Abstract

Global carbon emissions have been rising sharply since the start of the 20th century, and countries have adopted various policies in recent years to reduce greenhouse gas (GHG) emissions in different sectors. Nuclear energy is one energy source that is least polluting with minimum GHG emissions. India’s nuclear power programme started with Heavy water reactors in the first stage followed by Fast Reactors in the second stage. Third stage of Thorium utilisation is yet to start. The deployment of Pu/depleted U from Heavy water reactors in fast reactors would help in the effective utilisation of the indigenous uranium resources to a large extent besides reducing the waste. The thorium technology to obtain uranium 233 is equally important as India possesses large amounts of thorium deposits. With sufficient U233 we can provide a significant long-term solution to fuel our nuclear reactors to produce electricity needed for its development. Linked to the nuclear programme is the availability of fuel, ability to reprocess the spent fuel and manage the wastes. India’s waiver from the Nuclear Suppliers’ Group and its agreement with the global atomic energy body, IAEA, have resulted in limited breakthroughs in the nuclear sector in the last decade and allowed the import of fuel. This paper undertakes a review of the different steps taken by India in the nuclear arena and makes a realistic assessment of its current nuclear power programme.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

India‘s Atomic Energy programme has been based right from its inception on self-reliance through the utilization of domestic mineral resources and building up capability to minimise possible restrictions in international support. The Department of Atomic Energy (DAE) in India is a broad-based multidisciplinary organization today incorporating basic and applied research, technology development and their translation into industrial application. As a result, India today builds its own Pressurised Heavy Water Reactors (PHWR) and associated nuclear fuel cycle facilities and is poised to march on to the second and third stages of its planned programme involving fast breeder and thorium utilization technologies respectively. While the Pu/depleted U fast breeders would help in the effective utilisation of the indigenous uranium resources to a large extent, the thorium technology to obtain uranium 233 fuel is equally important as India possesses large amounts of thorium deposits. With sufficient U233, we can provide a significant long-term solution to fuel supply for nuclear reactors to produce electricity needed for India’s future development. Several papers and a few books [1–4] have been published so far on India’s nuclear Power programme. These have dealt, except for a couple of them [5] with only design and safety features of the power plants besides brief mention of challenges faced and achievements. More than four decades after the first nuclear power plant RAPS-1 went operational in 1972, the contribution of nuclear electricity today is a meagre 6700 MWe to the total installed capacity of 370,100 MWe amounting to less than two percent. One recent paper [5] has critically reviewed the Indian fast reactor programme and the challenges it is facing. The present paper looks at the Indian Nuclear power programme in totality including related developments.

The paper starts with a quick look at the various power reactor types followed by a brief history of Indian Atomic Energy Commission, and the choice of reactor for the first stage of the power programme. While the history has been covered in many articles, the same is briefly brought out for the sake of understanding. It then presents a detailed discussion of the early power plants, their construction, and difficulties during operation. In the later part the paper deals with fast breeder reactors forming the second stage of the programme and briefly covers some aspects of thorium utilization. It concludes briefly covering the industry support, safety regulation, human resources, and power plant economics before setting out recommendations for accelerating the nuclear programme. It is hoped that this paper would give the right perspective to the decision makers to evolve the policy on nuclear power deployment in the country.

2 The role of nuclear power [6]

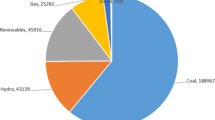

It is well known that the human development index is largely related to per capita electricity consumption. Developed countries have a higher per capita electricity consumption. To meet the large electricity production needs, we must tap all the available energy sources. While coal-fired thermal power plants would remain the mainstay for our electricity production for quite some time, we would need to supplement them with sizeable additional resources with nuclear power and renewable energy technologies to assure long-term energy security as well as environmental protection. The need to limit the release of greenhouse gases into the environment from fossil fuelled plants is important to minimise global warming.

2.1 Comparison of electricity generating options

Today coal fired thermal plants, Hydro plants and nuclear power plants are the major contributors to electricity generation. Solar and wind power plants provide electricity when sun and wind are respectively available. Since both are not continuous the electricity generation from these sources is intermittent. All methods of generating energy have wider effects on the human community. They are all hazardous to some degree in different ways, and these hazards must be considered when choosing which energy source to use. The same applies to their effects on the climate and the pollution of the environment. There is no completely safe way to produce energy. Studies have been carried out in detail to compare the different energy sources based on the metrices of greenhouse gas (GHG) emissions, Energy return on investment (EROI), Levelized Cost of Electricity (LCOE) and external costs.

EROI represents the ratio of Energy Returned (ER) in output over Energy Invested (EI).

The energy return on (energy) investment (EROI) is defined as:

Lower EROI means that society must divert more of its total economic activity to get the energy to run the rest of the economy. EROI integrates the counteracting effects of depletion and technological improvements.

The LCOE can also be regarded as the minimum constant price at which electricity must be sold to break even over the lifetime of the project. This can be roughly calculated as the net present value of all costs over the lifetime of the asset divided by an appropriately discounted total of the energy output from the asset over that lifetime. LCOE was devised before the advent of variable renewable energies (VRE) and therefore, has no parameter to account for intermittency. Hence, it cannot capture additional balancing costs imposed by intermittency. When aiming to integrate more intermittent renewable sources to the grid, continued use of LCOE as a metric for comparison of technology options is erroneous. While nuclear power cost is location independent, in case of coal, it is very sensitive to distance of the power plant from coal mine as cost of coal transportation is quite significant. The levelized costs of generation at 2005–2006 prices in India using 5% and 10% discount rates have been evaluated for a nuclear plant and coal fired plant situated at 800 km from coal pit (table 1). From the above one can conclude that to reduce dependence on coal fired power plants, supplementary base load power can be obtained only from nuclear and not solar or wind which are seasonal.

2.2 Types of nuclear reactors

There are many different types of nuclear reactors with different fuels, coolants, fuel cycles, moderators and purposes [6]. Table 2 lists the different types and number of reactors built and operated in the world. Of these, Pressurized water reactors (PWR), Boiling Water reactors (BWR), Pressurized Heavy water reactor (PHWR) and Sodium cooled fast reactor (SFR) are the once in vogue now.

Pressurised Water Reactor (PWR): The largest number of reactors are PWRs. A schematic is given in figure 1. Russians call this as VVER type. For a greater probability of fission reaction, the neutrons must be at low/thermal energies (~0.025 eV). Such reactors wherein fission is caused by low-energy neutrons are referred to as thermal reactors (also includingBWR, PHWR). Since energies of neutrons are high when produced, moderators are used to slowing them down to low energy levels. The coolant picks up the heat from the core and exchanges it to another light water circuit in a steam generator, to produce saturated steam for running a turbine generator. The coolant and moderator are both light water in PWR. The fuel used is U235 enriched up to 5% as compared to natural uranium which contains only 0.7% of fissile U235.

Boiling Water Reactor (BWR): The second most common, the BWR is like the PWR and uses enriched U235 as fuel. However, it has only one coolant loop. The water boils in the reactor core and produces saturated steam, which leaves from the top of the reactor and passes on to the turbine (figure 2). Since the steam produced in the core is directly passed to the turbine any radioactivity picked up by the coolant will reach the turbine, thereby making maintenance of steam/water systems slightly difficult. Also, the turbine area is not accessible during operation. Since there is only one coolant circuit, in place of two in a PWR, the capital cost is less for BWR.

Pressurised Heavy Water Reactors (PHWR): PHWRs are basically a Canadian design (figure 3). They use heavy water (D2O), where the Hydrogen in H2O has an extra neutron (making it Deuterium instead of Hydrogen). Deuterium is more effective in reducing the neutron energy and absorbs fewer neutrons than Hydrogen, and therefore a better moderator. Here heavy water is both the coolant and moderator. A great advantage of heavy water reactors is their ability to operate using only natural uranium (0.7% U235, 99.3% U238) instead of enriched uranium in case of PWR and BWR which use light water. They can be refuelled while operating, keeping capacity factors high.

Sodium Cooled Fast Reactor (SFR): The first electricity-producing nuclear reactor in the world was an SFR (the EBR-1 in Arco, Idaho). As the name implies, these reactors are cooled by liquid sodium (figure 4).

They do not use moderator, operate at high neutron energies (fast neutrons) and need highly enriched fuel of uranium and plutonium. It may be noted that in the natural uranium containing 0.7% U235 and 99.3% U238, only the former is fissile and small portions of latter get converted to fissile Pu239. SFRs have higher conversion of U238 to Pu 239, effectively producing more Pu239 than that consumed, thus eliminating any concerns about fuel shortages. These reactors operate at high temperatures producing superheated steam resulting in higher efficiencies of power production (~38%) compared to ~30% in water reactors.

In the early days of nuclear energy, a major concern was uranium supply; this led to a period of intensive work on sodium cooled fast breeder reactors which could effectively produce more fissile Pu239 and ensure continued supply of the fissile material. Subsequent discovery of large deposits of uranium, primarily in Canada, Australia, Kazakhstan, and Russia has obviated the need for breeder reactors, thus increasing concentration on building thermal reactors. However, in countries where uranium is not in abundance, for example, India, breeder reactors have an important role. Thus the "winners" of the reactor race so far are the PWR, BWR, and PHWR systems.

3 Formation of Indian Atomic Energy Commission (AEC)

Dr Bhabha had started laying the foundation for a robust atomic energy program in India even before independence. The Tata Institute of Fundamental Research (TIFR) was set up in 1945 in a modest way with the munificence of the Tata Trust. The AEC was set up on 10 August 1948 under the erstwhile Department of Scientific Research [1]. In March 1958 the AEC was brought under the Department of Atomic Energy (DAE) reporting directly to the Prime minister. The Government of India created the Atomic Energy Establishment Trombay (AEET) on 3 January 1954, which was renamed as Bhabha Atomic Research Centre (BARC) in 1967 [3]. With his vision, Bhabha set up research reactors and associated laboratories in metallurgy, reactor physics, reactor chemistry, reactor engineering, health physics, and nuclear fuel development and so on. Vikram Sarabhai, father of India’s space programme, who took over the mantle of atomic energy after Bhabha’s unfortunate death in 1966, was also a visionary [1]. He had succeeded earlier in setting up the space technology base for India. It was during his tenure when the implementation of the fast reactor programme took concrete shape. Unfortunately, Sarabhai also passed away in 1971 itself.

4 India’s three stage programme

India’s natural uranium reserves are modest. The first stage of India’s nuclear power programme therefore involves use of natural uranium with heavy water moderator in PHWRs, which produce not only energy but also some fissile plutonium [1]. The spent fuel from PHWRs contain small quantities of unutilized U235, Pu239 and large quantities of U238. The recovered Pu239 along with U238 forms the fuel for the SFRs.

Domestic natural uranium availability can sustain PHWRs power programme of ~10,000 MWe capacity, after which no further reactors can be fuelled, and the programme would be difficult to sustain. These reactors use only 0.7% of U235 present in natural uranium. A large portion of the remaining 99.3% U238 can be converted to fissile Pu239 in fast breeder reactors. Hence the second stage involving fast breeder reactor became essential for India. The second stage will use Pu239 recovered from the reprocessed PHWR spent fuel along with depleted uranium, mostly containing U238, in sodium cooled fast reactor or SFR. This will convert the fertile U238 to fissile Pu239.

The capability of conversion of fertile U238 or Th232 depends on the number of neutrons produced in fission. This is denoted by factor η which is the ratio of number of neutrons emitted per fission of a fissile nucleus. Besides one neutron to continue the fission chain, additional neutrons would be used for converting the fertile nuclei to fissile. This factor must be greater than 2, allowing for parasitic absorption of neutrons in other structural materials. Table 3 shows the value of η for the different fissile nuclei and isotopes of interest. Pu239 has highest η in the fast neutron region while U233 has the highest in the slow neutron region. Hence when Pu is used as the fissile material the reactor must be a fast reactor while with U233 as the fissile material, thermal reactors would be the preferred choice.

In the latter period of the second stage, SFR will use Th232 as blanket material producing U233 as fissile material. The third stage will then use U233/Th232 combination in fast and/ or thermal breeders to fully exploit available Thorium to produce power. It must be borne in mind that India can generate up to 300 GWe with depleted uranium itself available from spent fuel of PHWR which may last for about 100 years. The third stage is still under development and issues of presence of Pa 233 leading to formation of U234 needs to be sorted out, as detailed in section 7. Also, fissile material needed for the third stage must come from the second stage.

Thorium utilisation is also important as India has considerable large thorium reserves. Indian priorities are, thus, quite unique. For its long-term energy security India has no option but to deploy nuclear power according to a strategy precisely tuned to its needs and resources.

4.1 Research reactors

Several research reactors were built in BARC Trombay and one experimental fast reactor at Kalpakkam in the south of India as a prelude to power reactor programme. Of these the 40 MWt CIRUS and 40 MWt/13.2 MWe FBTR are important (table 4). Other reactors were low power reactors basically for understanding the physics of the critical assemblies.

Some of these reactors e.g., CIRUS have provided valuable experience in operating various systems of a PHWR. Unlike other research reactors, Fast Breeder Test Reactor (FBTR) is an SFR and has a steam production circuit with a turbine generator for producing electricity. It is representative of a nuclear power plant [5] and has given the confidence in developing a prototype fast breeder reactor.

4.2 Choice of nuclear power reactor type for India

In the 1960s, the options were to choose between the light water moderated and cooled enriched uranium fuelled PWR and BWR or the Pressurised Heavy Water moderated, and cooled natural uranium fuelled PHWR. For the former choice, the critical technologies required were of enrichment of uranium and of making of thick pressure vessels, while for the latter it was the technology for heavy water production [3]. Mastering the energy-intensive and complicated technology of uranium enrichment was considered more difficult and was not accessible due to its strategic importance. In contrast, heavy water production from natural water by chemical exchange process appeared feasible with the technological infrastructure available in the country at that time. PHWRs being of pressure tube type construction did not require large and thick pressure vessels and, therefore, were not difficult to manufacture in the country. The familiarity of Indian scientists and engineers with research reactor CIRUS, was also a factor in favour of the selection of PHWRs. Besides, a heavy water plant was also operational at Nangal in North India producing about 10 tons of heavy water per year.

4.3 Collaborations with USA and Canada in 1960s

As 15 years had passed after the formation of AEC, Bhabha was anxious to demonstrate the economic viability of nuclear power by initially importing commercially available reactors. The initial tender was for natural uranium fuelled reactor but was changed later to include enriched uranium fuelled reactors, at the request of US government [3] and a revised global tender was issued for 2 reactors of 150 MWe each in 1961. Seven Tenders were received. GE’s offer of 2 Boiling Water Reactors (BWR) was chosen based on the lowest cost and offer of soft loan from the USA, besides a continuous supply of enriched uranium fuel for the reactors.

By 1960 the site for India’s first nuclear power station with 2 BWRs was selected at Tarapur. During negotiations, GE wanted an indemnity protection, as the nuclear liability law was passed in USA in 1957 itself [13]. This was built into the contract and the construction started in Jan 1964. A novel design of containment evolved by USA and India was used in Tarapur. The first unit was connected to the grid in Oct 1969.The two reactors were housed in a single building and the equipment layout was kept very compact for reasons of economy, though this led to problems in terms of maintenance in later years [3].

Initially, the Tarapur reactors were having problems with fuel failures and called for extensive clean up and remedial measures. These were improved by indigenous efforts [14]. After the peaceful nuclear explosions (PNE) in 1974, USA not only went back on its promise of continued fuel supply but also did not allow India to reprocess the spent fuel and use it in the same reactors as Pu+U oxide (MOX) fuel [15]. However, she did not object to import and use of enriched uranium fuel initially from France and later from Russia [1]. More storage pools had to be built to store the spent fuel. One of the key technical issues resolved in the Indo-US nuclear agreement [16] is the right of India to reprocess nuclear fuel received from the USA. The 123 agreement offers a suitable compromise by permitting India to reprocess US nuclear fuel in India, but in a dedicated plant under IAEA safeguards. The Tarapur reactors are still in operation after almost 50 years having undergone, refurbishments and safety upgrades locally and obtaining license for extended use. These reactors now supply the cheapest nuclear power in the world, having written off their capital cost.

Within a year or so after the Tarapur agreement, DAE went for a contract with Atomic Energy of Canada Limited (AECL) for PHWRs, even before Canada commissioned its first PHWR at Douglas Point [3]. Just as in case of Tarapur for GE, an indemnity protection was extended to AECL and its suppliers as well [13]. Two units (RAPS1, and 2) were built at Kota in Rajasthan under the agreement. The design adopted was a replica of the one used earlier by the Canadians in their Douglas Point reactor, though no operational feedback from this reference reactor was available at that time. Several improvements were made before the construction started, while some changes were made during construction, based on the experience at Douglas Point. Many of the problems faced in the Rajasthan and Madras stations can be attributed to the use of this premature Canadian technology.

RAPS 1 went into operation in 1973 and its initial performance was disappointing. RAPS 1 suffered a delay of 3 years due to difficulties faced during the manufacture of the reactor vessel (Calandria) in Canada and repair works on another component namely the dousing tank. RAPS1 also faced delays in the supply of heavy water. Canadians who had agreed to supply the 230 t of heavy water could spare only 150 t [2]. Russia filled the deficit and RAPS1 was commissioned. Even the commissioning of RAPS2 and MAPS reactors was delayed due to shortage of Heavy water.

RAPS2 took 12 years to commission. Major delays were in identification of material and manufacturer and placing order that took 4 years. The two end shields took 5 years to manufacture [2]. The PNE conducted by India in 1974 worsened the situation with cutting off Canadian assistance and it took another 8 years to complete RAPS2. Soon after operation of RAPS1, one of the end shields cooling circuits developed a leak. Radiation activity of the vessel did not allow any major repairs and the reactor was down rated to 100 MWe from 220 MWe [2]. From MAPS2 the end shield was made of better material Austenitic stainless steel. In RAPS 1 there was also an accidental dousing of the reactor building with water from the dousing tank and this took forty-one days for clean-up and return to normalcy [17]. A more severe problem occurred in 1994 when the gasket in the over pressure relief device gave way resulting in a loss of expensive heavy water. It took three long years to put back the plant in service again [2]. Due to these and other problems the capacity factors for RAPS-1 were very low ranging between 9.3% and 44.3% during the period from 1973 to 1978. The original pressure tube material in both RAPS1 and RAPS2 was cold-worked Zircaloy-2 and this material undergoes degradation due to hydrogen embrittlement, because of accelerated hydrogen pick-up after about seven years of full power operation. Hence the pressure tube material was changed to Zr-2.5% Nb alloy, which is a high strength material and has low pick-up rate of hydrogen [18].

Prior to the framing up of the RAPS-1 contract, AEET was reported to be working on a 15 MWe prototype, PHWR [3]. The work on this prototype power reactor was stopped thinking that we could "leapfrog" based on experience gained in the construction and operation of the Madras and Rajasthan Stations. In dropping this prototype, an important step of understanding the design and construction of a new reactor was missed at that time (1965). It should be clear that in any collaboration, it is not possible to understand fully the know-how and know-why and actual technology can be assimilated only when we build our own designed reactors and overcome problems.

4.4 Front end

India’s uranium resources are modest and of low grade (~0.15%). Despite that low grade, India is exploiting whatever uranium resource is available and continuing exploration to locate further resources. The exploration of Uranium in the states of Meghalaya and Andhra Pradesh have been on a low key, due to protests from the local populations due to the fear of radiation effects. As a result of the efforts of DAE, identified conventional uranium resources (Reasonably assured resources and inferred) are approaching 300,000 tonnes of U3O8. Two decades back this number was less than 100,000 tonnes [19]. In the 1990s there was a significant mismatch between the demand and domestic supply of uranium and many reactors were operated at lower power. Thanks to the nuclear deal; we have been able to reach agreements with Australia, Kazakhstan, and Canada for the supply of natural uranium. It is hoped that natural uranium would not become a constraint at a later stage due to international relations. Without natural Uranium our nuclear power programme with PHWRs would come to a standstill.

The requirement of natural uranium (as Uranium dioxide) is ~45 t/year. for a 220 MWe, 110 t/year. for a 540 MWe and 125 t/year for a 700 MWe PHWRs [20]. It is understood that for the 14 reactors under IAEA safeguards (out of which only 10 are PHWRs) the natural uranium requirements are met from imports from Russia, Canada, and Kazakhstan. The remaining PHWRs are fuelled by domestic natural uranium. However, it is essential to have sufficient stocks of domestic natural uranium so that we are not affected by short term shortages, and we can operate more PHWRs. As to thorium mostly available in the beach sands of Kerala and Orissa, it is explored and processed by the Indian Rare Earths Ltd, a unit of DAE.

The Nuclear Fuel Complex (NFC) at Hyderabad is the only large scale PHWR and BWR fuel fabrication facility in India. The NFC caters to the fuel need of 14 PHWRs operating at 90% capacity factor. With addition of new PHWRs a new facility, NFC-Kota at Kota, Rajasthan, adjacent to the existing Heavy Water Plant-Kota, is under construction [19].

The PHWR program also owes its progress to the Heavy Water production based on indigenous knowhow. Heavy Water plants are at 8 locations of which 6 were built with imported technology based on ammonia exchange process and the rest with indigenous technology based on H2S–H2O process [21]. Finally, it was the indigenous technology that proved a major success and presently we are self-sufficient in Heavy water. It took nearly 30 years for us to be self-sufficient in Heavy water.

5 PHWRs-(MAPS-1 to KAPP-3)

The first unit of PHWRs, RAPS 1 was constructed with Canadian assistance. It was commissioned in 1973. Commercial operation started in December 1976. The second unit, RAPS 2 started construction in April 1968. Halfway through the construction in 1974 the Canadians walked out of the cooperation because of India’s PNE. However, India continued the construction on its own by quickly developing the required technology indigenously and harnessing the industrial infra-structure in the country. RAPS 2 finally went into commercial operation in April 1981. The indigenous technology fully turned the corner only after commissioning of 2 units each at Kalpakkam (MAPS1, 2) and Narora (NAPS 1, 2). MAPS 1 could be described as the first fully indigenous PHWR. The MAPS 1 took 14 years to complete due to various reasons like embargo on supplies from Canada, delays in heavy water availability (4 years) and developing our industrial capabilities to meet nuclear standards. From the PHWRs in Madras onwards, all the components manufacture, erection, construction and commissioning were fully with indigenous efforts.

These reactors are rated for 220 MWe nominal with capability to go up to a maximum of 235 MWe. During 1989 during a shutdown maintenance to probe the increase in the activity in the moderator, pieces of zircalloy were found in the suction filter of the moderator pumps in both MAPS1 and 2 reactors. Investigations using remote cameras inside the calandria showed cracks in the moderator inlet manifolds, apparently due to higher fluid velocities [22]. These manifolds are meant to ensure uniform moderator flow across the length of the Calandria. Engineers made a long-articulated arm with a gripper at its end and this arm could be inserted into the Calandria (reactor vessel) through a 10 cm hole. This helped in removing the debris from the damaged inlet manifold and this could be stored safely in some pockets within the Calandria [23]. Repair of the manifold was ruled out and as a short-term rehabilitation, the moderator outlet was converted into an inlet for moderator entry and the dump ports at the bottom of the Calandria were used to take out the moderator. This needed evaluation of flow fields and temperatures in the Calandria to ensure acceptable temperatures at different locations as the flows were not uniform and these were done with computer codes developed inhouse. With the above modifications the plants were taken to 50% power without any problem. Later few Calandria tube locations were converted to accept sparger tubes, which could ensure uniform moderator flow throughout the length of Calandria as in the original design. The evaluation involved analysis and experiments by multiple agencies and the reactors were taken to full power after due approval by the atomic energy regulatory board (AERB). Though good amount of time was taken in these modifications, we proved our technical ingenuity in overcoming this complex issue and saving the investment.

After MAPS, twin units at Narora, Kakrapar and Kaiga besides additional four similar units all of 220 MWe capacities at Kota and two more at Kaiga came online. Narora (NAPS) design was the first opportunity to apply India’s operating experience with PHWRs, including aspects such as ease of maintenance, in-service inspection requirements, improved constructability, increased availability, and standardisation. Some of the significant design improvements made were the adoption of an integral Calandria (reactor vessel) and end shields assembly, two independent fast acting reactor shutdown systems which eliminated the moderator dump tank required for the similar purpose in the RAPS and MAPS, a high-pressure emergency core cooling system (ECCS), and a double containment reactor building with suppression pool.

Unfortunately, NAPS was the scene of a very bad incident, when some turbine blades snapped resulting in a severe imbalance in the turbine generator leading to rupturing of hydrogen seals and lube oil lines. This led to a large fire that spread to several cable trays, relay panels etc. in a short duration [24]. The well-trained operators took over and manually tripped the reactor and used diesel driven fire water pumps to supply water to the steam generator to remove residual heat from the reactor core. In this case though the diesel supply was available, the pumps could not be run due to burnout of electric cables. The reason for losing both cooling loops was traced to common mode failure where the system of independent routing of the electric power and control cables was not followed in a small portion, at the location of cable entry into the reactor building. The plant suffered an outage period of 1.5-year over which repairs were made and normal operation resumed. After NAPS, new PHWR units were constructed and commissioned at Kakrapar in Gujarat, Kaiga in Karnataka, and Kota in Rajasthan.

During 1998/1999 the data on in reactor creep rate of zirconium alloys (zircalloy-2 and zirc-2.5%Nb) developed indigenously was obtained by irradiation tests on pressurized sample tubes of these materials [25]. The capsules were placed in a special carrier assembly in the Fast Breeder Test Reactor (FBTR) at Kalpakkam. FBTR was chosen for this irradiation campaign as it provided a fast neutron flux about ten times higher than that available in a PHWR. This resulted in completing the testing in much shorter time. Duration of irradiation was from 35 to 80 EFPDs at a reactor power of 8 MWt. The sodium coolant exit temperature was suitably lowered to match with exit coolant temperature in the PHWR.

Pressurised capsules of Zirconium alloys and D9 alloy (modified stainless steel type 316 with controlled additions of titanium and silicon) have been developed to determine the in-reactor creep performance of indigenously developed zirconium alloys and D9 alloy. Pressurised capsules made of zirconium alloys were subjected to a fluence level of 1.1 × 1021 n/cm2 (E > 1 MeV) in FBTR at temperatures of 579–592K and diameter measurements were carried out in the hot cell facility to determine the irradiation creep rate.

Indian 540 MWe units at Tarapur (TAPS-3&4) are an extension of the standardised 220 MWe PHWR. Many components were ordered in advance even without financial sanction for the project, which was a bold step. The project construction was very well managed and construction time for these two units was only 5.25 years. From commissioning of RAPS-1 in 1971 up to 2009 when RAPS 6 was commissioned, the nuclear power contribution was only 3520 MWe. Had the department put its efforts into standardising the 540 MWe designs early, we could have started constructing many such units much earlier instead of the 220 MWe units and achieved higher nuclear power contributions. According to David Hart [1] the design of 500 MWe PHWR was initiated in 1981 well before commissioning of the Madras plant, but for some reason the Indian government embarked on a nuclear holiday during the period 1990–1997. It is thus clear that had the NPCIL concentrated on finalizing the 500 MW design early, we could have embarked on construction of 500 Mwe PHWR much earlier adding a good nuclear power contribution. Nuclear power stations are not cost competitive below 500–600 MWe [3].

A 700 MWe PHWR with improved design features than the 540 MWe reactors has become critical recently (July 2020) at Kakrapar. These units use the component designs of only the 540 MWe unit for the primary system but allow partial boiling in end fuel bundles of the core, resulting in higher power extraction. The second 700 MWe unit is expected to become critical over the next 2 years.

There have been some issues like problems of fuel failures that occurred in the Tarapur BWRs, the moderator entry manifold failure at the MAPS reactors and the Narora fire incident. In all cases remote handling tools were developed and refurbishment carried out with the approval of the regulatory authorities [24]. In brief one can say that the technology of PHWRs has been mastered through indigenous developmental efforts.

5.1 Construction times for nuclear plants

The PHWRs built up to 2009 in India with their construction times are given in figure 5. Also presented alongside is the average construction time in other countries during the same period. It is seen that construction times have been reducing since the start of nuclear reactors in the 1970s and they average around 80–90 months by the year 2000. Countries with standardized reactor designs (France, Japan, and Russia) were able to build plants in shorter times. Countries that succeeded to establish a more collaborative environment among utilities, constructors, regulators, and energy planners through effective partnerships were able to build PWRs in shorter times. The average construction time in Germany, France and Russia was around 80 months and in Japan, about 60 months. The peak period of setting up nuclear reactors in USA and in Europe was during 1970–2000.

The construction times for Indian plants have been significantly higher than the world average. There are two main reasons for this difference (a) complex construction of CALANDRIA (reactor vessel) with several hundreds of calandria tubes and pressure tubes and End shields in PHWRs absent in PWRs, besides additional cooling circuit for moderator and (b) embargoes on MAPS and Narora plants, following India’s peaceful nuclear explosion in mid-1974. Significant modifications to the reactor from the Narora plant onwards have also had their share in delays when the Indian PHWR was standardised.

For KAIGA-1, the inner containment (IC) structure was designed as a prestressed concrete cylindrical shell (42.56 m diameter and 610 mm thick) capped with a pre-stressed concrete dome having 340 mm thickness. On 13 May 1994, the inner containment dome of unit 1 of the Kaiga nuclear power plant developed problems of partial delamination during reactor construction. The dome itself had been completed but cabling and other tasks were being carried out. The failure was in the form of delamination. The under surface of the dome in the central portion delaminated and fell down. As a result of the investigation, several recommendations had been made for re-engineering of the delaminated dome [28]. This led to a pause in the construction of KAIGA 1&2 and RAPS 3&4 and construction was resumed after the modified design was cleared for construction by the nuclear regulator AERB.

Somewhat reduced constructions periods for plants completed in 2001–2005, referring to TAPS 3 &4 as also KAIGA-3 plant in 2007 are due to advance component ordering. Delays in the later plants RAPS 5 &6 as also KAIGA 4 were more due to severe fuel shortage. The present 4360 MWe capacity of PHWRs could have been achieved long ago, say by the turn of the previous century if the government had sanctioned a fleet of 500/540 MWe plants after Narora.

For a country like India with fewer high technology industries, it is necessary to adopt a consortium approach, comprising the government, DAE/NPCIL and industrial partners. The energy planners, regulators and utilities must have a collaborative approach with the common goal. The government needs to think on a long-term nuclear plan instead of piecemeal sanctions to ensure that industries who invest a large capital on facilities for the manufacture of nuclear components have enough orders for survival.

5.2 Fuel reprocessing- Pu239 and U233 recovery

Reprocessing of irradiated fuel to separate plutonium from uranium and U233 from irradiated thorium are the basic steps required for initiating a fast reactor program. In 1961 work for setting up a 30t reprocessing plant at Trombay started without any foreign collaboration and the plant was commissioned in 1964 [29]. The reprocessing technology is not shared by other countries as it pertains to separation of Pu which can be used in a bomb. So, we have been completely on our own. Subsequently a Power reactor Fuel reprocessing plant (PREFRE 1) of 100 t/annum capacity was built at Tarapur in 1979. Then at Kalpakkam, two plants KARP 1, and 2 were built each with 100 t capacity to reprocess spent fuel from MAPS. Presently an integrated nuclear reactor fuel cycle plant with 600 t capacity, which can handle both reprocessing of PHWR spent fuel and its subsequent waste management is under construction at Tarapur [19].

Techniques on a laboratory scale were developed for separating U233 from irradiated thorium rods which were irradiated in CIRUS reactor. Thereafter construction of a 30 KW research reactor KAMINI fuelled with U233 was commissioned at Kalpakkam [30]. This compact reactor is used for neutron radiography studies of the fast reactor fuel besides rendering services for the space program.

Fast reactors either use enriched uranium or plutonium up to about 25%. In India, the emphasis is on using only Plutonium as fissile material and this plutonium must come from the reprocessing of the PHWR spent fuel or from the reprocessing of the SFR spent fuel. As of now FBTR is the only reactor operating for the last 35 years on plutonium- Uranium carbide fuel. With reprocessing of this fuel at the reprocessing laboratory at Kalpakkam, some Plutonium is available, but this is Pu in the carbide form and would be needed to keep FBTR in operation further. Therefore, for first few cores of Prototype Fast Breeder Reactor (PFBR) and those of the proposed two fast reactors after PFBR, Plutonium must come from the PHWR reprocessing plants. Hence the Integrated Reprocessing plant at Tarapur needs to be speeded up. Back of the envelope calculations show that Pu availability for SFRs could become an issue. Tongia and Arunachalam [31] have dwelt at length about the plutonium availability issue for PFBR and future FBRs. Fast reactor fuel cycle must be closed with Fast Reactor spent fuel reprocessing plant to get Pu for further cores of FBR.

Timely completion of the on-going and planned projects, safe and efficient operation of the current operating plants (both reactors and Fuel Cycle Facilities) should be of the highest priority. Failing in this target will derail all other ambitious objectives of fast reactors and subsequent thorium reactors.

5.3 Radioactive waste management

Radioactive waste management has been an integral part of the entire nuclear fuel cycle in India. Over the past four decades radioactive waste management facilities have been set up at Trombay, Tarapur, Kota, Kalpakkam, Narora, Kakrapara, Hyderabad and Jaduguda [32]. One seeks to dispose-off the high-level radioactive waste packages contained in multiple metal-barrier canisters within natural or man-made repositories, to contain radioactivity. As far as the choice of natural barriers is concerned; land-based mined repositories over stable geological formations are preferred over disposal in the oceans. The total volume of high-level waste accumulated so far is rather small due to a small installed nuclear power capacity and the operation of the closed fuel cycle.

6 Fast reactors

Fissile materials such as U233 or U235 or Pu239 are harnessed for producing energy through fission. Of these U233 and Pu239 are manmade and produced by conversion of the fertile materials Th232 and U238, respectively. The ratio of fissile material produced, and fissile material consumed in a reactor is termed as ‘conversion ratio’. The conversion ratio, if greater than 1 is called breeding ratio for then the reactor is creating more fissile material than it is consuming. Light water reactors using enriched (~5%) U235 have conversion ratio of 0.5–0.6. In the case of PHWRs, with more efficient neutron moderation by heavy water conversion ratios of 0.6–0.9 are possible [33].

With fast neutron fission in fast reactors, the number of neutrons produced per fission is higher than in thermal reactors which make it a breeder rather than a converter. As we go from oxide to carbide to metal fuels, breeding ratio improves from 1.1 in oxide, to 1.2–1.4 in carbide fuel and 1.4–1.5 in metallic fuel. Immense amount of work on metal fuels was done at the Argonne National Lab., USA, and a new pyro processing process for reprocessing and subsequent fuel fabrication has been developed at Argonne. Though some work is going on in India on pyro processing for nearly a decade, the accomplishment of full-scale engineering set up is still to gain momentum [34]. Hence India needs to fast track progress in metal fuel design, fabrication, and reprocessing.

6.1 FBTR and PFBR

On the SFR front, a research reactor FBTR was built with French collaboration at Kalpakkam which went operational in 1985 [5]. It should be noted that nearly 90% of the components were manufactured by Indian Industry with technical knowhow from France. This gave the impetus to go for an indigenous design of a 500 MWe prototype reactor (PFBR). FBTR being a test reactor was to use enriched fuel (85% U235). This was supposed to come from France but after the PNE in 1974, the deal fell through. With the non-availability of enriched uranium from within the country at that time and even abroad on sound economics, the Pu reprocessed from the heavy water research reactors was used to make a mixed Pu and natural Uranium Carbide fuel. This was a bold decision since no country had hitherto used Pu enriched mixed carbide fuel to operate a fast reactor and it has worked well since 1985 to date. This is a case of competency of our scientists when pushed to the wall.

To accomplish a closed cycle for the FBTR, reprocessing the Pu-U mixed carbide fuel was required and a pilot plant CORAL (Compact Reprocessing of Advanced Fuel) was set up for the purpose [29]. Reprocessed Pu from the spent fuel of FBTR has been converted as fresh fuel, which is loaded back into FBTR, thus establishing the Indian capability in closed fuel cycle operation for the fast reactor. The requirement of Pu for annual make-up being quite large for future fast reactors, the setting up of the Fast Reactor Fuel Cycle Facility (FRFCF) nearly simultaneously with PFBR is quite important. The first lot of U-Pu MOX fuel for the initial loading of PFBR has already been fabricated using the Pu from the PHWR reprocessing plants. The construction of FRFCF is in progress.

The preliminary PFBR design was prepared in mid 1980s. For the design of such a large plant being attempted indigenously, it was thought very useful to seek a design review by peer groups in France and Russia who had experience in the design and construction of large fast reactors [5]. The reviews were indeed very useful as soundness of the design was verified albeit a few grey areas were identified needing additional development efforts. A fall out of the review was a suggestion by the “peer group” to reduce the number of loops and components of heat transport system thereby reducing the overall cost of the project while preserving the plant safety. A thorough design review was made based on the recommendation of a senior level committee setup by DAE in 1992/93. The decade of 1990 saw the Design and R&D groups going through the optimization phase to produce a techno-economic design. A detailed project report was submitted to the Government of India in early 2002 and the plant construction started in 2004. The plant is at the commissioning stage but is beset with some component problems which are causing delays. Kale [5] has reviewed the development of fast reactors in India bringing out the problems faced and recommendations for faster solutions to the existing issues. Being a first of a kind plant with no similar plants, it is not surprising that we have problems. However, one needs to make a conscientious effort to come out of the problems at the earliest. Any slowing down will affect our nuclear programme.

7 Thorium utilisation

While Bhabha had emphasized use of thorium in the second and third stage of the power programme primarily owing to availability of large thorium resources, there was not enough knowledge at that time of the problems that would be faced in its use during his time. DAE scientists did make some efforts for thorium utilisation by irradiating thorium rods in PHWRs as also in FBTR to obtain U233. However, there are some important issues that need to be tackled in the path to thorium utilisation as detailed below.

While it is possible in principle to breed U233 from thorium in reactors of conventional design, it suffers from one disadvantage. Pa233 is an intermediate isotope in the chain of nuclear reactions, which results in the conversion of Th232–U233 [29]. However, the half-life of Pa233 is about 27 days, and this poses a problem not found in U/Pu system. The presence of Pa233 for longer duration in a reactor core can lead to formation of U234, a useless material and corresponding loss of U233 that was anticipated. This is unavoidable in solid-fuelled reactors because the fuel pins need to be exposed to certain burnups before being extracted from the reactor for reprocessing. This can be avoided if the fuel is in fluid form, so that Pa233 is separated out as soon as it is produced and allowed to decay to U233 out of the reactor core. A feasible way of doing this is the Molten Salt Reactor (MSR) which uses the fuel in liquid form. A crucial part for achieving reasonable breeding in such reactors is the need to reprocess the liquid fuel continuously, during reactor operation to remove Pa233. Also, the production of U233 through the irradiation of Th232 invariably produces small amounts of U232. The decay chain of U232 yields strong gamma radiation emitters. This makes the handling of U233–Th232 more complex [4].

An experimental 8 MWt MSR was built in early 1960s at the Oak Ridge National Lab in USA [35]. However, it posed several problems such as continuous reprocessing of liquid fuel/ coolant stream, and a restrictive choice of construction materials due to high corrosion by molten salts. Furthermore, the breeding ratio obtained was about 1.05 which could possibly get reduced further due to reprocessing losses [36]. The project was shelved after shutting down the experiment having run for five years owing to lack of further funding. That is history.

Today there is a renewed interest worldwide for Molten Salt Reactor (MSR). In 2001, the MSR was chosen by the Generation IV forum as one of the six future reactor concepts. BARC scientists are developing design of an Indian Molten Salt Breeder Reactor with a capacity of 850 MWe for potential use in the third stage of the programme [37]. There is no mention of any experimental MSR though. BARC would do well to construct an MSR of a small capacity say, 10 MWt and operate it to acquire first-hand experience of the various problems associated with such a system involving online reprocessing of liquid fuel. This should particularly include demonstration of confirmed breeding ratio well above unity. Without practically achieving reasonable breeding, it would not be possible to harness the Thorium resources despite their vastness.

Towards thorium utilisation a 300 MWe Advanced Heavy Water Reactor (AHWR) was conceived, and its design developed by BARC some years back [38]. However, it does not find even a mention in a recent report of a task force on “Nuclear Power- India’s Development imperative [39]. Large-scale thorium-based power generation still looks to be at least 3–4 decades away.

8 Import of foreign reactors

To increase the nuclear power share without affecting the indigenous nuclear power programme, DAE was pursuing an objective for setting up of nuclear power plants with external technology and funds in the 1990s. The introduction of large unit size of ~1000 MWe capacity would give momentum to the growth of nuclear power. With this in view, a collaboration agreement was made with the Russian Federation for supply of two VVERs (1000 MWe) like PWR and built at Kudankulam in the state of Tamil Nadu.

This plant construction has taken nearly 13 years or more. There were many regulatory issues involved, besides delays in supply of components from Russia after breakup of the Russian Federation. It was the first time a commercial PWR was being licensed in India. Added was the local public opposition to the plant construction after the Fukushima accident. Construction work on two more of such plants at Kudankulam has commenced. The Kudankulam reactors have been facing some teething problems for some time but hopefully this should not be a major cause for worry. Enriched Uranium for the Kudankulam reactors comes from Russia and if at all reprocessing is to be done it can only be done in a reprocessing plant under IAEA safeguards.

The nuclear deal in 2008 also promised business for foreign reactor suppliers like Westinghouse and General Electric. Unfortunately, after the deal, while GE got out of the nuclear business, the former sold its nuclear business to Toshiba [1]. In 2010, the Indian Parliament passed the Civil Liability for Nuclear Damage Act. As per the Act, an operator of a nuclear plant (so far only NPCIL) will be liable for damages worth up to Rs. 1500 crores [40]. Since the Act provides for the right of recourse for the operator against the supplier, insurance companies in India must provide a policy to enable a supplier to take insurance to cover liability. If written into the contract, the operator can claim the liabilities from the manufacturer and supplier of individual components that caused the issue. Most of the suppliers, domestic as well as international, are concerned over this clause. As indicated earlier, delay in placing orders for components of 700 MWe Kakrapar unit 3 were due to the above clause and NPCIL had to provide a waiver. It is essential that nuclear liability law is made clear and suitable modifications introduced.

After the nuclear deal, India was in talks with France for supply of 1640 MWe Evolutionary Power reactor (EPR) and AP 1000 MWe PWRs from USA. The first operational EPR unit was China's Taishan 1, which started in December 2018. Taishan 2 started operations in September 2019. The first two EPR units to start construction, in Finland and in France, are both facing costly delays with forecast of commissioning them in 2021 and 2023, respectively. Two units at Hinkley point in the United Kingdom approved in September 2016 are expected to be completed around 2026. The first AP1000 began operations in China at Sanmen, where Unit 1 became the first AP1000 to achieve criticality in June 2018. Six AP1000s are currently in operation or under construction, four in China and two in USA. As of 2019, all four Chinese plants have completed construction and are at various stages of connecting to the grid. Construction at Vogtle, USA has suffered numerous delays and is now expected to be completed in 2021. Cost overruns at Vogtle led to Westinghouse's bankruptcy in 2017.

In brief both EPR and AP 1000 are facing many technical and manufacturing issues. As of now it may be worthwhile to go for a series of proven French 900/1450 MWe designs. As far as India is concerned, it is essential to combine the knowledge gained from the submarine PWR design and the experience with the VVER reactors to develop an Indian PWR of say 500 MWe as a first step. This would give us the experience in design, manufacture and operation of an indigenous unit and can be a part of a learning curve.

9 Industrial support

All nuclear facilities built in India have taken longer time to build. One reason for the delay was the unreasonable expectations of the capabilities of domestic industry, which was unable to manufacture some of the specialized equipment in a reasonable time. They needed to set up special shops for nuclear components which demanded a very clean area and involved sufficient investment in setting them up. The problem was not that the industry lacked the technological base and knowledge needed to carry out the fabrication, but that they did not have enough nuclear orders to make such manufacturing activity economical. Many industries were therefore reluctant, and those that fulfilled the manufacturing orders did so at great expense. This was reflected in much higher costs for such equipment.

In this background, it becomes uneconomic for the industry to set up special facilities for just a few components of a single or two reactors. There is a need for ordering say 6–7 reactors at a stretch. Under the present situation, vendors who have quoted for one reactor do not quote for the next one after a few years. A new vendor takes up the order, but he must understand the technology again. Also, with delays in project sanctions and orders for components, the experienced manpower in the department and industries superannuate and then the new set of people must start learning from scratch again.

Technology management has been affected by the lack of clear policy of the government. The department needs to be clear in developing vendors who need to specialise in nuclear component manufacture. This is unlike fossil-fired or renewable energy systems for which we have vendors throughout the world. For nuclear we must depend on few local industries and unless they get substantial orders, it costs more to develop new technologies for just one component.

10 Human resource

The most important task for the introduction of nuclear technology in India was to establish a cadre of scientists and engineers and generate interaction among various scientific disciplines and, at an appropriate stage, translate this interaction into concrete projects. That is the reason BARC and other research centres of DAE have many scientists and engineers working on different R&D areas. A Training School to impart training in nuclear science and engineering was first set up in BARC and later in other units of the DAE to recruit graduates/postgraduates in Physics, Chemistry, mechanical, electrical, electronics, metallurgical and chemical engineering, and train them through classroom teaching for 1 year [41]. NPCIL has its own training programme slightly different from the BARC programme, where more emphasis is on operation of reactors.

Few educational institutions in India started B. Tech and M. Tech courses in nuclear engineering after the Indo-US deal was signed. All these courses had a common problem of lack of specialists to teach. Most of them used retired personnel from the units of DAE and NPCIL. Except a few most of the students from these institutions have not been absorbed for jobs in DAE, as the programme never grew as expected. These courses have been discontinued at present. Nuclear power being managed totally by the Government, the trained manpower is lost when a person crosses 60 years being the superannuation age in India. This is the age when a person can guide and give his best. There is no suitable mechanism developed in the department to have a formal think tank of retired persons and utilise them effectively. In the absence of such an initiative, the country is losing valuable human resource inputs to the programme. DAE needs to look at this aspect seriously.

11 Safety regulation

Atomic Energy Regulatory Board (AERB) of India has been in existence for nearly three decades and during this period it has grown into a mature and effective regulatory body. AERB has put in place a comprehensive system for design and operational safety review of nuclear power plants within the country. The safety analysis for all reactors start from normal operation to accident conditions and these are covered in the safety report. Many safety documents have been developed to aid in such reviews [42]. Feedback of operational experience and lessons learned from major incidents both have been appropriately utilized for modifying designs and procedures for enhanced safety.

AERB also maintains close liaison with premier R&D centres and other academic institutions of the country to draw upon expertise available in support of its regulatory works. Similarly, close interactions with international organizations like IAEA and regulatory bodies of other countries are also maintained to be abreast of the latest developments in nuclear safety. AERB has also brought into its fold a systematic review and regulation of facilities using radiation in medicine, industry, and food.

Though much has been said about the AERB being not an independent body a perusal of ref. [24], would show the firmness with which AERB has dealt with safety clearances. Even if AERB is made an independent body not reporting to the Atomic Energy Commission, it must still rely on the human resources of DAE/NPCIL for its various reviews and inspections as such experts are not usually available in the country.

12 Nuclear plants delays and costs

Nuclear power plants, more so than any other kind of power plants, have high upfront costs—costs that go into planning and building the plant and making it operational before any energy is ever produced. These costs are due to many factors, including capital costs (the cost of constructing and engineering the plant), the owner's costs (such as the cost of the land, infrastructure, and administration), and those from other sources such as financing/borrowing, cost escalation, and interest. Present capital cost of 700 MWe PHWRs is ~Rs.16 Crore/MWe, while for imported Russian PWRs it is ~Rs. 25 crores/MWe [39].

India’s history of delays and cost overruns in executing the nuclear power projects can be judged from table 5. The delays in project implementation and resulting cost overruns could be perhaps justified up to the time of Narora plants, as they were the initial few plants and additionally the west had clamped embargo for several key imports following India’s peaceful nuclear test in 1974. However, it is surprising that even after standardization of NAPS 1&2, further projects from KAPS 1&2 onwards through to Kaiga 1 &2 in all six units, have been delayed significantly (table 5).

NPCIL was converted from a fully government body to a public sector undertaking in 1987. NPPs are funded with a debt equity ratio of 70:30. While the equity part is funded through the budgetary support route and internally generated reserves, the debt part is funded through bonds, commercial borrowing. NPCIL has a memorandum of understanding with the National Thermal Power Corporation (NTPC), Indian Oil and National Aluminium Company, for jointly setting up nuclear power plants on a Commercial Scale [26]. However, without sanction of new projects, these joint ventures have not taken off.

Recently the government has accorded project and financial sanction for a fleet of 10 units of 700 MWe PHWRs. Nevertheless, the funding expected by NPCIL from the government is only to the tune of Rs 3000 crore per year, which is much below Rs. 66,000 crores needed as equity in the next 10–12 years [39]. The joint venture partners like NTPC can infuse capital besides take the role of tendering out the “balance of plant” as a first step, which is in their expertise. Unlike NTPC, NPCIL cannot raise equity from the international market or through FDI route. However, the nuclear island besides overall coordination should remain responsibility of NPCIL, for it only has the nuclear expertise.

Coming to generation costs of nuclear electricity there are several factors that have an impact on these costs of which the most important ones are: Discount rate at which capital is available, Lifetime plant load factors, Economic lifetime of the plant and Fuel price. Of these the effect of discount rate is the most sensitive. Normally a 5% discount rate is in vogue in India. A calculation by NPCIL [43] in 1999, shows that below a certain discount rate (~6.7%) nuclear is better than a coal-fired plant situated at 1200 Km from coal pithead. Ramana et al [44], have worked out detailed levelized cost of electricity generation from Kaiga nuclear plants and Raichur thermal power station and drawn a comparison of their unit electricity costs. Both plants are situated at distances within about 1200 km from coal pit heads. It is noted that nuclear power is cheaper for discount rates below ~ 2.5% only. For both power stations a capacity or load factor of 80 % and plant life of 40 years for NPP and 30 years for coal thermal station were assumed.

To reduce the project gestation period and thereby the capital costs, increased level of mechanization, simultaneous construction activities and above all strengthening project management are some essential measures that are needed. It is equally important to seek timely clearances from agencies such as AERB, ministry of Environment and Forests (MOEF) and other relevant agencies. It is also necessary to have coherent planning and coordination among various agencies like the DAE, the Government and NPCIL for better management of the project. Lack of such coordination can cause harm to the project planning and implementation.

13 Concluding remarks

Nuclear power is a big source for India and can provide clean energy, enabling it to meet the power demand with minimal release of GHG. This article has brought out the developments in the Indian nuclear power programme and it is seen that DAE has realized the objective of developing technologies as envisaged. Despite embargoes India has been able to develop technologies for building PHWRs including fuel fabrication, heavy water production, spent fuel reprocessing, waste management and other nuclear technologies on a broad front. The progress towards self-reliance to date is adequate testimony to the high capability of Indian Scientists and Engineers. They have shown their mettle in overcoming many problems in the operation of PHWRs and FBRs, without external help. The below par performance of the programme can be attributed to the following:

-

(a)

Hurry in acquiring foreign designs that were not proven,

-

(b)

Trying to leapfrog without assimilation of new reactor technology,

-

(c)

Mismatch between demand and domestic supply of uranium,

-

(d)

Long delay in achieving requisite Heavy Water Production,

-

(e)

Industrial Infrastructure had to be developed along with reactor construction.

Following are other salient observations:

-

Nuclear power is much more technologically oriented. India should have gone ahead with a prototype before embarking on commercial reactors.

-

After the success of the Tarapur PHWR units 3, and 4, DAE should have gone to the government to get financial sanction for a fleet of 540 MWe PHWRs instead of going for the 700 MWe PHWR, the first unit of which was commissioned only in July, 2020. This would have kept the industry alive with orders and nuclear contribution could have improved.

-

Several years of delay in finalising the design of PFBR has resulted in the loss of experienced designers and operators in-house and in industry, all having superannuated in service.

-

Effectively we are importing both natural uranium and enriched uranium to run our nuclear reactors.

In keeping with the above, the following recommendations are being made. These recommendations are based on the authors’ personal opinions and do not represent the views of the DAE.

-

The exploration and mining of Uranium deposits need to be undertaken urgently after resolving the local issues (Andhra Pradesh & Meghalaya) through a strong public awareness programme. DAE could use the services of its retired personnel.

-

Establishment of PHWR spent fuel reprocessing plants in a timely manner is essential to avoid Pu shortage for the initial few FBRs.

-

Future project sanctions and orders must also be for a series of reactors to achieve economy and effective utilisation of the design and manufacturing personnel as well as manufacturing facilities created so far.

-

The import of PWRs with imported uranium is only a short-term measure. Looking at the way the fuel supply for Tarapur plants was suspended by USA midway; this approach cannot be recommended on a large scale towards sustainable nuclear development. While doing so, NPCIL should absorb technology so that in due course of time, it can set up PWRs on its own as has been done by South Korea and China.The commissioning of PFBR at Kalpakkam needs to be taken up on a war footing with the involvement of the experienced personnel. The FBR programme is crucial to effective utilisation of the limited indigenous natural uranium resource in India and later for thorium utilisation or generating power.

-

A consortium approach is needed to build nuclear power plants. There are very few industries with sufficient capability to build components for nuclear reactors and only a consortium approach would bring in these industries which would be assured of orders. Working together with Indian industry, NPCIL must look at innovative ways to complete projects on time and within budget.

-

Given India’s ambitious nuclear power program, there is a need for a systematic and well-organised initiative for public acceptance. The public outreach programme needs to be strengthened. Greater attention is required at the time of site selection/evaluation to obviate delays once the construction begins. It is best to take immediate note of the objections raised by the people, particularly those residing in the vicinity regarding employment and compensation to land losers appropriately.

-

Efforts on Thorium utilisation in molten salt reactors must be given an impetus and a prototype reactor of small power say 10 MWt should be built early. Realistic projections should be made on Thorium reactors based on ground realities.

-

In short, timely completion of the on-going and planned projects, safe and efficient operation of the operating plants (Reactors and Fuel Cycle Facilities) should be of the highest priority. Failing in this target will derail all other ambitious objectives of fast reactors and subsequent thorium reactors.

Abbreviations

- GHG:

-

Greenhouse emissions

- IAEA:

-

International Atomic Energy Agency

- DAE:

-

Department of Atomic Energy India

- PHWR:

-

Pressurised heavy water reactor

- RAPS:

-

Rajasthan Atomic Power Station

- PWR:

-

Pressurised water reactor

- BWR:

-

Boiling water reactor

- SFR:

-

Sodium fast reactor

- CANDU:

-

Canada Deutrium

- RBMK:

-

Reaktor Bolshoy Moshchnosty Kanalny

- GCR:

-

Gas cooled reactor

- FBR:

-

Fast breeder reactor

- VVER:

-

Vodo-Vodyanoi Energetichesky Reaktor

- EBR-1:

-

Experimental breeder reactor I

- AEC:

-

Atomic Energy Commission

- AEET:

-

Atomic Energy Establishment, Trombay

- BARC:

-

Bhabha Atomic Research Centre

- FBTR:

-

Fast breeder test reactor

- AECL:

-

Atomic Energy of Canada Limited

- PNE:

-

Peaceful nuclear explosion

- MOX:

-

Mixed oxide

- MAPS:

-

Madras Atomic Power Station

- NFC:

-

Nuclear fuel complex

- KAPS:

-

Kakrapar Atomic Power Station

- NAPS:

-

Narora Atomic Power Station

- TAPS:

-

Tarapur Atomic Power Station

- NPCIL:

-

Nuclear Power Corporation of India

- KAMINI:

-

Kalpakkam mini reactor

- PFBR:

-

Prototype fast breeder reactor

- CORAL:

-

Compact reprocessing of advanced fuel

- FRFCF:

-

Fast reactor fuel cycle facility

- MSR:

-

Molten salt reactor

- AHWR:

-

Advanced heavy water reactor

- EPR:

-

Evolutionary power reactor

- AERB:

-

Atomic Energy Regulatory Board

- MOEF:

-

Ministry of Environment and Forests

- IDC:

-

Interest during construction

References

Iyer M R 2020 The Saga of Atomic Energy in India- Why is Nuclear Power still Subcritical? Authors Press, Delhi

Sarma N and Banerjee B 2008 Nuclear Power in India: A Critical History. Rupa & Co., Delhi

Hart D 1983 Nuclear Power in India: A Comparative Analysis. George Allen & Unwin, London. https://doi.org/10.4324/9780429278303

Bhardwaj SA 2013 Indian nuclear power programme—Past, present, and future, S ̄adhan ̄a 38: Part 5, pp. 775–794

Kale R D 2020 India’s fast reactor programme—A review and critical assessment. Progress Nuclear Energy 122: 103265

Vaidyanathan G and Purniah B 2020 Energy, and Environment- from Cradle to Grave. Yes Dee Publishing, Chennai

Grover RB 2006 Role of Nuclear Energy in India’s Energy Mix, IANCAS Bulletin, April

Uwe R Fritsche et al., Energy and Land Use, September 2017, International renewable energy Agency IRENA& UN Convention to Combat, desertification, http://iinas.org/tl_files/iinas/downloads/land/IINAS_2017_UNCCD-IRENA_Energy-Land_paper.pdf

Neumeyer C and Goldston R 2016 Dynamic EROI Assessment of the IPCC 21st Century Electricity Production Scenario Sustainability 2016, 8, 421. https://doi.org/10.3390/su8050421

IAEA-TECDOC-892, Comparison of Energy Sources in Terms of Their Full-Energy-Chain Emission Factors of Greenhouse Gases, IAEA, Vienna, 1996

Nuclear Electricity Generation: What Are the External Costs? OECD, NEA4372, Nuclear Energy Agency, 2003. https://www.oecd-nea.org/jcms/pl_13756/nuclear-electricity-generation-what-are-the-external-costs?details=true

IAEA 2006 Nuclear Power Reactors in the World, International Atomic Energy Agency (IAEA). Austria, Vienna

Balachandran G and Kapil Patil K 2012 Nuclear Power Plant and Civil Nuclear Liability, Institute for Defence Studies and Analysis, Delhi

Shah JC et al. 1977 Experience from the Construction and Operation of Tarapur and Rajasthan Nuclear Power Station" [IAEA-CN-36/360 (VII.3)], Salzburg Conference

Sundaram CV, Krishnan LV and Iyengar TS 1998 Atomic energy in India: 50 years. Department of Atomic Energy, New Delhi

Agreement for cooperation between the Government of India and the Government of United States of America concerning peaceful uses of nuclear energy (2007). http://www.meaindia.nic.in/pressrelease/2007/08/03pr01.pdf

Sarma MSR, Sah BML and Subbaratnam T 1981 Dousing incident at RAPS Unit I, Regional seminar for Asia and the Pacific Region—radiation emergency preparedness (health physics and medical aspects), Kalpakkam, India, 30 Nov 1981

Sinha RK et al 2010 Plant life management (PLIM) practices for pressurised heavy water nuclear reactors (PHWR) in understanding and mitigating ageing in nuclear power plants Materials and operational aspects of plant life management (PLIM), Edited by Philip G. Tipping, Wood Head Publishing, pp. 739–794

Grover R B and Srinivasan M R 2020 Vikram Sarabhai: his vision for the development of atomic energy in India. Curr. Sci. 118(8): 1191–1195

Bharadwaj A, Krishnan LV and Rajagopal S 2017 Nuclear viewpoint in India, MRS energy & sustainability: a review. J. Mater. Res. Soc., 4, Article number: 6

Sharma S and Mukherjee SP 2009 A Dream Comes True- The Saga of Heavy Water Production in India, Heavy Water Board, Mumbai

Bhasin V, Kushwaha HS and Kakodkar A 2011 Failure Analysis of MAPS Inlet Manifold. In Transactions of the 11th International Conference on Structural Mechanics in Reactor Technology, Tokyo

Kakodkar A 2019 Fire and Fury Rupa publications, 2019, P49 & 53

Sundarrajan AR, Parthasarathy KS and Sinha S 2008 Atomic Energy Regulatory Board- 25 years of Safety Regulation. https://www.aerb.gov.in/images/PDF/Silver_Jubilee_Book/SJBook.pdf0

Murugan S et al. 2013 Irradiation testing of zirconium alloys and stainless steel in fast breeder test reactor, India. In Effects of Radiation on Nuclear Materials: 25th Volume, ed. T. Yamamoto, M. Sokolov, and B. Hanson (West Conshohocken, PA: ASTM International), pp. 176–191

https://www.iaea.org/resources/databases/power-reactor-information-system-pris

Basu P C and Gupchup V N 2004 Safety evaluation of rehabilitation of delaminated containment dome. Nucl. Eng. Des. 228: 195–205

Rajamani N 2017 Reprocessing of spent nuclear fuel in India: present challenges and future programme. Prog. Nucl. Energy 101: 118

Manoharan N, Suresh Kumar KV and Srinivasan G 2011 Fifteen years of operating experience of Kamini Reactor, IAEA

Tongia R and Arunachalam V S 1998 India’s nuclear breeders: Technology, viability and options. Curr. Sci. 75(6): 549

RaoKR2001, Radioactive waste: the problem and its management. Curr. Sci. 81(12): 25

Nagarajan K et al. 2011 Development of pyrochemical reprocessing for spent metal fuels. Energy Procedia 7: 431

Jess CG 2015 History of the ORNL molten salt program. In Workshop on Molten Salt Reactor Technologies, Oak Ridge National Laboratory

Paranjpe SR 1998 Fast Breeder Reactor Development in India (unpublished)

Vijayan P K 2015 Conceptual design of Indian molten salt breeder reactor. Pramana J. Phys. 85(3): 539

Nayak AK et al. 2019 Thorium technology development in an Indian perspective. In Thorium—Energy for the Future, A. K. Nayak and B. R. Sehgal (eds.), Springer Nature

Kakodkar A et al. 2019 Nuclear Power: India’s Development Imperative, Report Vivekananda International Foundation, Delhi

Grover R B 2017 The civil liability for nuclear damage act of India: An engineering perspective regarding Supplier’s liability. Prog. Nucl. Energy 101: 168

Grover R B and Puri R R 2013 Development of human resources for Indian nuclear power programme. Sadhana 38(5): 1051–1064

Bajaj S S 2013 Regulatory practices for nuclear power plants in India. Sadhana 38(5): 1027–1050

Mishra L 1999 India's Quest for Technological Self- Reliance, PhD Thesis, Jawaharlal Nehru University, Delhi

Lok Sabha Secretariat 1994 Ninth Report Standing Committee on Energy, Department of Atomic Energy Demands for Grants (1994-95) Presented to Parliament