Abstract

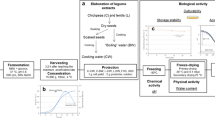

A synbiotic product of combined Lactobacillus plantarum TISTR 875 with water extracts and crude fibers from corn, mungbean, and soybean was formulated to investigate the survival of L. plantarum during freeze-drying and storage. The impacts of those water extracts and crude fibers on probiotic survival were determined in both a cultural medium and a freeze-drying medium. L. plantarum cultivated in de Man, Rogosa, and Sharpe (MRS) broth containing 2 % of water extract from soybean with 2 % mungbean fiber showed only 0.11 log CFU/ml cell reduction. The survival of L. plantarum harvested at the late log phase, mid stationary, phase and late stationary phase did not show statistical significance (P > 0.05), whereas an initial pH of 6.5 and growth temperature of 37 °C showed greater impact (P < 0.05). The addition of corn extract to the freeze-drying medium as a cryoprotectant had a similar effect on L. plantarum survival as sucrose, but it was better (P < 0.05) than fructo-oligosaccharide and exopolysaccharides from Weissella cibaria A2, soybean extract, mungbean extract, soybean, corn, and mungbean fibers. A protective coating of corn extract was revealed and observed using scanning electron microscopy. The freeze-dried L. plantarum, cultivated in MRS broth containing soybean extract and mungbean fiber with corn extract as a cryoprotectant, retained high viability of 7.21 and 6.88 log CFU/ml after 8-week storage in a vacuum-packed aluminum foil-laminated polyethylene sachet and a nitrogen-flushed glass vial, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lactobacillus plantarum is a ubiquitous lactic acid bacterium (LAB) commonly found in a wide range of fermented foods and in the human gastrointestinal tract (GI tract). This wide range may be due to its ability to uptake different sugars and peptides and to adapt to various environmental conditions. Furthermore, its ability to maintain a large number of surface-anchored proteins may enhance survival in highly competitive niches like the human GI tract. L. plantarum is claimed to be a potential probiotic due to various health-promoting effects and long history of safe use. The beneficial effects including the suppression of pathogenic bacteria, prevention of intestinal infection, improvement of the immune system, and reduction of both inflammatory reactions and serum cholesterol stimulation were evaluated both by in vitro and in vivo studies in animal models, healthy volunteers, and patients (De Vries et al. 2006; Tannock 1998).

Nevertheless, the survival of such bacteria in the probiotic products is critical to ensure the associated functional benefits. The number of living probiotic organisms should meet a suggested minimum of >106 CFU/ml to achieve optimal potential health benefits (Dave and Shah 1997; Lourens-Hattingh and Viljoen 2001). Unfortunately, many surveys found that the high number of lactobacilli/bifidobacteria in many commercial probiotic products was not achieved as claimed in the product label information, particularly in dry form of probiotic products. More than 67 % of dry powder or granule products distributed in Taiwan markets contained LAB lower than 106 CFU/ml, and half of the product brands contained no viable LAB (Lin et al. 2006). In the European countries, 30 % of dried probiotic supplement brands available in the market contained no viable cells (Temmerman et al. 2002). Similar observations on such products available in the UK have been made by Hamilton-Miller and Shah (2002). Several factors affect the survival of probiotics in dry form. These include drying methods and temperatures, probiotic strains, growth conditions, the addition of protectants, and the storage atmosphere (Otero et al. 2007).

Prebiotics are non-digestible polysaccharides which can selectively stimulate the growth of one or more species of beneficial bacteria in the colon, thus improving the host’s health (Gibson and Roberfroid 1995). Prebiotics and probiotics may be combined in a single product called a synbiotic, and this is an effective approach to establish probiotics in the host colon (Bielecka et al. 2002). Currently, such food products combining probiotics with water-soluble and water-insoluble fibers are gaining attention. It would be valuable if fibers could protect probiotic cells during processing, formulation, and/or storage, thereby improving their viability and stability. Many prebiotic carbohydrates and plant fibers have been reported to improve bacterial survival during freezing and dehydration processes. For example, the addition of commercial galacto-oligosaccharides significantly increased the survival of Lactobacillus delbrueckii subsp. bulgaricus CIDCA 333 during freeze-drying (Tymczyszyn et al. 2011). Similarly, the survival of Lactobacillus reuteri during freeze-drying improved in the presence of sucrose, fructo-oligosaccharides (FOS) and skimmed milk. Furthermore, inulin and skimmed milk provided the highest stability during storage (Schwab et al. 2007). UnipectineTM RS 150 was the most protective cryoprotectant with 80 % improvement of Bifidobacterium longum 536 survival in frozen yogurt, but only 30 % improvement in the survival of Lactobacillus spp. was reported (Capela et al. 2006). On the contrary, the survival of many probiotics in frozen yogurt was not improved in the presence of prebiotics such as Hi-maize, fructo-oligosaccharides (FOS), and inulin (Capela et al. 2006). There was little difference in L. plantarum and Lactobacillus rhamnosus in terms of survival and viability during freeze-drying in either the presence or absence of inositol, sorbitol, fructose, trehalose, monosodium glutamate, and propyl gallate. However, these compounds increased cell stability during storage (Carvalho et al. 2002). These reported differences in survival and viability can be attributed to many factors such as bacterial species, cultivation conditions, initial bacterial concentration, growth stage, and bacterial cell size (Capela et al. 2006; Carvalho et al 2004; Otero et al. 2007).

Apart from water-soluble prebiotics, many water-insoluble fibers function as probiotic protectants when applied in a drying medium (Charalampopoulos et al. 2002; Saarela et al. 2006; Santivarangkna et al. 2008). A few studies have focused on the addition of prebiotics in a growth medium to improve the adaptation of probiotics to freeze-drying conditions. Michida et al. (2006) demonstrated that probiotic cultivation in cereal extracts and fiber-based media improved probiotic survival in the harsh environment of simulated gastric conditions. However, no improvement in survival was observed after freeze-drying when polymers (xanthan gum, gelatin, and maltodextrin) were added to a cultivation medium of L. rhamnosus (Champagne et al. 1996).

The objective of this study was to evaluate the protective effects of prebiotics and crude fiber preparations (water extracts and crude fibers) of sweet corn, mungbean, soybean, and exopolysaccharides (EPSs) from Weissella cibaria A2. These preparations were added to the cultivation and freeze-drying media, and the survival qualities of freeze-dried L. plantarum were determined in comparison to commercially available sugars and prebiotics.

Materials and Methods

Bacterial Strains and Cultivation Condition

Lactobacillus acidophilus TISTR 1034 and L. plantarum TISTR 875 were obtained from the Microbiological Resources Centre, Bangkok, Thailand. Bifidobacterium bifidum DSM 20456 and B. longum DSM 20215 were obtained from the Deutsche Sammlung von Mikroorganismen und Zellkulturen GmbH, Germany. W. cibaria A2 was isolated and identified in our laboratory (Hongpattarakere et al. 2012). The bacteria were stored as stock cultures in 30 % glycerol (0.5 ml of 60 % sterile glycerol and 0.5 ml of the culture broth) at −80 °C for 1 year. The bacterium was activated in modified de Man, Rogosa, and Sharpe (MRS) broth containing 0.05 % l-cysteine hydrochloride to create anaerobic environments and incubated at 37 °C for 24 h. The activated bacterial suspension (100 μl) was then transferred to 10 ml of freshly prepared MRS and incubated at 37 °C for another 24 h before being applied in further experiments.

EPSs from W. cibaria A2, previously evaluated as prebiotics (Hongpattarakere et al. 2012), were prepared from culture supernatant obtained from the cultivation of W. cibaria A2 in 2 % w/v sucrose containing modified MRS broth at 37 °C 48 h in accord with Hongpattarakere et al. (2012). The culture broth was centrifuged at 8,000 rpm for 15 min at 4 °C to remove the bacterial cell. The addition of two volumes of 95 % chilled ethanol to the supernatant was performed at 4 °C and the mixture was left overnight to precipitate EPSs from the culture broth before drying in a hot-air oven at 60 °C for 24 h.

Evaluation of Probiotic Potential of L. plantarum

The probiotic potential of L. plantarum in terms of tolerance to gastric acid and bile was evaluated in accord with Buntin et al. (2008). The antibacterial activities of L. plantarum against Escherichia coli O157:H7, Staphylococcus aureus, and Salmonella enterica serovar Typhi in a co-cultivation study were determined in a minimal medium containing 2.0 g peptone water, 2.0 g yeast extract, 0.1 g NaCl, 0.04 g K2HPO4, 0.04 g KH2PO4, 0.01 g CaCl2·6H2O, 2 g NaHCO3, 0.01 g MgSO4·7H2O, 0.5 g bile salt, 2 ml Tween-80, 0.05 g hemin, 0.5 g/l cysteine, and 1 % mungbean extract (with glucose as a positive control) at 37 °C for 72 h (Salazar et al. 2008). Samples were taken at 0, 12, 24, 48, and 72 h. These were used to determine the growth of lactic acid bacteria and the pathogens on 0.02 g/l bromocresol purple containing MRS agar and Mueller Hinton agar, respectively.

Effects of Freezing Temperatures on Survival of L. plantarum in Comparison to Various Probiotics

One microliter of each bacterial suspension (L. acidophilus, L. plantarum, B. bifidum, B. longum) was dispensed into a 1.5-ml microtube. The samples were frozen at −20, −80, and −196 °C for 20 h, 12 h, and 10–15 min, respectively, before vacuum drying as mentioned in “Freeze-Drying Condition”. Viable cell counts before and after freeze-drying were determined by pour-plating the appropriate dilution with 0.02 % bromocresol purple containing MRS agar. The plates were incubated at 37 °C for 48 h under anaerobic conditions using BD GasPak EZ Anaerobe Container System (Becton Dickinson) for bifidobacterial counts.

Preparation of Water Extracts and Water-Insoluble Fibers

Soybean (Glycine max) and mungbean (Vigna radiate) (packed under the same brand) were purchased from two retail shops located in Hat Yai, Songkhla, Thailand. Fresh sweet corn (Zea mays convar. saccharata var. rugosa) was obtained from a fresh market. Corn seeds were washed and dried at a temperature of 50 °C for 24 h. Grain extraction was performed according to Al-Rwaily et al. (2005) with some modifications. All dried grains were finely ground using a food blender (Model DPA1, Moulinex, France). Ten grams of the dried grain powders was extracted and placed in 90 ml of hot distilled water (70 °C) under constant stirring for 1 h. The mixture was centrifuged at a speed of 8,000 × g for 15 min at 4 °C to obtain “water extract” (supernatant) and residue. The residues were then washed twice with distilled water to yield “crude fibers”. The water extracts (water-soluble) and the crude fibers (water-insoluble) were freeze-dried and stored in a desiccated condition at −20 °C for further use. The freeze-dried water extracts were assessed for total sugar and reducing sugar content by the modified phenol–sulfuric (Fox and Robyt 1991) and modified dinitrosalicylic acid (Robertson et al. 2001) methods, respectively.

Freeze-Drying Condition

Each probiotic bacterium (L. acidophilus, L. plantarum, B. bifidum, B. longum) was cultivated in modified MRS broth containing 0.05 % l-cysteine hydrochloride and incubated at 37 °C for 24 h. One milliliter of the culture broth was dispensed in a microtube. The bacterial cells were harvested by centrifugation at 10,000 × g for 10 min at 4 °C, washed twice with 0.85 % NaCl, and then resuspended in 1 ml of 10 % sterile reconstituted skimmed milk. Each microtube was immerged in liquid nitrogen at −196 °C for 10–15 min. The sublimation was performed at a capacity of 14 l/24 h using a Dura-Dry MP freeze-dryer (FTS System, USA) for 15–18 h. Bacterial viability was determined immediately after the freeze-drying process. For cell recovery, the dried samples were brought to their original volume with 0.15 % peptone water to obtain bacterial suspension, which was then serially diluted and transferred to the appropriate medium for viable counts on 0.02 g/l bromocresol purple containing MRS agar. The bacterial counts were expressed as log mean colony-forming units (CFU) per milliliter of the original volume of the culture broth (Jagannath et al. 2010).

Cultivation Factors Influencing Freeze-Drying Survival of L. plantarum

Addition of Water Extracts in Culture Media

Freeze-drying survival of L. plantarum, cultivated in MRS broth containing the water extracts from “Preparation of Water Extracts and Water-Insoluble Fibers”, was evaluated. One hundred microliters of L. plantarum, prepared in accord with “Bacterial Strains and Cultivation Condition”, was cultivated at 37 °C for 24 h in 10 ml of modified MRS broth with 2 % of glucose, sucrose, FOS (Raftilose P95, Orafti, Belgium), and water extracts from soybean, mungbean, and corn. The bacterial cells from each treatment were harvested and subjected to freeze-drying as described in “Freeze-Drying Condition”. The viable cells before and after freeze-drying were enumerated and expressed as described in the said section. The water extract that resulted in the highest protective effect and specific growth rate was selected as the carbon source in the growth medium for L. plantarum cultivation in further experiments.

Addition of Crude Fibers and EPSs in Culture Media

One hundred microliters of L. plantarum (in accord with “Bacterial Strains and Cultivation Condition”) was cultivated at 37 °C for 24 h in 10 ml of modified MRS broth containing 2 % water extract from soybean. This had the addition of 2 % crude fibers from soybean, mungbean, corn, and EPSs with no crude fiber addition as a control. The bacterial cells (adhering to the crude fibers) from each treatment were harvested by centrifugation (8,000 rpm, 15 min) and washed twice using sterile saline (0.8 % w/v NaCl) (Michida et al. 2006). The washed pellets were subjected to freeze-drying as described in “Freeze-Drying Condition”. The viable cells before and after freeze-drying were enumerated and expressed as described in the same section. The crude fiber that enhanced the greatest cell survival and specific growth rate was selected to add to the growth medium for further experiment.

Effects of Incubation Temperatures, Initial pH of Culture Media, and Growth Stages

One hundred microliters of L. plantarum (see “Bacterial Strains and Cultivation Condition”) was cultivated in 10 ml of modified MRS broth containing 2 % water extract from soybean and mungbean crude fiber at pH 6.5. The cultivation was conducted at 30, 37, and 45 °C for 24 h, and then bacterial cells were harvested and subjected to freeze-drying before viable cell enumeration was performed in accord with “Freeze-Drying Condition”. The temperature at which probiotic cells showed the highest survival from freeze-drying was chosen to study the effect of the initial pH.

L. plantarum was cultivated in modified MRS broth containing 2 % water extract from soybean and mungbean crude fiber at various initial pH values, which were adjusted to 4.0, 5.0, 6.5, and 7.0 using either 6N HCl or 6N NaOH. The cultivation was conducted at the best temperature for 24 h, and then bacterial cells were harvested and subjected to freeze-drying as described in “Freeze-Drying Condition”. The best initial pH was chosen to study the effect of the growth phase.

L. plantarum, cultivated in modified MRS broth containing 2 % water extract from soybean and mungbean crude fiber, at pH 6.5, was harvested at 9, 24, and 36 h of incubation at 37 °C to obtain the bacterial cells at the late log, mid stationary, and late stationary phases of growth, respectively. These cells were washed and then re-suspended in 10 % sterile reconstituted skimmed milk before freeze-drying. The viable cells before and after freeze-drying were enumerated and expressed as described in “Freeze-Drying Condition”. The stage of growth resulting in the highest survival was chosen for the studies described in the following three sections.

Effects of Water Extract, Crude Fiber, and EPSs Additions in Freeze-Drying Media on Survival of L. plantarum TISTR 875

L. plantarum was activated in 10 ml of modified MRS broth at 37 °C for 24 h, and 1 ml transferred to 9 ml modified MRS broth containing 2 % of soybean extract and 2 % mungbean fiber, pH 6.5, was cultivated at 37 °C. The cells were harvested and were resuspended in 10 % of sucrose, skimmed milk, soybean extract, soybean fiber, corn extract, corn fiber, mungbean extract, and mungbean fiber as cryoprotectants. The viable cells before and after freeze-drying were then determined.

Morphology of Freeze-Dried L. plantarum Cells

The morphology of freeze-dried cells was observed by scanning electron microscopy in accord with Eun et al. (2007). The freeze-dried samples were affixed to “stubs” using double-sided adhesive metallic tape and then coated with gold using sputter coater (WI-RES-Coater-001). Cell morphology was observed under a JEM-2010 scanning electron microscope (JEOL, Tokyo, Japan) operated at an accelerating voltage of 15–20 kV. Scanning electron micrographs were obtained under × 5,000 and × 8,000 magnification.

Stability of Freeze-Dried Powders

The freeze-dried L. plantarum immobilized on fine mungbean fiber (fiber was simply added to the crude fiber) with corn extract as a carrier was packed in a glass vial flushed with nitrogen gas and in the vacuum aluminum foil-laminated polyethylene sachet as synbiotic products. The storage stability of the product was tested at 4 and 30 °C for 8 weeks. The stability test was performed twice.

Statistical Analysis

To determine if significant differences existed between the different treatments and the parameters tested, all data obtained from three replicates were analyzed using one-way analysis of variance and Duncan’s multiple-range test. Significant differences were indicated at P < 0.05.

Results

Probiotic Potential of L. plantarum

L. plantarum was able to grow in MRS agar supplemented with 3,000 ppm bile salt (data not shown), which is approximately the concentration in the human intestine. The bacterium was further tested for its ability to tolerate acidic conditions at pH 1.0, 2.0, 2.5, and 3.0 and the number of viable cells remaining after 0, 1, 2, 3, and 4 h of exposure. L. plantarum could tolerate an acidic condition of pH 3 for 4 h, but no survival was observed at pH 1 and 2 (data not shown). According to a co-culture study, L. plantarum significantly inhibited all food-borne pathogens tested with complete inhibition against S. Typhi (Fig. 1).

Survival of L. plantarum TISTR 875 from Freeze-Drying at Various Freezing Temperatures

High freezing temperatures significantly (P < 0.05) affected the survival of L. plantarum. Lower survival (P < 0.05) was observed at freezing temperatures of −20 and −80 °C, while the cell reduction caused by a temperature of −196 °C was lower (Table 1). L. plantarum exposed to a temperature of −196 °C showed the lowest cell reduction of 0.18 log CFU/ml, while freezing at −20 and −80 °C caused significant cell damage with 0.37 and 0.52 log CFU/ml cell reduction, respectively.

L. plantarum was most tolerant to the freezing temperatures of −20, −80, and −196 °C compared to all probiotics tested. B. longum was most sensitive to freeze-drying than L. plantarum and L. acidophilus. In general, L. plantarum, B. longum, and B. bifidum exposed to a temperature of −196 °C showed the lowest cell reduction of 0.18, 0.61, and 0.57 log CFU/ml, respectively, while freezing at −20 and −80 °C caused significant cell mortality (Table 1). On the contrary, L. acidophilus exhibited better survival at −20 °C with cell reduction of 0.32 log CFU/ml than at −80 and −196 °C. This observation did not correlate with L. plantarum, B. bifidum, and B. longum which showed an increase of cell reduction at these higher freezing temperatures.

Effects of Water Extract and Crude Fiber Addition in Culture Medium on Growth and Survival of L. plantarum After Freeze-Drying

L. plantarum grown in the water extracts of corn, mungbean, and soybean was more tolerant to freeze-drying than those grown on commercial sugars and prebiotic FOS (Table 2). The addition of water extract from soybean significantly (P < 0.05) enhanced the freeze-drying survival of L. plantarum compared to corn extract, FOS, sucrose, and glucose. L. plantarum grown in the presence of soybean extract showed the highest survival (77.07 %), while those grown in corn extract, glucose, sucrose, and FOS survived at lower levels (70.78, 54.09, 28.62, and 35.78 % survival, respectively). The probiotic cells grown in the presence of mungbean extract insignificantly survive freeze-drying (76.65 %) compared with those cultivated in the presence of soybean extract (P > 0.05). In addition, the specific growth rate of L. plantarum in the medium containing soybean extract was not significant (P > 0.05) compared to glucose (Table 2). Although L. plantarum grew significantly (P < 0.05) better in sucrose than in soybean extract, its freeze-drying survival was significantly lower (P < 0.05). The results indicate that soybean extract can function as a potential carbon source for cell cultivation and can enhance the freezing survival of L. plantarum. Therefore, it can substitute glucose and sucrose, which are commonly used as a carbon source in cell cultivation.

Crude fiber addition exhibited a variable impact on the survival of L. plantarum from freeze-drying (Table 3). The highest survival, with a cell reduction of 0.25 log CFU/ml, was observed in the presence of mungbean crude fiber. Meanwhile, corn and soybean crude fibers reduced the survival significantly (P < 0.05) compared to the control (no fiber addition).

Effects of pH, Temperatures, and Growth Stage on Freeze-Drying Survival of L. plantarum

Growth temperature and initial pH significantly impacted on the survival of freeze-dried L. plantarum cultivated in modified MRS broth containing soybean extract and fine mungbean fiber (Fig. 2a, b). L. plantarum cultivated in the medium with an initial pH 6.5 at a temperature of 37 °C was most tolerant to freeze-drying compared to the cells grown at other levels of pH and temperatures (Fig. 2b). Freeze-drying tolerance was not observed in L. plantarum grown in an acidic condition (pH 4) and high temperature (45 °C). Although the bacterial cells harvested at the mid stationary phase showed the highest survival with a cell reduction of only 0.16 log CFU/ml, it was not significantly different (P > 0.05) from the cells harvested at late log and late stationary phases (Fig. 2c).

Effect of Prebiotic Addition in Freeze-Drying Medium on Survival of L. plantarum

L. plantarum grown in modified MRS broth containing soybean extract and crude mungbean fiber was harvested at the mid stationary phase. The bacterial cells were resuspended in freeze-drying media containing sucrose, FOS, skimmed milk, water extracts, and crude fibers from soybean, corn, and mungbean before being subjected to freeze-drying. Corn extract improved the survival (cell reduction 0.26 log CFU/ml) better than skimmed milk (cell reduction 0.35 log CFU/ml) (P < 0.05) but was slightly lower than sucrose (P < 0.05), which is commonly used as carriers in freeze-drying (Fig. 3). The addition of sucrose as a cryoprotectant showed the highest survival with a cell reduction of 0.19 log CFU/ml, while the incorporation of soybean fiber showed the lowest survival with a cell reduction of 1.48 log CFU/ml. The scanning electron micrograph (SEM) revealed the attachment of L. plantarum to mungbean fiber (Fig. 4). In the presence of corn extract or sucrose, no cell shrinkage was found, whereas many damaged, flattened, and concaved (club-shaped) characteristics were clearly observed in the presence of skimmed milk (Fig. 4c). However, intact cells of L. plantarum attached to the mungbean fiber under a thin layer coating were revealed (Fig. 4a, b). Such a protective coating, which did not appear in the presence of skimmed milk, may explain the higher survival of L. plantarum when sucrose and corn extract were added as cryoprotectants in the freeze-drying medium.

When the storage temperature was increased, the viability of L. plantarum grown in soybean extract and mungbean crude fiber and freeze-dried in the presence of corn extract as a cryoprotectant decreased dramatically (P < 0.05) as shown in Fig. 5. The survival for 8 weeks of the freeze-dried L. plantarum with corn extract as a cryoprotectant packed in the glass vial flushed with nitrogen gas (1.18 log reduction) was slightly lower than that kept in the vacuum aluminum foil-laminated polyethylene sachet (0.85 log reduction). However, the survival of L. plantarum with sucrose as a cryoprotectant was greatly reduced in the glass vial (1.54 log reduction) in comparison to the sachet (0.33 log reduction). The bacterial cells freeze-dried with corn extract as a cryoprotectant remained more stable than those freeze-dried with sucrose when stored in the glass vial under nitrogen gas at 5 °C.

Discussion

Freeze-drying has been a traditional way to produce dry bacteria powder because thermal inactivation can be avoided. However, freeze-drying and subsequent storage are accompanied by a significant reduction of probiotic viability and stability. This may be caused by sub-zero temperatures and dehydration (De Giulio et al. 2005; Schwab et al. 2007). The important contributors to loss of viability due to freezing are osmotic shock and recrystallization (Saarela et al. 2006). In this study, L. plantarum survived at a freezing temperature of −196 °C better than at −20 and −80 °C. When the bacterial cells were subjected to rapid freezing at −196 °C, ice crystals can form uniformly. However, slow freezing at temperatures above −30 °C may result in poor survival. This causes a loss of water from the cell but increases the effects of solute concentration according to Perry (1998). Ice crystal formation and an increase in solute concentration within and around the cells might be responsible for the damage to cell membranes during the freezing process. This may explain why certain bacteria, particularly the strains which adapt better under osmotic stress condition, survive better at high freezing temperatures (Zhao and Zhang 2005).

In this study, L. plantarum was most resistant to freeze-drying, whereas bifidobacteria were more sensitive. The results support previous findings showing that the survival of probiotic during freeze-drying and subsequent storage is unique among probiotic species. Gram-positive bacteria such as L. acidophilus and Enterococcus faecium were more resistant than the Gram-negative E. coli, Pseudomonas putida, and Enterobacter cloacae (Shinohara et al. 2006). Champagne et al. (1996) reported the highest survival (118 %) of L. rhamnosus RO11, whereas Streptococcus thermophilus RO57 and Lactococcus lactis RO58 and B. longum RO23 survived only at the rates of 73, 54, and 37 % after freeze-drying, respectively. Streptococcus salivarius subsp. thermophilus exhibited lower survival after freeze-drying compared to L. delbrueckii subsp. bulgaricus (DSM20081) and L. acidophilus (DSM20079), although the latter was most sensitive to freezing (De Giulio et al. 2005). A higher survival of B. longum than L. acidophilus was reported by Capela et al. (2006), but there was no statistical significance. Moreover, the freeze-drying resistance of bacteria was also strain dependent (Capela et al. 2006; Carvalho et al. 2002; Champagne et al. 1996; Saarela et al. 2006). The viability of L. rhamnosus E800 was higher than L. rhamnosus E522 in freeze-dried powder stored at 37 °C for 8 weeks (Saarela et al. 2006). However, there are multiple factors involved in the variability of bacterial resistance to freeze-drying. These factors are identified and discussed at length by Carvalho et al. (2004).

Synbiotic products are increasingly in demand. Prebiotics and fibers can protect probiotics from environmental stresses in products. As reported by many researchers, carbohydrate addition reduced bacterial inactivation during freezing, drying, and subsequent storage (Capela et al. 2006; Castro et al. 1997; De Giulio et al. 2005; Tymczyszyn et al. 2011). According to this present study, the addition of the water extracts from corn, mungbean, and soybean in the growth media greatly improved the survival of L. plantarum during freeze-drying. The bacterial cells cultivated in glucose, sucrose, and FOS were much less tolerant, hence their lower survival (P < 0.05) after freeze-drying. The results indicate that the addition of water-soluble extracts from soybean in the growth medium prevents cell damage caused by freeze-drying. The water extracts could serve not only as potential carbon sources for cell growth but also as osmotic stress inducers in the growth media for L. plantarum. Water extract from soybean is rich in soluble amino acids, proteins, and oligosaccharides. These constituents may possibly behave as osmolytes that improve cell tolerance against the hyperosmotic stress that occurs during freeze-drying processes as reported by De Antoni et al. (1989) and Santivarangkna et al. (2008).

According to many reports, protective effects were observed when bacterial cells accumulated many compatible solutes including amino acids (such as glutamate and proline), quaternary amines (such as betaine and carnitine), and some sugars (including sucrose and trehalose) through intracellular processes. The synthesis and accumulation of these solutes were promoted in response to stressful growth conditions, such as osmotic pressure from the cultivation medium (Kets et al. 1996; Silva et al. 2004). The freeze-drying tolerance of L. plantarum increased significantly when the water extract concentration was raised from 1 % to 2 %, and there was no significant difference at the concentrations of 2, 3, and 4 % (data not shown). Freeze-drying survival was significantly reduced when L. plantarum was cultivated at a low pH and high temperature. According to Santivarangkna et al. (2008), lactic acid bacteria have a low possibility for synthesizing compatible solutes under stress but are mostly dependent on the uptake from the growth medium. In addition, Kleerebezem et al. (2003) reported a high number of genes encoding putative sugar transporters in the L. plantarum genome. Twenty-five complete phosphotransferase systems were found. This supports the high ability of L. plantarum in transporting and accumulating sugar. Therefore, the addition of water extract should be performed in the cultivation medium to allow enough time for the solutes to accumulate.

Moreover, the freeze-drying survival of stationary phase cells remained highest compared to late log phase cells. These results are in agreement with previous findings (Schwab et al. 2007). Bacterial cells entering the stationary phase have been through the complete development of their cell structure and physiology. These include membrane composition, cell wall structure, and expression levels of stress-related proteins, all resulting in the increase of resistance to freeze-drying.

A protective effect was also observed when the water extracts and the crude fibers were added to the freeze-drying medium. However, less protection was observed with fiber addition. Corn extract provided protection to L. plantarum similar to sucrose. The addition of cryoprotective compounds to improve cell survival is a common practice. The most common ones are polyhydroxylated compounds, such as polyalcohol (manitol, sorbitol), monosaccharide (glucose, xylose), disaccharides (sucrose, maltose, trehalose, and lactose), trisaccharides (raffinose), and polysaccharides (dextran, mannan, dextrin). These carbohydrates can substitute water molecules to stabilize the native structure of phospholipid membranes and proteins by forming hydrogen bonds around the charged groups of these cell components in the absence of water (Huba’lek 2003; Saarela et al. 2006).

Skimmed milk and sucrose have been commonly used as cryoprotectants in a freeze-drying medium. It is considered to be capable of preventing cellular injury by stabilizing the cell membrane and providing a protective coating for the cell (Carvalho et al. 2004). The protective mechanisms might be due to the ability of sugar to prevent injurious eutectic freezing of cell fluids by trapping salts in highly viscous or glass-like phases (Huba′lek 2003). The incubation of probiotics in 32 % of trehalose, sucrose, lactose, and glucose at 4 °C for 2 h significantly improved resistance to freeze-drying (Capela et al. 2006; De Giulio et al. 2005).

The addition of the crude fibers in the growth medium was a more effective approach than in the freeze-drying medium. During cultivation, the bacterial cells were simultaneously immobilized or adhered to the crude fiber as revealed by SEM in Fig. 4. In this study, L. plantarum cultivated in the presence of fine mungbean fiber showed the best survival after freeze-drying. The SEM results showed bacterial attachment on the mungbean fiber, which occurred during cell growth. The results conformed to previous reports to the effect that the addition of carbohydrate has been an effective approach to enhance probiotic tolerances against various environmental stresses. For example, apple or quince pieces were protective supports of L. casei for fermentation under acidic and high temperature conditions (Kourkoutas et al. 2005). Michida et al. (2006) successfully improved the acid and bile tolerance of L. plantarum by the addition of cereal extracts from malt and barley. Immobilized probiotics in alginate bead significantly increased probiotic survival during freeze-drying (De Giulio et al. 2005). Similarly, wheat dextrin and polydextrose were proven to be potential carriers for yielding the high freeze-drying survival of L. rhamnosus. However, poor storage stability at 37 °C was observed in the powder product containing apple fiber and inulin as carriers (Saarela et al. 2006). Bacterial cellulose produced by Acetobacter xylinum was as effective for cryoprotection as skimmed milk and an encapsulation of calcium alginate (Jagannath et al. 2010). A similar result was reported by Schwab et al. (2007) that showed that low molecular weight fructan such as FOS and inulin significantly enhanced the survival of L. reuteri TMW1.106 at a greater level than sucrose. However, no improvement was observed in the survival of probiotics in the presence of gelatin, xanthan gum, and maltodextrins in a milk–sucrose medium (Champagne et al. 1996). The protective mechanism of many non-permeable cryoprotectants was intended to form a viscous layer, which induced the partial efflux of water from the cell, therefore inhibiting the growth of ice crystals and maintaining the structure of amorphous ice in the proximity of cell membranes (Huba’lek 2003). According to the SEM results, the protective mechanism of corn extract was proved to be the same as sucrose, which can be explained by the hypotheses of vitrification and water replacement (Santivarangkna et al. 2008).

The synbiotic product of L. plantarum grown in the medium containing soybean extract and fine mungbean fiber and freeze-dried in the presence of corn extract as a cryoprotectant exhibited high stability during storage at 5 °C under nitrogen. Obviously, the mortality of L. plantarum increased as storage temperature increased. Such a relationship is in agreement with the literature (Champagne et al. 1996; Jagannath et al. 2010). The approach in this study showed the high survival (96.81 ± 1.43 %) of L. plantarum. The initial cell concentration of 8.00 ± 0.01 log CFU/ml was reduced to 7.74 ± 0.01 log CFU/ml immediately after freeze-drying. A similar result of high survival was also observed in L. casei immobilized by wheat grain being introduced in the growth medium (Bosnea et al. 2009). However, Jagannath et al. (2010) reported higher cell losses with 2–3 log cycle reduction right after freeze-drying of many lactic acid bacteria immobilized on nata cubes (bacterial cellulose) and cellulose powder during cultivation. Moreover, a dramatic loss of viability (6–7 log cycle reduction) occurred in the subsequent storage for 30 days (Jagannath et al. 2010). Champagne et al. (1996) observed 33–73 % survival of L. lactis, S. thermophilus, L. rhamnosus, and B. longum in the presence of various polymers in the freeze-drying medium.

Conclusion

Synbiotic powder from freeze-dried L. plantarum adhered on mungbean crude fiber and corn extract was formulated to achieve maximum probiotic viability. Soybean extract was added to substitute glucose in MRS broth to increase the freeze-drying tolerance of L. plantarum. Mungbean crude fiber functioned as a supporting material during cell growth in the cultivation medium; hence, there was a significant improvement in the viability of the freeze-dried probiotic (P < 0.05). Furthermore, the addition of corn extract in the freeze-drying medium protected the lethal destruction of L. plantarum much better than fructo-oligosaccharides. It also increased probiotic stability during storage. Therefore, this synbiotic formulation not only provided a health benefit by controlling the growth of bacterial pathogens, including E. coli O157:H7 and S. Typhi, but also had the additional effect of maximizing probiotic viability and stability.

References

Al-Rwaily, M. A., Herzallah, S. M., Humeid, M. A., & Yamani, M. I. (2005). Effect of dried dates extract on the growth and viability of Bifidobacteria in different milk types. Pakistan Journal of Nutrition, 4(3), 142–147.

Bielecka, M., Biedrzycka, E., & Majkowska, A. (2002). Selection of probiotics and prebiotics for synbiotics and confirmation of their in vivo effectiveness. Food Research International, 35(2–3), 125–131.

Bosnea, L. A., Kourkoutas, Y., Albantaki, N., Tzia, C., Koutinas, A. A., & Kanellaki, M. (2009). Functionality of freeze-dried L. casei cells immobilized on wheat grains. LWT- Food Science and Technology, 42(10), 1696–1702.

Buntin, N., Chanthachum, S., & Hongpattarakere, T. (2008). Screening of lactic acid bacteria from gastrointestinal tracts of marine fish for their potential use as probiotics. Songklanakarin Journal of Science and Technology, 30(Suppl 1), 141–148.

Capela, P., Hay, T. K. C., & Shah, N. P. (2006). Effect of cryoprotectants, prebiotics and microencapsulation on survival of probiotic organisms in yoghurt and freeze-dried yoghurt. Food Research International, 39(2), 203–211.

Carvalho, A. S., Silva, J., Ho, P., Teixeira, P., Malcata, F. X., & Gibbs, P. (2002). Survival of freeze-dried Lactobacillus plantarum and Lactobacillus rhamnosus during storage in the presence of protectants. Biotechnology Letters, 24(19), 1587–1591.

Carvalho, A. S., Silva, J., Ho, P., Teixeira, P., Malcata, F. X., & Gibbs, P. (2004). Relevant factors for the preparation of freeze-dried lactic acid bacteria. International Dairy Journal, 14(10), 835–847.

Castro, H. P., Teixeira, P. M., & Kirby, R. (1997). Evidence of membrane damage in Lactobacillus bulgaricus following freeze-drying. Journal of Applied Microbiology, 82(1), 87–94.

Champagne, C. P., Mondou, F., Raymond, Y., & Roy, D. (1996). Effect of polymers and storage temperature on the stability of freeze-dried lactic acid bacteria. Food Research International, 29(5–6), 555–562.

Charalampopoulos, D., Wand, R., Pandiella, S. S., & Webb, C. (2002). Application of cereals and cereal components in functional foods: a review. International Journal of Food Microbiology, 79(1), 131–141.

Dave, R. T., & Shah, N. P. (1997). Viability of yogurt and probiotic bacteria in yogurt made from commercial starter cultures. International Dairy Journal, 7(1), 31–41.

De Antoni, G. L., Perez, P., Abraham, A., & Anon, M. C. (1989). Trehalose, a cryoprotectant for Lactobacillus bulgaricus. Cryobiology, 26(2), 149–153.

De Giulio, B., Orlando, P., Barbal, G., Coppolal, R., De Rosa, M., Sadal, A., De Priscol, P. P., & Nazzaro, F. (2005). Use of alginate and cryo-protective sugars to improve the viability of lactic acid bacteria after freezing and freeze-drying. World Journal of Microbiology and Biotechnology, 21(5), 739–746.

De Vries, M.C., Vaughan, E.E., Kleerebezem, M., & De Vos, W.M. (2006). Lactobacillus plantarum - survival, functional and potential probiotic properties in the human intestinal tract. International Dairy Journal, 16(9), 1018–1028.

Eun, Y. A., Younghoon, K., Sejong, O., Jee-Young, I., Dong-Jun, P., Kyoung, S. H., & Sae, H. K. (2007). Microencapsulation of Lactobacillus acidophilus ATCC 43121 with prebiotic substrates using a hybridisation system. International Journal of Food Science and Technology, 42(4), 411–419.

Fox, J. D., & Robyt, J. F. (1991). Miniaturization of three carbohydrate analysis using a microsample. Analytical Biochemistry, 195(1), 93–96.

Gibson, G. R., & Roberfroid, M. B. (1995). Dietary modulation of the human colonic microbiota: introducing the concept of prebiotics. Journal of Nutrition, 125(6), 1401–1412.

Hamilton-Miller, J. M., & Shah, S. (2002). Deficiencies in microbiological quality and labeling of probiotic supplements. International Journal of Food Microbiology, 72(1–2), 175–176.

Hongpattarakere, T., Cherntong, N., Wichienchot, S., Kolida, S., & Rastall, R. A. (2012). In vitro prebiotic evaluation of exopolysaccharides produced by marine isolated lactic acid bacteria. Carbohydrate Polymers, 87(1), 846–852.

Huba’lek, Z. (2003). Protectants used in the cryopreservation of microorganisms. Cryobiology, 46(3), 205–229.

Jagannath, A., Raju, P. S., & Bawa, A. S. (2010). Comparative evaluation of bacterial cellulose (nata) as a cryoprotectant and carrier support during the freeze drying process of probiotic lactic acid bacteria. LWT- Food Science and Technology, 43(8), 1197–1203.

Kets, E. P. W., Teunissen, P. J. M., & de Bont, J. A. M. (1996). Effect of compatible solutes on survival of lactic acid bacteria subjected to drying. Applied and Environmental Microbiology, 62(1), 259–261.

Kleerebezem, M., Boekhorst, J., van Kranenburg, R., Tarchini, D. R., Peters, S. A., Sandbrink, H. M., Fiers, M. W. E. J., Stiekema, W., Lankhorst, R. M. K., Bron, P. A., Hoffer, S. M., Groot, M. N. N., Kerkhoven, R., de Vries, M., Ursing, B., de Vos, W. M., & Siezen, R. J. (2003). Complete genome sequence of Lactobacillus plantarum WCFS1. Proceedings of the National Academy of Sciences of the United States of America, 100(4), 1990–1995.

Kourkoutas, Y., Xolias, V., Kallis, M., Bezirtzoglou, E., & Kanellaki, M. (2005). Lactobacillus casei cell immobilization on fruit pieces for probiotic additive, fermented milk and lactic acid production. Process Biochemistry, 40(1), 411–416.

Lin, W. H., Hwang, C. F., Chen, L. W., & Tsen, H. Y. (2006). Viable counts, characteristic evaluation for commercial lactic acid bacteria products. Food Microbiology, 23(1), 74–81.

Lourens-Hattingh, A., & Viljoen, B. C. (2001). Yoghurt as probiotic carrier food. International Dairy Journal, 11(1–2), 1–17.

Michida, H., Tamalampudi, S., Pandiella, S. S., Webb, C., Fukuda, H., & Kondo, A. (2006). Effect of cereal extracts and cereal fiber on viability of Lactobacillus plantarum under gastrointestinal tract conditions. Biochemical Engineering Journal, 28(1), 73–78.

Otero, M. C., Espeche, M. C., & Nader-Macías, M. E. (2007). Optimization of the freeze-drying media and survival throughout storage of freeze-dried Lactobacillus gasseri and Lactobacillus delbrueckii subsp. delbrueckii for veterinarian probiotic applications. Process Biochemistry, 42(10), 1406–1411.

Perry, S. F. (1998). Freeze-drying and cryopreservation of bacteria. Molecular Biotechnology, 9(1), 59–64.

Robertson, J. A., Ryden, P., Botham, R. L., Reading, L., Gibson, G. R., & Ring, S. G. (2001). Structural properties of diet-derived polysaccharides and their influence on butyrate production during fermentation. LWT- Food Science and Technology, 34(8), 567–573.

Saarela, N., Virkajarvi, I., Nohynek, L., Vaari, A., & Matto, J. (2006). Fiber as carrier for Lactobacillus rhamnosus during freeze-drying and storage in apple juice and chocolate-coated breakfast cereal. Journal of Food Microbiology, 112(2), 171–178.

Salazar, N., Gueimonde, M., Hernández-Barranco, A. M., Ruas-Madiedo, P., & de los Reyes-Gavilán, C. G. (2008). Exopolysaccharides produced by intestinal Bifidobacterium strains act as fermentable substrates for human intestinal bacteria. Applied and Environmental Microbiology, 74(15), 4737–4745.

Santivarangkna, C., Higl, B., & Foerst, P. (2008). Protection mechanisms of sugars during different stages of preparation process of dried lactic acid starter cultures. Food Microbiology, 25(3), 429–441.

Schwab, C., Vogel, R., & Ganzle, M. G. (2007). Influence of oligosaccharide on the viability and membrane properties of Lactobacillus reuteri TMW1.106 during freeze-drying. Cryobiology, 55(2), 108–114.

Shinohara, Y. M., Sukenobe, J., Imaizumi, T., & Nakahara, T. (2006). Survival curves for microbial species stored by freeze-drying. Cryobiology, 52(1), 27–32.

Silva, J., Carvalho, A. S., Pereira, H., Teixeira, P., & Gibbs, P. A. (2004). Induction of stress tolerance in Lactobacillus delbrueckii ssp. bulgaricus by the addition of sucrose to the growth medium. The Journal of Dairy Research, 71(1), 121–125.

Tannock, G. W. (1998). Studies of the intestinal microflora: a prerequisite for the development of probiotics. International Dairy Journal, 8(5–6), 527–533.

Temmerman, R., Pot, B., Huys, G., & Swings, J. (2002). Identification and antibiotic susceptibility of bacterial isolates from probiotic products. International Journal of Food Microbiology, 81(1), 1–10.

Tymczyszyn, E. E., Gerbino, E., Illanes, A., & Zavaglia, A. G. (2011). Galacto-oligosaccharides as protective molecules in the preservation of Lactobacillus delbrueckii subsp. bulgaricus. Cryobiology, 62(2), 123–129.

Zhao, G., & Zhang, G. (2005). Effect of protective agents, freezing temperature, rehydration media on viability of malolactic bacteria subjected to freeze-drying. Journal of Applied Microbiology, 99(2), 333–338.

Acknowledgments

This research was funded by Annual Government Expenditure, Prince of Songkla University, Thailand (2010-2011 AGR530023S), the PSU—General Income Budget 2008, and the Graduate School, Prince of Songkla University. Our great appreciation is expressed to the Scientific Equipment Center at Prince of Songkla University for the assessment in the Electron Microscopy Facility and their excellent SEM technical assistance. Special gratitude is expressed to Professor Anthony G. Hopkin for his professional proofreading service.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hongpattarakere, T., Rattanaubon, P. & Buntin, N. Improvement of Freeze-Dried Lactobacillus Plantarum Survival Using Water Extracts and Crude Fibers from Food Crops. Food Bioprocess Technol 6, 1885–1896 (2013). https://doi.org/10.1007/s11947-012-1018-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-012-1018-z