirmed. In contrast, the effect of density was not significant on root yield, sugar yield, and white sugar yield. The results showed that sugar beet from processed seeds had more harmful nitrogen and potassium in the root than the control seed (foreign cultivar). In addition, the sugar content and extraction coefficient were higher in the foreign cultivar. Seed size is one of the factors in seed threshing that varies even within a cultivar (Rochalska and Orzeszko-Rywka 2008). Large seed sizes may lead to better seedling survival and stability through adaptation (Hamidi and Chegini 2016). Baraloto and Forget (2007) suggested that seed grading by size may improve seedling survival and stability through adaptation. Larger seeds are in a better position for germination, vigor, and yield than small seeds. In general, under field conditions, larger seeds produce stronger seedlings than small seeds, which in some crops results in an increase in yield (Finch-Savage and Bassel 2016; Kimmelshue et al. 2022). Chegini and Ettehad, (2010) reported that seed diameter increased germination percentage. Taleghani et al. (2003) showed that graded seeds with a diameter wider than 3.5 mm had the highest germination percentage. Moreover, to evaluate the effect of different seed sizes on germination characteristics and seedling stability, an experiment was conducted on three different sizes (small, medium and large) of four safflower cultivars and it was found that large seeds had a higher germination percentage (Sadeghi et al. 2011). However, in this experiment, for root impurity traits (harmful nitrogen and potassium), sugar content, and extraction coefficient, there was no difference between ordinary and special threshing treatments. Similar to the present study, there are many reports on seed size’s effect on plant quantitative and qualitative traits. In this regard, Hamidi and Chegini (2016) showed that the traits related to germination and growth of sugar beet cultivars were significantly affected by seed size, so that the seeds of Rasta cultivar at a diameter of 2 mm and Sharif cultivar at a diameter of 3.5 mm had higher germination characteristics and seedling vigor, which in later stages would be able to produce plants with higher yield and quality. The presence of small seedlings indicates weak and abnormal seed vigor (Finch-Savage and Bassel 2016). Tavakoli and Beheshti (2010) studied the effect of seed disinfection on wheat seeds. They showed that this processing was not significant on some growth and germination traits and other traits, which is consistent with the results of the present study.

Plants cultivated in Kermanshah region had higher sugar content, alkalinity, and extraction coefficient than in Karaj region. In contrast, harmful nitrogen and potassium levels were higher in Karaj region plants. This can be attributed to the climatic conditions of cultivation in the two regions. Previous studies have reported that sugar beet quality depends on the region where it is grown (Kenter et al. 2006; Hoffmann et al. 2009). The effect of different cultivation areas, especially on sugar beet sugar content, has been reported in other researcher’s research. Climatic conditions can affect sugar content changes during growing. It has been shown that the less the maximum temperature in the last months, the higher the final sugar content (Hoffmann et al. 2009). According to meteorological stations, in Kermanshah region, the maximum temperature in plant breeding months was less than in Karaj region. Therefore, one of the reasons for the high sugar content in this region can be attributed to this (Fig. 1). In addition, plants grown in the Karaj region had a higher root yield than the Kermanshah region. According to the reported research (Abdollahian-Noghabi et al. 2005), larger sugar beet roots have more impurities and lower sugar content and lower extraction coefficient than smaller roots, which was confirmed in our experiment so that larger roots with high yield obtained from the Karaj region showed higher impurities, lower sugar content and lower extraction coefficient than roots with less yield in Kermanshah. Similar results have been reported in different studies on the effect of different environments on root impurities, sugar content, and extraction coefficient of sugar beet (Milford et al. 2000; Hoffmann and Märländer 2005; Bahrami and Honarvar 2017).

In this experiment, by increasing plant density from 7 to 13 plants per square meter, root yield, sugar yield, and white sugar yield of sugar beets significantly increased. However, density had no significant effect on sugar beet quality characteristics. Different results on the effect of density on sugar beet yield and quality have been reported in several studies (Johnson and Hanson 2003; Mohammadnia et al. 2006). Varga et al. (2021) found that most of the studied traits improved with greater plant density, especially increasing plant density improved root yield. Khayamim et al. (2003) showed that density levels had a significant effect on the percentage of impure sugar and sugar extraction efficiency. By increasing the density, the percentage of impure sugar decreased. They also reported that different levels of density treatments had no significant effect on the number of green and yellow leaves of the sugar beet plant. This increased the number of leaves per plant as density decreased. In addition, the number of leaves per unit area increases with greater density. The main reason for the lack of yield increase in high densities of sugar beet is due to the overlap of the leaves of neighboring plants, even in the early growing season. As the leaf overlap expands, the plant alone receives less light, so each plant individually produces less dry matter. Regarding the effect of spacing between rows, it was shown that the highest sugar yield and root yield in the sugar beet plant were obtained at 30 cm distance between planting rows (Marey 2015). Similar results were reported by Refay in 2010. At a distance of 30 cm between sugar beet rows, the maximum root yield and quality were observed.

In terms of the effect of plant density changes on the quality characteristics of sugar beet, some studies indicate a reduction in root impurities (sodium and potassium) following an increase in plant density from 60 to 120 thousand plants per hectare (Jafarnia et al. 2013). In another study, increasing plant density from 87.5 to 100 thousand plants per hectare led to a significant increase in sugar content, purity, white sugar content, and sugar yield (Masri 2008). In densely cultivated plants, the root system remains small, and a small reserve is provided for each plant to extract nutrients during the growing season and finally, sugar extraction is also difficult because of the small size. In fields with low plant density, the roots have more opportunity to grow and as a result, crown and root growth increases, and their quality decreases. Naturally, increasing the weight of the crown relative to the root reduces the degree of root purity (Mohammadnia et al. 2006). Due to that the shoot produces carbohydrates, with a low leaf area index at dense distances, the reservoir is not fed properly and causes growth abnormalities such as more growth in the crown, and on the other hand, nutrients such as nitrogen can be used, which does not drain faster and ultimately increases root impurities, which show a high correlation with molasses sugar content (Mohammadnia et al. 2006). However, the interaction of seed processing and density was not significant for any of the studied traits. In this regard, the results of research by Scott and Hay (1974) showed that regardless of plant density, plants from larger seeds have higher yields than plants from smaller seeds, and cultivation at high densities has no advantage in producing high yields. In another report, Long and Holmes (1964) stated that the effect of seed size on root yield of sugar beet was not affected by plant density. High yield and quality of sugar beet, especially its stability under different environmental conditions is of great importance in the agricultural industry. In the Kermanshah region, no difference was observed between ordinary and special threshing treatments in terms of root yield, sugar yield, white sugar yield, sodium, and molasses sugar. However, these threshed seeds showed a lower yield than control seeds (foreign cultivar) in terms of these traits, while in Karaj region, threshing increased the yield of these traits compared to the control cultivar. In Karaj region, there was no difference between ordinary and special threshing except for the sodium content of the root. To conclude, although the plants obtained from unthreshed seeds (foreign seeds) were higher in terms of quantity and quality in Kermanshah region, threshing had a significant effect on yield and quality of sugar beet in Karaj region, indicating that standard seed size used might have been different for different areas.

Conclusion

According to the results of the present study, despite the highest content of impure and pure sugar, as well as the highest sugar extraction coefficient, as well as the lowest molasses sugar, nitrogen, and potassium contents observed for the KWS cultivar, plants grown from processed seeds in Karaj region had higher root yields, sugar yields, and white sugar yields. Furthermore, the effect of planting density on sugar beet quantity and quality showed that root yield, sugar yield, and white sugar yield significantly increased with increasing plant density. Regarding different areas of sugar beet cultivation, Karaj plants had higher root yield, sugar yield, and white sugar yield. In addition, they had harmful nitrogen, potassium, sodium, and molasses sugar. In contrast, plants grown in Kermanshah had greater pure and impure sugar content, alkalinity, and sugar extraction coefficient. Finally, based on the results of this study, the use of seed processing methods to provide a sufficient number of plants per unit area and also improve the quantity and quality of the sugar beet crop in different planting areas is positively evaluated and its use is recommended.

References

Abdollahian-Noghabi, M., R. Sheikholeslami, and B. Babaee. 2005. Technical terms of sugar beet quantity and quality. Sugar Beet Journal 21: 101–104. https://doi.org/10.22092/jsb.2005.8201.

Anonymous. 2017. Annual agricultural statistics of Iran. Ministry of Jihad-e-Agriculture of Iran

Bahrami, M., and M. Honarvar. 2017. The effect of environmental conditions, planting and harvest time on the quantity and technological values of beet sugars cultivated in west part of Iran. Journal Food Technology Nutrition 14: 49–62.

Baraloto, C., and P.M. Forget. 2007. Seed size, seedling morphology, and response to deep shade and damage in neotropical rain forest trees. American Journal Botany 94: 901–911. https://doi.org/10.3732/ajb.94.6.901.

Chegini, M., Sadeghzadeh Hemayati, S., Khodadadi, S., Jalilian, A., and Matloubi, F 2015. ‘Quantity and quality of sugar beet seed.’ (Agricultural Research, Education and Extension Organization (AREEO). Sugar Beet Seed Institute (SBSI)).

Chegini, M., and M. Etehad. 2010. The effects of seed grading, polishing and air- separation on some important seed characters of sugar beet monogerm cultivar gadouk seed. Sugar Beet Journal 31: 157–166.

Copeland, L.O., and M.F. McDonald. 2012. Principles of seed science and technology. Springer Science and Business Media. https://doi.org/10.1007/978-1-4615-1619-4.

Finch-Savage, W.E., and G.W. Bassel. 2016. Seed vigor and crop establishment: Extending performance beyond adaptation. Journal of Experimental Botany 67 (3): 567–591. https://doi.org/10.1093/jxb/erv490.

Hamidi, A., and M. Chegini. 2016. Effect of seed size of sugar beet varieties on some germination characters and seedling vigor. Sugar Beet Journal 31: 154–163. https://doi.org/10.22092/jsb.2016.105777.

Hoffmann, C.M., and B. Märländer. 2005. Composition of harmful nitrogen in sugar beet (Beta vulgaris L.): Amino acids, betaine, nitrate—as affected by genotype and environment. European Journal of Agronomy 22: 255–265. https://doi.org/10.1016/j.eja.2004.03.003.

Hoffmann, C.M., T. Huijbregts, N. Van Swaaij, and R. Jansen. 2009. Impact of different environments in Europe on yield and quality of sugar beet genotypes. European Journal of Agronomy 30: 17–26. https://doi.org/10.1016/j.eja.2008.06.004.

Ismail, A., and Allam, S. 2007. Yield and technological traits of sugar beet as affected by planting density, phosphorus and potassium fertilization, Proceedings of the 3rd Conference of sustainable agricultural development. Faculty of agriculture, Fayoum University, Pakistan.

ISTA. 2013.'International rules for seed testing: seed health testing methods is the supplement to chapter 7 International rules for seed testing; edition 2013; catalogued separately. (International Seed Testing Association)

Jafarnia, B., R. Ghorbani, A.Z. Feizabady, and A.R. Ghaemi. 2013. Impact of crop density and soil fertilization on sugar beet. International Journal of Agriculture and Crop Sciences 5: 2991–2999.

Johnson, B.L., and B.K. Hanson. 2003. Row-spacing interactions on spring canola performance in the northern great plains. Agronomy Journal 95: 703–708. https://doi.org/10.2134/agronj2003.7030.

Kenter, C., C.M. Hoffmann, and B. Märländer. 2006. Effects of weather variables on sugar beet yield development (Beta vulgaris L.). European Journal of Agronomy 24: 62–69. https://doi.org/10.1016/j.eja.2005.05.001.

Khayamim, S., D. Mazaher, M. Banaian Aval, J. Govhari, and M.R. Jahansooz. 2003. Assessment of sugar beet physiologic and technologic characteristics at different plant density and nitrogen use levels. Journal of Pajouhesh and Sazandegi 60: 21–29.

Kimmelshue, C.L., S. Goggi, and K.J. Moore. 2022. Seed size, planting depth, and a perennial groundcover system effect on corn emergence and grain yield. Agronomy 12 (2): 437. https://doi.org/10.3390/agronomy12020437.

Lukaszewska, E., R. Virden, and E. Sliwinska. 2012. Hormonal control of endoreduplication in sugar beet (Beta vulgaris L.) seedlings growing in vitro. Plant Biology 14: 216–222. https://doi.org/10.1111/j.1438-8677.2011.00477.x.

Marey, S. 2015. Affecting each of ridger furrow opener parameters and planting methods on water use efficiency and sugar beet yield. Bulgarian Journal of Agricultural Science 21: 1304–1311. https://doi.org/10.21608/jssae.2014.49601.

Marinković, B., M. Grujić, D. Marinković, J. Crnobarac, J. Marinković, and G. and D.V. Jaćimović, Mircov. 2008. Use of biophysical methods to improve yields and quality of agricultural products. Journal of Agricultural Sciences 53: 235–242. https://doi.org/10.2298/JAS0803235M.

Masri, M. 2008. Effect of nitrogen level and planting density on sugar beet yield and its attributes. Egyptian Journal of Agronomy 30: 119.

Milford, G., M. Armstrong, P. Jarvis, B. Houghton, D. Bellett-Travers, J. Jones, and R. Leigh. 2000. Effect of potassium fertilizer on the yield quality and potassium offtake of sugar beet crops grown on soils of different potassium status. The Journal of Agricultural Science 135: 1–10. https://doi.org/10.1017/S0021859699007881.

Mohammadnia, M., A. Soleymani, A. Shiranirad, and M. Naderi. 2006. Effect of planting pattern on white sugar yield and components of two cultivars sugar beet. The Journal of Agricultural Science 12: 75–85. https://doi.org/10.3390/agronomy9070405.

Olsson, R. 2012. Insecticide seed treatments against pests in sugar beet. NBR (Nordic Beet Research). Report from Syngenta Seeds AB (No. 450–2012). Report.

Paravar, A., R. Piri, H. Balouchi, and Y. Ma. 2023. Microbial seed coating: an attractive tool for sustainable agriculture. Biotechnology Reports 37: 1–15. https://doi.org/10.1016/j.btre.2023.e00781.

Rašovský, M., V. Pačuta, L. Ducsay, and D. Lenická. 2022. Quantity and quality changes in sugar beet (Beta vulgaris provar. Altissima doel) induced by different sources of bio stimulants. Plants 11 (17): 2222. https://doi.org/10.3390/plants11172222.

Refay, Y. 2010. Root yield and quality traits of three sugar beet (Beta vulgaris L.) varieties in relation to sowing date and stand densities. World Journal of Agricultural Sciences 6: 589–594.

Rocha, I., Y. Ma, P. Souza-Alonso, M. Vosátka, H. Freitas, and R.S. Oliveira. 2019. Seed coating: a tool for delivering beneficial microbes to agricultural crops. Frontiers in Plant Science 10: 1357. https://doi.org/10.3389/fpls.2019.01357.

Rochalska, M., and A. Orzeszko-Rywka. 2008. Influence of alternating magnetic field on respiration of sugar beet seeds. International Agrophysics 22: 255–259.

Sadeghi, H., F. Khazaei, S. Sheidaei, and L. Yari. 2011. Effect of seed size on seed germination behavior of safflower (Carthamus tinctorius L.). Journal of Agriculture and Biological Sciences 6: 5–8.

Salimi, Z., and B. Boelt. 2019. Optimization of germination inhibitors elimination from sugar beet (Beta vulgaris L.) seeds of different maturity classes. Agronomy 9 (11): 763. https://doi.org/10.3390/agronomy9110763.

Scott, D., and R.J. Hay. 1974. Some physical and nutritional effects of seed coating. In Proceedings of 12th International Grassland Congress. pp 523–531, Moscow, Russia.

Sohail, M., T. Pirzada, C.H. Opperman, and S.A. Khan. 2022. Recent advances in seed coating technologies: Transitioning toward sustainable agriculture. Green Chemistry 24 (16): 6052–6085. https://doi.org/10.1039/D2GC02389J.

Steinbrecher, T., and G. Leubner-Metzger. 2017. The biomechanics of seed germination. Journal of Experimental Botany 68: 765–783. https://doi.org/10.1093/jxb/erw428.

Taleghani, D.F., M. DehghanShoar, A. Ghasemi, V. Yossefabadi, M.A. Chegini, M. Mesbah, and F. Hamdi. 2003. Determination of optimum seed size and quantity of peleting materials for monogerm sugar beet seed. Sugar Beet Journal. 18: 95–108. https://doi.org/10.22092/jsb.2003.8276.

Taleghani, F., Khayamim, D., Hosseinpur, S., and Moharramzadeh, M 2006. Planting date and density of the sugar beet plant. Sugar Beet Seed Institute.

Tavakoli-Kakhki, H., and A. Beheshti. 2010. Wheat seed treatment and its effect on seed vigor indices from bioenvironmental aspect. Agroecology 2: 185–192. https://doi.org/10.22067/jag.v2i1.7616.

Varga, I., Z. Lončarić, S. Kristek, A.M. Kulundžić, A. Rebekić, and M. Antunović. 2021. Sugar beet root yield and quality with leaf seasonal dynamics in relation to planting densities and nitrogen fertilization. Agriculture 11 (5): 407. https://doi.org/10.3390/agriculture11050407.

Zhang, K., Z. Khan, Q. Yu, Z. Qu, J. Liu, T. Luo, and L. Luo. 2022. Biochar coating is a sustainable and economical approach to promote seed coating technology seed germination plant performance and soil health. Plants 11 (21): 2864. https://doi.org/10.3390/plants11212864.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Safari, A., Hemayati, S.S., Moballeghi, M. et al. Seed Coating: A Sustainable Way to Compensate for the Loss of Plant Number Per Unit Area in Sugar Beet Fields. Sugar Tech (2024). https://doi.org/10.1007/s12355-023-01349-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12355-023-01349-x