Abstract

Aquacultural shrimps suffer economic lost due to the white spot syndrome virus (WSSV) that is the most notorious virus for its fatality and contagion, leading to a 100% death rate on infected shrimps within 7 days. However, the infection of mechanism remains a mystery and crucial problem. To elucidate the pathogenesis of WSSV, a high abundance of protein is required to identify and characterize its functions. Therefore, the optimal WSSV355 overexpression was explored in engineered Escherichia coli strains, in particular C43(DE3) as a toxic tolerance strain remedied 40% of cell growth from BL21(DE3). Meanwhile, a trace amount of WSSV355 was observed in both strains. To optimize the codon of WSSV355 using codon adaption index (CAI), an overexpression was observed with 1.32 mg/mL in C43(DE3), while the biomass was decreased by 35%. Subsequently, the co-expression with pRARE boosted the target protein up to 1.93 mg/mL. Finally, by scaling up production of WSSV355 in the fermenter with sufficient oxygen supplied, the biomass and total and soluble protein were enhanced 67.6%, 44.9%, and 7.8% compared with that in flask condition. Herein, the current approach provides efficacious solutions to produce toxic proteins via codon usage, strain selection, and processing optimization by alleviating the burden and boosting protein production in E. coli.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

White spot disease (WSD) has been a rigorous challenge to aquacultural fishery, which provokes abnormal accumulation of calcium salts in decapod species since 1992. The white spot syndrome virus (WSSV) is the dominant cause of the WSD, triggering white spots in the carapace of cultured shrimp [1]. WSSV is an enveloped virus containing a ~ 300 kbps dsDNA genome. By far, multiple infected shrimps have been obtained, and thus, the highly conserved WSSV genes will be gradually confirmed from the hosts [2]. Surprisingly, the potential hosts or carriers have a wide range of over 93 species involving shrimps, crabs, copepods, crayfishes, and lobsters [3]. However, through a body of carriers above, the penaeid shrimps are the only family suffering from virulent pathogens and are the major commercial species. According to the economic loss in Indian shrimp farming, WSSV has the highest loss of production up to tons per hectare among infections, leading to an incomparable financial loss of US$ 240 million [4]. In most cases, the mortalities of WSSV in shrimp farms triggered a 100% death rate within 7 days [5]. The outbreak of severe viral disease has impacted the shrimp aquatic industries severely [6].

In recent years, the complete WSSV genomic sequence drives forward its functional analysis [7]. However, the open reading frames (ORFs) of WSSV in the known proteins showed only 10% similarity to other viruses [8]. Although the major structure of the proteins from WSSV is identified, the function of the structural proteins is still questioned. To further investigate the pathogenesis, a high-yield production of target proteins is required and desired. The common approach is to acquire the intact WSSV viral particles by centrifugation and extraction of infected tissue from crayfish [9]. However, the result was restricted by the cost and time-consuming experiment cycle. Efficient methods to obtain WSSV with a low threshold and rapid collection stand out to be the critical points of such research.

The versatile recombinant proteins are mainly produced in the genetic Escherichia coli with low cost and short culturing time [10]. The fact that expressing heterologous gene especially the toxin gene is a demanding task, thus, the heterologous expression was developed and reported unceasingly. To date, fusion tags such as thioredoxin A (TrxA) [11], glutathione S-transferase (GST) [12], maltose-binding protein (MBP) [13], small ubiquitin related modifier (SUMO) [14], and N-utilization substance A (NusA) [15] have been utilized to facilitate protein expression and overcome expression obstacles. However, the addition of fusion tags either on the N- or C-terminal of proteins may alter the protein structure, activity, and function, which will be required the enzymatic digestion prior to study protein characteristic. Besides, the codon usages have significantly affected the heterologous protein expression in E. coli [16]. Rare codon results in translation deficiency and errors, and the tRNA level is highly related to the frequency of codons in the sequence [17]. With the codon optimization, the target gene augments the translation efficiency thereby contributing to overexpression itself.

In this study, the heterologous production of WSSV355 [18] was optimized and scaled up through the stepwise strategies in E. coli. The appropriate host was selected for overexpressing the original sequence of WSSV355 without the signal peptide at the first time. The effect of rare codon was solved and evaluated by using a pRARE plasmid. Afterwards, the better gene codon was performed with higher codon adaption index (CAI) to boost WSSV355 expression and solubility in the genetic host. Finally, the scaling up production of WSSV355 was achieved in a 1-L fermenter. The presented results provided a fundamental concept and feasible paradigm to the production of toxic proteins using engineered E. coli.

Materials and Method

Luria–Bertani (LB) powder was purchased from Difco (USA). Yeast extract was purchased from OXOID (UK). Ampicillin (Ap), chloramphenicol (Cm), kanamycin (Km), and β-D-1-thiogalactopyranoside (IPTG) were purchased from Sigma-Aldrich (USA). Q5 polymerase was purchased from New England Biolabs (USA), and fermenter was purchased from MOUBIO (Taiwan). All chemicals were used at analytic grade.

Plasmid Construction and Transformation

Plasmids and strains used in this study are listed in Table 1. Construction of plasmids was transformed into DH5α, while BL21(DE3) (BD), BL21-CodonPlus(DE3)-RIPL (BC), C43(DE3) (C43), and WL [19] were selected as hosts for overexpression of WSSV355 protein. The signal peptide of the original WSSV355 sequence was predicted using SignalP 6.0 [20] and forming the WSSV355 without signal peptide as WNP1. The codon adaptation index (CAI) of gene sequences was calculated by Codon Adaptation Index Calculator (Biologics International Corp.). The CAI of WNP1 was 0.57 while a WNP2 with CAI of 0.63 was synthesized by Integrated DNA Technologies (USA). The sequences of WNP1 and WNP2 are shown in Table S1. Both DNA were amplified by polymerase chain reaction (PCR) using Q5® High-Fidelity DNA Polymerase (New England Biolabs, USA). The WNP1 and WNP2 genes were then constructed into pET28a( +),with NdeI/XhoI to generate pET28a-WNP1 and pET28a-WNP2. All the plasmid transformations were implemented by heat shock at 42 °C for 90 s, and the cells were subsequently cultured in LB for recovery. After the recovery, the cell was spread onto agar plates with proper antibiotics.

Culture Conditions

Luria–Bertani (LB) medium was used for all the strains listed in Table 1. The cell preculture was carried out by cultivating the strains in 4 mL LB at 37 °C and 200 rpm for 12 h aerobically with the proper antibiotic as follows: 50 μg/mL kanamycin (Km), 25 μg/mL chloramphenicol (Cm), and half concentration of both antibiotics were applied to dual-plasmid strains. The cells were inoculated by 2% (v/v) into a 250-mL Erlenmeyer flask containing 50 mL LB, and the culture process was under 37 °C, 200 rpm. Subsequently, the cultivations were induced by 0.1 mM β-D-1-thiogalactopyranoside (IPTG) when the optical density (OD600) achieved 0.6 to 0.8, and adjusted to 22 °C, 200 rpm for the following cultivation till 24 h. The flasks with a single baffle, and three baffles were used to examine the protein expression of WNP1 and WNP2.

Scale-Up Production in the 1-L Fermenter

To further enhance the aeration during cultivation, the optimal strain was cultured in 1-L fermenter. The preculture was performed as mentioned before, and 2% (v/v) inoculation of the pre-culture cell was applied into 300 mL LB in a 1-L fermenter (MOUBIO, Taiwan) at 37 °C and 250 rpm with 1 vvm aeration. The induction was performed with the addition of 0.1 mM IPTG when the OD600 reached 0.6 to 0.8, and the culture condition was adjusted to 22 °C and 400 rpm with 2 vvm aeration.

Analytical Assay

The cell concentration was measured by optical density at 600 nm (OD600) using SpectraMax 340PC (Molecular Devices, USA). To convert the OD600 to the dry cell weight (g/L), the cells were washed with deionized water 3 times, and the cell suspension was dried by an infrared moisture analyzer (Kett, Japan), and the relationship between the OD600 and biomass was calculated as Eq. 1. The cells were harvested by centrifuging 12,000 × g at 4 °C for 3 min and washed with deionized water twice. The cell was then adjusted to OD600 of 4 by diluting with deionized water before being disrupted by OneShot® high-pressure homogenizer (Constant Systems, UK) at 30 kpsi to obtain soluble proteins. For sodium dodecyl sulfate–polyacrylamide gel electrophoresis (SDS-PAGE) analysis, gels containing 10% separating gel and 4% stacking gel were prepared for whole-cell (W) and soluble (S) proteins for the observation of the expression. Proteins were visualized by staining with Coomassie blue R-250 and scanned through an Image scanner (Biolab2000, Taiwan). The software Image Lab (Bio-Rad, USA) was used to quantify the protein amounts by bovine serum albumin (BSA) as standard [21].

Result and Discussion

WSSV355 Expression in Different E. coli Hosts

Since the WSSV355 is a toxic protein affecting the cellular physiology and causing cell growth deficiency, the production of WSSV355 protein is a formidable task in microorganisms along with the accumulation of target protein. Nonetheless, it has been widely acknowledged that E. coli possesses a paucity of resistance against the toxin, which can be remedied by lowering expression, reducing cultural temperature, or using toxicity-durable strain of C43(DE3) [22]. Thus, carving out a proper host strongly fosters the system to producing toxic proteins.

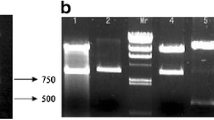

WNP1 as the original sequence of WSSV355 without signal peptide was expressed in BL21(DE3) (BD in short) as standard T7 expression strain, BL21-CodonPlus (DE3)-RIPL (BC in short) as codon favor and optimized host, C43(DE3) (C43 in short) as less T7RNA polymerase to reduce cell burden [22], and WL as a derivation of W3110 that is tolerant to toxic chemical [23]. As shown in Fig. 1A, the best cell growth occurred in C43, reaching 1.35 g/L after 24-h cultivation, while WL strain obtained the lowest biomass with 0.71 g/L. However, scarcity of protein accumulation was in a trace amount on the SDS-PAGE analysis for the four strains with 0.1 mM IPTG induction (Fig. 1B). Even though the induction with 0.2 and 0.5 mM IPTG were applied for WNP1 expression under T7 promoter, the expression was not improved (data no shown). The decent results such as exceptional cell growth and abundance of inherent expression accounted for the enhanced growth peculiarity, T7 polymerase reduction, and substantial recombination protein expression [24]. Therefore, the BD and C43 strains were selected to optimize the expression of WSSV355 in the following design due to its advantage on cell growth among the other strains.

Characterization of WNP1 expression by plasmid pET28a-WNP1 in different hosts, including BC, BD, C43, and WL. A The cell growth was measured at 0, 3, 4, 8, 12, and 24 h. B Protein expression was observed at 24 h using SDS-PAGE analysis. The arrow indicated the WNP1 expression (43 kDa). W, whole cell protein; S, soluble protein

Effect of Rare Codons on WSSV355 Expression in E. coli

Heterologous gene expression is a feasible strategy to produce various proteins owing to the development of biotechnology, while a wide outlook is accompanied by obstacles. As the meager tendency of folding the WNP1 protein can be attributed to low-level tRNAs stemming from rare codons, thereby rare codons supplementary should be considered as a key factor [25]. To compensate the supportive rare codons in gene of interest, pRARE co-expression enriched tRNAs which avoided protein aggregation and cell growth deficiency, and co-expression of pET28a-WNP1 with the pRARE plasmid in BD and C43 was designed. Afterward, the cultivations were carried out at 22 °C after induction to slow down the translation of the protein and avoid forming inclusion body [26]. Furthermore, through culturing at a low temperature, the decrease of elongation rate, translation speed, and protein misfolding was reported to escalate expression in E. coli [27]. The biomass of strains containing pET28a-WNP1 with or without pRARE at 24 h is shown in Fig. 2A. The dominating cell growth of 1.35 g/L appeared in C43, while C43(R) showed less biomass at 1.20 g/L with the pRARE, indicating that the cell burden occurred in dual plasmid expression. On the contrary, the biomass of BD(R) was improved to 0.85 g/L from 0.79 g/L in BD. Meanwhile, the expression of WNP1 was not enhanced in either BD(R) or C43(R) (Fig. 2B). In terms of pRARE effect, dual plasmids of pRARE with recombination plasmid commonly impaired cell growth, while no augmentation of protein expression was observed. The maintenance of multiple plasmid DNA would cause severe metabolism in E. coli, resulting in less biomass [28]. Nevertheless, pRARE has been rather a useful saver than a futile hurter by preventing the strains from crashing in repetition experiments [29]. It was speculated that supporting rare codons was less pressure to the strain with toxic protein which even in a trace amount of WNP1 would hinder the cell growth. Thus, pRARE plasmid was applied for further optimization of WSSV355 expression.

Characterization of pET28-WNP1 co-expressed with and without pRARE plasmid in BD or C43 at 24 h. The strains BD(R) and C43(R) were harboring dual plasmids. A Biomass and B protein expression observed using SDS-PAGE analysis. The arrow indicated the WNP1 expression (43 kDa). W, whole cell protein; S, soluble protein

Effect of Aeration on Protein Production

Shake flask has been widely utilized in the scope of animal, plant, and microorganisms with low expenses and high efficiency to provide sufficient dissolved oxygen [30, 31]. Additionally, the abundance of protein expression had an intense correlation with the concentration of environment oxygen [32]. Therefore, we attempted to use two types of Erlenmeyer flask with single or triple baffle (Fig. S1), which mimic the conditions in different oxygen supply. As shown in Fig. 3A, the biomass of all strains was escalated after 24-h cultivation in triple-baffled flasks by 75%, 51.6%, 13.3%, and 94.3% in BD, BD(R), C43, and C43(R), respectively. The result was consistent to the previous report, in which an oxygen controller with a fuzzy system to investigate was developed to elevate the dissolved oxygen in E. coli culture for the production of foreign protein [32].

Characterization of pET28-WNP1 co-expressed with and without pRARE plasmid in BD or C43 using the triple baffled flask at 24 h. The strains BD(R) and C43(R) were harboring dual plasmids. A Biomass and B protein expression observed using SDS-PAGE analysis. The arrow indicated WNP1 expression (43 kDa). W, whole cell protein; S, soluble protein

The baffled design was conducive to the aeration of culture, sediment prevention, and available to nutrients, which are crucial to bacterial growth. As shown in Fig. 3A, the significant amelioration on the cell growth verified the effect of different types of flasks for oxygen supplementary on cellular behavior, which was beneficial to protein production. With respect to the target protein production, appreciation of oxygen culminated in scarcely protein abundance (Fig. 3B). Through the optimization of host selection, rare codon supplementary and dissolved oxygen remedied the cell growth inhibition triggered by the heterologous expression with toxic variants, while it was followed by the paucity of protein abundance. To further augment the expression level of WNP1, the sequence of gene codon was adjusted.

Escalating WSSV355 Expression via Codon Optimization

Codon optimization via synonymous substitution has been a common strategy expressing the recombination, accomplishing high-level protein expression compared with wild type [33]. To date, solving rare codons in the course of protein synthesis by synonymous codon mutations in mRNA is a predominant approach [34]. Hence, the sequence of WNP1 was changed regarding to the codon adaption index (CAI), forming a new gene WNP2. The CAI of WNP2 was 0.63 while the WNP1 was only 0.57. As shown in Fig. 4A, B, the biomass of BD and BD(R) was slightly increased while no obvious WNP2 expression was observed. On the contrary, C43 and C43(R) had 35.3% and 21% plunge in biomass with overexpression of WNP2 in both C43 and C43(R) on the SDS-PAGE (Fig. 4B). The overexpression of WNP2 attributed to the deficiency of biomass implied that the foreign protein production suppressed the cell growth. In terms of offsetting rare codons, the biomass, whole cell, and soluble protein level were enhanced by 8.1%, 47.7%, and 28.6%, respectively, indicating that the rare codons supplementary elevated the transfer RNA level for protein expression. The outcome supported the report from previous research that the codon optimization to eliminate rare codons and the supplementary of rare codons tRNAs showed positive effect on the expression of heterologous and toxic proteins.

Characterization of pET28-WNP2 co-expressed with and without pRARE plasmid in BD or C43 using the triple baffled flask at 24 h. The strains BD(R) and C43(R) were harboring dual plasmids. A Biomass and B protein expression observed using SDS-PAGE analysis. C The protein amount of WNP2 expression. The arrows indicated the WNP2 expression (43 kDa). W, whole cell protein; S, soluble protein

Sequence optimization imposed a larger proportion of genes than tRNA improvement. Herein, a feasible and competitive method was implemented to produce heterologous expression WNP2 through the CAI adjustment and rare codons offset, despite the deleterious effect stemming from toxin variants. However, considering the remediation for impaired cell growth and abundant protein for the analysis of WSSV pathogenesis, cultivating in a larger container such as a fermenter is supposed to achieve high protein accumulation and cell growth.

Scaling Up Production by Fermentation

Currently, fermentation has been regarded as one of the prevailing approaches to obtain high-density cell growth in E. coli, thus achieved a cost-effectiveness and mass production [35, 36]. As the sophisticated functions of agitation and dissolved oxygen adjustment that was considered a strong potential to enlarge the WNP2 protein expression and mitigate the growth deficiency, the strain C43 containing pET28a-WNP2 with pRARE was performed in a 1-L fermenter. In terms of cell growth (Fig. 5A), the cell growth was 7.8% higher than that in a flask. As shown in SDS-PAGE (Fig. 5B), the abundance of WNP2 was significantly increased via fermentation. Subsequently, we further attested the WNP2 protein level and shown in Fig. 5C. The accumulation of whole cell expression and soluble protein was augmented by 67.6% and 44.9%, respectively. In the magnitude of aspects, fermentation strategy achieved the all-round improvement.

Characterization of pET28a-WNP2 culturing in flask and 1-L fermenter with pRARE plasmid in BD and C43. A The cell growth was measured at 0, 3, 4, 8, 12, and 24 h. B The protein expression was observed at 24 h using SDS-PAGE analysis. The arrows indicated the WNP2 expression (43 kDa). C The protein amount of WNP2 expression. W, whole cell protein; S, soluble protein

As the oxygen considerations, the cells were aerated with sufficient air influx, overcoming the limit of oxygen transfer resistance. In addition, the LB medium supplied ample carbon and nitrogen resources to attain nutrient requirement, especially under the inhibition of toxic excretion by the bacteria community in the course of growth. The strong motivation towards folding the recombination protein and growing in E. coli occurred when satisfying the demand for adequate nutrient and air input supplied.

The strategies of obtaining WSSV proteins from the peculiarities are summarized Table 2. So far, the prevailing method is to acquire the intact WSSV viral particles from crayfish. However, the extraction method is restricted by a long process and low titer, while using genetically engineered E. coli strains is broadly employed to produce versatile recombinant proteins in a cost-effective mode and high titer. To sum up, by comparing to gain virions from crayfish [9, 37, 38], heterologous expression of toxic WSSV355 in genetic E. coli is a durable, time-saving, cost-effective, and industrial accessible approach.

Conclusion

The engineered E. coli expressed an optimized sequence of WSSV355 with supplementary of rare tRNAs, solving the difficulties aroused from foreign gene expression with excreting the toxic variants. To remove the original signal peptide is crucial to reduce the cell burden while using the toxic durable strain selection, the E. coli strain C43(DE3) with less T7RNAP recruited 1.4-fold biomass over BL21(DE3). Furthermore, the rare codons were offset by co-expressing the pRARE plasmid, followed by adjusting the CAI of WSSV355 to 0.63 and assigned as WNP2, which was responsible for high abundance of toxic protein expression and significant biomass drop. In terms of mass production, the best host was applied in the fermenter, attaining well-rounded progression of cell growth, protein expression, and solubility simultaneously. The current approach provides the successful production of WSSV355 for further investigation of mechanism between virus infection and shrimp.

Data Availability

Data will be made available on reasonable request.

Ethics Approval, Consent to Participate and Publication.

All the authors have read and agreed the ethics for publishing the manuscript.

References

Durand, S., Lightner, D. V., Nunan, L. M., Redman, R. M., Mari, J., & Bonami, J. R. (1996). Application of gene probes as diagnostic tools for white spot baculovirus (WSBV) of penaeid shrimp. Diseases of Aquatic Organisms, 27(1), 59–66.

Kumar, R., Huang, J. Y., Ng, Y. S., Chen, C. Y., & Wang, H. C. (2022). The regulation of shrimp metabolism by the white spot syndrome virus (WSSV). Reviews in Aquaculture, 14(3), 1150–1169.

Li, C., Weng, S., & He, J. (2019). WSSV–host interaction: Host response and immune evasion. Fish & Shellfish Immunology, 84, 558–571.

Patil, P. K., Geetha, R., Ravisankar, T., Avunje, S., Solanki, H. G., Abraham, T. J., Vinoth, S. P., Jithendran, K. P., Alavandi, S. V., & Vijayan, K. K. (2021). Economic loss due to diseases in Indian shrimp farming with special reference to Enterocytozoon hepatopenaei (EHP) and white spot syndrome virus (WSSV). Aquaculture, 533, 736231.

Liu, L. K., Liu, M. J., Li, D. L., & Liu, H. P. (2021). Recent insights into anti-WSSV immunity in crayfish. Developmental & Comparative Immunology, 116, 103947.

Xu, T., Shan, X., Li, Y., Yang, T., Teng, G., Wu, Q., Wang, C., Tang, K. F. J., Zhang, Q., & Jin, X. (2021). White spot syndrome virus (WSSV) prevalence in wild crustaceans in the Bohai Sea. Aquaculture, 542, 736810.

Oakey, H. J., & Smith, C. S. (2018). Complete genome sequence of a white spot syndrome virus associated with a disease incursion in Australia. Aquaculture, 484, 152–159.

Leu, J. H., Yang, F., Zhang, X., Xu, X., Kou, G. H., & Lo, C. F. (2009). Whispovirus. Lesser known large dsDNA. Viruses, 197–227.

Xie, X., Li, H., Xu, L., & Yang, F. (2005). A simple and efficient method for purification of intact white spot syndrome virus (WSSV) viral particles. Virus Research, 108(1–2), 63–67.

Alemdar, S., Hartwig, S., Frister, T., König, J. C., Scheper, T., & Beutel, S. (2016). Heterologous expression, purification, and biochemical characterization of α-humulene synthase from Zingiber zerumbet Smith. Applied Biochemistry and Biotechnology, 178(3), 474–489.

Mahamad, P., Boonchird, C., & Panbangred, W. (2016). High level accumulation of soluble diphtheria toxin mutant (CRM197) with co-expression of chaperones in recombinant Escherichia coli. Applied Microbiology and Biotechnology, 100(14), 6319–6330.

Ajayi, B. O., Olajide, T. A., & Olayinka, E. T. (2022). 6-Gingerol attenuates pulmonary inflammation and oxidative stress in mice model of house dust mite-induced asthma. Advances in Redox Research, 5, 100036.

Gumpena, R., Lountos, G. T., & Waugh, D. S. (2018). MBP-binding DARPins facilitate the crystallization of an MBP fusion protein. Acta Crystallographica Section F: Structural Biology Communications, 74(9), 549–557.

Kim, D. S., Kim, S. W., Song, J. M., Kim, S. Y., & Kwon, K. C. (2019). A new prokaryotic expression vector for the expression of antimicrobial peptide abaecin using SUMO fusion tag. BMC biotechnology, 19(1), 1–12.

Hemmati, S., & Ranjbari, J. (2019). Soluble form production of recombinant human insulin-like growth factor-1 by NusA fusion partner in E. coli. Trends in Peptide and Protein Sciences, 4, 1–5.

Yu, T. H., Tan, S. I., Yi, Y. C., Xue, C., Ting, W. W., Chang, J. J., & Ng, I. S. (2022). New insight into the codon usage and medium optimization toward stable and high-level 5-aminolevulinic acid production in Escherichia coli. Biochemical Engineering Journal, 177, 108259.

Fu, H., Liang, Y., Zhong, X., Pan, Z., Huang, L., Zhang, H., Xu, Y., Zhou, W., & Liu, Z. (2020). Codon optimization with deep learning to enhance protein expression. Scientific Reports, 10(1), 1–9.

Wang, H. C., Wang, H. C., Kou, G. H., Lo, C. F., & Huang, W. P. (2007). Identification of icp11, the most highly expressed gene of shrimp white spot syndrome virus (WSSV). Diseases of Aquatic Organisms, 74(3), 179–189.

Ting, W. W., Yu, J. Y., Lin, Y. C., & Ng, I. S. (2022). Enhanced recombinant carbonic anhydrase in T7RNAP-equipped Escherichia coli W3110 for carbon capture storage and utilization (CCSU). Bioresource Technology, 128010.

Teufel, F., Armenteros, J. J. A., Johansen, A. R., Gíslason, M. H., Pihl, S. I., Tsirigos, K. D., Winther, O., Brunak, S., Heijne, G., & Nielsen, H. (2022). SignalP 6.0 predicts all five types of signal peptides using protein language models. Nature Biotechnology, 40, 1023–1025.

Effendi, S. S. W., Tan, S. I., Ting, W. W., & Ng, I. S. (2021). Genetic design of co-expressed Mesorhizobium loti carbonic anhydrase and chaperone GroELS to enhancing carbon dioxide sequestration. International Journal of Biological Macromolecules, 167, 326–334.

Zhang, Z. X., Nong, F. T., Wang, Y. Z., Yan, C. X., Gu, Y., Song, P., & Sun, X. M. (2022). Strategies for efficient production of recombinant proteins in Escherichia coli: Alleviating the host burden and enhancing protein activity. Microbial Cell Factories, 21, 191.

Ting, W. W., Tan, S. I., & Ng, I. S. (2020). Development of chromosome-based T7 RNA polymerase and orthogonal T7 promoter circuit in Escherichia coli W3110 as a cell factory. Bioresources and Bioprocessing, 7, 54.

Mittal, P., Brindle, J., Stephen, J., Plotkin, J. B., & Kudla, G. (2018). Codon usage influences fitness through RNA toxicity. Proceedings of the National Academy of Sciences, 115(34), 8639–8644.

Schlegel, S., Genevaux, P., & de Gier, J. W. (2015). De-convoluting the genetic adaptations of E. coli C41 (DE3) in real time reveals how alleviating protein production stress improves yields. Cell Reports, 10(10), 1758–1766.

Effendi, S. S. W., Xue, C., Tan, S. I., & Ng, I. S. (2021). Whole-cell biocatalyst of recombinant tyrosine ammonia lyase with fusion protein and integrative chaperone in Escherichia coli for high-level p-Coumaric acid production. Journal of the Taiwan Institute of Chemical Engineers, 128, 64–72.

Liu, Y. (2020). A code within the genetic code: Codon usage regulates co-translational protein folding. Cell Communication and Signaling, 18(1), 1–9.

Silva, F., Queiroz, J. A., & Domingues, F. C. (2012). Evaluating metabolic stress and plasmid stability in plasmid DNA production by Escherichia coli. Biotechnology Advances, 30, 691–708.

Yi, Y. C., Xue, C., & Ng, I. S. (2021). Low-carbon-footprint production of high-end 5-aminolevulinic acid via integrative strain engineering and RuBisCo-equipped Escherichia coli. ACS Sustainable Chemistry & Engineering, 9(46), 15623–15633.

Takahashi, M., & Aoyagi, H. (2020). Analysis and effect of conventional flasks in shaking culture of Escherichia coli. AMB Express, 10(1), 1–6.

Crofts, A. A., Giovanetti, S. M., Rubin, E. J., Poly, F. M., Gutiérrez, R. L., Talaat, K. R., Porter, C. K., Mark, S., DeNearing, B., Brubaker, J., Maciel, M., Jr., Alcala, A. N., Chakraborty, S., Prouty, M. G., Savarino, S. J., Davies, B. W., & Trent, M. S. (2018). Enterotoxigenic E. coli virulence gene regulation in human infections. Proceedings of the National Academy of Sciences, 115(38), E8968–E8976.

Akisue, R. A., Horta, A. C., & de Sousa Jr, R. (2018). Development of a fuzzy system for dissolved oxygen control in a recombinant Escherichia coli cultivation for heterologous protein expression. In Computer Aided Chemical Engineering (Vol. 43, pp. 1129–1134). Elsevier.

Saito, Y., Kitagawa, W., Kumagai, T., Tajima, N., Nishimiya, Y., Tamano, K., Yasutake, Y., Tamura, T., & Kameda, T. (2019). Developing a codon optimization method for improved expression of recombinant proteins in actinobacteria. Scientific Reports, 9(1), 1–10.

Mauro, V. P. (2018). Codon optimization in the production of recombinant biotherapeutics: Potential risks and considerations. BioDrugs, 32(1), 69–81.

Huang, P., Shi, J., Sun, Q., Dong, X., & Zhang, N. (2018). Engineering Pichia pastoris for efficient production of a novel bifunctional Strongylocentrotus purpuratus invertebrate-type lysozyme. Applied Biochemistry and Biotechnology, 186(2), 459–475.

Coenen, A., Marti, V. G., Müller, K., Sheremetiev, M., Finamore, L., & Schörken, U. (2022). Synthesis of polymer precursor 12-oxododecenoic acid utilizing recombinant papaya hydroperoxide lyase in an enzyme cascade. Applied Biochemistry and Biotechnology, 1–19.

Yang, H., Jiang, Y., Lu, K., Xiong, H., Zhang, Y., & Wei, W. (2021). Herbicide atrazine exposure induce oxidative stress, immune dysfunction and WSSV proliferation in red swamp crayfish Procambarus clarkii. Chemosphere, 283, 131227.

Jiang, H. F., Chen, C., Jiang, X. Y., Shen, J. L., Ling, F., Li, P. F., & Wang, G. X. (2022). Luteolin in Lonicera japonica inhibits the proliferation of white spot syndrome virus in the crayfish Procambarus clarkii. Aquaculture, 550, 737852.

Funding

The study was financially supported by the Ministry of Science and Technology (MOST 110–2221-E-006–030-MY3 and MOST 111–2221-E-006–012-MY3) in Taiwan.

Author information

Authors and Affiliations

Contributions

Ying-Chen Yi and I-Son Ng conceived the study. Po-Yen Chen performed all the experiments and sketched the original draft. Han-Ching Wang provided the original DNA of WSSV355. I-Son Ng did methodology validation, supervised the experiments, reviewed, and edited the manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, PY., Yi, YC., Wang, HC. et al. Heterologous Expression of Toxic White Spot Syndrome Virus (WSSV) Protein in Eengineered Escherichia coli Strains. Appl Biochem Biotechnol 195, 4524–4536 (2023). https://doi.org/10.1007/s12010-023-04369-1

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-023-04369-1