Abstract

The purpose of this investigation was to study the effect of Streptomyces erumpens cells immobilized in various matrices, i.e., agar–agar, polyacrylamide, and luffa (Luffa cylindrica L.) sponge for production of α-amylase. Luffa sponge was found to be 21% and 51% more effective in enzyme yield than agar–agar and polyacrylamide, respectively. Response surface methodology was used to evaluate the effect of three main variables, i.e., incubation period, pH, and temperature on enzyme production with immobilized luffa cells. The experimental results showed that the optimum incubation period, pH, and temperature were 36h, 6.0, and 50 °C, respectively. The repeated batch fermentation of immobilized cells in shake flasks showed that S. erumpens cells were more or less equally physiologically active on the support even after three cycles of fermentation (3,830–3,575 units). The application of S. erumpens crude enzyme in liquefying cassava starch was studied. The maximum hydrolysis of cassava starch (85%) was obtained with the application of 4ml (15,200 units) of crude enzyme after 5 h of incubation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Thermostable enzymes have a number of commercial applications in baking, brewing, alcohol production, cheese making, pulp, and textile industries because of their inherent stability [1, 2]. However, most of these organisms are of bacterial origin [2, 3], and comparatively few organisms from yeasts and actinomycetes groups have been explored for these purposes. Microbial amylases are usually produced either by free or immobilized cells. Modification of biotechnology and processes using immobilized enzymes or whole cells is advantageous because such biocatalysts display better operational stability and higher efficiency of catalysis [4] and they are reusable.

Cell immobilization has some advantages when compared with free cell culture. The reaction speed can be accelerated, a high dilution rate can be used in continuous fermentation without cell washing, and it is less susceptible to the effect of inhibitory compounds and nutrient depletion [5]. Further, the use of immobilized cells as industrial catalysts can be advantageous compared to batch fermentation process [4]. The immobilization of whole microbial cells and their application in bioprocessing has been of interest for nearly 30 years [6]. Different immobilization techniques have been used extensively in fermentation industries for producing amino acids [7], enzymes [4], organic acids [8], and ethanol [9].

Luffa (Luffa cylindrica L.; Family: Cucurbitaceae) is a common Cucurbitaceous vegetable crop grown abundantly in Indian continent. The plant is a climber with fruits, which are berry, elongated and cylindrical. The fibrous vascular network of the dried fruits of luffa is used as a bath sponge and also for the manufacture of table, door, and bath mats [10]. Due to the spongy nature, this is a most suitable carrier for microbial cell immobilization [11, 12] because this technique is cheap, the material is highly porous, resistant to autoclaving, pH and temperature variations, and is an ideal material for use in industrial fermentation in developing countries [5].

The optimization of fermentation conditions is an important problem in the development of economically feasible bioprocesses. Combinatorial interactions of medium components with the production of α-amylase are numerous, and the optimum processes may be developed using an effective experimental design procedure. Response surface methodology (RSM) is a collection of statistical techniques for designing experiments, building models, evaluating the effect of factors, and searching for the optimum conditions of factors for desirable responses [13]. RSM consists of a group of mathematical and statistical procedure that can be used to study the optimization of culture conditions. Statistical optimization not only allows quick screening of large experimental domain but also reflects the role of each of the components. RSM has already been successfully applied for optimization of the media and culture conditions in many cultivation process for the production of amino acid [14], ethanol [15], and enzymes [16, 17].

In our earlier studies, a moderately thermostable α-amylase-producing actinomycete strain (Streptomyces erumpens MTCC 7317) was isolated from soil in the high temperature zone (>80 °C) of a brick kiln [18]. The parametric optimization of α-amylase production showed that a pH of 6.0, incubation period 36 h, temperature of 50 °C, 0.02% glycerol as surfactant, 1% beef extract, and 1% soluble starch as nitrogen and carbon source, respectively, are required for optimum α-amylase production in submerged fermentation (SmF), and the molecular mass of the enzyme was estimated to be 54.5 kDa. The purpose of the present investigation was to study the immobilization of S. erumpens MTCC 7317 cells for higher amylase production using three different immobilization matrices (agar–agar, polyacrylamide, and luffa sponge disc) and optimization of the major fermentation parameters (incubation period, pH, and temperature) by applying RSM.

Materials and Methods

Microorganism

An α-amylase-producing strain of S. erumpens used in the present study was isolated earlier [18] and identified at the Institute of Microbial Technology, Chandigarh, India and given the code number MTCC 7317. The culture was maintained on starch–beef extract (SB) agar (soluble starch, 1%; beef extract, 1%; MgSO4, 0.01%; glycerol, 0.02%; agar, 2%; pH adjusted to 7.0) slants at 4 °C. The optimal growth temperature of this strain is 50 °C [18].

The inoculum was prepared in SB broth by transferring a loop full of microorganism from a fresh culture and incubating for 24h at 50 °C at 120 rpm in an orbital shaker incubator (Remi Pvt, Ltd, Bombay, India). Then, the content of flasks was centrifuged at 8,000 rpm for 20 min in a refrigerated centrifuge (Model C-24, Remi Pvt. Ltd) and the supernatant was decanted. Finally, the cell pellet was suspended in sterile water. This cell suspension was used as inoculum for immobilization.

Immobilization of Whole Cells in Different Matrices

Agar–Agar

One gram of agar powder was dissolved in 18 ml of 0.9% NaCl solution and sterilized by autoclaving at 15 psi pressure for 1 h. The cell suspension (equivalent to 2 ml) was added to the molten agar maintained at 40 °C, shaken well for a few seconds (without forming foam), poured into sterile Petri plates (20 × 100 mm), and allowed to solidify. The solidified agar blocks were cut into equal size cubes (4 mm3), added to sterile 0.1 M phosphate buffer (pH 7.0), and kept in the refrigerator (1 h) for curing. After curing, phosphate buffer was decanted, and the cubes were washed with sterile distilled water three to four times and stored in sterile distilled water at 4 °C until use.

Polyacrylamide

The cell suspension (equivalent to 2 ml) was added to 10 ml of chilled sterile distilled water. To another 10 ml of 0.2 M sterile phosphate buffer (p H7.0), the following chemicals were added: 2.88 g acrylamide, 0.15 g bis-acrylamide, 50 mg ammonium persulfate, and 1ml TEMED (N,N,N,N-tetramethylethylenediamine). The cell suspension and the above phosphate buffer mixture was mixed well and poured into sterile Petri plates (20 × 100 mm). After polymerization (solidification), the acrylamide gel was cut into equal size cubes (4 cm3), transferred to 0.2 M phosphate buffer (pH 7.0), and kept in the refrigerator for 1 h for curing. The cubes were washed three to four times with sterile distilled water and stored in sterile distilled water at 4 °C until use.

Luffa Sponge Discs

The luffa sponge discs were obtained from matured dried fruit of L. cylindrica. The sponge was cut into discs of 2.5-cm diameter, 2–3 mm thick, soaked into boiling water for 30 min, thoroughly washed under tap water, and changed three to four times. The luffa discs were oven-dried at 70 °C, autoclaved for 20 min at 15-lb pressure, and soaked in SB broth for 5–10 min under aseptic condition. Four luffa sponge discs were transferred to 100 ml SB broth contained in 250-ml flasks. Each of these flasks was incubated with 2 ml, 24-h-old stationary phase cultures of S. erumpens and incubated at 50 °C and 120 rpm for 48 h in an orbital shaker as those for developing inoculum biomass. The luffa discs were removed from the culture flasks and washed thoroughly with fresh medium to remove any free cells.

Enzyme Production

The immobilized beads/blocks and discs (two numbers) were transferred into 50 ml of production medium (SB broth) in 250-ml Erlenmeyer flasks (n = 3) and were incubated at 50 °C and 12 rpm for 60 h in an orbital shaker incubator. Samples were withdrawn at regular intervals of 12 h and centrifuged for 20 min at 4 °C. The clear supernatant was used for enzyme assay. The immobilized cells, separated after fermentation, were reused for successive three batches.

Experimental Design Using Immobilized Cells in Luffa Sponge Disc

RSM consists of a group of empirical techniques devoted to the evaluation of relations existing between a cluster of controlled experimental factors and the measured responses according to one or more selected criteria [19]. A prior knowledge and understanding of process and the process variables under investigation are necessary for achieving a more realistic model. The first step in this study was the identification of variables likely to be effective on the response, enzyme production. Our earlier studies have revealed that incubation period (36 h), pH (6.0), and temperature (50 °C) were the important variables which influenced amylase production by S. erumpents [18]. Screening experiments were, therefore, performed to confirm the optimization level by taking incubation period (12–60 h), pH (4.0–8.0), and temperature (30–70 °C) in this study. To explore the effect of variables on the response in the region of investigation, a central composite design (CCD) with these variables at five levels (Table 1) was performed with 20 experiments. The operating conditions at the central point were incubation period (36 h), pH (6.0), and temperature (50 °C). All variables were taken at a central coded value considered as zero. The minimum and maximum ranges of variables were used, and the full experimental plan is listed in coded form in Table 2. One experiment was conducted per point with the identified levels of factors in this design which consists of eight factorial runs and six axial runs with six replications at the central point to evaluate the pure error.

Statistical Analysis and Optimization

The data obtained from RSM of α-amylase production was subjected to a test for significant sequential models, which was performed by analysis of variance (ANOVA). In developing the regression equation, the results obtained from RSM were used to fit a second-order polynomial equation given below.

Where Y is response variable, β 0 is intercept, β 1, β 2, and β 3 are linear coefficients, β 11, β 22, and β 33 are squared coefficients, β 12, β 13, and β 23 are interaction coefficients, and A, B, C, A2, B2, C2, AB, AC, and BC are levels of independent variables. The statistical significance of this equation was determined by ‘F’ test. The quality of polynomial model was checked by coefficient of determination R 2 value. The optimization process searches for a combination of factor levels that simultaneously satisfy the requirements placed (i.e., optimization criteria) on each one of the responses and process factors. Numerical and graphical optimization methods were used in this work by selecting the desired goals for each factor, and response was used in this investigation. All the statistical analyses from experimental design to optimization were performed using statistical software Design Expert (version 7.1; STATEASE INC.; Minneapolis, MN, USA).

The effect of pH and temperature were studied by evaluating the enzyme activity at various pHs (4.0–8.0) and incubation temperatures (30–70 °C) of the medium. The pH measurements were carried out with a pH meter (Systronic, Ahamadabad, India) using a glass electrode. The pHs of 4.0–6.0 were maintained with acetate buffer (0.2 M), while pH 6.0–8.0 were achieved with phosphate buffer (0.1 M). The temperature stability of enzyme was also determined by incubating the cell-free supernatant at various temperatures (30–70 °C) for 30 min using 0.1 M phosphate buffer of pH 6.0.

Amylase Assay

Alpha-amylase assay was based on the reduction in blue color intensity resulting from enzymatic hydrolysis of starch and formation of starch–iodine complex [20]. The reaction mixture consisted of 0.2 ml enzyme (cell-free supernatant), 0.25 ml of 0.1% starch solution, and 0.5 ml of phosphate buffer (0.1 M, pH 6.0) incubated at 50 °C for 10 min. The reaction was stopped by adding 0.25 ml of 0.1 N HCl, and the color was developed by adding 0.25 ml of I/KI solution (2% KI in 0.2% I). The optical density of the blue color solution was determined using a UV–vis spectrophotometer (Model no CE 7250, Cecil Instrument, UK) at 690 nm. One unit of enzyme activity is defined as the quantity of enzyme that causes 0.01% reduction of blue color intensity of starch iodine solution at 50 °C in 1 min/ml [20].

Rate of Hydrolysis of Cassava Starch

A 2% (w/v) suspension of cassava starch (Manihot esculenta, Crantz) in water was incubated with 2–4 ml (7,660–15,200 units) of S. erumpens crude enzyme (obtained from luffa sponge immobilized S. erumpens cells), and the volume was made to 20 ml. The starch–enzyme mixture was incubated at 50 °C in an incubator. The hydrolysis of starch was evaluated (reduction of blue color intensity of starch iodine solution at 50 °C) at 1-h interval up to 5h [17].

Results

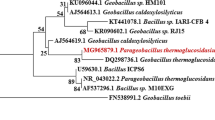

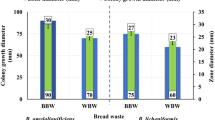

Amylase production by immobilized cells of S. erumprns MTCC 7317 in various matrixes started in the log phase of growth, and maximum enzyme production was achieved during the stationary phase (36 h) of the growth of the organism (Fig. 1). Further at 36 h, the enzyme production was 20.6% and 51.4% more in luffa sponge immobilization than in agar–agar and polyacrylamide immobilization, respectively. The amylase production by immobilized cells when compared with free cells was found higher (3,830 units) using immobilized cells in luffa sponge than with free cells (3,700 units) at 36 h of incubation. Therefore, further experiments were conducted only with luffa-immobilized cells.

Effect of Treatment Conditions

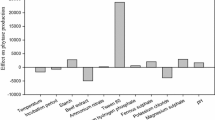

The effect of three independent variables (i.e., incubation period, pH, and temperature) for α-amylase production by immobilized cells of S. erumpens in luffa sponge is presented along with predicted and observed responses in Table 2. Regression analysis was performed to fit the response function with the experimental data. The statistical significance of the second-order equation was checked by an F test (ANOVA), and the data are shown in Table 3. The regression model for α-amylase production was highly significant (p < 0.01) with a satisfactory value of determination coefficient (R 2 = 0.9697), indicating that 96.97% of the variability in the response could be explained by the following second-order polynomial equation:

where Y is enzyme production, A is incubation period (h), B is pH, and C is temperature (°C). The R 2 value is always lies between 0 and 1. The closer the value of R 2 is to 1.0, the stronger the model and the better it predicts the response [16]. An adequate precision of 16.21 for α-amylase production was recorded. The predicted R 2 of 0.7774 is in reasonable agreement with the adjusted R 2 of 0.9424. Further, a high similarity was observed between the predicted and experimental result (Fig. 2).

The model F value of 35.52 and values of prob> F (<0.05) indicated that the model terms are significant. For α-amylase production, the coefficients of A, B, C, A 2, B 2, and C 2 are significant at 1% level, but the interaction terms (AB, AC, BC) are not significant. The incubation period and pH had significant positive effect on amylase production, while temperature displayed negative effect.

Response Surface Estimation for Maximum Enzyme Production

To investigate the interactive effect of variables on the amylase production, the response surface graphs were employed by plotting the effect of independent variables (incubation period, pH, and temperature). Out of three variables, one was fixed at zero level, while the two were varied.

Figure 3A depicts three dimensional diagram and contour plot of calculated response surface from the interaction between incubation period and pH while keeping the other variable (temperature) at zero level. The result demonstrated that with increase in incubation period and pH up to 36 h and 6.0, respectively, the enzyme production has increased up to 3,754 units and, thereafter, it declined.

Figure 3B shows the effect of incubation period and temperature on enzyme production, keeping pH at zero level. The graph shows that the maximum amylase production (3,760 units) occurred at temperature of 50 °C and incubation period of 36 h, which is in conformity with the model. An interaction between the remaining two parameters (pH and temperature; Fig. 3C) suggested a little difference with the earlier responses.

Optimization

To find out optimum level of process parameters for maximizing the response, the criteria were set, as given in Table 4. The optimization criteria were used to get maximum yield of amylase by minimizing incubation period as well as pH and maximizing temperature.

Testing of Model Adequacy

Usually, it is necessary to check the fitted model to ensure that it provides an adequate approximation to the real system. Unless the model shows an adequate fit, processing with investigation and optimization of the fitted response surface likely gives poor or misleading results. By constructing a normal probability plot of the residuals, a check was made for the normality assumption, as given in Fig. 4. The normality assumption was satisfied, as the residuals are approximated along a straight line.

Practical Verification of Theoretical Results

Further, to support the optimized data as given by statistical modeling under optimized condition, the confirmatory experiments were conducted with the parameters as suggested by the model (incubation period, 36 h; pH 6.0, and temperature 50 °C). The optimized process condition yielded amylase production (3,781 units), which was closer to the predicted amylase production (3,744 units) at same optimal point.

The thermostability of enzyme produced by S. erumpens was also studied (3,385, 3,615, 3,830, 2,550, and 1,018 units of enzyme production in 30, 40, 50, 60, and 70 °C, respectively). The enzyme was most stable at 50 °C (3,830 units), and a reduction in activity was observed at temperature above 55 °C. When the crude enzyme was heated at 60 °C for 30 min, it resulted in loss of 33.4% of the original enzyme activity.

Rate of Hydrolysis of Starch

There was a gradual hydrolysis of cassava starch with increase in incubation period from 1 to 5 h, and the rate of hydrolysis also increased with the increase in enzyme concentration (data not shown). For example, with application of 4 ml (15,200 units), there was 43%, 52%, 60%, 75%, and 85% hydrolysis of starch after 1, 2, 3, 4, and 5 h of incubation, respectively.

Discussion

The present study confirmed luffa sponge as an excellent support and a promising method for S. erumpens immobilization for α-amylase production due to high values of biomass aggregated to it. Further, α-amylase production with immobilized cells in luffa sponge was found to be higher than free cells as well as immobilized cells in agar–agar and polyacrylamide. In literature, 10–60% increase in enzyme production has been reported with immobilized cells, i.e., protease [4, 21, 22], α-amylase [17, 23, 24], pectinase [25, 26], etc. Low level of amylase (1,375–2,530 units) production observed with polyacrylamide was probably due to considerable amount of cell leakage. Slokoska and Angelova [25] reported that luffa sponge is an ideal immobilization material for pectinase production. Luffa sponge was used as an efficient material for removal of heavy metal ions [27] and also for immobilization of Saccharomyces cerevisiae cells in ethanol production [28].

RSM used in this investigation suggested the importance of various fermentation parameters at different levels. In the present investigation, a high similarity was observed between the predicted and experimental results (Fig. 2), which reflected the accuracy and applicability of RSM to optimize the process for enzyme production in SmF. In this study, an incubation period (36 h), pH (6.0), and temperature (50 °C) were the major factors that influenced the enzyme titer. The enzyme production was maximal when the cell population entered into stationary phase. Similar findings have been recorded for Streptomyces rimosus [29], S. megasporus [30], and Bacillus subtilis [20, 31]. Also, the reusability of S. erumpens cells immobilized in luffa sponge disc was examined. The cells not only survived but also were more or less active physiologically on the support even after three cycles of fermentation (3,830, 3,655, and 3,575 units of enzyme production in cycle 1, 2, and 3 respectively), which could save considerable time and energy.

This strain failed to produce enzyme at pH below 4.0 and above 8.0, but the optimum pH for enzyme production was 6.0. The decline in enzyme production at pH lower than 6.0 was probably due to poor microbial growth [18, 32]. A pH range of 6.0–7.0 was reported to be optimum for growth and enzyme production by several Streptomyces [30, 33] and Bacillus spp. [20, 23, 24].

The isolate S. erumpens showed maximum α-amylase production and stability at 50 °C [18]. Beyond 50 °C, there was gradual decrease in the enzyme production as well as stability. The optimum α-amylase production for other actinomycetes, i.e., Thermoactinomyces vulgaris and S. rimosus were found to be 62.5 and 45°C, respectively [29, 32].

When the applicability of the S. erumpens amylase in liquefying cassava starch was studied at its optimum temperature of 50 °C, the crude enzyme (15,200 units) could hydrolyze 85% starch after 5 h of incubation. Similar finding was also observed with α-amylase from this microbial strain immobilized in calcium alginate beads in hydrolyzing cassava starch [34]. In another study, 99% hydrolysis of soluble starch as well as cassava starch was reported by α-amylase (72,700 units) obtained from B. subtilis CM3 in solid-state fermentation using cassava fibrous residue [17].

Further work is in progress in our laboratory on the use of this enzyme in cassava and sweet potato (Ipomoea batata L.) starch saccharification for production of fructose syrup, organic acids, and other fermented food additives.

References

Demirijan, D., Moris-Varas, F., & Cassidy, C. (2001). Current Opinion in Chemical Biology, 5, 144–151.

Haki, G. D., & Rakshit, S. K. (2003). Bioresearch and Technology, 89, 17–34.

Pandey, A., Nigam, P., Soccol, C. R., Soccol, V. T., Singh, D., & Mohan, R. (2000). Biotechnology and Applied Biochemistry, 31, 135–152.

Adinarayana, K., Jyothi, B., & Ellaiah, P. (2005). AAPS PharmaSciTech, 6, 391–397.

Marques, L. L. M., Buzato, J. B., & Celligoi, M. A. P. C. (2006). Brazilian Archives of Biology and Technology, 49, 873–880.

Carvalho, W., Silva, S. S., Converti, A., & Vitolo, M. (2002). Biotechnology and Bioengineering, 79, 165–169.

Bodalo, A., Bastida, J., Gomez, J. L., Alcarz, I., & Asaza, M. L. (1996). Enzyme and Microbial Technology, 9, 176–180.

John, R. P., Nampoothiri, K. M., & Pandey, A. (2007). Journal of Basic Microbiology, 47, 25–30.

Swain, M. R., Kar, S., Sahoo, A. K., & Ray, R. C. (2007). Microbiological Research, 162, 93–98.

Kochhar, S. L. (1995). Economic botany in tropics. New Delhi: Rajiv Beri, Macmillan India Ltd.

Akhtar, N., Iqbal, J., & Iqbal, M. (2003). Letters in Applied Microbiology, 37, 149–153.

Saeed, A., & Iqbal, M. (2006). World Journal of Microbiology & Biotechnology, 22, 775–782.

Liew, S. L., Ariff, A. B., Raha, A. R., & Ho, Y. W. (2005). International Journal of Food Microbiology, 102, 137–142.

Xiong, C., Shouwen, C., Ming, S., & Ziniu, Y. (2005). Applied Microbiology and Biotechnology, 69, 390–396.

Carvalho, J. C. M., Vitolo, M., Sato, S., & Aquarone, E. (2003). Applied Biochemistry and Biotechnology, 110, 151–164.

Rao, J. L. M., & Satyanarayana, T. (2003). Journal of Applied Microbiology, 95, 712–718.

Swain, M. R., & Ray, R. C. (2007). Journal of Basic Microbiology, 47, 417–425.

Kar, S., & Ray, R. C. (2008). Journal of Scientific and Industrial Research, 67, 58–64.

Silva, C. J. S. M., & Roberto, I. C. (2001). Process Biochemistry, 36, 1119–1124.

Swain, M. R., Kar, S., Padmaja, G., & Ray, R. C. (2006). Polish Journal of Microbiology, 55, 289–296.

Bashay, U. (2003). African Journal of Biotechnology, 2, 60–65.

Adinarayana, K., Bapi Raju, K. V. V. S. N., & Ellaiah, P. (2004). Process Biochemistry, 39, 1331–1339.

Dobreva, E., Tonkova, A., Ivanova, V., Stfanova, M., Kabivanova, L., & Spasova, D. (1998). Journal of Industrial Microbiology, 20, 166–170.

Stefanova, M., Tonkova, A., Dobreva, E., & Spasova, D. (1998). Folia Microbiologica, 43, 42–46.

Slokoska, L., & Angelova, M. (1998). Zeitschrift für Naturforschung, 53, 968–972.

Demir, N., Acar, J., Saryoolu, K., & Muttu, M. (2001). Journal of Food Engineering, 47, 275–280.

Iqbal, M., Saeed, A., Edyvean, R. G. J., O’sullivan, B., & Styring, P. (2005). Biotechnology Letters, 27, 1319–1323.

Ogbonna, J. C., Tomiyama, S., Liu, Y. C., & Tanaka, H. (1997). Journal of Bioengineering, 84, 271–274.

Yang, S. S., & Wang, J. Y. (1999). Botanical Bulletin of Academia Sinica, 40, 259–265.

Dey, S., & Agarwal, S. O. (1999). Indian Journal of Biochemistry & Biophysics, 36, 150–157.

Najafi, M. F., Deobagkar, D., & Deobagkar, D. (2005). Protein Expression and Purification, 41, 349–354.

Heese, O., Hansen, G., Hohne, W. E., & Korner, D. (1991). Biomedica Biochimica Acta, 5, 225–232.

Georis, J., Giannotta, F., De Buyl, E., Granier, B., & Frere, J. (2000). Enzyme and Microbial Technology, 26, 177–183.

Sivaramakrishnan, S., Gangadharan, D., Nampoothiri, K. M., Soccol, C. R., & Pandey, A. (2006). Food Technology and Biotechnology, 44, 173–184.

Acknowledgment

The authors thank the Director, CTCRI, Thiruvanathapuram for providing facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kar, S., Swain, M.R. & Ray, R.C. Statistical Optimization of Alpha-Amylase Production with Immobilized Cells of Streptomyces erumpens MTCC 7317 in Luffa cylindrica L. Sponge Discs. Appl Biochem Biotechnol 152, 177–188 (2009). https://doi.org/10.1007/s12010-008-8248-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-008-8248-6