Abstract

As diseases, natural disasters, and man-made disruptions become more frequent and severe, enhancing the resilience of agri-food supply chain operations poses an increasing challenge.This study aims to identify and analyze the key capabilities and impact factors contributing to agri-food supply chain resilience (AFSCRE). By conducting a comprehensive literature review and engaging in expert consultations, fifteen significant capability factors were identified. We utilized the decision making trial and evaluation laboratory (DEMATEL) technique to determine and categorize AFSCRE factors into cause and effect groups. Subsequently, we employed interpretive structural modelling and a cross-impact matrix multiplication applied to classification (ISM-MICMAC) to establish interrelationships among these factors. The results indicated supply chain leadership is a fundamental factor for fostering AFSCRE, which is located at the bottom level of ISM hierarchy. Moreover, the study identifies the importance of government support in developing AFSCRE. The findings of this study can guide supply chain leaders and government officials to initiate targeted activities for improving resilience.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The development of supply chain resilience has gained prominence, particularly in the wake of the COVID-19 outbreak. This concept has been embraced due to its potential to lessen risks and uncertainties, hasten recovery from disruptions, and enhance performance (Negri et al. 2021). Agri-food supply chain resilience (AFSCRE) is defined as “the capacity over time of a food supply chain and its units at multiple levels, to provide sufficient, appropriate and accessible food to all, in the face of various and even unforeseen disturbances” (Tendall et al. 2015, p.19). This includes the ability of the agri-food supply chain (AFSC) to adapt and respond to a wide range of disruptions, such as natural disasters, diseases, economic crises, market fluctuations, and other unexpected events. The recent locust invasion in East Africa illustrates the practical significance of AFSCRE. This event posed a serious threat to the AFSC, placing millions of people at risk of food insecurity. However, the use of resilience strategies, such as early warning systems, pest management, and crop diversification, helped mitigate the impact of the locust invasion. This provided a valuable buffer, allowing time for recovery and reestablishment of the AFSC. Therefore, the achievement of a resilient supply chain (SC) within the agri-food system is an imperative goal, since population food security relies upon this system (Irani et al. 2018). Ahmed et al. (2020) directed such emphasis to the vulnerability of the agri-food system and how its resilience should be imperative in order to limit consequences that could affect food security and even health-related outcomes. Ali et al. (2023) contended that agri-food firms must achieve supply chain resilience as a dynamic capability to bounce back from adversities and ensure continuity of operations.

To develop resilience in supply chains, it is essential for firms to continuously adopt and enhance their capabilities (Pettit et al. 2013; Ponomarov and Holcomb 2009). In line with the suggestion by Jüttner and Maklan (2011), this study uses the term “capability” to encapsulate the foundational factors of resilience at the capability level. Previous studies in the supply chain resilience field explored a variety of capabilities (Christopher and Peck 2004a, b; Jüttner and Maklan 2011; Pettit et al. 2010; Sheffi and Rice 2005). Brusset and Teller (2017) focused on a conceptual model that proposed a relationship between supply chain capabilities and resilience. Ali et al. (2017) categorized capabilities for supply chain resilience based on proactive, concurrent, and reactive strategies. Zhao et al. (2024) investigated AFSCRE capability factors through a cross-country comparative analysis. Han et al. (2020) conducted a systematic review and identified 11 capabilities essential in constituting supply chain resilience. Christopher and Peck (2004a, b) defined supply chain resilience according to the categories of supply chain risk: supply chain reengineering, collaboration, agility and supply chain risk management culture. Other studies have focused on specific capabilities, including visibility (Fiksel et al. 2015), redundancy (Ivanov et al. 2018), and agility (Ivanov et al. 2014). Marcucci et al. (2023) revealed the causal relationships that occur among different factors as a result of a disruption, and assessed how these causal relationships strengthen or weaken supply chain resilience.

Existing studies, as illustrated by literature reviews conducted by Kamalahmadi and Parast (2016), Stone and Rahimifard (2018), Ali and Govindan (2023), and Shi et al. (2023), have primarily focused on exploring AFSCRE capability factors, principles, performance measures, and the development of resilience frameworks. However, empirical research dedicated to identifying critical AFSCRE capability factors and understanding their interrelationships is limited (Ali et al. 2017; Zhao et al. 2024). It is essential to understand the relationship between these elements and the more frequently cited factors (Stone and Rahimifard 2018). As Dong et al. (2021) identified, over 80% of companies in China’s AFSC are small to medium-sized, often with limited resources to build AFSCRE. Therefore, these companies would significantly benefit from identifying key AFSCRE capability factors, enabling them to strengthen their resilience, mitigate disruptions, and secure smooth operations.

Furthermore, a range of research methods have been utilized in AFSCRE investigations, encompassing single and multiple case studies, mathematical modeling, multi-criteria decision-making, static modeling, and others (e.g., Esteso et al. 2018; Hendry et al. 2019; Ali and Govindan 2023; Kumar and Singh 2022; Mishra et al. 2021). Despite the increasing number of empirical studies and quantitative modeling approaches in the AFSCRE field, qualitative empirical research on the topic remains scant (Ali and Govindan 2023; Shishodia et al. 2023). Our study address this research gap through employing a multi-method qualitative approach involving DEMATEL-ISM- MICMAC analysis. Therefore, our study aims to address this research gap and aim to answer two main questions:

-

RQ1 What are the key supply chain resilience capability factors used to construct AFSCRE?

-

RQ2 What are the relationship between the recognized AFSCRE capability factors?

To answer these questions, a blended approach, combining decision making trial and evaluation laboratory (DEMATEL), interpretive structural modeling (ISM) and a cross-impact matrix multiplication applied to classification (MICMAC) was used (Mehregan et al. 2014). Using DEMATEL-ISM-MICMAC methods allows for a comprehensive understanding and evaluation of various interconnected factors within a system. It effectively illustrates the hierarchical structure between these factors, while also highlighting their respective influences and dependencies. Our study sheds light on a AFSCRE and adopt a combined DEMATEL, ISM and MICMAC approach to identify AFSCRE capability factors and their interrelationships in AFSC. Initially, our study uses the DEMATEL technique to identify resilience capability factors and categorizes them into cause-and-effect groups. This classification offers a fresh perspective on understanding the dynamics within the AFSC. Subsequently, employing ISM-MICMAC to determine the interrelationships among these factors provides new insights into their interactions and influences. These methodological advancements contribute to the theoretical understanding of supply chain resilience and lay a foundation for future research in this area.

The remainder of this paper is organized as follows. Section 2 provides a review of the relevant literature and introduces the factors identified as critical for enhancing supply chain resilience in the AFSC. Section 3 delineates the research methods employed throughout this study. In Section 4, we demonstrate the practical application of our proposed framework with a case study of National Key Leading Enterprises in the realm of Agricultural Industrialization in China. Section 5 delves into the discussion of our findings and their implications. Finally, Section 6 synthesizes the study’s conclusions, acknowledges its limitations, and suggests avenues for further research.

2 Literature review of AFSCRE

2.1 Supply chain resilience capabilities and strategies

AFSCRE is “the collective ability of AFSC stakeholders to ensure acceptable, sufficient and stable food supplies, at the required times and locations, via accurate anticipations and the use of strategies which delay impact, aid rapid recovery and allow cumulative learning post-disruption.” (Stone and Rahimifard 2018, p.219). Much previous supply chain research has concentrated on these supply chain resilience-building capability factors to enhance resilience (Ali et al. 2017; Faruquee et al. 2021; Nikookar and Yanadori 2022). In this perspective, AFSCRE is viewed as a multidimensional concept comprising the capacity to absorb shocks, the rate of recovery, the extent of adaptation to changes, and the resistance to disruptions (Gligor et al. 2019). Consequently, supply chain resilience can be regarded as an essential “dynamic capability” for withstanding unexpected disruptions, bouncing back, and ensuring long-term survival (Gölgeci and Kuivalainen 2020; Golgeci and Ponomarov 2013).

The capability factors studied in the extant literature encompasses broad approaches such as improving flexibility, creating redundancy, improving supply chain agility, and enhancing visibility (Hohenstein et al. 2015). Some more specific practices include fostering a risk management culture (Ali et al. 2023), encouraging supply chain collaboration (Hendry et al. 2019), promoting information sharing (Brandon-Jones et al. 2014), considering supply chain design features (Craighead et al. 2007), and reconfiguring resources (Ambulkar et al. 2015). Hendry et al. (2019) suggested that dynamic capabilities and collaboration between stakeholders can both enhance resilience vertically and horizontally, enabling AFSC to address challenges and capitalize on growth opportunities. Hernandez et al. (2021) also advocated for stakeholder collaboration in the AFSC as a crucial measure for reducing costs and waste, and for achieving equilibrium in food supply and demand throughout the chain. Leat and Revoredo-Giha (2013) emphasized that enhancing communication between processor and retailer, in relation to product quality, animal welfare and product governance, is vital for ensuring AFSCRE. Ates and Bititci (2011) argued that risk management culture drives the change process, which is a key capability for resilience. InThus, businesses keen on applying their knowledge to foster a culture of risk management and supply chain resilience are often motivated to invest in their knowledge management systems (Ali et al. 2023). Manning and Soon (2016) identified several critical capability factors that facilitate AFSCRE, including value-based dynamics, SC dynamics, strategic decision making, strategic leadership, and the use of performance indicators to anticipate, withstand, respond to, and recover from SC disruptions. Stone et al. (2015) have identified nine essential aspects of AFSCRE: concentration, adaptability, redundancy, efficiency, awareness, anticipation, market status, security, and financial readiness.

The factors available for building resilience have been commonly classified into proactive and reactive strategies, depending on their use in averting or recovering from a threat (e.g. Hohenstein et al. 2015; Dabhilkar et al., 2016; Tukamuhabwa et al. 2017). For example, increasing visibility (e.g. Boone et al. 2013), and sharing valuable information (Ghadge et al. 2022) can be considered proactive strategies. Flexibility (e.g. Pettit et al. 2013), and redundancy (e.g. Sheffi and Rice 2005) can be considered reactive strategies. It’s important to note, however, that broader strategies like collaboration (Scholten and Schilder 2015) could serve either a proactive or reactive purpose depending on deployment timing and intent. When implementing any supply chain strategy, it’s crucial to establish procedures and practices aligned with a targeted resilience strategy. Therefore, managers crafting such a strategy for their supply chain must identify the key success factors vital for effective strategy adoption (Hartono et al. 2015). In this context, capability factors refer to the success variables and resources contributing to AFSCRE’s success.

2.2 Empirical research on AFSCRE and gaps in existing literature

Given the potential positive effects of AFSCRE on business competitiveness and continuity, a variety of qualitative and quantitative methods have been utilized to identify, prioritize AFSCRE factors, evaluate performance, and examine the specific factors that enhance AFSCRE (Hendry et al. 2019; Dubey et al. 2021). For example, Leat and Revoredo-Giha (2013) employed a case study that involved in-depth interviews to identify resilience capability factors. Hendry et al. (2019) used multiple case studies to investigate how local AFSC resilience responds to constitutional change. Ali and Govindan (2023) examined the impact of integrating knowledge management and risk management culture on AFSCRE using surveys and modelling techniques. Zhao et al. (2024) explored AFSCRE through a multi-method qualitative approach involving semi-structured interviews, thematic analysis, total ISM and MICMAC. Despite the increasing number of empirical studies and quantitative modelling of AFSCRE in recent years, empirical research to identify key AFSCRE capability factors and their interrelationships is still limited (Ali and Govinda 2023; Shishodia et al. 2023). Our study aims to fill this research gap by employing a multi-method qualitative approach that incorporates DMETAL-ISM-MICMAC analysis within the context of China’s agri-food supply chain. This research contributes to extant knowledge by identifying the capability factors for AFSCE, drawn from the literature and expert inputs. These identified factors were further analyzed using DEMATEL, assisted by expert input, to divide them into cause and effect groups. To examine the contextual relationships between these groups and to understand their hierarchical relationships, an evaluation was conducted using ISM, again relying on expert input. Finally, the factors were categorized into independent, linkage, autonomous, and dependent variables using MICMAC.

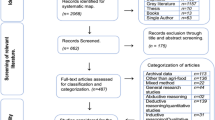

2.3 Capability factors

Multiple key capability factors were hypothesized to exist and a systematic literature review was conducted. Publications here presented and analyzed were collected as the result of a set of searches on the Web of Science database where the following terms were explored: “agr* supply chain” AND resilien* AND factor; “agr* supply chain” AND resilien* AND enabler; “agr* supply chain” AND resilien* AND driver; “agr* supply chain” AND resilien* AND capability. The sign “*” was used at the end of some keywords to expand the range of possible studies (Gimenez and Tachizawa 2012). To better define the papers that should be the focus of further analysis, articles with the following conditions were considered: published in English language and published in a peer-review journal until May 2023. Publications that do not focus on supply chain resilience were excluded; Publications regarding non capabilities of supply chain management were excluded.

A total of fifteen important AFSCRE capability factors were identified from the literature (Table 1). The selection of the these capability factors was based on their frequent appearance in the literature, as well as their applicability to the agricultural supply chain.

SC leadership is “a set of behaviors exhibited by a firm influencing and orchestrating the actions and behaviors of its SC partners” (Mokhtar et al. 2019, p. 7). It can optimize the chain’s resources and create value by managing operations efficiently and utilizing partners’ strengths, thereby influencing their collaboration and contributing to the chain’s success (Mokhtar et al. 2019).

Information sharing is the exchange of intangible resources intrinsically tied to the shared information, which is considered a resource itself (Barney 1991). The transfer of relevant and timely information among supply chain participants can amplify visibility (Brandon-Jones et al. 2014), cultivate collaboration (Kamalahmadi and Parast 2016), and nurture agility (Baah et al. 2022). These benefits are realized by sustaining transparency and fostering trust (Mandal 2017). Efficient information sharing can alleviate the impacts of disruptions (Blackhurst et al. 2011) and enhance supply chain resilience independently (Chowdhury and Quaddus 2016).

Collaboration is a crucial element of supply chain resilience by ensuring the availability, safety, and accessibility of food to consumers through teamwork (Stone and Rahimifard 2018). De Sa et al. (2019) highlight that without collaboration at the supply chain level, attaining supply chain resilience remains an elusive goal. As a foremost strategy, collaboration serves not only as a preventive measure to minimize risks in supply chains (Pereira et al. 2021), but also as an adaptive tool, equipping the supply chain to swiftly respond to evolving scenarios (Chen et al. 2016).

Enhancing visibility by spreading risk awareness and knowledge throughout the chain is a potent strategy to mitigate the effects of disruptions (Blackhurst et al. 2005), and it also strengthens supply chain resilience (Jüttner and Maklan 2011). Attaining supply chain visibility hinges on cultivating robust collaboration with customers and suppliers, and also on committing to information sharing (Barratt and Oke 2007; Brandon-Jones et al. 2014).

The impact of resilience culture should never be underestimated (Sheffi and Rice 2005). In line with this, Soni et al. (2014) recognized the culture of risk management as a primary driver of resilience. The resilience culture equips employees with the ability to discern risks inherent in their supply chains. Simultaneously, it promotes internal efficiency and coordination in handling disruptions, thereby safeguarding business stability and continuity (Christopher and Peck 2004a, b). For this to happen, it is critical that resilience culture permeates both the central company and its supply chain partners (Mandal 2012).

SC innovation plays a crucial role in enhancing resilience. It has been established that both the innovativeness of a firm and the scale of its innovation positively correlate with supply chain resilience (Golgeci and Ponomarov 2013). This is particularly so when it comes to revisiting organizational values, processes, and behaviors that prioritize continuity over change (Hamel and Valikangas 2003). The recent wave of technological developments, coupled with the impacts of the COVID-19 pandemic, has prompted AFSC to push new boundaries in ensuring product safety, traceability, and in crafting more resilient business models (Cricelli et al. 2022).

Flexibility is a core component of supply chain resilience, enabling a variety of responses to potential disruptions (Stone and Rahimifard 2018). Such flexibility is a critical factor in establishing agility, a necessary trait for a resilient supply chain (Christopher and Peck 2004a, b; Faisal et al. 2006). The uncertainties inherent in farming and food production, like seasonal variations, logistical interruptions, and demand shifts, necessitate high flexibility in supply chain processes (Dania et al. 2018). This level of flexibility requires adaptable transportation systems, production facilities, supply bases, capacities, and labor arrangements (Colicchia and Strozzi 2012; Pettit et al. 2013). The option for alternative solutions, such as different suppliers, also contributes to a supply chain’s swift response and recovery, which can be bolstered by redundancy.

Redundancy adds extra capacity that can be employed during disruptions, thereby improving flexibility and facilitating response (Adobor and McMullen 2018). It becomes more effective when there is a high response diversity, especially when the redundant components react differently to changes and disturbances (Biggs et al. 2015). To enhance AFSCRE, a variety of redundancy strategies can be implemented, including backup suppliers, fortification (Namdar et al. 2017), and pre-positioning inventory (Kamalahmadi and Parast 2017).

Resource reconfiguration is crucial variables that can support the SC resilience (Parker and Ameen 2018). Ambulkar et al. (2015) argued that to become resilient, a firm’s ability to reconfigure resources plays a major role in times of SC disruptions. In the context of a major disruption like the COVID-19 pandemic, the ability to restructure and reconfigure existing resources and acquire new resources re-strengthens the SC (Nandi et al. 2020; Pan et al. 2020).

Disruption mitigation is also a critical aspect of SC resilience as it enables SC to quickly recover from any disruptions (Singh and Singh 2019; Xu et al. 2020). Effective mitigation strategies, including facility locations, emergency stock from retailers, back-up capacity and safety stock reserved at suppliers and risk-mitigation inventories at distribution centers can minimize the severity and duration of disruptions (Yavari and Ajalli 2021; Rahman et al. 2022).

Robustness, often considered a component of resilience, is the absorptive capacity that determines when general variability escalates into a disturbance (Brandon-Jones et al. 2014; Behzadi et al. 2017; Mackay et al. 2020). SC managers may prioritize enhancing the system’s response to disruptions by improving its robustness. This could involve creating reserves or backup plans to reduce vulnerability to change (Azadegan et al. 2013), thus ensuring continuous operation.

Agility is also a significant factor that contributes to resilience. SC agility excels in identifying potential threats in the environment, such as SC disruptions (Teece 2007; Ali and Gölgeci 2019). It addresses these threats by fostering collaboration among SC partners, redundancy, and a shared risk response infrastructure (Scholten et al. 2020). Such practices empower companies and their supply chains to enhance their resilience (Aslam et al. 2020).

“Resilient SC must be adaptable” (Christopher and Rutherford 2004, p. 24), as the capacity for continuous adaptation is crucial in managing unexpected disruptions (Ivanov et al. 2014). This adaptability can provide resilient SC with a competitive advantage (Van der Vegt et al. 2015). Ivanov and Dolgui (2021) demonstrated that the adaptation of network structures and associated production-inventory control policies at individual firms are critical factors for SC resilience during a pandemic. Importantly, understanding adaptation requires ongoing observation over time, not just a one-time assessment (Tukamuhabwa et al. 2015).

Given the inherent uncertainty in AFSC negatively impacts performance and resilience, numerous authors (Borodin et al. 2016; Esteso et al. 2018) have advocated for AFSC design models that consider these uncertainties and product perishability. Scholten et al. (2014) stressed the necessity for resilience to be built into the SC design. A successful SC redesign hinges on a thorough understanding of the SC architecture, bottlenecks, and sourcing strategies (Cardoso et al. 2015). Uncertainties can be lessened through an optimal design that incorporates the actions of multiple supplier and customer tiers, alongside collaboration with firms at each level (Gunasekaran et al. 2015).

3 Research method

A combination of the DEMATEL-ISM-MICMAC approach was designed and executed for this study. It has been found to be more effective than other interpretive and decision modeling techniques, such as the Analytic Hierarchy Process (AHP), Analytic Network Process (ANP), Structural Equation modeling (SEM), Interpretive Ranking Process (IRP), and the Graph theory. A comprehensive comparison of DEMATEL-ISM-MICMAC with these other approaches is provided in Table 2 (Wagner and Neshat 2010; Raj et al. 2010; Rahman and Subramanian 2012; Mathiyazhagan et al. 2013; Jakhar and Barua 2014; Mangla et al. 2015; Luthra et al. 2017).

This study combines the DEMATEL, ISM, MICMAC methods for the following reasons (Chuang et al. 2013). Firstly, the DEMATEL-ISM-MICMAC approach effectively illustrates complex relationships among decision-making variables in uncertain environments. Secondly, it uncovers the cause-and-effect relationships among these variables through the driving and dependence power in ISM and prominence and relation in DEMATEL. Thirdly, its combined application aids in understanding the relative importance of the decision variables, as demonstrated by well-structured diagrams (i.e., the hierarchical diagram in ISM, the causal diagram in DEMATEL, and the dependence diagram in MICMAC). Lastly, it provides insights into the direction and intensity of the complex causal relationships without the need for prioritizing key factors, thereby offering a comprehensive feedback system that takes into account both the significance and interrelationships among factors.

3.1 DEMATEL

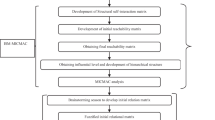

The DEMATEL method is a highly effective tool for exploring complex causal relationships and intertwined problems (Fontela and Gabus 1976). It is particularly useful in multi-criteria decision problems, helping to identify direct and indirect influences among criteria, as well as computing the relationship and strength among the factors involved (Gandhi et al. 2015). Moreover, the DEMATEL method combines graph theory and matrices to construct a direct influence matrix based on the logical relationships between the various factors in the system, and then calculates the impact, affectedness, centrality, and causality of each factor (Du and Li 2021). It can assist in categorizing variables into cause and effect groups (Mangla et al. 2016). Implementing the DEMATEL technique consists of several steps (Fig. 1), which are briefly outlined below (for a more details please refer to Sect. 4):

-

1.

Formation of an expert panel and evaluation criteria. The key factors for AFSCRE are listed through literature.

-

2.

Development of the direct relation matrix (A).

-

3.

Construction of the normalized initial direct relation matrix (B).

-

4.

Creation of the total-relation matrix (C).

-

5.

Determination of the summation of rows (D) and the summation of columns (R).

-

6.

Development of a cause and effect graph.

3.2 ISM

The ISM method is a structural modeling technique to identify and summarize relationships among specific factors (Warfield 1974). This technique is adept at creating a hierarchical structure of variables, requiring minimal expert involvement, and effectively highlights the logic of interdependencies between variables using an adjacency matrix and reachable matrix, in accordance with principles of graph theory (Sushil 2012). This method proves particularly useful in analyzing systems characterized by numerous variables, complex relationships, and unclear structures (Dhir and Dhir 2020). The ISM involves several steps (Warfield 1974), summarized as follows:

-

1.

Constructing a Structural Self-interaction Matrix (SSIM) to examine the contextual relationships among identified factors.

-

2.

Developing an initial Reachability Matrix from the SSIM, followed by a transitivity check to create the final Reachability Matrix.

-

3.

Partitioning various levels of identified factors using the final Reachability Matrix.

-

4.

Creating a Digraph by removing the all transitivity links.

-

5.

Developing an ISM model from the constructed digraph.

-

6.

Evaluating the conceptual consistency of the ISM model and making necessary adjustments, if needed.

3.3 MICMAC

The MICMAC analysis was utilized to identify AFSCRE capability factors and validate the ISM models by categorizing the variables into four clusters, i.e., as autonomous, dependent, linkage or driver, based on their relationships with and influence on each another (Mani et al. 2016). Subsequently, a diagram representing the driving power and dependency of the factors was developed.

Factors in the independent quadrant represent strong driving characteristics and fragile dependency power, thus designated as drivers (Khaba and Bhar 2018). Factors in the dependent quadrant exhibit substantial dependencies and weak driving characteristics. Their characteristics stay influenced by the drivers or independent variables. Factors occupying autonomous display weak dependent and driving characteristics. These factors are somewhat incoherent within the system and do not significantly influence the remaining variables. Linkage factors represent strong driving power along with solid dependency. These variables exhibit unsteady characteristics.

3.4 Validation analysis

The rationale for using the DEMATEL-ISM-MICMAC approach in our research lies in its ability to handle complex and multiple relationships among variables, which is inherent in our study. This approach allows us to not only identify but also prioritize key influencing factors in a systematic and objective manner, which is crucial in our analysis. This method also provides a visual structure of the relationships between these factors, aiding in the understanding and interpretation of our results.

As for the validation and validity analysis of our model, we have conducted a two-step process. Firstly, we performed an internal validity check to ensure the accuracy and consistency of our findings. We have cross-verified our results with the input data and have conducted numerous iterations until we reached a stable model. Secondly, for external validity, we have compared our results with existing literature and empirical evidence. We found a high degree of alignment between our findings and previous research, which reinforces the validity of our results.

4 Modeling and Analysis based on DEMATEL-ISM-MICAMC

To support the practical objective of the National Key Leading Enterprises in Agricultural Industrialization in China, an expert panel comprising of fifteen professionals (six professors with expertise in AFSC management, two general managers, one procurement manager, three production managers, two marketing managers and one logistics manager in agri-food industry, as shown in Table 3) was formed. The experts selected were highly skilled in decision-making and applying interpretive structural techniques. The experts were highly competent in the field of SC planning and operations management.

4.1 AFSCRE capability factors models generated through DEMATEL

4.1.1 Developing direct relation and total-relation matrix

The AFSCRE capability factors, denoted as \({\text{A}}\left({a}_{ij}=\mathrm{1,2},\cdots ,15\right)\) in sequence, where \({a}_{ij}\) denotes the direct impact strength of factor \({a}_{i}\) on \({a}_{j}\)(\({\text{i}},{\text{j}}=\mathrm{1,2},\cdots ,15\)). We use the 3-point scale method, which is represented by scores from 0 to 3, where 0, 1, 2, and 3 respectively indicate no impact, low impact, moderate impact, and high impact.

Through the Delphi method, 15 experts in the field of supply chain resilience were invited to score the direct interaction relationship between each influencing factor, and the average score was rounded to the nearest integer to obtain the direct impact matrix \({{\text{A}}}_{{\text{ij}}}={\left[{a}_{ij}\right]}_{15\times 15}\). The direct relation matrix for AFSCRE capability factors is shown in Table 4.

Prior to the formulation of the total-relation matrix, it was imperative to normalize the direct influence matrix \(\mathbf{A}\) using Eq. (1) to obtain the normalized matrix \({\mathbf{B}}_{{\text{ij}}}={\left[{{\text{b}}}_{{\text{ij}}}\right]}_{15\times 15}\).

It is generally believed that the normalized matrix \(\mathbf{B}\) is a one-step influence relationship matrix, while \({{\varvec{B}}}_{{\text{n}}}\) is an \({\text{n}}\)-step influence relationship matrix. Equation (2) represents the total-influence matrix that includes \({\text{n}}\)-step indirect influences, which is calculated as

where \(\mathbf{I}\) is the identity matrix, \({\left(\mathbf{I}-\mathbf{B}\right)}^{-1}\) is the inverse matrix of \(\left(\mathbf{I}-\mathbf{B}\right)\). The normalized \({b}_{ij}\) belongs to [0,1], and when \({\text{n}}\to \infty\), \({\mathbf{B}}^{{\text{n}}-1}\to 0\), so the total-influence matrix \({\mathbf{C}}_{{\text{ij}}}={\left[{{\text{c}}}_{{\text{ij}}}\right]}_{15\times 15}\) of AFSCRE capability factors is calculated using Eq. (3), presented in Table 5.

4.1.2 Developing a cause-and-effect groups for AFSCRE capability factors

Based on the total-influence matrix, the degree of influence (\({\text{D}}\)), degree of being influenced (\({\text{R}}\)), centrality (\({\text{D}}+{\text{R}}\)), and causality (\({\text{D}}-{\text{R}}\)) for AFSCRE capability factors were calculated, as shown in Table 4. The degree of influence (\({\text{D}}\)) refers to the degree to which this factor affects or influences other factors, represented by the sum of rows of the total-influence matrix \(\mathbf{C}\). Conversely, its column summation is the degree of being influenced (\({\text{R}}\)) for this factor. Let \(i=j i,j\in \mathrm{1,2},\cdots ,15\), centrality (\({\text{D}}+{\text{R}}\)) stands for the degree of central role that the factor plays in the system. Alike, the causality (\({\text{D}}-{\text{R}}\)), shows the net effect that the factor contributes to the system. If (\({{\text{d}}}_{{\text{j}}}-{{\text{r}}}_{{\text{j}}}\)) is positive, then the factor \({a}_{j}\) has a net influence on the other factors and can be grouped into cause group; if (\({{\text{d}}}_{{\text{j}}}-{{\text{r}}}_{{\text{j}}}\)) negative, then the factor \({a}_{j}\) is being influenced by the other factors on the whole and should be grouped into effect group.

Datasets (\({\text{D}}+{\text{R}})\) and (\({\text{D}}-{\text{R}})\) datasets for AFSCRE capability factors were calculated, as shown in Table 6. Further, the importance order of AFSCRE capability factors was obtained through \(({\text{D}}+{\text{R}})\) dataset (Rahman and Subramanian 2012), as shown in Column 6 Table 6. The first three variables are SC redesign (a15), visibility (a9) and collaboration (a2).

Next, the cause-and-effect map for AFSCRE capability factors is constructed (see Fig. 2) using the dataset (\({\text{D}}+{\text{R}}\); \({\text{D}}-{\text{R}}\)). The factors in quadrant I are identified as core factors or intertwined givers since they have high prominence and relation (i.e., a2, a5, a8, a9). The factors in quadrant II are identified as driving factors or autonomous givers because they have low prominence but high relation. The factors in quadrant III have low prominence and relation and are relatively disconnected from the system (called independent factors or autonomous receivers). The factors in quadrant IV have high prominence but low relation (called impact factors or intertwined receivers), which are impacted by other factors and cannot be directly improved (i.e., a1, a10, a11, a13, a15). From Fig. 2, decision makers can visually detect the complex causal relationships among factors and further spotlight valuable insights for decision making.

4.2 AFSCRE models generated through ISM

4.2.1 Developing reachability matrix

To determine the reachable matrix, it is necessary to introduce a threshold \(\uplambda\) to eliminate relationships with relatively small impact to simplify the structure of the system. To determine the threshold \(\uplambda\), the mean and standard deviation of all elements in the total-influence matrix \(\mathbf{C}\) are used, which can effectively reduce the subjective impact.

where \(\overline{{\text{c}} }\) and \(\upsigma\) represent the mean and standard deviation, respectively, of all elements in the total-influence matrix \(\mathbf{C}\).

By solving, \(\overline{{\text{c}} }=0.149\) and \(\upsigma =0.048\) are obtained, therefore the threshold \(\uplambda\) is determined to be 0.1.

where \({m}_{ij}\) is the element of the reachable matrix \(\mathbf{M}\), and \({{\text{m}}}_{{\text{ii}}}=1\). Then the reachable matrix \(\mathbf{M}\) is calculated, as shown in Table 7.

4.2.2 Building a hierarchical structural model

Partitioning was conducted to determine the hierarchical level of AFSCRE capability factors. The reachability and antecedent set for each factor were obtained using the reachability matrix (Warfield 1974) and next, the intersection between reachability and the antecedent set was obtained (see Table 8). If the reachability set and the intersection set have the same values, then highest rank or level is assigned to that factor, i.e., \({\text{M}}\left({a}_{i}\right)={\text{M}}\left({a}_{i}\right)\bigcap {\text{Q}}\left({a}_{i}\right)\), and the particular factor is eliminated from subsequent iterations. This procedure is repeated to produce the final iteration.

As shown in Table 7, \({{{\text{a}}}_{3},{{\text{a}}}_{7},{{\text{a}}}_{10},{{\text{a}}}_{12},{{\text{a}}}_{13},{\text{a}}}_{14}\) belong to the first level. Cross out the factors that have already been layered and continue this operation until all influencing factors are layered. A total of four iterations were performed to obtain the level of each factor. Four levels were identified by partitioning: \({{\text{F}}}_{1}=\left\{3,\mathrm{7,10,12,13},14\right\}\), \({{\text{F}}}_{2}=\left\{4,11\right\}\), \({{\text{F}}}_{3}=\left\{\mathrm{1,2},\mathrm{6,9},\mathrm{11,15}\right\}\), \({{\text{F}}}_{4}=\left\{5\right\}\), \({{\text{F}}}_{5}=\left\{8\right\}\).

Based on the final reachability matrix and the final levels of the factors, a hierarchical structural model with five-level for AFSCRE capability factors was constructed (see Fig. 3). Factors at lower levels of the ISM model have more influence on the whole system and can induce more AFSCRE capability factors, whereas factors at higher levels have less influence on the system and can induce fewer AFSCRE capability factors. The factors at levels I are redundancy (a3), robustness (a10), resource configuration (a12), adaptation (a13), and disruption mitigation (a14) and government support (a7). Resilience culture (a4) and agility (a11) are at level II. The factors at levels III are collaboration (a2), SC innovation (a6), visibility (a9), SC redesign (a15), flexibility (a1). The two remaining factors, information sharing (a5) and SC leadership (a8) are at levels IV and level V.

The findings show SC leadership (a8) is the most important independent factor. This involves facilitating information sharing (a5) among various stakeholders, which plays a critical role in developing resilient SC. Information sharing is a critical enabler for SC redesign (a15), innovation (a6), and collaboration (a2) in the AFSC. Flexibility (a1) and agility (a11) are essential for AFSC to adapt to changing circumstances quickly, necessitating collaboration (a2) among SC members. Enhancing SC robustness (a10) can be achieved through resource reconfiguration (a12) and disruption mitigation (a14), crucial in an uncertain business environment. Collaboration (a2) among stakeholders can promote SC innovation (a6), further enhance this robustness (a10) through information sharing (a5). Government support (a7) can enhance redundancy (a3), robustness (a10), adaptation (a13), and disruption mitigation (a14) in the AFSC. Redundancy (a3) enhances SC robustness (a10) by offering backup systems or alternative suppliers, improving resource configuration (a12) by providing alternative resources, and minimizing disruption impacts on SC performance.

4.3 Categories generated through MICMAC analysis

MICMAC analysis was implemented to validate the ISM model and categorize the AFSCRE capability factors into independent, linkage, autonomous and dependent variables (see Fig. 4) to show the dependence of the factors. This was performed by analyzing the dependence and driving power of the AFSCRE capability factors.

The Independent region has four factors, i.e., a2 (SC collaboration), a5 (Information sharing), a8 (SC leadership) and a9 (visibility). These factors have low dependence but high driving power and are thus classified as “key factors”. Based on (\({\text{D}}-{\text{R}}\)) dataset in DEMATEL, these four factors are categorized in the cause group, which should be the focus for enhancing AFSCRE. They form the base of the structural model. The key factors triggering resilience in AFSC are a8 (SC leadership), as it resides at the lowest level of the ISM hierarchy.

Next, the Dependent region comprises four factors, i.e., a10 (robustness), a11 (agility), a13 (adaptation), a15 (SC redesign). These factors, characterized by high dependence and low driving power, represent the desired outcomes. When Figs. 3 and 4 are considered together, it is evident that although a11 (agility) and a15 (SC redesign) occupy the model’s middle layer, they are subject to the influence of factors below them. According to the (\({\text{D}}-{\text{R}}\)) dataset, these factors belong to the ‘effect’ group, requiring special attention to enhance the effectiveness of resilient development initiatives.

The Autonomous region contains several factors, including a1 (flexibility), a3 (redundancy), a4 (resilience culture), a6 (SC innovation), a7 (government support), a12 (resource reconfiguration) and a14 (disrupt mitigation). These factors exhibit relatively less driving and dependency power, and are closely situated to the origin in the figure, thereby indicating their comparably weaker connections to the system as a whole. Among these, factors a3, a4, a6, a7 belong to the cause group, while a1, a12 and a14 belong to the effect group. Factors such as resilience culture and government support rank highly in the (\({\text{D}}-{\text{R}}\)) dataset, suggesting their significant influence on other elements, although the reverse influence is relatively minor. Despite the dependencies and driving forces of a1 (flexibility), a4 (resilience culture), and a6 (SC innovation) are not high in this study, they occupy an intermediary position and fulfill a mediatory and correlational role. They can impact the factors above them while also being influenced by the ones below them.

Lastly, is the Linkage region, and no factors is recognized with high driving and dependence power. Such factors are generally unstable in nature because any attempt to address them will affect other factors and can also result in a feedback effect on themselves.

After discussing with our expert team, it’s clear they concur with the research findings. Yet, gauging the relative significance of each capability factor in terms of SC resilience isn’t simple, given their unique importance within the system. A proper evaluation of these factors demands an understanding of both their contextual associations and cause-and-effect relationships. Hence, managers should assess these factors based on their contextual and causal links, logically applying them using hierarchical and cause-and-effect maps. Employing an ISM-based hierarchical structure, categorizing factors through MICMAC analysis, and crafting a cause-and-effect diagram via DEMATEL can help decipher the intricate interplay between factors that boost the resilience of AFSC. This could support managers in consistently enhancing and managing resilient initiatives within the system. Future research will delve into these scenarios to validate and corroborate these considerations.

5 Discussion and implications

5.1 Discussion

Our findings make significant contributions to existing knowledge on AFSCRE building by identifying capability factors. It provides empirical evidence underscoring the crucial roles of SC leadership and government support, setting the stage for fresh research trajectories.

Firstly, our DEMATEL-ISM-MICMAC analyses reveal that SC leadership is a pivotal factor for AFSCRE with the topmost (\({\text{D}}-{\text{R}}\)) score of 1.61. This aligns with Shin and Park’s (2021) research, emphasizing the significance of leadership responsibility in managing the overall resilience capabilities within the supply chain network.While earlier studies suggest that factors such as supply chain collaboration, agility, and supply chain reengineering are crucial for enhancing supply chain resilience (Kamalahmadi and Parast 2016; Durach et al. 2020), these studies primarily focus on ‘what’ elements can develop supply chain resilience. However, they often overlook a systems thinking approach to understand ‘how’ resilience can be achieved across the entire chain and fail to consider how these research findings can be generalized. The resilience models built through DEMATEL-ISM-MICMAC analyses in our study provide clear routes to foster AFSCRE by bolstering SC leadership. This is especially significant for the supply chain of agricultural products in China, where farmers are often perceived as lacking information, visibility, and support. They are typically positioned on the supply side of the supply chains, with limited opportunities to transform into focal firms (Shukla and Jharkharia 2013). SC leadership can empower farmers to resist, adapt to, and recover from disruptions.

Secondly, our DEMATEL-ISM-MICMAC analysis underscores the critical role of government support. This factor operates independently, without reliance on other factors. It holds profound implications for the resilience of China’s agricultural supply chain. This necessity arises from the fact that China’s agricultural sector consists predominantly of small-scale farmers. These farmers often lack the requisite technology and financial resources to navigate the complexities and challenges of agricultural production. According to da Silva et al. (2019), farmers, who represent the most vulnerable and least resilient link in the AFSC, should be the focal point for resilience development. Government support can equip them with necessary resources and skills, augment their production efficiency, and fortify their capacity to manage risks (Das et al. 2022). Further, the prices of agricultural products are susceptible to various factors, such as market supply and demand dynamics, climate change, among others, resulting in high volatility. The government can mitigate these market risks and stabilize farmers’ income through strategic market regulation and risk compensation mechanisms.

5.2 Managerial implications

First, effective SC leadership plays a crucial role in improving the AFSCRE. To realize this, companies need to hone the requisite leadership skills and proficiency within their organizations, especially concerning SC management. This could entail the implementation of training and development initiatives for present and future leaders, nurturing an ethos of innovation and risk-taking, and encouraging collaboration and information exchange within the SC network. Moreover, it is advised that companies place a premium on SC leadership during the selection and evaluation of potential partners and suppliers. This can help ascertain that the entire SC network aligns with the objectives of augmenting resilience and collaboratively working towards this goal.

Second, resilience culture and government support are ranked as autonomous elements in the MICMAC analysis but hold a high ranking in the DEMATEL analysis. Managers should fully acknowledge the fundamental role these elements play in the entire system and prioritize the establishment of processes and systems that bolster resilience culture, such as frequent risk assessments and contingency planning. Moreover, companies should factor resilience culture into their decisions when choosing partners and suppliers to ensure alignment with their own ethos.

Third, companies should actively engage with governments to amplify the impact of government support. The government can contribute relevant policies and resource backing, and companies can provide feedback on the utilization of policies and resources through diverse channels. Doing so allows the government to comprehend the implementation effect of their policies promptly and make the necessary modifications.

6 Conclusions

This study advances the evaluation of AFSCRE capability factors by adopting an integrated DEMATEL-ISM-MICMAC approach, which has been applied to address the intricacies of China’s unique agricultural context. We systematically identified fifteen key AFSCRE capability factors through an extensive literature review and expert consultations. Our findings offer a nuanced understanding of these factors, underscoring their pivotal roles in adopting AFSCRE and providing a structured resource for policymakers, technology providers, and small-scale agricultural enterprises.

Particularly, the DEMATEL approach has elucidated the causal interactions among the capability factors, enhancing our comprehension of their interplay in reinforcing resilience within the AFSC. The ISM method facilitated the construction of comprehensive models that delineate the interrelationships among these factors. The subsequent MICMAC analysis strategically categorized the factors into four quadrants, reflecting their driving and dependency attributes, which is essential for prioritizing interventions.

Our results highlight SC leadership and government support as crucial for bolstering resilience within China’s agricultural supply chain, characterized by its fragmented structure, extensive reach, and risk vulnerability. SC leadership effectively coordinates efforts and orchestrates risk management strategies, while government aid provides the necessary resources and information to support the establishment of vital infrastructure.

This study acknowledges several limitations. First, the external validity of the empirical findings remains unestablished, suggesting that the results may not extend to other contexts or populations beyond this study’s scope. Ongoing research should strive to recreate these findings in varied settings to bolster the robustness and generalizability of the conclusions. Second, the resilience capability factors identified herein were derived from literature and industry expert judgment. Yet, the enduring truth and effectiveness of these factors over time are yet to be tested. Longitudinal studies spanning extended periods could ascertain these factors’ sustainability and persistent effectiveness. Such research is vital to validate the practical utility of these identified factors. Third, this study lacks proposed specific approaches or methods to extend the application of the findings to a broader context. To address this limitation, we recommend future research to engage in longitudinal and multidisciplinary studies to scrutinize and authenticate the specific resilience capability factors. By investigating these factors from different perspectives and involving diverse stakeholders, the adaptability, profitability, generalizability, and sustainability of the resilience capability factors can be better assessed. Additionally, it is advisable to quantify the identified factors for AFSCRE. By employing various decision-making techniques, appropriate quantitative measures can be developed to obtain more precise and actionable results. This will contribute to the practical implementation of these factors in real-world scenarios.

This work serves as a foundation for further research in the field of AFSCRE. It opens up opportunities for expanding the scope of inquiry and delving deeper into the subject matter. Future studies could probe into AFSCRE from multiple perspectives, including the viewpoints of farmers and wholesalers, for a broader understanding of the key factors influencing resilience in adaptive food supply chains.

Data availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

Adobor H, McMullen RS (2018) Supply chain resilience: a dynamic and multidimensional approach. Int J Logist Manag 29(4):1451–1471

Ahmed S, Downs SM, Yang C, Chunlin L, Ten Broek N, Ghosh-Jerath S (2020) Rapid tool based on a food environment typology framework for evaluating effects of the COVID-19 pandemic on food system resilience. Food Secur 12:773–778

Ali A, Mahfouz A, Arisha A (2017) Analysing supply chain resilience: integrating the constructs in a concept mapping framework via a systematic literature review. Supply Chain Management: an International Journal 22(1):16–39

Ali I, Gölgeci I (2019) Where is supply chain resilience research heading? A systematic and co-occurrence analysis. Int J Phys Distrib Logist Manag 49(8):793–815

Ali I, Govindan K (2023) Extenuating operational risks through digital transformation of Agri-food supply chains. Prod Plan Control 34(12):1165–1177

Ali I, Golgeci I, Arslan A (2023) Achieving resilience through knowledge management practices and risk management culture in agri-food supply chains. Supply Chain Management: an International Journal 28(2):284–299

Ambulkar S, Blackhurst J, Grawe S (2015) Firm's resilience to supply chain disruptions: Scale development and empirical examination. J Oper Manag 33:111–122

Aslam H, Khan AQ, Rashid K, Rehman S (2020) Achieving supply chain resilience: the role of supply chain ambidexterity and supply chain agility. J Manuf Technol Manag 31(6):1185–1204

Ates A, Bititci U (2011) Change process: a key enabler for building resilient SMEs. Int J Prod Res 49(18):5601–5618

Azadegan A, Patel PC, Zangoueinezhad A, Linderman K (2013) The effect of environmental complexity and environmental dynamism on lean practices. J Oper Manag 31(4):193–212

Baah C, Agyeman DO, Acquah ISK, Agyabeng-Mensah Y, Afum E, Issau K, Ofori D, Faibil D (2022) Effect of information sharing in supply chains: understanding the roles of supply chain visibility, agility, collaboration on supply chain performance. Benchmarking: An International Journal 29(2):434–455

Barney J (1991) Firm resources and sustained competitive advantage. J Manag 17(1):99–120

Barratt M, Oke A (2007) Antecedents of supply chain visibility in retail supply chains: a resource-based theory perspective. J Oper Manag 25(6):1217–1233

Behzadi G, O’Sullivan MJ, Olsen TL, Scrimgeour F, Zhang A (2017) Robust and resilient strategies for managing supply disruptions in an agribusiness supply chain. Int J Prod Econ 191:207–220

Biggs R, Schlüter M, Schoon ML (eds) (2015) Principles for building resilience: sustaining ecosystem services in social-ecological systems. Cambridge University Press

Blackhurst J, Craighead CW, Elkins D, Handfield RB (2005) An empirically derived agenda of critical research issues for managing supply-chain disruptions. Int J Prod Res 43(19):4067–4081

Blackhurst J, Dunn KS, Craighead CW (2011) An empirically derived framework of global supply resiliency. J Bus Logist 32(4):374–391

Boone CA, Craighead CW, Hanna JB, Nair A (2013) Implementation of a system approach for enhanced supply chain continuity and resiliency: a longitudinal study. J Bus Logist 34(3):222–235

Borodin V, Bourtembourg J, Hnaien F, Labadie N (2016) Handling uncertainty in agricultural supply chain management: A state of the art. Eur J Oper Res 254(2):348–359

Brandon-Jones E, Squire B, Autry CW, Petersen KJ (2014) A contingent resource-based perspective of supply chain resilience and robustness. J Supply Chain Manag 50(3):55–73

Braunscheidel MJ, Suresh NC (2009) The organizational antecedents of a firm’s supply chain agility for risk mitigation and response abstract. J Oper Manag 27(2):119–140

Brusset X, Teller C (2017) Supply chain capabilities, risks, and resilience. Int J Prod Econ 184:59–68

Cardoso SR, Barbosa-Póvoa AP, Relvas S, Novais AQ (2015) Resilience metrics in the assessment of complex supply-chains performance operating under demand uncertainty. Omega 56:53–73

Chen J, Sohal AS, Prajogo DI (2016) Supply risk mitigation: a multi-theoretical perspective. Prod Plan Control 27(10):853–863

Chowdhury MMH, Quaddus MA (2016) Supply chain readiness, response and recovery for resilience. Supply Chain Management: an International Journal 21(6):709–731

Christopher M, Holweg M (2017) Supply chain 2.0 revisited: a framework for managing volatility-induced risk in the supply chain. Int J Phys Distrib Logist Manag 47(1):2–17

Christopher M, Peck H (2004a) Building the resilient supply chain. Int J Logist Manag 15(2):1–14

Christopher M, Peck H (2004b) The five principles of supply chain resilience. Logistics Europe 12(10):16–21

Christopher M, Rutherford C (2004) Creating supply chain resilience through agile six sigma. Critical Eye 7(1):24–28

Chuang HM, Lin CK, Chen DR, Chen YS (2013) Evolving MCDM applications using hybrid expert-based ism and DEMATEL models: an example of sustainable ecotourism. Sci World J:1–18

Colicchia C, Strozzi F (2012) Supply chain risk management: a new methodology for a systematic literature review. Supply Chain Management: an International Journal 17(4):403–418

Craighead CW, Blackhurst J, Rungtusanatham MJ, Handfield RB (2007) The severity of supply chain disruptions: design characteristics and mitigation capabilities. Decis Sci 38(1):131–156

Cricelli L, Mauriello R, Strazzullo S (2022) Technological innovation in Agri-food supply chains. British Food J ahead-of-print

da Silva FP, Jerónimo HM, Vieira PR (2019) Leadership competencies revisited: A causal configuration analysis of success in the requirements phase of information systems projects. J Bus Res 101:688–696

Dabhilkar M, Birkie S E Kaulio M (2016) Supply-side resilience as practice bundles: a critical incident study. Int J Oper Prod Man 36(8):948–970

Dania WAP, Xing K, Amer Y (2018) Collaboration behavioural factors for sustainable agri-food supply chains: A systematic review. J Clean Prod 186:851–864

Das D, Datta A, Kumar P, Kazancoglu Y, Ram M (2022) Building supply chain resilience in the era of COVID-19: an AHP_DEMATEL approach. Oper Manag Res 15:245–267

De Sa MM, De Souza Miguel PL, De Brito RP, Pereira SCF (2019) Supply chain resilience: the whole is not the sum of the parts. Int J Oper Prod Manag 40(1):92–115

Dhir S, Dhir S (2020) Modelling of strategic thinking enablers: A modified total interpretive structural modelling (TISM) and MICMAC approach. Int J Syst Assur Eng Manag 11(1):175–1488

Dong L (2021) Toward resilient agriculture value chains: challenges and opportunities. Prod Oper Manag 30(3):666–675

Du YW, Li XX (2021) Hierarchical DEMATEL method for complex systems. Expert Syst Appl 167

Dubey R, Luo Z, Gunasekaran A, Akter S, Hazen BT, Douglas MA (2018) Big data and predictive analytics in humanitarian supply chains: enabling visibility and coordination in the presence of swift trust. Int J Logist Manag 29(2):485–512

Dubey R, Gunasekaran A, Childe SJ, Wamba SF, Roubaud D, Foropon C (2021) Empirical investigation of data analytics capability and organisational flexibility as complements to supply chain resilience. Int J Prod Res 59(1):110–128

Durach CF, Wiengarten F, Choi TY (2020) Supplier-supplier coopetition and supply chain disruption: First-tier supplier resilience in the tetradic context. Int J Oper Prod Manag 40(7/8):1041–1065

Esteso A, Alemany MME, Ortiz A (2018) Conceptual framework for designing agri-food supply chains under uncertainty by mathematical programming models. Int J Prod Res 56(13):4418–4446

Faisal MN, Banwet DK, Shankar R (2006) Supply chain risk mitigation: modeling the enablers. BPM 12(4):535–552

Faruquee M, Paulraj A, Irawan CA (2021) Strategic supplier relationships and supply chain resilience: Is digital transformation that precludes trust beneficial? Int J Oper Prod Manag 41(7):1192–1219

Fiksel J, Polyviou M, Croxton KL, Pettit TJ (2015) From risk to resilience: learning to deal with disruption. MIT Sloan Manag Rev 56(2):79–86

Fontela E, Gabus A (1976) The DEMATEL observer. Battelle Geneva Research Center, Geneva

Gandhi S, Mangla SK, Kumar P, Kumar D (2015) Evaluating factors in implementation of successful green supply chain management using DEMATEL: a case study international strategic. Manag Rev 3(1–2):96–109

Ghadge A, Er M, Ivanov D, Chaudhuri A (2022) Visualisation of ripple effect in supply chains under long-term simultaneous disruptions: a system dynamics approach. Int J Prod Res 60(20):6173–6186

Gimenez C, Tachizawa EM (2012) Extending sustainability to suppliers: a systematic literature review. Supply Chain Manag: Int J 17(5):531–543

Gligor D, Gligor N, Holcomb M, Bozkurt S (2019) Distinguishing between the concepts of supply chain agility and resilience: a multidisciplinary literature review. Int J Logist Manag 30(2):467–487

Gölgeci I, Kuivalainen O (2020) Does social Capital matter for supply chain resilience? The role of absorptive capacity and marketing-supply chain management alignment. Ind Mark Manage 84:63–74

Gölgeci I, Ponomarov SY (2013) Does firm innovativeness enable effective responses to supply chain disruptions? An empirical study. Supply Chain Management: an International Journal 18(6):604–617

Gunasekaran A, Subramanian N, Rahman S (2015) Supply chain resilience: role of complexities and strategies. Int J Prod Res 53(22):6809–6819

Gunessee S, Subramanian N, Ning K (2018) Natural disasters, PC supply chain and corporate performance. Int J Oper Prod Manag 38(9):1796–1814

Hamel G, Valikangas L (2003) The quest for resilience. Harv Bus Rev 81(9):52–63

Han Y, Chong WK, Li D (2020) A systematic literature review of the capabilities and performance metrics of supply chain resilience. Int J Prod Res 58(15):4541–4566

Hartono Y, Astanti RD, Ai TJ (2015) Enabler to successful implementation of lean supply chain in a book Publisher. Procedia Manuf 4:192–199

Hendry LC, Stevenson M, MacBryde J, Ball P, Sayed M, Liu L (2019) Local food supply chain resilience to constitutional change: the Brexit effect. Int J Oper Prod Man 39(3):429–453

Hernandez JE, Mortimer M, Panetto H (2021) Operations management and collaboration in agri-food supply chains. Production Planning & Control 32(14):1163–1164

Hohenstein NO, Feisel E, Hartmann E, Giunipero L (2015) Research on the phenomenon of supply chain resilience: a systematic review and paths for further investigation. Int J Phys Distr Log 45(1/2):90–117

Irani Z, Sharif AM, Lee H, Aktas E, Topaloğlu Z, van’t Wout T, Huda S (2018) Managing food security through food waste and loss: Small data to big data. Comput Oper Res 98:367–383

Ivanov D, Dolgui A (2021) OR-Methods for coping with the ripple effect in supply chains during COVID-19 pandemic: managerial insights and research implications. Int J Prod Econ 232

Ivanov D, Sokolov B (2013) Control and system-theoretic identification of the supply chain dynamics domain for planning analysis and adaptation of performance under uncertainty. Eur J Oper Res 224(2):313–323

Ivanov D, Sokolov B, Dolgui A (2014) The ripple effect in supply chains: Trade-off “Efficiency-Flexibility-Resilience” in disruption management. Int J Prod Res 52(7):2154–2172

Ivanov D, Dolgui A, Sokolov B (2018) Scheduling of recovery actions in the supply chain with resilience analysis considerations. Int J Prod Res 56(19):6473–6490

Jain V, Kumar S, Soni U, Chandra C (2017) Supply chain resilience: model development and empirical analysis. Int J Prod Res 55(22):6779–6800

Jakhar SK, Barua MK (2014) An integrated model of supply chain performance evaluation and decision-making using structural equation modelling and fuzzy AHP. Prod Plan Control 25(11):938–957

Jüttner U, Maklan S (2011) Supply chain resilience in the global financial crisis:an empirical study. Supply Chain Manag: Int J 16(4):246–259

Kamalahmadi M, Parast MM (2016) A review of the literature on the principles of enterprise and supply chain resilience: Major findings and directions for future research. Int J Prod Econ 171:116–133

Kamalahmadi M, Parast MM (2017) An assessment of supply chain disruption mitigation strategies. Int J Prod Econ 184:210–230

Khaba S, Bhar C (2018) Analysing the barriers of lean in Indian coal mining industry using integrated ISM-MICMAC and SEM. Benchmarking: Int J 25(7):2145–2168

Kochan CG, Nowicki DR (2018) Supply chain resilience: a systematic literature review and typological framework. Int J Phys Distrib Logist Manag 48(8):842–865

Kumar P, Singh RK (2022) Strategic framework for developing resilience in Agri-food supply chains during COVID 19 pandemic. Int J Logist Res 25(11):1401–1424

Kwak DW, Seo YJ, Mason R (2018) Investigating the relationship between supply chain innovation, risk management capabilities and competitive advantage in global supply chains. Int J Oper Prod Man 38(1):2–21

Leat P, Revoredo-Giha C (2013) Risk and resilience in Agri-food supply chains: the case of the ASDA PorkLink supply chain in Scotland. Supply Chain Manag: Int J 18(2):219–231

Liu CL, Lee MY (2018) Integration, supply chain resilience, and service performance in third- party logistics providers. Int J Logist Manag 29(1):5–21

Luthra S, Govindan K, Kannan D, Mangla SK, Garg CP (2017) An integrated framework for sustainable supplier selection and evaluation in supply chains. J Clean Prod 140:1686–1698

Machado SM, Paiva EL, Silva EMD (2018) Counterfeiting: addressing mitigation and resilience in supply chains. Int J Phys Distrib Logist Manag 48(2):139–163

Mackay J, Munoz A, Pepper M (2020) Conceptualising redundancy and flexibility towards supply chain robustness and resilience. J Risk Res 23(12):1541–1561

Mandal S (2012) An empirical investigation into supply chain resilience. IntJSupply Chain Manag 9(4):46–61

Mandal S (2017) The influence of organizational culture on healthcare supply chain resilience: Moderating role of technology orientation. J Bus Ind Mark 32(8):1021–1037

Mangla SK, Kumar P, Barua MK (2015) Flexible decision modeling for evaluating the risks in green supply chain using fuzzy AHP and IRP methodologies. Glob J Flex Syst Manag 16(1):19–35

Mangla SK, Govindan K, Luthra S (2016) Critical success factors for reverse logistics in Indian industries: a structural model. J Clean Prod:129608–129621

Mani V, Agrawal R, Sharma V (2016) Impediments to social sustainability adoption in the supply chain: An ISM and MICMAC analysis in Indian manufacturing industries. Glob J Flex Syst Manag 17(2):135–156

Manning L, Soon JM (2016) Building strategic resilience in the food supply chain. Br Food J 118(6):1477–1493

Marcucci G, Ciarapica FE, Mazzuto G et al (2023) Analysis of ripple effect and its impact on supply chain resilience: a general framework and a case study on agri-food supply chain during the COVID-19 pandemic. Oper Manag Res

Marley KA, Ward PT, Hill JA (2014) Mitigating supply chain disruptions a normal accident perspective. Supply Chain Manag: Int J 19(2):142–152

Mathiyazhagan K, Govindan K, Noorulhaq A, Geng Y (2013) An ism approach for the barrier analysis in implementing green supply chain management. J Clean Prod 47:283–297

Mehregan MR, Hashemi SH, Karimi A, Merikhi B (2014) Analysis of interactions among sustainability supplier selection criteria using ISM and fuzzy DEMATEL. Int J Appl Decis Sci 7(3):270–294

Mishra DK, Ghadi MJ, Azizivahed A, Li L, Zhang J (2021) A review on resilience studies in active distribution systems. Renew Sust Energ Rev 135:110201

Mokhtar ARM, Genovese A, Brint A, Kumar N (2019) Supply chain leadership: A systematic literature review and a research agenda. Int J Prod Econ 216:255–273

Namdar J, Li X, Sawhney R, Pra N (2017) Supply chain resilience for single and multiple sourcing in the presence of disruption risks. Int J Prod Res 56(6):2339–2360

Nandi S, Sarkis J, Hervani A, Helms M (2020) Do blockchain and circular economy practices improve post COVID-19 supply chains? A resource-based and resource dependence perspective. Ind Manag Data Syst 121(2):333–363

Negri M, Cagno E, Colicchia C, Sarkis J (2021) Integrating sustainability and resilience in the supply chain: A systematic literature review and a research agenda. Bus Strateg Environ 30(7):2858–2886

Nikookar E, Yanadori Y (2022) Preparing supply chain for the next disruption beyond covid-19: managerial antecedents of supply chain resilience. Int J Oper Prod Manag 42(1):59–90

Pan SL, Cui M, Qian J (2020) Information resource orchestration during the COVID-19 pandemic: A study of community lockdowns in China. Int J Inf Manage 54

Parker H, Ameen K (2018) The role of resilience capabilities in shaping how firms respond to disruptions. J Bus Res 88:535–541

Peck H (2005) Drivers of supply chain vulnerability: an integrated framework. Int J Phys Distrib Logist Manag 35(4):210–232

Pereira SCF, Scarpin MRS, Neto JF (2021) Agri-food risks and mitigations: a case study of the Brazilian mango. Prod Plan Control 32(14):1237–1247

Pettit TJ, Fiksel J, Croxton KL (2010) Ensuring supply chain resilience: development of a conceptual framework. J Bus Logist 31(1):1–21

Pettit TJ, Croxton KL, Fiksel J (2013) Ensuring supply chain resilience: development and implementation of an assessment tool. J Bus Logist 34(1):46–76

Ponomarov SY, Holcomb MC (2009) Understanding the concept of supply chain resilience. IntJLogistManag 20(1):124–143

Rahman T, Paul SK, Shukla N, Agarwal R, Taghikhah F (2022) Supply chain resilience initiatives and strategies: a systematic review. Comput Ind Eng 170:108317

Rahman S, Subramanian N (2012) Factors for implementing end-of-life computer recycling operations in reverse supply chains. Int J Prod Econ 140(1):239–248

Raj T, Shankar R, Suhaib M (2010) GTA-based framework for evaluating the feasibility of transition to FMS. J Manuf Technol Manag 21(2):160–187

Reinmoeller P, Van Baardwijk N (2005) The link between diversity and resilience. MIT Sloan Manag Rev 46(4):61–65

Ruiz-Benitez R, Lopez C, Real JC (2018) The lean and resilient management of the supply chain and its impact on performance. Int J Prod Econ 203:190–202

Scholten K, Sharkey SP, Fynes B (2014) Mitigation processes–antecedents for building supply chain resilience. IntJSupply Chain Manag 19(2):211–228

Scholten K, Schilder S (2015) The role of collaboration in supply chain resilience. Supply Chain Manag: Int J 20(4):471–484

Scholten K, Stevenson M, van Donk DP (2020) Dealing with the unpredictable: supply chain resilience. Int J Oper Prod Manag 40(1):1–10

Sheffi Y, Rice J (2005) A supply chain view of the resilient enterprise. MIT Sloan Manag Rev 47(1):41–48

Shi X, Liu W, Lim MK (2023) Supply chain resilience: new challenges and opportunities. Int J Log Res Appl:1–28

Shin N, Park S (2021) Supply chain leadership driven strategic resilience capabilities management: A leader-member exchange perspective. J Bus Res 122:1–13

Shishodia A, Sharma R, Rajesh R, Munim ZH (2023) Supply chain resilience: a review conceptual framework and future research the. Int J Logist Manag 34(4):879–908

Shukla M, Jharkharia S (2013) Agri-fresh produce supply chain management: a state-of-the-art literature review. Int J Oper Prod Man 33(2):114–158

Singh NP, Singh S (2019) Building supply chain risk resilience: role of big data analytics in supply chain disruption mitigation. Benchmarking: Int J 26(7):2318–2342

Singh RK, Gupta A, Gunasekaran A (2018) Analysing the interaction of factors for resilient humanitarian supply chain. Int J Prod Res 55(3):1–19

Soni U, Jain V, Kumar S (2014) Measuring supply chain resilience using a deterministic modeling approach. Comput Ind Eng 74:11–25

Spieske A, Birkel H (2021) Improving supply chain resilience through industry 4.0: a systematic literature review under the impressions of the COVID-19 pandemic. Comput Ind Eng 158:107452

Stewart GT, Kolluru R, Smith M (2009) Leveraging public-private partnerships to improve community resilience in times of disaster. Int J Phys Distrib Logist Manag 39(5):343–364

Stone J, Rahimifard S, Woolley E (2015) An overview of resilience factors in food supply chains. Available at: https://core.ac.uk/download/pdf/288374238.pdf. Accessed 12 Aug 2021

Stone J, Rahimifard S (2018) Resilience in agri-food supply chains: A critical analysis of the literature and synthesis of a novel framework. IntJSupply Chain Manag 23(3):207–238

Sushil S (2012) Interpreting the interpretive structural model. Glob J Flex Syst Manag 13(2):87–106

Teece DJ (2007) Explicating dynamic capabilities: the nature and microfoundations of (sustainable) enterprise performance. Strateg Manag J 28(13):1319–1350

Tendall DM, Joerin J, Kopainsky B, Edwards P, Shreck A, Le QB, Kruetli P, Grant M, Six J (2015) Food system resilience: Defining the concept. Glob Food Sec 6:17–23

Treiblmaier H (2018) Optimal levels of (de) centralization for resilient supply chains. Int J Logist Manag 29(1):435–455

Tukamuhabwa BR, Stevenson M, Busby J, Zorzini M (2015) Supply chain resilience: definition, review and theoretical foundations for further study. Int J Prod Res 53(18):5592–5623

Tukamuhabwa B, Stevenson M, Busby J (2017) Supply chain resilience in a developing country context: a case study on the interconnectedness of threats strategies and outcomes. Supply Chain Manag: Int J 22(6):486–505

Urciuoli L, Mohanty S, Hintsa J, Gerine BE (2014) The resilience of energy supply chains: a multiple case study approach on oil and gas supply chains to Europe. Supply Chain Manag: Int J 19(1):46–63

Van der Vegt GS, Essens P, Wahlstrom M, George G (2015) From the Editors: managing risk and resilience. Acad Manag J 58(4):971–980

Wagner SM, Neshat N (2010) Assessing the vulnerability of supply chains using graph theory. Int J Prod Econ 126(1):121–129

Warfield JW (1974) Developing interconnected matrices in structural modeling. IEEE Trans Syst Men Cybern 4(1):51–81

Wieland A, Wallenburg CM (2012) Dealing with supply chain risks: Linking risk management practices and strategies to performance. Int J Phys Distrib Logist Manag 42(10):887–905

Williams Z, Ponder N, Autry CW (2009) Supply chain security culture: measure development and validation. Int J Logist Manag 20(2):243–260

Xu S, Zhang X, Feng L, Yang W (2020) Disruption risks in supply chain management: a literature review based on bibliometric analysis. Int J Prod Res 58(11):3508–3526

Yang CC, Hsu WL (2018) Evaluating the impact of security management practices on resilience capability in maritime firms—a relational perspective. Transp Res A Policy Pract 110:220–233

Yavari M, Ajalli P (2021) Suppliers’ coalition strategy for green-resilient supply chain network design. J Ind Prod Eng 38(3):197–212

Zhao G, Liu S, Wang Y, Zubairu N, Chen X, Xie X, Zhang J (2024) Modelling enablers for building Agri-food supply chain resilience: insights from a comparative analysis of Argentina and France. Prod Plan Control 35(3):283–307

Acknowledgements

This work has been supported by the National Natural Science Foundation of China (No. 71801049), the Major Projects of Fujian Social Science Base (No. FJ2022JDZ036), 2023 Fujian Agriculture and Forestry University Special Fund for Scientific and Technological Innovation Project (Social Science Category), the China Scholarship Council Funding (No.202008350075).

Funding

The National Natural Science Foundation of China, 71801049, Jianlan Zhong, the Major Projects of Fujian Social Science Base, FJ2022JDZ036, Jianlan Zhong, 2023 Fujian Agriculture and Forestry University Special Fund for Scientific and Technological Innovation Project, CXZX2023036.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript. The authors have no relevant financial or non-financial interests to disclose. The authors have no financial or proprietary.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhong, J., Cheng, H. & Jia, F. Supply chain resilience capability factors in agri-food supply chains. Oper Manag Res (2024). https://doi.org/10.1007/s12063-024-00470-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12063-024-00470-8