Abstract

This study presents an integrative design of experiment (intDoE) methodology for process optimization using a combination of experimental design, process flowsheet simulation, and economic model. This multilayered framework was implemented to simulate and optimize a simultaneous saccharification and co-fermentation (SSF) process of sugarcane bagasse to ethanol for improving process economic efficiency. Using intDoE based on product titer and economic profit criteria, the SSF process was designed for operation at optimal xylanase/cellulases enzymes, optimal Scheffersomyces stipitis/Saccharomyces cerevisiae yeast cells, and optimal oxygen supply to maximize ethanol titer and to minimize ethanol selling price. The optimal SSF process achieved an ethanol titer of 81.5 g/L, equivalent to the minimal ethanol selling price of 1.4 USD/gal. The results proved the efficiency of intDoE approach that permitted the design and optimizing of fully integrated processes which was not considered by the traditional design of experiment methods. Hence, this novel intDoE optimization tool is useful for bioprocess design in which the integrated process simulation can be performed to select the optimal operating conditions for maximized production efficiency and process economy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Due to concerns about finite fossil fuel resources and their environmental impacts, efforts have been developed to replace oil with biomass-derived fuels and chemicals that are renewable and essential for bio-based economy [1]. Biorefineries using lignocellulosic biomass for bioconversion to transportation biofuels and chemicals are among the most promising options. The focus has, therefore, shifted toward designing sustainable biorefinery process that can be technological and economical feasible and provide energetic and environmental benefits. Simultaneous saccharification and co-fermentation (SSF) process configuration has attracted many investigators as a feasible option to reach high production efficiency [2] by minimizing feedback inhibition effects of enzyme hydrolysis. Efficient conversion systems of biomass-derived sugars to ethanol required a completed utilization of both C6/C5 sugars available which could be achieved using a yeast consortium system of Saccharomyces cerevisiae and Scheffersomyces stipitis [3]. In this study, we investigated and optimized the integrated SSF process using yeast consortium for sugarcane bagasse to ethanol conversion to design the optimal process meeting technological and economic feasibility.

The biorefinery process is a complex, nonlinear network of upstream and downstream process stages including pretreatment, hydrolysis, fermentation, and purification in which each involves multivariable process parameters. Changes in input process parameters affect the performance of each processing step (e.g., yield, titer) and of the entire integrated process due to interdependency of these process units. Optimizing these process parameters is essential to the overall profitability of lignocellulosic bioprocess, ethanol selling price. Developing a cost-effective, commercial-scale biorefinery process, therefore, requires multivariable nonlinear optimization framework that can capture impact of process parameters within one stage of the process on the performance of a fully integrated process. One of the process analysis tools frequently used for design of optimal process conditions is design of experiment (DoE). DoE facilitates the design of optimal process operations through statistical analysis of variables affecting a process and their responses based on a structured methodology [4]. Although DoE methodology provides optimization studies of multivariable process parameters and how they affect process output, the approach focuses on optimizing individual processing step independently rather than optimizing the fully integrated process as a whole [5]. Hence, the DoE only captures a section of biorefinery process and overlooks tradeoffs incorporated among interdependent process stages.

Other optimization models have been developed for biorefinery process design and selection. A systematic process optimization of biorefinery configurations based on a linear program (LP) was created by Bao [6]. The LP-based model for economic value optimization of biorefining systems has been implemented [7]. A multi-objective optimization model to design optimal biorefineries based on financial and environmental performances using a mixed-integer linear model was also utilized [8]. These systematic optimization frameworks, however, are based on linear models, which may not be able to capture the inherently nonlinear nature of fully integrated conversion processes. In addition, these modeling studies were based on fixed values for process parameters with no multivariable process optimization. Furthermore, these optimization frameworks are not considered all processing steps together as the fully integrated process thereby cannot mimic the actual process operations with significant interconnection among processing steps. Hence, these modeling tools may not be able to identify the true optimum process operating conditions of the integrated process on the production and profitability of cellulosic ethanol that would meet processing technology and economic requirements.

The complexity and interconnection of integrated biorefineries prompts the need for developing a novel optimization framework, which can integrate the nonlinearities and multivariable involved in the fully integrated biorefinery process. Process integration modeling platform for optimizing the integrated SSF process based on efficiency and economic criteria has also not yet been developed. Therefore, in this study, we present the development and implementation of a multilayered framework called integrative design of experiment (intDoE) for the optimal design of bagasse-to-ethanol SSF process. The methodology incorporates a bilayer, interlinked optimization strategy based on experimental design of multivariable optimization (STATISTICA) and process flowsheet/techno-economic modeling (SuperPro Designer), which was not previously addressed in the literatures. intDoE was implemented to optimize three key process parameters of integrated SSF process which are enzymes dosage, yeast cells loading and oxygen supply, to identify the optimal operating conditions to meet objective functions based on maximized production (ethanol titer) and minimized operating costs (minimal selling price). The optimal, cost-effective sugarcane bagasse-to-ethanol SSF process yielding a maximum ethanol titer of 81.5 g/L and minimal ethanol selling price of 1.40 USD/gal was reported in this study. The intDoE optimization tool using a combination of experimental design and techno-economic process simulation can assist in designing an optimal integrated biorefinery process with maximized techno-economic characteristics and profitability, thereby enhancing the commercial viability of lignocellulose-based bioprocess.

Materials and Methods

Strain and Media

S. cerevisiae (Thermosacc® Dry yeasts; Lallemand, Milwaukee, WI) and recombinant S. stipitis expressing endoglucanase and xylanase enzymes [9] were the organisms used throughout all experiments. The strains were routinely maintained at 4 °C on YPD agar plate (yeast extract, 10 g/L; peptone, 20 g/L; dextrose, 20 g/L and agar, 20 g/L) supplemented with an antibiotic as appropriate.

Raw Material

Pretreated bagasse used throughout SSF experiments was prepared via stream pretreatment with 0.5% (w/v) H2SO4 at 121 °C for 30 min as previously reported in Unrean et al. [10]. The biomass slurry after pretreatment was washed and separated by filtration into a pretreated solid fraction and a liquid hydrolysate fraction. The liquid hydrolysate formed during pretreatment was composed of approximately 0.5 g/L glucose and 10–15 g/L xylose. The pretreated solid was used for SSF experiment, while the liquid hydrolysates were used for yeast cell cultivation and enzyme production (Fig. 2). Inhibitors present in the liquid hydrolysates were acetic acid (<0.5 g/L) and furfural (<0.1 g/L). Sugar composition in pretreated bagasse, determined by the National Renewable Energy Laboratories (NREL) standard procedures [11], was 0.40 g-glucose and 0.25 g-xylose per gram bagasse. Water-insoluble solid (WIS) content in the pretreated solid was determined by washing the pretreated bagasse with excess deionized water before drying in an oven at 80 °C for 24 h and weighing.

Yeast Cell Cultivation and On-Site Enzyme Production

Recombinant S. stipitis used in SSF was produced in aerobic culture using molasses and bagasse hydrolysate mixture. The culture media contained 0.75 g/L (NH4)2SO4, 0.35 g/L KH2PO4, 0.07 g/L MgSO4·7H2O, 1 g/L yeast extract, molasses, and bagasse hydrolysates at a concentration as indicated in the “Results and Discussion” section. The composition of molasses in hydrolysate culture media was varied from 2.5–10% (v/v) for optimizing yeast cells and enzyme production. The use of hydrolysates in culture media provides several advantages including eliminating water use in media preparation, reducing the loss of sugars present in hydrolysates, and allowing yeast cells to adapt to pretreated biomass environment before use in SSF. The culture was carried out in a cotton-plugged 500-ml shake flask with 30% working volume and 1% (v/v) inoculum, grown for 12 h in YPD media prior to use. Cultivation conditions were 30 °C and 200 rpm for 24 h.

S. cerevisiae used in SSF was cultured aerobically in the culture media containing 0.75 g/L (NH4)2SO4, 0.35 g/L KH2PO4, 0.07 g/L MgSO4·7H2O, 1 g/L yeast extract, and 5% (v/v) molasses under the same cultivation conditions as recombinant S. stipitis. Yeast cells and crude xylanase enzymes harvested by centrifugation were being used for SSF process.

Batch Simultaneous Saccharification and Fermentation

Batch simultaneous saccharification and fermentation (SSF) was carried out in a shake flask at 30 °C, initial pH 5 with no pH control, and was composed of 10% WIS pretreated bagasse, 10% (v/v) molasses, 0.75 g/L (NH4)2SO4, 0.35 g/L KH2PO4, 0.07 g/L MgSO4·7H2O, 1 g/L yeast extract, enzymes, and yeast cells. SSF process diagram of S. stipitis/S. cerevisiae consortium with on-site enzyme production is shown in Fig. 2. It should be noted that the supplementation of 10% (v/v) molasses yields approximately 35 g/l fermentable sugars. Enzymes, yeast cell loading, and oxygen supply were simultaneously optimized in batch SSF process and their impacts on ethanol titer and production cost were examined. The ratio of xylanase/cellulase enzymes and S. stipitis/S. cerevisiae yeast cells was varied between 0 and 2.0 U/FPU and 0–6.4 g-S. stipitis/g-S. cerevisiae, respectively. On-site crude xylanase produced by S. stipitis and commercial cellulases (Cellic C-TEC2, Novozyme DK) at total enzyme loading of 12.5 FPU/g-solid (equivalent to approximately 16 mg-protein/g-solid) was used. Yeast cell load of 0.02 g-cell/g-solid was implemented. Oxygen supply via agitation was also varied in SSF process from 32 to 368 rpm, equivalent to oxygen transfer coefficient (k L a) of 7.6–108.4 1/h. The value of k L a based on working volume and agitation rate was determined using an empirical correlation \( \left({k}_L a=16.61\times {n}^{1.09}\times {\left(\frac{A}{V}\right)}^{0.87}\right) \) previously reported by Reynoso-Cereceda et al. [12] for shake flask operation. Variables n and \( \frac{A}{V} \) represent orbital shaking speed and superficial area per filling volume, respectively. Optimal process operations for batch SSF was systematically determined using integrative design of experiment (intDoE) optimization tool and was experimentally validated. SSF kinetics was examined by sampling 1 mL culture for viable cell count and ethanol concentration determination every 3 h for 12 h. All experiments were performed in duplicate. The optimal batch SSF process was then utilized in fed-batch SSF for high ethanol titer.

Fed-Batch Simultaneous Saccharification and Fermentation

Fed-batch SSF experiments were started as batch at 30 °C, initial pH 5 with no pH control, under optimal conditions for enzymes, yeast cell load, and oxygen supply for 24 h before feeding of additional pretreated solid, enzymes, and yeast cells. Manual pulse feeding of pretreated solid applied in fed-batch SSF was designed according to enzymatic hydrolysis rate as previously determined in Unrean et al. [10]. Cellulases and crude xylanase enzymes were fed along with solid feeding to maintain enzyme load and ratio at the same optimal values of 12.5 FPU/g-solid for cellulase and 2.5 U/g-solid for xylanase as optimal batch SSF. Pulse feed profile for addition of S. cerevisiae and S. stipitis were determined according to cell death rate to replenish yeast cell loss in order to maintain constant yeast cell ratio at the same optimal value as batch SSF. Throughout fed-batch SSF in shake flask, oxygen supply via k L a was constantly maintained at the optimal value by increasing agitation (50–150 rpm) as shown in Fig. 6D in correspondence to changing volume caused by the addition of solid, enzymes, and yeast cells. Change in culture volume along the fed-batch process was monitored manually through weighing assuming density of 1 kg/L (Supplementary S3).

Batch and fed-batch SSF operation in bioreactor was carried out in Labfors bioreactor (Infors HT, Switzerland) at 30 °C and initial pH 5 with no pH control. Oxygen supply in bioreactor operation was maintained at the optimal value via increased aeration rate instead of increased agitation (Fig. 6e). The stirrer speed was kept at 100 rpm during batch and fed-batch bioreactor run. Detailed feeding profiles for fed-batch SSF in shake flask and bioreactor scales were summarized in Fig. 6 and Supplementary S3. The 10% (v/v) molasses was supplemented initially during batch process and the final molasses content at the end of fed-batch SSF was equivalent to 1.2% (v/v). Final WIS content accumulation during fed-batch SSF was 22% in shake flask and 33% in bioreactor. Higher accumulated WIS content was implemented in bioreactor because of better mixing efficiency in bioreactor than in shake flask. Samples (1 mL) were collected for analysis of residual sugars and ethanol every 12–24 h for kinetics analysis and fed-batch SSF lasted 108 h.

Analyses

Cell Concentration

Yeast cell concentration was measured by cell dry weight during seed cultivation and by plate count during SSF. The cell samples were collected via centrifugation and washed with DI water. For cell dried weight determination, washed cells were transferred to a pre-weighed tube and dried at 80 °C for 24 h and subsequently weighed. The concentration of viable cells was measured by counting colony-forming units (CFU), after appropriated serial dilution incubating for 24 h, on YE agar plate supplemented with 20 g/L glucose (for determining total viable cells) and with 20 g/L xylose (for determining viable S. stipitis). The plating method can be reliably used for determining cell concentration in SSF process since no agglomeration of cells nor adherence of cells to solid matter was observed. the concentration of viable S. cerevisiae was then determined by subtracting the concentration of viable S. stipitis from the total viable cell concentration. Hence, plating on two different sugars, glucose and xylose, permits monitoring for cell growth of S. cerevisiae and S. stipitis individually.

Analysis of Enzyme Activity, Sugars, and Ethanol

Samples were centrifuged at 13,000 rpm for 5 min and the supernatant was collected. Xylanase and cellulase enzyme activity in units per milliliter and filter paper units per milliliter, respectively, was determined according to the NREL protocol TP-510-42,628 [13]. The concentration of sugars and ethanol was measured by HPLC equipped with Aminex HPX-87P (for sugars) or Aminex HPX-87H (for ethanol) column (Bio-Rad, Hercules, CA, USA) and a refractive index detector. Operating conditions of Aminex HPX-87H column were at 65 °C with 5 mM H2SO4 as the mobile phase at a flow rate of 0.6 mL/min. Operating conditions of Aminex HPX-87P column were at 80 °C with DI water as the mobile phase at a flow rate of 0.6 mL/min. The concentrations were calculated from the calibration curve of standard solution.

Yield and Rate Calculation

Cell growth rate was determined from a slope of a natural log plot of cell concentration over cultivation time. Ethanol yield was calculated by dividing total ethanol produced by total sugars present in SSF process. Ethanol productivity was calculated as a slope from the time profile plot of ethanol concentration over 24 h for batch and 48 h for fed-batch SSF process.

Integrative Design of Experiment for Integrated Process Optimization

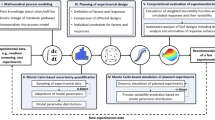

A novel methodology based on process optimization and simulation was developed and designated as integrative design of experiment (intDoE) for modeling nonlinear characteristics of integrated SSF process and for process optimization. Figure 3 shows a general description of the proposed mechanism of intDoE for SSF process optimization. The intDoE is composed of bilayer and interlinked modeling of [1] design of experiment and [2] techno-economic analysis.

Design of Experiment

Design of experiment (DoE) is a multivariable optimization tool which is relied on nonlinear regression model for determining critical point (minimal/maximal) of output response based on statistical significance. The model can be used for investigating nonlinear process mechanisms to study the individual effects of the factors as well as the effect of the interaction between the factors toward process output. In this study, three process variables which typically influenced ethanol production in SSF process were analyzed: xylanase/cellulase ratio, S. stipitis/S. cerevisiae cell ratio and oxygen supply via agitation. Each factor was varied at three factorial levels, coded as −1 (lowest value), 0 (middle value), and +1 (highest value). The factors are varied together, instead of one at the time. The 20 experimental runs with different combinations of the three process parameters and levels based on DoE analysis was summarized in Supplementary S1. The SSF optimization experiments were performed for 12 h in duplicate. STATISTICA (StatSoft Inc., USA) was employed for all experimental designs and statistical and graphical analysis for evaluation of effects and interactions of the factors on the output response.

Techno-economic Analysis

SSF optimization experiments with different process variables and different ethanol titer output response were then estimated for their technological and economical potentials using process simulations with SuperPro Designer software (Intelligen Inc., USA). This techno-economic modeling software permits process material and energy balance calculation based on flowsheet simulation and process cost analysis based on economic model. The simulated process was an integrated bagasse-to-ethanol conversion process composing of the basic steps of diluted-acid pretreatment, yeast cell production, enzyme production, simultaneous saccharification and fermentation, downstream process and utilities system (Supplementary S2). Techno-economic analysis was based on a process scale model with the capacity of 1 ton raw bagasse per batch. Materials and energy flows for all streams in the integrated process were calculated based on process parameters (e.g., yields, titers, rates) obtained from experimental studies in this work. Process configuration, input, output, and process economic analysis were previously described in details in Unrean and Khajeeram [14] for upstream processing and in Wingren et al. [15] for downstream processing. The integrated SSF process simulation under different process variables were economically evaluated based on ethanol minimal selling price (MSP), determined as total production cost (e.g., raw materials, utilities, and labor costs associated with the integrated process) divided by liter of ethanol produced. The MSP refers to the ethanol price where production cost and income of selling ethanol are equal. It should be noted that the MSP is by no mean to determine the exact selling price. Finally, the process economy in terms of MSP along with the process titer of each SSF optimization experiment was returned back to the DoE optimization model to determine the optimal operating conditions with the highest ethanol titer and the lowest MSP, which are output SSF process targets in this intDoE model analysis.

Results and Discussion

Development of a lignocellulose-based process that meets process efficiency and process economy requirements is essential for industrialized biorefinery processing. We have developed an integrated bioprocess modeling tool, based on hybridization of experimental design and techno-economic models, to facilitate process design and optimization strategies. The integrative model was utilized to design simultaneous saccharification and fermentation (SSF) process by S. stipitis/S. cerevisiae cell consortium with on-site enzyme production for maximized ethanol titer and minimized ethanol minimal selling price.

Yeast Cell and Enzyme Production Optimization

The production of yeast cells and xylanase enzyme used in SSF process were performed in batch fermentation of molasses and liquid hydrolysates mixture. The impact of hydrolysates and molasses supplementation in culture media with respect to yeast cell growth and xylanase enzyme production was examined. Fig. 1a shows similar cell titer and xylanase production in recombinant S. stipitis batch culture in the absence and presence of hydrolysates, indicating that the liquid hydrolysates was not toxic to the yeast cell and can be used to replace water during yeast cell and on-site enzyme production processes. Although there is an acetic acid inhibitor (< 0.5 g/L) present in the liquid hydrolysates, the concentration is likely too low to have any significant inhibitory effect on yeast cell growth. Cultivation of yeast cell in liquid hydrolysates also allowed the cell to adapt to the pretreated biomass environment. Previous study has shown that yeast cells pre-cultivated in hydrolysates showed an improved robustness against inhibitors, leading to enhanced fermentation capacity of the yeast cell in SSF process [16]. Effects of molasses composition in culture media were also examined in Fig. 1b to determine optimal condition for efficient active yeast cell and enzyme production. Comparison of cell titer at different molasses composition in batch culture media showed a decrease in cell growth at decreasing concentration of molasses. At 2.5% molasses culture, S. stipitis grew to a final cell titer of 5.15 ± 0.78 g/L which was more than a twofold reduction compared to the titer obtained in 10% molasses culture under the same condition. At decreasing percent molasses, less sugar and nutrients are available for biosynthesis processes and cell growth, resulting in reduced biomass production. The xylanase produced in 2.5–10% (v/v) molasses cultures, however, was relatively similar suggesting that the molasses composition has little influence on enzyme production. No significant effect of molasses composition on yeast cell growth in S. cerevisiae was observed (results not shown). Hence, in integrated SSF process, 5% molasses in hydrolysates was chosen as optimal culture media for the yeast cell propagation and on-site xylanase production processes as it would minimize the cost of culture media while enabling relatively high yeast cell and enzyme production.

Optimization of S. stipitis cultivation in sugarcane bagasse hydrolysates. a Effect of hydrolysates replacement in culture media on yeast cell growth and enzymes synthesis. b Effect of molasses (%, v/v) composition in hydrolysates media on cell growth and enzymes synthesis during batch cultivation. Results are based on average of two independent experiments

Development of Integrative Design of Experiment for SSF Process Optimization

To design a commercial-scale biorefinery process, it is crucial during process optimization to incorporate true estimates of process parameters, nonlinear dynamic nature of bioprocesses, and interdependency of processing units within the entire integrated production process. Figure 2 depicts schematic diagram of integrated SSF process implemented in this study which included multiple process units from lignocellulosic feedstock (bagasse) to ethanol product. The pretreated bagasse along with enzymes and yeast cells produced on site were added to the SSF process. Owing to the complex, nonlinear nature of integrated bioprocess, optimizing the whole SSF process would require multilayered framework for designing cost-effective process configurations with feasible techno-economic characteristics. In this work, a hybrid bioprocess modeling framework called integrative design of experiment (intDoE) was developed which incorporated a two-layer optimization strategy based on experimental design together with process simulation and techno-economic models as depicted in Fig. 3. The two-level intDoE approach would permit simultaneous investigation of multiple process parameters for optimization of fully integrated process in order to maximize the profitability of the process based on production efficiency and economic values. To the best of the authors’ knowledge, this novel modeling framework for optimization of integrated biorefinery process has not yet been addressed in previous literatures.

Scheme of simultaneous saccharification and fermentation (SSF) using S. stipitis/S. cerevisiae consortium with on-site enzyme production under optimization in this study. Diluted-acid pretreated bagasse was separated into solid fraction (pretreated biomass) and liquid fraction (hydrolysates). Solid fraction was used in SSF process whereas liquid fraction was applied for yeast cell cultivation and enzyme production before adding to SSF. Process parameter targets (shown in blue) are [1] xylanase/cellulase enzyme ratio, [2] S. stipitis/S. cerevisiae yeast cell ratio and [3] oxygen supply, which was systematically optimized using integrated process optimization tool (intDoE) as described in Fig. 3

Structure of integrative design of experiment (intDoE) methodology for optimization of simultaneous saccharification and fermentation (SSF) process. The integrated process optimization tool intDoE was developed through a combination of [1] statistic-based process optimization, design of experiment and [2] techno-economic model describing process simultation and economic analysis. intDoE which permitted process optimization by considering both process efficiency and process economy simultaneously was applied to determine operating conditions of SSF process yielding maximal ethanol titer while minimizing ethanol minimal selling price (MSP)

As a case demonstration, we implemented intDoE for optimizing the integrated SSF process of sugarcane bagasse to ethanol in order to determine optimum process conditions for maximizing ethanol production titer and minimizing ethanol selling price (MSP). The model analysis began with utilizing experimental design based on central composite design (CCD) to design optimization experiments (Supplementary S1). CCD has proven to be an efficient tool for estimating effects of multiple parameters and their interacting effects on process outputs with minimized number of experiments and high accuracy of predicting optimum [17]. In this work, the following operating variables that can influence ethanol production significantly in SSF process were optimized: [1] xylanase/cellulase ratio, [2] S. stipitis/S. cerevisiae ratio, and [3] oxygen supply. The optimized parameters in this study were ranged from 0 to 2.0 U/FPU for enzyme ratio, 0–6.4 g/g for yeast cell ratio and 32–368 rpm for agitation speed which resulted in 20 experimental runs based on CCD design including three blocks of five experiments with five center points. These 20 process optimization conditions were experimentally evaluated for their effects on ethanol production titer. It should be noted that since the optimization runs were performed under the same concentration of total sugars and fermentation time, evaluating ethanol titer, yield, or productivity would result in the same optimum. Therefore, we have chosen to consider ethanol titer as the only performance parameter. The CCD-based optimization model was integrated with process simulation. All process performance (yield, titer, rate) for each operating condition was then sent to process simulation of the whole bagasse-to-ethanol SSF process (Supplementary S2) for materials and energy flows analysis using SuperPro Designer simulation software, which was linked to a techno-economic model for determination of ethanol minimal selling price (MSP). Consequently, the MSP obtained from each simulated process operations was passed back to experimental design for determination of the optimum process operating conditions of the SSF process that resulted in maximal profit based on ethanol titer and MSP.

Optimum SSF Process Design with Maximal Profitability

Influences of SSF process parameters, which were [1] xylanase/cellulase ratio, [2] S. stipitis/S. cerevisiae ratio, and [3] oxygen supply, on ethanol production titer and minimal selling price were simultaneously investigated by integrative design of experiment based on batch shake flask cultures (Fig. 4a–d). The predicted response surface plot of ethanol titer and production cost as a function of the process parameters indicated that decreasing enzyme and yeast cell ratios as well as lowering agitation speed to reduce oxygen supply promoted high ethanol titer and low ethanol minimal selling price. According to the integrated model, an optimum SSF operating condition for maximal profit was predicted at xylanase/cellulase ratio of 0.20 U/FPU, S. stipitis/S. cerevisiae ratio of 0.5 g/g and agitation at 100 rpm, equivalent to k L a = 26.3 h−1. Under these optimum conditions, the ethanol titer was maximized at 44.7 g/L and the ethanol minimal selling price was minimized at 20.6 baht/L (equal to 2.18 USD/gal based on the exchange rate of 35.7 baht/USD). Compared with traditional experimental design, intDoE identified different optimum outputs (Table 1). This is expected as intDoE modeling approach incorporated both process efficiency and techno-economic characteristics when determining optimal values. This was different from traditional DoE which determined the optimum based solely on process efficiency. Application of intDoE for integrated SSF process design predicted true cost-effective operating conditions with 7% higher ethanol titer and 22% lower ethanol production cost than traditional DoE application. Hence, the intDoE approach is an effective tool for integrated process design and optimization to maximize profitability of the process. Ethanol production titer and cost experimentally observed under optimal conditions agreed well with the predictive values by intDoE model as shown in Fig. 4e, validating predictive capacity of the model.

Effect of SSF batch process parameters on ethanol production titer and minimal selling price (MSP) by S. stipitis/S. cerevisiae yeast consortium. a Ethanol titer at varying xylanase/cellulases and S. stipitis/S. cerevisiae cell ratios. b Ethanol titer at varying S. stipitis/S. cerevisiae cell ratios and oxygen supply via agitation. c Ethanol MSP at varying xylanase/cellulases and S. stipitis/S. cerevisiae cell ratios. d Ethanol MSP at varying S. stipitis/S. cerevisiae cell ratios and oxygen supply via agitation. The data were average of triplicate SSF batch experiments. All analysis were based on intDoE process optimization described in Fig. 3 which identified optimal SSF process for maximized ethanol titer and minimized MSP at 0.2 xylanase(U)/cellulases(FPU) ratio, 0.5 S. stipitis (g)/S. cerevisiae (g) ratio and 100 rpm agaitaiton equivalent to oxygen supply at k L a = 26.3 1/h as shown in white asterisk. (E) SSF process performance predicted by intDoE compared with experiment under optimal conditions yielding ethanol titer of 44.7 g/L and MSP of 20.6 baht/L. Consistency between model and experimental analysis validated intDoE modeling approach

Integrated Fed-Batch SSF Enabling Economic Feasibility of Bagasse-to-Ethanol Conversion

Optimum batch SSF shake flask using a consortium of S. cerevisiae and S. stipitis with on-site enzyme production outperformed batch SSF using a single-strain culture as shown in Fig. 5a, b. The titer, yield, and productivity of ethanol was improved by 14% compared to the single-strain batch SSF culture. Kinetics of cell growth and ethanol production by S. cerevisiae/S. stipitis consortium in optimum batch SSF process are shown in Fig. 5c revealed a constant decrease in viable cell number of both yeasts despite a continued production of ethanol. The loss of viable yeast cell was likely a result of stresses generated by a combined effect of multiple inhibitory compounds such as weak acids, aldehydes, and phenolic compounds present in pretreated biomass [18, 19]. Interestingly, the death rate of S. stipitis was 45% lower than that of S. cerevisiae, indicating that S. cerevisiae was more sensitive to these inhibitors than S. stipitis did in the integrated SSF process (Fig. 6a). This was expected as S. stipitis was adapted to the inhibitors in pretreated biomass environment when being propagated in mixed molasses and liquid hydrolysate culture media leading to improved tolerance compared to unadapted S. cerevisiae which was propagated in a culture media without hydrolysates.

Batch SSF performance of S. stipitis/S. cerevisiae consortium optimized by integrative design of experiment compared to single cultures. Ethanol titer (a), yield and productivity (b) was compared for 12 h batch SSF by S. cerevisiae, S. stipitis, and S. stipitis/S. cerevisiae under optimal conditions. c Time profiles for cell growth and ethanol fermentation during optimal S. cerevisiae/S. stipitis SSF process. Data are average from two biological replicates. Loss in cell viability over fermentation time was caused by the presence of inhibitors in pretreated biomass hydrolysates

Designing fed-batch SSF with on-site enzymes production by S. stipitis/S. cerevisiae consortium. a Cell growth kinetics of S. cerevisiae and S. stipitis during optimal batch SSF process (0.2 xylanase(U)/cellulases(FPU) ratio, 0.5 S. stipitis (g)/S. cerevisiae (g) ratio, and 100 rpm agaitaiton at k L a = 26.3 1/h) . The natural logarithm plot was applied to determine the death rate of S. cerevisiae (−0.35 1/h) and S. stipitis (−0.19 1/h). Design of optimal feed profiles in fed-batch SSF in flask (b) and bioreactor (c). Solid feeding (black) was based on enzymatic hydrolysis rates as previously described in Unrean et al., 2015. The yeast cell feed was designed according to each cell death rate. The pulse addition of each yeast cell (S. cerevisiae: orange line; S. stiptis: blue) was to replenish cell death. Solid line represented accumulated WIS content (%), while dashed lines are accumulated yeast cells (g). Controlled oxygen supply during fed-batch SSF operation. The k L a (cyan) was maintained at optimal value through increasing agitation in flask (d) and increasing aeration in bioreactor (e). Enzymes (green) and yeast cell (yellow) ratios were also maintained at the optimal values throughout the fed-batch process

Due to elevated cell death observed over time, a strategy of feeding yeast cell is necessary to maintain sufficient active yeast cell and optimum yeast cell ratio for higher ethanol titer and lower production cost in integrated SSF process [20]. Fig. 6b–e presents the optimized feed profiles of pretreated biomass, yeast cells, enzyme ratios and oxygen supply designed based on the predictive optimum condition for maximizing ethanol titer and minimizing ethanol selling price. The pulse feed profiles for S. cerevisiae and S. stipitis were designed according to the death rate of each yeast strain in order to maintain the yeast cell ratio at 0.5 g/g optimum in a small-scale shake flask as well as in a scale-up bioreactor. The optimal feed rate for pretreated biomass to achieve high overall solid content was according to a previous design based on enzyme hydrolysis rate to prevent a too high viscosity and severe mixing problem in the SSF [10]. The enzyme feeding was to ensure the optimum xylanase/cellulase ratio and was initially maintained at 0.20 U/FPU initial during every pulse addition of pretreated solid. To maintain constant oxygen supply at optimum k L a of 26.3 h-1, agitation rate was step-wise increased along with the increasing working volume due to addition of pretreated solid, yeast cells, and enzymes during fed-batch SSF. The agitation rate was determined according to the empirical correlation reported in Reynoso-Cereceda et al. [12] which linked k L a value as a function of agitation rate and working volume of shake flask with orbital mixing. Viscosity impact on k L a was neglected in this study as relatively low viscosity was observed during sampling throughout fed-batch SSF, indicating that the enzymes performed quite well in hydrolyzing biomass even at high-solid content. This could be because of the synergism of cellulase and xylanase which enhances hydrolysis efficiency as well as the enzyme feeding strategy which permits the addition of fresh enzymes to replenish any degraded enzymes during fed-batch operation. Nevertheless, the effect of viscosity may become significant when operating at higher solid content. In such a case, viscosity impact should be taken into consideration for the estimation of k L a value. During scale-up SSF process in bioreactor, the k L a value was kept at the optimum by maintaining a constant aeration rate at 2 vvm based on a previous experimental measurement of k L a-dependent aeration rate [21].

The optimal addition of pretreated solid combined with the maintenance of S. stipitis/S. cerevisiae and xylanase/cellulase ratios through feeding and oxygen supply at the optimum throughout the SSF process in a shake flask led to a continued ethanol fermentation to reach a high titer of 56.4 ± 1.3 g/L, a 1.3-fold improvement in titer when compared with optimum batch SSF process (Fig. 7a). A relatively constant ethanol concentration over processing time does not mean that the fermentation was stalled, instead a result of increasing volume caused by the pulse feeding. As shown in Fig. 7a, the amount of ethanol produced shown in grams constantly increased throughout SSF processing time, indicating the continuity of ethanol fermentation. Small concentration of the residual glucose and xylose was observed at the end at approximately 0.4 g/L and 2 g/L, respectively, indicating the good balance between enzymatic hydrolysis and ethanol fermentation in the integrated SSF process. More xylose remaining than glucose is expected as the rate of xylose consumption by S. stipitis was typically lower than that of glucose. The condition gives overall ethanol yield of 0.40 ± 0.02 g/g equivalent to 80% of the theoretical and maximum ethanol production rate of 1.05 g/L-hr (Table 2). Ethanol yield based on total sugars and rate of ethanol production in shake flask fed-batch SSF was decreased approximately 6 and 39%, respectively, compared to batch process which could possibly be explained by limited mass and heat transfer at higher solid operation as observed in several previous studies [22, 23].

Optimized fed-batch, high-solid SSF with on-site enzymes production by S. stipitis/S. cerevisiae consortium. Fermentation kinetics of fed-batch, high-solid SSF a in shake flask at 22% final accumulated WIS and b in bioreactor at 33% final accumulated WIS. Concentration time profiles for glucose (X), xylose (*), ethanol (●), total ethanol in gram (∆), and accumulated volume (%) during feeding are shown. The data are average of duplicate experiments. c Comparison of ethanol production performance in titer, yield, and productivity by 10% WIS batch and 22% WIS fed-batch SSF in flask and 33% WIS fed-batch SSF in bioreactor. The fed-batch SSF process based on the designed feed profiles in Fig. 6 achieved a maximum ethanol titer of 81.5 g/L, equivalent to the yield of 0.25 g-ethanol per g-dry pretreated bagasse, and was scalable from flask to bioreactor

Scaling Up of Optimum SSF Based on intDoE Process Design

To prove the scalability and commercial feasibility of optimum SSF process designed by intDoE, the integrated SSF process was scaled up in a 3-L high-solid bioreactor. Under optimum operating conditions, maximum ethanol titer of 81.57 ± 1.64 g/l was achieved in scale-up fed-batch SSF process. Figure 7b reveals time profiles for ethanol and residual sugars during fed-batch SSF in high-solid bioreactor under the optimized yeast cell, enzyme ratios, and oxygen supply. This is approximately equal to 0.25 g-ethanol per g-dry pretreated bagasse. Detailed feeding profiles for fed-batch SSF in shake-flask and bioreactor scales were summarized in Supplementary S3. Material and utility requirements for the optimal fed-batch, high-solid SSF process were provided in Supplementary S4. Figure 7c compares process performance of fed-batch, high-solid SSF in flask, and bioreactor scales compared to batch SSF. Lower ethanol productivity in SSF with higher solid loading was likely due to a gradually increasing concentration of inhibitors (e.g., weak acids, phenolic compounds) in the pretreated biomass together with an increase in ethanol end-product at high WIS content, which are known to inhibit cell growth and viability [24]. Table 2 summarizes ethanol production performance in titer, productivity, and yield achieved by integrated fed-batch SSF process in both shake flask and bioreactor scale. Relatively similar ethanol yield between small shake flask and bioreactor scales confirmed the scale-up feasibility of the predictive SSF process. The high titer of ethanol achieved by the optimum SSF in this study also outperformed the previously reported values which were approximately 40–70 g/L [23, 25,26,27,28,29,30], and could potentially meet industrial requirements for economical lignocellulosic ethanol production. The minimal selling price of ethanol by the optimal fed-batch, high-solid SSF process was 12.9 baht/L (equal to 1.4 USD/gal based on an exchange rate of 35.7 baht/USD), which was 38% reduction compared to the optimum batch SSF making the integrated process highly competitive with the current selling price in the market at 1.76 USD/gal (December 2016; www.tradingeconomics.com/commodity-ethanol). Hence, application of intDoE for integrated SSF process optimization together with high-titer fed-batch strategy is an effective combinatorial approach for the development of cost-effective bioprocess in order to meet technical and economic requirements of biorefinery industry.

Conclusion

A bilayer optimization framework, integrative design of experiment (intDoE), was proposed and implemented to analyze fully integrated, nonlinear biorefinery processes. The optimization algorithm was composed of experimental design, process flowsheet, and economic analysis which permitted investigation of several process parameters and multi-objective process optimization. To demonstrate the utility of this novel tool, process operations of simultaneous saccharification, and co-fermentation (SSF) process of sugarcane bagasse to ethanol using S. cerevisiae and S. stipitis consortium and on-site enzymes production were optimized via intDoE modeling. The implicit correlations between process units in upstream and downstream stages were taken into consideration during the integrated process optimization. The SSF process parameters including enzyme load, yeast cell dosage, and oxygen supply were simultaneously optimized by experimental design which was linked with process flowsheet and economic analysis to evaluate how the change of these parameters affecting the mass and energy flows and economic efficiency of the integrated process. This hybrid optimization tool successfully identified an optimum bagasse-to-ethanol SSF process for maximizing ethanol production and process profitability yielding high ethanol titer at 81.5 g/L with a minimal ethanol selling price of 1.4 USD/gal. This intDoE modeling imparts a degree of realism to the optimization of actual biorefinery process which is essential for the design of optimal process conditions meeting technological and economic feasibility.

References

Bezerra TL, Ragauskas AJ (2016) A review of sugarcane bagasse for second-generation bioethanol and biopower production. Biofuels. Bioprod Bioref 10:634–647

Zhou J, Ouyang J, Xu Q, Zheng Z (2016) Cost-effective simultaneous saccharification and fermentation of l-lactic acid from bagasse sulfite pulp by Bacillus coagulans CC17. Bioresour Technol 222:431–438

Suriyachai N, Weerasaia K, Laosiripojana N, Champreda V, Unrean P (2013) Optimized simultaneous saccharification and co-fermentation of rice straw for ethanol production by Saccharomyces cerevisiae and Scheffersomyces stipitis co-culture using design of experiments. Bioresour Technol 142:171–178

Tveit TM (2005) Experimental design methods and flowsheet synthesis of energy systems. Appl Therm Eng 25:283–293

von Stosch M, Hamelink JM, Oliveira R (2016) Toward intensifying design of experiments in upstream bioprocess development: an industrial Escherichia coli feasibility study. Biotechnol Prog 32(5):1343–1352

Bao BP, Ng DKS, Tay DHS, Jimenez-Gutierrez A, El-Halwagi MM (2011) A shortcut method for the preliminary synthesis of process-technology pathways: an optimization approach and application for the conceptual design of integrated biorefineries. Comput Chem Eng 35:1374e83

Geraili A, Sharma P, Romagnoli JA (2014) Technology analysis of integrated biorefineries through process simulation and hybrid optimization. Energy 73:145–159

Giarola S, Zamboni A, Bezzo F (2011) Spatially explicit multi-objective optimisation for design and planning of hybrid first and second generation biorefineries. Comput Chem Eng 35:1782–1797

Puseenam A, Tanapongpipat S, Roongsawang N (2015) Co-expression of endoxylanase and endoglucanase in Scheffersomyces stipitis and its application in ethanol production. Appl Biochem Biotechnol 177:1690–1700

Unrean P, Khajeeram S, Laoteng K (2016) Systematic optimization of fed-batch simultaneous saccharification and fermentation at high-solid loading based on enzymatic hydrolysis and dynamic metabolic modeling of Saccharomyces cerevisiae. Appl Microbiol Biotechnol 100:2459–2470

Sluiter AD, Hames BR, Ruiz RO, Scarlata C, Sluiter JB, TempletonDW CD (2008) Determination of structural carbohydrates and lignin in biomass: laboratory analytical procedure (LAP) NREL/TP-510-42618 Golden, CO. National Renewable Energy Laboratory, CO

Raynoso-Cereceda GI, Garcia-Cabrera RI, Valdez-Cruz NA, Trujillo-Roldan MA (2016) Shaken flasks by resonant acoustic mixing versus orbital mixing: Mass transfer coefficient k L a characterization and Escherichia coli cultures comparison. Biochem Eng J 105:379–390

Adney B, Baker J. 1996. Measurement of cellulase activities: laboratory analytical procedure (LAP). Issue date 08/12/1996, NREL/TP-510-42628.

Unrean P, Khajeeram S (2016) Optimization and techno-economic assessment of high-solid fed-batch saccharification and ethanol fermentation by Scheffersomyces stipitis and Saccharomyces cerevisiae consortium. Renew Energy 99:1062–1072

Wingren A, Galbe M, Zacchi G (2008) Energy considerations for a SSF-based softwood ethanol plant. Bioresour Technol 99(7):2121–2131

Nielsen F, Tomás-Pejó E, Olsson L, Wallberg O (2015) Short-term adaptation during propagation improves the performance of xylose-fermenting Saccharomyces cerevisiae in simultaneous saccharification and co-fermentation. Biotechnol Biofuels 8:219

Kumar V, Bhalla A, Rathore AS (2014) Design of experiments applications in bioprocessing: concepts and approach. Biotechnol Prog 30(1):86–99

Guo W, Chen Y, Wei N, Feng X (2016) Investigate the metabolic reprogramming of Saccharomyces cerevisiae for enhanced resistance to mixed fermentation inhibitors via 13C metabolic flux analysis. PLoS One 11(8):e0161448

Chen Y, Sheng J, Jiang T, Stevens J, Feng X, Wei N (2016) Transcriptional profiling reveals molecular basis and novel genetic targets for improved resistance to multiple fermentation inhibitors in Saccharomyces cerevisiae. Biotechnol Biofuels 9:9

Koppram R, Olsson L (2014) Combined substrate, enzyme and yeast feed in simultaneous saccharification and fermentation allow bioethanol production from pretreated spruce biomass at high solids loadings. Biotechnol Biofuels 7(1):54

Unrean P, Nguyen NH (2012) Metabolic pathway analysis of Scheffersomyces stipitis: effect of oxygen availability on ethanol synthesis and flux distributions. Appl Microbiol Biotechnol 94(5):1387–1398

Liu ZH, Chen HZ (2016) Simultaneous saccharification and co-fermentation for improving the xylose utilization of steam exploded corn stover at high solid loading. Bioresour Technol 201:15–26

Zhu JQ, Qin L, Li WC, Zhang J, Bao J, Huang YD, Li BZ, Yuan YJ (2015) Simultaneous saccharification and co-fermentation of dry diluted acid pretreated corn stover at high dry matter loading: overcoming the inhibitors by non-tolerant yeast. Bioresour Technol 198:39–46

Zhang J, Shao X, Townsend OV, Lynd LR (2009) Simultaneous saccharification and co-fermentation of paper sludge to ethanol by Saccharomyces cerevisiae RWB222—part I: kinetic modeling and parameters. Biotechnol Bioeng 104(5):920–931

Cheng J, Leu SY, Zhu J, Gleisner R (2015) High titer and yield ethanol production from undetoxified whole slurry of Douglas-fir forest residue using pH profiling in SPORL. Biotechnol Biofuels 8:22

Narra M, James JP, Balasubramanian V (2015) Simultaneous saccharification and fermentation of delignified lignocellulosic biomass at high solid loadings by a newly isolated thermotolerant Kluyveromyces sp. for ethanol production. Bioresour Technol 179:331–338

Qureshi AS, Zhang J, Bao J (2015) High ethanol fermentation performance of the dry dilute acid pretreated corn stover by an evolutionarily adapted Saccharomyces cerevisiae strain. Bioresour Technol 189:399–404

Katsimpouras C, Christakopoulos P, Topakas E (2016) Acetic acid-catalyzed hydrothermal pretreatment of corn stover for the production of bioethanol at high-solids content. Bioprocess Biosyst Eng 39(9):1415–1423

Li K, Qin JC, Liu CG, Bai FW (2016) Optimization of pretreatment, enzymatic hydrolysis and fermentation for more efficient ethanol production by Jerusalem artichoke stalk. Bioresour Technol 221:188–194

Ren X, Wang J, Yu H, Peng C, Hu J, Ruan Z, Zhao S, Liang Y, Peng N (2016) Anaerobic and sequential aerobic production of high-titer ethanol and single cell protein from NaOH-pretreated corn stover by a genome shuffling-modified Saccharomyces cerevisiae strain. Bioresour Technol 218:623–630

Acknowledgements

This work has been financially supported by The Thailand Research Fund (TRF) and the National Center for Genetic Engineering and Biotechnology (BIOTEC), Thailand.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khajeeram, S., Puseenam, A., Roongsawang, N. et al. Optimal Design of Cost-Effective Simultaneous Saccharification and Co-fermentation Through Integrated Process Optimization. Bioenerg. Res. 10, 891–902 (2017). https://doi.org/10.1007/s12155-017-9851-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-017-9851-6