Abstract

The green husk coir fibres were treated with different levels of soaking time and concentration of alkali solution. As a result of alkali treatment, the surface modifications were done on the fibre surface and were studied using scanning electron micrographs. The coir–polyester composites were fabricated using hand lay up process and the mechanical properties (tensile, flexural and impact strength) were evaluated as per ASTM standards. The effect of soaking time and concentration of NaOH solution were studied based on evaluated values of mechanical properties to find out optimum fibre treatment parameters.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Renewable natural fibres could be potential substitutes for energy-intensive synthetic fibres in many applications where high strength and modulus are not required (Mallick 1993). It is, therefore, important to characterize and improve the strength properties of the available natural fibre and to search out new sources of applications of these fibres in composites. Coir fibres are found between the hard, internal shell and the outer coat of a coconut (Harish et al 2009). The individual fibre cells are narrow and hollow, with thick walls made of cellulose. They are pale when immature but later become hardened and yellowed as a layer of lignin is deposited on their walls. The coir fibre is relatively water-proof and is one of the few natural fibres resistant to damage by salt water (Mishra et al 2003; Monteiro et al 2008).

The increase of treated fibre content resulted in a significant increase in tensile strength, flexural strength and impact strength of composites. Alkali treatment increased the strength of natural fibre composites (Prasad et al 1983; Nayak et al 2000). A strong sodium hydroxide treatment removed lignin, hemicellulose and other alkali soluble compounds from the surface of the fibres to increase the numbers of reactive hydroxyl groups on the fibre surface available for chemical bonding. Moreover, the alkali treatment made the fibre surface clean by removing of waxes, hemicellulose, pectin and part of lignin (Mwaikambo and Ansell 2002). The removal of these substances enhanced the surface roughness. Therefore, mechanical interlocking at the interface could be improved.

Natural fibres can be considered as composites of hollow cellulose fibrils held together by a lignin and hemicellulose matrix. The cell wall in a fibre is not a homogenous membrane. Each fibre has a complex, layered structure consisting of a thin primary wall which is the first layer deposited during cell growth encircling a secondary wall. The secondary wall is made up of three layers and the thick middle layer determines the mechanical properties of the fibre. The middle layer consists of a series of helically wound cellular microfibrils formed from long chain cellulose molecules. The angle between the fibre axis and the microfibrils is called the microfibrillar angle. The characteristic value of microfibrillar angle varies from one fibre to another. Such microfibrils have typically a diameter of about 10–30 nm and are made up of 30–100 cellulose molecules in extended chain conformation and provide mechanical strength to the fibre. The amorphous matrix phase in a cell wall is very complex and consists of hemicellulose, lignin, and in some cases pectin. The hemicellulose molecules are hydrogen bonded to cellulose and act as cementing matrix between the cellulose microfibrils, forming the cellulose–hemi cellulose network, which is thought to be the main structural component of the fibre cell. The hydrophobic lignin network affects the properties of other network in a way that it acts as a coupling agent and increases the stiffness of the cellulose/hemicellulose composite (Ray et al 2001; Rout et al 2001a, b).

The mechanical properties of untreated coir fibre-reinforced polyester composites were evaluated in the previous works (Jayabal and Natarajan 2010, 2011). In continuation of these works, an improvement of mechanical properties of coir fibre-reinforced polyester composites has been studied in relation with the fibre treatment parameters in this work.

2 Experimental

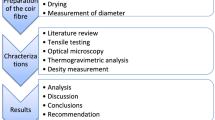

2.1 Fibre treatment

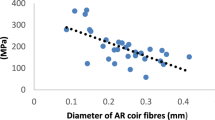

The green husk coir fibres were mechanically extracted from the green husk of coconut after soaking the husk in water. The physical properties of green husk coir fibre are given in table 1. The structure of coir fibre is shown in figure 1 and the sample of treated coir fibres are shown in figure 2. The coir fibre consisted of 4 layers viz. primary wall, three secondary walls (S1, S2 and S3) and inside filled with Lumen. Lignin and cellulose were the major constituents in the chemical composition of coir fibre. The chemical composition of green husk coir fibre is given in table 2.

Green husk coir fibres were chemically treated in order to remove lignin-containing materials such as pectin, waxy substances and natural oils covering the external surface of the fibre cell wall. This reveals the fibrils and gives a rough surface topography to the fibre. Sodium hydroxide (NaOH) was the most commonly used chemical for bleaching and/or cleaning the surface of plant fibres. It also changed the fine structure of the native cellulose I to cellulose II by a process known as mercerization. The reaction of sodium hydroxide with cellulose is as follows:

For alkali treatment, three levels of concentration of NaOH (2%, 5% and 8%) were selected and five levels of soaking time (24, 48, 72, 96 and 120 h) were selected based on literatures (Prasad et al 1983; Ray et al 2001; Mwaikambo and Ansell 2002). Figures 3–5 show SEM images of treated coir fibres for 2%, 5% and 8% NaOH concentration, respectively.

The treatment process removed lignin, hemi cellulose and other soluble compounds on the surface of the fibre and made the fibre soft to adhere easily with the polyester resin matrix. The reasons for the improved mechanical properties were the removal of impurities on the fibres during alkali treatment. The level of interfacial adhesion was increased by the use of treated fibres in composites. It can be expected that due to alkaline treatment, hemicellulose and lignin are removed, the inter fibril region is likely to be less dense and less rigid, and that makes the fibrils more able to rearrange themselves along the direction of loading. The high solution concentration and more treatment hours removed more amounts of internal constituents which were observed by the formation of hollows inside the fibres in SEM images.

2.2 Materials and manufacturing process

The hand lay-up process was followed for fabricating treated coir fibre reinforced polyester composites. Poly vinyl acetate (PVA) release agent was applied to the surfaces before fabrication. The treated coir fibres were distributed randomly in the matrix system consisting of unsaturated polyester resin, cobalt octoate accelerator and MEKP catalyst in the ratio of 1:0·015:0·015. The composite sheet of 360 × 360 mm were prepared and pressed at 0·5 kN for 1 h. Thereafter, the composites were removed from the mould and cured at room temperature for 24 h.

2.3 Mechanical testing

Tensile tests were conducted using Shimadzu tensile testing machine at a cross head speed of 5 mm/min as per ASTM D638 - 08. The length, width and thickness of each sample were approximately 165, 25 and 3 mm, respectively. Five identical specimens were tested in each combination and average result was derived. The test results for different levels of soaking time and concentration of NaOH solution are given in table 3.

The rectangular test pieces of 127 × 12·7 × 3 mm dimension for flexural test were cut from the prepared non-woven composites. Flexural test was conducted as per ASTM D 790–07ε1. The test was conducted on the Instron machine at 2·8 mm/min rate of loading. For statistical purposes, a total of 5 samples were tested. The tested flexural strength values for the different combinations of fibre treatment processes are given in table 4.

The impact strength of the samples was measured using ATS FAAR Impact tester as per ASTM D256–06aε1 standards. The length, width and thickness of each sample were 63·5, 12·7 and 3 mm, respectively. The test specimen was supported as a vertical cantilever beam and broken by a single swing of a pendulum. The pendulum strikes face of the sample and total of 5 samples were tested and the mean value of the absorbed energy was taken. The tested result of impact strength values are given in table 5.

3 Results and discussion

The comparison of mechanical properties of untreated and treated coir fibre reinforced composites are given in table 6. The untreated green husk coir fibre-reinforced composites exhibited the average tensile, flexural and impact strength of 16·17 MPa, 38·49 MPa and 41·18 kJ/m2, respectively which is greatly improved in treated coir fibre-reinforced polyester composites. The treated coir fibre-reinforced polyester composites exhibited the maximum value of tensile, flexural and impact strength of 23·56 MPa, 48·08 MPa and 58·75 kJ/m2, respectively.

3.1 Effect of soaking time on mechanical properties

-

(i)

For the maximum value of tensile strength, 96 h treatment in 2% aqueous solution gives 22·83 MPa, 72 h treatment in 5% aqueous solution gives 23·56 MPa and 48 h treatment in 8% aqueous solution gives 23·17 MPa.

-

(ii)

For the maximum value of flexural strength, 96 h treatment in 2% aqueous solution gives 48·08 MPa, 72 h treatment in 5% aqueous solution gives 39·85 MPa and 48 h treatment in 8% aqueous solution gives 44·45 MPa.

-

(iii)

For the maximum value of impact strength, 72 h treatment in 2% aqueous solution gives 56·86 kJ/m2, 48 h treatment in 5% aqueous solution gives 58·45 kJ/m2 and 24 h treatment in 8% aqueous solution gives 58·75 kJ/m2.

-

(iv)

The mechanical properties are lower in other treatment conditions due to the less and more removal of lignin and pectin compounds. SEM images were studied with evaluated mechanical properties to correlate treatment parameters. The effect of soaking time for different concentrations of alkali solution for tensile, flexural and impact properties are shown in figures 6, 7 and 8, respectively.

3.2 Effect of concentration of NaOH on mechanical properties

The effect of concentration of NaOH solution for different levels of soaking time for tensile, flexural and impact properties are shown in figures 9, 10 and 11, respectively. The NaOH concentration also plays a significant role on the improved value of mechanical properties. In general, high concentration of alkali solution and shorter soaking time provides better impact strength whereas low and medium concentration of alkali solution for longer shorter time provides improved flexural and tensile properties, respectively.

3.3 SEM analysis of fracture surfaces

SEM images of untreated and treated green husk fibre reinforced polyester composites after tensile, flexural and impact testing are shown in figures 12–17. From the SEM images of fracture surfaces after tensile testing, it was observed that the uneven matrix cracking and void formation are reduced due to the good laminar bond between treated coir fibre and polyester resin. The treated fibres restricted the applied flexural load better than untreated coir fibres. This observation was made by studying the breakage of fibres in SEM image. The coir fibres exhibited greater improvement of impact strength due to the removal of hemicelluloses and impurities in the fibre treatment process.

3.4 Possible applications of coir–polyester composites

Figure 18 shows various products manufactured using coir fibres and polyester resin matrix. Engine guard, name plate, front panel and light doom are prepared using treated short coir fibres. The treated coir fibres are very soft, so they can be easily distributed in the mould. Other possible applications are tank shield, front panel, tool box etc. As the natural fibre composites are developing now a days, the treated coir fibres definitely play an important role in the development of natural fibre composites in automobile, commercial and general applications.

4 Conclusions

Alkali treatment of coir fibre in 5% aqueous solution for 72 h results in a 31% increase in tensile strength, 2% aqueous solution for 96 h results in a 22% increase in flexural strength and 8% aqueous solution for 24 h results in a 30% increase in impact strength. The mechanical properties are greatly improved by the fibre treatment process and treatment parameters viz. soaking time and concentration of NaOH solution, also play a major role to increase the tensile, flexural and impact properties of green husk coir fibre reinforced composites.

References

Harish S, Peter Michael D, Bensely A, Mohan Lal D and Rajadurai A 2009 Mater. Charact. 60 44

Jayabal S and Natarajan U 2010 J. Metall. Mater. Sci. 52 341

Jayabal S and Natarajan U 2011 Int. J. Adv. Manuf. Technol. 54 639

Mallick P K 1993 Fibre reinforced composites—materials, manufacturing and design (New York: Marcel Dekker Inc.) 2nd ed., p. 74

Mishra S, Mohanty A K, Drzal L T, Misra M, Parija S, Nayak S K and Tripathy SS 2003 Compos. Sci. Technol. 63 1377

Monteiro S N, Terrones L A H and D’almeida J R M 2008 Polym. Test. 27 591

Mwaikambo L Y and Ansell M P 2002 J. Appl. Polym. Sci. 84 2222

Nayak S K, Tripahy S S, Rout J and Mohanty A K 2000 Int. Plastics Eng. Technol. 4 79

Prasad S V, Pavithran C and Rohatgi P K 1983 J. Appl. Polym. Sci. 18 1443

Ray D, Sarkar B K, Rana A K and Bose N R 2001 Bull. Mater. Sci. 24 129

Rout J, Nayak S S, Misra M and Mohanty A K 2001a J. Appl. Polym. Sci. 79 1169

Rout J, Misra M, Mohanty A K, Nayak S K and Tripathy S S 2001b Compos. Sci. Technol. 61 1303

Acknowledgements

Authors thank post graduate scholars D Naveen, Kongu Engineering College, Erode, V Thirukumaran, S Rajamuneeswaran and M Udhayakumar, A. C. College of Engineering and Technology, Karaikudi and G Kannan, Government College of Engineering, Tirunelveli, for their help in experimentation and testing works.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

JAYABAL, S., SATHIYAMURTHY, S., LOGANATHAN, K.T. et al. Effect of soaking time and concentration of NaOH solution on mechanical properties of coir–polyester composites. Bull Mater Sci 35, 567–574 (2012). https://doi.org/10.1007/s12034-012-0334-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-012-0334-2