Abstract

Oil pollution in marine environment caused by oil spillage has been a main threat to the ecosystem including the ocean life and to the human being. In this research, three indigenous purple photosynthetic strains Rhodopseudomonas sp. DD4, DQ41, and FO2 were isolated from oil-contaminated coastal zones in Vietnam. The cells of these strains were immobilized on different carriers including cinder beads (CB), coconut fiber (CF), and polyurethane foam (PUF) for diesel oil removal from artificial seawater. The mixed biofilm formed by using CB, CF, and PUF as immobilization supports degraded 90, 91, and 95% of diesel oil (DO) with the initial concentration of 17.2 g/L, respectively, after 14 days of incubation. The adsorption of DO on different systems was accountable for the removal of 12–16% hydrocarbons for different carriers. To the best of our knowledge, this is the first report on diesel oil degradation by purple photosynthetic bacterial biofilms on different carriers. Moreover, using carriers attaching purple photosynthetic bacteria to remove diesel oil in large scale is considered as an essential method for the improvement of a cost-effective and efficient bioremediation manner. This study can be a promising approach to eliminate DO from oil-contaminated seawater.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Diesel oil contamination in marine seriously threatens ecosystems and human health especially in highly industrialized areas [1]. There are various clean-up strategies that exist to remediate oil-polluted water which includes mechanical, chemical, and biological removal approaches [2,3,4,5]. Among these, biodegradation (either by microorganisms and plants) is considered as more advanced than other methods such as chemical oxidation, electrokinetic degradation, and thermal approaches since it is economical and environmentally friendly as well as implementable in many conditions [6,7,8,9]. Recently, it has been discovered that using biofilms formed by microbes on different carrier materials has been able to enhance diesel biodegradation and bioremediation [2, 10,11,12,13]. In addition, to increase oil degradation, currently, different carriers including cinder beads (CB), coconut fiber (CF), and polyurethane foam (PUF) were applied. Those are considered as organic, non-toxic, and nonpolluting natural materials, and their availability is highly potential for various applications [10, 13,14,15]. The usage of CB, CF, and PUF as carriers is able to demonstrate economical and ecological aspects in the removal approach of these waste materials. Moreover, microbial biofilm formation in petroleum hydrocarbon component sorbents as CB, CF, and PUF can create a synergy interaction of sorption-bioremediation response as published by Wang et al. (2015) and Alessandrello et al. (2017b) [14, 16]. However, as to our knowledge, researches on diesel oil degradation by purple photosynthetic bacterial biofilms on different carriers are limited.

Purple photosynthetic bacteria (PPB) exhibit remarkable flexibility in hydrocarbon transformations and degradations [17,18,19,20]. A phototrophic purple bacterium, Rhodovibrio parvus (now named as Rhodopseudomonas palustris) was first reported to transform phenylpropionate to benzoate during photosynthetic metabolism [21] . Benzoate, toluene, and other aromatic compounds utilization were demonstrated by a number of PPB such as Phaeospirillum fulvum [22], Rhodomicrobium vannielii [23], family Rhodospirillaceae [24] including Rhodopseudomonas capsulate [25] and Rhodopseudomonas palustris [18], Roseiflexus castenholzii [26] Blastochloris sulfoviridis [27], Rubrivivax benzoatilyticus sp. nov. [28] Though numerous researches have conducted concerning diesel oil from ASW using adherence cells [11, 29, 25, 30], lack of publication on PPB was attached to carriers to remove oil pollution.

In this study, genetic, morphological, and chemo-physical tests have been used for the identification of three biofilm-forming PPB strains and have identified their name as Rhodopseudomonas sp. DD4, DQ4, and FO2. The gene sequences were registered in DNA Data Bank of Japan with accession numbers of LC318127, LC318128, and LC318129, respectively. These strains were originally found in coastal areas of Vietnam where were contaminated with oil including Quang Ngai and Vung Tau. The bacteria can utilize polycyclic aromatic hydrocarbons (PAHs). A co-culture of PPB strains including DD4, DQ4, and FO2 was immobilized by biofilm formation on different carriers such as CB, CF, and PUF to decrease diesel oil pollution. The obtained results showed that bacterial attachment on carriers was able to maximize their oil-degrading capacities. To our knowledge, this is the first and novel work in which a mixture of purple phototrophic bacteria was immobilized on different carriers to enhance diesel oil-contaminated water removal capacity. And the application of biofilm, forming PPB, may especially be useful both in bioremediation and cost-effective value.

Materials and Methods

Growth Medium and Cultivation Conditions

Culture Media

For the entire experimentations, cultures were anaerobically cultivated at 30 ± 2 °C in minimal RCV medium [25], with minor alterations of Hillmer and Gest (1977) [30] procedures and at a distance of 20 cm from a 60-W tungsten lamp. Aromatic growth substrates were adjusted to pH 7 and a final concentration of 3 mM. Medium RCVBN is similar to RCV but supplemented with nicotinic acid (1 mg/l). For tests on utilization of different carbon sources for growth, RCVBN was modified by replacing malic acid as single organic substances. Solid RCVBN medium was supplemented with 2% agar.

Enrichment and Isolation of Hydrocarbon-Degrading PPB

Bacteria

Ten PPB strains were isolated by using diesel oil or naphthalene, pyrene, and anthracene as the unique source of carbon and energy from oil-contaminated samples taken in several coastal sites in Vietnam. In details, water and sediment samples were taken from oil-polluted coastal zones in Quang Ngai and Vung Tau, Vietnam. The enrichment was repeated three times and were performed as described by Nhi-Cong et al. (2016) [31] with RCVBN culturing supplemented with diesel oil, naphthalene, pyrene, or anthracene (100 ppm) as the unique carbon source, standing culture in 5000 Lux illumination at 30 ± 2 °C. About 1 mL of third enrichment solution was diluted into 3 logs and transferred onto the respective oil component spreading solid RCVBN plates. After 2 days of cultivation at 30 ± 2 °C, the colonies which formed clear sites on the spray-coated plates were chosen as the candidates for oil -utilizing strains. All selected strains were stored at − 20 °C in a liquid glycerol (20% (v/v)) stock.

Biofilm Formation Test

The biofilm-forming tests were conducted utilizing the technique defined by Schimada et al. (2012) [32]. In details, PPB strains were cultured overnight then the biomass was diluted to OD600 = 0.3 and inoculated (1% - v/v) into 300 μL of RCV medium in a 1.5 mL micro-centrifuge tubes (TC131615, Nippon Genetics, Tokyo, Japan). The standing tubes were kept in 5000 Lux illumination at 30 ± 2 °C for 2 days. Subsequently the pellicles and the medium were removed, and the tubes were gently rinsed with distilled water and filled with 500 μL of 1% crystal violet (CV) solution. After 25 min, the CV solution was removed, and the tubes were washed with distilled water again. The CV attached to the biofilm was extracted by 400 μL of 95% ethanol and quantified by measuring its absorbance at 570 nm. The RCV medium was used to analyze bacterial biofilm formation capacity. Positive control was the Acinetobacter calcoaceticus P23 [33] and negative control was a tube without an inoculum. Each experiment was carried out in triplicate. The strongest selective biofilm-forming strains were taken for further experiments.

Classification of Diesel Oil Utilizing Photosynthetic Purple Bacteria

All isolates were characterized by Gram staining, microscopical observations for intact cellular maximum absorption, and carbon source stimulation. PPB strains were identified by biochemical tests according to Bergey’s Manual of Determinative Bacteriology [34].

For identification of photosynthetic purple bacteria, a 1500 bp section located within the 16S rRNA gene was amplified by applying two primers (Fermentas) with the following sequences: 27f primer: (5′-GAGTTTGATCCTGGCTCAG-3) and 1527r primer: (5′-AGAAAGGAGGTGATCCAGCC-3′). A detailed protocol was presented by Ramana et al. (2012) [30]. The obtained sequence gene was identified under sequencing ABI Systems (USA) and was analyzed by Bioedit, Clustal X, and Mega4 softwares.

Operating Conditions and Procedures

All tests were carried out under light (5000 Lux illumination) at 30 ± 2 °C.

Pre-treatment Carriers

PPB were attached on porous, nontoxic, recyclable, and low-cost CB, CF, and PUF carriers. The method was reported by Huang et al. (2016) [35]. CF pieces were prepared as published by Chen et al. (2016). PUF cubes (5 mm size) were washed and entirely submerged in rectangular pieces (1 × 1 × 0.5 cm) as described by Alessandrello et al. (2017c) [15].

Bacterial Immobilization

Cells of equal proportion mixed strains of DD4, DQ41, and FO2 were produced in medium known as RCV. A volume of 5 mL of turbid cell suspension at O.D600 nm was washed along with phosphate buffer and resuspended in 100 mL RCV medium for 72 h with a temperature of 30 °C to achieve about 2 × 109 CFU. The cell suspension was subsequently cultivated in RCV medium containing 100 ml of volume and with 1.5 g of CB, CF, or submerged PUF. This combined incubation was cultured at a temperature of 30 °C for 120 h in fixed settings to help bacterial biofilm attach on the surfaces of the carriers. For every 48 h, the spent medium was replaced with fresh medium. The adherence cells were either utilized instantly or kept at 4 °C for 3 weeks. Therefore, these biofilm carriers were used within 3 weeks. Single-strain biofilm and mixed-species biofilm performed in the same manner without supplement carriers and with the initial bacterial density of 8 × 102 CFU/L.

Removal of Diesel Oil by Formation of Biofilm Cells on Carriers

Roughly 4 g of biofilm-CB, biofilm-CF, or biofilm-PUF (six pieces) were put into artificial seawater (ASW) with a volume of 10 ml supplemented with 17.2 g/L diesel oil in 100-ml rubber stopper glass bottles to eliminate oxygen and oil volatilization. The oil-removing experiments were continued for 14 days. At different times, biofilm-CB, CF, and PUF fragments were taken from the solution to estimate residual oil in the ASW and the absorbed oil by biofilm – carriers. The samples were extracted three times with hexane and concentrated by a rotary evaporation system to obtain the residual oil. The remaining oil was measured gravimetrically. The abiotic control was carried out by using a sterile carrier.

Quantification of Cell Number

For cell number quantifying, the procedure mentioned by Allessandrello et al. (2017a) [10] was employed with alterations. CB, CF, and PUF attached by biofilm were selected; their moisture weight were estimated and was rinsed two times with 5 ml of NaCl of 0.9% w/v saline solution to eliminate the planktonic cells and was sliced into tiny portions. For cell separation, the portions were placed in a saline solution with a volume of 5 mL and were vortexed for 10 min. Subsequently, the solution was diluted into 10-fold serials, and 1 mL of the dilution suspension was cultured in solid RCVBN plates. The plates were incubated under light (5000 lx) at 30 ± 2 °C for 5 days when the colonies of DD4, DQ41, and FO2 were visibly differentiated and counted. Logarithmic CFU/mL values for each strain existing as single, mixture biofilm without carrier assays as well as mixed biofilm immobilized on carrier assays were determined. These experiments were repeated three times.

Scanning Electron Microscope SEM

Scanning of biofilm-forming bacteria on carriers wad done by using electron microscopy (SEM, JSM-840, Japan) to observe cellular morphology. Single biofilm of PPB cells, grown in RCV medium under light (5000 lx) at 30 ± 2 °C were stepwise fixed on slides as reported by Nhi-Cong et al. (2014) [36]. Mixed-species biofilms were fixed on microscope slide by polylysine and then were assessed as the same manner with the single cells.

Analyses

The residues oils were extracted with 10-ml hexane/acetone (1:1, v/v) at different times. Each sample supplemented with 20-ppm (w/v) biphenyl (Wako, Tokyo, Japan) as an internal standard. The quantity of each hydrocarbon segment was evaluated by the gas chromatography (GC/FID) as described by Kunihiro et al. (2005) [37]. The average data were calculated by triplicate experiments.

Results and Discussion

Biofilm Formation

Ten PPB strains were isolated by using diesel oil or naphthalene, pyrene, and anthracene as the unique source of carbon and energy from oil-contaminated samples taken in several coastal sites in Vietnam. Biofilm formation of the 10 strains was evaluated, and as a result, the four tested strains including P23 (positive control), DD4, DQ41, and FO2 formed vigorous biofilms, whereas the others formed negligible biofilms. Moreover, the DD4, DQ41, and FO2 exhibited the best hydrocarbon degradation capacity among the isolated strains (Table 1). When using a batch cultivation condition for biofilm formation, the biomass of DD4, DQ41, and FO2 biofilms continued to increase even after 7 days (Fig. 1.). Thus, the DD4, DQ41, and FO2 were chosen as model PPB strains for further investigation.

Quantity of biofilm formation by hydrocarbon-degrading PPB strains and Acinetobacter calcoaceticus P23. Biofilm formation was measured via crystal violet staining technique. Positive control-Acinetobacter calcoaceticus P23 and negative control-K (without inoculation) (Yamaga et al. 2010). Error bar signifies standard deviation (n = 3)

Characterization and Identification

For characterization of the isolates, RCV mineral salt medium (Weaver et al. 1975) [25] supplemented with succinate (3 mM) instead of malic acid as a carbon source and nicotinic acid (1 mg/l) as a source of nitrogen were utilized, with cultivation under light (5000 lx) at 30 ± 2 °C. Colonies of photoheterotrophically growing strain DD4 were found to be in the shape of circular, convex, with smooth surface, tiny, and dark red in color; colonies of strain DQ41 were also circular, convex, smooth with dark red in color, and encompassed with a thin opaque margin; and colonies of strain FO2 were round, smooth, tiny, and light-red in color and enveloped with a thin opaque margin. Under SEM with a Model S-4800 (Hitachi, Japan), the structure of cell, size, cell division, and flagella were observed. As for the inner membrane structures, transmission electron microscope as mentioned by Hanada et al. (2002) [26] were performed. These isolates are Gram negative. The suspended cellular strains were estimated by spectrophotometry method with a wavelength of 400–900 nm in Novaspec II (England) and UV-1650PC (Japan) equipment. As a result, all strains have bacteriochlorophyll and carotenoids including spirilloxanthin and sphaeroidene; however there were no structures of internal membrane. DD4 cells had maximum absorption at 866, 806, and 591 nm; intact DQ41 cells had absorption maxima at 865, 806, 591, 492, 464, 445, and 406 nm; intact FO2 cells had absorption maxima at 865, 806, 591, 491, and 460 nm. These characters indicate that these strains differ from 2 species of Rhodopseudomonas including R. viridis and R. sulfoviridis which contained bacteriochlorophyll b and carotenoids 1,2-dihydroneurosporene và 1,2-dihydrolycopene [34].

For classification, all strains were grown on RCVBN mineral salts medium supplemented with different carbon sources such as formate, methanol, acetate, succinate, citrate, tartate, benzoate, glycerol, and malate (3 mM). The obtained results were compared with several species of Rhodopseudomonas and described in Table 2. The results indicate that all the strains can grow on some carbons such as acetate, succinate, malate, and glycerol but cannot grow on some others including methanol, citrate, tartate, and formate. Such capacities of the isolates are similar to species of Rhodopseudomonas. To confirm this result, all selected strain 16S rRNA gene sequences were analyzed, and the results were presented in Fig. 2. Based on the morphological characters and sequence alignment of 16S rRNA encoding gene, three selected strains were classified to have a high sequence homology and were named as Rhodopseudomonas sp. DD4, Rhodopseudomonas sp. DQ4, and Rhodopseudomonas sp. FO2. The gene sequences were recorded in DNA Data Bank of Japan with accession number LC318127, LC318128 and LC318129, respectively.

Scanning electron micrograph of the PPB strains; (b) dendrogram illustrating the phylogenetic relationships of three PPB strains within the family of the Rhodopseudomonas based on 16S rRNA gene sequence analysis. Numbers at nodes are referred as confidence values of bootstrap analyzed with 100 resamplings. Bar, 2 nucleotide substitution per 100 nucleotides

Counting the Number of Cells

The number of PPB containing in single and mixture species biofilm with the presence or excluding carriers was counted prior and following the assay of diesel oil removal. The value of logarithmic CFU of every exhibiting strain in the biofilms is presented in Fig. 3. The similar quantity with 8 × 102 (CFU m/L) (SD = 13) of each initial bacterial strain was set up at day 0. After 9 days of cultivation with original diesel oil concentration of 17.2 g/L, the CFU numbers of every single strain reported were nearly 7.93 log units. The number of cells of each PPB strain was detected in both biofilm particularly single and mixed species, and those enclosed to CF was not changed, while cultivable bacterial counts attached to CB and PUF were lower than other assays.

Furthermore, Fig. 4 illustrated the SEM images of CB, CF, and PUF with and without the immobilized PPB consortium. Results exhibited that CB and PUF surfaces contain pores and crevices, whereas CF demonstrated a flat structure, and all of the carriers were appropriate for the attachment of bacteria. Therefore, great microbe colonization on biocarriers’ surface was observed when the bacteria and carriers were cultured for 9 days. Single-layer cell immobilization was observed in all biocarriers. Besides, Fig. 3 showed that the number of PPB attached on CF was higher than on CB and PUF. The structure of CB and PUF may be the reason why it is difficult to cultivate PPB cells; also, the cultivable cells adhered to CB, and PUF was lower than those attached to CF and in mixed biofilm without carrier. Wang et al. (2015) [16] reported used biocarriers to grow bacterial cells using expanded graphite (EG), expanded perlite (EP), and bamboo charcoal as adsorbents. Oil was absorbed into pores of the carriers then the spread of oil was controlled and shortened with a straight connection between the oil and attached cells. The authors mentioned that the entire process could be revealed in two phases. In the first phase, the biocarriers rapidly adsorbed diesel oil and greatly reduced the oil concentration. The second phase was the bioremediation procedure in which bacteria utilized petroleum hydrocarbons as a carbon source to reduce oil components in water. End products of this process were carbon dioxide and water. Chen et al. (2016) [2] proposed that modified bamboo charcoal advanced the contact of hydrophobic diesel oil and adhered cells, bringing about an enhanced accessibility of the substrates for the oil degraders, improved contact between the embedded degraders and substrates, and synergistically expanding the total degradation/transformation approach [2]. This carrier structure permitted the accessible interaction surface between the diesel oil and adhered bacteria to increase remarkably. Therefore, these obtained results demonstrated that CB, CF, and PUF were suitable carriers to attach PPB strain and could enhance the diesel oil degradation by formed PPB biofilms.

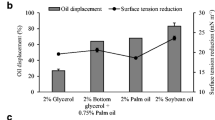

Diesel Oil Degradation by Immobilized Cells on Carriers

The capacity of the selected PPB for diesel oil degradation was separately estimated by GC [37]. Their efficiency of diesel oil degradation was performed by individually culturing them as biofilms for every single strain. Distinct profiles of oil disintegration were discovered, as displayed in Fig. 5a. The findings of GC analyses revealed that biofilms developed by the DD4, DQ41, and FO2 strains reduced diesel oil with 56, 60, and 58% after 14 days that has an initial concentration of 17.2 (g/l). By utilizing a mixed-species biofilm with no carrier, it was found that 78% of diesel oil degradation was achieved after 14 days. The maximum diesel oil degradation was discovered during the treatments that involve three types of biocarrier cell immobilization for 14 days (Fig. 5a and Fig. 5b). The mixed-species biofilm formed on CB, CF, and PUF showed significant reduction of diesel oil (p < 0.05) of 90, 91, and 95%, correspondingly, while diesel oil degradations shown in the use of three biocarrier without cell treatments were 16, 12, and 15% after 14-day incubation. Figure 5a and Fig. 5b showed that the increase in CFUs of the viable cell numbers can only be seen after 5 days, which leads to greater diesel oil removal. After 9 days, the number of cells tends to decrease, and this was associated with microorganisms’ dead-phase owing to long incubation period. From the results obtained, it can be deduced that for biomass production, the cells requires the exploitation of the diesel oil as the sole carbon and energy source. It was observed that in all the assessed treatments, there was nearly no difference in cultivable numbers. At the end of the 14-day incubation, overall bacterial counts in the treatments comprising all the biocarrier-attached cells and single-species counts were not significantly different (p > 0.05) from each other. In contrast, diesel oil degradation capacity was significantly different in PPB biofilm attached to biocarrier treatment, and all reductions were substantially higher than the abiotic control. The results indicated that PPB biofilms adhered to biocarrier, and it has the potential for diesel oil removal, especially the treatment with CF demonstrated the greatest (p < 0.05) oil degradation with 95% compared to other treatments.

Reduction in Different n-Alkane Containing in Diesel Oil

The results in Fig. 6 demonstrated no major difference in results for all control experiments using only carriers without cells (abiotic controls) in diesel oil degradation. Further experiments to estimate reduction of n-alkanes containing in diesel oil were carried out with only CF as abiotic control. Figure 7 shows the reduction of n-alkane components remaining in diesel oil in different mixed-species biofilm treatment. In general, more than 77% of hydrocarbon component degradation was achieved after 14 days in all biocarrier assessments. The highest reduction in n-alkanes was found in CF treatment ranging from 80 to 94%. Comparing to CB and PUF treatments, there was no major difference (p > 0.05) discovered. The findings of the diesel oil degradation components via in vitro artificial seawater bioremediation experiments revealed that the reduction of oil content relative to the negative control explains the abiotic losses. This implied that reductions in oil content in the treatments could only be attributed to either biotic degradation or removal by biofilm attached to biocarriers. Coconut fiber (CF) showed the best carrier for removing diesel oil. These results agreed with those reported in previous works demonstrating that immobilized bacteria on carriers enhanced diesel oil removal [4, 11, 16, 28]. It is considered that biofilm formation possibly protects cells against various environmental conditions and toxic pollutants [38]. The stable microenvironment of pores may safeguard immobilized cells from undesirable environmental factors [11].

Using aerobic bacteria and yeast immobilized on carriers to enhance hydrocarbon compounds containing in diesel oil have been reported by various authors [10,11,12, 35, 36, 39]. Chen et al. (2016) reported that Acinetobacter venetianus cells immobilized on modified bamboo charcoal as immobilization matrix had a superior efficiency in degrading diesel oil (94%) compared with planktonic cells culture (82%) over a 3-day period (initial concentration: 200 ppm) [2]. Lin et al. (2015) investigated the role of bagasse as a carrier to immobilize A. venetianus for the degradation of n-alkane. They obtained 93.3, 77.7, and 24.0% of tetradecane removal (initial concentration: 400 ppm) by the immobilized cells, free cells, and bagasse after 36 h incubation, respectively [4]. Hou et al. (2013) [11] demonstrated that a diesel oil-degrading marine bacterial strain, Acinetobacter sp. F9 immobilized on a novel floatable and biodegradable carrier material made by coating puffed foxtail millet (PFM) with a calcium alginate (CA)-chitosan compound membrane could reduce diesel oil up to 90% within the second day, while the planktonic F9 was not able to degrade 90% of the diesel oil even up to the seventh day (initial concentration: 1% (v/v) in 150 mL Erlenmeyer flasks) [11]. Liu et al. (2015) reported diesel oil removal of 78% with initial concentration of 2342 ppm) from ASW in 16 days using optimal aeration settings by applying calcium alginate-entrapped cells [13]. Nunal et al. (2014) analyzed the efficacy of cocopeat and rice hull powder acquired from agricultural wastes as biocarriers for an oil-degrading bacterial consortium [29]. They demonstrated that substantial oil degradations in both aliphatic and aromatic fractions were enhanced by using carrier-attached bacterial consortia rather than the treatments accompanied with similar consortium in free-living and encapsulated forms. Wang et al. (2015) used three diesel oil-degrading bacterial strains that included Pseudomonas sp. ODB-1, Brevundimonas sp. ODB-2, and Brevundimonas sp. ODB-3 [16]. With the aim to remove diesel oil, the strains were immobilized on the surface of expanded graphite (EG), expanded perlite (EP), and bamboo charcoal (BC). From the study, it was revealed that EG-bacteria immobilization system showed favorable remediation method with almost 100% diesel oil removal (initial concentration: 1614 mg/L diesel oil). This research utilized diesel oil with high concentration of 17.2 g/L which composed of complex hydrocarbons mixture. Additionally, this study focused on the economic aspect of using agro-industrial wastes as culture medium to attach biofilm formed by PPB. This aspect is vital for the development of innovative technologies for oil pollution mitigation. Moreover, there are lack of literatures on biofilm forming photosynthetic purple bacteria (PPB) adhered on biocarrier to remove diesel oil.

PPB, as reported by several authors could degrade and transform aromatic hydrocarbon components under both aerobic and anaerobic conditions [23, 40,41,42]. They were reported to metabolize diverse aromatic compounds such as phenolic, dihydroxylated, and methoxylated aromatic acids, as well as aromatic aldehydes and hydro-aromatic acids in both the presence and absence of oxygen [17, 43]. Gibson and Harwood (1995) firmly established that while aerobic attack on the benzene ring appears to follow patterns common to aerobic pseudomonads, the anaerobic pathway is radically different and the reductive attack on the ring [18]. Rhodopseudomonas (Rps.) palustris has served as a model organism to elucidate a central reductive pathway of benzoate degradation that is used to process most compounds anaerobically [43]. O’Toole et al. (2000) mentioned that the concentration of oxygen inside the biofilm was low [38]. The capacity of flexible hydrocarbon utilization in the presence or absence of oxygen of PPB offered a significant advantage in biofilm study.

Results of this study elucidated that inexpensive waste materials can be utilized as biocarriers of an oil-degrading PPB and that immobilization on biocarriers can enhance the bioremediation of oil-contaminated seawater. Especially, biofilm-CF approach was considered as the greatest remediation technique with 95% of diesel oil removal. As far as the author’s knowledge, this is the first report in which PPB immobilized on cheap and abundant carriers including cinder bead, coconut fiber, and polyurethane foam were used to degrade diesel oil. These results enhance our understanding of the degradation of diesel oil by adherence PPB on carriers and may give new insight into the potential role of such species in reduction of other recalcitrant aromatic compounds.

Conclusions

From this study, 3 oil-degrading PPB strains were isolated from oil-contaminated sediment and water samples collected in coastal sites including Quang Ngai and Vung Tau in Vietnam and marked as DD4, DQ41, and FO2. These strains were identified as Rhodopseudomonas sp. DD4, DQ41, and FO2. These cells were successfully immobilized on the surface of CB, CF, and PUF. The 14-day diesel oil biodegradation rates for single biofilm formed by each strain PPB were above 56%, while mixed-species biofilm without carrier could degrade 78% (initial concentration of 17.2 g/l); in contrast, the mixed biofilm formed by bacteria on carriers showed remarkable removal 95% on diesel oil compared with single biofilm formed by each strain PPB and mixed-species biofilm without carrier. The efficiency of the biofilms formed by bacteria on carriers for diesel oil biodegradation was more than 90%, and biofilm coconut fiber system gave the highest removal rate with 95%. Further studies should be conducted to provide data for constructing a model that can predict aromatic hydrocarbon degradation by immobilized PPB cells on carriers. The bacterial attachment on carriers was able to maximize their oil-degrading capacities, and to our knowledge, the application of biofilm-forming PPB is a cost-effective process and is useful for the advancement of bioremediation technique. Therefore, PPB biofilm-CF system could be a promising remediation option for oil-polluted sites. Hitherto, none of the published studies has reported on diesel oil degradation by photosynthetic purple bacterial biofilm attached to cinder beads, coconut fiber, and polyurethane foam.

References

Mendiola, S., Achutegui, J. J., Sanchez, F. J., & San, M. J. (1998). Polluting potential wastewater from fish-meal and oil industries. Grasas Aceites, 49, 30–33.

Chen, Y., Yu, B., Lin, J., Naidu, R., & Chen, Z. (2016). Simultaneous adsorption and biodegradation (SAB) of diesel oil using immobilized Acinetobacter venetianus on porous material. Chem Eng J, 289, 463–470.

Li, H., Liu, L., & Yang, F. (2012). Hydrophobic modification of polyurethane foam for oil spill cleanup. Mar Pollut Bull, 64(8), 1648–1653.

Lin, J., Gan, L., Chen, Z., & Naidu, R. (2015). Biodegradation of tetradecane using Acinetobacter venetianus immobilized on bagasse. Biochem Eng J, 100, 76–82.

Varjani, S. J., Rana, D. P., Jain, A. K., Bateja, S., & Upasani, V. N. (2015). Synergistic ex-situ biodegradation of crude oil by halotolerant bacterial consortium of indigenous strains isolated from on shore sitesof Gujarat. India Inter Biodeterio Biodegrad, 103, 116–124.

Manohar, S., Kim, C. K., & Karegoudar, T. B. (2001). Enhanced degradation of naphthalene by immobilization of Pseudomonas sp. strain NGK1 in polyurethane foam. Appl Microbiol Biotechnol, 55, 311–316.

Patel, V., Cheturvedula, S., & Madamwar, D. (2012). Phenanthrene degradation by Pseudoxanthomonas sp. DMVP2 isolated from hydrocarbon contaminated sediment of Amlakhadi canal, Gujarat, India. J. Hazard. Mater. 201-202: 43-51. https://doi.org/10.1016/j.jhazmat.2011.11.002.

Varjani, S. J., & Upasani, V. N. (2016). Biodegradation of petroleum hydrocarbons by oleophilic strain of Pseudomonas aeruginosa NCIM 5514. Bioresour Technol, 222, 195–201.

Wu, M., Li, W., Dick, W. A., Ye, X., Chen, K., Kost, D., & Chen, L. (2017). Bioremediation of hydrocarbon degradation in a petroleum contaminated soil and microbial population and activity determination. Chemosphere, 169, 124–130.

Alessandrello, M. J., Tomás, M. S. J., Raimondo, E. E., Vullo, D. L., & Ferrero, M. A. (2017a). Petroleum oil removal by immobilized bacterial cells on polyurethane foam under different temperature conditions. Mar Pollut Bull. https://doi.org/10.1016/j.marpolbul.2017.06.040.

Hou, D., Shen, X., Luo, Q., He, Y., Wang, Q., & Liu, Q. (2013). Enhancement of the diesel oil degradation ability of a marine bacterial strain by immobilization on a novel compound carrier material. Mar Pollut Bull, 67(1-2), 146–151.

Liang, Y., Zhang, X., Dai, D., & Li, G. (2009). Porous biocarrier-enhanced biodegradation of crude oil contaminated soil. Inter Biodeterio Biodegrad, 63, 80–87.

Lin, M., Liu, Y., Chen, W., Wang, H., & Hu, X. (2014). Use of bacteria-immobilized cotton fiber to absorb and degrade crude oil. Inter. Biodeterio. Biodegrad., 88, 8–12.

Alessandrello, M. J., Tomás, M. S. J., Isaac, P., Vullo, D. L., & Ferrero, M. A. (2017b). PAH removal by immobilized bacterial cells-support systems using low-cost culture media for biomass production. Inter. Biodeterio. Biodegrad., 120, 6–14.

Alessandrello, M. J., Parellada, E. A., Tomás, M. S. J., Neske, A., Vullo, D. L., & Ferrero, M. A. (2017c). Polycyclic aromatic hydrocarbons removal by immobilized bacterial cells using annonaceous acetogenins for biofilm formation stimulation on polyurethane foam. J Environ Chem Eng, 5, 189–195.

Wang, X., Wang, X., Liu, M., Bu, Y., Zhang, J., Chen, J., & Zhao, J. (2015). Adsorption–synergic biodegradation of diesel oil in synthetic seawater by acclimated strains immobilized on multifunctional materials. Mar Pollut Bull, 92(1-2), 195–200.

Harwood, C. S., & Gibson, J. (1988). Anaerobic and aerobic metabolism of diverse aromatic compounds by the photosynthetic bacterium Rhodopseudomonaspalustris. Appl Environ Microbiol, 54(3), 712–717.

Gibson, J., & Harwood, C. S. (1995). Degradation of aromatic compounds by nonsulfur purple bacteria. In R. E. Blankenship, M. T. Madigan, & C. E. Bauer (Eds.), Anoxygenic photosynthetic bacteria (pp. 991–1003). Dordrecht: Kluwer Academic Publishers.

Madigan, T. M., & Jung, D. O. (2009). An overview of purple bacteria: Systematics, physiology and habitats. In C. N. Hunter, F. Daldal, & B. Thurnauer (Eds.), The purple phototrophic Bacteria (pp. 1–15). Dordrecht: Springer.

Rajasekhar, N., Sasikala, C., & Ramana, C. V. (2000). Toxicity of N-containing heterocyclic aromatic compounds and their utilization for growth by a few purple non-sulfur bacteria. Bull Environ Contam Toxicol, 65(3), 375–382.

Frank, J., & Gaffron, H. (1941). Photosynthesis. Facts and interpretations Adv Enzymol Relat Subj Biochem, 1, 199–202.

Pfennig, N., Eimhjellen, K. E., & Liaaen-Jensen, S. (1965). A new isolate of the Rhodospirillum fulvum group and its photosynthetic pigments. Arch Mikrobiol, 51, 258–266.

Wright, G. E., & Madigan, M. T. (1991). Photocatabolism of aromatic compounds by the phototrophic purple bacterium Rhodomicrobiumvannielii. Appl Environ Microbiol, 57(7), 2069–2073.

Biebl, H., & Pfennig, N. (1981). Isolation of members of the family Rhodospirillaceae. In M. P. Starr, H. Stolp, H. G. Trueper, A. Balows, & H. G. Schlegel (Eds.), The prokaryotes (pp. 167–273). New York: Springer.

Weaver, P. F., Wall, J. D., & Gest, H. (1975). Characterisation of Rhodopseudomonas capsulata Arch Microbiol, 105(1), 207–216.

Hanada, S., Takaichi, S., Matsuura, K., & Nakamura, K. (2002). Roseiflexuscastenholzii gen. Nov., sp. nov., a thermophilic, filamentous, photosynthetic bacterium that lacks chlorosomes. Int J Syst Evol Microbiol, 52(Pt 1), 187–193.

Zengler, K., Heider, J., Rossello Mora, R., & Widdel, F. (1999). Phototrophic utilization of toluene under anoxic conditions by a new strain of Blastochloris sulfoviridis. Arch Microbiol, 172(4), 204–212.

Ramana, C. V., Sasikala, C., Arunasri, K., Anil Kumar, P., Srinivas, T. N. R., Shivaji, S., Gupta, P., Sueling, J., & Imhoff, J. F. (2006). Rubrivivax benzoatilyticus sp. nov., an aromatic, hydrocarbon-degrading purple betaproteobacterium. Int J Syst Evol Microbiol, 56(Pt 9), 2157–2164.

Nuñal, S. N., Santander-de Leon, S. M. S., Bacolod, E., Koyama, J., Uno, S., Hidaka, M., Yoshikawa, T., & Maeda, H. (2014). Bioremediation of heavily oil-polluted seawater by a bacterial consortium immobilized in cocopeat and rice hull powder. Biocontrol Science, 19(1), 11–22.

Hillmer, P., & Gest, H. (1977). H2 metabolism in the photosynthetic bacterium Rhodopseudomonas capsulata: H2 production by growing cultures. J Bacteriol, 129(2), 724–731.

Nhi-Cong, L. T., Mai, C. T. N., Minh, N. N., Ha, H. P., Lien, D. T., Tuan, D. T., Quyen, D. V., Ike, M., & Uyen, D. T. T. (2016). Degradation of sec-hexylbenzene and its metabolites by a biofilm-forming yeast Trichosporonasahii B1 isolated from oil-contaminated sediments in Quangninh coastal zone, Vietnam. J. Environ. Sci. Health, Part A, 51(3), 267–275.

Shimada, K., Itoh, Y., Washio, K., & Morikawa, M. (2012). Efficacy of forming biofilms by naphthalene degrading Pseudomonas stutzeri T102 toward bioremediation technology and its molecular mechanisms. Chemosphere, 87(3), 226–233.

Yamaga, F., Washio, K., & Morikawa, M. (2010). Sustainable biodegradation of phenol by Acinetobacter calcoaceticus P23 isolated from the rhizosphere of duckweed Lemna aoukikusa. Environ Sci Technol, 44(16), 6470–6474.

Imhoff, J. F., & Trueper, H. G. (1980) Purple non-sulfur bacteria (Rhodospirillaceae Pfening and Trueper 197, 17AL) in: Staley JT, Bryant MP, Pfening N, Holt JG (Eds.), Bergey’ manual of Systematic Bacteriology, vol. 3, Williams and Wilkins, Bantimore, pp. 1438-1680.

Huang, R., Tian, W., Liu, Q., Yu, H., Jin, X., Zhao, Y., Zhou, Y., & Feng, G. (2015). Enhanced biodegradation of pyrene and indeno (1,2,3-cd) pyrene using bacteria immobilized in cinder beads in estuarine wetlands. Mar Pollut Bull. https://doi.org/10.1016/j.marpolbul.2015.11.044.

Nhi-Cong, L. T., Mai, C. N., Thanh, V. T., Nga, L. P., & Minh, N. N. (2014). Application of a biofilm formed by a mixture of yeasts isolated in Vietnam to degrade aromatic hydrocarbon polluted wastewater collected from petroleum storage. Water Sci Technol, 70(2), 329–336.

Kunihiro, N., Haruki, M., Takano, K., Morikawa, M., & Kanaya, S. (2005). Isolation and characterization of Rhodococcussp. Strains TMP2 and T12 that degrade 2,6,10,14-tetramethylpentadecane (pristane) at moderately low temperatures. J. Biotechnol., 115(2), 129–136.

O’Toole, G. A., Kaplan, H. B., & Kolter, R. (2000). Biofilm formation as microbial development. Annu Rev Microbiol, 54, 49–79.

Deng, F., Liao, C., Yang, C., Guo, C., & Dang, Z. (2016). Enhanced biodegradation of pyrene by immobilized bacteria on modified biomass materials. Inter. Biodeterio. Biodegrad., 110, 46–52.

Madigan, M. T., Jung, D. O., & Resnick, S. M. (2001). Growth of the purple bacterium Rhodobacter capsulatus on the aromatic compound hippurate. Arch Microbiol, 175(6), 462–465.

Ramana, V. V., Chakravarthy, S. K., Raj, P. S., Kumar, B. V., Shobha, E., Ramaprasad, E. V. V., Sasikala, C., & Ramana, C. V. (2012). Descriptions of Rhodopseudomonas parapalustris sp. nov., Rhodopseudomonas harwoodiae sp. nov. and Rhodopseudomonas pseudopalustris sp. nov., and emended description of Rhodopseudomonas palustris. Int J Syst Evol Microbiol, 62, 1790–1798.

Trüper, H. G., & Pfennig, N. (1981). Characterization and identification of the Anoxygenic phototrophic Bacteria. In M. P. Starr, H. Stolp, H. G. Trüper, A. Balows, & H. G. Schlegel (Eds.), The prokaryotes: A handbook of on habitats, isolation and identification of bacteria (pp. 299–311). Berlin, Heidelberg: Springer.

Harwood, C. S. (2009). Degradation of aromatics compounds by purple non-sulfur bacteria. In C. N. Hunter, F. Daldal, & B. Thurnauer (Eds.), The purple phototrophic Bacteria (pp. 577–594). Dordrecht: Springer.

Funding

This research is funded by Vietnam National Foundation for Science and Technology Development (NAFOSTED) under grant number 106-NN.04–2015.45, Yayasan Universiti Teknologi PETRONAS under grant number YUTP 015LC0–047 and Fundamental Research Grant Scheme (Malaysia, FRGS/1/2019/STG05/UNIM/02/2).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors are aware with the ethical responsibilities required by the journal and are committed to comply them.

Conflict of Interest

The authors declare that they have no competing interests.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nhi-Cong, L.T., Lien, D.T., Gupta, B.S. et al. Enhanced Degradation of Diesel Oil by Using Biofilms Formed by Indigenous Purple Photosynthetic Bacteria from Oil-Contaminated Coasts of Vietnam on Different Carriers. Appl Biochem Biotechnol 191, 313–330 (2020). https://doi.org/10.1007/s12010-019-03203-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-019-03203-x