Abstract

MgB2 bulk sample with porous structure was produced by using the in-situ solid-state reaction method under argon (Ar) atmosphere of 10 bar. Elemental Er in powder form was doped into MgB2 with different compositions (Mg 1−x Er x )B2, where x=0.00, 0.03 and 0.05, in order to investigate the effect of rare-earth (RE) element Er on the structural and electromagnetic properties of porous MgB2. The Er-doped samples result in small grain size structure compared to the undoped one. The lattice constants a and c of the doped samples, determined from X-ray diffraction (XRD) analysis, increase with the increasing Er content, and consequently the superconducting transition temperature (Tconset) of MgB2, determined from resistivity measurements, is slightly suppressed. Also, the upper critical field (B c2), the irreversibility field (B irr) and the critical current density (J c) values are significantly enhanced in the doped samples. For the best sample (x=0.03), at 15 K under a magnetic field of 4 T, the J c value reaches 2.4 ×104 A cm−2, which is higher than that of the porous sample by an order of 103, and the B irr value at 20 K reaches 9.7 T. These results imply that the RE element Er fills the pores, enhances the density and the grain connectivity. Hence, the superconducting properties of the porous MgB2 sample improve by Er doping.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The discovery of superconductivity in MgB2[1] has stimulated great scientific and technological interest, not only because of its simple electronic structure and high critical temperature (T c),[1] but also due to its high critical current density (J c),[2]large coherence length[3] and the absence of weak-link effect.[4]

It is well known that the rapid drop in J c with the increasing applied magnetic field is one of the major problems for MgB2-based superconductor technologies. A rapid drop in J c indicates low irreversibility field (B irr) and poor pinning ability due to a lack of effective pinning centres in MgB 2. The density also has an important effect on the superconducting performance of MgB2. It is well known that the high occupation fraction of pores in sintered MgB 2 bulk samples decreases the density and the effective cross-section area for carrying current.[5] If the porosity can be decreased and the density can be increased, the critical current density of MgB 2 will be increased significantly. It is well known that the resistivity of dense MgB2 is smaller than that of porous one.[6] Also, the J c (H=0) of MgB 2 is inversely proportional to Δρ (Δρ=ρ(300 K)−ρ(50 K)). This follows because the ratio of Δρ in fully dense and clean MgB2 to Δρ in MgB2 sample is a measure of the reduction in current-carrying area.[7]

It is possible to improve the pinning behaviour of MgB 2 by many methods, such as adding or doping[8,9]and the introduction of defects by irradiation,[10] etc. Chemical doping is known to be one of the most effective methods in improving the superconducting properties of MgB 2. Doping can substitute dopant atoms for atoms in MgB 2 crystal lattice to increase the upper critical field (B c2) and induce defects and precipitates to increase flux pinning centres of MgB2.[9,11]However, the results of chemical doping are categorized into two types, as reported by Zhao et al:[12] the doping which leads to the decrease of T c and the loss of superconductivity, such as doping of Al,[13] and the other doping which cannot dope the element in the MgB 2 crystal lattice and has no effect on T c, such as Be doping.[14] The second type of doping creates non-superconducting phases, which may work as pinning centres if a proper microstructure of the second phases can be formed in MgB 2. It has been reported by Feng et al[15] and Zhao et al[12] that doping of MgB 2 with Zr and Ti, respectively, increases the sample density, reduces the porosity and increases the J c values.

Magnetic impurities usually have a stronger interaction with magnetic flux lines than non-magnetic impurities. If the impurities can be properly introduced into the MgB 2 matrix, they may exert a stronger force to trap the flux lines and improve the pinning behaviour of MgB 2. The magnetic doping elements, such as Mn, Fe, Co and Ni, which can depair Cooper pairs, often degrade the superconducting performance of MgB 2 in a magnetic field due to the presence of a local magnetic field.[16–18]On the other hand, rare-earth (RE) elements often possess a strong magnetic moment, however, they do not suppress the superconductivity of MgB2.[19–21]When RE oxides and elements are doped into MgB2, they form impurity phases with boron, which can act as effective pinning centres in MgB2. The main resultants are REB6 for light REs (La, Ce, Pr, Nd, Sm, Eu, Gd) and REB4 for heavy RE elements (Tb, Dy, Ho, Er). Also the density of the doped samples increases compared with the undoped one.[22] Doping with RE oxides Pr6 O 11 and Eu2 O 3 provides strong flux pinning due to the PrB 6 and EuB6 impurity phases and increases J c(H), H c2 and H irr of MgB 2. J c values at 10 K under a field of 5 T for undoped (x=0.00), Pr6 O 11-doped (x=0.03) and Eu2 O 3-doped (x=0.05) MgB2 samples have been found to be 2.21 × 103, 1.15 × 104 and 1.10 × 104 A cm−2, respectively.[23] In total 0.1–10% Ho2 O 3-doped MgB2 samples show no change in its crystal structure, T c and H c2, but exhibit significant enhancement in J c and H irr.[24] A similar study of RE oxide-doped MgB2 samples, where RE oxides = La 2 O 3, Nd2 O 3, Tb4 O 7, Er2 O 3, Lu2 O 3, has shown that the doping causes no change in T c and does not lead to a serious decrease in J c, despite the generation of larger amounts of impurity phases, such as RE borides and MgO.[22]

In the literature, there are very few studies on the doping effects of RE elements on the superconductivity of MgB2. Therefore, more investigation needs to be done on doping MgB2 with RE elements to find possible options for improving the superconducting performance of this compound. In this work, the doping effects of Er on the superconducting properties of porous MgB2 have been studied.

2 Experimental

(Mg1−x Er x )B 2 samples with different stoichiometric ratios were prepared by the in-situ solid-state-reaction method. Commercially available high-purity powders of crystalline Mg (99.8%), Er (99.9%) and amorphous B (95–97%) were weighed to give a nominal composition of (Mg1−x Er x )B 2, where x = 0.00, 0.03 and 0.05. The mixtures of Mg, B and Er powders were thoroughly ground for 1 h in an agate mortar by hand in air. The mixtures, weighing about 2 g, were pressed into rectangular pellets 10 × 15 mm2 in size under 1.3 GPa pressure. The pellets were put in a chrome tube and sintered at 650∘C for 2 h under constant 10 bar Ar gas pressure. After the heat treatment, the chrome tube was cooled to room temperature by furnace cooling. Then, the second grinding process was performed.

Finally, the obtained powders were pressed into the same rectangular pellet form under 1.3 GPa pressure and sintered at 750 ∘C for 2 h under 10 bar Ar gas pressure, followed by furnace cooling to room temperature.

The phase compositions of the samples were determined from X-ray diffraction (XRD) patterns using a Rikagu D/Max-IIIC diffractometer with CuK α radiation, and the microstructures of the samples were analysed by a scanning electron microscope (SEM, JEOL JSM 6400). The upper critical field B c2 and the irreversibility field B irr were defined as B c2 = 0.9R(T c) and B irr = 0.1R(T c)[25]from the resistance (R) vs. temperature (T) curves (5 mA ac) obtained by a four-probe resistivity measurements. Also, the T c values were obtained from the resistivity curves of the samples. The magnetic properties (M–H loops) of the samples were determined using a vibrating sample magnetometre within the Quantum Design Physical Properties Measurement System for the temperature ranges from 4.2 to 35 K. The magnetic J c (in A cm −2) of the samples was calculated from the M(H) curves via J c = 20ΔM/[aV(1−a/3 b)] on the basis of Bean’s critical state model.[26] In this relationship, ΔM (in emu) is the width of the M(H) hysteresis. V (in cm 3), a (in cm) and b (in cm) are the volume, length and width of the sample (a<b), respectively.

3 Results and discussion

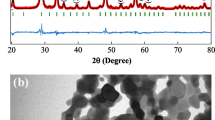

Figure 1 shows the XRD patterns of the (Mg1−x Er x )B 2 (x=0.00, 0.03 and 0.05) samples. It is very apparent from figure 1 that the undoped sample has the major phase of MgB2, with a little amount of MgO. Also, it can be seen that the boride impurities ErB4, ErB 2 and also an oxide phase Er2 O 3 have formed. As clearly seen from figure 1, the main peak belonging to MgB2 at around 42.4∘ has decreased in intensity and has broadened for the doped samples. It is an indication of reducing the crystallite size for the doped samples. Table 1 also shows the variation of the lattice parameters of all samples. The lattice parameters a and c of the porous undoped sample are smaller than that of the dense MgB2 reported in literature. The difference is possibly due to the porous structure of the undoped sample. It is well known that the lattice parameters of MgB2 decrease with the increasing porosity.[27] Both the lattice parameters a and c increase with the increasing Er concentration, as given in table 1. It is expected from these results that some Er atoms have partially substituted into MgB 2, possibly at Mg sites.

The SEM images show the porous structure (the black area) and the agglomeration of particles in the undoped sample (see figure 2a). The porous structure decreases and the homogeneity increases with Er doping (see figure 2b and c). Also, it can be seen that the MgB 2 grains are smaller for the doped samples compared to the undoped one. It leads to an increase in the surface area of grain boundaries, which act as pinning centres in MgB2.

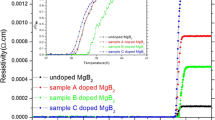

Figure 3 shows the normal state resistivity vs. temperature measured at different applied magnetic fields up to 10 T for all samples over a temperature range of 10–300 K. The inset shows the resistivity vs. temperature curves at the temperatures between 10 and 45 K. It can be seen that the scattering in the undoped porous MgB 2 sample decreases with the increasing Er content. The resistivity at 40 and 300 K decreases from extraordinarily high value of 613.86 and 1158.08 μΩ cm, respectively, for the porous MgB2, to 103.09 and 249.07 μΩ cm, respectively, for the 3 wt% Er-doped MgB2 sample. Such high resistivity of the undoped sample can be a result of the presence of pores between the superconducting grains. As known, dense MgB 2-based materials have a significantly lower resistivity.[6] Hence, the relatively lower resistivity may be related to higher sample density and better inter-granular connectivity. In a polycrystalline bulk sample produced by hot press method at 700 ∘C, the resistivity values are 2050 and 1560 μΩ cm at 300 and 50 K, respectively, as reported by Rogado et al[28] (the resistivity values have been taken from the small figures in Rogado et al[28]). Also, Sharma et al[29] have reported the T c value of the MgB2 sample, which was deliberately made with Mg deficiency, is to be around 39 K even as the resistivity at 300 K of the sample is above 100 m Ω cm. From these results, it can be said that the resistivity values of the doped and undoped samples are compatible with literature. The resistivity of 5 wt% Er-doped sample is higher than the resistivity of 3 wt% Er-doped sample. It is probably the result of the excess impurity phases. It can be seen from figure 3 that all samples show a sharp superconducting transition at around 38–39 K in zero field regime. However, the transition range becomes narrower for the doped samples. The \(T_{\mathrm {c}}^{\text {onset}} \) and the ΔT c values determined from figure 3 have been obtained to be 38.63, 38.49, 38.57 K and 1.97, 0.67, 0.89 K for 0, 3 and 5 wt% Er-doped samples, respectively (see table 1). The \(T_{\mathrm {c}}^{\text {onset}}\) value of the undoped sample is acceptable, because in some high resistivity MgB 2 samples, it has been reported that T c is surprisingly over 35 K.[30] Also, the minute suppression in \(T_{\mathrm {c}}^{\text {onset}}\) values supports the partial substitution of Er into MgB 2 lattice. The narrower transition to superconductivity for the doped samples implies the improvement in homogeneity and grain connectivity. The transition temperatures of all samples decrease as usual with the increasing applied field, as seen from figure 3.

The residual resistivity ratios RRR related with the intragrain effect of grain boundary junctions have been calculated from the resistivity measurements (RRR =ρ(300 K)/ ρ (40 K)). Also, the active area fractions (A F) related with intergrain effect, have been evaluated by using the formula A F=Δρ ideal/[ ρ(300 K) −ρ(40 K)]. Here, Δρ ideal is the ideal change in resistivity from 300 to 40 K for a fully connected sample, for which the value of 7.3 μΩ cm is typically used.[30,31]The residual resistivity ratios and the active area fractions for the undoped, 3 and 5 wt% Er-doped samples are 1.89, 2.42, 2.35 and 0.013, 0.050, 0.021, respectively, as shown in table 1. It is observed that the RRR and A F values are higher for the doped samples than that of the undoped one. It is well known that the relatively high values of RRR indicate good quality of the samples. The fact that RRR shows an increasing trend is possibly due to the decrement of the grain sizes and the substitution of Er in MgB2. The increase in A F of the doped samples signals decreasing porosity, improving grain boundary and a better connectivity.

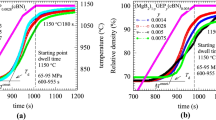

The temperature dependence of B c2 and B irr for all samples is shown in figure 4. The B irr and B c2 at various temperatures for the samples have been estimated from the resistive transition curves using the criteria of 0.1 and 0.9 of ρ(B,T c), respectively.[25] It is observed that the B c2 and B irr values are significantly enhanced for the doped samples. The best B c2 and B irr increments have been obtained for the 3 wt% Er-doped sample, because the slope of d B c2/d(T/T c) for the 3 wt% Er-doped sample is larger compared to those for both the undoped and the 5 wt% Er-doped samples. For the best sample (x=0.03) the B irr value at 20 K reaches 9.7 T. It can be expected that the improvement in B irr is because of the flux pinning induced by grain boundaries, which increase in the doped samples due to the suppression of grain growth. In addition, the reason of the increment in B c2 is probably the partial substitution of Er into MgB2 crystal lattice.

The J c characteristic of all samples have been estimated from the high field magnetization measurements M(H), by invoking Bean’s critical state model.[26] In this manner, the J c(B) results are plotted in figure 5 at the temperatures between 4.2 and 35 K. As seen from this figure, the J c of the doped samples are higher than that of the undoped one for all fields and at all temperatures. The values of J c at 4.2 K and under a field of 3 T have been calculated to be 2.2 ×103 A cm −2 for the undoped MgB 2 sample, 1.1 ×105 A cm−2 for 3 wt% Er-doped sample and 8.3×104 A cm−2 for 5 wt% Er-doped sample. The values of J c under a field of 3 T and at the temperatures of 4.2 and 15 K have been listed in table 1.

For the best sample (x = 0.03), at 15 K under a magnetic field of 4 T, the J c value reaches 2.4×104 A cm −2, which is higher than that of the undoped sample by an order of 10 3 (see figure 5). The J c values show clearly that the Er-doped samples exhibit better current-carrying capabilities under external magnetic fields. This is an indication of the enhancement in the flux pinning strength of the doped samples. The J c variation with the increasing Er content are compatible with the resistivity results (see table 1), as reported by Rowell[30] that an important implication of the high resistivity, if they are indeed due to limitations in the area of the sample that carries current, is that exactly the same limitations should apply to the sample area that carries supercurrent. It might be expected that the improvement in J c of the doped samples is related with the depression on the growth rate of MgB2 grains by Er doping and so, the increment in the surface area of the grain boundaries, which act as pinning centres in MgB2. Also, the impurity phases can act as effective pinning centres in the doped samples.

4 Conclusions

In this study, the effects of Er doping on the superconducting properties of porous MgB 2 have been systematically studied. The B c2, B irr and J c values are significantly enhanced for the doped samples, due to the degradation of porosity, the reduction in grain size and thus, the enhancement on grain connectivity and grain boundary pinning. Substantially enhanced B c2, B irr and J c values have been observed in the 3 wt% Er-doped sample. It can be concluded from this experimental study that the RE element Er is an excellent candidate as a doping source for improving the superconducting properties of MgB 2, without significantly affecting the T c of the material.

References

Nagamatsu J, Nakagawa N, Muranaka T, Zenitani Y and Akimitsu J 2001 Nature 410 63

Kim H J, Kang W N, Choi E M, Kim M S, Kim K H P and Lee S I 2001 Phys. Rev. Lett. 87 087002

Lyard L, Szabó P, Klein T, Marcus J, Marcenat C, Kim K H, Kang B W, Lee H S and Lee S I 2004 Phys. Rev. Lett. 92 057001

Larbalestier D C et al 2001 Nature 410 186

Liu C F, Yan G, Du S J, Xi W, Feng Y, Zhang P X, Wu X Z and Zhou L 2003 Physica C 386 603

Putti M, Braccini V, Galleani E, Napoli F, Pallecchi I, Siri A S, Manfrinetti P and Palenzona A 2003 Supercond. Sci. Technol. 16 188

Rowell J M, Xu S Y, Zeng X H, Pogrebnyakov A V, Li Q, Xi X X, Redwing J M, Tian W and Pan X 2003 Appl. Phys. Lett. 83 102

Li H L, Ruan K O, Li S Y, Yu Y, Wang C Y and Cao L Z 2003 Physica C 386 560

Yao C, Zhang X, Wang D, Gao Z, Wang L, Qi Y, Wang C, Ma Y, Awaji S and Watanabe K 2011 Supercond. Sci. Technol. 24 055016

Bugoslavsky Y, Cohen L F, Perkins G K, Polichetti M, Tate T J, Gwilliam R and Caplin A D 2001 Nature 411 561

Dou S X, Soltanian S, Horvat J, Wang X L, Zhou S H, Ionescu M, Liu H K, Munroe P and Tomsic M 2002 Appl. Phys. Lett. 81 3419

Zhao Y, Feng Y, Cheng C H, Zhou L, Wu Y, Machi T, Fudamoto Y, Koshizuka N and Murakami M 2001 Appl. Phys. Lett. 79 1154

Slusky J S et al 2001 Nature (London) 410 343

Felner I 2001 Physica C 353 11

Feng Y, Zhao Y, Sun Y P, Liu F C, Fu B Q, Zhou L, Cheng C H, Koshizuka N and Murakami M 2001 Appl. Phys. Lett. 79 3893

Kuhberger M and Gritzner G 2002 Physica C 370 39

Kitaguchi H and Kumakura H 2005 Supercond. Sci. Technol. 18 S284

Cheng C H, Zhao Y, Zhu X T, Nowotny J, Sorrell C C, Finlayson T and Zhang H 2003 Physica C 386 588

Wang J, Bugoslavsky Y, Berenov A, Cowey L, Caplin A D, Cohen L F, Cooley L D, Song X and Larbalestier D C 2002 Appl. Phys. Lett. 81 2026

Chen S K, Wei M and MacManus-Driscoll J L 2006 Appl. Phys. Lett. 88 192512

Pan X F, Shen T M, Li G, Cheng C H and Zhao Y 2007 Phys. Status Solidi (a) 204 1555

Katsura Y, Shimoyama J, Yamamoto A, Horii S and Kishio K 2007 Physica C 463–465 225

Ojha N, Varma G D, Singh H K and Awana V P S 2009 J. Appl. Phys. 105 07E315

Cheng C and Zhao Y 2006 Appl. Phys. Lett. 89 252501

Hossain M S A, Kim J H, Xu X, Wang X L, Rindfleisch M, Tomic M, Sumption M D, Collings E W and Dou S X 2007 Supercond. Sci. Technol. 20 L51

Bean C P 1962 Phys. Rev. Lett. 8 250

Grinenko V, Krasnoperov E P, Stoliarov V A, Bush A A and Mikhajlov B P 2006 Solid State Commun. 138 461

Rogado N, Hayward M A, Regan K A, Wang Y, Ong N P, Zandbergen H W, Rowell J M and Cava R J 2002 J. Appl. Phys. 91 274

Sharma P A, Hur N, Horibe Y, Chen C H, Kim B G, Guha S, Cieplak M Z and Cheong S W 2002 Phys. Rev. Lett. 89 167003

Rowell J M 2003 Supercond. Sci. Technol. 16 R17

Jiang J, Senkowicz B J, Larbalestier D C and Hellstrom E E 2006 Supercond. Sci. Technol. 19 L33

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

ERDEM, O., YANMAZ, E. Effect of Er doping on the superconducting properties of porous MgB 2 . Bull Mater Sci 38, 89–93 (2015). https://doi.org/10.1007/s12034-014-0810-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-014-0810-y