Abstract

The results of a small-scale method for the extraction of a range of feedstock samples, comprising herbaceous, hard, and soft wood, were compared to the conventional method using accelerated solvent extraction (ASE). In general, the extractives were in the range of 97.3 to 104.4 % of the values obtained by the conventional method, and the manual method was highly reproducible (0.1–1.6 % relative standard deviation, n = 5). The analysis of the water phases from sugarcane revealed that the two methods resulted in almost identical soluble sugar composition. The composition of the resulting biomass was 98.8–103.7 % (average 100.9 %) Klason lignin, 96.2–99.5 % (average 98.2 %) glucan, and 97.5–101.1 % (average 98.0 %) xylan of the results obtained from an analysis starting with ASE. The newly developed has been shown to be a fast and inexpensive alternative to the conventional ASE and an ideal tool when only small amount of sample is available.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The terminology of extractives defines all compounds of the plant that are not part of the cell wall structure and that can be extracted by water or organic solvents [1]. Therefore, the term “extractives” contains a complex and nonuniform mixture of compounds, such as nonstructural sugars, amino acids, lipids, salts, waxes, terpenes, flavonoids, sterols, and chlorophyll, all with different chemical properties.

It has long been known that removal of extractives prior to analysis improved the accuracy of the Klason lignin assay [2] and structural carbohydrates [3]. The technical report for determination of extractives in biomass developed by National Renewable Energy Laboratory (NREL) also recommends the use of extracted biomass for carbohydrates and lignin analysis [4]. Omission of this extraction step may result in a bias of structural carbohydrates and lignin levels [4, 5].

Whereas the presence of certain extractives compounds can reduce accessibility to carbohydrate polymers causing incomplete hydrolysis resulting in lower structural carbohydrates, some extractives are acid-insoluble and can coprecipitate with lignin leading to elevated Klason lignin levels. In addition, biomass with higher amounts of nonstructural free sugars (e.g., sugarcane) must be subject to an extraction step. This ensures that these sugars are not determined together with the sugars released from cellulose and hemicellulose hydrolysis causing a higher measured structural carbohydrate content. Furthermore, extractives removal is necessary in order to distinguish between structural and nonstructural inorganics [6]. Thus, it is evident that biomass extraction is a required step in order to obtain accurate biomass compositional analysis data.

Methods for determination of extractives are based on a standard method (TAPPI T 264 cm-07) developed by the pulp and paper industry [6–8]. Standard methods describing the preparation of extractive-free wood have been validated and are available from the American Society for Testing and Materials (ASTM). One standard procedure (“ASTM D1105-96: preparation of extractive-free wood” [9]) describes a 4-h Soxhlet extraction with an ethanol-toluene mixture followed by a 4-h ethanol extraction and a subsequent hot water extraction of the previously extracted and air-dried material for another 3 h. A second standard method (“ASTM E1690-08: determination of ethanol extractives in biomass” [10]) is a gravimetric determination of ethanol extractives in biomass after a 24-h exhaustive Soxhlet extraction. This procedure is suitable for hard and soft wood, herbaceous materials (e.g., switchgrass), agricultural residues (e.g., corn stover, wheat straw, and bagasse), and wastepaper.

In addition, NREL has established extraction laboratory analytical procedures (LAPs) for biomass feedstocks which have been extensively cited in the literature [5]. For herbaceous feedstock, a water extraction step was added before the ethanol extraction because of the higher amount of water-soluble material compared to woody biomass [6].

The NREL methods describe two alternative extraction procedures. Since the traditional standard Soxhlet method is time consuming and takes up to 24 h for each extraction step, the method has also been validated using the Dionex accelerated solvent extraction (ASE) system operating at higher temperature and higher pressure (around 100 bar) which greatly reduces both extraction time and solvent use [6, 11].

A variation of the Soxhlet method is the automated and accelerated Soxtec procedure reducing the extraction time by about 75 %. The main difference compared to the Soxhlet methods is that the sample in the thimble is lowered and totally immersed in the boiling solvent [12, 13].

The chemical inhomogeneity of the extractives makes gravimetry an ideal analytical method for their combined quantification. Therefore, a widespread procedure is to remove the solvent (e.g., under reduced pressure) and weigh out the leftover residue. However, this adds another labor- and time-intensive step to the extractives determination method. In our laboratory, we predominantly use the ASE with the two-step water/ethanol solvent method [4], but we then quantitatively remove the extracted biomass from the extraction cell for the purpose of drying and determination of the percentage weight loss after extraction. This weight loss directly corresponds to the amount of extractives present in the biomass.

For this method, the high pressure applied during the ASE procedure impedes the use of very fine particles (e.g., finely ball-milled biomass) because the biomass can be pressed out of the extraction cell onto the filter making the separation of filter and biomass complicated. This makes the accurate determination difficult or even impossible, especially when parts of the filter are stuck to the frit (see Fig. S1). Ball-milling is often the method of choice for homogenization of biomass, especially when available sample amount is low and knife-milling with sieve screens would lead to high sample losses.

In order to be able to prepare biomass for compositional analysis, a fast and reliable extraction method for ball-milled biomass is needed. The method should result in comparable compositional data as the conventional applied method. Therefore, we have developed a small-scale manual extraction method that can handle small sample amounts (100–300 mg) as well as small particle sizes. The results were compared to the conventional method using ASE extraction.

Materials and Methods

Chemicals and Biomass

All chemicals were from Sigma-Aldrich (St. Louis, MO) or Fisher Scientific (Pittsburgh, PA) unless otherwise mentioned.

Polypropylene solid phase extraction (SPE) filtration tubes (3-mL volume) with polyethylene frits (20-μm porosity) and vacuum manifold (Visiprep™) were from Sigma-Aldrich. Depending on the biomass used for extraction, the filtration cartridges were heat-pretreated before usage at 105 °C for 15 h or at 45 °C under vacuum for 15 h.

Miscanthus (Miscanthus x giganteus), corn stover (Zea mays ssp. mays), eastern cottonwood (Populus deltoids, “poplar”), Sherburne willow (Salix x Sherburne 9871-31, “willow”), sugarcane (Saccharum officinalis), and loblolly pine (Pinus taeda) were obtained dried from Energy Biosciences Institute, Urbana-Champaign, IL. “Miscanthus A” was harvested in December 2009 in Fairfield, IL; “Miscanthus B” and “Miscanthus C” were harvested in October 2009 in Orr and Dixon Springs, IL, respectively. Energy cane (Saccharum sponteneum) was obtained dried from the BP Global Technology Center, San Diego, CA. All biomass was ground by an SM200 cutting mill (Retsch, Haan, Germany) with a 2-mm sieve screen.

Monterey pine (Pinus radiata) RM 8493 and wheat straw (Triticum aestivum var. Thunderbird) RM 8494 were obtained from the National Institute of Standards and Technology (NIST).

Unless mentioned otherwise, all drying steps for experiments with biomass samples except for sugarcane were performed at 105 °C for 15 h. In experiments involving sugarcane, drying was performed at 45 °C under vacuum for 15 h in order to prevent soluble sugar degradation.

ASE Extraction

One gram of dried biomass (passed a 2-mm sieve screen) was weighed into a 5-mL extraction cell (Dionex, Sunnyvale, CA, USA) fitted with a preweighed dried glass fiber filter (Dionex) and was extracted three times each with water and 190 proof ethanol at 100 °C using an automated solvent extractor (ASE 350, Dionex). Settings are the following: 150 % rinse, three cycles per solvent, 60-s nitrogen purge after extraction [4]. The extracted biomass of the cell including glass fiber filter was transferred into a dry and preweighed aluminum pan and dried at 105 °C for 15 h. The weight was determined, and the amount of extractives was calculated as the percentage weight loss based on the initial dried biomass used for extraction. A 1-g aliquot of the extracted biomass was ground in a canister ball-mill (model 8200, Kleco, Visalia, CA, USA) for 5 min, and the powder was dried as specified in “Chemicals and Biomass” and stored in a closed container for compositional analysis.

Small-Scale Extraction

One gram of 2-mm ground biomass was homogenized by ball-milling for 5 min in a canister ball-mill (model 8200, Kleco) and dried as specified in “Chemicals and Biomass.” For the 10- and 15-min ball-milling time experiments, a cooling time of about 15 min was applied after each 5-min ball-milling interval. About 250-mg sample of dried and ball-milled biomass was weighed to the nearest 0.1 mg into a predried (as specified in “Chemicals and Biomass”) 3-mL filtration tube with a frit (Fig. 1a). The tubes were placed on the vacuum manifold (Fig. 1b). Biomass was mixed first with 70 °C hot deionized water and then with 70 °C hot 95 % ethanol in aliquots of 2 mL up to the total volume used per extraction (e.g., if total extraction volume is 12 mL, 3 × 2 mL water and then 3 × 2 mL of ethanol was used). Biomass and solvent were suspended after each addition of a 2-mL aliquot by stirring with a metal spatula, and the solvent was then removed by vacuum filtration. The metal spatula was left inside the filtration tube until the addition of the last aliquot of ethanol which was split in half (Fig. 1b). The first milliliter was used to resuspend the biomass using the spatula. The second milliliter was used to rinse off any biomass from the spatula into the filtration tube. Filtration was performed by applying vacuum to manifold, and filtrate was collected inside the manifold in 15-mL tubes for further analysis (sugarcane) by high-pressure anion exchange chromatography with pulsed amperometric detection (HPAEC-PAD).

Extracted biomass was dried inside filtration tubes as specified in “Chemicals and Biomass” and weighed to nearest 0.1 mg. Extractives amount was calculated as the percentage weight loss based on the initial dried biomass used for extraction. Recovery of the extracted biomass from the filtration tube was achieved by inserting a thin metal rod (e.g., Allen key) from the tip end and pushing the frit and biomass out of the barrel.

Compositional Analysis

The determined carbohydrate and lignin composition was adjusted to a “dried and nonextracted” biomass basis by multiplying by a conversion factor of (100 − (extractives content [%]) / 100).

Determination of Carbohydrates

About 50 mg of extracted, ball-milled, and dried biomass were weighed to the nearest 0.01 mg into a modified hungate vial and incubated with 0.5 mL of 72 % (w/w) sulfuric acid at room temperature with vortexing every 15 min. After 1 h, 14 mL of deionized water was added, the vial was crimp-sealed, vortexed, and the mixture was autoclaved for 60 min (liquid cycle) [14]. A sugar recovery standard containing the same sulfuric acid concentration was prepared in a similar way and coautoclaved with the samples for calculation of monosaccharide degradation during autoclaving. After cooling to room temperature, the mixture was vortexed and kept in refrigerator overnight, and 1 mL of the clear supernatant was filtered (0.45 μm, polyethersulfone) and analyzed by high-pressure liquid chromatography with refractive index detection (HPLC-RID).

Determination of Klason Lignin

Insoluble and precipitated material was resuspended by vortexing, and the suspension was filtered through a pretreated glass fiber filter (Millipore, Billerica, MA, USA) [14]. The hungate vial was extensively rinsed with water in order to ensure quantitative transfer of solids onto the filter. Retained solids on the filter were washed extensively with deionized water and then dried at 105 °C for 15 h. The weight (m1) was determined. Both filter and solids were then ashed at 575 °C for 3 h and weighed (m2). The difference of m1–m2 results in the ash-corrected Klason lignin.

Determination of Ash After Extraction

The ash determination was performed with 50 mg of extracted, ball-milled, and dried samples in a preweighed aluminum pan at 575 °C for 3 h, and the weight was recorded after cooling to room temperature [15]. Ash amount was calculated as the percentage weight loss based on the initial dried biomass used for ashing.

HPLC-RID and HPAEC-PAD

For the determination of total glucose, xylose, and arabinose content, samples were injected onto an HPX-87H (300 × 7.8 mm, Bio Rad, Richmond, CA) column with a 30 × 4.8-mm cation H guard column (Bio Rad). The instrument (1200 series, Agilent Technologies, Santa Clara, CA) was equipped with a refractive index detector. Elution was performed at 50 °C with 5 mM sulfuric acid at a flow rate of 0.6 mL/min. On the HPLC column used, galactose and mannose coelute with xylose, and these sugars were therefore quantified together as parameter “xylan” during total sugar analysis. For calculation of polysaccharide content, conversion factors of 0.9 (glucan) and 0.88 (xylan, arabinan) were used.

Soluble sugar extractives in the water phase of sugar cane were analyzed using an ICS-3000 HPLC system (Dionex) equipped with a pulsed amperometric detector. Samples were injected onto a 150 × 3 mm i.d. PA20 column (Dionex) with a 50-mm × 3-mm guard column of the same material and eluted at 30 °C with a mobile phase of 30 mM KOH at a flow rate of 0.4 mL/min.

Results and Discussion

Method Development

A reduction of the particle size by ball-milling increases the surface area, and we assumed that this could also increase the extraction efficiency making higher pressure (as applied with the automated solvent extractor) or longer extraction times (as applied with the Soxhlet method) unnecessary. The common size comminution procedure in our lab for the homogenization of feedstock samples for compositional analysis is canister ball-milling for 5 min. Since the samples should be used for compositional analysis after extraction anyway, this milling procedure was used as a starting point for method development (for particle size characteristics of ball-milled biomass, see Table S1). The solvents of choice were water and ethanol in accordance with the NREL procedure [4], although ethyl acetate and petrolether have also been tested but did not result in a higher extractives removal (data not shown).

Both water and ethanol were heated to 70 °C in order to enhance solubility of compounds in the solvents. In initial attempts, the biomass was extracted in 2-mL plastic tubes. After each extraction step, the mixture was centrifuged (10 min at 16,000 g) and the supernatant removed. Besides being labor-intensive, this procedure often resulted in floating particles making a quantitative recovery of the extracted biomass impossible. This loss of material was prevented when the extraction was performed in a filtration tube and the solvent removed by vacuum filtration through a frit (Fig. 1) leaving behind the entire extracted biomass inside the tube. Hence, this setup was further investigated as a way to accurately and reproducibly determine the extractives content of biomass samples. The mixing of the biomass and extraction solvent was achieved by stirring with a metal spatula. A pretreatment/preconditioning step of the filtration cartridges by drying them under the same conditions as applied later is necessary to improve the accuracy of the method since the tubes lose a small amount (although less than 1 mg) upon drying. Prewashing with the solvents (water/ethanol) did not cause any additional weight loss, and this step was therefore omitted. All method development experiments were performed in triplicate on poplar and Miscanthus samples, with a higher (~19 %) and a lower (~4 %) extractives content, respectively.

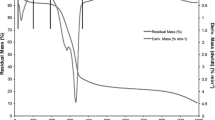

Effect of Extraction Volume on Extractives Content

Figure 2a shows the total extractives content (water and ethanol) depending on the total volume (8–20 mL) of solvents used. For poplar, the total extractives content yielded 18.8–19.3 %, and the maximum of 19.3 % was obtained with the 12-mL total volume. For Miscanthus, the 20-mL total extraction volume yielded the maximum extractives content of 4.5 %, whereas the 8-mL total volume resulted in the lowest (4.3 %) extractives content. However, all volumes tested gave very similar extractives content for both poplar and Miscanthus. An extraction volume of 12 mL (3 × 2 mL water and 3 × 2 mL ethanol) was therefore deemed to be sufficient and kept for the following experiments. With certain biomass not presented here, e.g., agave, Arabidopsis thaliana, and orange peel (data not shown), we noticed deterioration of the filtration. We assume that the higher amount of, e.g., pectins, led to a swelling of the biomass and holding back of the water making filtration difficult. For such biomass containing a higher amount of pectins, we therefore recommend using either cold water or directly extracting with 70 or 95 % ethanol.

Extractives content of poplar and Miscanthus depending on the a total volume of solvent used, b total amount of biomass used, c ball-milling time applied for sample preparation. Composition (based on a “dried and nonextracted” basis) of the biomass after 5- and 15-min ball-milling of d poplar and e Miscanthus. Composition of f soluble sugars of sugarcane determined by the small-scale manual extraction (ME) at 70 °C and accelerated solvent extraction (ASE) at 70 and 100 °C. Error bars represent ±1 standard deviation (n = 3)

Effect of Biomass Amount on Extractives Content

The amount of biomass used for extraction was also examined. The upper limit was set to 300 mg of biomass, and 100 mg was chosen for the lower limit based on the fact that a certain amount of extracted biomass is needed for accurate and reliable compositional analysis. As can be seen in Fig. 2b, for both poplar and Miscanthus, 100, 200, and 300 mg starting biomass resulted in almost identical extractives concentrations (19.1–19.2 % and 4.3–4.4 %, respectively) reflecting the method robustness in this range. We envision that the method can be further downscaled using smaller tubes in order to accommodate smaller sample sizes.

Effect of Ball-Milling Time on Extractives Content and Biomass Composition

Excessive ball-milling of biomass can lead to destruction of certain compounds and can result in changes of the composition. However, ball-milling is required for all small-scale methods in order to ensure homogeneity of the biomass ensuring that a representative sample is used for the analysis. An increase of extractives for poplar from 19.2 to 19.9 % and for Miscanthus from 4.4 to 5.2 % was observed when ball-milling time was increased from 5 to 15 min (Fig. 2c). Interestingly, the resulting composition of the biomass (calculated on a “dried and nonextracted” basis) was hardly affected. After the 15-min ball-milling procedure, the composition of glucan, xylan, arabinan, and lignin in poplar was only 0.1–0.2 % absolute percent lower compared to the 5-min ball-milling time (Fig. 2d). The composition of Miscanthus after the 15-min ball-milling did not change for xylan, arabinan, and lignin, and only the glucan composition increased slightly by 0.2 % absolute (Fig. 2e). The changes in the biomass composition during the longer ball-milling time were therefore minor and can be seen irrelevant for compositional analysis purpose. This will make it easier to adapt this method in other laboratories where the ball-milling conditions applied here cannot be exactly reproduced.

Comparison of Small-Scale Manual Extraction to Accelerated Solvent Extraction Using Various Feedstocks

The method settings (250 mg of biomass ball-milled for 5 min, extraction with 3 × 2 mL water and 3 × 2 mL ethanol) were then applied to a range of feedstocks (including two NIST standard reference materials) comprising herbaceous (Miscanthus, corn stover, energy cane, sugarcane, wheat straw), hard wood (willow, poplar) and softwood (pine) and compared to the results obtained by the conventional extraction method using an accelerated solvent extractor (ASE350, Dionex) with extraction conditions specified in the NREL LAP [4]. These experiments were performed with five replicates each. Small deviation of the compositional analysis data for poplar and Miscanthus A compared to the method development data (Fig. 2) were observed. This is not surprising since the analysis was conducted at a different time point and also with five instead of three replicates. However, the absolute deviations (mainly for poplar) were only in the range of 0.0–0.3 % and can be seen insignificant for compositional analysis purpose.

Using the filtration tubes and starting from dried and ball-milled biomass, 48 samples can easily be prepared and extracted in about half a day. In this respect, the small-scale method is about two to four times faster than the conventional ASE method.

Comparison of Extractives

In general, the results of extractives of the two methods were in very good agreement (Fig. 3). The relative standard deviations (RSD%) for the manual extraction were between 0.1 and 1.6 % and therefore similar or even slightly better than for ASE (0.1–3.4 %). For most of the samples analyzed, the results of the small-scale manual extraction method were in the range of 97.3 to 104.4 % of the values obtained by the conventional method. Exceptions were Miscanthus A and loblolly pine where the results of the small-scale method were 9.8 and 10.6 % higher, respectively. Since the extractives content of these two samples was low (4.1 and 4.7 %, respectively, determined by ASE), the absolute deviation between the two methods was only 0.4 and 0.5 %, respectively. This is still in the range of reported errors for the conventional methods [1]. The NIST pine sample also showed a higher deviation of the values from small-scale (3.6 %) and conventional method (2.0 %), and both results were also significantly lower than the reported value of 5.1 % determined by a round-robin [16]. Interestingly, the extractives content of the second NIST standard material wheat straw (17.1 %, [17]) was accurately determined by the developed small-scale method (16.7 %). It is noteworthy to mention that the small-scale extraction can even be applied to biomass with a very high content of extractives. In the case of sugarcane, the high extractives content determined by ASE (57.9 %) was reproduced by the small-scale method (58.2 %). The extractives of sugarcane consists of a high percentage of soluble sugars, and their accurate determination is important, e.g., in bioenergy applications since the soluble sugars are a major part of the energy stored. Therefore, we collected and analyzed the water extractions which contained these water-soluble sugars (Fig. 2f). In addition to the temperature of 100 °C used during ASE extractions, the ASE extraction was also performed at a temperature of 70 °C similar to the maximum temperature applied during the small-scale extraction. The higher temperature of 100 °C during ASE extraction did not result in any sugar degradation or an improved extraction efficiency for the soluble sugars compared to the 70 °C condition (Fig. 2f). The sucrose content of the sugarcane (31.6 %) was identical determined by the small-scale extraction and both ASE conditions. The glucose and fructose content was only slightly lower with the small-scale method (7.2 and 6.4 %, respectively) compared to both ASE extraction conditions (7.5 and 6.5 %, respectively).

Extractives content of various feedstocks including NIST reference materials determined by the small-scale manual and accelerated solvent (ASE) extraction. Error bars represent ±1 standard deviation (n = 5). The standard deviation of the NIST reference values were calculated by dividing confidence interval by the coverage factor reported [16, 17]

Comparison of Resulting Biomass Composition

The developed small-scale extraction method was also tested for its effect on the overall composition of the extracted biomass (calculated as “dried, nonextracted” biomass) compared to the conventional ASE extraction (Table 1). As seen before with the extractives content, the values for glucan, “xylan,” arabinan, Klason lignin, and ash after extraction for the small-scale and ASE extraction were in very good agreement. For Klason lignin, the results obtained by the small-scale method were in the range of 98.8–103.7 % (average 100.9 %) of the ASE method. This is a good indication that the small-scale method is capable of removing Klason lignin-interfering compounds as effectively as the conventional ASE method.

Similar findings were observed for the ash after extraction (structural inorganic), a parameter that can be used as an indicator how complete the extraction process can remove extractable inorganic matter. If the ash content of the small-scale method is higher or lower compared to the conventional ASE method, the extraction efficiency of the small-scale method is lower or higher, respectively. The ash content was slightly higher for corn stover (5.4 vs 4.9 %) and energy cane (3.7 vs 3.4 %) but somewhat lower for willow (2.9 vs 3.5 %) and poplar (2.1 vs 2.4 %) with the small-scale method compared to the ASE extraction.

The carbohydrate composition determined by the small-scale method was in general only slightly lower. Glucan resulted in 96.2–99.5 % (average 98.2 %) and xylan in 97.5–101.1 % (average 98.0 %) of the content determined by ASE. The arabinan values differed by a maximum of only 0.2 % absolute.

Conclusion

The developed small-scale manual extraction (ME) method has been shown to be a fast and inexpensive alternative to the conventional ASE resulting in comparative composition of extractives, cell wall sugars, lignin, and ash. Since it requires ball-milled material, it is an ideal extraction method when only small amount of sample is available. The method will also enable researchers to apply extraction of biomass before compositional analysis if instruments of higher cost (ASE) are unavailable. We envision this method to become a valuable tool for all researchers dealing with compositional analysis of feedstock samples.

References

Hames BR (2009) Biomass compositional analysis for energy applications. In: Mielenz JR (ed) Biofuels, Methods in Molecular Biology. Vol. 581. Humana Press, pp 145-167

Ritter GJ, Barbour JH (1935) Effect of pretreatments of wood on the lignin determination. Ind Eng Chem 7:238–240

Thammasouk K, Tandjo D, Penner MH (1997) Influence of extractives on the analysis of herbaceous biomass. J Agric Food Chem 45:437–443

Sluiter A, Ruiz R, Scarlata C, Sluiter J, Templeton D (2008) Determination of extractives in biomass; Laboratory Analytical Procedures (LAP); National Renewable Energy Laboratory (NREL): Golden, CO, revised version January 2008. http://www.nrel.gov/biomass/analytical_procedures.html. (accessed February 2014).

Burkhardt S, Kumar L, Chandra R, Saddler J (2013) How effective are traditional methods of compositional analysis in providing an accurate balance for a range of softwood derived residues? Biotechn Biofuels 6:90

Sluiter JB, Ruiz RO, Scarlata CJ, Sluiter AD, Templeton DW (2010) Compositional analysis of lignocellulosic feedstocks. 1. Review and description of methods. J Agric Food Chem 58:9043–9053

Preparation of wood for chemical analysis (2011) In: Technical association of pulp and paper industry (TAPPI) standard T 264 cm-07 (replaced former T 12 os-75), TAPPI Standards & Technical Information Papers; http://www.tappi.org/s_tappi/sec.asp?CID=2&DID=3 (accessed February 2014).

Templeton DW, Scarlata CJ, Sluiter JB, Wolfrum EJ (2010) Compositional analysis of lignocellulosic feedstocks. 2. Method uncertainties. J Agric Food Chem 58:9054–9062

Standard test method for preparation of extractive-free wood (2007) In: American Society for Testing and Materials (ASTM) Standard D1105-96. http://www.astm.org/Standard/index.shtml (accessed February 2014)

Standard test method for determination of ethanol extractives in biomass (2008) In: American Society for Testing and Materials (ASTM) Standard E1690-08. http://www.astm.org/Standard/index.shtml (accessed February 2014)

Luthria DS, Vinjamoori D, Moel K, Ezzell J (2004) Accelerated solvent extraction. In: Luthria DL (ed) Oil Extraction and Analysis, Critical Issues and Comparative Studies. AOCS Press, pp 25-38

Anderson S (2004) Soxtec: its principle and applications. In: Luthria DL (ed) Oil Extraction and Analysis, Critical Issues and Comparative Studies. AOCS Press, pp 11-24

Sitholë BB, Vollstaedt P, Allen LH (1991) Comparison of Soxtec and Soxhlet systems for determining extractives content. TAPPI J 187-191

Ibanez AB, Bauer S (2014) Downscaled method using glass microfiber filters for the determination of Klason lignin and structural carbohydrates. Biomass Bioenergy, accepted

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D (2008) Determination of ash in biomass; Laboratory Analytical Procedures (LAP); National Renewable Energy Laboratory (NREL): Golden, CO, 2005; http://www.nrel.gov/biomass/analytical_procedures.html. (accessed February 2014)

National Institute for Standards and Technology (NIST) Report of Investigation (2011) Reference Material 8493, Monterey Pine, Whole Biomass Feedstock. National Institute of Standards and Technology, Gaithersburg, MD

National Institute for Standards and Technology (NIST) Report of Investigation (2011) Reference Material 8494, Wheat Straw, Whole Biomass Feedstock. National Institute of Standards and Technology, Gaithersburg, MD

Acknowledgments

This work was funded by the Energy Biosciences Institute. The authors would like to thank Tim Mies (University of Illinois at Urbana-Champaign) and Dr. Rebecca Arundale (former University of Illinois at Urbana-Champaign, now BP) for providing biomass samples.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 329 kb)

Rights and permissions

About this article

Cite this article

Kuchelmeister, C., Bauer, S. Rapid Small-Scale Determination of Extractives in Biomass. Bioenerg. Res. 8, 68–76 (2015). https://doi.org/10.1007/s12155-014-9493-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-014-9493-x