Abstract

The present decade has witnessed a huge volume of research revolving around a number of Additive Manufacturing (AM) techniques, especially for the fabrication of different metallic materials. However, fabrication of ceramics and cermets using AM-based techniques mainly suffers from two primary limitations which are: (i) low density and (ii) poor mechanical properties of the final components. Although there has been a considerable volume of work on AM based techniques for manufacturing ceramic and cermet parts with enhanced densities and improved mechanical properties, however, there is limited understanding on the correlation of microstructure of AM-based ceramic and cermet components with the mechanical properties. The present article is aimed to review some of the most commonly used AM techniques for the fabrication of ceramics and cermets. This has been followed by a brief discussion on the microstructural developments during different AM-based techniques. In addition, an overview of the challenges and future perspectives, mainly associated with the necessity towards developing a systematic structure-property correlation in these materials has been provided based on three factors viz. the efficiency of different AM-based fabrication techniques (involved in ceramic and cermet research), an interdisciplinary research combining ceramic research with microstructural engineering and commercialisation of different AM techniques based on the authors’ viewpoints.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The past decades have witnessed ceramics and cermets becoming the centre of attraction in material science especially owing to excellent properties, ranging from enhanced high-temperature strength to high-wear resistance at both room and elevated temperatures [1,2,3,4,5,6]. Although significant work has been done with the main aim of designing ceramics with enhanced mechanical properties, the major limitations are set especially by the structural complexity of ceramics, considering high-performance requirements in aerospace, defence, electronic, energy sectors, etc. [7,8,9,10,11,12]. Fabrication of complex ceramic and cermet parts poses severe challenges, especially in mould manufacturing process which tends to be costly and time-consuming through conventional forming techniques such as dry pressing, isostatic pressing, etc. [8, 13,14,15]. This has led to an ever-increasing demand for a novel forming method, in order to manufacture high-performance ceramic and cermet components with complex shapes. Selective laser sintering (SLS®), since its onset, has delivered promising results in direct fabrication of metals, polymers, ceramics, etc. [16]. Wu et al [17] have reported a technique for preparation of powder beds for direct SLS® using aerosol-assisted spray deposition of Al2O3 suspension. Usually, a conventional roller is used to deposit powder layers which are subsequently made to undergo local heating and sintering according to geometries (predefined using 3D Computer-Aided Design (CAD) data) using selective laser beam scanning. A heating system is then used to preheat powder bed during SLS® in order to reduce thermal stresses, minimising the chances of crack formation in sintered parts [18].

The main challenges associated with the use of SLS® for manufacturing high performance ceramics and cermets with complex shapes are: (i) Difficulty in manufacturing crack-free dense ceramic and cermet components using SLS owing to the extremely high melting points of these materials and (ii) Poor thermal shock resistance (associated with extremely high rates of heating and cooling during SLS) coupled with negligible plasticity of ceramics, leading to high chances of crack formation in these brittle materials. In the context of direct SLS®-fabricated ceramic parts, easy cracking is extremely difficult to avoid, primarily owing to thermal stresses during the sintering process, leading to poor mechanical properties of finished products [19]. A number of studies have highlighted that indirect SLS method may be used as an alternative method to densify ceramics and prevent cracking in these materials through sintering of polymer binders (with low melting points) with the ceramic powder compositions, subsequently followed by removal of the polymer binder with slow heating rate and finally, furnace sintering to densify the final product with minimal chances of crack formation [20].

Powder bed fusion processes have been described as additive manufacturing (AM)-based processes in which thermal energy undergoes selective fusion into zone of a powder bed [21]. Generally, a laser beam or an electron beam is utilized as the origin of thermal energy for irradiation of powder particles. However, till date, AM processes like Electron Beam Melting (EBM) have only been used for fabricating metal-matrix composites (MMCs) and not for ceramics [22]. As shown in table 1, the irradiation of powder particles by thermal energy (originating from a laser beam) may initiate a number of processes such as: complete or a partial melting of powder particles, solid state sintering of powder particles and gelation (formation of a 3D network that traps the powder particles) [23]. Moreover, if the powder particles are not fully melted by the laser beam, the process may be referred to as Selective Laser Melting (SLM). All other laser based powder bed fusion operations can be referred to as Selective Laser Sintering® (SLS®) process [24].

On the other hand, interfaces are 2-D defects which separate two crystals with difference in crystallographic orientation [25]. The structure coupled with the localised atomic arrangement at these interfaces play a vital role in measuring the overall mechanical response of a material [26]. The present decade has witnessed the evolution of “Correlative Microscopy” methodology which involves using multiple microscopy techniques in a given microstructure to obtain both structural and spectroscopic information [27,28,29,30]. Moreover, this technique has been widely employed to understand structure-property correlation in a number of metallic materials and has also been reported to provide a major development in the understanding of different interfaces in these materials. In other words, the present research in the field of AM mainly revolves around a number of metallic materials. However, there is a very little emphasis on understanding structure-property correlation in AM-based ceramics and cermets which exhibit a number of interesting properties. Most interestingly, AM-based techniques may be used to design complex-shaped ceramic and cermet components unlike the parts fabricated using conventional techniques [22]. Low density and poor mechanical properties arising due to microstructural heterogeneities may be attributed as the main reasons for limited investigations in AM-based ceramics and cermets [10,11,12,13,14,15,16,17,18,19,20,21].

To this end, the present review is aimed at discussing some of the common AM techniques (both conventional and advanced) for the fabrication of ceramics and cermets with complex geometries and a wide range of applications. Sections 2 and 3 highlight the conventional and advanced AM-based fabrication techniques (for ceramics), respectively. Section 4 discusses the recently-developed AM-based techniques for the fabrication of cermets. Moreover, a brief discussion (from both industrial and fundamental viewpoints) on the present status and future perspectives has been provided in section 5 with a special emphasis on the requirement for investigations based on structure-property correlation in AM-based ceramics and cermets. In section 5.1, challenges associated with AM of ceramics and cermets have been discussed from the viewpoint of different .AM-based fabrication techniques. In section 5.2, microstructural heterogeneities arising due to non-equilibrium processing conditions in AM-based techniques have been specially highlighted. The last section (section 5.3) of the present review highlights the perspectives and outlooks on AM of ceramics and cermets from the authors’ viewpoint.

2 A few commonly used AM techniques for fabrication of ceramics

2.1 Material jetting

The material jetting methods which are used to shape ceramic components are as follows:

2.1.1 Inkjet printing (IJP) (Direct) [31,32,33,34]:

During this process, there is a direct deposition of a suspension of ceramic powder particles from a print nozzle (for depositing single droplets of the powder suspension) on a substrate. Upon contact between droplets and the substrate, the droplets undergo phase transformation to solid state.

2.1.2 Aerosol jet printing (AJP) [35, 36]:

In this technique, a suspension comprising of fine ceramic powders with droplets in a gaseous medium is used, unlike liquid ink droplets used as printing media in IJP technique.

2.2 Material extrusion techniques

The material extrusion techniques used to shape different ceramic components mainly include:

2.2.1 Fused deposition of ceramics (FDC):

FDC is referred to as multiphase jet solidification (MJS) or extrusion free forming (EFF) [22, 37, 38], has an advantage of being able to fabricate a wide variety of materials owing to similarities with metal injection molding (MIM) technique. However, the main limitations of the process are: (i) materials must possess a suitable viscosity (10-200 Pa.s), and (ii) melting temperature of the binder must be less than 200°C [31].

In the context of ceramics, powder particles (~ 60 vol.%) are initially dispersed into a thermoplastic filament (acting as a binder) followed by a subsequent layer by layer melting (partial) of the same filament and its extrusion from a moving deposition head onto a fixed worktable [22]. The powder-binder mixture is passed as a feedstock through the machine, where it is initially heated above its melting point (in order to achieve a suitable viscosity) and subsequently squeezed out of the nozzle by a pumping system for a layer by layer deposition. The molten material undergoes solidification once in contact with the platform [31].

2.2.2 Robocasting [37,38,39,40,41,42,43,44,45,46,47,48]:

In robocasting, also referred to as 3D fibre deposition (3DFD [41]) or Micropen [42,43,44,45], a concentrated sol is made to undergo extrusion through a nozzle so as to form a filament for a controlled layer by layer deposition to form 3D structures [22].

Unlike FDC (mentioned previously,) this method does not involve partial melting of the polymer. Freeze-Form Extrusion Fabrication (FEF) has been reported as a special Robocasting technique which involves deposition and subsequent freezing of a colloidal gel on a cooled substrate [22, 40]. This technique has been used to fabricate Al2O3 by Leu et al [47]. In the context of Borides meant for ultra-high-temperature applications (exceeding 2500°C), Huang et al [48] have reported the fabrication of ZrB2 cones using the FEF technique. McMillen et al [49] have demonstrated the use of AM-based Ceramic On-Demand Extrusion (CODE) technique for the fabrication of dense monolithic ZrB2 ultra-high temperature ceramics (UHTCs) (with relative density ~99%) using a mixture of oxide-carbide-nitride based ceramic powders and water-soluble organic binders (mostly Polyvinyl alcohol (PVA)). CODE has been reported as an extrusion-based AM technique for the production of complex-shaped mesoscale components [49]. However, there is hardly any report on the mechanical properties of FEF- and CODE-based ZrB2 components to date. Feilden et al [50] have reported the fabrication of HfB2 UHTC using Robocasting technique with theoretical densities of complex-shaped monolithic parts as high as ~94-97% and with a bending strength of ~196 ± 5 MPa at temperatures as high as ~ 1950°C [50], which is comparable with the HfB2 UHTCs fabricated using conventional techniques.

2.3 Directed energy Deposition (DED) techniques

The DED (also known as laser cladding) methods utilized to fabricate macroscopic ceramic parts can be classified as follows.

2.3.1 Traditional DED (or laser cladding) techniques:

In this technique, the printing head comprises of a nozzle for feeding ceramic powder particles to the focal point of the laser beam [51]. This is followed by the melting and solidification of the powder particles on a substrate [51].

2.3.2 Hybrid fused deposition modelling – Directed energy deposition:

As reported by Wang et al [52], this technique has been used to fabricate Ti-6Al4V-TiC composite by feeding TiC powder and Ti-6Al-4V wire into the focus of a CO2 laser.

2.4 Sheet lamination (Laminated Object Manufacturing (LOM)) techniques

These processes may be classified as: (i) Traditional LOM and (ii) Computer-Aided Manufacturing of Laminated Engineering Materials (CAM-LEM).

2.4.1 Traditional LOM technique:

The traditional LOM technique consists of a system for deposition of green ceramic tape casted layers onto a bed for cutting the outline of each layer of the ceramic part using a CO2 laser [22, 31]. This is followed by the passage of a heated roller over the layer for thermal activation of the binder system (of the tape) and lamination of the sheet (to the previous layer) as reported by Williams [31]. However, it needs to be mentioned that the boundary between the tapes should be untraceable after being compressed by the roller [53]. The final ceramic parts are obtained only after debinding and sintering in a furnace [22, 53].

2.4.2 Computer-Aided Manufacturing of Laminated Engineering Materials (CAM- LEM):

Another version of the LOM technique is the CAM-LEM method. This process has a huge similarity with that of traditional LOM, but here, instead of cutting stacked layers, each layer is cut previously and then stacked robotically for lamination (onto the working portion). The main advantage of this method as compared to traditional LOM is the formation of internal voids within each layer [31].

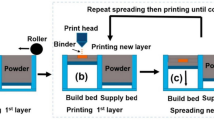

2.5 Binder jetting 3D printing (BJ3DP)

These techniques involve a selective deposition of a liquid bonding agent onto powder materials. In order to shape ceramic components, a 3DP device deposits a layer of ceramic powder and then a jetting binder material for a selective binding of the ceramic powder [22, 31]. These methods may be classified as:

2.5.1 P-3DP (P-3DP: Powder-based three-dimensional printing) technique:

This technique involves a sequential deposition of powder particles with a scraper or roller and subsequent printing of binder material using ink-jet printing (IJP) [31]. Using his technique, a consolidated ceramic part is obtained after burning out of the binder during sintering [31].

2.5.2 S-3DP (Slurry based three-dimensional printing) technique:

For the purpose of processing fine powders (< 20 µm) and improvement in sinterability of the green part, S-3DP technique tends to be much more advantageous as compared to P-3DP technique [22]. During S-3DP technique, each layer of powder bed is formed by the jetting of ceramic slurry onto a substrate. This is followed by subsequent drying of the as-cast and a selective deposition of a binder in the desired pattern [22, 31].

2.6 Single step powder bed fusion (or SLM)

This technique employs a laser-beam for a complete melting of ceramic powder particles. In literature [22], three different variations of powder layer deposition techniques for SLM of ceramics have been reported, namely, (i) conventional deposition (using a scraper or a counter current roller), (ii) slurry based deposition and (iii) aerosol assisted spray deposition (table 1) [22].

2.6.1 Conventional Deposition:

Systems for conventional deposition systems have an advantage of depositing heavy and large (typically with sizes > 5 µm) ceramic powder particles [22, 54, 55]. During this process, the gravity forces overcome the electrostatic attraction is overcome by the gravitational forces, leading to the flowing of the powder particles. Although ceramics such as pure ZrO2, Al2O3 and MgAl2O4 ceramics have been processed using SLM technique, but, unfortunately micro-cracks have been observed in the manufactured ceramic parts [52]. Moreover, It has also been reported that SLM of single-phase ceramics, e.g. ZrO2 and Al2O3 results in coarse grained microstructures [22, 53].

In order to reduce the extent of micro-cracking phenomenon arising due to excessively high thermal gradients, a high temperature preheating system using a CO2 laser beam (for preheating powder layers) and a Nd:YAG laser beam (for localised melting of the ceramic powder particles), has been reported by Deckers et al [22]. Although using the high temperature preheating system, ceramics such as pure ZrO2, Al2O3 and MgAl2O4 could be processed, however, micro-cracks were also observed in the fabricated parts. Moreover, for ZrO2 and Al2O3, coarse grained microstructures were obtained [22].

2.6.2 Slurry based deposition technique:

SLM in combination with slurry coating as been used to produce silica-clay parts [22]. The clay used, acts as an inorganic binder for silica (SiO2) powder during the process of drying. In this way a green layer ceramic substrate is produced in order to minimise balling and provide a structural support to the ceramic part during building process. During laser scanning, the dried silica-clay layer undergoes complete melting, leading to a significant reduction of porosity in ceramic parts. However owing to the brittle nature of SiO2 and no preheating of the deposited layers, high-energy laser scanning has been reported to easily induce thermal cracks in ceramic parts [22], rendering this process unsuitable for production of high strength parts [56,57,58,59].

2.6.3 Aerosol assisted spray deposition:

Preparation of powder beds for subsequent laser scanning, using this technique, was first reported by Wu et al [17]. This process has been reported to be useful for fabrication of single layered ceramic parts. Based on the report of Deckers et al [22], preparation of Alumina (Al2O3) suspension was performed by an addition of 5 wt.% Al2O3 powder to a solvent (ethanol, purity: 99.5%) with dispersant as 0.2 wt.% of polyacrylic acid (PAA). During the irradiation of the Al2O3 powder beds by the laser beam, the PAA has been reported to evaporate with the melting of Al2O3 particles (submicrometer-sized) so as to form a liquid-phase, in order to facilitate densification through liquid-phase sintering (LPS) [22]. With increasing energy density of the laser beam, an increasing extent of densification has also been reported [17, 22, 60]. Figure 1 shows a completely densified microstructure of an Al2O3 sample fabricated using SLM of layers deposited using aerosol assisted spray deposition technique.

Scanning Electron Microscope (SEM) micrograph of the (a) surface and (b) cross-section of Al2O3 sample fabricated using SLM of layers deposited using aerosol assisted spray deposition technique [17].

2.7 Single step powder bed fusion (partial melting)

2.7.1 Conventional deposition technique:

Lakshminarayan et al [61, 62] have fabricated alumina (Al2O3)-ammonium phosphate ((NH4)3PO4) and alumina-boron oxide ceramics using this technique. Besides, both ammonium phosphate (melting point: 190°C) and boron oxide (460°C) have also been reported to play a dual role as structural materials and binders for gluing Al2O3 particles [61,62,63].

2.7.2 Slurry coating technique:

In this technique, a slurry layer (powder containing) is deposited with subsequent drying. This has been reported to highly enhance the packing density of the deposited powder particles, as compared to that in case of conventionally deposited powder particles (by ~ 46 vol.%) for highly loaded solid slurries [22]. Moreover, through SLS® of slurry coated layers, hydroxyapatite, Al2O3-SiO2 and porcelain parts have been successfully fabricated [64,65,66,67,68,69,70,71].

2.7.3 Slurry spraying technique:

Klocke et al [72] have produced yttria stabilized zirconia (YSZ) by using direct SLS® technique. As reported [72], the process involved formation of powder layers by spraying (instead of a layer-wise deposition) ceramic suspension before drying. Moreover, cracks, observed on the SLSed layers were reported to occur by thermal contraction during cooling after irradiation using a laser beam). The amount of open porosity in the finished parts was reported to be ~24–32% [72]. However, the molten powder was unable to fill all the gaps between the unmelted powder particles inspite of high packing density of the deposited green layers [72].

2.7.4 Ring blade technique:

This process, patented in 2004 [73] consists of a ring blade [74], also known as 'powder rack', for deposition of dry non- agglomerated submicrometer sized ceramic powder. Moreover, using this technique, it is also possible to partially melt the deposited powder particles. For the purpose of inhibit overheating of the laser scanned material, the laser is mostly applied in a pulsed mode instead of a continuous mode [75]. Partial melting of submicrometer sized powder particles using the micro SLS® device (using Ring blade technique) has been reported to be used for the fabrication of the following ceramic parts: Al2O3-feldspar [74], Al2O3- SiO2 [73, 75,76,77], feldspar [73] etc. However, the fabricated ceramic parts were reported to contain pores [22].

2.7.5 Electrophoretic deposition (EPD) technique:

An experimental setup for his technique as reported by Deckers et al [22], consists of a vertical tubular furnace for a homogeneous heating till 800°C (within a range of ± 50°C). The layer deposition process has been reported to consist of two steps. The 1st step involves deposition of a powder layer on a deposition electrode by the EPD process in an EPD cell, consisting of a positively charged Al2O3 suspension with a counter electrode mounted at the bottom and a deposition tool at the top of the cell. During EPD process, a DC power source is used to negatively charge deposition electrode and positively charge counter electrode. The 2nd step involves the removal of deposition tool with EPD deposited powder layer from the EPD cell and subsequent mounting into a gearbox for deposition of the powder layer in the vertical tubular furnace. Optimisation of the layer deposition and laser scanning parameters has been reported for the fabrication of Al2O3 ceramic parts with a high density (~ 85%) and a microstructure with average grain size < 5 µm [78,79,80,81,82]. Although the main consolidation mechanism of this technique appears to be partial melting, but however, at present, it remains unclear as to which consolidation mechanism is active during the process. Therefore, the laser consolidation process has also been specified as direct Selective Laser Sintering®/Melting (direct SLS®/SLM) [22]. Figure 2 shows the SEM images of α-Al2O3 ceramic part fabricated using SLS®/SLM technique.

SEM images of α-Al2O3 ceramic part fabricated using SLS®/SLM technique: (a) unpolished scan surface with crack (b) polished cross-section. The image in part (b) has been acquired perpendicular to scan tracks [78].

2.8 Conventional deposition technique

Solid state sintering (SSS) as consolidation mechanism during SLS® of ceramic materials at 800°C, was reported by Bertrand et al [83] where sintering of the preheated powder (close to the sintering onset temperature) was performed using Nd:YAG laser.

2.9 Chemically induced binding (CIB) for single step powder bed fusion (or Selective Laser Reaction Sintering (SLRS))

During this technique, initiate a chemical reaction occurs due to the heat of the laser beam resulting in binding of the powder particles [22, 84]. The following powder deposition systems are employed for the ceramic part fabrication through this process.

2.9.1 Conventional deposition technique:

Based on the report on SLS® of SiC powders in inert Ar atmosphere by Klocke et al [85], SiC decomposes into Si and C during laser irradiation and despite the inert nature of the Ar atmosphere, Si atoms react with O2 to form SiO2, which leads to the binding the SiC particles [85]. Owing to the high melting temperature of Si (~1420°C), SiC particles are also bound by molten Si [85].

2.9.2 Slurry coating (Ceramic Laser Sintering (CLS)) technique:

Deposition of slurry layers, consisting of aluminium phosphate and SiO2 was first reported by Tang et al [86] and is based on an irreversible chemical reaction of slurry containing aluminum phosphate and silica at a temperature above 250°C.

2.9.3 Ring blade technique:

This technique was first used to fabricate Si-SiC parts through SLS® of SiC [22] using an Nd:YAG laser (wavelength ~ 1064 nm) in a continuous mode (in order to decompose a fraction of the irradiated SiC powder particles). This yielded Si (in elementary form), which became the bridging material for unreacted SiC grains [73, 76,77,78,79].

2.9.4 Conventional deposition system:

This is a method for fabrication of ceramic parts (for elevated temperature applications) by low temperature selective laser sintering (SLS®) of ceramic particles and a binder material (sacrificial in nature) [87]. The binder melts and hence binds the ceramic particles together. Using this process, a ceramic part is obtained after debinding in a furnace, as shown in table 2 [22].

Indirect SLS® with the use of a sacrificial binder phase aids in the fabrication of crack free ceramic parts, but however, there is a compromise on the final density, i.e. the density of the part after debinding and before sintering has been reported to be generally low (limited to only ~ 39- 80%) [22, 88, 89] which has been attributed to the occurrence of voids powder particles (size: 10-100 µm) [22], after SLS®. Moreover, these voids have been reported not to disappear during debinding and Solid State Sintering (SSS) and hence, are present in the finished part [88,89,90,91,92]. In order to reduce the number of voids (primarily, inter-agglomerate in nature), Shahzad [93] and Deckers [94] have reported: (i) laser re-melting (multiple irradiation of powder layers), (ii) cold, quasi and warm isostatic pressing of the parts (produced by SLS®) and (iii) infiltration of parts obtained during different stages of the partial melting process. Moreover, Indirect SLS® (through partial melting of composite agglomerates) has not only been used to produce pure ceramics, but also composites [95,96,97,98,99,100]. For instance, Gill et al [96] have reported SLS® of SiC-PA ceramic-polymer composites. Evans et al [100] have reported that infiltration of SiC preforms with molten Si produces SiC-Si cermets. Stucker et al [97, 98] have used the SLS® technique to manufacture ZrB2 green parts (with a density of ~31% in pre-infiltrated condition) followed by debinding, sintering, and infiltration (with Cu) for applications in Electrode Discharge Machining (EDM) electrodes. In addition, a previous investigation on ZrB2 by Sun and Gupta [99] has reported that fine ZrB2 powders produced by the SLS® technique have enhanced surface wettability and sinterability. Leu et al [91, 92] have fabricated ZrB2 flexural test bars and 3D fuel injection components (for application in spacecraft) (using SLS) with ~80% density and flexural strength ~195 MPa.

2.9.5 Multi-step powder bed fusion by Ceramic Laser Gelling (CLG):

This process works on the principle of initiation of physical or chemical gelling of a colloidal suspension (a sol) by the induction of heat energy through a laser beam, leading to an increase in viscosity of the sol (once gelled) and subsequent development of rigidity through formation of crosslinked 3D network [22]. For instance, during deposition of a thin film using a slurry coater, CO2 laser irradiation can be utilised for the purpose of drying a portion of the deposited layer, in order to form a physically gelled network of solid particles. The portion of slurry film, left unscanned by the laser beam, remains as a slurry [22, 100]. Yen et al [101] have used slurry comprising mainly of Al2O3 powder, SiO2 sol and deionized (DI) water, in order to fabricate Al2O3 - SiO2 components. Liu et al [102, 103] have reported that using CLG technique, a pure SiO2 part (figure 3) can be obtained by mixing SiO2 sol with SiO2 powder.

A silica part with inner channel structure fabricated using CLG technique. Parts (a) and (b) show the image of the same part with different views [102].

2.9.6 Vat photopolymerization techniques:

These techniques (based on stereolithography (SLA) and also termed as Ceramic Stereolithography (CerSLA [22], CSL [22]) and sometimes, even termed as Lithography based Ceramic Manufacturing (LCM [22])) involve a selective curing of a liquid photopolymer using light-activated polymerisation [1]. During SLA, a UV radiation is typically used to scan ceramic powder containing slurry layers, leading to chemical gelling of these layers. The final ceramic part is obtained after debinding the resulting polymer and sintering the material obtained after debinding [22]. Moreover, based on the sizes of the final ceramic parts produced these techniques can be classified into two types, namely, (i) Macro SLA and (ii) Micro SLA.

2.9.6.1 Macro SLA technique:

In the context of macro SLA technique, Griffith et al [104] and Halloran et al [105] have suggested the replacement of laser source by Light Emitting Diodes (LEDs) or even halogen lamps while transferring the desired pattern on the photocuring liquid and coined this technology as Large Area Maskless Photopolymerization (LAMP). As reported by Deckers et al [22], during LAMP, each layer undergoes a rapid patterning through UV exposure in the form of a bitmap defined using a light modulator. Moreover, it is also possible to use a medium consisting of UV curable resin (acing as an organic binder) and methanol (acting as both solvent and dispersant), resulting in shrinkage of the deposited slurry volume [106]. Besides, another route to produce the UV curable resin was devised by De Hazan et al [107], in which, adsorption of the surfactants was carried out in an aqueous media under controlled pH conditions on Al2O3/ZnO powder particles. The extent of photopolymerisation can be described using the equation developed by Jacobs [108], based on Beer-Lambert’s Law. Figures 4 (a-d) show fabrication process of ZrO2 toughened Al2O3 (ZTA) ceramic gear using SLA technique.

Schematic showing the fabrication process of ZrO2 toughened Al2O3 (ZTA) ceramic components using SLA technique: (a) ZrO2/ Al2O3 powders for preparing paste, (b) 3D printing of ceramic parts using SLA, (c) Sintered Al2O3 /ZrO2 ceramic gear and (d) its microstructure [109].

2.9.6.2 Micro SLA technique:

This technique is more or less similar to that of macro SLA technique, but with the only exception that this technique has the capability to produce complex shaped 3D components with length scales less than even 1 mm, as reported by Bertsch et al [110].

3 Alternative AM methods for fabrication of ceramic parts (highlighted in table 1)

3.1 Electrophoretic deposition (EPD) technique

This technique involves electrophoresis (migration of charged colloidal particles in a liquid medium) and a controlled deposition of these particles to shape a 3D component using an electric field between electrodes [111].

3.2 Electro photographic printing (EP) technique

In this method, as described by Deckers et al [22], a photoreceptor plate, containing an electrostatic image of a layer belonging to the ceramic part (to be manufactured), is aligned over a powder bed. Due to the electrostatic charge, the ceramic powder particles get attracted towards the photoreceptor plate in the exact shape of the layer (or sometimes, in the negative shape of the layer if printing of support material is required). After a sequential charging and deposition of powder layers, the printed layers are made to undergo compaction and final sintering for producing the ceramic part.

4 Fabricating cermets through additive manufacturing

On the basis of feedstock, AM processes are classified into three categories: namely, powder-based, liquid-based, and solid-based techniques [112, 114]. At present, selective laser sintering/melting (SLS®/SLM), binder jet (3D printing (3DP)), laser engineering net shaping (LENS), direct laser deposition (DLD) and more recently, robocasting [114,115,116,117,118,119] are processes commonly used for the fabrication of cermets. Figure 5 shows cermet parts fabricated by three common AM processes.

4.1 Selective Laser Melting (SLM)

Khmyrov et al [120, 121] have investigated the phase evolution during fabrication of WC with variation in wt.% Co using SLM and reported a complete dissolution of WC in all samples except for the sample containing 6 wt.% Co and also attributed the dissolution of WC with the formation of different carbides to the reduction in carbon content of SLM samples.

Moreover, for producing crack-free WC-Co samples, two compositions with 75 wt.% and 50 wt.% Co were used [120]. For a uniform distribution in the powder particles, the powder mixture was milled for 2 h at 200 rpm. Fabrication of SLM samples was carried out using a hatching distance of 100 μm (Power: 50 W, scan speed: 100 mm/min) [120]. The sample with 75 % Co was reported to be crack free (figure 4). The formation of brittle W3Co3C phase was reported to be the main reason for the formation of cracks in samples with 50 wt.% Co [120]. Moreover, a correlation of the hardness of metal-ceramic composites with the size of the carbide particles after SLM has also been reported [120, 121]. Figure 6(a) shows a schematic of SLS®/SLM process and figure 6(b) represents exposure parameters influencing volumetric energy density (EV) during SLM technique.

(a) Schematic of SLS®/SLM process: (1) laser, (2) scanner system, (3) molten pool, (4) printed object, (5) powder bed, (6) build platform, (7) powder roller, and (8) new powder stock. (b) Schematic representation of parameters (exposure parameters) influencing volumetric energy density (EV) during SLM [112].

Grigoriev et al [122] and Campanelli et al [123] have reported that formation of cracks in the manufactured specimens with WC (brittle phase) content occurs due to a significant difference in the melting points and coefficient of thermal expansion between WC and binder. Domashenkov et al [124] have investigated the microstructural evolution and mechanical response of WC-12% Co samples produced by SLM process using (i) conventional powder particles and (ii) nanophase powder particles and reported that formation of W2C and W2Co4C occurs due to decarburization of WC during melting and solidification. Based on the experimental observations [124], two regions containing coarse and fine carbides were observed and hardness values were reported to depend on the size of carbides in samples fabricated using conventional and nanophase powder particles. Higher hardness values were reported for finer carbides (table 3).

4.2 Selective Laser Sintering (SLS®)

Gu and Shen [125] have investigated the microstructure and mechanical properties of laser sintered WC-Co/Cu nanocomposites using X-ray Diffraction (XRD), Atomic Force Microscopy (AFM), Scanning Electron Microscopy (SEM) and Energy Dispersive Spectroscopy (EDS). Based on this work [125], a double stage wetting mechanism during laser sintering of WC-Co/Cu nanocomposites was proposed (figure 7). From figure 7, it may be observed that at the initial stages of wetting, Co forms a homogeneous coating on WC particles (figures 7(a and b)). However, once temperature exceeds melting point of the matrix (Cu [125]), there is formation of a sintering (melt) pool leading to Maragoni convection [108]. Maragoni convection, formed as a result of the large temperature gradient between the edge and centre of the melt pool due to Gaussian laser beam, leads to wetting of WC-Co with liquid Cu (2nd stage of wetting) (figure 7(c)). The two-stage wetting mechanism of WC leads to a homogeneous distribution of WC phase in a metal matrix (Cu [125]) (figure 7(d)).

Schematics (a-d) illustrating double stage wetting mechanism during direct laser sintering (DLS) of WC-Co/Cu composite [125].

Kumar [126] have investigated the influence of isothermal heat treatment (at 400, 600, 800 and 1000°C for 3h) on the hardness and wear behaviour of the fabricated specimens and reported that diffusion of the elements leading to the homogenization and formation of the eta phases: M6C and M12C during heat treatment, leads to improvement in mechanical properties [112]. Gu and Meiners [127] have reported hardness fluctuations in the longitudinal section of WC-10 %Co cermet as a result of inhomogeneous distribution of WC particles (figures 8(a-c)). Gu et al [128] have reported an increase in the microhardness of SLS samples with the addition of a rare earth oxide (La2O3) to WC-Co/Cu powder (weight ratio: 50(WC-Co):49Cu:La2O3). Moreover, from figures 8(d-k), it may be inferred that the morphology of M6C carbides is largely dependent on laser scan speed during SLM [127].

Cross-sectional SEM micrographs of SLM-based samples at (a, i-k) 1.2 m/s, (b, g, h) 1.0 m/s, (c, d-f) 0.8 m/s scan speeds of the laser. For part (d), M1: Ceramic Matrix and B1: Metallic binder. For part (h), M2: Ceramic Matrix, B2: Metallic binder and I1: Granular precipitates at interface. For parts (j and k), M3: Ceramic Matrix, B3: Metallic binder and I2: Ring-shaped interfacial layer [127].

4.3 Laser engineered net shaping (LENS)

This technique has been widely used for fabricating cermet components in addition to being a surface treatment technique [112]. Based on an extensive review on AM of cermets by Aramiana et al [112], the effective process parameters influencing the microstructural evolution during the LENS process are: (i) laser power, (ii) powder feed rate, (iii) traverse speed of the laser beam, and (iv) working distance. For example, in order to obtain large layer thickness, the laser power or powder feed rate may be increased, or the traverse speed of the laser beam may be decreased. Short working distance has been reported to lead enhance microstructural uniformity and a slight increase in density of the final product [128, 129].

Xiong et al [129] have reported that on the basis of position along the height of the samples (during LENS process), mechanical properties may be varied due to change in the cooling rate along the height of the specimen of WC-10 % Co cermets (with lower hardness values reported at layers close to the top surface). Moreover, it has been stated optimisation of process parameters during LENS is necessary for the production of dense and crack-free thin wall specimens [129]. Sahasrabudhe and Bandyopadhyay [130] have reported AM of reactive in-situ ZrB2-based UHTCMCs in Zr metal matrix using the LENS technique. It has been reported that a proper bonding was achieved between Zr metal (in α-phase) and Zr-BN composites with Ti-6Al-4V (α-β Ti alloy) substrate [130]. In this context, LENS processing of the mixture of Zr and Zr-BN powders has been reported to lead to β phase of Zr [130]. Vickers microhardness of pure Zr was measured to be ~280 ± 12 HV and was reported to increase with increasing BN content [130]. For instance, Vickers microhardness for Zr-10% BN was reported to be ~ 562 ± 10 HV [130]. In addition, it has also been highlighted that Zr-BN composites cannot be fabricated using conventional fabrication techniques, which are currently used in the field of UHTCMCs [130].

High magnification SEM-BSE image of the sample shown in figure 9 shows that the boundary between two deposited layers consists of fine (< 100 nm) particles of WC in the darker region and large WC particles (submicron scale) on the brighter side, formed as a result of grain growth in the binder [131,132,133,134]. Moreover, from figures 10(a and b), it may be inferred that the low intensity of laser beam coupled with short working distance (for the laser), leads to a uniform microstructure without layer boundaries.

SEM-BSE images of a LENS WC–Co thin walled specimen fabricated using a laser beam (power: 200 W): (a) side view image of the alternate layers; (b) cross-sectional view (the circle with a cross shows the direction of deposition, normal to the section); (c) SEM micrograph (at higher magnification) of (a) showing details of the boundary region between the sintered layers [131].

SEM-BSE images of WC-10 wt.% Co sample at (a) low magnification and (b) High magnification. The black arrow in part (a) represents deposition direction. Part (b) shows fine WC particles [131].

4.4 Direct laser fabrication (DLF) technique

DLF has been reported to be a promising method for a layer-by-layer deposition of complex 3D samples with a direct deposition of powders in the melt pool [114]. In-situ fabrication of TiC-(20, 30, 40 vol.%) Ni cermet by direct laser fabrication (DLF) has been reported [136]. Moreover, it has also been reported that the bending strength and hardness of the TiC samples (fabricated using DLF technique) decrease due to reduction in the volume fraction of ceramic phase with increasing Ni content in the binder. However, the influence of Ni (present in binder phase) on the above mechanical properties of TiC-(x vol.%) Ni cermet still remains unaddressed.

4.5 Binder jet 3D printing (BJ3DP) technique

This is another technique that has been used for the fabrication of WC-12 %Co cermet [134,135,136]. Enneti et al [116] have reported the wear behaviour of WC-12% Co cermet fabricated using BJ3DP technique. Binder jet 3D printed cermet has been reported to exhibit a lower loss of volume in comparison to the conventionally fabricated cemented carbides [137, 138]. Moreover, the enhancement in wear resistance of WC has been attributed to a dual grain-sized microstructure in the BJ3DP material (after sintering, figure 11).

Dual grain sized microstructure (after sintering) of WC-12 %Co [116].

Post infiltration of BJ3DP components with a molten metal can be used for fabricating cemented carbides [112]. A number of investigations in this direction have reported that by using this approach, fully densified cermet parts with high hardness and fracture toughness comparable with that of conventional cermets can be attained. However, even with this technique, some of the major AM challenges including cracks, shrinkage and porosities remain unavoidable [137,138,139,140].

4.6 Extrusion-based 3D Printing technique

In this technique the feedstock can be a wire or granulated powder particles which are known as fused-filament fabrication (FFF) and composite-extrusion modeling (CEM), respectively. In both techniques, the feedstock is in fused state [112]. Lengauer et al [117] and Michael et al [141] have reported the fabrication of (Ti(C,N), WC,(Ta,Nb)C, Cr3C2)-Co, Ni cermet by FFF method and WC-Co by CEM process. Although, the microstructure obtained was reported to have a high level of similarity to that of conventionally fabricated parts, however, the full density could not be attained. Besides, the surface topography was reported to be rough with a high level of porosity between the deposited layers. These were attributed to the lack of process parameter optimisation [112].

4.7 3D Gel Printing (3DGP) technique

Zhang et al [118] have reported the fabrication of cermets (density: 99.93 %) through solid loading by 3DGP. Moreover, it was reported that the lower the extent of solid loading, the higher is the amount of solvent and organic binder in 3DGP samples [118]. The high content of both the solvent and organic binder has been reported to lead to the formation of a high level of porosity in samples during debinding and sintering [118]. Increasing the extent of solid loading has been reported to improve the hardness and transverse rupture strength of sintered 3DGP specimens [118]. However, surface treatment methods (such as polishing and finishing) are necessitated to fulfill the requirements of the part for real-life applications [112].

Table 4 summarises the starting materials and working principles of different AM-based techniques. But, table 5 shows the power source along with strengths and weaknesses of different AM techniques for the fabrication of ceramics and cermets.

5 Future perspectives and outlooks

5.1 From the viewpoint of fabrication techniques

It appears that there currently exist a number of limitations on the practical applications of AM based ceramics, which mainly includes the lack of microstructural quality control with the fabricated ceramic and cermet parts. Besides, a number of defects, particularly ranging from 2-D (surface) defects (such as grain boundaries, interphase boundaries, etc.) to various 3D (volume) defects (mainly, porosity) are associated with AM based ceramic and cermet parts 147, 148, which require extensive microstructural investigations to be overcome. Moreover, the intrinsic staircase effect associated with AM techniques leads to notch sensitivity issues of final ceramic and even cermet parts 147. Besides, the need for post-processing techniques (debinding and sintering), as discussed in the previous sections, signifies that a lot of challenges associated with complex geometry designs for traditional ceramic and cermet manufacturing are also applicable for ceramics and cermets fabricated using AM based techniques, which primarily include the limitation of thickness of the final part and distortion associated with debinding/sintering.

In the context of indirect (multi-step) AM processes, making use of a binder material, the time-consuming debinding (binder removal) step, renders these processes as unsuitable for a rapid production of ceramics. Although direct (single step) AM processes (Powder bed fusion and Directed energy deposition) do not have this limitation, but however suffer from non-versatility, in terms of producing ceramic parts, unlike that of indirect AM processes [22].

Moreover, during powder bed AM approach, ceramic powder particles tend to exhibit lower flowability [144]. On the other hand, the major problem associated with powder suspension feedstock based AM techniques is the limitation in terms of the content of the ceramic solid, limiting the maximum achievable density of the finished ceramic parts and hence, necessitating optimisation of different process parameters in sintering strategies such as liquid phase sintering (LPS) and Hot Isostatic Pressing (HIP) [145, 146].

Although, a number of reviews on AM of ceramics and cermets have mentioned about the key factors required for the fabrication of the ceramic pastes during extrusion based shaping processes [144, 146], however the flow of viscous ceramic pastes needs be modeled, in order to prevent cracking in final parts [145]. Moreover, a textured microstructure may be obtained due to flow-induced alignment of ceramic particles during material extrusion processes [145], necessitating the viscous ceramic paste to be free of large aggregates. In addition, during debinding of green ceramic parts made of powder injection molding (PIM), broad temperature range of binder decomposition leading to an easy escape of the evaporated gas phase from the binder has been reported to minimise the extent of cracking in the debinded parts [118, 144]. In this regard, slow decomposition of the binder has also been reported to be beneficial for retention of the final part shape [145]. However, the development of new binder and slurry systems for AM based ceramics and cermets is an avenue which is presently unexplored and offers huge potential for future investigations.

5.2 From the viewpoint of fundamental research

Although there have been a number of investigations aimed at optimisation of different processing parameters in AM based manufacturing of ceramics and cermets [1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24], however, there still remains a limited understanding on the influence of different processing parameters on the microstructural evolution which is critical to address the major challenges, particularly, (i) low density and (ii) poor mechanical properties which act as major obstacles to a large scale application of these materials in different sectors, such as defence, aerospace, electronics, healthcare etc. Poor mechanical properties in AM-based ceramics and cermet components primarily arise due to microstructural heterogeneities [22]. The microstructural heterogeneities mainly arise due to non-equilibrium processing involved in AM-based techniques [22] . Recently, Liu et al [147] have reported the microstructural evolution of Al2O3/GdAlO3/ZrO2 ternary eutectic ceramics using the SLM technique. It has been reported that there is a transition from “Chinese-script” to lamellar and to rod-like eutectic structure and from lamellar to rod-like eutectic structure in a single melt pool due to variations in eutectic growth behavior and volume fraction of constituent phases (figure 12) [147]. The evolution of the “Chinese-script” morphology of the ternary eutectic has been attributed to a high undercooling and solidification rate associated with SLM [147].

(a) Morphological transitions in the microstructure of SLM-based Al2O3/GAP/ZrO2 eutectic ceramic, (b) transition from “Chinese-script” to rod-like eutectic morphology, (c) transition from “Chinese script” to lamellar eutectic morphology and (d) transition from lamellar eutectic structure to rod-like eutectic morphology. GAP abbreviates for Al2O3/GdAlO3 eutectic phase [147] .

Moreover, an increase in the solidification rate (from the surface to the bottom of the melt pool) has been reported to decrease interphase spacing and an increase in Vickers microhardness and fracture toughness. This has been attributed to extensive crack propagation at the top of the melt pool and cracks bridging and arrest at Al2O3/GdAlO3 (GAP) eutectic phase at the bottom of the melt pool. As shown in figures 13(a-d), there is no apparent cracking or porosity on the surface or in the interior of the sample other than the quenching zone [147]. Besides, figures 13(b and c) show a well-developed bond between the substrate and the solidified layer. The absence of cracks in the Al2O3/GdAlO3/ZrO2 ceramic has been attributed to sufficient energy input by the laser, spherical powders, and high-temperature preheating in an oxygen-free atmosphere. Figure 13(b) also shows that the solid-liquid interface shows a non-planar shape at the macroscopic level, leading to a modification in the eutectic morphology of GAP. Based on Triantafyllidis’ Model 151, pores are formed due to the trapping of air bubbles at the solidification interface front in the quenching zone. High cooling rates caused an abrupt turning off of the laser beam leads to higher solidification interface velocity than bubble velocity, as shown in figures 13 (a-d). Figure 14 shows the microstructural evolution at different distances along with the melt pool. Figure 15 illustrates the microstructural features along the edge and vertical center direction of the melt pool (as marked in figures 13(b and c)). It is observed that there is a parallel growth of the microstructure perpendicular to the melt pool boundary (figures 15(a-c)). As shown in figures 15(d-f), there is a decrease in the angle between the growth direction and laser scanning direction from the bottom to the top of the melt pool. Similar observations have also been reported by Cao et al [149] and Larrea et al [150].

(a) As-solidified Al2O3/GAP/ZrO2 eutectic sample, (b) Transverse section, (c) Longitudinal section, and (d) Molten pool [147].

SEM images at different regions of the melt pool: (a and b) bottom-zone, (c and d) middle zone, and (e and f) top-zone [147].

SEM images showing microstructure growth directions at different regions of the melt pool: (a) left boundary, (b) bottom boundary, (c) right boundary, (d) bottom zone, (e) middle zone, (f) top zone [147].

Guessasma et al [151, 152] have reported that the discontinuity associated with layer-by-layer deposition technique in AM gives rise to a number of limitations in AM components such as mechanical anisotropy, poor interfacial cohesion between deposited layers, and porous microstructures. All the aforementioned limitations promote cracking between deposited layers and hence, degrade the overall mechanical performance of the AM components 155. More particularly, during tensile deformation, the pores act as sites of local stress concentration leading to the initiation of micro-cracks [152]. Most of the engineering applications dealing with ceramics and cermets utilize their high compressive strengths. Under compressive loads, although porosities may undergo closure, however, lateral expansion may lead to shear-induced failure of the AM-based components [152]. Besides, microstructural heterogeneities associated with AM-based parts have been reported to promote shear-induced failure during compressive deformation of AM-based components [152]. Additionally, the difference between real and virtual design (CAD-based) of AM components may lead to detrimental consequences (during component fabrication) [147, 148]. For instance, during DED (discussed in section 2.3), the major limitation is that may not be captured the internal features of a component accurately during CAD-based virtual design [149]. This may lead to the rough surface finish of the final component [150]. Besides, the other drawback of AM-based methods is the trapping of the support material between internal surfaces during layered deposition (in AM-based methods) [147]. This has been reported to degrade the load-bearing capacity of AM-based components [151, 152]. However, this problem is more significant in the case of metallic components manufactured using AM-based techniques.

Although a number of ways for minimisation of cracking and enhancement of density (of the final part) along with mechanical properties of AM based ceramics have been devised [22], however, these post-processing techniques have failed to render these materials as suitable candidates for high performance applications in the aforementioned sectors, unlike that of conventionally fabricated ceramic parts. This necessitates an understanding of microstructures in AM-based ceramic and cermet parts through a systematic structure-property correlation using extensive structural cum chemical characterisation techniques.

Liu et al [153] have studied the influence of scanning speed (of laser) on the solidification of Al2O3/GdAlO3/ZrO2 ternary eutectic ceramics during SLM. It has been reported that a scanning speed of ~ 12 mm/min reduced the volume fraction of solidification defects such as cracks and pores (figure 16) [153]. Besides, the relative density of the aforementioned ternary eutectic decrease from ~98.7 to ~95.4%, with an increase in scanning speed to 48 mm/min [153].

SLM-based Al2O3/GAP/ZrO2 ternary eutectic samples under different laser scanning speeds: (a) 6 mm/min, (b) 12 mm/min, (c) 18 mm/min, (d) 24 mm/min, (e) 30 mm/min, and (f) 48 mm/min [153].

Eutectic spacing (in the top zone of the molten pool) has also been reported to decrease initially with increasing laser scanning speed from 6 mm/min to 12 mm/min and then undergo a subsequent increase with increasing scanning speed till 48 mm/min [153] (figure 17). This has been attributed to the dominance of laser scanning speed as a significant influencing factor during solidification for SLM. Liu et al [154] have reported the influence of high-temperature (~1500-2500°C) preheating on the SLM of YSZ. It has been reported that with increasing preheating temperature from 1500 to 2500°C, there is a modification of crack morphology of YSZ [154]. Vertical cracks, in particular, have been reported to undergo shortening, which prevents their coalescence leading to restricted propagation (between the adjacent layers) along the same scanning direction (of the laser during SLM) (figure18) [154].

SEM-based images at different zones of the melt pool with various laser scanning speeds (during SLM): (a1) - (a2) 6 mm/min, (b1) - (b2) 12 mm/min, and (c1) - (c2) 48 mm/min, where 1 and 2 represent the bottom and the top zones (of the melt pool), respectively [153].

Influence of different preheating temperatures on the microstructure of SLM-processed YSZ: (a and b) 1500°C, (c and d) 2000°C, and (e and f) 2500°C [154].

Recently, Liu et al [155] have reported the synthesis of Al2O3/GdAlO3/ZrO2 ternary eutectic ceramics using laser directed energy deposition (LDED) technique. The microstructure was reported to comprise periodic banded structures (figure 19), and this was attributed to abnormal coarsening occurring close to the melt pool. Figures 19 (a and b) show the and microstructure at low and high magnifications, respectively. Based on partial remelting using a CO2 laser, it has been reported that microstructural coarsening zone (MCZ) exists only in regions where a fine initial (the term “initial” refers to the state before laser remelting) eutectic structure is present (figures 19(c and d)) [155]. However, there is no MCZ in regions where a coarse initial eutectic structure is present (figures 19(e and f)) [155]. The formation of MCZ has been attributed to the microstructural coarsening behavior observed during fabrication. An initially fine eutectic structure tends to undergo coarsening to minimizing its interfacial energy [155]. In this context, the finer the initial eutectic structure, the higher is the driving force for coarsening. Based on the aforementioned study [155], it has been proposed that during solidification of the melt pool (during LDED), there is nucleation and growth of crystals leading to a branched microstructure in the upper boundary of the MCZ. Fan et al [156] have reported the presence of a periodically banded microstructure of nanostructured Al2O3-YAG-ZrO2 (AYZ) ternary eutectic ceramic fabricated using laser engineered net shaping (LENS). It has been reported that in each solidified layer, there is a microstructural transition from planar to cellular morphology along the building direction (BD) [156]. The characteristic dimensions achieved during microstructural evolution have been reported to possess an excellent correlation with the Jackson-Hunt relationship [156]. Figure 20 shows Transmission Kikuchi Diffraction (TKD)-based inverse pole Figure (IPF) maps and the corresponding pole Figures of Al2O3, YAG, and ZrO2 phases. An electron transparent lamella extracted from a cellular region in the central portion of the AYZ eutectic using Focussed Ion Beam (FIB)-based lift-out technique. Figure 21 shows high-resolution transmission electron microscopy (HRTEM) image of a triple junction (TJ) between Al2O3, YAG, and ZrO2 phases along the transverse section and the corresponding Fast Fourier Transform (FFT)-based diffraction pattern in LENSed AYZ eutectic ceramic. Both figures 20 and 21 suggest that an orientation relationship (OR) of <0001>Al2O3 || <001>YAG || <001>ZrO2 at the interior of LENSed eutectic region along BD, but there is a deviation (deviation of (200)YAG ~3° with respect to (11-20) Al2O3 and (002)ZrO2) in the aforementioned OR due to a transition from planar to cellular morphology of the LENSed AYZ eutectic (from center to edge of the specimen) [156]. In addition, ffigure 20 also shows that there is a strong coherence at TJ between Al2O3, YAG, and ZrO2 phases. Both Al2O3/ZrO2 and YAG/ZrO2 interfaces have been reported to possess a lower extent of lattice disregistry as compared to that of the Al2O3/YAG interface [157,158,159], suggesting that the dispersion of the ZrO2 phase must contribute to the atomic matching in the LENSed AYZ specimen. Figure 22 shows the TKD-based analysis of a longitudinal section of LENSed AYZ specimen extracted using the FIB-based lift-out technique in SEM. Figure 22 indicates that the primary growth direction of the cellular microstructure in LENSed AYZ eutectic ceramic is <0001>Al2O3 || <001>YAG || <001>ZrO2. The LENSed eutectic specimen has been reported to exhibit nearly isotropic properties with Vickers microhardness and fracture toughness values of \( \sim 18.9~ \pm ~0.96{\text{ GPa and }}3.84~ \pm ~0.44{\text{ MPa}}\;{\text{m}}^{{{\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 2}}\right.\kern-\nulldelimiterspace} \!\lower0.7ex\hbox{$2$}}}} \), respectively along the longitudinal section and \( \sim \;{\text{18}}.{\text{73}} \pm 0.{\text{94}}\;{\text{GPa and 3}}.{\text{53}} \pm 0.{\text{32}}\;{\text{MPa}}\;{\text{m}}^{{{\text{1}}/{\text{2}}}} \), respectively along the transverse section. These values were almost comparable with those of the AYZ eutectic ceramics fabricated using conventional techniques [156]. Table 6 shows typical ceramics (both structural and functional) and cermets manufactured using different AM-based techniques.

(a and b) The as-synthesized LDED-processed Al2O3/GdAlO3/ZrO2 eutectic sample, (c and d) the partial-laser-remelted eutectic sample with a fine initial eutectic structure, and (e and f) partial-laser-remelted eutectic sample with a coarse initial eutectic structure [155]. The term “initial” refers to the state before laser remelting.

(a) Field-Emission (FE)-SEM image of the electron transparent lamella of a transverse section of the LENSed AYZ sample prepared using FIB-based lift-out technique in SEM, (b) TKD analysis of the region inside cellular eutectic (indicated using a red-dotted square in part (a)); (c, d, and e) TKD-based IPF maps of Al2O3, YAG and ZrO2 phases respectively, and (f) pole Figures of Al2O3, YAG and ZrO2 phases corresponding to (c), (d) and (e), respectively [156].

(a) HRTEM image of the transverse section in LENSed AYZ eutectic showing a triple junction between Al2O3, YAG, and ZrO2 phases, and (b) Corresponding FFT diffraction pattern with zone axis: [0001] Al2O3 || [001] YAG || [001]ZrO2 [156].

TKD analysis of the electron transparent lamella extracted from the longitudinal section of the LENSed AYZ specimen using FIB-based lift-out technique in SEM: (a) FE-SEM image, and (b) TKD-based pole Figures of Al2O3, YAG, and ZrO2 phases based on multiple scanning in the intercellular region highlighted using black dotted rectangle in part (a) [156].

As discussed earlier, the onset of “Correlative Microscopy” involving both structural and chemical characterisation from the same region in the microstructure [25,26,27,28,29,30], in recent times, has provided a major breakthrough in understanding a number of different properties in different metallic materials [25,26,27,28,29,30]. However, at present, there is hardly any report on understanding the mechanical properties of AM-based ceramic and cermet parts using the aforementioned approach. In this regard, it becomes highly essential to mention about the role of different 2D interfaces in influencing the mechanical properties of these materials. The simplest of the 2D interfaces in crystalline ceramics (and even cermets) are grain boundaries (GBs) and interphase boundaries (IBs) (for multiphase materials). In the context of metallic materials, during plastic deformation, stress concentration at GBs and IBs (both mechanically “weaker” as compared to the lattice) leads to intergranular fracture [157,158,159,160,161,162,163,164,165,166,167]. This is the most common mode of failure in metallic materials during service [151, 164]. Moreover, in the context of metallic materials, it has been reported that by controlling the fraction of different GBs in the microstructure (also reported as “GB engineering” (GBE) in many literatures), it is possible to engineer mechanical properties [164,165,166,167,168,169,170,171,172,173,174,175,176,177,178,179,180,181,182,183,184,185,186,187,188]. However, for AM-based crystalline ceramics and cermets with low-symmetry crystal structures, the structure of GBs and IBs tends to be much more complex as compared to those in metallic materials which mainly comprise of high-symmetry crystal structures [156]. This has been the main reason as to why there is hardly any report on GBE of AM-based ceramics and cermets.

Thus, in addition to optimisation of different processing parameters, “Correlative microscopy” approach may be utilised for a systematic structure-property correlation combined with tailoring of microstructures in these materials based on GBE, in order to overcome the problem of poor mechanical properties in AM-based ceramics and cermets. Moreover, this avenue is presently unexplored and hence, offers a great potential for future investigations.

5.3 From the authors’ viewpoint

As rightly highlighted by Zocca et al [144], AM-based techniques enable the fabrication of porous ceramic parts with complex geometries with a high level of accuracy, which is not achievable by any present traditional fabrication technique. However, the AM-based techniques suitable for fabricating fine porous ceramic components face a major challenge in bulk scale. Similarly, the AM-based techniques face difficulties for fabricating dense and bulk components [156,157,158,159,160,161,162,163,164,165, 172, 173]. Moreover, there are very few commercially available AM-based techniques for the fabrication of fully dense monolithic ceramic parts [144]. This still remains a major scientific challenge and needs to be addressed in order to promote AM of ceramics for large-scale industrial applications. As discussed earlier (in sections 5.1 and 5.2), the other challenges associated with AM of ceramics include high processing costs (even for small-scale production), complex machining, and low flexibility. Besides, many of the challenges involved with AM of ceramics are also associated with the traditional ceramic fabrication techniques.

The aforementioned practice in the field of AM-based ceramic research may solve most of the processing-based challenges for structural and functional ceramics and even cermets. However, the other major obstacle is the limited interaction between the industry and academia in the above context. This mainly leads to challenges in terms of material properties during upscaling of AM-based ceramic parts from laboratory to industrial scale and even during the downscaling of dense and bulk AM-based ceramic parts to laboratory-scale prototypes. Therefore, both industry and academia must make a combined effort (of multidisciplinary nature) towards a systematic understanding of the structure-property correlation to solve the challenge mentioned earlier. This is one of the areas where the correlative methodology of material characterization (ranging from bulk to atomic scale) may be employed as a potential tool to obtain both structural and chemical information.

The same region in a given microstructure (as extensively discussed in section 5.2), thereby enabling one to explore different microstructural defects (evolved during AM) in extensive details and new perspectives. However, the primary challenges in the avenue of correlative characterization are the requirement of high-end characterization techniques and the expertise to capture the required micrstructural features. Besides, the other challenge associated with the aforementioned characterization methodology is the lack of repeatability associated with the visualization of nanoscale features throughout the entire microstructure. This is especially significant for AM-based components (metallic materials, ceramics, and polymers) in which the non-equilibrium processing conditions (during AM) lead to large-scale microstructural heterogeneities.

Unlike AM of ceramics, AM of metals (a more mature technology at present) suffers from the limitation in terms of availability of raw materials for feedstock production [144, 155]. Ceramic powders for almost all-ceramic systems are commercially available. The molds used for forming ceramic parts are highly expensive. They require a large number (of the order of a few thousand) of components to be fabricated before becoming cost‐effective [144]. However, the market demands only a single piece with the size (of a lot) typically varying between 10 and 20 parts [155], which necessitates CAD/CAM processing followed by the machining of green components (ceramic components) [152]. Despite the emergence of a large number of AM-based techniques for the fabrication of ceramics and cermets, the main problem (at present) lies in the coupling of a specific AM-based technique with a proper feedstock formulation for the purpose of enabling the fabrication of dense ceramic components with optimal properties (mechanical strength, surface finish, etc.).

Powder-based AM techniques have a much higher potential for extensive applications in the immediate future when compared to the other AM-based techniques using solid-sheet, paste, or liquid as starting materials [155, 156] (shown in table 4). They are owing to the low processing cost coupled with easy scalability (to bulk and dense components) and parallel processing of multiple components. However, the major challenge with powder-based AM techniques that still remains to be solved is the low packing density and stability of dry powders for dry powders (used as feedstock), which necessitates support structures. Zocca et al [144] have proposed replacing dry powders with ceramic slurries (with ceramic powder sizes ranging from <100 nm to > 100 nm) as a solution to the problem as mentioned above. Besides, the above solution (proposed in Ref. [144]) is already in use in the SLS technique. Hence, in the near future, the SLS technique is the only AM technique that may be expected to dominate global ceramic markets. On the other hand, based on the report of Qian and Shen [174], Laser sintering as an AM-based fabrication technique is suitable for rapid prototyping and the synthesis of a wide range of materials (including metallic materials, plastics, and ceramics). However, in plastics and metallic materials, Laser sintering is a more mature technology than that for ceramics. At present, a number of Laser sintering techniques are commercially for the construction of complex 3D components. Laser sintering techniques offer a number of advantages, including fabrication of ceramics with non-equilibrium phases with hierarchically structured heterogeneities (not achievable by any conventional sintering technique) [174]. Besides, these techniques enable the sintering of very high-melting ceramics (including transition metal boride-based UHTCs). At present, minimization of residual thermal stresses during Laser sintering in ceramics is a major scientific challenge. Besides, attaining extremely low dimensional tolerances for fabricating micrometer-scale components is another significant challenge in the context of Laser sintering of ceramics. These two aforementioned challenges need to be extensively addressed to render Laser sintering techniques suitable for large-scale industrial production of complex ceramic components. At present, large-scale commercial use of AM-based techniques for ceramic fabrication remains a major challenge. The solutions (proposed recently) towards the fabrication of dense monolithic ceramic parts [22, 35,36,37,38,39,40, 172,173,174,175, 189,190,191,192,193,194,195,196,197] are most likely to deviate from the powder processing techniques followed by the traditional ceramic fabrication techniques.

6 Conclusions

There remains absolutely no doubt that AM based techniques for fabrication of ceramics and cermets are likely to benefit from close collaborative research between the academia and industry. However, optimisation in processing parameters coupled with a proper understanding of structure-property correlation in AM based ceramic parts, is crucial for a complete utilisation of the enormous potential (both in terms of academic and industrial research) offered by these materials and aiming towards their mass production.

References

Conrad H J, Seong W J and Pesun I J 2007 Current ceramic materials and systems with clinical recommendations: a systematic review. J. Prosthet. Dent. 98: 389–404

Blatz M B, Sadan A and Kern M 2003 Resin-ceramic bonding: a review of the literature. J. Prosthet. Dent. 89: 268–274

Kingery W D 1955 Factors affecting thermal stress resistance of ceramic materials. J. Am. Ceram. Soc. 38: 3–15

Cao X Q, Vassen R and Stoever D 2004 Ceramic materials for thermal barrier coatings. J. Eur. Ceram. Soc. 24: 1–10

De Aza A H, Chevalier J, Fantozzi G, Schehl M and Torrecillas R 2002 Crack growth resistance of alumina, zirconia and zirconia toughened alumina ceramics for joint prostheses. Biomaterials. 23: 937–945

Akhtar F, Rehman Y and Bergström L 2010 A study of the sintering of diatomaceous earth to produce porous ceramic monoliths with bimodal porosity and high strength. Powder Technol. 201: 253–257

Wu J M, Lu W Z, Lei W, He J P and Wang J 2011 Effects of aqueous gel-casting and dry pressing on the sinterability and microwave dielectric properties of ZnAl2O4-based ceramics. Ceramics Int. 37: 481–486

Wu J M, Lu W Z, Wang X H, Fu P, Ni M, Yang J L, Wang C and Zeng Q C 2013 Ba0.6Sr0.4TiO3-MgO ceramics from ceramic powders prepared by improved aqueous gel casting-assisted solid-state method. J. Eur. Ceram. Soc. 33: 2519–2527

Chen A N, Wu J M, Liu M Y, Cheng L J, Chen J Y, Xiao H, Zhang X Y, Li C H and Shi Y S 2017 Rapid in-situ solidification of SiO2 suspension by direct coagulation casting via controlled release of high valence counter ions from calcium iodate and pH shift. Ceram. Int. 43: 1930–1936

Sebastian M T, Ubic R and Jantunen H 2015 Low-loss dielectric ceramic materials and their properties. Int. Mater. Rev. 60: 392–412

Zhang X and Zhao L D 2015 Thermoelectric materials: energy conversion between heat and electricity. J. Materiomic. 1: 92–105

Simonenko E P, Sevast’yanov D V, Simonenko N P, Sevast’yanov V G and Kuznetsov N T 2013 Promising ultra-high-temperature ceramic materials for aerospace applications. Russ. J. Inorg. Chem. 58: 1669–1693

Baklouti S, Bouaziz J, Chartier T and Baumard J F 2001 Binder burnout and evolution of the mechanical strength of dry- pressed ceramics containing poly(vinyl alcohol). J. Eur. Ceram. Soc. 21: 1087–1092

Trunec M, Klimke J and Shen Z J 2016 Transparent alumina ceramics densified by a combinational approach of spark plasma sintering and hot isostatic pressing. J. Eur. Ceram. Soc. 36: 4333–4337

Jabbari M, Bulatova R and Tok A I Y, Bahl C R H, Mitsoulis E, Hattel J H 2016 Ceramic tape casting: a review of current methods and trends with emphasis on rheological behaviour and flow analysis. Mater. Sci. Eng. B. 212: 39–61

Beaman J J and Deckard C R 1990 Selective laser sintering with assisted powder handling. United States patent 4(938): 816

Wu Y, Du J, Choy K L and Hench L L 2007 Laser densification of alumina powder beds generated using aerosol assisted spray deposition. J. Eur. Ceram. Soc. 27: 4727–4735

Wu Y, Du J, Choy K L and Hench L L 2007 Fabrication of titanium dioxide ceramics by laser sintering green layers prepared via aerosol assisted spray deposition. Mater. Sci. Eng. A. 454–455: 148–155

Zhu W, Yan C, Shi Y, Wen S, Liu J and Shi Y 2015 Investigation into mechanical and microstructural properties of polypropylene manufactured by selective laser sintering in comparison with injection molding counterparts. Mater. Des. 82: 37–45

Ma A, Roters F and Raabe D 2006 Studying the effect of grain boundaries in dislocation density based crystal plasticity finite element simulations. Int. J. Solids Struct. 43: 7287–7303

ISO/ASTM, 17296 standard on Additive Manufacturing (AM) Technologies

Deckers J, Vleugels J and Kruth J P 2004 Additive Manufacturing of Ceramics: A Review. J. Ceram. Sci. Tech., pp. 1-51

Kruth J P, Levy G, Klocke F and Childs T H C 2007 Consolidation phenomena in laser and powder-bed based layered manufacturing. Annals of the CIRP. 56: 730–759

Mahale T H 2009 Electron Beam Melting of advanced materials and structures. PhD thesis, North Carolina State University

Raabe D, Ponge D, Dmitrieva O and Sander B 2009 Nano-precipitate hardened 1.5 GPa steels with unexpected high ductility. Scr. Mater. 60: 1141–1144

Herbig M, Raabe D, Li Y J, Choi P, Zaefferer S and Goto S 2014 Atomic-scale quantification of grain boundary segregation in nanocrystalline material. Phys. Rev. Lett. 112: 126103

Lejcek P 2010 Grain boundary segregation in metals. Springer Verlag, Berlin, Heidelberg

Felfer P J, Alam T, Ringer S P and Cairney J M 2012 A reproducible method for damage- free site-specific preparation of atom probe tips from interfaces. Microsc. Res. Techniq. 75: 484–491

Toji Y, Matsuda H, Herbig M, Choi P P and Raabe D 2014 Atomic-scale analysis of carbon partitioning between martensite and austenite by atom probe tomography and correlative transmission electron microscopy. Acta Mater. 65: 215–228

Gault B, Moody M P, Cairney J M and Ringer S P 2012 Atom probe crystallography. Mater. Today. 15: 378–386

Williams C B 2008 Design and development of a layer-based Additive Manufacturing process for the realization of metal parts of designed mesostructured. PhD thesis, Georgia Institute of Technology

Sirringhaus H and Shimoda T 2003 Inkjet Printing of functional materials. Mater. Res. Soc. Bull. Inkjet Print. Func. Mater. 28: 802–806

Ebert J, Özkol E, Zeichner A, Uibel K, Weiss Ö, Koops U, Telle R and Fischer H 2009 Direct Inkjet Printing of dental prostheses made of zirconia. J. Dent. Res. 88: 673–676

Özkol E, Wätjen M, Bermejo R, Deluca M, Ebert J, Danzer R and Telle R 2010 Mechanical characterisation of miniaturised direct inkjet printed 3Y-TZP specimens for microelectronic applications. J. Eur. Ceram. Soc. 30: 3145–3152

Hon K K B, Li L and Hutchings I M 2008 Direct writing technology - advantages and developments. CIRP Ann. Manuf. Technol. 57: 601–620

Sukeshini M, Meisenkothen F, Gardner P and Reitz T L 2013 Aerosol Jet Printing of functionally graded SOFC anode interlayer and microstructural investigation by low voltage Scanning Electron Microscopy. J. Power Sourc. 224: 295–303

Grida I and Evans J R G 2003 Extrusion freeforming of ceramics through fine nozzles. J. Eur. Ceram. Soc. 23: 629–635

Yardimci M A and Güçeri S 1996 Conceptual framework for the thermal process modelling of fused deposition. Rapid Prototyp. J. 2: 26–31

Venkataraman N, Rangarajan S, Matthewson M J, Harper B, Safari A, Danforth S C, Wu G, Langrana N, Guceri S and Yardimci A 2000 Feedstock material property—process relationships in Fused Deposition of Ceramics (FDC). Rapid Prototyp. J. 6: 244–253

Miranda P, Siaz E, Gryn K and Tomsia A P 2006 Sintering and Robocasting of beta-tricalcium phosphate scaffolds for orthopaedic applications. Acta Biomaterialia 2: 457–466