Abstract

A new liquid chromatographic method with an ion trap detector for the determination of chloramphenicol residues in animal feed is described. The developed method consists of an organic extraction and a two-step cleanup. For the cleanup, solid phase and liquid–liquid extractions were applied to minimize the ion suppression effects. One precursor and three product ions were monitored obtaining 5.5 identification points, which provided the method with a very high selectivity/specificity and gave a great confidence to the results. The described method was fully validated according to the requirements of the 2002/657/EC European Decision and the estimated decision limit and detection capability were 6 and 8 μg Kg−1, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Chloramphenicol (CAP) is a broad spectrum antibiotic and its use in food-producing animals is forbidden in the European Union member states since 1994 (Commission Regulation 1430/94 of 22 June 1994). In spite of it, this drug is still illicitly used in animal farming because of its effectiveness and low cost, as shown in the recent findings which occurred in Spain in a broiler meat. Therefore, an effective surveillance and monitoring of this substance are hardly required not only in animal products but also in feeding stuffs.

Surprisingly, although a large number of methods for the determination of chloramphenicol residues in animal products (animal tissue, milk, honey, royal jelly and egg) by liquid chromatography coupled with mass spectrometry have been reported in recent years (Hormazábal and Yndestad 2001; Gantverg et al. 2003; Impens et al. 2003; Mottier et al. 2003; Thorsen et al. 2006; Nicolich et al. 2006; Forti et al. 2005; Ramos et al. 2003), as far as we know, no method concerning the determination of CAP in animal feed by this technique has still been proposed.

To ensure a harmonized implementation of the Council Directive 96/23/EC (Council Directive 96/23/EC of 29 April 1996) and the same level of protection for consumers in all EU member states, the European Commission established a minimum required performance limit (MRPL) of the analytical method for the determination of CAP in different animal products of 0.3 μg Kg−1 (Commission Decision 2003/181/EC of 13 March 2003), but it has not been yet established an MRPL for this determination in animal feed. Therefore, the aim was to achieve a decision limit (CCα) value as low as possible in this complex matrix by a quantitative and confirmation LC-MS2 method to be applied in the regulatory control programme.

Material and Methods

Standards

Chloramphenicol was purchased from Fluka®. Chloramphenicol-D5 (CAP-D5) (internal standard) was purchased from Cambridge Isotope Laboratories, Inc. Stock standard solutions were prepared in methanol at concentrations of 1,000 and 10 μg mL−1, respectively and they were stored at −20 °C. Intermediate solutions were also prepared in methanol at 10 and 0.03 μg mL−1, respectively, and they were stored at 5 °C. The working solutions of chloramphenicol were prepared daily by diluting 100- and 1,000-fold the intermediate solution in a water/acetonitrile mixture (75:25, v/v).

Reagents and Chemicals

All chemicals were of analytical reagent grade. Acetonitrile used as mobile phase was of hypergrade quality from Merck®. Acetonitrile used for sample preparation, water, methanol and ethyl acetate were of HPLC grade from Merck®. Bond Elut® C18 (500 mg, 6 cm3) cartridges used for sample preparation were obtained from Varian, Inc.

Apparatus

The LC system consisted of an LC 1100 series Agilent Technologies and G2440A ion trap–mass spectrometer. Separation was obtained at 40 °C under isocratic conditions using a 50 × 3 mm, 5 μm Hypurity C8 column from Thermo and water (solvent A)/acetonitrile (solvent B) at 0.300 mL min−1 as mobile phase. Gradient conditions were used to wash and equilibrate the column. The linear gradient programme was 0–6 min 75% A, 6–11 min 100% D and 11–21 min 75% A. The entire LC flow was directed into the MS detector between 1 and 6 min using the divert valve.

Acquisition parameters were nebuliser (40 psi); dry gas (8.00 L min−1); dry temperature (350 °C); skim 1 (−23.0 V); skim 2 (−6.0 V) and capillary exit offset (−69.0 V). Negative electrospray ionization [ESI (−)] and multiple reaction monitoring mode were used for CAP and CAP-D5. Fragmentation amplitude for CAP (322 m/z) and CAP-D5 was 0.7 V for both analytes. Product ions for CAP were 257 (ion used for quantification), 194 and 152 and 262 m/z for CAP-D5.

Feed Samples

Samples were collected by the Spanish veterinary inspectors for Agricultural Authority at livestock farms. The samples were kept in the dark at 20 ± 5 °C in a dried atmosphere. Porcine, bovine, ovine, caprine, equine, rabbit and broiler feed samples were used during the validation of the proposed method.

Sample Preparation and Extraction

An animal feed was milled and homogenized in a blender (4L-LCB15 from Waring®). To a 0.5-g aliquot, 200 μL of CAP-D5 solution (0.03 μg mL−1) was added as the internal standard.

Then, 2 mL of water was added. The mixture was thoroughly homogenized using a vortex. After mixing, the homogenate was extracted two times with 5 mL of ethyl acetate. The extraction was performed after mixing approximately 1 min and centrifuging at 3,080×g for 5 min. The two organic extracts were transferred into a polypropylene tube and evaporated to dryness in a TurboVap® (Zymark®) under a nitrogen stream at 50 °C. The residue was reconstituted in 5 mL of water and introduced in an ultrasonic bath during 5 min and it was ready for being loaded onto a previously conditioned C18 column.

Solid Phase Extraction and Cleanup Process

SPE was carried out using C18 column (500 mg, 6 mL, Bond Elut®, Varian, Inc.). The column was activated with 5 mL of methanol followed by 5 mL of water. The reconstituted residue was then loaded by gravity onto the column that was sequentially washed with 5 mL of water and 5 mL of acetonitrile/water (5:95, v/v) mixture. CAP and CAP-D5 were eluted with 5 mL of acetonitrile/water (30:70, v/v) mixture.

The eluate was extracted with 3 × 2 mL of ethyl acetate. The combined extracts were evaporated to dryness in a TurboVap® (Zymark®) under a nitrogen stream at 50 °C. The residue was redissolved in 500 μL of water/acetonitrile (75/25, v/v) mixture and filtered using 0.2 μm PTFE syringeless filters and 20 μL was injected into the LC-MSn system.

Validation Process

The method validation was carried out according to the criteria specified in the 2002/657/EC European Decision. The performance characteristics that have to be determined for quantitative methods are CCα, detection capability (CCβ), trueness, precision (repeatability and within-laboratory reproducibility), selectivity/specificity and applicability (analytes, concentration range).

Trueness and within-laboratory reproducibility were determined by analysing the spiked samples of animal feed (ten different samples; one of each species and four broiler feed) at the levels of 10, 25 and 100 μg Kg−1 in ten different days by two different operators. Repeatability experiment was performed by analysing six replicates (the same day and the same operator) of identical spiked samples at 10, 25 and 100 μg Kg−1. The repeatability and within-laboratory reproducibility were evaluated by calculating the coefficients of variation.

The CCα was established according to the requirements for identification plus quantification. The CCα was experimentally estimated after spiking several samples at decreasing concentration level to 1 in which the less abundant ion was detected with a signal-to-noise near 3 and the confirmation was possible in 50% of the cases. The CCα was determined by spiking 20 samples at the described level verifying that the confirmation was possible in 50% of the cases. The corresponding concentration at the CCα for chloramphenicol plus 1.64 times the standard deviation of the within-laboratory reproducibility equals the CCβ.

Ion Suppression Study

Ion suppression was evaluated during the method development to optimize sample weight and to select a particular solid phase extraction cartridge. In order to calculate these effects, ion suppression (IS) and recovery (RE) of the extraction procedure are taken into account. In this way, three different sets (A, B and C) were prepared and determined by using the ESI interface and the optimized factor settings. The presence of ion suppression effect on the quantification was evaluated by comparing the absolute peak areas of the sets (Antignac et al. 2005). Different animal feeds (n = 10) were used for this approach.

-

Set A:

Consisted of ten replicates of a standard solution of 25 ng mL−1 for CAP (concentration in the vial) in mobile phase. Twenty microlitres were injected into the LC-MSn system.

-

Set B:

Consisted of three subsets for each sample weight: B0.5, B1.0 and B2.0. Extracts of ten different blank animal feed samples of 0.5, 1.0 and 2.0 g were obtained and then spiked after extraction. Five hundred micolitres of a solution of 25 ng mL−1 for CAP were added to the dry final extracts. Twenty microlitres were injected into the LC-MSn system.

-

Set C:

Consisted of three subsets for each sample weight: C0.5, C1.0 and C2.0. Ten different pre-extraction blank spiked samples of 0.5, 1.0 and 2.0 g were processed and 20 μl were injected into the LC-MSn system.

IS and RE were calculated as follows:

Where A is the mean peak area obtained from the set A. B and C are the mean peak areas obtained from the sets B and C, respectively. IS = 100% indicates total inhibition of the analyte response. The RE values can be considered as the actual recovery of the extraction procedure values because it is not affected by the matrix.

The same scheme was followed to select a particular solid phase extraction cartridge at the same concentration. This experiment was carried out with a porcine feed sample. Four subsets (four types of cartridges: C18 Bond Elut® Varian, Oasis HLB® Waters, Plexa® Varian and SampliQ OPT® Agilent) composed sets B and C and five replicates were processed in each case.

Results

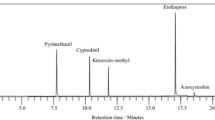

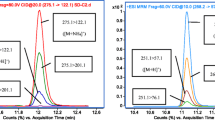

The specificity of the method was demonstrated by analysing 35 blank samples of equine, bovine, porcine, ovine, caprine, rabbit and broiler feed (five different samples of each species). No interferences were observed after analysis of these blank samples. It was verified that in all these blank samples, the relative response in the analyte expected time was less than 5% of the relative response of the analytes in each spiked blank sample at the CCα level and the molecule confirmation was not affected. Figures 1a and 2a show chromatograms of blank porcine and ovine feed, respectively. In Figs. 1b and 2b, the chromatograms of spiked porcine and ovine feed, respectively at 10 μg Kg−1 are presented.

As the MS system was an ion trap mass spectrometer, the full scan MS2 mass spectrum of CAP was obtained, which gave more than four identification points (IPs) required in the 2002/657/EC European Decision. Figures 1c and 2c show mass spectrum of CAP in an extract of samples from porcine and ovine feed spiked at 10 μg Kg−1, respectively. Three transitions were monitored and therefore, 5.5 IPs (1.0 precursor + (3 × 1.5 product) were achieved, which provided the method with a very high selectivity and a great confidence in the results.

Identification was also validated by monitoring two ion ratios by molecule. Table 1 shows the maximum permitted variation (mean ± standard deviation) for relative intensities of the qualifier ions at the different concentrations of CAP. CCα and CCβ were estimated as indicated above and the results are also presented in Table 2. It demonstrates the very high sensitivity of the method never previously reported for the determination of chloramphenicol in animal feed.

Table 3 summarizes the ion suppression phenomenon study and the total recovery at different sample weights. The use of 0.5 g of sample for the analysis provided the lower ion suppression effect and the best actual recovery. No significant differences between the different feed were observed.

Discussion

Extraction and Cleanup Process

Animal feeds are samples that lead to ion suppression in the ESI probe of the mass spectrometer system. Therefore, not only the internal standard for quantitative purposes is required but also cleaner extracts must be achieved to get a sensitive method for banned substances as chloramphenicol. The combination of solid phase extraction and organic liquid–liquid extraction after the elution step allowed obtaining very clean extracts and substantial reduction of ion suppression phenomenon.

Different sorbents were tried during optimization of the sample cleanup step. Both C18 (Bond Elut®, Varian) and polymeric sorbents (Oasis HLB® Waters, Plexa® Varian and SampliQ OPT® Agilent) gave satisfactory extraction efficiency and clean final extracts. Table 4 shows the results of the average ion suppression and recovery for each sorbent. Five replicates were performed for each, as previously described. Finally, the stationary phase C18 was selected according to economical criteria.

Validation

The linearity of the developed method was evaluated for chloramphenicol by standard calibration curves in a concentration range 10–100 μg Kg−1 matrix equivalent. Regression coefficients R 2 > 0.990 were obtained.

As no certified reference material was available, the trueness of the measurements was determined by fortifying blank animal feed samples at 10, 25 and 100 μg Kg−1. This was performed in 20 replicates at each level on ten different days and with two different operators. As can be deduced from Table 2, the calculated trueness fulfils the criteria established in the Decision 2002/657/EC (80–110% for a mass fraction greater than 10 μg Kg−1).

To evaluate the precision of the method, repeatability and within-laboratory reproducibility were determined. The results summarized in Table 2 indicate the good precision of the method, repeatability was lower than within-laboratory reproducibility and the obtained CVs were in accordance with the Decision 2002/657/EC stating that CVs obtained for mass fraction lower than 100 μg Kg−1 should be as low as possible.

There is neither an official MRPL for chloramphenicol in an animal feed established by the European Union nor a recommended MRPL proposed by the community reference laboratories in the guidance paper of the CRLs [CRL Guidance Document (December 2007)], but as a banned substance, decision limit and detection capability of the methods must be as low as possible.

So far, no method has been reported yet for the determination of chloramphenicol in animal feed by liquid-chromatography and mass spectrometry. The method will contribute to carry out a more complete regulatory control programme at various stages in the food chain by applying not only in animal products but also in animal feed.

References

Antignac JP, De Wasch K, Monteau F, De Brabander HF, Andre F, Le Bizec B (2005) Anal Chim Acta 529:129

Commission Decision 2003/181/EC of 13 March 2003, Off J Eur Commun. L71, 17, (2003)

Commission Regulation 1430/94 of 22 June 1994, Off J Eur Commun. L156 6, (1994)

Council Directive 96/23/EC of 29 April 1996, Off J Eur Commun. L125, 10, (1996)

CRL guidance document (December 2007), http://www.rivm.nl/bibliotheek/digitaaldepot/crlguidancepaper2007.pdf

Forti AF, Campana G, Simonella A, Multari M, Scortichini G (2005) Anal Chim Acta 529:257–263

Gantverg A, Shishani I, Hoffman M (2003) Anal Chim Acta 483:125–135

Hormazábal V, Yndestad M (2001) J Liq Chromatogr Relat Technol 24:2477–2486

Impens S, Reybroeck W, Vercammen J, Courtheyn D, Ooghe S, DeWasch K, Smedts W, DeBrabander H (2003) Anal Chim Acta 483:153–163

Mottier P, Parisod V, Gremaud E, Guy PA, Stadler RH (2003) J Chrom A 994:75–84

Nicolich RS, Werneck-Barroso E, Sipoli Marques MA (2006) Anal Chim Acta 565:97–102

Ramos M, Munoz P, Aranda A, Rodriguez I, Diaz R, Blanca J (2003) J Chrom B 791:31–38

Thorsen H, Ronning K, Einarsen TN (2006) Asp. J Chrom A 1118:226–233

Acknowledgment

The authors would like to thank C. Navarro, C. Gargallo, X. Saez, M. Lamas and A. Miro for their assistance in experimental work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moragues, F., Igualada, C. & León, N. Validation of the Determination of Chloramphenicol Residues in Animal Feed by Liquid Chromatography with an Ion Trap Detector Based on European Decision 2002/657/EC. Food Anal. Methods 5, 416–421 (2012). https://doi.org/10.1007/s12161-011-9261-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-011-9261-x