Abstract

A facultative anaerobic bacterium was isolated from an industry effluent and designated as VITDM1. The partial 16S rRNA gene sequence and analysis of this gram negative, motile isolate suggested that VITDM1 clusters with Pseudomonas genus and exhibited highest similarity (98 %) with Pseudomonas aeruginosa. The temperature and pH optimum for growth were 30 °C and 7.0 respectively. In this study, electricity generation with effluent degradation was investigated in a two compartment microbial fuel cell with methylene blue as mediator for 3 days. VITDM1 was able to utilize the substrate existing in the effluent and the maximum open circuit voltage achieved was 610 mV which was stable for duration of 26 h. The highest power density and current density were 173.3 mW/m2 and 288.8 mA/m2 respectively at ambient temperature (30 ± 2 °C). In order to provide surface criteria and morphological information the surface images of the anode were successfully obtained.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microbial fuel cells hold promise in green technology for the production of bioenergy simultaneously treating wastewater [1–4]. Microbial fuel cell is an electrochemical device which converts the chemical energy of fuel to electrical energy by the catalytic action of microorganisms [5]. Anaerobic microorganisms present in the anodic chamber act as biocatalyst by directly transforming chemical energy from substrate to electrical energy through electrochemical reactions under ambient temperature, pressure and mild pH conditions. Thus the degradation of organic materials produces electrons which travel to the cathode side via an electrical circuit. A lot of research has been done by using different bacterial species such as Enterobacter cloacae, Escherichia coli, Shewanella oneidensis, Geobacter sulfurreducens and Bacillus subtilis with respect to current generation with different wastewaters [6–10]. Considerable amount of work has been performed to this end which focuses on the use of microbes in wastewater rather than the growth of the microorganisms for the sole purpose of electricity production which is influenced by several factors. Most of the microbial fuel cells use mediator molecule to speed up the generated electron to the electrode surface [11, 12]. Recently, mediator less microbial fuel cells have also been developed in which the electrons are directly transferred to the electrode [13, 14]. In our earlier work a microbial fuel cell was tested for batch and continuous operational modes using wastewater from our institute’s wastewater treatment plant as the substrate [15]. In order to maximize the power output from the microbial fuel cell a better understanding of the microorganism characteristics and optimum culture conditions for the growth of Pseudomonas sp. VITDM1 was necessary. Hence in the present study the isolated strain was investigated for its morphological and biochemical characteristics. The mediator concentration, pH and temperature were optimized for the growth of VITDM1. Microbial fuel cell experiments were conducted under those optimal conditions and electricity generation using wastewater as substrate was investigated. In order to understand the electron transfer process between the bacterial cell and the anode, scanning electron microscopy studies were also carried out to examine the characteristic structure and anodic surface colonization.

Materials and Methods

Microorganism, Characterization and Growth Conditions

Pseudomonas sp. VITDM1, a locally isolated bacterium reported for wastewater degradation and current generation [16] was used in all the experiments. Nutrient agar medium was prepared for the isolation of microorganism from the industrial effluent. 0.1 ml of the industrial effluent was spread over the nutrient agar plate and incubated at ambient temperature for 24 h. The potential colony was isolated and sub cultured by quadrant streak method. The culture was maintained on King’s B medium agar slants and sub cultured by transferring into minimal medium broth containing the following composition per litre. Beef extract – 1.0 gm, Yeast extract – 2.0 gm, Peptone – 5.0 gm and Sodium chloride – 5.0 gm. The pH of the medium was adjusted to 7.0, prior to autoclaving (120 °C for 20 min).The purity and the colony morphology of the isolate was identified using light microscopy on the basis of colony color, shape, size, margin and appearance. For the physiological and biochemical characterizations, the isolated strain was precultured on King’s B agar plates at 30 °C under aerobic conditions.

The optimum pH, temperature of the isolate was determined. The initial pH of the minimal medium broth was adjusted to 5, 6, 7 and 8 separately with 0.1 N NaOH or 0.1 N HCl. The flasks were sterilized and inoculated with 1 ml of a suspension culture and incubated at ambient temperature (30 °C ± 2) for 48 h on rotary shaker (150 rpm). Four Erlenmeyer flasks (250 ml), each with 100 ml of minimal medium broth were taken and inoculated as mentioned above and incubated on rotary shaker (150 rpm) for 48 h at four different temperatures (20, 25, 30 and 35 °C).

The isolate was subjected to indole test, citrate test, mannitol-motility test, methyl red–voges proskauer test, hydrogen sulphide production and carbohydrate fermentation test, nitrate reduction test, urease test, oxidase test, catalase and other tests as per standard protocol for biochemical testing described elsewhere [17]. The inoculated tubes were incubated at ambient temperature (30 °C ± 2) for 24–48 h. The ability to produce pyoverdin (yellow–green fluorescent) pigment was further confirmed by plating them on King’s B medium.

16S rRNA Gene Sequencing and Analysis

The genomic DNA of Pseudomonas sp. VIT DM1 strain was isolated and amplified using universal bacterial forward and reverse primer. The primer sequence which was used for the amplification of 16S rRNA are 5′-AGAGTRTGATCMTYGCTWAC-3′ and 5′-CGYTAMCTTWTTACGRCT-3′ forward and reverse primer respectively. The molecular characterization was performed using ABI 3130 Genetic Analyser and Big Dye Terminator version 3.1″ Cycle sequencing kit (Chromous Biotech Pvt. Ltd., India). The 1.4 kb rRNA fragment was amplified using high fidelity PCR polymerase. The homology of the 16S rRNA partial gene sequence was compared with the existing sequence available in data bank using BLAST search. The sequence alignment was carried out using ClustalW (version 2) of DDBJ and the phylogenetic tree was constructed using the Neighbor Joining (NJ) method with 1,000 replicates as bootstrap value using the MEGA software (version 5.2). The scale bar indicates the average number of amino acid substitutions per site. The obtained 16S rRNA sequence was submitted to the Genbank, NCBI, USA under the accession number HQ232955.

Scanning Electron Microscopy (SEM)

The bacterial morphology on the surface of the anode and the cation exchange membrane were studied using FEI Quanta FEG 200-F high resolution scanning electron microscope at 30 kV. The carbon fibre electrode and the membrane were carefully removed at the end of the batch experiment from microbial fuel cell and washed with 0.1 M phosphate buffer. The samples were then immersed in 4 % (v/v) glutaraldehyde in 0.1 M phosphate buffer for 2 h at 4 °C. The fixed samples were then incubated for 1 h in 0.1 M phosphate buffer and then rinsed for 5 min in distilled water to remove the salts. The fixed specimens were then dehydrated with immersing in increasing concentration of ethanol [18]. The samples were dried at room temperature for 2 h. Pieces of 1 × 1 cm were cut and used for the SEM analysis.

Construction and Operation of Microbial fuel cell

The microbial fuel cell consisted of a 4.0 × 4.0 × 1.0 cm acrylic chamber with provision for the electrode and the inlet [15]. The setup was assembled using steel studding, washers and nuts and physically separated by a cation exchange membrane (NCBE Reading, University of Reading, UK) having 16 cm2 surface area. Each chamber contained a sheet of carbon fiber electrode tissue (NCBE Reading, University of Reading, UK) with a projected surface area of 18 cm2, along with one graphite rod and connected using copper wires. The anode compartment consisted of equal volumes of Pseudomonas sp. VITDM1 suspension culture, methylene blue as mediator and wastewater as substrate. The cathode compartment consisted of 0.02 M ferricyanide dissolved in phosphate buffer (0.1 M, pH 7.0) as the electron acceptor. The microbial fuel cell volumes in the anode and cathode chambers were 15 ml. The batch experiments were carried out for 3 days at ambient temperature.

Results and Discussion

Isolation and Identification

The isolate VITDM1 was grown on King’s B medium and the colonies were easily recognized in this medium as their growth was found to be small, opaque, and irregular with distinctive fruity odor surrounded by yellow green pigmented colonies (pyoverdin). The colonies grown on solid medium were found to be rod shaped, and approximately 1.2–1.5 μm long and 0.6–0.9 μm wide and motile by means of single polar flagellum. Staining of the cells of VITDM1 showed clearly that the isolate was gram negative rod shaped bacterium. The isolate VITDM1 was able to hydrolyse gelatin, casein and fat but not starch. Oxidase and catalase were produced but indole was not produced. The other physiological characteristics are shown in Table S1 which compared well with Pseudomonas aeruginosa as described elsewhere [19]. The strain did not ferment glucose, lactose, sucrose. The sequence similarity of the 16S rRNA gene was compared with those of reference organisms obtained from the Gen bank data libraries. The results revealed that the isolate VITDM1 is a member of the genus Pseudomonas (Fig. S1). P. aeruginosa was the nearest neighbor with 16S rRNA similarity of 98 %. The isolated strain was identified as P. aeruginosa and designated as Pseudomonas sp. VITDM1 based on morphological, physiological, biochemical, and 16S rRNA sequence analysis.

Growth Characteristics

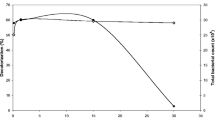

The growth profile for the Pseudomonas sp. VITDM1 was investigated both in the presence and absence of the mediator methylene blue for a period of 48 h (Fig. S2). The cell growth increased exponentially in both cases for the first 20 h of cultivation. In the culture with the mediator the cell mass was found to decrease after 30 h of cultivation with the maximum cell optical density at 20 h. Further investigations revealed that the specific growth rate with and with out the mediator was 0.219 per hour and 0.285 per hour respectively.

Effect of pH and Temperature on Cell Growth

Figure S3 shows the effect of temperature on the growth of Pseudomonas sp. VITDM1. On increasing the temperature from 20 to 35 °C, the specific growth rate gradually increased from 0.121 per hour to 0.257 per hour, but the maximum cell density was observed at 30 °C beyond which minimum cell growth rate was observed. Since the cell growth was observed to be stable at 30 °C, this temperature was selected for the microbial fuel cell experiments for current generation. Similar observations on increased cell growth and stability at 30 °C have been reported earlier [3]. The effect of pH on cell growth was studied for the range of 5.0–8.0 (Fig. S4). Optimal growth was obtained at pH 7.0. At lower pH, the cell growth was inhibited significantly (pH 5.0). It should be noted that Pseudomonas sp. VITDM1 has been isolated from an industrial effluent under near neutral pH condition [16]. These results indicate that maintenance of pH and temperature are the most critical parameters for the growth of VITDM1.

Effect of Methylene Blue Concentration on Cell Growth and Microbial Fuel Cell Performance

There are several parameters that reflect the performance of microbial fuel cells. Electron transfer in a microbial fuel cell is dependant on the type of electron mediator used. From our earlier work it was found that methylene blue mediated electron transfer more efficient than neutral red [15]. Therefore in order to find out the effect of mediator concentration on the growth of the cell, varying concentrations of methylene blue within the range 0.01–0.1 mM were used and the specific growth rate determined (Fig. S5). A maximum specific growth rate of 0.463 per hour was observed with methylene blue concentration of 0.01 mM. This observation indicates that higher concentrations of methylene blue proved toxic to the bacteria [20].

The isolated strain was tested for its ability to generate current in the microbial fuel cell. Figure S6 depicts the performance of the single microbial fuel cell with varying concentrations of methylene blue from 0.01 to 0.1 mM in the anodic chamber along with the culture and the wastewater. The open circuit voltage was measured and found to increase with the increase in the mediator concentration. A maximum open circuit voltage of 0.61 V was obtained with 0.1 mM mediator concentration which was stable for 26 h. This was contrary to our expectation because the cell growth rate was found to decrease at higher concentrations of methylene blue. The increase in the open circuit voltage may probably be due to the improvement in the electron transfer efficiently by the lesser number of cells involved.

The microbial fuel cell was prepared using Pseudomonas sp. VITDM1 and fed with wastewater as the substrate. When the potential reached a plateau (26 h), the fuel cell was discharged through an external resistance of 0.27 kΩ and change in the current at closed circuit condition was monitored and found to be stable over the testing period. Figure S7 shows the current generated pattern of the microbial fuel cell containing Pseudomonas sp. VITDM1 with the resistance across the anode and the cathode. The current production continued as the substrate was consumed and the growth of the cells of Pseudomonas sp. VITDM1 was demonstrated by the continuous current production for longer period. When the 0.27 kΩ resistance was applied, there was a rapid increase in the current output in the initial stage of the discharge and after 10 min, the current density reached a plateau resulting in a steady current density of 138 mA/m2. On increasing the external resistance from 0.27 to 0.5 kΩ, the current and power output was found to decrease with values as 105.5 mA/m2 and 63.3 mW/m2 respectively. However further increase in the external resistance, decreased both the power and current output because the bacterium was unable to sustain the load beyond 0.5 kΩ. These observations suggest that the microbial cells attached to the surface of the anode were primarily responsible for current production and they could not sustain higher loads. The maximum current density and power density was found to be 288.8 mA/m2 and 173.3 mW/m2 respectively. The experiment was repeated twice and the results were highly reproducible in terms of the measured values from the each resister used. These results show that the external resistance becomes rate limiting step in current generation over 0.27 kΩ. This observation in the current and power output was also observed by Gunasekaran and coworkers with C. freundi with definite conclusions [4]. Further experiments were carried out with methylene blue concentrations above 0.1 mM, but the open circuit voltage however was found to decrease.

Surface Characteristics using Scanning Electron Microscopy

Scanning electron microscopy technique provides substantial surface and morphological information. The microbial fuel cell was operated for 24 h to observe the anode surface characteristics. The electrode and the membrane were removed carefully from the anodic chamber and were subjected to scanning electron microscopic analysis. Figure S8a shows the outer surface of the carbon fiber electrode before inoculation and startup of the microbial fuel cell. After the inoculation and operation of the microbial fuel cell it was observed that the bacterial cells colonized on the carbon fiber electrode. However the filamentous like appendages were not seen. It was found that the cells were rod shaped with a thin coverage over the anodic surface (Fig. S8b). Filamentous distribution over the surface establishes electron transfer among the cells and long range electron transfer across the anode [21]. The current and the power obtained after the 24 h operation was found to be lower because of the thin colonies spread unevenly on the surface of the anode.

The morphology of the membrane was examined before and after use in the microbial fuel cell and is depicted in figures S9a and S9b respectively. On comparing these images it was observed that there were clusters of cell at several places on the membrane. The decreased output from the microbial fuel cell might probably be due to these clusters which caused cell death as well as reduction in the electrochemical reactions across the membrane. Further, the cation exchange membranes were prone to be fouled by iron precipitation when a ferric iron catholyte is used (Fig. S10). Such fouling can affect mass transport through the membrane, and increases the electrical resistance which makes the membrane inefficient. From the images it was evident that the membrane needs to be frequently regenerated for enhancement of the microbial fuel cell output.

Conclusion

We have isolated and described Pseudomonas sp. VITDM1 from an industrial effluent. The isolate is facultative anaerobe with 16S rRNA sequence similarity of 98 % with P. aeruginosa. This strain was used in a microbial fuel cell using wastewater from our institute’s water treatment plant. Electric current was generated in a dual chamber microbial fuel cell where this isolate was used as biocatalyst for bioelectricity generation. Methylene blue as an electron promoter and its concentration had an important role in the enhancement of the microbial fuel cell output. The surface characteristics of the anode and the membrane were investigated for their influence on the performance of the microbial fuel cell. A maximum power density of 173.3 mW/m2 was obtained at a current density of 288.8 mA/m2. Based on these findings it is proposed that Pseudomonas sp. VITDM1 is a novel strain and can be used as a model organism to operate a microbial fuel cell. Thus it has been shown that a microbial fuel cell can be constructed with environment in mind and operated at low cost.

References

Mohan Y, Kumar SMM, Das D (2008) Electricity generation using microbial fuel cells. Int J Hydrog Energy 33:423–426. doi:10.1016/j.ijhydene.2007.07.027

Oh SE, Kim JR, Joo JH, Logan BE (2009) Effects of applied voltages and dissolved oxygen on sustained power generation by microbial fuel cells. Water Sci Tech 60:1311–1317. doi:10.2166/wst.2009.444

Kim MS, Lee YJ (2010) Optimization of culture conditions and electricity generation using Geobacter sulfurreducens in a dual chambered microbial fuel cell. Int J Hydrog Energy 35:13028–13034. doi:10.1016/j.ijhydene.2010.04.061

Gunasekaran G, Shobhana C, Srivatcha N, Rodrigues PV, Rambabu B (2011) Microbial fuel cell constructed with miocroorganisms isolated from industry effluent. Int J Hydrog Energy 36:14914–14922. doi:10.1016/j.ijhydene.2011.03.031

Benetto HP, Stirling JL, Tanaka K (1983) Anode reaction in microbial fuel cells. Biotechnol Bioeng 25:559–568. doi:10.1002/bit.260250219

Kim HJ, Park HS, Hyun MS, Chang IS, Kim M (2002) A mediatorless microbial fuel cell using a metal reducing bacterium, Shewanella putrefaciens. Enzyme Microbial Tech 30:145–152. doi:10.1016/S0141-0229(01)00478-1

Bond DR, Lovley DR (2003) Electricity production by Geobacter sulfurreducens attached to electrodes. Appl Environ Microbiol 69:1548–1555. doi:10.1128/AEM.69.3.1548-1555.2003

Chaudhuri SK, Lovley DR (2003) Electricity generation by direct oxidation of glucose in mediatorless microbial fuel cells. Nat Biotechnol 21:1229–1232. doi:10.1038/nbt867

Masih SA, Devasahayam M, Srivastava R, Gupta S (2012) Enterobacter species specific microbial fuel cells show increased power generation with high coulombic efficiency. Trends Biosci 5:114–118

Sushmita P, Surbhi K (2011) Geobacter: the electric microbe efficient microbial fuel cells to generate clean, cheap electricity. Indian J Microbiol 51:240–241. doi:10.1007/s12088-011-0180-8

Park DH, Zeikus JG (1999) Utilization of electrically reduced neutral red by Actinobacillus succinogens: Physiological function of neutral red in membrane driven fumarate reduction and energy conservation. J Bacteriol 181:2403–2410 PMCID: PMC93664

Park DH, Zeikus JG (2000) Electricity generation in microbial fuel cells using neutral red as an electronophore. Appli Environ Microbiol 66:1292–1297. doi:10.1128/AEM.66.4.1292-1297.2000

Venkatamohan S, Mohankrishna G, Reddy B, Saravanan R, Sarma P (2008) Bioelectricity generation from chemical wastewater treatment in mediatorless (anode) microbial fuel cell (MFC) using selectively enriched hydrogen producing mixed culture under acidophilic microenvironment. Biochem Engg J 39:121–130. doi:10.1016/j.bej.2007.08.023

Zou Y, Xiang C, Yang L, Sun LX, Xu F, Cao Z (2008) A mediatorless microbial fuel cell using polypyrrole coated carbon nanotubes composite as anode material. Int J Hydrogen Energy 33:4856–4862. doi:10.1016/j.ijhydene.2008.06.061

Daniel DK, Mankidy BJ, Ambarish K, Manogari R (2009) Construction and operation of a microbial fuel cell for electricity generation from wastewater. Int J Hydrogen Energy 34:7555–7560. doi:10.1016/j.ijhydene.2009.06.012

Manogari R, Daniel D, Krastanov A (2008) Biodegradation of rice mill effluent by immobilized Pseudomonas sp. cells. Ecological Engg Environ Prot 1:30–35

James GC, Natalie S (1999) Microbiology: a laboratory manual, 4th Edn., Addison-Wesley Longman Inc. http://faculty.washington.edu/korshin/Class-486/MicrobiolTechniques.pdf. Accessed 15 Jan 2013

Zhang L, Zhu X, Li J, Liao Q, Ye D (2011) Biofilm formation and electricity generation of a microbial fuel cell started up under different external resistances. J Power Sources 196:6029–6035. doi:10.1016/j.jpowsour.2011.04.013

George G, Don JB, Noel RK, James TS (2007) The Proteobacteria Part B: the gammaproteobacteria. In: Bergey’s manual of systematic bacteriology, vol 2, 2nd edn. Springer, verlag, pp 323–379. http://www.springer.com/life+sciences/book/978-0-387-24144-9. Accessed 20 May 2013

Yong Y, Sunghyun K (2008) Polypyrrole- coated reticulated vitreous carbon as anode in microbial fuel cell for higher energy output. Bull Korean Chem Soc 29:168–172

Kyungmi C, Satoshi O (2009) Characterization of electrochemical activity of a strain ISO2-3 phylogenetically related to Aeromonas sp. isolated from a glucose fed microbial fuel cell. Biotechol Bioeng 104:901–910. doi:10.1002/bit.22453

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Manogari, R., Daniel, D.K. Isolation, Characterization and Assessment of Pseudomonas sp. VITDM1 for Electricity Generation in a Microbial Fuel Cell. Indian J Microbiol 55, 8–12 (2015). https://doi.org/10.1007/s12088-014-0491-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12088-014-0491-7