Abstract

Gold nanoparticles are promising materials for many applications that include imaging, drug delivery, and photothermal therapy. However, AuNPs can be unstable and/or toxic. We purposed to improve the stability and reduce toxicity of gold nanorods (AuNR) upon coating with biocompatible polymer, chitosan–ceramide (CS–CE), without replacing the original layer, CTAB. CS–CE-coated AuNR was prepared by simple mixing for 24 h and purified by centrifugation. The coating was confirmed by UV–Vis absorption analysis and surface charge and size measurement. We prepared nanorods with CS or CS–CE coating at two different concentrations (5 and 10% AuNR), the resulting in larger nanorods with a more positive surface-charge than that of AuNR. We investigated the UV-absorption and protein adsorption of the polymer coated nanorods. Based on the protein adsorption, AuNR-CS–CE was found to be more stable under physiological conditions than AuNR-CS. The cell internalization assay revealed that Hela cells internalized higher amounts of AuNR-CS–CE than that of AuNR-CS. Cytotoxicity study revealed that AuNR-CS–CE has lower toxicity than AuNR against HeLa cells. The CS–CE coating improved the stability of AuNR under physiological conditions via the hydrophobic interactions between the AuNR lipid surface and the ceramide anchor in the CS backbone as well as.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Gold nanoparticles (AuNPs) are a promising material for targeted cancer drug delivery and imaging, commonly referred to as theranostics (Voon et al. 2014; Muddineti et al. 2015), due to their small size and significant characteristics. Several physicochemical properties of AuNPs distinguish them from other nanocarriers. These properties include chemical inertness, facile surface functionalizability, electronic structure that is amenable to plasmon resonance, and optical properties that are suitable for the utilization of AuNPs as imaging agents (Jeong et al. 2014; Muddineti et al. 2015). AuNPs can also be used as computed tomography imaging agent owing to a high absorption coefficient, which generates a higher contrast than the typical imaging agents (Sun et al. 2009). AuNPs induce hyperthermia upon irradiation by near infrared (NIR) light. Owing to their optical properties, AuNPs can potentially be used in photothermal therapy (PTT), which is considered an effective cancer treatment (Wang et al. 2014). In addition to PTT, AuNPs can successfully be utilized as carriers for chemotherapeutic drugs in cancer therapy (Kim et al. 2013).

AuNPs easily aggregate, especially in cases of non-spherical particles it is common due to their anisotropic nature (Gao et al. 2012). High curvature and the nature of the surface ligands are responsible for their flocculation (Dreaden et al. 2012; Afrooz et al. 2013; Kobayashi et al. 2014). Therefore, synthesis of a stable colloidal system using AuNPs is a challenge. To improve the stability of AuNR, cetyltrimethylammonium bromide (CTAB) with different lengths and aspect ratios is widely used (Tebbe et al. 2015). Although CTAB-coated AuNR shows optimal optical properties for biomedical applications, usage is limited due to the cytotoxicity of CTAB above a certain concentration (Ray et al. 2009). In addition, CTAB-coated AuNRs have low colloidal stability in aqueous salt conditions, are incompatible with other solvents, and instable during long-term storage (Tebbe et al. 2015).

Many studies have reported about coating of gold nanoparticle with PEG (Manson et al. 2011), polyelectrolytes (Huang et al. 2009), proteins (Tebbe et al. 2015) and polysaccharides (Sun et al. 2014). Improving or replacing the coating of AuNPs with other materials would increase their possible applications. In this study, we try to form a double layer on CTAB-coated AuNR using chitosan-ceramide polymer. As a coating material, chitosan and its derivatives are favored owing to their biocompatibility, biodegradability, and nontoxicity (Thanou et al. 2000; Gamboa and Leong 2013). Chitosan is a long non-branched polysaccharide similar to cellulose derivatives in which the hydroxyl group at the C2 position has been replaced with an amino group (Hejazi and Amiji 2003). The positive charge allows these polymers to bind more efficiently to mammalian cells (Kobayashi et al. 2014). Chitosan and its derivatives are widely used for coating of nanoparticles, including gold (Sun et al. 2014) silver (Jena et al. 2012), and graphene oxide (Wang et al. 2014), in order to improve the stability of these nanoparticles. Similarly, coating nanoparticles with hydrophobic anchor-grafted polymers improves the stability and reduces toxicity (Lin et al. 2008; Maity and Jana 2011). Herein we used ceramide-chitosan for phase transfer of AuNR to improve the stability of AuNPs. In our previous report (Battogtokh and Ko 2014a), we confirmed that chitosan-ceramide conjugate can self-assemble with hydrophobic drugs, resulting in a stable nanoparticle in physiological condition. As compared to chitosan, chitosan–ceramide can form strong binding between ceramide-anchor and lipid chain of CTAB. Additionally, toxicity of CTAB can be reduced because the lipid anchor (ceramide) of chitosan can interact with CTAB on the surface of AuNR via hydrophobic interactions, resulting in a stable double layered nanoparticle. The novelty of this study is the coating of AuNR with our synthesized biocompatible chitosan–ceramide by hydrophobic interaction between lipid surface of AuNR and ceramide anchor in chitosan–ceramide.

Materials and methods

Reagents

Chitosan (3–5 kDa) with 75% deacetylation was purchased from Kitto Life (Seoul, South Korea). Ceramide 3B (DS-Y30; N-oleoyl phytosphingosine) was obtained from Doosan Biotech (Yongin, South Korea). The synthesis of CS–CE conjugate was performed as previously described. CTAB, sodium borohydride (NaBH4), silver nitrate (AgNO3), ascorbic acid, and hydrogen tetrachloroaurate(III) trihydrate (HAuCl4·3H2O) were purchased from Sigma-Aldrich Co (St Louis, MO, USA). All other reagents were purchased from Sigma-Aldrich (St. Louis, MO) and Tokyo Chemical Industry (Tokyo, Japan) unless otherwise stated.

Preparation of AuNRs

AuNRs were prepared by a modified seed-mediated method described earlier.(Zhu et al. 2014; Kang and Ko 2015) Initially, the seed solution was prepared by mixing 250 μL of 0.01 M HAuCl4 with 7.5 mL of 0.1 M CTAB and 600 μL of ice-cold 0.01 M NaBH4 with vigorous stirring at room temperature (RT). The growth solution was prepared by adding 400 μL of 0.01 M HAuCl4, 64 μL of 0.1 M ascorbic acid, and 35.6 μL of 0.1 M AgNO3 to 9.5 mL of 0.1 M CTAB. Finally, 10 μL of 2.5 h old seed solution was added to the solution, and the mixture was left for 24 h at RT. In this synthesis protocol, AgNO3 allows better control of the resulting shapes in the AuNR formation, while ascorbic acid functions as the reducing agent.

Synthesis of chitosan–ceramide-coated gold nanorods

Three milliliters of aqueous chitosan (CS) or CS–CE conjugate (5 mg) in 0.1% acetic acid solution was prepared in a 70 °C water bath. Next, 16.5 µL or 33 µL (5 or 10% w/w, respectively) of the prepared polymer solution was mixed with 1 mL of gold nanorods (AuNRs) solution (1 mM, 0.3 mg/mL) while stirring for 2 h at 70 °C or for 24 h at RT at 200 rpm. The solution was cooled to RT. The colloid was centrifuged at 14,000 rpm for 20 min and washed twice with distilled water and subsequently sonicated for 10 min to uniformly disperse the nanoparticles.

Physical characterization

Hydrodynamic diameter and zeta potential were measured by dynamic light scattering (DLS) and electrophoretic light scattering (Laser Doppler) using a zeta-potential and particle size analyzer (ELSZ-1000, Otsuka Electronics Co, Osaka, Japan). Scattered light was detected at 23 °C at an angle of 90°. A viscosity value of 0.933 mPa and a refractive index of 1.333 were used for data analysis.

The fluorescence emission spectra were measured by a Cary Eclipse fluorescence spectrophotometer (Agilent Technology, Santa Clara, CA). The UV–Vis absorption spectra were acquired by a Cary 60 UV–Vis spectrophotometer (Agilent Technology, Santa Clara, CA). All optical measurements were performed at RT.

Colloidal stability and protein adsorption of nanoparticles

To analyze time-dependent storage stability of CS- or CS–CE-coated AuNR, the size and zeta potential of formulations were measured by DLS at 24 °C for a week.

To test the stability in physiological solutions, protein adsorption on CS- or CS–CE- coated AuNRs was determined by the bicinchoninic acid (BCA) assay. Briefly, 0.5 mL AuNRs, CS-, or CS–CE-coated AuNRs were centrifuged at 14,000 rpm at 20 °C for 20 min. Then 0.5 mL cell culture medium with FBS (10%) was added to the pellet and vortexed for 2 min. After incubation for 1 or 24 h at 37 °C, the solution was centrifuged at 14,000 rpm at 20 °C for 20 min. The residue was washed once with PBS (0.5 mL) to remove loosely bound protein. To the pellet, 0.5 mL PBS (pH 7.4) was added and vortexed, and the mixture was centrifuged under the same conditions. The separated supernatant (10 µL) was mixed with 2 µL compatibility solution and incubated at 37 °C for 15 min. Finally, 130 µL of mixture A and B solution (25:1) was added and incubated for 30 min. The absorption at 562 nm was measured by ELISA absorption reader.

Flow cytometer

The cells were incubated with AuNR-CS or AuNR-CS–CE (10 μg/mL) for 3 h. The cells were then washed and resuspended in PBS and transferred to a flow cytometry tube. The cells were measured by a BD FACS Calibur flow cytometer using a Cell Quest software (BD, Ann Arbor, MI).

Statistical analysis

All of the studies were carried out in triplicate, and the results were expressed as mean ± standard deviation (SD). The statistical significance of the data was analyzed by ANOVA and Student’s t test. In all cases, p < 0.05 was considered to be statistically significant.

Results

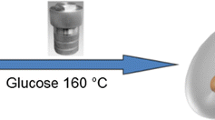

As shown in Fig. 1, AuNR was coated with 5 or 10% (weight of AuNR) of CS or CS–CE by stirring at 70 °C for 2 h or at RT for 24 h, respectively. Our hypothesis is that CS–CE strongly covers the nanorod for phase transfer due to the hydrophobic interaction between the ceramide anchor and lipid layer of the nanorod surface, resulting in a stable nanoparticle. The additional layer on the native surface of nanoparticles does not affect the original environment and can prevent sensitive core materials from oxidation. (Sperling and Parak 2010).

After coating the nanorods with 5 or 10% polymer, size and surface charge were measured by DLS and the results are shown in Table 1. By coating with polymers, the nanorod size increased and the surface charge became more positive compared to the original AuNR due to the positive charge of chitosan.

We prepared AuNR-CS and AuNR-CS–CE with different concentrations of polymer at different time points (2 and 24 h) and temperature (70 °C and RT). The 5% polymer-coated AuNRs incubated for 24 h increased in size and zeta potential while the size and zeta potential of 10% polymer-coated AuNRs did not increase in a consistent manner.

We measured the UV-absorption of the AuNR and polymer-coated AuNRs (Fig. 2) and all spectra reveal an absorption band around 640 nm, which is a typical plasmon resonance band for gold nanorods. In addition, a slight red shift (from 640 to 650 nm) was observed in the UV-spectra of 5% polymer-coated AuNR (Fig. 2a, b), whereas a negligible shift appeared for 10% polymer-coated AuNR (Fig. 2c, d). The results demonstrate that coating AuNR with 5% polymer was more efficient than that of 10% polymer.

We also measured fluorecence of the CS- or CS–CE-coated AuNRs in PBS by flourospectometer. Interestingly, fluorescence intensity of polymer-coated AuNR increased as polymer concentration increased (Fig. 3a, b), which is reverse of the UV absorption spectra. This was observed for 10% polymer-coated AuNRs. These results indicate that 5% polymer was coated more compared to 10% polymer AuNR.

Based on these data, we have chosen the 5 and 10% polymer-coated AuNRs prepared by incubating for 24 h for further study.

To investigate colliodal stability, we incubated the CS- or CS–CE-coated nanorods at RT for a week and measured size and zeta potential by DLS. As illustrated in Fig. 4, the upper panel shows the profiles obtained from 5% polymer-coated AuNRs, while the lower panel shows the profiles of 10% polymer-coated AuNRs. Size and zeta potential of 5% CS- and CS–CE-coated AuNRs (Fig. 4a, b) were stable for a week, whereas those of 10% CS- and CS–CE-coated AuNRs were not stable. Therefore 5% CS- and CS–CE-coated AuNRs are more sustainable than 10% CS- and CS–CE -coated AuNRs.

Based on the results of colloidal stability study, we decided to perform further experiments with only 5%-polymer-coated AuNR. To determine the stability of CS–CE-coated AuNRs in physiologically relevant conditions, the nanoparticle solution was incubated in DMEM cell culture medium containing 10% FBS at 37 °C. As shown in Fig. 5, after incubating for 1, 6, and 24 h in DMEM, AuNR-CS–CE (5%) exhibited 2-, 3-, twofold less protein adsorption, respectively, on its surface compared with AuNR-CS.

Protein adsorption on AuNR-CS (5%) and AuNR-CS–CE (5%) analyzed by BCA assay (a). Serum stability of AuNR (i), AuNR-CS (5%) (ii), and AuNR-CS–CE (5%) (iii) in DMEM medium containing 10% FBS after incubating for 24 h at 37 °C (b). Cell uptake of AuNR-CS (5%) (red) and AuNR-CS–CE (5%) (green) by HeLa cells after incubating for 3 h as determined by FACS analysis (c). Significant differences in protein adsorption of AuNR-CS–CE (5%) are marked with *p < 0.05 compared with AuNR-CS (5%) at each time point. The data represent the mean ± SD (n = 3)

Therefore, coating with CS–CE significantly improved physiological stability of AuNR for biomedical applications. We also compared the physiological stability of AuNR, AuNR-CS, and AuNR-CS–CE (Fig. 5b) and a difference was observed after incubating for 24 h. Furthermore, we measured the internalization of AuNR-CS–CE and AuNR-CS by Hela cells. AuNR-CS–CE was internalized by the cells after 3 h of incubation, thereby indicating that CS–CE stabilized the nanorod and increased the cell surface interaction.

As shown in Fig. 6, there was less cytotoxicity for AuNR-CS compared to AuNR-CS–CE at 60 and 120 µg/mL in HeLa cells by MTT assay, suggesting that the CS–CE coating of AuNR could decrease toxicity of coated AuNRs.

Discussion

CTAB stabilized AuNRs are unstable and severely cytotoxic. To overcome these issues, CS–CE was introduced onto the surface of AuNR in a phase transfer manner because chitosan is a natural polymer with great potential for coating (Jennings et al. 2015). We expected that the viscosity and strong hydrophobic interaction between the lipids and hydrophobic anchor, ceramide, in the chitosan molecule would be important for coating AuNRs. In our previous studies, CS–CE strongly interacted with hydrophobic molecule (Battogtokh and Ko 2014a, b). After coating with the chitosan polymers, the size of AuNR increased by 5–18 nm compared to AuNR. The average sizes of AuNR-CS (5%) and AuNR-CS–CE (5%) obtained after a 24 h incubation were bigger (around 40 nm) than those of others, indicating a dense layer formed on the AuNR surface. These results are similar to those reported by Zhang et al. (Zhang et al. 2012); however, they found the size of chitosan-coated nanoparticles to be around 200 nm, which may be due to the use of a high molecular weight chitosan. In our study, we used a low molecular weight chitosan (5 kDa), which has some advantages over high molecular chitosan, including low toxicity and water solubility (Patel et al. 2010). Although average size distribution of AuNR increased after polymer coating, in some cases, the surface charge of AuNR did not change after coating, suggesting less polymer coated the AuNR surface, especially in 10% polymer-coated AuNRs. The reason of better coating with 5% polymer than with 10% polymer is due to optimal amount of polymer for coating the nanoparticle, whereas in case of 10% polymer coating saturation could occur on the surface of AuNR.

Further, there was no significant difference between colloidal stabilities of CS- or CS–CE-coated AuNRs. The protein adsorption results show that the coating of AuNR with CS–CE results in a more stable nanorod under physiological condition.

Additionally, a decrease of absorption peaks and a slight red shift in the UV-spectra of 5% polymer-coated AuNRs suggests the successful formation of a double layer. The polymer layer changed the refractive index of the AuNR (Sun et al. 2014), whereas a negligible shift appeared in the UV spectra of 10% polymer-coated AuNRs. These data are consistent with results reported by Cai et al. in which they found that as the nanoparticle size increases, the absorption wavelength shifts to red (Cai and Yao 2014).

Although the coating by PEG prolongs the circulation in mice bloodstream (Niidome et al. 2006), a smaller amount of PEGylated AuNPs within HeLa cells and PC-3 cells compared to noncoated AuNPs (Arnida et al. 2010). In contrast to the PEGylated gold nanoparticles, the positively-charged CS–CE- coated nanorods were internalized by the cells, possibly because of a stable coating by CS–CE compared to that by CS, which prevents detachment.

In conclusion, we coated gold nanorods using our previously synthesized chitosan–ceramide conjugate for phase transfer manner without replacing the original lipid layer to improve the stability and reduce toxicity by incubating for different time point and with different concentrations of polymer. We found that after coating, the size of the nanorod increased (25–40 nm) and the zeta potentials became more positive (40–50 mV). In addition, a slight red shift for the UV absorption spectra of 5% polymer-coated AuNR was confirmed that the coating was made on the surface of AuNR with polymer. More importantly, the physiological stability of the coated nanoparticles with CS–CE (5%) was higher than that of nanorods coated with only CS (5%), suggesting that CS–CE is a promising coating material. Also AuNR coated with CS–CE is known to have higher internalization efficiency and less cytotoxicity in cells.

References

Afrooz AR, Sivalapalan ST, Murphy CJ, Hussain SM, Schlager JJ, Saleh NB (2013) Spheres vs. rods: the shape of gold nanoparticles influences aggregation and deposition behavior. Chemosphere 91:93–98

Arnida A, Malugin A, Ghandehari H (2010) Cellular uptake and toxicity of gold nanoparticles in prostate cancer cells: a comparative study of rods and spheres. J Appl Toxicol 30:212–217

Battogtokh G, Ko YT (2014a) Self-assembled chitosan-ceramide nanoparticle for enhanced oral delivery of paclitaxel. Pharm Res 31:3019–3030

Battogtokh G, Ko YT (2014b) Self-assembled polymeric nanoparticle of PEGylated chitosan-ceramide conjugate for systemic delivery of paclitaxel. J Drug Target 22:813–821

Cai H, Yao P (2014) Gold nanoparticles with different amino acid surfaces: serum albumin adsorption, intracellular uptake and cytotoxicity. Colloids Surf B 123:900–906

Dreaden EC, Austin LA, Mackey MA, El-Sayed MA (2012) Size matters: gold nanoparticles in targeted cancer drug delivery. Ther Deliv 3:457–478

Gamboa JM, Leong KW (2013) In vitro and in vivo models for the study of oral delivery of nanoparticles. Adv Drug Deliv Rev 65:800–810

Gao J, Huang X, Liu H, Zan F, Ren J (2012) Colloidal stability of gold nanoparticles modified with thiol compounds: bioconjugation and application in cancer cell imaging. Langmuir 28:4464–4471

Hejazi R, Amiji M (2003) Chitosan-based gastrointestinal delivery systems. J Control Release 89:151–165

Huang HC, Barua S, Kay DB, Rege K (2009) Simultaneous enhancement of photothermal stability and gene delivery efficacy of gold nanorods using polyelectrolytes. ACS Nano 3:2941–2952

Jena P, Mohanty S, Mallick R, Jacob B, Sonawane A (2012) Toxicity and antibacterial assessment of chitosan-coated silver nanoparticles on human pathogens and macrophage cells. Int J Nanomedicine 7:1805–1818

Jennings JA, Wells CM, McGraw GS, Velasquez Pulgarin DA, Whitaker MD, Pruitt RL, Bumgardner JD (2015) Chitosan coatings to control release and target tissues for therapeutic delivery. Ther Deliv 6:855–871

Jeong EH, Jung G, Hong CA, Lee H (2014) Gold nanoparticle (AuNP)-based drug delivery and molecular imaging for biomedical applications. Arch Pharmacal Res 37:53–59

Kang JH, Ko YT (2015) Lipid-coated gold nanocomposites for enhanced cancer therapy. Int J Nanomedicine 10:33–45

Kim CS, Tonga GY, Solfiell D, Rotello VM (2013) Inorganic nanosystems for therapeutic delivery: status and prospects. Adv Drug Del Rev 65:93–99

Kobayashi K, Wei JJ, Iida R, Ijiro K, Niikura K (2014) Surface engineering of nanoparticles for therapeutic applications. Polym J 46:460–468

Lin CA, Sperling RA, Li JK, Yang TY, Li PY, Zanella M, Chang WH, Parak WJ (2008) Design of an amphiphilic polymer for nanoparticle coating and functionalization. Small 4:334–341

Maity AR, Jana NR (2011) Chitosan-cholesterol-based cellular delivery of anionic nanoparticles. J Phys Chem C 115:137–144

Manson J, Kumar D, Meenan BJ, Dixon D (2011) Polyethylene glycol functionalized gold nanoparticles: the influence of capping density on stability in various media. Gold Bull 44:99–105

Muddineti OS, Ghosh B, Biswas S (2015) Current trends in using polymer coated gold nanoparticles for cancer therapy. Int J Pharm 484:252–267

Niidome T, Yamagata M, Okamoto Y, Akiyama Y, Takahashi H, Kawano T, Katayama Y, Niidome Y (2006) PEG-modified gold nanorods with a stealth character for in vivo applications. J Control Release 114:343–347

Patel MP, Patel RR, Patel JK (2010) Chitosan mediated targeted drug delivery system: a review. J Pharm Pharm Sci 13:536–557

Ray PC, Yu HT, Fu PP (2009) Toxicity and environmental risks of nanomaterials: challenges and future needs. J Environ Sci Health C 27:1–35

Sperling RA, Parak WJ (2010) Surface modification, functionalization and bioconjugation of colloidal inorganic nanoparticles. Philos Trans A 368:1333–1383

Sun IC, Eun DK, Na JH, Lee S, Kim IJ, Youn IC, Ko CY, Kim HS, Lim D, Choi K, Messersmith PB, Park TG, Kim SY, Kwon IC, Kim K, Ahn CH (2009) Heparin-coated gold nanoparticles for liver-specific CT imaging. Chem Eur J 15:13341–13347

Sun IC, Na JH, Jeong SY, Kim DE, Kwon IC, Choi K, Ahn CH, Kim K (2014) Biocompatible glycol chitosan-coated gold nanoparticles for tumor-targeting CT imaging. Pharm Res 31:1418–1425

Tebbe M, Kuttner C, Mannel M, Fery A, Chanana M (2015) Colloidally stable and surfactant-free protein-coated gold nanorods in biological media. ACS Appl Mater Inter 7:5984–5991

Thanou MM, Kotze AF, Scharringhausen T, Luessen HL, de Boer AG, Verhoef JC, Junginger HE (2000) Effect of degree of quaternization of N-trimethyl chitosan chloride for enhanced transport of hydrophilic compounds across intestinal caco-2 cell monolayers. J Control Release 64:15–25

Voon SH, Kiew LV, Lee HB, Lim SH, Noordin MI, Kamkaew A, Burgess K, Chung LY (2014) In vivo studies of nanostructure-based photosensitizers for photodynamic cancer therapy. Small 10:4993–5013

Wang SM, Dai ZF, Ke HT, Qu EZ, Qi XX, Zhang K, Wang JR (2014) Contrast ultrasound-guided photothermal therapy using gold nanoshelled microcapsules in breast cancer. Eur J Radiol 83:117–122

Zhang GD, Sun XH, Jasinski J, Patel D, Gobin AM (2012) Gold/chitosan nanocomposites with specific near infrared absorption for photothermal therapy applications. J Nanomater 2012:1–9

Zhu Y, Ramasamy M, Yi DK (2014) Antibacterial activity of ordered gold nanorod arrays. ACS Appl Mater Interfaces 6:15078–15085

Acknowledgements

This research was supported by the Basic Science Research Program (NRF 2014R1A1A2053373) and (NRF2015R1D1A1A01057545) and the Pioneer Research Center Program (NRF 2014M3C1A3054153) through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interests.

Rights and permissions

About this article

Cite this article

Battogtokh, G., Gotov, O. & Ko, Y.T. Chitosan–ceramide coating on gold nanorod to improve its physiological stability and reduce the lipid surface-related toxicity. Arch. Pharm. Res. 40, 356–363 (2017). https://doi.org/10.1007/s12272-017-0888-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12272-017-0888-z