Abstract

A coordinatively immobilized laccase was prepared using a new cryogel type carrier. The support has a wide-pore texture facilitating diffusion of different substrates to the enzyme reaction center. The biocatalyst proved to be efficient in decolorization of two anthraquinone derivatives, namely Acid Blue 62 and bromaminic acid. After 24 h over 80% of the two substrates have been oxidated. The kinetic data (K m and V max) for the oxidation of the two anthraquinone derivatives, with the free and immobilized enzyme, have been determined and compared. Other parameters, like k cat and the specificity constant have been calculated and analyzed. The influence of substrate properties (hydrophobicity, polarity, etc.) has been discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The synthetic dyes have many industrial applications due to their relatively easy preparation and moderate cost. Textile industry is one of the most important beneficiaries as it uses dyes for fabric coloration [1]. Unfortunately, synthetic dyes are a source of pollution for the wastewaters of textile or other industries, with a number of negative effects on the environment. Among the most important ones we can mention: reduction of water transparency with diminution of the chlorophyll light absorption and consequently, of the photosynthetic process, and the toxicity of the dyes or of their degradation products. Thus, a number of physical, chemical, and biochemical methods have been proposed for dye removal from wastewaters [2–7].

A green solution for dye pollution elimination is the use as catalysts of redox type enzymes, like laccases [8–10]. An important number of papers are dedicated to laccase decolorization and detoxification of waters polluted with dyes, some of the most recent being mentioned [11–20].

The usual low stability of the free enzyme makes the process difficult for large-scale applications. The immobilization of the enzyme seems to be a solution for better practical results [21–24]. Thus, a reasonable choice of the appropriate carrier and immobilization method are the key points for facilitating a desirable activity and operation characteristics of immobilized enzyme biocatalyst. In the case of laccase immobilization, one promising and technically simple approach was the enzyme attachment to a special insoluble carrier via coordination bonds, resulting in the formation of sufficiently stable metal–chelate structures, e.g., Cu-IDA-Sepharose as carrier [25, 26]. However, the latter resin is rather expensive, and can hardly be employed in scaled-up processes. Therefore, it was of interest to evaluate an alternative metal–chelate matrix, in this case, a wide-porous gel (called cryogel) [27–29] as immobilization carrier.

The kinetics of an anthraquinone acid dye and its precursor, with free and coordinatively immobilized laccase on cryogel matrix, are presented, and comparatively discussed.

Experimental

Chemicals

2,2′-Azinobis-(3-ethylbenzothiazoline-6-sulfonate, disodium salt) (ABTS) was provided by Sigma (USA); N,N-dimethylacrylamide (DMAAm), allyl glycidyl ether (AGE) and N,N′-methylene-bis-acrylamide (MBAAm) were purchased from Aldrich (USA); N,N,N′,N′-tetramethylethylene diamine (TMEDA) and iminodiacetic acid (IDA) from Fluka (Switzerland); and potassium persulfate (PPS) was from Acros Chemicals (Belgium); all of them were used as received. All other chemicals used were of analytical grade.

Carrier for Laccase Immobilization

The synthesis of the polymer carrier was performed as follows. A mixture was prepared from 0.168 mL of DMAAm and 0.026 g of MBAAm dissolved in 3.5 mL of water, and the solution was bubbled with argon for 20 min. Further, 0.022 mL of AGE and 0.011 mL of TMEDA were added, then the solution was cooled in an ice bath for 15 min, after which 0.5 mL of PPS aqueous solution (0.02 g mL−1) were finally added. This reaction mixture was sucked in a 5-mL plastic syringe, which was sealed, and placed in the chamber of a precision programmable cryostat FP 45 HP (Julabo, Germany), where the sample was frozen and kept at −12 °C for 18 h. After thawing at room temperature, 250 mL of pure water were passed through the syringe with a rate of 100 mL h−1, for rinsing of the unreacted monomers from the spongy cryogel (4 mL in volume). Then, 50 mL of 0.5 M Na2CO3 aqueous solution, and 50 mL of 1 M Na2CO3 aqueous solution were sequentially passed through the wide-porous matrix, followed by 30 mL of 0.5 M solution of IDA in 1 M Na2CO3 (Scheme 1). The cryogel was stored in this solution for a night and then sequentially rinsed with 100 mL of 0.5 M Na2CO3 aqueous solution and 200 mL of pure water. Prior to enzyme immobilization, the carrier was saturated with copper ions by passing 100 mL of 0.5 M CuSO4 aqueous solution through the column, followed by rinsing the resin with pure water for eliminating unbound copper.

Enzyme

Laccase Roglyr Lite 1540 was a commercial product supplied by Hungarian Industry Products KFT and produced by Rotta Manheim. The protein content of the commercial laccase was determined by the Bradford method [30], measuring the complex of Coomassie Brilliant Blue G250 at 595 nm. The standard protein solution was bovine serum albumin. According to the experimental results [31] there is a quantity of 25.7 ± 1.2 mg protein g−1 in the commercial product (average value of triplicate experimental determinations)

Characterization of Substrates

The Acid Blue 62 has been kindly supplied by CHT Bezema.

The Bromaminic acid (1-amino-4-bromo-9,10-dihydro-9,10-dioxo-anthracene-2-sulfonic acid, sodium salt, 2), orange solid (λ max = 490 nm); water soluble, has been purchased from Sigma-Aldrich.

The structure of the commercial dye has been confirmed by UV–vis and NMR spectroscopy. UV–vis spectra were recorded on a Jena apparatus. 1H and 13C NMR spectra were acquired on a Bruker Avance DRX400 spectrometer in deuterated dimethylsulfoxide (DMSO-d6).

CI Acid Blue 62—CI 62045 (1-amino-4-cyclohexylamino-9,10-dihydro-9,10-dioxo-anthracene-2-sulfonic acid, sodium salt, 1), blue solid (λ max = 585 nm), water soluble.

1H-NMR spectrum (DMSO-d6, δ ppm): 1.3–1.5 (5H, m; H12–16); 1.55–1.65 (1H, m, H14); 1.7–1.8 (2H, m, H13,15); 1.95–2.05 (2H, m, H12,16); 3.65–3.75 (1H, large, H11); 7.79 (1H, s, H3); 7.75–7.85 (2H, m, H5,8); 8.2–8.3 (2H, m, H6,7).

13C NMR spectrum (DMSO-d6, δ ppm): 24.83(C13,15); 26.11(C14); 33.84 (C12,16); 50.85 (C11); 109.57 (C4a); 110.04 (C9a); 122.19 (C3); 126.68 (C6 or C7); 126.82 (C7 or C6); 133.34 (C5 sau C8); 133.46 (C8 or C5); 134.88 (C8a); 134.93 (C10a); 143.96 (C1); 144.47 (C4); 145.38 (C2); 181.59 (C9); 182.41 (C10).

Enzyme Immobilization

The polymer carrier was formed as 4-mL continuous cylinders in 5-mL plastic syringes. The column was washed with 0.1 M NaOAc buffer (2 mL min−1), and then, a solution in the same buffer of 0.3 mg mL−1 commercial laccase, in amount of 150 mL (2 mL min−1), was added. The enzyme solution was passed twice through the column in order to enhance the immobilized enzyme content. Finally, the column was washed with 100 mL buffer solution which was combined with the enzyme solution passed through the column. The content of protein fixed on the column resulted from the difference between the initial content of protein and the final protein content of the solution obtained after immobilization and washing.

Enzyme Activity

The activity of the free and immobilized laccase was determined using ABTS as standard based on the previously described procedure [31]. The assays have been performed with a solution of 60 mM ABTS as substrate, at 37 °C, by monitoring the absorbance at 420 nm (ε420 = 3.6·104 M−1 cm−1). One unit of laccase activity (U) is defined as the amount of enzyme required for oxidizing 1 μmol of ABTS per minute. The average value for the immobilized enzyme, at the working pH (4.7) obtained for a triplicate was 51.6 U g−1. Measurements of activity at lower or higher pH have given lower values as previously observed in the Sepharose case [25].

Kinetic Measurements

The kinetics of the decolorization process was analyzed in a cuvette system, at 25 °C, containing different quantities of substrate (concentrations of compounds 1 and 2 from 0.08 to 0.8 mM) dissolved in a NaOAc buffer solution (pH = 4.7). The substrate content has been in excess toward the enzyme content, which was 0.11 μM for the free enzyme and 0.1 mL biocatalyst per cuvette (0.135 μM), respectively. The variation of the absorbance corresponding to λ max of the two substrates was monitored with a 200R Analytic Jena Spectrophotometer. The K m and V max were determined applying the Lineweaver–Burk relationship.

Results and Discussion

A macroporous cryogel carrier was prepared by the redox-initiated co-polymerization of DMAAm, AGE, and MBAAm mixture in a moderately frozen aqueous medium. The advantages of cryogel type substrate for laccase immobilization were underlined in a previous paper [31]. The applied synthetic procedure is based on the results of studies of poly(acrylamide) cryogel synthesis, where the main experimental characteristics have been previously established [32–34]. A subsequent attachment of IDA to the epoxy functional groups afforded the chelating resin IDA–poly(DMAAm)–cryogel (see Scheme 1).

The differences from the previous synthetic procedure of the carrier consisted in the fact that a more functionalized poly(N,N-dimethylacrylamide)-based matrix was prepared by using potassium persulfate for the initiation of radical polymerization, instead of the ammonium persulfate employed earlier. Thus, the undesirable side reaction of ammonia with the epoxy groups, reducing the amount of sites for subsequent IDA coupling, was avoided. As a result a wide-pore IDA-bearing polymer was obtained, as proved by the microscopic analysis. The micrograph in Fig. 1 demonstrates that this gel carrier possesses a system of interconnected gross pores with a 70–120-μm cross-section. A semi-quantitative evaluation of the image displayed a matrix porosity of about 92%.

The macroporous structure was confirmed also by the value of 400 mL h−1 obtained for the water flow rate, when passed through the polymer, at a constant hydrostatic pressure of 100 cm water column.

The resulted gel matrix was used as a carrier for the immobilization of commercial laccase, by coordination of the enzyme to the cooper atoms of a preformed IDA complex. A coordinated complex is formed by Cu2+ with the amino and the two carboxyl groups of the functionalized carrier, together with an amino or thiol group of the enzyme (see Fig. 2). The coordination process of immobilization is suitable for the enzyme, due to the higher affinity of copper for the N and S atoms of the appropriate amino acids (histidine [35], cysteine, lysine, arginine, etc.) of the enzyme, compared with the O atoms of the other compounds contained in the commercial product (adipic acid, etc.).

The quantity of enzyme immobilized was of 0.30 mg protein mL−1, comparable with the results obtained with Sepharose as carrier [25]. The small content of immobilized enzyme may be caused by the reduced protein content, previously evidenced into the commercial product [31].

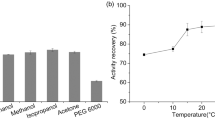

The advantages of such immobilization process, compared with a covalent immobilization described before [31] consist in the simplicity of the procedure as well as in the possibility to regenerate the biocatalyst as previously described for a similar metal–chelate [25], process not possible in the case of the covalently-linked enzyme. The carrier leads to the change of optimum pH to 4.7 from 3.8 characteristic to the free enzyme [31]. The immobilized enzyme activities at pH 3.8 and 5.8 are 70% and 35% from the value obtained at a pH of 4.7. A similar value for the optimum pH (5.0) was previously indicated for a similar immobilization of laccase [25].

The biocatalyst obtained by immobilization is more stable than the free enzyme. Its activity is 85% preserved after 50 h at 60 °C while the free enzyme is totally inactive in similar conditions. It may be preserved at 5 °C, the activity being 95% from the initial one after 5 months.

The immobilized laccase as well as the free laccase have been used for the treatment of water solutions containing two anthraquinone derivatives 1 and 2.

The structure of the commercial product 1 was confirmed by NMR analysis, the spectral data being in agreement with literature [36]. The chemical shift assignment was based on a series of 2D NMR experiments (COSY, HMQC, HMBC, or HSQC). The 2D NMR experiment HSQC, shown in Fig. 3, makes clear the correspondence between the carbon and the hydrogen atoms, indicating a reversed spectral attribution, compared with literature [36] data, for carbons 8, 5 and 6, 7.

Solutions of compounds 1 and 2 have been treated with free and the equivalent quantities of immobilized enzymes. The ratio dye/enzyme is almost the same in both types of experiments. The enzymatic biodegradation of compounds 1 and 2 was followed by monitoring the variation of absorption at 585 and 490 nm, respectively.

The decolorization process monitored on a solution of 0.78 mM of compounds 1 and 2 and a molar ratio substrate/enzyme of 3·103, displayed the following results.

For the acid dye 1, the process is working comparatively with free and immobilized enzyme (see Fig. 4a). For this compound there are small differences, first at the beginning of the process due to adsorption of the dye on the carrier; after 1 h the decolorization being 14.3% and 24% for the free and immobilized enzyme, respectively. After 24 h, the free enzyme gave 80% decolorization, while the immobilized enzyme experiments evidenced only 75%.

In the case of compound 2 (see Fig. 4b), it is clear that free enzyme is more efficient. After 6 h the free enzyme has decolorized almost all the compound, while with the immobilized enzyme 25% of the compound 2 is still present. The difference is most probably generated by the high polarity of the compound, making it less accessible to the immobilized enzyme due to the carrier polar structure.

In the immobilized enzyme case, for calculating the enzyme kinetics, the influence of the cryogel polymer as adsorbent was eliminated by performing similar experiments with the matrix free of enzyme. The enzyme action was measured by subtracting the absorbance variation value for the polymer carrier alone, from that for the polymer with the immobilized enzyme. The diminishing of the absorbance due to the carrier was around 20% of the total value for both compounds. The possibility of eliminating dyes by simple adsorption was previously mentioned [4].

The kinetics of these compounds transformation can be described by a Michaelis–Menten model, in agreement with literature data [17]. Based on Lineweaver–Burk relationship, the values for K m, V max, as well as for the calculated k cat and k cat/K m (specificity constant) have been obtained, and are presented in Table 1.

According to the experimental data, for the compounds 1 and 2, with similar structures, there are not very important differences concerning the V max values. The ratio between V max2 /V max1 is comparable for the free and immobilized enzyme, 1.67 and 1.5, respectively. This indicates an apparent more rapid transformation of compound 2 (richer in electrons to be donated to the cooper atoms of the enzyme, due to the presence of Br) in comparison with compound 1. For each compound, the V max values decreased at almost half in the reaction with the immobilized enzyme, most probably due to the limitation of the substrate–enzyme encounter, through diffusion. A possible coordination of the amino-antraquinone compounds to the copper atoms attached to the carrier may also diminish the access to the catalytic site.

Due to the fact that the enzyme concentrations were similar in both types of experiments, a similar variation is observed for the k cat (V max/[E t]) values. The values indicated a more rapid transformation into products (or release of products [37]) of compound 2 compared to compound 1.

The K m experimental values reflect the apparent higher “affinity” of the free enzyme for the substrate 1 (to capture it [37] forming the complex) compared with substrate 2, K m2/K m1 being almost 5. For the immobilized enzyme there is a smaller difference (K m2/K m1 = 1.1) revealing the carrier influence on the reaction kinetics. The higher values of K m for the immobilized enzyme may be connected with the mass transport constraint [38].

The specificity constant (k cat/K m) values for compounds 1 and 2 are higher in the case of free enzyme, fact reflecting once more the carrier influence. In a competition between 1 and 2, the compound 1 is captured easier in the case of the free enzyme (may be due to its higher hydrophobicity), while for the immobilized enzyme the compound 2 (with a smaller molecule) seems to be favored. The same variation is observed for the V/K values, defined by Northrop, as the “apparent rate constant for capture of the substrate into enzyme complexes” leading later on to products [37].

Conclusions

A new immobilized biocatalyst has been obtained by coordinatively linking the enzyme to a functionalized matrix of poly(N,N-dimethylacrylamide)-cryogel type carrier. Such immobilization process is simpler compared with the previous covalent immobilization, and the carrier could be reused after the deactivation of the enzyme. A higher stability of the immobilized enzyme was observed.

The biocatalyst gives a decrease of over 80% of the Acid Blue 62 and bromaminic acid content, in the experimentally treated aqueous solutions, which recommends the new catalyst for wastewaters treatment. The matrix has a positive effect on the dyes elimination by the experimentally evidenced adsorption effect.

Based on the kinetic parameters determined (K m and V max), or calculated (k cat and the specificity constant) some substrate characteristics influencing the enzymatic oxidation, (hydrophobicity, polarity, etc.) may be evidenced.

References

Venkata Mohan, S., & Karthikeyan, J. (2004). Clean Technologies Environmental Policy, 6, 196–200.

Hai, F. I., Yamamoto, K., & Fukushi, K. (2007). Critical Reviews in Environmental Science and Technology, 37, 315–377.

Crini, G. (2006). Bioresource Technology, 97, 1061–1085.

Prigione, V., Tigini, V., Pezzella, C., Anastasi, A., Sannia, G., & Varese, G. C. (2008). Water Research, 42, 2911–2920.

Bes-Pia, A., Mendoza-Roca, J. A., Roig-Alcover, R., Iborra-Clar, A. I., Iborra-Clar, M. I., & Alcaina-Miranda, M. I. (2003). Desalination, 157, 73–80.

Lachheb, H., Puzenat, E., Houas, A., Ksibi, M., Elaloui, E., Guillard, C., et al. (2002). Applied Catalysis B: Environmental, 39, 75–90.

Van der Zee, F. (2002). Anaerobic azo dye reduction, Ph. D. Thesis Wageningen University, Wageningen, Netherlands

Gianfreda, L., Xu, F., & Bollag, J. (1999). Bioremediation Journal, 3, 4–25.

Zille, A. (2005) Lacasse reactions for Textile Applications, Ph. D. Thesis University of Minho, Guimaraes, Portugal

Desai, S. S., & Nityanand, C. (2011). Asian Journal of Biotechnology, 3, 98–124.

Niladevi, K. N., Niladevi, K. N., Sheejadevi, P. S., & Prema, P. (2008). Applied Biochemistry and Biotechnology, 151, 9–19.

Rodriguez Couto, S. (2007). Journal of Hazardous Materials, 149, 768–770.

Khlifi, R., Belbahri, L., Woodward, S., Ellouz, M., Dhouib, A., Sayadi, S., et al. (2010). Journal of Hazardous Materials, 175, 802–808.

Majeau, J.-A., Brar, S. K., & Tyagi, R. D. (2010). Bioresource Technology, 101, 2331–2350.

Vanhulle, S., Enaud, E., Trovaslet, M., Billottet, L., Kneipe, L., Jiwan, J.-L. H., et al. (2008). Chemosphere, 70, 1097–1107.

Baldrian, P., & Snajdr, J. (2006). Enzyme and Microbial Technology, 39, 1023–1029.

Michniewicz, A., Ledakowicz, S., Ullrich, R., & Hofrichter, M. (2008). Dyes and Pigments, 77, 295–302.

Neifar, M., Jaouani, A., Ellouze-Ghorbel, R., & Ellouze-Chaabouni, S. (2010). Journal of Molecular Catalysis B: Enzymatic, 64, 68–74. doi:10.1016/j.molcatb.2010.02.004.

Russo, M. E., Giardina, P., Marzocchella, A., Salatino, P., & Sannia, G. (2008). Enzyme and Microbial Technology, 42, 521–530.

Yang, X. Q., Zhao, X. X., Liu, C. Y., Zheng, Y., & Qian, S. J. (2009). Process Biochemistry, 44, 1185–1189.

Champagne, P.-P., & Ramsay, J. A. (2010). Applied Microbiology and Biotechnology, 101, 2230–2235.

Duran, N., Rosa, M. A., D’Annibale, A., & Gianfreda, L. (2002). Enzyme and Microbial Technology, 31, 907–931.

Rasera, K., Ferla, J., Dillon, A. J. P., Riveiros, R., & Zeni, M. (2009). Desalination, 245, 657–661.

Bayramoglu, G., Ylmaz, M., & Arica, M. Y. (2010). Bioresource Technology, 101, 6615–6621.

De Stefano, G., Piacquadio, P., & Sciancalepore, V. (1996). Biotechnology Techniques, 10, 857–860.

Piacquadio, P., De Stefano, G., Sammartino, M., & Sciancalepore, V. (1997). Biotechnology Techniques, 11, 515–517.

Lozinsky, V. I., Galaev, I. Y., Plieva, F. M., Savina, I. N., Jungvid, H., & Mattiasson, B. (2003). Trends in Biotechnology, 21, 445–451.

Lozinsky, V. I. (2008). Russian Chemical Bulletin, 57, 1015–1032.

Plieva, F. M., Galaev, I. Y., Noppe, W., & Mattison, B. (2008). Trends in Microbiology, 16, 543–551.

Bradford, M. M. (1976). Analytical Biochemistry, 72, 248–254.

Stanescu, M. D., Fogorasi, M., Shaskolskiy, B. L., Gavrilas, S., & Lozinsky, V. I. (2010). Applied Biochemistry and Biotechnology, 160, 1947–1954. doi:10.1007/s12010-009-8755-0.

Lozinsky, V. I., Morozova, S. A., Vainerman, E. S., Titova, E. F., Shtil’man, M. I., Belavtseva, E. M., et al. (1989). Acta Polymerica, 40, 8–15.

Arvidsson, P., Plieva, F. M., Savina, I. N., Lozinsky, V. I., Fexby, S., Bulow, L., et al. (2002). Journal of Chromatography. A, 977, 27–38.

Plieva, F. M., Karlsson, M., Aguilar, M.-R., Gomez, D., Mikhalovsky, S., & Galaev, I. Yu. (2005). Soft Matter, 1, 303–309.

Do Rosario Freixo, M., Karmali, A., Frazao, C., & Arteiro, J. M. (2008). Process Biochemistry, 43, 1265–1274.

Enaud, E., Trovaslet, M., Bruyneel, F., Billottet, L., Karaaslan, R., Sener, M. E., et al. (2010). Dyes and Pigments, 85, 99–108.

Northrop, D. B. (1999). Advances in Enzymology and Related Areas of Molecular Biology, 73, 25–55.

Rekuć, A., Jastrzembska, B., Liesiene, J., & Bryjak, J. (2009). Journal of Molecular Catalysis B: Enzymatic, 57, 216–223.

Acknowledgments

Thanks for financial support are due to the Romanian Academy (grant-1R-2008) and the Russian Foundation for Basic Research (Project no. 07-03-91682_RA_a)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Stanescu, M.D., Sanislav, A., Ivanov, R.V. et al. Immobilized Laccase on a New Cryogel Carrier and Kinetics of Two Anthraquinone Derivatives Oxidation. Appl Biochem Biotechnol 165, 1789–1798 (2011). https://doi.org/10.1007/s12010-011-9395-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-011-9395-8

) and immobilized (

) and immobilized ( ) laccase

) laccase