Abstract

The physical, mechanical, and structural changes in French fries at different frying temperatures (170, 180, and 190 °C) during par and finish frying were investigated. The experimental frying process includes blanching, par frying, freezing, and finish frying at the point of consumption. Par frying temperature had a greater effect on moisture reduction than on processing time with the greatest moisture loss at 180 °C after 160 s. At 180 °C, fries had the highest total oil uptake (29.56 % wb). Frying caused a significant change in color with the greatest effect at 190 °C. Micro-CT scan images showed structural changes in French fries over the course of the frying process. Frying time increased the volume of the pores relative to the size of the crust, and this was positively correlated with the hardness and shear cutting force. Overall, within the range of frying conditions studied, the higher temperature (190 °C) resulted in the lowest amount of oil uptake and the crispiest texture.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

French fries are a popular potato product worldwide (Al-Khusaibi et al. 2012; Kalogianni and Smith 2013; Kita and Lisińska 2005; van Loon et al. 2005) and are prepared by a deep-fat frying process. This is a popular style of restaurant cooking because of its speed and efficiency. Deep-fat frying is a complex heat and mass transfer phenomenon and causes several physicochemical and structural changes to the fried food (Kalogianni and Papastergiadis 2014; Krokida et al. 2001b; Moyano and Pedreschi 2006; Ziaiifar et al. 2008). During the frying process, the food is submerged in a hot oil bath (in the range of 175–195 °C) causing rapid removal of water (Aguilera and Gloria-Hernandez 2000) and displacement with absorbed oil (Aguilera and Gloria-Hernandez 2000; Alvarez et al. 2000; Bouchon et al. 2003; Krokida et al. 2000b; Moyano and Pedreschi 2006; Ziaiifar et al. 2008) resulting in a crispy outer crust and soft interior, both of which are highly desirable traits of French fries and other fried food. Depending upon the potato cultivar, as well as the frying oil and process conditions used, the properties of French fries can be dramatically altered.

French fries destined for most food service operations are produced through a two-stage process consisting of par frying and finish frying steps with intermediate freezing and frozen storage in between them. Par frying induces initial dehydration allowing for the formation of the crust. Frying begins with the removal of free water from the surface of the French fry, after which dehydration continues within the subsurface layers creating a crust (Al-Khusaibi et al. 2012; Van Loon et al. 2007). According to Al-Khusaibi et al. (2012), the moisture and oil contents will be approximately 64–65 and 14–18 % (wb), respectively, by the end of par frying. The moisture content of the finished fry is cultivar and sugar content dependent. O’Connor and coworkers (O’Connor et al. 2001) reported higher final moisture content (70 %) for “Agria” and “Russet Burbank” potato varieties obtained from commercial par frying operations, in which the par frying temperature was in the range of 175–180 °C (45 s), depending upon the potato sugar content.

Several parameters significantly alter the mechanical and structural properties of French fries. Kita and coworkers (Kita and Lisińska 2005) reported changes in fry hardness with variations in oil type (e.g., refined sunflower oil, rapeseed oil, soy oil, olive oil, palm oil, partially hydrogenated rapeseed oil, and a blend of vegetable oils), frying time (5 to 12 min), and frying temperature (150 to 190 °C). Similar findings were reported by others (Van Loon et al. 2007), finding that par frying at 180 °C led to a crispier product than did frying at lower temperatures (160 and 170 °C).

Considering the extreme variability in the final product that could result due to the aforementioned variables, there is a need to use a systematic approach to understand the physicochemical changes in French fries during the complete production process. This understanding can help to optimize the frying process to obtain products with crispier textures and lower oil contents. Most studies (Agblor and Scanlon 1998, 2000; Aguilera and Gloria-Hernandez 2000; Bouchon and Aguilera 2001; Bouchon et al. 2003; Bouchon et al. 2001; Kita and Lisińska 2005; Kita et al. 2007; Krokida et al. 2000a, 2001a, b; Maté et al. 1998; Tajner-Czopek 2003; Ufheil and Escher 1996; Ziaiifar et al. 2010) investigating French fry processing report on specific effects related to final or finished French fry quality but do not systematically monitor the changes occurring during each step of French fry processing. Understanding the incremental changes in oil uptake, texture, and appearance that occur during the processing of French fries is important for generating a finished product with the desired characteristics. Several techniques have been used to quantify the internal structures of fried foods, e.g., using scanning electron microscopy (SEM) and confocal laser scanning microscopy (CLSM) to achieve information of the pore structure and location of the oil in the crust (Carolina Moreno and Bouchon 2013; van Koerten et al. 2015). These methods provide only qualitative information and are invasive with respect to the sample preparation. There is a need for non-invasive quantitative characterization of food microstructures. X-ray micro-computed tomography (micro-CT) is a novel non-invasive and non-destructive technique that permits quantification of the microstructure of small samples like French fries. The microscan is accomplished by collecting radiographs of the sample at small angular increments (0.9°). Radiographs are then reconstructed into a series of 2D slices. The series of slices can be reconstructed into 3D images at different depths and directions (Miri et al. 2006; Mousavi et al. 2005). Exploring the structure development as a function of the frying temperatures is crucial to assess the physical and structural properties of fried foods.

Thus, the aim of this study was to evaluate the physical, mechanical, and structural properties of French fries as a function of the process temperature and time through a simulated commercial production process. Moisture content and oil uptake were evaluated using standard analytical methods. Mechanical and structural properties were determined by texture analysis and X-ray micro-CT followed by porosity analysis.

Materials and Methods

Raw Materials

Fresh potatoes (Solanum tuberosum, Russet Burbank cultivar) were provided by ConAgra Foods, Inc. (Richland, WA, USA). Potatoes were stored in a walk-in cold room at 8 °C in the dark prior to experiments. French fries (three batches) were produced following common processing steps of washing, peeling, cutting, blanching, predrying, par frying, freezing, and finish frying with modifications to suit batch pilot-scale processing. Peeling was conducted using a commercial abrasion batch peeler (Model 15A, MJM. Mfg Co., Culver City, CA, USA) for 20 s. Peeled potatoes were cut into shoe-string strips (0.8 cm × 0.8 cm × 8 cm) using a manual Keen Kut Shoe Stringer Shaver (Specialty Co., Los Angeles, CA, USA), then each batch of strips was placed in a wire basket (0.23 m × 0.38 m × 0.20 m) and blanched in boiling tap water for 2.5 min within a steam kettle (Model DLT-40, Groen, Direct Steam Kettle, Jackson, MS, USA). Blanched potato strips were pat-dried on adsorbent paper (multifold single ply Scott, Kimberly Clark). This pat drying process was used in place of a predrying operation with the purpose of removing excess surface moisture, allowing dehydration and color changes before frying as suggested by Tajner-Czopek et al. (2008).

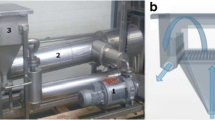

Frying Process

The frying process was carried out in two steps: (i) par frying and (ii) final frying. Each batch of potato strips (1 kg) was par fried in 25 L of high oleic canola oil using a commercial fryer (Model H117TDSC, Frymaster Co., Shreveport, LA, USA). Frying oil temperatures of 170, 180, or 190 °C were used for each par and finish frying steps. The frying temperature was kept nearly constant (±1 °C) and recorded every 1 s for the oil bath using a Copper/Constantan type T thermocouple. Par frying time intervals were 10, 20, 30, 40, 50, or 60 s. A constant level of oil was maintained in the fryer by adding fresh oil between the batches, by allowing time for the recovery of the desired initial frying oil temperature. This ensured the constant ratio between the frying oil and the potato strips for all the drying experiments. After each frying time, the samples were immediately removed from the oil and quick-frozen in liquid N2. The fries were then placed on a stainless steel tray and held in a walk-in freezer (Environmental Growth Chambers, Chagrin Falls, Ohio, USA) at −20 °C for 30 min. Frozen fries were then transferred to a sealed plastic bag with a zip closure and held in the −20 °C freezer for 2 weeks prior to finish frying. Frozen par fried strips were finish fried at either 170, 180, or 190 °C for 20, 40, 60, 80, 100, 120, 140, or 160 s (Supplemental information, Fig. S1). These fried strips were quick-frozen in liquid N2, packaged as previously described, and then held at −20 °C until further analysis. For all the tests, other than moisture content, color development, and texture analysis, frozen French fries were first freeze dried (Genesis 25XL, VirTis, SP Scientific, Warminster, PA, USA) prior to subsequent analysis and stored in a desiccator at room temperature.

Analytical Determinations

Moisture Content

Moisture content (% wb) was determined by AACCI Method 44-15.02 (1999). Free moisture was determined by placing ca. 15 g of whole French fries into a 130 °C hot air oven (VWR Symphony 414004-568, VWR International, LLC, Bridgeport, NJ, USA) for 24 h or until constant weight was achieved. Moisture analysis was conducted in triplicate.

Oil Uptake

Oil uptake in potato strips was determined using AOAC 920.39C (2002), employing a semicontinuous Soxhlet extraction apparatus with petroleum ether (Avantor Performance Materials Inc., Phillipsburg, NJ, USA) as the solvent. Oil content analysis was conducted in triplicate for each process replicate and expressed as g oil/100 g dry sample.

Physical Properties

Color Development

French fry color after par and finish frying was measured using the L*a*b* (CIELAB) color scale using a Minolta colorimeter (Minolta Chroma Meter CR-400, Konica Minolta Sensing, Inc., Osaka, Japan) as described by Limbo and Piergiovanni (2006). Each measurement was standardized against a white tile (L* = 97.63, a* = −68, b* = 2.77). Color analysis was performed immediately after the French fries were removed from the frying oil, to avoid any effects of the post frying moisture and heat equilibration of the fried strips.

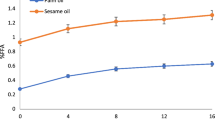

Oil Viscosity

The viscosity of the frying oil was measured using a rheometer (Advanced Rheometer AR 2000, TA Instruments, New Castle, DE, USA). Viscosity measurement was taken at a constant shear rate of 50 s−1 with a temperature ramp of 5 °C/min from 25 to 195 °C.

Structural Properties

X-Ray Micro-CT

French fries structure and porosity were determined through micro-CT scanning.

Two-dimensional projection images were acquired as the sample was rotated through small angular steps and then reconstructed into the axial cross sections based on a modified Feldkamp cone-beam algorithm. The French fry scans were acquired on a SkyScan 1172 high-resolution micro-CT (Bruker MicroCT N.V., Kontich, Belgium) at 5.3-μm isotropic pixel size, 40-kV peak voltage, and 220-ms exposure time for 997 projections. Scanning was conducted by Micro Photonics, Inc. (Allentown, PA, USA). Dataset reconstructions were performed using NRecon (v 1.6.9.8) and analysis was conducted using CTAn software (v.1.13, Bruker MicroCT N.V., Kontich, Belgium). Since the preparation for micro-CT scan acquisition was time consuming, only potato strips from the shortest and longest of both the par and finish frying period at each temperature were scanned (12 samples in total), with one sample per treatment. In addition, a control sample which was blanched but not fried was scanned.

Porosity Analysis

Cross-sectional images acquired from the micro-CT scans of the dried French fries were analyzed for porosity, as well as oil content and localization of the oil within the fries. To conduct these analyses, the crust and core of the fried samples first had to be recovered separately, as the oil and the core regions have the same density. Therefore, the core region had to be deleted from the image to avoid errors in calculating the oil content. This segregation was conducted manually by outlining the boundary of the crust-core interface and independently saving the crust and the core as separate regions of interest (ROIs). Analysis of the core involved manually identifying a threshold radio-density value that matched the core material. The analysis of the core involved manually finding a threshold (radio-density that matched the core) based off of the density of the core material. This threshold value was selected from the gray-scale range of 0–255 (Supplemental Information Fig. S2), excluding anything below an intensity of 20, thus ensuring inclusion of only the core cell material. Porosity analysis was done in duplicate (Table 1).

A 3D model was then constructed for each core ROI section. Porosity and oil contents were calculated only for crust ROI. To determine porosity, threshold values that would clearly highlight all the crust pores and cell material were selected, while excluding the oil absorbed into the French fry crust. The threshold value for the cell crust material was in the range of 40–45/255. Next, the pores within a given French fry strip were filled in, using an operation called an “ROI Shrink Wrap,” creating a reference image that exhibited a complete lack of porosity. To calculate total porosity, the image possessing open pores was subtracted from the reference image possessing filled-in pores, providing an image depicting only the pores. Porosity was calculated as the total volume of the pores in relation to the total volume of the French fry crust.

Oil content was determined in a similar manner as porosity. The oil in the crust and the cell material comprising the crust were selected at the appropriate thresholds. Since the oil has a lower density than the crust cells do, the threshold was selected to be in the range of 14–18/255. The images of only the crust cells, containing no oil, in a threshold range of 40–45/255, was subtracted from the images depicting the oil within the crust, leaving images displaying only the oil. Oil content was calculated as the proportion of the volume occupied by the oil in relation to the total volume of the French fry crust.

Mechanical Properties

Textural Analysis

Texture analysis was conducted on freshly par and final French fries following the method described by Aguilar (1997). Both texture profile analysis (TPA) and a puncture test were conducted using a TA-XT2i Texture Analyzer (Texture Technologies, Hamilton, MA, USA). Whole French fries (8–10) were held under a heating lamp to keep them warm immediately after frying. A 2-cm section of a whole French fry was cleanly cut and placed under a puncture test device. The punch diameter and the cross-head speed were 2 mm and 1 mm/s, respectively. In order to ensure that the punch passed through the sample completely, we made two readings at the ends of the French fries and two at the center. Force vs distance curves were generated in triplicate with puncture test at different frying times. The maximum force (F max ), expressed in Newton (N) was obtained using the software Texture Expert Exceed (Texture Technologies, Hamilton, MA, USA). F max is defined as the force at which the punch penetrates the outer layer of the surface of the fried potato strips. Texture test was conducted using n = 9.

For the TPA test, a 10-cm cylinder was used. For the first compression of TPA, the cylinder was lowered onto the French fry at 1 mm/s and raised when it had reached 1/3 of the French fry thickness. The second compression occurred at the same rate. Higher values indicate that the probe required more force to puncture the French fry, which correlates with the hardness values obtained by TPA.

Statistical Analysis

A completely randomized design (CRD) was used in this research work, with 2 × 3 factors (par frying, finish frying, and the three temperatures). One-way multivariate analysis of variance (MANOVA) was performed to determine the individual main effects of the frying time, as well as combined effects of time and frying temperature on physical and mechanical properties of French fries.

A Wilks’s lambda, Pillai’s trace, Hostelling’s trace, and Roy’s largest root test were applied to examine the individual main effect and combined effects of frying time and temperatures on the French fries’ physicochemical and mechanical properties. Pearson’s correlation analysis was used to calculate the relationship between the French fries’ properties and the processing variables. Analysis of variance, means, and standard deviations (Tukey’s honest significant difference test (HSD)) at a 95 % confidence level (p < 0.05), were calculated with SPSS (Version 22.0 SPSS, Inc., Chicago, IL) statistical software.

Results and Discussion

Physical Properties

Moisture Content

Moisture loss during a frying process has been described as a desorption phenomenon (Moreira and Bakker-Arkema 1989). Moisture content in the French fries generally decreased with an increase in frying time. Raw potato strip moisture content averaged 79.0 % (wb) for all the samples tested and did not change significantly after blanching, which is in agreement with those of other researchers (Alvarez et al. 2000). The blanching step improves the color and texture of potato strips and could reduce the oil uptake by gelatinization of the surface starch (Moyano and Pedreschi 2006). During par frying, the moisture content decreased by approximately 8 % regardless of the frying temperature (Fig. 1), whereas during finish frying, the moisture loss was temperature dependent. Results showed that the lowest moisture content was 27.9 % at 180 °C, the highest one was 37.9 % at 170 °C and 32.8 % was observed at 190 °C.

The two frying steps, par and finish frying, were separated by a 2-week frozen storage period, which had an effect on the French fry moisture content as well. There was an average of 7.0 % decrease in moisture content between the last par frying step and the first finish frying step, which can be attributed to dehydration of the frozen French fries during freezing.

Generally, high frying temperature causes evaporation of the water from the surface, which migrates away from the food and into the surrounding oil. Oil is absorbed by the food, replacing some of the lost water (Oliveira et al. 1994). When frying, moisture can easily be removed because of the efficiency of heat and mass transfer process resulting in water loss. The intermediate frying temperature (180 °C) resulted in fries with the lowest moisture content, while the lowest frying temperature (170 °C) yielded fries with the highest moisture content. Final moisture content was higher in comparison with a report from industry (<2 % wb) (Moyano and Pedreschi 2006). It is known that oil frying temperature has a negative effect on the moisture content in fried potatoes. As the frying temperature increases, the moisture content decreases (Krokida et al. 2000b); however, moisture content at 190 °C was not the lowest as expected. Although the moisture contents at 180 and 190 °C were close to each other.

One-way MANOVA allowed us to statistically evaluate the effect of the process variables on product quality parameters. Wilk’s lambda (λ) distribution is a measure of the percent of variance in the dependent variables that is not explained by differences in the independent variable. The multivariate analysis indicates that in the par frying process, the temperature had a stronger effect on moisture loss compared to processing time (Table S1, Supplemental Information), with Wilk’s λ = 0.047, F (10, 95.0) = 22.9, p < 0.005, partial η2 = 0.782, and power to detect the effect equal to 1.0. These results confirmed that the rate of water loss increased with temperature and is related to strip thickness (Krokida et al. 2000b). Considering the complete frying process (par frying + finish frying), the processing time had a stronger effect than temperature, since Wilk’s λ = 0.001, F (65,382) = 18.6, p < 0.001, partial η2 = 0.741, and power to detect the effect = 1.0.

Oil Uptake

Oil uptake is an important aspect in a deep fat frying processes, since it involves simultaneous heat and mass transfer mechanisms. During the par frying, the oil uptake ranged from 5 to 6.3 % at 170 °C, 7.6 % at 180 °C, and 8.3 % at 190 °C (Fig. 2). Further, for the finish frying process, oil uptake ranged from 15.6 % at 10 s to 25.1 % at 60 s, 15.5 % at 10 s to 30.9 % at 60 s, and 11.2 % at 10 s to 21.2 %, at 60 s, at 170, 180, and 190 °C respectively. French fries were removed from the fryer and immediately frozen in liquid N2, so whatever oil could have entered the French fries during frying and, in the time frame, following removal from the fryer to freezing, was measured as the oil content.

The distribution and amount of oil absorbed during frying are affected by several factors such as predrying, frying time, surface treatments, initial interfacial tension, and crust size (Krokida et al. 2000a, b). In the present work, oil uptake was determined after removing the samples from the fryer and cooling them. Studies have demonstrated that oil adsorption occurs during the cooling step (Aguilera and Gloria-Hernández 2000; Bouchon et al. 2003; Moyano and Pedreschi 2006). If a high temperature is used for the blanching step (∼100 °C), this could enhance oil migration as a result of heat-induced cell rupture. This phenomenon was observed by others (Pedreschi and Moyano 2005), who found a ~15.0 % increase in oil uptake following blanching for 3.5 min at 85 °C, compared to raw potatoes.

A possible reason for the higher oil content in this study is the lower air temperatures during frying, compared to conditions present in a production plant. The greater the temperature difference between the frying oil and the air temperature, the greater the cooling effects (Aguilera and Gloria-Hernandez 2000). Typically, in a French fry production plant, fries are carried out of the fryer on a converyor belt that is enclosed, allowing the fries to remain at a higher temperature for a longer period of time. This could allow more oil to drain before the fries cool down reducing the amount of oil absorbed.

It is well known that moisture loss and oil uptake have an inverse relation. Pearson’s test (Table 2) showed a significant correlation between them (R 2 = −0.953, p < 0.01). This relation can be attributed to the development of the crust on the French fries, since surface moisture is first removed, followed by moisture being removed from the subsurface; causing the crust layer to extend further into the French fries. In summary, at greater moisture loss, the more extensive the crust development becomes. Consequently, there is more opportunity for oil to enter into the product as the crust becomes thicker and develops larger pores.

Color

The heat and mass transfer phenomena during deep frying leads to physicochemical changes affecting the color of fried foods. Water loss and oil uptake along with non-enzymatic browning reactions occurring within the potato, are responsible for color, aroma, and texture development properties and subsequent dehydration forming a crusty surface (Moyano and Pedreschi 2006).

Color development (ΔE) comparing the raw with par frying and finish fried products with different treatments are shown in Fig. 3. ΔE values ranged from 6.16 to 13.44 at 170 °C, from 4.4 to 20.95 at 180 °C, and from 10.9 to 29.33 at 190 °C. Frying at 190 °C showed the largest color changes as anticipated. French fry color is the result of Maillard reactions that depend upon the content of reducing sugars and amino acids on the potato surface, as well as temperature and frying times (Moyano et al. 2002). The presence of surface moisture can affect the color due to light reflection (Krokida et al. 2001a).

Our results showed a small change for a* and b* values at 170 °C as observed by Heredia et al. (2014). The development of a yellow color could indicate non-enzymatic browning for longer time frying. Values between 0 and −5 for a* and 0 to 10 for b* are usually considered an optimal tone for French fries (Krokida et al. 2001a). The significance of the overall test was examined by MANOVA. The univariate main and the combined effects (time processing and temperature) have statistical significance: for oil uptake, F (26, 9.7) = 7.45, p < 0.001, partial η2 = 0.70, and power = 1.0 and for color, F (26, 8.860) = 2.08, p < 0.006, partial η2 = 0.392, and power = 0.990 during the total frying processing.

Structural Properties

Micro-CT Scanning

X-ray micro-computed tomography (micro-CT) is a non-destructive technique that utilizes the absorption properties of transmitted X-rays through materials to generate axial slice images representing the cross section of the internal structure. The microstructure of the crust of French fries has been defined as the single most important product-related determinant of the final oil uptake (Bouchon and Aguilera 2001). One way to quantify the porous structure is through the analysis of visual images acquired by non-destructive imaging techniques. The micro-CT scanning has been applied for the collection of high-resolution images, finding it suitable for textural analysis and determination of structure and porosity (Carolina Moreno and Bouchon 2013).

Micro-CT images of raw and blanched potato strips (Figs. 4a, c) clearly show intact cells with inner starch granules that have not been disrupted at this point by heat. There is also no cell separation or porosity development at this stage as a result of washing, peeling, and cutting.

a Raw potato strips showing cell material (in green) and starch granules (in purple), b a monochrome image of Fig. 4a, and c a blanched potato strip showing the gelatinized starch throughout the in cells (in purple)

French fry images from micro-CT scanning in their reconstructed two-dimensional forms are shown in Figs. 5, 6, and 7. Micro-CT images revealed the increase in crust thickness with an increase in the frying time for all processes. This is true for all the three frying oil temperatures studied. Location of the oil within the crust is also apparent. Most of the oil in the French fries is seen to be located in the smaller-sized pores. The crust and core were roughly of the same size at all temperatures for the samples par fried at 20 s. Increasing the par frying time to 60 s increased the crust thickness in the high-temperature frying oil, whereas the crust remained roughly the same size for the medium and low frying temperatures. With respect to finish frying, crust thickness was about the same for the temperatures of 190 and 180 °C, whereas the low temperature (170 °C) maintained a thinner crust throughout frying. This is strictly related to moisture content, since when the lowest temperature was applied, it was not possible to remove as much water. Our results agreed with Miri and coworkers (Miri et al. 2006), who also showed that increasing frying time increases crust thickness.

Table 1 shows the percentage of oil uptake along with porosity as calculated through the image analysis software. The results show that the oil uptake was not significantly different (around 3 %) for par frying in all the temperatures. These results are in agreement with a previous study (Van Loon et al. 2007), which reported oil content at the end of the par frying stage to be near to 4.0 %. Conversely, at the end of finish frying, the percentage of the absorbed oil during finish frying was twofold higher.

The porosity was defined as the cumulative volume of all the pores relative to the volume of the entire fry. Porosity can be seen in all the images when looking at the pore distribution inside the crust (Figs. 5, 6, and 7). Conversely to the crust thickness, there was no significant increase in the relative amount of pores during par frying at 190 °C. This is to be expected since only surface water is being evaporated at this stage (van Koerten et al. 2015). The pores are developed mainly in the par frying process, whereas during finish frying, pores are expanded allowing for a high oil uptake. This also explains why oil uptake following par frying at different temperatures were similar since there were lots of small pores present in French fries following par frying.

Structural differences were observed after finish frying at different temperatures. At 190 °C, the oil viscosity is lower (Fig. S3, Supplemental Information), allowing most of the oil to drain from the product when removed from the fryer. At the lowest temperature (170 °C), the oil was the most viscous (Fig. S3, Supplemental Information); at this temperature, there was less crust structure developed, one reason that the oil uptake was lower compared to the higher frying temperatures.

Texture Analysis

The texture of the French fries is recognized as one of the most important quality aspects of the product. Two sections with different textural properties can be distinguished: a crispy outer crust of about 1–2 mm and a moist and soft interior, similar to cooked potato tissue (Bouchon and Aguilera 2001).

The blanching step decreased hardness around 36, 16, and 27.5 % at 190, 180, and 170 °C, respectively (data not shown). Blanching caused a significant drop in both the hardness and puncture force in comparison to raw potato. This tissue softening is a result of the starch gelatinization and degradation of the middle lamella. The par frying process decreased hardness from 21.0 to 7.9 N at 170 °C, from 17.0 to 6.7 N at 180 °C, and from 32.2 to 9.7 N at 190 °C. Hardness slightly increased following the finish frying step from 2.1 to 3.6 at 170 °C, from 2.4 to 5.8 N at 180 °C, and from 3.7 to 6.5 N at 190 °C (Fig. 8a), with the greatest changes observed at 190 °C. Our results agree with those of Kita et al. (2007), who showed that fry hardness increased with increasing temperature.

A significant positive correlation between hardness and moisture during the par frying process (R 2 = 0.383, p < 0.01) was observed using Pearson’s test, while during the finish frying process, there is an inverse correlation between them (R 2 = −0.505, p < 0.01) (Table 3). During the par frying process, the potato strip had high moisture content (around 80 %) and low oil content (around 8 %) after only 60 s of frying and this is not enough time to form the external crust, thus the absence of the characteristic French fry crispness. Dehydration, along with the removal from hot oil after frying, caused cellular collapse and the formation of a porous structure.

Table 3 shows the results of the selected TPA test parameters (hardness, cohesiveness, springiness, chewiness, and gumminess) in French fries, depending on the oil frying temperature and the process step. Hardness decreased with increasing frying time during the par frying step in all the three temperatures of frying; on the contrary, an increase was observed as frying progressed during the final fry process reaching the highest value with 6.62 N at 190 °C. Cohesiveness is an indicator of intercellular bonds resulting from the modification of pectin compounds by methyl esterase during blanching (Aguilar 1997). Cohesiveness increased in all the treatments. The swelling pressure of the hydrated starch granules might not have been enough to rupture the cell walls. Also, the nature of gelatinized starch may bring out tissues to stick together, increasing the cohesiveness. Chewiness is the required energy for the mastication of a solid food to a state ready for swallowing and is the product of hardness, cohesiveness, and springiness (Bourne 2002). Chewiness presented the same trend as chewiness, slightly increasing with the time processing at lower temperatures.

In puncture tests, the shear cutting force decreased by about 42 % for all the temperatures during the blanching (data not shown). It is well known that the activation of methyl esterase may take place in blanched potato reducing firmness (Aguilar 1997). The par frying process led to a reduction in shear cutting force from 2.9 to 0.8 N at 170°C, from 2.9 to 1.4 N at 180 °C, and from 3.4 to 1.6 N at 190 °C. Although, finish frying resulted in a slight increase in the shear force from 1.0 to 1.5 N at 190 °C and from 0.7 to 1.2 N at 180 °C, with no change observed at 170 °C. There was a significant correlation between shear cutting force and moisture content (R 2 = 0.461, p < 0.01) by Pearson’s test, as well as with hardness (R 2 = 0.623, p < 0.01) during the par frying process. For the finish frying process, there was a significant positive correlation between color (R 2 = 0.628, p < 0.01) and hardness (R 2 = 0.678, p < 0.01) and an inverse correlation with moisture (R 2 = −0.351, p < 0.01). The MANOVA analysis confirmed that shearing of the potato strips is highly dependent on the processing time and temperature (Table S1, Supplemental Information).

Conclusions

The physical, mechanical, and structural properties of French fries were evaluated during over the course of fry production mimicking that of commercial operations. Temperatures (170–180 °C and 190 °C) for par frying and finish frying were evaluated. Multivariate analysis confirmed that temperature had the greatest effect on moisture content during par frying, while time had a greater impact than temperature did on oil uptake. Frying oil temperature of 190 °C provided the lowest oil uptake and fries with the greatest hardness indicative of a crispier texture. Frying temperature and time both had a significant effect on color development as well as oil uptake, hardness, and shear cutting force. French fries became harder as the temperature of frying increased. Further, X-ray micro-CT demonstrated its capability as a non-invasive technique to study the internal microstructure of French fries. Micro-CT scan images also provided a detailed characterization of the location of the oil. The data from this research can be used potentially by the food industry to achieve different desired product characteristics, including the texture and oil content of the final product, by varying the frying conditions (time vs. temperature).

References

44-15.02, A. I. M. (1999). AACC international method 1–15.02 Approved Methods of Analysis. 11th Edition (pp. 1–4).

920.39C, A. (2002). Official methods of analysis, 239C.

Agblor, A., & Scanlon, M. G. (1998). Effects of blanching conditions on the mechanical properties of French fry strips. American Journal of Potato Research, 75(6), 245–255.

Agblor, A., & Scanlon, M. G. (2000). Processing conditions influencing the physical properties of French fried potatoes. Potato Research, 43(2), 163–178.

Aguilar, C. N. A.-M. A. (1997). Low-temperature blanch improves textural quality of French-fries. Journal of Food Science, 62(3).

Aguilera, J. M., & Gloria-Hernandez, H. (2000). Oil absorption during frying of frozen par fried potatoes. Journal of Food Science, 65(3), 476–479. doi:10.1111/j.1365-2621.2000.tb16031.x.

Al-Khusaibi, M., Gordon, M. H., Lovegrove, J. A., & Niranjan, K. (2012). Provenance of the oil in par-fried French fries after finish frying. Journal of Food Science, 77(1), E32–E36. doi:10.1111/j.1750-3841.2011.02460.x.

Alvarez, M. D., Morillo, M. J., & Canet, W. (2000). Characterization of the frying process of fresh and blanched potato strips using response surface methodology. European Food Research and Technology, 211(5), 326–335.

Bouchon, P., & Aguilera, J. M. (2001). Microstructural analysis of frying potatoes. International Journal of Food Science and Technology, 36(6), 669–676.

Bouchon, P., Aguilera, J. M., & Pyle, D. L. (2003). Structure oil-absorption relationships during deep-fat frying. Journal of Food Science, 68(9), 2711–2716.

Bouchon, P., Hollins, P., Pearson, M., Pyle, D. L., & Tobin, M. J. (2001). Oil distribution in fried potatoes monitored by infrared microspectroscopy. Journal of Food Science, 66(7), 918–923.

Bourne, M. (2002). Food texture and viscosity: concept and measurement: Academic press.

Carolina Moreno, M., & Bouchon, P. (2013). Microstructural characterization of deep-fat fried formulated products using confocal scanning laser microscopy and a non-invasive double staining procedure. Journal of Food Engineering, 118(2), 238–246. doi:10.1016/j.jfoodeng.2013.03.007.

Heredia, A., Castello, M. L., Argueelles, A., & Andres, A. (2014). Evolution of mechanical and optical properties of French fries obtained by hot air-frying. LWT- Food Science and Technology, 57(2), 755–760. doi:10.1016/j.lwt.2014.02.038.

Kalogianni, E. P., & Papastergiadis, E. (2014). Crust pore characteristics and their development during frying of French-fries. Journal of Food Engineering, 120(0), 175–182. doi:10.1016/j.jfoodeng.2013.07.029.

Kalogianni, E. P., & Smith, P. G. (2013). Effect of frying variables on French fry properties. International Journal of Food Science and Technology, 48(4), 758–770. doi:10.1111/ijfs.12024.

Kita, A., & Lisińska, G. (2005). The influence of oil type and frying temperatures on the texture and oil content of French fries. Journal of the Science of Food and Agriculture, 85(15), 2600–2604. doi:10.1002/jsfa.2319.

Kita, A., Lisińska, G., & Gołubowska, G. (2007). The effects of oils and frying temperatures on the texture and fat content of potato crisps. Food Chemistry, 102(1), 1–5. doi:10.1016/j.foodchem.2005.08.038.

Krokida, M. K., Oreopoulou, V., & Maroulis, Z. B. (2000a). Effect of frying conditions on shrinkage and porosity of fried potatoes. Journal of Food Engineering, 43(3), 147–154.

Krokida, M. K., Oreopoulou, V., & Maroulis, Z. B. (2000b). Water loss and oil uptake as a function of frying time. Journal of Food Engineering, 44(1), 39–46.

Krokida, M. K., Oreopoulou, V., Maroulis, Z. B., & Marinos-Kouris, D. (2001a). Colour changes during deep fat frying. Journal of Food Engineering, 48(3), 219–225. doi:10.1016/S0260-8774(00)00161-8.

Krokida, M. K., Oreopoulou, V., Maroulis, Z. B., & Marinos-Kouris, D. (2001b). Effect of pre-drying on quality of French fries. Journal of Food Engineering, 49(4), 347–354.

Limbo, S., & Piergiovanni, L. (2006). Shelf life of minimally processed potatoes: part 1. Effects of high oxygen partial pressures in combination with ascorbic and citric acids on enzymatic browning. Postharvest Biology and Technology, 39(3), 254–264.

Maté, J. I., Quartaert, C., Meerdink, G., & Van’t Riet, K. (1998). Effect of blanching on structural quality of dried potato slices. Journal of Agricultural and Food Chemistry, 46(2), 676–681.

Miri, T., Bakalis, S., Bhima, S. D., & Fryer, P. (2006). Use of X-ray micro-CT to characterize structure phenomena during frying. doi:10.1051/IUFoST:20060023

Moreira, R.G. & Bakker-Arkema, F.W. (1989). Moisture desorption model for nonpareil almonds. Journal of Agricultural Engineering Research. 42(2), 123–133

Mousavi, R., Miri, T., Cox, P. W., & Fryer, P. J. (2005). A novel technique for ice crystal visualization in frozen solids using X-ray micro-computed tomography. Journal of Food Science, 70(7), E437–E442. doi:10.1111/j.1365-2621.2005.tb11473.x.

Moyano, P. C., & Pedreschi, F. (2006a). Kinetics of oil uptake during frying of potato slices: effect of pre-treatments. LWT- Food Science and Technology, 39(3), 285–291. doi:10.1016/j.lwt.2005.01.010.

Moyano, P. C., Rioseco, V. K., & Gonzalez, P. A. (2002). Kinetics of crust color changes during deep-fat frying of impregnated French fries. Journal of Food Engineering, 54(3), 249–255. doi:10.1016/s0260-8774(01)00211-4.

O’Connor, C. J., Fisk, K. J., Smith, B. G., & Melton, L. D. (2001). Fat uptake in French fries as affected by different potato varieties and processing. Journal of Food Science, 66(6), 903–908.

Oliveira, J. C., Pereira, P. M., & Oliveira, F. A. (1994). The role of transport phenomena. In R. P. Singh, & F. A. Oliveira (Eds.), Minimal processing of foods and process optimization. Boca Raton, USA: CRC Press

Pedreschi, F., & Moyano, P. (2005). Oil uptake and texture development in fried potato slices. Journal of Food Engineering, 70(4), 557–563. doi:10.1016/j.jfoodeng.2004.10.010.

Tajner-Czopek, A. (2003). Changes of pectic substances concentration in potatoes and French fries and the effect of these substances on the texture of the final product. Nahrung – Food, 47(4), 228–231.

Tajner-Czopek, A., Figiel, A., & Carbonell-Barrachina, A. A. (2008). Effects of potato strip size and pre-drying method on French fries quality. European Food Research and Technology, 227(3), 757–766.

Ufheil, G., & Escher, F. (1996). Dynamics of oil uptake during deep-fat frying of potato slices. LWT - Food Science and Technology, 29(7), 640–644. doi:10.1006/fstl.1996.0097.

van Koerten, K. N., Schutyser, M. A. I., Somsen, D., & Boom, R. M. (2015). Crust morphology and crispness development during deep-fat frying of potato. Food Research International, 78, 336–342. doi:10.1016/j.foodres.2015.09.022.

van Loon, W. A. M., Linssen, J. P. H., Legger, A., Posthumus, M. A., & Voragen, A. G. J. (2005). Identification and olfactometry of French fries flavour extracted at mouth conditions. Food Chemistry, 90(3), 417–425. doi:10.1016/j.foodchem.2004.05.005.

Van Loon, W. A. M., Visser, J. E., Linssen, J. P. H., Somsen, D. J., Jan Klok, H., & Voragen, A. G. J. (2007). Effect of pre-drying and par-frying conditions on the crispness of French fries. European Food Research and Technology, 225(5–6), 929–935.

Ziaiifar, A. M., Achir, N., Courtois, F., Trezzani, I., & Trystram, G. (2008). Review of mechanisms, conditions, and factors involved in the oil uptake phenomenon during the deep-fat frying process. International Journal of Food Science and Technology, 43(8), 1410–1423. doi:10.1111/j.1365-2621.2007.01664.x.

Ziaiifar, A. M., Courtois, F., & Trystram, G. (2010). Porosity development and its effect on oil uptake during frying process. Journal of Food Process Engineering, 33(2), 191–212. doi:10.1111/j.1745-4530.2008.00267.x.

Acknowledgments

We would like to thank M/s. Micro Photonics, Inc. for their micro-CT scanning support and the image analysis. Special thanks are due to Lamb Weston (ConAgra Foods, Inc.) for supplying with the potatoes and oil for all the frying experiments. We are thankful to Drs. Armando McDonald, Carl Morrow, Helen Joyner, Mr. Jim Nelson, and Ms. Binying Ye of the University of Idaho for their help in the use of their laboratories. In addition, thanks are given to Mr. Frank Younce at the School of Food Science, Washington State University, for his support with the texture analysis and to Mr. Bhim Thapa for his significant assistance with the frying experiments and sample analysis.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

ESM 1

(DOCX 57 kb)

Rights and permissions

About this article

Cite this article

Millin, T.M., Medina-Meza, I.G., Walters, B.C. et al. Frying Oil Temperature: Impact on Physical and Structural Properties of French Fries During the Par and Finish Frying Processes. Food Bioprocess Technol 9, 2080–2091 (2016). https://doi.org/10.1007/s11947-016-1790-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-016-1790-2