Abstract

The effects of high-temperature, short-time hot air treatment (45 °C for 3 h) on soluble sugar metabolism and chilling tolerance in loquat fruit stored at 5 °C for 5 weeks were investigated. Heat treatment significantly reduced chilling severity, as evidenced by lower firmness and internal browning and higher levels of extractable juice. Meanwhile, this treatment accelerated the activities of acid invertase, neutral invertase, sucrose phosphate synthase and sucrose synthase during storage. However, sucrose degradation was predominant, which caused lower levels of sucrose and higher levels of glucose and fructose in the heat-treated group. In addition, the ascorbate acid content and the activities of ascorbate peroxidase and glutathione reductase in the heat-treated fruit were much higher than those in control fruit, resulting in lower levels of hydrogen peroxide (H2O2) and malondialdehyde and decreased membrane permeability as well as a higher unsaturated/saturated fatty acid ratio at the end of storage. Our results suggest that the increased levels of reducing sugars, especially those of glucose, may induce the ascorbate–glutathione cycle activity to scavenge for H2O2, whose content relates to the heat-induced chilling tolerance of loquat fruit.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Loquat (Eriobotrya japonica Lindl.) is a non-climacteric fruit native to subtropical regions of Asia and other continents (Lin et al. 1999). The fruit is famous for its soft, juicy taste and nutritional value and is highly favoured by consumers, and it contains nearly all the essential nutrients, including proteins, minerals and carotenoids (Tian et al. 2007). China, with more than 100,000 ha of cultivating area and 380,000 t of annual production, is the leading producer of loquat (Tian et al. 2007). The harvest season of this fruit in China is usually hot and rainy, hence unfavourable for storage and transportation. For this reason, large post-harvest losses can occur (Cai et al. 2006).

Low-temperature storage is a common method to delay senescence and decay; however, the fruit of red-fleshed loquat cultivars is sensitive to low temperatures and is easily injured after 2–3 weeks storage at 1–5 °C (Rui et al. 2010). The major symptoms of chilling injury (CI) include flesh woodiness, adhesion of the peel to the flesh, leathery and juiceless pulp and internal browning (IB) (Cao et al. 2009a, b). CI is a major limitation for the long-term storage of the fruit. Post-harvest heat treatment can induce physiological changes related to the stress response in several fruits, including loquat (Bassal and El-Hamahmy 2011; Lara et al. 2009; Rui et al. 2010).

The soluble sugars fructose, glucose and sucrose are some of the most important factors affecting fruit taste and quality (Itai and Tanahashi 2008). They are consistently regarded as the parameters for the quality of post-harvest fruit (Zaharah and Singh 2011; Bassal and El-Hamahmy 2011; Lara et al. 2009). Meanwhile, soluble sugars also exert positive effects to protect plant cells from damage caused by cold stress (Ma et al. 2009). Sugar signalling, especially that of glucose and sucrose, and sugar-modulated gene expression are related to the control of oxidative stress (Couée et al. 2006; den Ende and Valluru 2009). However, there are few reports on the relationship between soluble sugars and CI in post-harvest fruit. Purvis and Grierson (1982) found that an increase in reducing sugar levels in the peel of grapefruit during winter could be a defence mechanism of tree-attached citrus fruits to resist cold stress. Holland et al. (2002) observed that increasing levels of sucrose via heat treatment was associated with an increase in the chilling tolerance of citrus fruit. However, sugar changes in the flavedo of Fortune mandarins were not related to its chilling tolerance (Holland et al. 1999). Thus, the relationship between sugar metabolism and chilling tolerance differs between fruit species.

To date, there is no published information about the relationship between sugar changes and chilling tolerance in heat-treated loquat fruit. Our previous report found that post-harvest hot air treatment at 45 °C for 3 h can reduce the CI symptoms and maintain the fresh quality of loquat fruit during cold storage (Song et al. 2011). The aim of the present work was to study whether soluble sugar changes induced by high-temperature conditioning play a role in increasing the chilling tolerance of loquat fruit.

Materials and Methods

Fruit Material and Treatment

Fresh red-flesh loquat (E. japonica Lindl. cv. “Jiefangzhong”) fruits were obtained from a commercial orchard in Fujian, China. Fruits were handpicked when ripe (light orange) and therefore suitable for the fresh fruit market. Fruits were selected for uniformity in size and colour and the absence of visual defects. After harvest, the fruits were distributed at random into two groups (120 fruits per group). In the control group (CK), fruits were untreated and directly placed into storage. In the second group (HT), fruits were treated at 45 °C and 90 ± 2 % relative humidity for 3 h in a 500-L heating chamber (HWS-500, Ningbo Jiangnan Instrument Factory, Ningbo, People’s Republic of China) with thermostatic control and air circulation before storage. Fruits of both groups were stored at 5 °C and 90 ± 2 % relative humidity for 5 weeks. The quality and physiology parameters, fruit firmness, extractable juice, IB index, soluble solids contents, titratable acidity, H2O2 and malondialdehyde levels; membrane permeability and fatty acid composition; levels of fructose, sucrose and glucose; activities of soluble acid invertase (SAI), neutral invertase (NI), sucrose synthase (SS) and sucrose-phosphate synthase (SPS); levels of ascorbate (AsA) and reduced glutathione (GSH); and activities of ascorbate peroxidase (APX) and glutathione reductase (GR) were measured during or at the end of cold storage. Twenty fruits from each sample were evaluated at each sampling time. The entire experiment was conducted three times; the values of each treatment were averaged and the standard errors from these independent replicates were calculated.

Determination of Fruit Firmness, Extractable Juice, IB Index, Soluble Solid Contents, Titratable Acidity Content and Weight Loss

Fruit firmness (in grams) was measured on two paired sides of five fruits from each replicate (skin removed) with a TA-XTplus texture analyser (Stable Micro System Ltd., Haslemere, UK) equipped with a 5-mm diameter probe at a speed of 1 mm/s. Two readings were taken per fruit and a mean value was calculated. Extractable juice was estimated from the weight loss from placental tissue plugs in response to low-speed centrifugation (Cao et al. 2009a); the results are expressed as per cent fresh weight loss of the tissue plugs after centrifugation. IB index was measured according to Cao et al. (2009b) as 0: none; 1: browning area <5 %; 2: browning area 5–25 %; 3: browning area 25–50 %; and 4: browning area >50 %. The results were expressed as an IB index calculated using the following formula:

Weight loss was the reduction in weight expressed as the percentage of total weight. Soluble solid contents were determined by measuring the refractive index of expressed juice with a hand refractometer (WYT-4, Quanzhou Optical Instrument Co., Ltd., Quanzhou, People’s Republic of China) and the results expressed as per cent. Titratable acidity content was measured by titrating 50 mL of the filtered expressed juice to pH 8.1 with 0.1 M NaOH and calculating the result as malic acid percentage (Shao et al. 2012).

Determination of Fructose, Sucrose and Glucose Levels

Aliquots of fresh fruit samples from different groups (5 g) were ground and extracted for 20 min with 100 mL of pre-boiled and cooled water containing 3.2 g/L acetic acid and 2.4 g/L potassium ferrocyanide, filtered with a 0.2-μm filter. A 20-μL aliquot was injected into a high-performance liquid chromatography system (model 2695, Waters, USA) equipped with a refractive index detector (model 2414, Waters) and an amino column (Kromasil®100A, Sweden). According to the method of Kafkas et al. (2006), with some modification, the eluent was a mixture of acetonitrile/water (75:25, v/v) at a flow rate of 1.0 mL/min at 35 °C. The results were expressed as milligrams per gram fresh weight (FW).

Determination of Sugar Metabolism Enzyme Activities

Aliquots (1 g) of flesh tissue were ground with 5 mL of 100 mM sodium phosphate buffer (pH 7.5) containing 5 mM MgCl2, 1 mM EDTA, 0.1 % (v/v) β-mercaptoethanol and 0.1 % (v/v) TritonX-100. Extracts were centrifuged at 10,000×g for 20 min at 4 °C. The supernatant was used for enzyme assays.

All these enzymes were assayed according to the methods of Miron and Schaffer (1991) and Mao et al. (2006), with modifications. NI activity was assayed in an incubation mixture containing 100 mM sodium phosphate (pH 7.5), 1 % (g/v) sucrose and crude extract. The mixture was incubated at 34 °C for 1 h and the reactions were stopped by boiling the mixture for 5 min. The SAI activity assay was similar to that of NI, except that the reaction was conducted at pH 4.5. The concentration of liberated glucose was determined by the DNS method (Miller 1959).

SS cleavage activity was measured in a mixture of 80 mM 2-(4-Morpholino) ethanesulfonic acid (pH 5.5), 5 mM NaF, 100 mM sucrose, 5 mM uridine diphosphate (UDP) and crude extract. The mixture was incubated for 30 min at 30 °C and terminated by boiling for 1 min. Glucose produced by this reaction was assayed using the DNS method (Miller 1959). The activities of SAI, NI and SS cleavage were expressed as milligrams Glu per hour per gram FW.

For SS synthesis activity determination, crude extract was incubated for 1 h at 34 °C with 0.06 M fructose and 4 mM uridine diphosphate glucose (UDPG) in 100 mM sodium phosphate (pH 8.0) containing 15 mM MgCl2. The reaction was stopped by adding 0.2 mL 30 % (v/v) KOH and boiling the mixture for 5 min. Sucrose produced by this reaction was assayed using the anthrone assay (van Handel 1963).

The assay mixture for SPS contained 100 mM boric acid buffer (pH 8.0), 10 mM UDPG, 5 mM fructose-6-p, 15 mM MgCl2, 1 mM EDTA and crude extract. Mixtures were incubated for 30 min at 34 °C and then the reactions were stopped by boiling for 3 min. The concentration of sucrose liberated was determined using the anthrone assay (van Handel 1963). SS synthesis and SPS activities were expressed as milligrams Suc per hour per gram FW.

Determination of AsA-GSH Cycle Content Levels and Enzyme Activities

For the measurement of AsA, 2 g of flesh tissue was homogenised in 5 mL ice-cold oxalic acid–EDTA solution (oxalic acid, 50 mM; EDTA, 0.2 mM) and centrifuged at 10,000×g for 20 min at 4 °C. The supernatant was used for the assay of AsA phosphomolybdate-blue spectrophotometry (Li 2000). The results were expressed in milligrams per 100 g FW.

GSH was extracted by grinding 1.0 g fresh tissue in 5 mL 50 mM sodium phosphate buffer (pH 7.0) and centrifuging at 10,000×g for 20 min at 4 °C. The supernatant was used for the GSH assay using assay kits purchased from Nanjing Jiancheng Institute of Bioengineering (Nanjing, Jiangsu, China) according to the instructions of the manufacturer.

Fresh sample (1 g) was ground with 5 mL of 100 mM sodium phosphate buffer (pH 7.0) containing 0.1 mM EDTA, 1 mM sodium ascorbate and 1 % polyvinylpyrrolidone for APX and GR. The extracts were then homogenised and centrifuged at 10,000×g for 20 min at 4 °C. The supernatant was used for the enzyme assay. APX was carried out as described by Cao et al. (2010); 1 U was defined as the amount of enzyme that oxidises 1 μmol ascorbate per minute. GR was conducted using assay kits purchased from Nanjing Jiancheng Institute of Bioengineering (Nanjing, Jiangsu, China) according to the manufacturer’s instructions.

Determination of the Levels of H2O2 and Malondialdehyde, Membrane Permeability and Fatty Acid Composition

For H2O2 level determination, 2 g of fresh tissue was homogenised with 5 mL of chilled 100 % acetone and then centrifuged at 10,000×g for 20 min at 4 °C. The supernatant was collected immediately for H2O2 analysis according to the method of Cao et al. (2009a). H2O2 content was expressed as micromoles per gram FW. Malondialdehyde content was determined according to the method of Shao et al. (2012); it was calculated and expressed as nanomoles per gram FW.

For membrane permeability, flesh disks (10-mm diameter × 2-mm height) from fruit were incubated in 20 mL deionised water for 3 h. The conductivity of solution (EC0) was measured using a conductivity meter (DDS-11A, Shanghai Precision Scientific Instrument Co., Ltd, People's Republic of China). The solution was then heated in a boiling water bath for 30 min and re-adjusted to a volume of 20 mL before the total conductivity of the solution (ECT) was measured. The results of membrane permeability were expressed as relative electric conductivity (%) = (EC0/EC T ) × 100 %.

Total lipids were extracted according to Cao et al. (2009b). Fatty acids were separated and quantified by gas chromatography–mass spectrometry (model GCMS-QP2010 Plus, Shimadzu, Japan). Aliquots of 20 μL of the sample solutions were injected under the following GC conditions: carrier gas, nitrogen; purity, ≥99.999 %; flow rate, 0.81 mL/min; Spb-50 silica capillary column (30 m × 0.25 mm, 0.25-μm film thickness); injection temperature, 250 °C; and temperature gradient, initial column temperature of 150 °C held for 3.5 min, programmed heating at 20 °C/min to 200 °C and held for 5 min, and then heating at 5 °C/min to 280 °C and held for 20 min. MS conditions were as follows: solvent delay, 3.5 min; transfer line temperature, 250 °C; ion source temperature, 200 °C; electron ionisation mode at 70 eV; and acquisition mode and selected ion monitoring from 50 m/z to 650 m/z.

The unsaturated/saturated fatty acid ratio was calculated using the formula: \( {{{\left( {18:1+18:2+18:3} \right)}} \left/ {{\left( {12:0+14:0+16:0+18:0+20:0} \right)}} \right.} \), where 12:0 is lauric acid, 14:0 is myristic acid, 16:0 is palmitic acid, 18:0 is stearic acid, 18:1 is oleic acid, 18:2 is linoleic acid, 18:3 is linolenic acid and 20:0 is eicosanoic acid.

Statistical Analysis

The data were analysed using one-way ANOVA. SAS Software (version 8.2; SAS Institute, Cary, NC, USA) was used to conduct all statistical analyses. Comparison of means was performed using Duncan’s multiple range tests. A value of p < 0.05 was considered statistically significant.

Results and Discussion

Effects of Heat Treatment on Fruit Quality

It was observed that fruit firmness and IB index in both groups increased and that extractable juice decreased at the end of cold storage (Table 1). These three parameters were always used to evaluate the development of CI of loquat fruit during the chilling stress (Cao et al. 2009a, b, 2010). Hot air treatment (45 °C for 3 h) can significantly (p < 0.05) delay the increase in loquat firmness and IB index and maintain higher levels of extractable juice (Table 1), thereby inducing chilling tolerance and alleviating CI symptoms.

Meanwhile, heat treatment also markedly (p < 0.05) reduced the soluble solid contents and weight loss, but had no significant (p < 0.05) effect on titratable acidity content. Although a decrease of soluble solid contents is generally considered a sign of overripeness, it should be noted that all treated fruits developed fewer CI symptoms and exhibited lower weight loss than the controls. This divergence illustrates the dichotomous effects of heat treatments in that some ripening characteristics are enhanced whilst others are attenuated (Klein and Lurie 1992). Cai et al. (2006) suggested that post-harvest strategies should concentrate on inhibiting an increase in firmness and browning of loquat fruit in the immediate post-harvest period. Thus, our results in this study show that this high-temperature, short-time hot air treatment may be a suitable method for commercial application to reduce CI symptoms and maintain the quality of loquat fruits.

Effect of Heat Treatment on Soluble Sugar Content

As shown in Fig. 1, glucose, fructose and sucrose levels were determined and fructose was found to be the predominant sugar in loquat (cv. Jiefangzhong). However, sorbitol could not be identified in this experiment, unlike the results found by Ding et al. (1998) and Xu et al. (2010). The quantity and types of sugar in loquat fruit may be cultivar-dependent.

Glucose levels in control fruits declined during the first week and then increased sharply with storage time (Fig. 1a). The HT group maintained profoundly (p < 0.05) higher levels of glucose than the CK group during the first 3 weeks of storage. Fructose levels in untreated fruits declined during the first week and then slightly increased (Fig. 1b). The HT group showed significantly (p < 0.05) higher fructose levels during the first 4 weeks of storage. Sucrose levels declined sharply with storage time in both groups (Fig. 1c). The HT group showed significantly (p < 0.05) lower levels of sucrose than the CK group after the first week. In general, heat treatment increased the levels of reducing sugars (glucose and fructose) and decreased the level of sucrose in loquat fruit during cold storage. A similar phenomenon has been observed in heat-treated peach fruits (Lara et al. 2009). Glucose and sucrose are now recognised as crucial compounds in coordinating plant developmental responses under oxidative stress (den Ende and Valluru 2009) and have several beneficial effects in protecting plants against chilling and oxidative stresses, including sugar signalling, sugar-modulated gene expression, feeding of anti-oxidative metabolism and direct antioxidant capacity against reactive oxygen species (Couée et al. 2006; den Ende and Valluru 2009; Ma et al. 2009). Purvis and Grierson (1982) suggested that higher reducing sugar contents, including those of glucose and fructose, were involved in an increased chilling tolerance. Conflicting results have been found; for example, Holland et al. (2002) demonstrated that heat treatment prevents a decline in sucrose content in mandarin fruit during chilling. These contrary reports indicate that the response of soluble sugars to heat treatment and chilling stress is dependent upon the particular fruit species and regulated by the relative enzymes. We thus conducted activity analyses of sugar metabolism enzymes to investigate which enzymes were involved in the accumulation of reducing sugars in heat-treated loquat fruit.

Effect of Heat Treatment on the Activity of Sugar Metabolism Enzymes

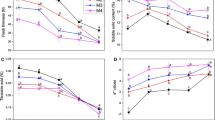

Among sucrose-metabolising enzymes, invertases (SAI and NI) and SS cleavage are involved in the cleavage of sucrose. SS synthesis and SPS catalyse sucrose biosynthesis (Itai and Tanahashi 2008; Li et al. 2011). Invertases cleave sucrose to glucose and fructose. SS can either cleave sucrose to UDP-glucose (uracil-diphosphate glucose) and fructose or catalyse the reverse synthetic reaction in which SPS synthesises sucrose-6-phosphate, which is dephosphorylated by sucrose–phosphate phosphatase to form sucrose (Mao et al. 2006). In our studies, the SAI activity of both groups increased with storage time, with the HT group showing markedly (p < 0.05) higher values than the CK group after the first week (Fig. 2a). NI activity also increased rapidly, peaking during the fourth week and then declining (Fig. 2b). The HT group maintained higher NI activity at the end of storage. The SS (cleavage direction) activity of both groups declined rapidly during cold storage (Fig. 2c). The HT group showed a significantly (p < 0.05) higher SS cleavage activity than the CK group during the first 4 weeks. SS and SPS activities increased initially and peaked after the fourth and third weeks, respectively (Fig. 2d, e). The HT group exhibited profoundly (p < 0.05) higher activities of both synthetic enzymes than the CK group.

Effects of heat treatment on the activity of SAI (a), NI (b), SS cleavage (c), SS synthetic (d), SPS (e) and the net activity of sucrose cleavage (f) in loquat fruits during storage at 5 °C for 5 weeks. Values are the means ± SE of triplicate assays. Vertical bars represent the standard errors of the means (n = 9). Note: Net activity = (SAI + NI + SS cleave activity) − (SS synthetic + SPS activity). The value is positive, indicating that sucrose cleavage is predominant

The net activity of sucrose-metabolising enzymes after harvest was calculated by the following formula: \( \left( {\mathrm{SAI}+\mathrm{NI}+\mathrm{SS}-\mathrm{cleave}\ \mathrm{activity}} \right)-\left( {\mathrm{SS}-\mathrm{synthetic}+\mathrm{SPS}\ \mathrm{activity}} \right) \). The resulting value was positive and increased with storage time (Fig. 2f), indicating that the activities of sucrose cleavage enzymes are higher than those involved in sucrose synthesis and that sucrose degradation is predominant in loquat fruit during storage. Meanwhile, the HT group had a significantly (p < 0.05) increased value of net activity (Fig. 2f), which was consistent with the enhanced decline of sucrose in the HT group (Fig. 1c). Lara et al. (2009) demonstrated that hot air treatment increased the NI activity and SS transcript encoding levels of peach fruit, which is in accordance with the decrease in the sucrose levels and increase in the reducing sugar levels observed in this study. In the present study, heat treatment improved the activities of all sugar metabolism enzymes of loquat fruit. However, the enhanced net activity from heating (Fig. 2f) indicated that more sucrose is hydrolysed and more hexoses, such as glucose and fructose, are accumulated in heat-treated loquat fruit.

Effect of Heat Treatment on the Activity of the AsA-GSH Cycle

In plant cells, AsA and GSH can function as direct antioxidants and reductants of APX and GR, which are the main enzymes in the AsA-GSH cycle (Nishikawa et al. 2003; Quan et al. 2008), which scavenges H2O2 in response to stress (Nishikawa et al. 2003). As shown in Fig. 3, the AsA contents of both groups slightly increased after 3 weeks of storage (Fig. 3a). Heat treatment significantly (p < 0.05) increased AsA levels during the entire storage duration. For GSH content, the HT group showed profoundly (p < 0.05) higher levels than the CK group during the first week and the last 2 weeks (Fig. 3b). The pattern of changes in APX activity was similar to the pattern of AsA levels (Fig. 3c). GR activity in the CK group decreased with storage time (Fig. 3d), with the HT group showing markedly (p < 0.05) higher activities of APX and GR than those of the CK group. In general, during cold storage, heat-treated loquat fruit showed higher APX (Fig. 3a) and GR (Fig. 3c) activities and AsA and GSH contents (Fig. 3b, d), which may play important roles in reducing H2O2 accumulation and improving chilling tolerance. Khademi et al. (2012) demonstrated that heat treatment significantly alleviated CI by affecting the anti-oxidative system enzymes. Other reports have also revealed that increased AsA-GSH cycle activity can enhance chilling tolerance of loquat fruit (Cai et al. 2011; Cao et al. 2011).

Sugar metabolism is essential to the synthesis of numerous compounds that are involved in anti-oxidative protection (Couée et al. 2006) and regulate chilling tolerance (Ma et al. 2009). Glucose feeding of primary metabolism can result in enhanced reducing power in the form of NADPH (reduced form of nicotinamide adenine dinucleotide phosphate), a major cofactor in the AsA-GSH cycle, provided by the OPP pathway (Couée et al. 2006; de Carvalho 2008). Glucose is also the main carbon initial precursor for AsA synthesis (Smirnoff et al. 2001) and for carbon skeletons of amino acids, which are the building blocks of GSH (Noctor and Foyer 1998). A reduction in AsA content in harvested broccoli florets can be reversed by sucrose feeding (Nishikawa et al. 2005), sucrose cleavage by invertase or sucrose synthase as the source of the signal to adjust gene expression (Janská et al. 2010). Therefore, the higher levels of AsA and the higher activity of the AsA-GSH cycle (Fig. 3) observed in our current study may be the result of the increased glucose content (Fig. 1a) in loquat fruit after heat treatment, suggesting that the reduction of CI by heat treatment is related to the increased glucose content, which caused an increase in AsA-GSH cycle activity of scavenging H2O2.

Effect of Heat Treatment on H2O2 and Malondialdehyde Content and Membrane Permeability and Fatty Acid Composition

The very stable molecule H2O2 is the most diffusive reactive oxygen species and has the longest half-life (de Carvalho 2008); it can induce peroxidation and the breakdown of unsaturated fatty acids in membrane lipids and orchestrate programmed cell death (Quan et al. 2008). As illustrated in Fig. 4a, it was found that the H2O2 levels in both groups generally increased with storage time. Heat treatment significantly (p < 0.05) decreased H2O2 accumulation during the entire storage period, which was related to increased activity in the AsA-GSH cycle in the treated group (Fig. 3).

Malondialdehyde is one of the intermediate products of lipid peroxidation and affects membrane structure, disturbing normal physiological metabolism (Shao et al. 2012). The pattern of changes in malondialdehyde levels was the same as that of H2O2 (Fig. 4b): the HT group maintained significantly lower malondialdehyde levels than that of the CK group during cold storage. Meanwhile, membrane permeability in both groups decreased, reaching its lowest values during the third week, and then increased dramatically (Fig. 4c). The HT group showed a lower value than the CK group; however, the difference was only significant (p < 0.05) after 3 weeks of storage.

In addition to malondialdehyde content and membrane permeability, changes in membrane fatty acid composition also can directly reveal lipid peroxidation in plants under stress. Compared with the CK group, the HT group showed significantly (p < 0.05) lower levels of lauric acid (12:0) and stearic acid (18:0) and higher levels of myristic acid (14:0) and linoleic acid (18:2; Table 2). Heat treatment did not significantly (p > 0.05) affect the levels of palmitic acid (C16:0), oleic acid (18:1), linolenic acid (18:3) or eicosanoic acid (20:0). Notably, the HT group maintained a significantly (p < 0.05) higher unsaturated/saturated fatty acid ratio than the CK group at the end of storage. A higher level of membrane lipid unsaturation supports the hypothesis that heat treatment can reduce lipid peroxidation and is beneficial in enhancing the resistance of loquat fruit to CI, similar to the results of Cao et al. (2011) and Rui et al. (2010).

Conclusions

Although this subject requires further study to fully understand the relationship between soluble sugars and chilling tolerance, the present data indicate that a high-temperature, short-time hot air treatment (45 °C, 3 h) can effectively reduce CI symptoms and maintain higher quality than untreated loquat fruits at the end of 5 weeks of storage at 5 °C. Heat treatment induced activities in all sugar metabolism enzymes; however, sucrose degradation was predominant in loquats during storage. Heating accelerated sucrose degradation, resulting in lower levels of sucrose and higher levels of glucose and fructose. It was concluded that the increase in reducing sugar levels, especially those of glucose, by heating may induce a higher AsA-GSH cycle activity towards H2O2 scavenging, which causes decreased membrane lipid peroxidation and increased chilling tolerance. Further studies are needed to evaluate the transcript profiles of sugar and ascorbate metabolism enzyme genes and to establish the relationship between sugar and ascorbate acid metabolisms.

Abbreviations

- CI:

-

Chilling injury

- IB:

-

Internal browning

- H2O2 :

-

Hydrogen peroxide

- SAI:

-

Soluble acid invertase

- NI:

-

Neutral invertase

- SS:

-

Sucrose synthase

- SPS:

-

Sucrose–phosphate synthase

- AsA:

-

Ascorbate acid

- APX:

-

Ascorbate peroxidase

- GSH:

-

Reduced glutathione

- GR:

-

Glutathione reductase

- FW:

-

Fresh weight

References

Bassal, M., & El-Hamahmy, M. (2011). Hot water dip and preconditioning treatments to reduce chilling injury and maintain postharvest quality of Navel and Valencia oranges during cold quarantine. Postharvest Biology and Technology, 60, 186–191.

Cai, C., Chen, K. S., Xu, W. P., Zhang, W. S., Li, X., & Ferguson, I. (2006). Effect of 1-MCP on postharvest quality of loquat fruit. Postharvest Biology and Technology, 40, 155–162.

Cai, Y., Cao, S., Yang, Z., & Zheng, Y. (2011). MeJA regulates enzymes involved in ascorbic acid and glutathione metabolism and improves chilling tolerance in loquat fruit. Postharvest Biology and Technology, 59, 324–326.

Cao, S., Zheng, Y., Wang, K., Jin, P., & Rui, H. (2009a). Methyl jasmonate reduces chilling injury and enhances antioxidant enzyme activity in postharvest loquat fruit. Food Chemistry, 115, 1458–1463.

Cao, S., Zheng, Y., Wang, K., Rui, H., & Tang, S. (2009b). Effect of 1-methylcyclopropene treatment on chilling injury, fatty acid and cell wall polysaccharide composition in loquat fruit. Journal of Agricultural and Food Chemistry, 57, 8439–8443.

Cao, S., Zheng, Y., Wang, K., Rui, H., & Tang, S. (2010). Effect of methyl jasmonate on cell wall modification of loquat fruit in relation to chilling injury after harvest. Food Chemistry, 118, 641–647.

Cao, S., Yang, Z., Cai, Y., & Zheng, Y. (2011). Fatty acid composition and antioxidant system in relation to susceptibility of loquat fruit to chilling injury. Food Chemistry, 127, 1777–1783.

Couée, I., Sulmon, C., Gouesbet, G., & Amrani, A. E. (2006). Involvement of soluble sugars in reactive oxygen species balance and responses to oxidative stress in plants. Journal of Experimental Botany, 57, 449–459.

de Carvalho, M. H. C. (2008). Drought stress and reactive oxygen species production, scavenging and signaling. Plant Signaling & Behavior, 3, 156–165.

den Ende, W. V., & Valluru, R. (2009). Sucrose, sucrosyl oligosaccharides, and oxidative stress: scavenging and salvaging? Journal of Experimental Botany, 60, 9–18.

Ding, C., Chachin, K., Ueda, Y., Ueda, Y., & Imahori, Y. (1998). Effects of storage temperatures on physiology and quality of loquat fruit. Postharvest Biology and Technology, 14, 309–315.

Holland, N., Sala, J. M., Menezes, H. C., & Lafuente, M. T. (1999). Carbohydrate content and metabolism as related to maturity and chilling sensitivity of cv. fortune mandarins. Journal of Agricultural and Food Chemistry, 47, 2513–2518.

Holland, N., Menezes, H. C., & Lafuente, M. T. (2002). Carbohydrates as related to the heat-induced chilling tolerance and respiratory rate of ‘Fortune’ mandarin fruit harvested at different maturity stages. Postharvest Biology and Technology, 25, 181–191.

Itai, A., & Tanahashi, T. (2008). Inhibition of sucrose loss during cold storage in Japanese pear (Pyrus pyrifolia Nakai) by 1-MCP. Postharvest Biology and Technology, 48, 355–363.

Janská, A., Maršík, P., Zelenková, S., & Ovesná, J. (2010). Cold stress and acclimation—what is important for metabolic adjustment? Plant Biology, 12, 395–405.

Kafkas, E., Koşar, M., Türemiş, N., & Başer, K. H. C. (2006). Analysis of sugars, organic acids and vitamin C contents of blackberry genotypes from Turkey. Food Chemistry, 97, 732–736.

Khademi, O., Salvador, A., Zamani, Z., & Besada, C. (2012). Effects of hot water treatments on antioxidant enzymatic system in reducing flesh browning of persimmon. Food Bioprocess Technology. doi:10.1007/s11947-012-0959-6.

Klein, J. D., & Lurie, S. (1992). Prestorage heating of apple fruit for enhanced postharvest quality: interaction of time and temperature. HortScience, 27, 326–328.

Lara, M. V., Borsani, J., Budde, C. O., Lauxmann, M. A., Lombardo, V. A., Murray, R., et al. (2009). Biochemical and proteomic analysis of ‘Dixiland’ peach fruit (Prunus persica) upon heat treatment. Journal of Experimental Botany, 60, 4315–4333.

Li, J. (2000). Determination of the content of reduction type VC with phosphomolybdate blue spectrophotometry. Food Science, 21, 42–45.

Li, W., Shao, Y., Chen, W., & Jia, W. (2011). The effects of harvest maturity on storage quality and sucrose-metabolizing enzymes during banana ripening. Food Bioprocess Technology, 4, 1273–1280.

Lin, S., Sharpe, R. H., & Janick, J. (1999). Loquat: botany and horticulture. Horticultural Reviews, 23, 233–276.

Ma, Y., Zhang, Y., Lu, J., & Shao, H. (2009). Roles of plant soluble sugars and their responses to plant cold stress. African Journal of Biotechnology, 8, 2004–2010.

Mao, L., Que, F., & Wang, G. (2006). Sugar metabolism and involvement of enzymes in sugarcane (Saccharum officinarum L.) stems during storage. Food Chemistry, 98, 338–342.

Miller, G. L. (1959). Use of dinitro salicylic acid reagent for determination of reducing sugar. Annals of Chemistry, 31, 426–428.

Miron, D., & Schaffer, A. A. (1991). Sucrose phosphate synthase, sucrose synthase and invertase activities in developing fruit of Lycopersicon esculentum Mill. and the sucrose accumulating Lycopersicon hirsutum Humb. and Bonpl. Plant Physiology, 95, 623–627.

Nishikawa, F., Kato, M., Hyodo, H., Ikoma, Y., Sugiura, M., & Yano, M. (2003). Ascorbate metabolism in harvested broccoli. Journal of Experimental Botany, 54, 2439–2448.

Nishikawa, F., Kato, M., Hyodo, H., Ikoma, Y., Sugiura, M., & Masamichi, Y. (2005). Effect of sucrose on ascorbate level and expression of genes involved in the ascorbate biosynthesis and recycling pathway in harvested broccoli florets. Journal of Experimental Botany, 56, 65–72.

Noctor, G., & Foyer, C. (1998). Ascorbate and glutathione: keeping active oxygen species under control. Annual Review of Plant Physiology and Plant Molecular Biology, 49, 249–279.

Purvis, A. C., & Grierson, W. (1982). Accumulation of reducing sugar and resistance of grapefruit peel to chilling injury as related to winter temperatures. Journal of Agricultural and Food Chemistry, 107, 139–142.

Quan, L., Zhang, B., Shi, W., & Li, H. (2008). Hydrogen peroxide in plants: a versatile molecule of the reactive oxygen species network. Journal of Integrative Plant Biology, 50, 2–18.

Rui, H., Cao, S., Shang, H., Jin, P., Wang, K., & Zheng, Y. (2010). Effects of heat treatment on internal browning and membrane fatty acid in loquat fruit in response to chilling stress. Journal of the Science of Food and Agriculture, 90, 1557–1561.

Shao, X., Tu, K., Tu, S., & Tu, J. (2012). A combination of heat treatment and chitosan coating delays ripening and reduces decay in ‘Gala’ apple fruit. Journal of Food Quality, 35, 83–92.

Smirnoff, N., Conklin, P. L., & Loewus, F. A. (2001). Biosynthesis of ascorbic acid in plants: a renaissance. Annual Review of Plant Physiology and Plant Molecular Biology, 52, 437–467.

Song, Y., Shao, X., Shi, T., & Cheng, S. (2011). Effects of short-time hot air treatment on the quality and chilling injury of loquat fruits during storage at low temperature. Journal of Fruit Science, 28, 837–842.

Tian, S., Li, B., & Ding, Z. (2007). Physiological properties and storage technologies of loquat fruit. Fresh Produce, 1, 76–81.

van Handel, E. (1963). Direct microdetermination of sucrose. Analytical Biochemistry, 22, 280–283.

Xu, H., Chen, J., & Xie, M. (2010). Effect of different light transmittance paper bags on fruit quality and antioxidant capacity in loquat. Journal of the Science of Food and Agriculture, 90, 1783–1788.

Zaharah, S. S., & Singh, Z. (2011). Postharvest nitric oxide fumigation alleviates chilling injury, delays fruit ripening and maintains quality in cold-stored ‘Kensington Pride’ mango. Postharvest Biology and Technology, 60, 202–210.

Acknowledgments

This study was sponsored by the National Science Foundation of China (no. 31000825), Natural Science Foundation of Zhejiang Province (no. Y3090537), International Foundation for Science (E/4412-1) and the K. C. Wong Magna Fund at Ningbo University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shao, X., Zhu, Y., Cao, S. et al. Soluble Sugar Content and Metabolism as Related to the Heat-Induced Chilling Tolerance of Loquat Fruit During Cold Storage. Food Bioprocess Technol 6, 3490–3498 (2013). https://doi.org/10.1007/s11947-012-1011-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-012-1011-6