Abstract

The impact of chilling injury (CI) on the colour of bananas at different ripening stages was investigated. Bananas were stored at 6 and 13 °C for 2 days to induce CI symptoms. Images of the bananas were acquired in 1-h time intervals during the subsequent appearance of CI at room temperature using RGB imaging system to monitor the colour changes. The raw RGB values obtained were transformed to normalized rgb and CIEL*a*b* space to remove the brightness from the colour and to distinguish the colour similar to human perception. The total colour difference (∆E) was calculated from CIEL*a*b* space to evaluate the overall colour difference of the samples. Hue (H) values were obtained after transformation into HSI space, since it provides reasonable data on the chlorophyll content as it was shown in many studies on fresh fruit. Visual assessment was carried out to grade the degree of injury and to correlate with colour parameters. Spectroscopy in the visible wavelength range, in diffuse reflectance geometry was applied to assess colour changes caused by variation in the fruit chlorophyll content. Results indicate significant (P < 0.0001) influence of temperature, ripening stage and post-chilling time on colour parameters. Strong correlations (R 2 > 0.9) were found between r, g and H colour parameters and visual assessment. The values of r increased while the g and H decreased. The kinetic of r, g and H development after chilling treatment fitted well to the first-order kinetic model. Based on the kinetic rate constant, banana at ripening stage 5 showed enhanced susceptibility to chilling injury when compared to banana at ripening stage 4. Spectral reflectance revealed that diminishing chlorophyll content as well as tissue browning and changes in the carotenoids need to be considered when monitoring the CI symptoms. Application of principal components analysis providing clear separation of control and stressed samples capturing variances of 80.91% and 7.24% (r), 82.96% and 7.52% (g), 91.57% and 3.15% (b) and 79.83% and 7.91% (H) for components PC1 and PC2, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cold storage is one of the most commonly used postharvest processes for enhancing the shelf life. However, when fresh produce is exposed to a temperature below its tolerance threshold, chilling injury (CI) symptoms might appear which strongly affect the fruit quality and marketability. CI is defined as physiological damage occurring at temperatures above freezing and generally below 10 °C (Abbott 1999). Banana is one of the chilling-sensitive produce which shows the initiation of chilling injury when subjected to a temperature below 10 °C (Murata 1969; Abd El-Wahab and Nawwar 1977; Broughton and Wu 1979; Nguyen et al. 2003). Symptoms appear most severe at 6 °C (Nguyen et al. 2003).

In chilled bananas, the pattern of carbon dioxide and ethylene production became abnormal, due to the effect of low temperature on enzyme activity (Murata 1969). Chilling injury symptoms are caused by damage of plant cell membranes (Skog 1998). The membrane damage sets off a cascade of secondary reactions, which may include autocatalytic ethylene production, increased respiration rate, interference in energy supply, accumulation of toxic compounds such as ethanol and acetaldehyde and altered cellular structure. After severe CI, the fruits fail to respire due to saturation of the intercellular spaces and resulting in oxygen shortage (Murata 1969; Abd El-Wahab and Nawwar 1977; Broughton and Wu 1979; Zhang et al. 2010). As a result, the chilled fruits experience a lack in energy supply and are more subject to decay due to fungal infection (Murata 1969; Broughton and Wu 1979; Gamal et al. 2009).

The visual symptoms of CI of bananas are colour changes and discoloration. Such symptoms appear due to enzymatic and non-enzymatic browning reactions involving oxidation of phenolics substrate and pigment degradation (Abd El-Wahab and Nawwar 1977; Nguyen et al. 2003; Trakulnaleumsai et al. 2006). An inverse relationship was found between total phenols content and the degree of CI symptoms of bananas (Abd El-Wahab and Nawwar 1977). When bananas were exposed to low temperatures, as the main reaction chains, an increase in the activities of both phenylalanine ammonia lyase (PAL) and polyphenol oxidase (PPO) occurred in which PPO converts free phenolics to quinones, while PAL converts phenyalanine to the free phenolic substrates for PPO (Nguyen et al. 2003). Bananas will change from green or yellow to brown and turn completely black when the symptoms become severe. A study on banana fruit tissue showed that polyphenols present in the chilled fruits were accumulated around the vascular tissues and the number increased with the progress of CI symptoms (Murata 1969). Meanwhile chlorophyll content decreased as the symptoms appeared (De Martino et al. 2007).

CI is a time by temperature problem, which is strongly dependent on the duration and temperature of chilling treatment as well as the period of post-chilling storage (Liu et al. 2006). Nguyen and co-workers (2003) reported that there were significant increases in the CI symptoms with extended application time. Detection and diagnosis of chilling injury is often difficult, as produce often look sound when removed from the chilling exposure. The symptoms may only develop when the produce is placed at higher temperatures and these symptoms may appear almost immediately, or development may take several days. Symptoms also may be invisible externally and sometimes a very slight browning discoloration, which appears first, has a tendency to be misclassified as normal by untrained inspectors (Skog 1998; Gamal et al. 2009). Nguyen and co-workers (2004) reported that the CI symptoms become rapidly worse to dark yellow after being transferred to ambient temperature whereas non-chilled controls stayed bright yellow. Such delayed appearance of CI symptoms creates problems in transportation, storage, and marketing (Murata 1969), leading to economic losses (Liu et al. 2006).

To minimize loss or deterioration of quality due to CI symptom, suitable management practises are needed in postharvest handling either during distribution or marketing by defining the description of the kinetic models of the reactions. As a result, kinetic studies of degradation of produce quality and nutrient losses during storage have received increasing attention in recent years (Yan et al. 2008). There are numerous publications on the kinetic of quality changes of fresh produce or processed food materials and most of them report that the kinetic changes follow either zero- or first-order models. In general, kinetic changes in colour are the main subject since the changes are obvious and easily identified by the consumer. Kinetic analysis of colour change has been reported for many fresh produce such as pears (Ibarz et al. 1999), bananas (Chen and Ramaswamy 2001; Roberto et al. 2009), potatoes (Nourian et al. 2003), tomatoes (Lana et al. 2006; Nisha et al. 2011), kiwifruits (Ali et al. 2008), guavas (Ganjloo et al. 2009) and jackfruit (Saxena et al. 2010). Colour readings have been reported to be able to classify a variety of food products, and the obtained colour values have been shown to be closely correlated with other chemical, physical and sensorial indicators such as visual assessment (Du and Sun 2005; Mendoza et al. 2006; Cubero et al. 2011).

Most often the colour spaces applied in food product classification are RGB (red, green and blue), HSI (hue, saturation and intensity) and L*a*b*. RGB is a linear colour space which can be obtained rapidly using computer vision systems (CVS). Signals are generated by CCD camera in CVS system, but are device dependent since its range of colours varies with the display device (Yam and Papadakis 2004; Mendoza et al. 2006; Cubero et al. 2011). The measurement of a colour in RGB space also does not represent colour differences in a uniform scale (Cheng et al. 2001). Therefore, it is difficult to differentiate the similarity of two colours from their distance using the RGB values. In order to overcome this problem, RGB values are transformed to other colour spaces such as HSI and L*a*b* which are non-linear.

HSI is an effective tool for colour image distinguishing. Compared to others, HSI space is intuitive, whose component can be easily related to the physical world (Du and Sun 2005). The others are unintuitive and their component has only an abstract relationship to the perceived colour, and therefore they have less meaning for human perceptions. Use of the HSI format for colour image instead of the conventional RGB format helps to overcome the speed limitations associated with colour-based machine vision (Gunasekaran 1996). HSI space can be used to represent a colour image in the computer and thus allow the various machine vision tasks to be segregated and performed with much greater efficiency. The method of using the HSI colour system proved to be highly effective for colour evaluation and image processing. The vision system achieved, e.g. above 90% accuracy in inspection of potatoes and apples by representing features with H histograms and applying multivariate discriminant techniques (Tao et al. 1995). Shearer and Payne (1990) were successfully sorted bell peppers up to 96% using H value.

Compared to RGB and HSI, the L*a*b* colour space has larger gamut encompassing all colours in the RGB which means the L*a*b* can display more colour than RGB (Yam and Papadakis 2004). L*a*b* is an international standard for colour measurement developed by the Commision International de l'Eclairage (CIE) to represent perceptual uniformity and thus meets similarity to human perception. It is device independent providing consistent colour regardless of the input or output device (Yam and Papadakis 2004; Mendoza et al. 2006). L* stands for brightness, while a* extends from green to red and b* from blue to yellow. They can be obtained through non-linear transformation of X, Y and Z values, and the X, Y and Z values can be computed by a linear transformation from RGB values (Cheng et al. 2001). It was reported that the transformation of RGB values to a* and b* colour components and the elimination of intensity resulted in enhanced separation for mushroom diseases (van de Vooren et al. 1992). Nevertheless, Lana et al. (2006) reported that since the HSI or L*a*b* colour space are derived from the RGB colour space, the changes of individual untransformed RGB values itself could reflect the changes of HSI or L*a*b*. Besides that, the measurement of L*a*b*, which generally measured using colorimeter, can only cover the colour of a small spot instead of total appearance of the produce by using CVS. Although the values can be obtained indirectly from CVS system via RGB values, the calculation is complicated rather than transformation of RGB to HSI.

Generally, colour has three sets of sensors with peak sensitivities at light wavelength ranging in visible spectrum from 400 to 700 nm in which 680 nm is for red, 540 nm for green and 450 nm for blue (Mendoza et al. 2006). Within this visible wavelength range, some chemical compositional information such as pigments can be obtained since the molecules absorb light energy. Pigment degradation can be analysed by means of physical colour measurements (Martin and Silva 2002). However, the fruit spectra can provide more specific information, since the pigments can be detected at their specific absorbance peaks, where electrons are excited into a higher orbital—the lowest unoccupied molecule orbital. One of the major pigment groups is the chlorophylls that absorb light energy in the red wavelength range between 640 and 720 nm (PSII 680 nm, PSI 700 nm). A shift in the balance of chlorophyll breakdown and synthesis of carotenoids occurs during fruit maturation and appearance of injuries that gradually diminishes the chlorophyll content. Therefore, the decrease in chlorophyll content provides a valuable indicator for fruit maturity as well as fruit quality (Zude 2003). Spectroscopy in the visible wavelength range has been proved to provide a non-destructive technique to detect the changes of fruit pigments and maturity progress (Merzlyak et al. 1999; Matile et al. 1999; Jacob-Wilk et al. 1999; Zude 2003). Many data processing methods are established to extract the quantitative pigment content from the fruit spectra such as red-edge, normalized difference vegetation index and multivariate calibration (Zude 2003). The red-edge is calculated as the difference between spectral reflectance values measured at 640 and 720 nm. The parameter was suitable for estimation of chlorophyll content in leaves and fruits (Lichtenthaler et al. 1996; Richardson et al. 2002; Zude 2003).

Although numerous study considering the appearance of CI symptoms have been conducted in the fresh produce generally and bananas specifically, no information is available on modeling kinetic of colour changes of CI symptoms in bananas. Most of the report concerns on the quality changes during ripening process. Thus, the objectives of this paper were (1) to investigate colour changes during CI in bananas using imaging system as an approach of automation technique for quality monitoring, (2) to develop related kinetic models which can well describe the associated changes on the colour, (3) to compare the performance of correlation between each colour parameter and visual assessment, and (4) to explain which pigment changes are responsible to the colour changes.

Materials and Methods

Plant Material and Chilling Treatments

Hands of good-quality bananas (Musa cavendishii) at ripening stages 4 (yellowish green) and 5 (greenish yellow) that were commercially graded were purchased from a commercial banana-ripening facility (FruchtExpress Import Export GmbH, Germany) who import the bananas mainly from Ecuador, Costa Rica and Columbia. For the purpose of this study, all the bananas were assumed to be the same and no differentiation was made as to which country they come from. This reflects the real market condition in which the consumer does not know the country of origin of the banana purchased. The bananas were transported to the laboratory at Leibniz Institute for Agricultural Engineering Potsdam-Bornim, Germany. Thirty-nine fingers of bananas were selected for the experiment. They were separated into two groups according to their ripening stage. Fifteen bananas at ripening stage 4 and 14 bananas at ripening stage 5 were stored in 6 °C (rH 90–95%) for 2 days to induce CI. Another five fingers from each ripening stage were selected as control samples and stored in the optimum storage temperature of 13 °C. Readings of RGB imaging, visual assessment and spectral reflectance were taken before they were moved into the cold storage. After storage, the bananas were taken out and exposed to ambient temperatures (15–25 °C) and all readings except spectral reflectance were taken again at every hour from 7 a.m. to 7 p.m.

Imaging

Colour images of bananas were obtained by RGB imaging system set-up in the laboratory. The system consisted of a CCD camera JVC KY-F50E with zoom lens (F2.5 and focal lengths of 18–108 mm) located vertically in the centre of the system. Samples were illuminated using four fluorescent lamps, which are power-controlled high-frequency lamps that would produce better quality illumination. They were arranged as front lighting located at 35 cm above the sample around the corner to give uniform light intensity over the samples. The angle between the camera lens axis and illumination system was arranged at 45°. Optimas grabber board (Bioscan Inc., USA) and software was used to acquire the images, and the size of the captured images was 720 × 576-pixel size by 24 bits.

Colour Space Transformation

Images were processed and analysed using image processing software (ezImage software, developed at Corvinus University of Budapest, Hungary). The region of interest (ROI) on each banana image was selected manually in the manner to obtain the largest possible surface area of the fruit. Banana fruits were placed on black background, but manual and supervised segmentation was performed so that dark surface regions of injured and overripe fruits can be also taken into account. Automatic segmentation may cut such parts and identify them as background along circumference. Average of each colour signal within this selected area was computed for achieving time series of the appearance of CI symptoms. The ROI was most affected by chilling injury shown in the picture of the fruit taken at the end of the experiment, i.e. after 1 day of storage at ambient temperature. Analysis was conducted on this labeled region in all images for each banana.

RGB values were transformed to obtain normalized values (Du and Sun 2004). The normalized RGB space (rgb) obtained from the three components of RGB were calculated using Eqs. 1, 2 and 3.

The RGB values also were converted to HSI colour space coordinates and particularly only H values were analysed since it showed the dominant colours, such as red, yellow, green and blue. The H values used in this study were obtained from the following formulation:

to obtain L*a*b* values, the non-linear rgb values first need to be transformed to linear sRGB (Mendoza et al. 2006). The sRGB values were obtained by the following equations:

else, if r, g, b > 0.04045

then, the sRGB values were converted to CIE XYZ system of white illuminant in order to measure an object in terms of device independent descriptors.

L*a*b* are defined as

where

Xn, Yn and Zn correspond to the XYZ values of a reference white point. The white point used is the standard D65 white point, X n = 0.950456, Y n = 1, Z n = 1.088754.

The total colour difference between two colours in L*, a* and b*colour space were evaluated as

Reference Data

After image acquisition of all samples, visual assessment and spectral reflectance readings of the bananas were carried out using a browning scale and a spectrophotometer (Lambda 950, Perkin-Elmer, USA), respectively. The browning scale was rated as described by Nguyen et al. (2003) as follows: 1—no chilling injury symptoms appears, 2—mild chilling injury symptoms in which the injury can be found in between the epidermal tissues, 3—moderate chilling injury symptoms in which the brown patches begin to become visible, larger and darker, 4—severe chilling injury symptoms in which the brown patches are visible, larger and darker than at scale 3 and 5—very severe chilling injury symptoms in which the patches are relatively large on the surface.

Before the fruit reflectance spectra were measured, the device was calibrated with white reference material (Spectralon 100%; Labsphere Ltd., North Sutton, USA). Diffuse reflectance on the fruit surface was measured by holding the fruit at the aperture of integrating sphere. Spectra were recorded in the wavelength range from 450 to 980 nm with 1 nm interval. The spectral reflectance were processed as the second derivative and the red-edge value which is the inflection point of the long-wave flank of the chlorophyll absorption peak was calculated at R″(λ) = 0 (Zude 2003).

Kinetic Data Analysis

Generally, the change in a certain parameter of produce can be estimated by the kinetic model (Eq. 13).

Here k is the rate constant which depends on temperature; C is the colour parameter; t is time; n is order of reaction and dC/dt is the rate of change of C with time. The negative and positive signs indicate whether colour parameters decrease or increase with time (Nourian et al. 2003; Yan et al. 2008).

In zero-order reactions the rate is independent of the colour parameter values. The rate reaction is expressed as below:

Integration of Eq. 14 results in:

The mathematical expression for a first-order rate reaction is as follows:

Integration of Eq. 16 yields:

where C 0 is the colour space value at time zero (initial value).

Statistical Analysis

Statistical analyses were carried out using Matlab software (Math Work Inc., USA). PLS_Toolbox 3.0 (Eigenvector Research, Inc. USA) was used for principal components analysis (PCA). The analysis of variances (ANOVA) was applied to compare the mean values of samples according to the different factors in Matlab. The goodness of fit of each model was evaluated using the coefficient of determination (R 2), the sum of squares of errors (SSE) and the root mean squares of errors (RMSE).

Results and Discussion

Correlation Between Colour Parameters and Visual Assessment

Visual assessment was carried out to grade the degree of CI symptoms, and the values were applied to analyse the correlation with the values of colour parameters obtained from the imaging readings. Based on visual assessment, bananas stored at control temperature were not affected by CI. Bananas at both ripening stages ripened marginally and the peel colour showed only slight changes. This temperature is suitable for preventing bananas from ripening rapidly and increasing their shelf life (Zhang et al. 2010). In contrast, bananas stored at 6 °C clearly exhibited CI symptom. The peel showed mild CI symptoms after 1 h of exposure to ambient temperature. Dark-brown streaks were observed between the sub-epidermal tissues for both ripening stages. However, there was no visible browning on the peel surface. Cross-sectional areas of the peel showed that the areas of dark-brown streaks are globular in shape (Nguyen et al. 2003). After 12 h, severe CI symptoms were observed in bananas at ripening stage 5. The symptoms of CI were visible and brown patches became larger and darker. Compared to bananas at ripening stage 4, the symptoms merely showed moderate CI in which the brown patches just began to be visible on the peel surface and several patches began to form continuous lines. Earlier studies also showed that the 6 °C induced the development of CI symptoms in banana (Nguyen et al. 2003). The peel showed discoloration already after being stored for 3 days at 6 °C. The colour changed to dark brown after storage period in chilling temperature was prolonged to 9 days.

Since each colour space has different colour information, the performance of each colour space was analysed using correlation with visual assessment. Results show that the normalized rgb colour space have strong correlation (R 2 > 0.95) with visual assessment excluding b (Table 1). The colour parameter r showed the highest values of R 2 in both ripening stages being equal to 0.9991 and 0.9703 for ripening stages 4 and 5, respectively. CIEL*a*b* space also shows strong correlation (R 2 > 0.84) at stage 5 but has moderate value (R 2 > 0.70) at stage 4. Total colour difference for bananas at ripening stage 5 correlated well with visual assessment, but no promising correlation was observed on bananas at ripening stage 4. L* parameter showed consistent correlation in both ripening stages with R 2 > 0.8 but they are heavily influenced by the curvature of the sample and background colour (Mendoza et al. 2006; Kang et al. 2008). The background colour could influence the light diffusivity in the system which in turn could influence the ability of the camera to catch the light reflection during image acquisition (Mendoza et al. 2006). Therefore, Du and Sun (2005) only used r and g parameters of normalized rgb, H and S parameters of HSV and a* and b* parameters of L*a*b* for colour features of pizza toppings to reduce the dimensionality of colour features and make the system more illumination independent. In agreements with the light influence and the strong correlation in both ripening stages with R 2 > 0.94 (Table 1), H was adopted for further analysis in the kinetic modeling for colour changes during CI.

Interaction of Factors

Bananas stored at 6 °C showed higher variability than bananas stored at control temperature in term of treatment time. The mean values of r, g, b and H ranged from 0.4232 to 0.4440, 0.3635 to 0.3591, 0.2123 to 0.1964 and 58.4894 to 55.5501, respectively, for bananas at ripening stage 4 and 0.4417 to 0.4722, 0.4346 to 0.3376, 0.1987 to 0.1898 and 55.4489 to 46.3711, respectively, for bananas at ripening stage 5 throughout the experiment. Meanwhile, the mean values of r, g, b and H for bananas stored at control temperature ranged from 0.4295 to 0.4488, 0.3880 to 0.3943, 0.1825 to 0.1573 and 64.3736 to 64.1866, respectively, for ripening stage 4 and 0.4571 to 0.4891, 0.3705 to 0.3816, 0.1724 to 0.1494 and 58.0767 to 59.6432, respectively, for bananas at ripening stage 5. Analysis of the interaction of the colour parameters with multifactor ANOVA test showed the individual factor of ripening stage between 4 and 5, post-chilling time and temperatures between 6 and 13 °C (control temperature) to colour parameter were highly significant with P < 0.0001 (Table 2). This means that the susceptibilities of chilling injury were different between the ripening stages and that they were significantly different in the colour space for both ripening stages between control temperature and chilling temperature. The colour parameter b showed the highest F values followed by g in the comparison between 6 and 13 °C temperatures. The interaction between post-chilling time and temperature for each colour parameter indicated significant differences (P < 0.01) reflecting the influence of time and temperature on chilling injury.

In order to observe the influence of temperature and ripening stage on the colour kinetics due to CI in two dimensions, PCA was applied to the data set. Two principal components were kept for H (PC1 capturing 79.83% variance and PC2 capturing 7.91% variance), providing clear separation of control and stressed samples. Separation by means of r, g, and b values were also obtained with two PC, where the covered variability were 80.91% and 7.24%, 82.96% and 7.52%, and 91.57% and 3.15% for PC1 and PC2, respectively (Fig. 1). Additional to the detection of damaged fruits, the PCA in Fig. 1a–d shows the influence of the ripening stage of bananas.

Score plot for the first two principle components of colour space r (a), g (b), b (c) and H (d) at different temperatures and ripening stages (plus sign ripening stage 4 at 6 °C, multiplication sign ripening stage 5 at 6 °C, empty circle ripening stage 4 at 13 °C, asterisk ripening stage 5 at 13 °C)

The scores plot of the two principle components for r obviously shows the influence of temperature and ripening stage, in which bananas stored at 6 °C positioned at lower quadrant while bananas stored at 13 °C positioned at upper quadrant. Ripening stages 4 and 5 were positioned at right and left quadrant respectively. For g colour space, the scores plot clearly distinguishes bananas at ripening stage 5 stored at 6 °C which shows more severe CI symptoms compared to the remaining samples. Although the pattern distribution for colour space b is spreading in the whole figure, the data set still can be grouped into their ripening stage and temperature condition. The pattern of PCA for H is almost similar with r in which the temperature effect were positioned in the lower and upper quadrant while the ripening stage were positioned in the right and left quadrant.

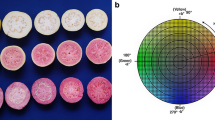

Kinetic of Colour Change

The colour changes in CI-induced samples happened rapidly once the samples were stored at ambient temperature. The colour failed to change from greenish yellow to golden yellow but change to brown and subsequently black instead. The dramatic change in colour was observed at every hour upon transfer to ambient temperature (Fig. 2). The changes were slow at the beginning but remarkably enhanced with time after storage for approximately 4 h. A steady increase in r and a gradual decrease in g as a function of time were noted, demonstrating a progressive increase in redness and decrease in greenness. In each of the r, g, b and H values, both ripening stages showed similar trend from the beginning until the end of the experiment. The b values did not show any particular trend in time. This is because the dominant colour of the peels is yellow which is composed of high red and green and low or minimal component of blue. However, the mean values indicated that the b values decreased, but the changes were small compared to other colour parameters. The H values showed similar trend changes to colour space g. The H values for both ripening stages were initially in the yellow region of the colour chart dimensions. Due to chilling injury, the H value decreased shifting towards the reddish region indicating that discoloration occurred throughout the period in which the banana peel colour changed to brown.

Discoloration was reported to be due to oxidative polymerisation of phenols and deterioration of chlorophyll. Therefore, study was conducted to investigate the connection of CI symptoms and deterioration of the pigment. Fruit spectra were recorded in the visible range to detect chlorophylls which absorb light at approx. 690 nm passband in vivo. The diffuse reflectance spectra revealed that significant changes occurred in the chlorophyll content in CI samples (Fig. 3). Before samples were stored in chilling temperature, reflectance spectra signature showed typical steep peak at the chlorophyll absorption band around 690 nm. However, after transferring the samples to ambient temperature for 1 day, the peak was vanished pointing to diminished chlorophyll content present in the samples for both ripening stages. The red-edge calculated from the spectra (Richardson et al. 2002; Zude 2003) by the second derivation showed decreased values for both ripening stages, when the samples were stored at ambient temperature (Fig. 4). However, no distinction was possible between the ripening stages due to completely diminished chlorophyll content in both stages.

Reflectance spectra signature before and after storage in 6 °C (a) and 13 °C (b) for bananas at ripening stage 4 and 5 (filled circle ripening stage 4 before storage, filled square ripening stage 5 before storage, empty circle ripening stage 4 after storage, empty square ripening stage 5 after storage)

The decrease of the chlorophyll content is likely to occur parallel with the synthesis of carotenoids during fruit ripening and injury appearance. This can be seen on the increment of carotenoid values at before and after storage for bananas treated at 13 °C which showed that the bananas continued to ripen normally and the colour of the peel changed from green to yellow (Fig. 4). In contrast, the values of carotenoid for CI samples decreased after treatment which means that the CI samples developed abnormal ripening pattern due to CI symptom appearance. Nevertheless, by taking into account the shift of spectral signatures, it is interesting to show that particularly the chlorophyll content decreased when CI symptoms appeared. Such distinct findings would not be possible by colour readings alone, since the colour does not address exclusively the specific absorbance passband under question. Based on colour space analysis, bananas at ripening stage 5 showed more severe CI symptoms than bananas at ripening stage 4 which is similar as reported by Marriott (1980) that the ripe fruit is considerably more susceptible to chilling injury than the unripe ones.

For the modeling of colour change of bananas during the appearance of CI symptoms, zero-order and first-order kinetic models were used (Table 3). The colour changes characterized by the zero-order model resulted in a poor fit with low coefficients of determination (R 2) and high RMSE value for all samples. Since control samples showed absent CI symptoms and no particular changes on each colour space, neither zero-order nor first-order model would describe the kinetic changes of them. In contrast, CI samples demonstrated particular changes that could be described by first-order model. The high R 2 values for first-order model pointed out a good agreement of predicted values by the model. Thus, all colour parameters were assumed to be well described by the first-order kinetic models and the models adequately described the associated changes in pigments. This means that the changes of the colour space r, g, b, and H is a logarithmic process, in which a constant proportion of the pigment contents is changed per time unit. The colour values increased or decreased exponentially as a function of time. Similar results were found in postharvest at different storage temperatures in tomato (Lana et al. 2006). The RGB intensities were well described and analysed with first-order model. It is difficult to compare the result obtained to others since most of the studies published used CIEL*a*b* colour space to describe the kinetic model. However, in agreement with Lana et al. (2006), the L*a*b* colour space is built up on RGB values which means that any particular changes can be represented by the relative amount of these variables. When converting RGB values into CIEL*a*b* values by taking ratios of the colour primaries R, G and B, the same effect will be obtained.

The kinetic rate constant of r, g, b and H for ripening stage 5 are higher than ripening stage 4. This implies that the ripe fruits are responding faster to CI treatment than the unripe ones. The results obtained were in agreement with the studies published by Murata (1969) who reported that green bananas took 5–7 days to reveal the partly browning symptoms on the peel surface while yellow bananas took only 4 days.

Conclusions

Chilling injury in bananas is influenced by post-chilling time, temperature and ripening stage of the fruit. In conclusion, a kinetic model that describes the changes of colour in bananas during chilling injury is presented. The changes in colour space r, g and H values were suitable to be described by first-order kinetic model. The statistical analysis of the colour space changes pointed out the significant difference between factors, i.e. ripening stage, time and temperature (P < 0.0001). There were high linear correlations between all colour parameters and visual assessment excluding b. Discoloration during CI might be due to deterioration of chlorophyll as the chlorophyll content decreased when CI symptoms appear. Therefore, besides the browning changes, the change in chlorophyll needs to be considered when monitoring the CI symptoms since it will provide high sensibility to the system. As a summary, the presented method has a great potential to be useful for predicting the quality change of bananas during chilling injury by providing essential elementary for designing a control system for storage or sorting the fresh produce quality. The data could be used to develop a monitoring system to detect or predict the appearance of CI symptoms in fruit. In future work, the authors will address a better insight in the pigment changes during development of CI symptoms.

References

Abbott, J. A. (1999). Quality measurement of fruit and vegetables. Postharvest Biology and Technology, 15(3), 207–225.

Abd El-Wahab, F. K., & Nawwar, M. A. M. (1977). Physiological and biochemical studies on chilling-injury of banana. Scientia Hoticulturae, 7(4), 373–376.

Ali, M., Shahin, R., Zahra, E., & Alireza, K. (2008). Kinetic models for colour changes in kiwifruit slices during hot air drying. World Journal of Agricultural Sciences, 4(3), 376–383.

Broughton, W. J., & Wu, K. F. (1979). Storage condition and ripening of two cultivars of banana. Scientia Horticulturae, 10(1), 83–93.

Chen, C. R., & Ramaswamy, H. S. (2001). Color and texture change kinetics in ripening bananas. Lebensmittel-Wissenschaft und-Technologie, 35(5), 415–419.

Cheng, H. D., Jiang, X. H., Sun, Y., & Wang, J. (2001). Color image segmentation: advances and prospects. Pattern Recognition, 34(12), 2259–2281.

Cubero, S., Aleixos, N., Moltó, E., Gómez-Sanchis, J., & Blasco, J. (2011). Advances in machine vision applications for automatic inspection and quality evaluation of fruits and vegetables. Food and Bioprocess Technology, 4(4), 487–504.

De Martino, G., Mencarelli, F., & Golding, J. B. (2007). Preliminary investigation into the uneven ripening of banana peel after 1-MCP treatment. Advances in Plant Ethylene Research, 4, 243–246.

Du, C.-J., & Sun, D.-W. (2004). Recent developments in the applications of image processing techniques for food quality evaluation. Trends in Food Science and Technology, 15(5), 230–249.

Du, C.-J., & Sun, D.-W. (2005). Comparison of three methods for classification of pizza topping using different colour space transformations. Journal of Food Engineering, 68(3), 277–287.

Gamal, E., Ning, W., & Clement, V. (2009). Detecting chilling injury in Red Delicious apple using hyperspectral imaging and neural networks. Postharvest Biology and Technology, 52(1), 1–8.

Ganjloo, A., Rahman, R. A., Osman, A., Bakar, J., & Bimakr, M. (2009). Kinetics of crude peroxidase inactivation and color changes of thermally treated seedless guava (Psidium guajava L.). Food and Bioprocess Technology. doi:10.1007/s11947-009-0245-4.

Gunasekaran, S. (1996). Computer vision technology for food quality assurance. Trends in Food Science and Technology, 7(8), 245–256.

Ibarz, A., Pagan, J., & Garza, S. (1999). Kinetic models for colour changes in pear puree during heating at relatively high temperatures. Journal of Food Engineering, 39(4), 415–422.

Jacob-Wilk, D., Holland, D., Goldschmidt, E. E., Riov, J., & Eyal, Y. (1999). Chlorophyll breakdown by chlorophyllase: isolation and functional expression of the Chlase1 gene from ethylene-treated Citrus fruit and its regulation during development. The Plant Journal, 20(6), 653–661.

Kang, S. P., East, A. R., & Trujillo, F. J. (2008). Colour vision system evaluation of bicolour fruit: a case study with ‘B74’ mango. Postharvest Biology and Technology, 49(1), 77–85.

Lana, M. M., Tijskens, L. M. M., & van Kooten, O. (2006). Effects of storage temperature and stage of ripening on RGB colour aspects of fresh-cut tomato pericarp using video image analysis. Journal of Food Engineering, 77(4), 871–879.

Lichtenthaler, H. K., Gitelson, A. A., & Lang, M. (1996). Non-destructive determination of chlorophyll content of leaves of a green and an aurea mutant of tobacco by reflectance measurements. Journal of Plant Physiology, 148, 483–493.

Liu, Y., Chen, Y. R., Wang, C. Y., Chan, D. E., & Kim, M. S. (2006). Development of hyperspectral imaging technique for the detection of chilling injury in cucumbers: spectral analysis and image analysis. Applied Engineering in Agriculture, 22(1), 101–111.

Marriott, J. (1980). Bananas—physiology and biochemistry of storage and ripening for optimum quality. Critical Reviews in Food Science and Nutrition, 13(1), 41–88.

Martin, R. C., & Silva, C. L. M. (2002). Modelling colour and chlorophyll losses of frozen green beans (Phaseolus vulgaris, L.). International Journal of Refrigeration, 25(7), 966–974.

Matile, P., Hörtensteiner, S., & Thomas, H. (1999). Chlorophyll degradation. Annual Review of Plant Physiology and Plant Molecular Biology, 50, 67–95.

Mendoza, F., Dejmek, P., & Aguilera, J. M. (2006). Calibrated color measurements of agricultural foods using image analysis. Postharvest Biology and Technology, 41(3), 285–295.

Merzlyak, M. N., Gitelson, A. A., Chivkunova, O. B., & Rakitin, V. Y. (1999). Non-destructive optical detection of pigment changes during leaf senescence and fruit ripening. Physiologia Plantarum, 106(1), 135–141.

Murata, T. (1969). Physiological and biochemical studies of chilling injury in bananas. Physiologia Plantarum, 22(2), 401–411.

Nguyen, T. B. T., Ketsa, S., & van Doorn, W. G. (2003). Relationship between browning and the activities of polyphenol oxidase and phenylalanine ammonia lyase in banana peel during low temperature storage. Postharvest Biology and Technology, 30(2), 187–193.

Nguyen, T. B. T., Ketsa, S., & van Doorn, W. G. (2004). Effect of modified atmosphere packaging on chilling-induced peel browning in banana. Postharvest Biology and Technology, 31(3), 313–317.

Nisha, P., Rekha, S. S., & Aniruddha, B. P. (2011). Kinetic modelling of colour degradation in tomato puree (Lycopersicon esculentum L.). Food and Bioprocess Technology, 4(5), 781–787.

Nourian, F., Ramaswamy, H. S., & Kushalappa, A. C. (2003). Kinetic changes in cooking quality of potatoes stored at different temperatures. Journal of Food Engineering, 60(3), 257–266.

Richardson, A. D., Duigan, S. P., & Berlyn, G. P. (2002). An evaluation of non-invasive methods to estimate foliar chlorophyll content. The New Phytologist, 153(1), 185–194.

Roberto, Q., Oscar, D., Betty, R., Franco, P., & Jose, M. G. (2009). Description of the kinetic enzymatic browning in banana (Musa cavendish) slices using non-uniform color information from digital images. Food Research International, 42(9), 1309–1314.

Saxena, A., Maity, T., Raju, P. S., & Bawa, A. S. (2010). Degradation kinetics of colour and total carotenoids in jackfruit (Artocarpus heterophyllus) bulb slices during hot air drying. Food and Bioprocess Technology. doi:10.1007/s11947-010-0409-2.

Shearer, S. A., & Payne, F. A. (1990). Color and defect sorting of bell peppers using machine vision. Transactions of ASAE, 33(6), 2045–2050.

Skog LJ (1998) Factsheet: Chilling injury of horticultural crops, Horticultural Research Institute of Ontaria, University of Guelph.

Tao, Y., Heinemann, P. H., Varghese, Z., Morrow, C. T., & Sommer, H. J., III. (1995). Machine vision for colour inspection of potatoes and apples. Transactions of the ASABE, 38(5), 1555–1561.

Trakulnaleumsai, C., Ketsa, S., & van Doorn, W. G. (2006). Temperature effects on peel spotting in ‘Sucrier’ banana fruit. Postharvest Biology and Technology, 39(3), 285–290.

van de Vooren, J. G., Polder, G., & van der Heijden, G. W. A. M. (1992). Identification of mushroom cultivars using image analysis. Transactions of the ASABE, 35(1), 347–350.

Yam, K. L., & Papadakis, S. E. (2004). A simple digital imaging method for measuring and analyzing colour of food surfaces. Journal of Food Engineering, 61(1), 137–142.

Yan, Z., Maria, J. S., & Fernanda, A. R. O. (2008). Mathematical modeling of the kinetic of quality deterioration of intermediate moisture content banana during storage. Journal of Food Engineering, 84(3), 359–367.

Zhang, H., Yang, S., Joyce, D. C., Jiang, Y., Qu, H., & Duan, X. (2010). Physiology and quality response of harvested banana fruit to cold shock. Postharvest Biology and Technology, 55(3), 154–159.

Zude, M. (2003). Comparison of indices and multivariate models to non-destructively predict the fruit cholorophyll by means of visible spectrometry in apple fruit. Analytica Chimica Acta, 481(1), 119–126.

Acknowledgments

The authors are grateful for the financial support received from the Ministry of Higher Education Malaysia, University Putra Malaysia and Leibniz Institute for Agricultural Engineering Potsdam-Bornim (ATB) for this project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hashim, N., Janius, R.B., Baranyai, L. et al. Kinetic Model for Colour Changes in Bananas During the Appearance of Chilling Injury Symptoms. Food Bioprocess Technol 5, 2952–2963 (2012). https://doi.org/10.1007/s11947-011-0646-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-011-0646-z