Abstract

The food-processing industry has made large investments in processing facilities relying mostly on conventional thermal processing technologies with well-established reliability and efficacy. Replacing them with one of the novel alternatives recently developed is a decision that must be carefully approached. Among them, high-pressure processing (HPP), at room or refrigerated temperature, is now a well-established option experiencing worldwide commercial growth. Surveys have shown an excellent consumer acceptance of HPP technology. For financial feasibility reasons, HPP treatments must be kept short, a challenge that can be met by some of the alternatives here reviewed such as the use of the hurdle technology concept. Although HPP technology is limited to pasteurization treatments, the combination of high pressure and high temperature used in pressure-assisted thermal processing (PATP) can be used to sterilize foods. An analysis of alternatives to achieve the inactivation of bacterial spores at the lowest temperature possible highlights the need for additional research on the use of germinants. Because of incomplete research, PATP presents several implementation challenges, including the modeling of food temperature, the determination of inactivation kinetics particularly for bacterial spores, and the prediction of chemical changes including the potential formation of toxic compounds.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

New processing technologies are necessary to deliver at the point of food consumption near-absolute chemical and microbial safety, to minimize or eliminate the need for chemical additives, to retain the sensory and nutritional quality of fresh ingredients, and to improve the convenience of processed foods (Lopez-Malo et al. 1999; Palou et al. 1999, 2000; San Martin-Gonzalez et al. 2006; Ramirez et al. 2009; Torres et al. 2009a,b; Welti-Chanes et al. 2009). On the other hand, the availability, cost and effectiveness of thermal processing technologies explain why they remain the prevailing method to achieve microbial safety and the inactivation of enzymes and microorganisms responsible for food spoilage (Torres et al. 2010). Particularly important disadvantages of conventional thermal processing technologies are chemical reactions leading to off flavors, destruction of nutrients, and other losses of product quality.

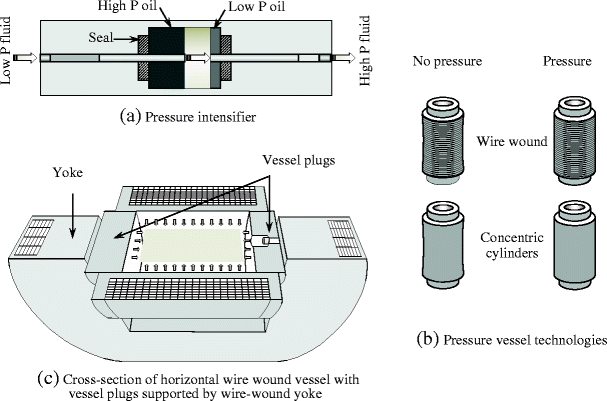

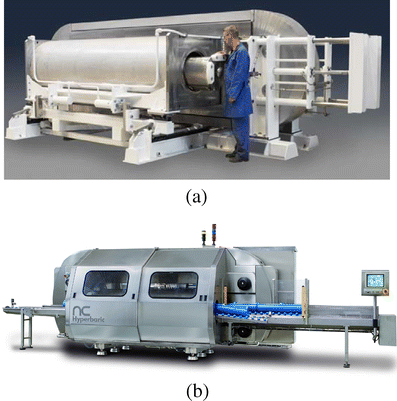

Among novel processing alternatives, high-pressure processing (HPP) pasteurization has been adopted at the fastest rate as reflected by the number of units installed (Fig. 1) and used mostly for the production of refrigerated foods. HPP will continue to expand because new analytical techniques facilitate the tracking to the source of microbial pathogens involved in food poisoning outbreaks. HPP is satisfying also the demand for minimally processed products and could be used to develop new functional foods for demanding niche markets. Finally, HPP technology can provide quality superiority over products obtained by conventional technologies, particularly by lowering the need for antimicrobial agents. Another emerging and particularly innovative conservation procedure, pressure-assisted thermal processing (PATP), could facilitate meeting the demand for more healthy, nutritious, varied, and convenient shelf-stable food. PATP is based on the combined application of high pressure and high temperature, typically in excess of 600 MPa and 100 °C (Valdez-Fragoso et al. 2010). The key components of HPP and PATP units are the high hydrostatic pressure vessel, the pressure generating pump or pressure intensifier, and the yoke to ensure secure sealing of the vessel while under pressure (Fig. 2). Oil at ~20 MPa is fed on the high-pressure oil side of the larger pump piston, which has an area ratio of ~30:1 with respect to the smaller piston displacing into the high pressure vessel pressurizing fluid at ~600–700 MPa. When the piston reaches the end of its displacement, the system is reversed, high-pressure oil is fed to the other side of the larger pump piston, and the high-pressure fluid exits on the other pump side. The pressurizing fluid is usually water with equipment-protecting additives (Torres and Velazquez 2005, 2008). Prestressing by wire winding and other technologies allows the construction of ~100–500 L size vessels operating at 600–700 MPa. Typically, the same technology is used for reinforcing the yoke holding the top and bottom seals (Torres and Velazquez 2008). Although the original HPP equipment units were vertical, the current trend is to supply horizontal units (Fig. 3). A horizontal orientation avoids sublevel construction requirements, eliminates height, and floor load restrictions, makes system installation and relocation more feasible, facilitates product flow in the plant and reduces the risk of confusing treated and unprocessed product. Another design trend is the use of multiple intensifiers, up to ~8 pressure intensifiers to reduce pressure come up time, and by working independently from each other they facilitate their maintenance and repair. It is also possible to share a set of intensifiers between two or more pressure vessels to reduce capital investment. Suppliers of industrial pressure processing units include Avure Technologies Inc. (www.avure.com/food), Elmhurst Research, Inc. (www.elmhurstresearch.com), NC Hyperbaric (www.nchyperbaric.com), and Uhde GmbH (www.uhde-hpt.com). Smaller units used for research (~0.1–10 L) can reach 1,400 MPa and should be acquired with pressurization rate and temperature control devices.

World growth of the food industry use of high-pressure processing technology. Source: NC Hyperbaric, Burgos, Spain (www.nchyperbaric.com)

High pressure processing technology components. Adapted from Torres and Velazquez (2005)

Examples of horizontal, large commercial pressure processing vessels. (a) Model Quintus Type QFP 687 L-310, courtesy of Avure Technologies, Kent, WA, USA, www.avure.com; (b) Model Wave 6000–55, courtesy of NC Hyperbaric, Burgos, Spain, www.nchyperbaric.com

The cost of the capital needed to implement HPP has been overcome in part by designing larger units with a tenfold increase in vessel capacity over the last 15 years. Another positive development has been the 60% reduction in the equipment cost to process one liter per hour reflecting commercial competition among suppliers and the economy of scale gained from increasing the vessel size (Hernando Saiz et al. 2008). By the end of 2010, about 160 industrial HPP processing units had been installed all over the world with an annual production capacity approaching 250,000 tons. Commercial HPP units cost US$ 0.5–2.5 million depending upon capacity and automation level. Capital and operating costs will continue to decrease as HPP implementation expands. The specific impact on product cost for HPP applications depends on multiple factors: (1) plant operation schedule (two shifts, 300 days per year is recommended); (2) pressure come up time (investing in multiple pressure intensifiers reduces it); (3) holding time (3 min desirable maximum for commercial viability); (4) vessel filling ratio (50% minimum recommended, improved by packaging design modifications); (5) product handling time (automatic loading/unloading recommended when feasible); and (6) equipment downtime (minimized by personnel training and maintaining an ample supply of spare parts). Table 1 provides estimations of the effect of the use level and vessel size on HPP (0.071–0.194 US$/lb) and PATP (0.101–0.308 US$/lb) processing costs.

Principles of High-Pressure Processing Technology

The effect of high hydrostatic pressure, unlike that of thermal processes and other conventional conservation technologies, is almost instantaneous and uniform (Torres and Velazquez 2008). Since pressure transmission is not mass/time-dependent, treatment times are short, particularly when comparing thermal and HPP treatments of solid foods. HPP effects are also independent of the equipment and product geometry and size; therefore, scaling of laboratory and pilot plant findings to commercial production is both simple and safe. This characteristic is also important when equipment renewal and changes to larger units become necessary, or when new marketing conditions require changes to the size and geometry of the package. None of these changes will require the determination of new pressure and time conditions for the HPP process. These advantages explain why a wide variety of novel HPP products have reached consumers in a very short time (Pérez Lamela and Torres 2008a, b). Food compression is about 15% for a 600 MPa treatment, reflecting mostly the compression of its moisture content but will be larger if the food contains empty spaces as in the case of fruits and vegetables that have between 9% and 30% of their volume filled with air, or in high-fat content products as fat has a higher compressibility than water. If the product is not vacuum-packed, the compression of the headspace increases pressurization time and thus processing costs. This must be considered when using modified atmosphere packaging technology to extend product shelf-life. Finally, the packaging material must withstand, and without compromising seal integrity, deformations equivalent to the food and headspace compression. Separations have been observed in multilayer structures containing an aluminum layer when subjected to elevated temperature (Ulloa-Fuentes et al. 2008a,b).

Effects of High-Pressure Processing on Food Systems

Chemical changes in HPP-processed foods are minimal because the break of covalent bonds does not occur (Ramirez et al. 2009). Therefore, sensory properties, nutrients, and particularly bioactive compounds of current high commercial interest, suffer no significant losses. Pressure affects weaker bonds such as van der Waals forces, electrostatic interactions and hydrogen bridges. Changes to them explain the preservation effect of HPP treatments (Lado and Yousef 2002; Torres and Velazquez 2005; Velazquez et al. 2005a,b). They cause changes in membrane structures resulting in microbial inactivation effects but they can also facilitate the access of an enzyme to its substrate causing product deterioration during storage. Changes in the structure of important macromolecules such as deoxyribonucleic acid and proteins with enzymatic activity contribute also to food preservation. However, pressure-induced changes in proteins and starches can modify texture with positive or negative effects on product quality.

Another important change contributing to microbial inactivation by HPP is the displacement of the equilibrium associated with food pH, typically towards more acid values (Mathys et al. 2008). However, reestablishment of the initial pH value occurs upon pressure release (Paredes-Sabja et al. 2007). The extent of the pH-shift can be theoretically predicted if values for the empirical constants involved in Eq. 1 are available (Neuman et al. 1973; El’Yanov and Hamann 1975):

where:

- (pK a )p :

-

pressure-shifted dissociation constant

- (pK a )0 :

-

dissociation constant at the reference pressure (0.1 MPa)

- p :

-

pressure (MPa)

- ∆V o :

-

partial molar volume change of the dissociating acid at 0.1 MPa (m3/mol)

- R :

-

universal gas constant, 8.31 × 10−6 (MPa m3)/(K mol)

- T :

-

absolute temperature (K)

- b :

-

9.2 × 10−4 MPa (assumed constant for all acids)

The effect on citric acid buffer pH as predicted by Eq. 1 is shown in Fig. 4 (Paredes-Sabja et al. 2007). In this example, when the pressure is increased to 650 MPa, pH is reduced from an initial pH value of 4.75 and 6.5 to a final pH value of 4.05 and 5.25, respectively. At 550 MPa, the corresponding pH shift values are 0.6 and 1.1, respectively (data not shown). In many studies, it is desirable to use solutions designed to have a pressure-independent pH. A combination of buffers that exhibit positive and negative pressure-induced pH shifts can be used for this purpose. Unfortunately, there is no data to estimate the effect of temperature on the pressure-induced pH shift in foods. Moreover, investigating food systems and making interpretation of pressure effects is more challenging because pH cannot be measured experimentally and the parameters for Eq. 1 have not been determined for foods.

Predicted pressure-induced pH shift in citric acid buffer. Adapted from Paredes-Sabja et al. (2007)

In addition to the pH shift, the compressive work against intermolecular forces during HPP treatments, known as adiabatic heating, increases the temperature rise of the food and pressure-transmitting fluid. Unfortunately, early HPP researchers failed to consider the pressure-induced effects on pH and temperature when interpreting pressure processing effects on foods (Torres et al. 2009a). Therefore, early publications do not include determinations of temperature and pH values during HPP treatments. The temperature increase depends mainly on the composition of the food and pressure-transmitting fluid, pressurization rate, location within the vessel, geometry of the processing equipment, and the volume of the vessel occupied by the food (Hartmann and Delgado 2002; Otero et al. 2007; Torres et al. 2009b). Under industrial-processing conditions, the adiabatic compression heat effect is minimized by processing previously refrigerated products in pre-cooled pressurizing fluid and equipment (<10 °C).

The correct application of pressure-processing technologies requires the ability to control the process. Although the pressure applied to foods can be assumed uniform, differences in temperature–time profiles among vessel locations for HPP-treated foods can cause non-uniform effects when the kinetics of the enzyme or microbial inactivation is temperature dependent (Denys et al. 2000a; van der Plancken et al. 2008). These differences can be monitored by temperature measurements inside the vessel, numerical simulations of the temperature distribution, or by pressure–temperature–time indicators (pTTIs) with time range similar to that of the HPP effect to be monitored and, most importantly, having kinetic equivalence with the target attribute (a safety or quality parameter). A complete kinetic characterization of the pTTI response to pressure and temperature is required. pTTIs have been successfully applied to demonstrate non-uniformity in the high-pressure process (Denys et al. 2000a, b; Claeys et al. 2003; Otero and Sanz 2003; Grauwet et al. 2009, 2010). Direct monitoring of the temperature profile is not yet a viable option for commercial vessels and is used only in experimental units to validate engineering models supporting numerical simulations of temperature profiles as a function of time and location in the vessel (Fig. 5). This modeling effort is limited by incomplete information on the pressure and temperature dependence of the thermo-physical properties of the pressure-transmitting medium and the food product including its packaging material (Otero et al. 2002, 2006; Khurana and Karwe 2009).

Modeling of temperature in a high pressure vessel. Surface and center temperature of an agar gel processed to 350 MPa using water as pressurizing fluid. Initial temperature of agar sample and pressurizing fluid = 20 °C. Adapted from Torres et al. (2009b)

Pressure Inactivation of Enzymes

HPP inactivates many food enzymes, reducing in many cases the degradation of food quality and nutritional value. However, the effects of pressure vary extensively with the enzyme causing these losses, the pressure, temperature and time of the process conditions selected, and finally the pH, moisture content, and other properties of the food matrix. Relatively low pressure (~100–200 MPa) may activate some enzymes while high pressure (400–1,000 MPa) may induce their inactivation. An effective means to accelerate the inactivation of enzymes is by increasing temperature; however, the effect of pressure and temperature has been determined only for a relatively few enzymes and food systems (e.g., Hurtado et al. 2002; Verlent et al. 2004; Chéret et al. 2005; Lakshmanan et al. 2005; Rademacher and Hinrichs 2006; Kouassi et al. 2007; Iucci et al. 2008). The largest contribution of pressure to enzyme inactivation comes from structural rearrangements of proteins under high pressure (Hendrickx et al. 1998) such as hydration changes that accompany other intramolecular non-covalent interactions (Mozhaev 1996a,b). Pressure-treated proteins retain their primary structure because covalent bonds are unaffected by pressure. Enzymes found in fruits, vegetables, milk, fish, and meat products include polyphenol oxidase (PPO), lipoxygenase (LOX), pectinmethylesterase (PME), peroxidase (POD), lipases, and proteases. A recent review on the pressure processing effects on enzymes present in fruits and vegetables can be found in Ludikhuyze et al. (2002). As in the case of microbial inactivation, the thermal resistance of enzymes cannot be used to predict their pressure resistance (Hendrickx et al. 1998). Enzymes such as PPO and LOX are inactivated at 300 MPa, while others such as PME and POD are very difficult to inactivate within the pressure range of the commercial units available today.

Information on enzyme inactivation kinetics is essential to model, design and optimize preservation processes (Torres et al. 2009a). For example, Ludikhuyze et al. (2002) determined the pressure and temperature required for 90% inactivation of key enzymes, six decimal reductions in microbial counts, and 90% loss in total chlorophyll content for 15-min treatments. This is necessary because the region defined by the reduction in spoilage organisms and the loss of quality (expressed by chlorophyll loss in this case) must correspond also to pressure and temperature combinations achieving enzyme inactivation if the process is to be feasible. Furthermore, enzyme inactivation depends on the enzyme source (green beans, peas and pears) and test matrix (in a whole or a fruit piece, or in a puree or juice) as shown for the case of lipoxygenase by Ludikhuyze et al. (2002). This means that substantial more research will be required to determine for each enzyme source and specific physicochemical environment effects on its inactivation rate.

Pressure Inactivation of Microorganisms

The acceptance of a new preservation technology depends on its efficacy to inactivate pathogenic and spoilage food-borne microorganisms (Lado and Yousef 2002). Another factor to consider is the availability and quality of the experimental microbial inactivation data required to design HPP and PATP processes. Variability of the experimental data must be minimized because the alternative of over processing to compensate for the uncertainty in the time required for a safe process is unlikely to be financially viable when using pressure processing and other novel technologies. In addition, food regulations are beginning to require determinations of the confidence level that the pathogen risk has been reduced to an acceptable probability level. Thus, it is now necessary to evaluate the impact of the variability in the microbial inactivation data required for decisions of safe processing. Although, this analysis has not been reported for HPP-treated foods, a confidence level evaluation using a Monte Carlo-based methodology was reported recently for thermal processing (Chotyakul et al. 2010a; Torres et al. 2010). In a Monte Carlo procedure (Cassin et al. 1998), model parameters are described as probability distributions which can be approximated using random number generators (Fig. 6). Calculations are repeated many times for each set of generated data yielding each time slightly different outcomes reflecting the variability of the input data (Schmidheiny 2008). On the other hand, in conventional or deterministic calculations, all input parameters have a fixed value and the same output values are always obtained. The output from Monte Carlo procedures can be represented as probability distributions or histograms and the conclusion reported as confidence intervals (Wittwer 2004).

Schematic representation of conventional deterministic (a) and Monte Carlo (b) calculation procedures for engineering model supporting food process, packaging and storage decisions. Estimates of the effect of the variability of model parameters in the Monte Carlo procedure involves repeating the same calculations using random sampling of each model parameter. Adapted from Chotyakul et al. (2010b)

The previously described process was recently demonstrated for the heat sterilization of canned mushrooms (Chotyakul et al. 2010a; Torres et al. 2010). In conventional microbial inactivation processes, a processing time at a reference temperature T (F T value) must be estimated to achieve a desired number of decimal reductions (SV) based on the decimal reduction time (D T ) defined as the time at temperature T to inactivate 90% of the target microorganism (Morales-Blancas and Torres 2003a,b,c). The Monte Carlo procedure generated a frequency distribution of the Clostridium botulinum type B spores (Fig. 7a) surviving a thermal process (= 5.96 min) calculated on the basis of average initial spore load (N o ) and mean D T value (Chotyakul et al. 2010b; Torres et al. 2010). This process would result in an unacceptable 55% under processing risk when considering the variability in N o and D T . The same procedure was used to estimate an F T value (= 8.89 min at 110 °C) sufficient to reduce the risk of under processing to 5% or less (Fig. 7b). However, a Monte Carlo analysis requirement is that the number of simulations needed to achieve an acceptable accuracy level must be determined (Floschet et al. 2003). In this example, the number of simulations recommended was 100 and that yielded 9.6 min at 110 °C as the process time recommended to ensure that the risk of under processing was 5% or less (Chotyakul et al. 2010a; Torres et al. 2010). If the standard deviation of N o and D T values could be lowered by 90%, the process time ensuring a risk of under processing of 5% or less would be 6.4 min at 110 °C (Chotyakul et al. 2010a; Torres et al. 2010). The Monte Carlo procedure here proposed has therefore two advantages. First, it can be used to select HPP or PATP conditions minimizing the risk of not meeting the microbial inactivation level required. Second, it can be used to explore how reducing the variability in the data used to select these HPP or PATP conditions would lead to less intense pressure treatments.

Effect of the reported variability in the initial load (N o , CFU/container) and decimal thermal inactivation values at 110 °C (D 110 °C , min) on the survival probability distribution of spores of Clostridium botulinum Type B in canned mushroom (log N, CFU/container). (a) Spore survival probability distribution when using a thermal process value calculated on the basis of average values for these two parameters (N o = −1.36 ± 0.87 log CFU/container, D 110 °C = 0.78 ± 0.17 min) showing a 55% underprocessing risk (i.e., log N > −9); (b) Survival probability distribution for a longer thermal process reducing the underprocessing risk to 5% or less. Adapted from Chotyakul et al. (2010b)

Inactivation of Vegetative Cells

HPP inactivates microorganisms by interrupting cellular functions responsible for reproduction and survival (Norton and Sun 2008; Torres and Velazquez 2008). HPP can damage microbial membranes interfering with nutrient uptake and disposal of cell waste. Additional damaging events include extensive solute loss during pressurization, protein denaturation and key enzyme inactivation. Intracellular fluid compounds found in the suspending fluid after pressure treatment indicate that leaks occur while cells are held under pressure (e.g., Shimada et al. 1993). Cell functions are altered when key enzymes are inactivated or membrane selectivity is disabled. Membrane disruption is likely responsible for the changes in morphology observed in HPP-treated cells (Lado and Yousef 2002). Gram-positive bacteria are inactivated at higher pressures than Gram-negative ones (Hayakawa et al. 1994) due to the rigidity of the teichoic acids in the peptidoglycan layer of the Gram-positive cell wall (Lado and Yousef 2002).

The physiological condition of the microorganism affects their behavior under pressure. The pressure resistance of exponential phase Escherichia coli NCTC 8164 cells is highest for cells grown at 10 °C and decreases with growth temperature up to 45 °C (Casadei et al. 2002). In contrast, pressure resistance of stationary-phase cells is the lowest in cells grown at 10 °C and increases with growth temperature reaching a maximum at 30–37 °C before decreasing at 45 °C. High membrane fluidity increases the resistance to HPP and low temperatures. Membranes with relatively high fluidity are rich in unsaturated fatty acids. The pressure effect reported by Casadei et al. (2002) was correlated to the proportion of unsaturated fatty acids in the membrane lipids which decreases with growth temperature. In exponential-phase cells, pressure resistance increased with greater membrane fluidity, whereas in stationary-phase cells, no simple relationship between membrane fluidity and pressure resistance was observed (Casadei et al. 2002).

Long processing times must be avoided to ensure the financial feasibility of HPP applications (Torres and Velazquez 2005). A first approach is to lower process temperature which increases the rate of microbial inactivation. For example, Reyns et al. (2000) evaluated eight spoilage yeasts for their sensitivity to inactivation by pressure. Determination of decimal inactivation values (D) showed that Zygosaccharomyces bailii and Zygosaccharomyces hellenicus were the most pressure resistant. The inactivation of Z. bailii, frequently associated with the spoilage of juices, showed first order kinetics for up to six decimal reductions followed by a tail fraction inactivated at a slower rate. At constant temperature, D values decreased with pressure and showed at constant pressure a maximum value at ∼20 °C. In the example shown in Fig. 8, treatment time could be reduced by 70% by processing juice at of 2 °C instead of 20 °C. A lower process temperature will improve the overall product quality too.

Temperature and pressure effects on the decimal inactivation value (D, min) by high pressure processing of Zygosaccharomyces bailii in 40 mM Tris–HCl buffer at pH 6.5. Adapted from Reyns et al. (2000)

Another alternative to reduce treatment time would be a hurdle technology strategy (Corbo et al. 2009). This would include the use of antimicrobial agents acceptable to consumers of HPP-treated foods such as essential oils, lactoferrin, lysozyme, lactoperoxidase system, etc. Essential oils (EOs) are aromatic oil liquids obtained mostly from plant material which have been shown to exhibit antiviral, antibacterial, antimycotic, antitoxigenic, antiparasitic, and insecticidal properties. Although EOs are composed of a large number of chemicals, phenolic compounds are chiefly responsible for their antibacterial properties (Burt 2004). Lactoferrin has iron-binding properties but many other roles have been proposed for this protein (Farnaud and Evans 2003). Although the antimicrobial activity of lactoferrin has been attributed to its iron sequestering ability, its effectiveness may have other components (Corbo et al. 2009). For example, human (LfcinH) and bovine lactoferricins (LfcinB) are peptides arising from pepsin cleavage of human and bovine lactoferrin, respectively. A region of 11 residues in LfcinB and two regions in LfcinH covering residues 1–5 and 19–31 were found to be important for the effectiveness of lactoferrins. Studies by Farnaud et al. (2004) suggest that these peptides should be classified as disorganizing or permeabilizing agents increasing the susceptibility of a microorganism to other treatments including HPP. Lysozyme, an enzyme with bactericidal properties against Gram-positive microorganisms, is ineffective against Gram-negative bacteria, owing to their lipopolysaccharide layer in the outer membrane. It has been used to extend meat shelf life and plays a role in cheese ageing through the reduction of butyric fermentation bacteria, which adversely affect cheese quality. Also, its bacteriolytic activity has been used to control the malolactic fermentation in wines. Its effectiveness could be increased through the use of chelating agents (Corbo et al. 2009). Finally, the lactoperoxidase system consists of the enzyme lactoperoxidase, thiocyanate, and hydrogen peroxide (H2O2) and may also improve HPP effectiveness. Lactoperoxidase is an oxidoreductase and catalyses the oxidation of thiocyanate at the expense of H2O2, to generate intermediate products with antibacterial properties. The lactoperoxidase system exerts both bacteriostatic and bactericidal activity on a variety of bacteria. Unfortunately, the combination of many of these antimicrobial agents with HPP treatments needs additional studies to assess their effectiveness. The reader could consult Corbo et al. (2009) for a more extensive review of this hurdle technology alternative to reduce HPP processing times.

Inactivation of Bacterial Spores

Although pressure levels in the range of 400–800 MPa inactivates the vegetative forms of pathogenic and spoilage bacteria (San Martin et al. 2002; Smelt et al. 2002; Velazquez et al. 2002, 2005a,b; Moermann 2005; Torres and Velazquez 2008; Valdez-Fragoso et al. 2010), the inactivation of bacterial spores by pressure alone is not possible. Therefore, current HPP products on the market rely on refrigeration, reduced water activity and/or low pH to prevent bacterial spore outgrowth. For example, spores of six Bacillus species pressurized at 980 MPa for 40 min at room temperature showed no significant inactivation (Nakayama et al. 1996); however, pressure treatments at temperatures higher than 50 °C can be very effective for some bacterial spores (e.g., Paredes-Sabja et al. 2007). Treating Bacillus subtilis spores at 404 MPa and 70 °C for 15 min can achieve 5 decimal reductions (DRs) at neutral pH (Stewart et al. 2000). However, subjecting spores of Clostridium sporogenes, considered a non-toxigenic equivalent to proteolytic C. botulinum and an important food spoilage bacteria, to 400 MPa at 60 °C for 30 min at neutral pH yields only 1 DR (Mills et al. 1998).

Many studies have shown that it is not possible to assume that the most heat-resistant spore is also the most baroresistant. Therefore, relying on the extensive knowledge of thermal resistance to select baroresistant spores for PATP tests of food safety is not possible. For example, spores of Clostridium perfringens type A strains carrying the C. perfringens enterotoxin (cpe) gene on the chromosome (C-cpe strains) are ~60 times more heat resistant than those carrying the cpe gene on a plasmid (P-cpe strains; Sarker et al. 2000; Raju et al. 2006). Unfortunately, information on decimal thermal inactivation values (D T °C ) cannot be used to predict which strain is more difficult to inactivate in PATP-treated foods. For example, when C. perfringens spores treated in pH 6.5 buffer, heat-resistant C-cpe strain SM101 (D 100 °C = 90 min) showed significantly higher pressure inactivation (DR15 min, 650 MPa, 75 °C = 3.1) than C-cpe strain E13 (DR15 min, 650 MPa, 75 °C = 0.1) and P-cpe F5603 (DR15 min, 650 MPa, 75 °C = 2.4) with D 100 °C of 30 and 0.6 min, respectively (Sarker et al. 2000; Raju and Sarker 2005; Paredes-Sabja et al. 2007).

Although many studies have shown that PATP treatments can inactivate bacterial spores, additional research will be required to reduce the severity of PATP treatments to enhance food quality, and most importantly, to ensure the financial feasibility of this technology. PATP strategies to achieve the inactivation of bacterial spores must consider that the commercialization of PATP technologies is limited by the maximum operating pressure of industrial units (at present ~700 MPa) and cost considerations limiting pressurization time to ~15 min for commercial sterilization of foods. In Table 2, strategy (a) combined the effect of preheating to moderate temperatures, compression heating to <100 °C, decompression cooling, formulation to maximize the pressure-induced pH shift, and pressure pulsing to promote spore germination. For example, spores of five C-cpe strains and four P-cpe of C. perfringens and two strains of C. sporogenes suspended in citric acid buffer at 4.75 and 6.5 pH before pressure-induced pH shift and preheated to 55 and 75 °C before compression heating were subjected to 15-min treatments at 550 and 650 MPa (Paredes-Sabja et al. 2007). Treatments at 650 MPa, 75 °C and pH 6.5 were moderately effective against spores of P-cpe (~3.7 DR) and C. sporogenes (~2.1 DR) but not for C-cpe spores (~1.0 DR). Treatments at pH 4.75 were moderately effective against spores of P-cpe (~3.2 DR) and C. sporogenes (~2.5 DR) but not of C-cpe (~1.2 DR) when combined with 550 MPa at 75 °C. Under the same conditions but at 650 MPa, higher inactivation levels of P-cpe (~5.1 DR) and C. sporogenes (~5.8 DR) spores and moderate inactivation of C-cpe (~2.8 DR) spores were observed. Unfortunately, even these higher inactivation levels would be insufficient to meet the needs of commercial food processors.

Alternative (b) shown in Table 2 is based on food-grade additives inducing spore germination and lowering their resistance to pressure and thermal inactivation. This application will require the identification of germinants effective on the spores of interest and determination of the kinetics of germination as affected by pH, temperature, germinant concentration, and food matrix (Paredes-Sabja and Torres 2010). Knowledge of the molecular mechanisms involved will facilitate attaining the full benefits of this strategy (Paredes-Sabja et al. 2008a,b,c). Particularly important, are models for germination kinetics to determine what process and product formulation conditions should be used in combination with PATP treatments (e.g., Akhtar et al. 2009). The kinetics for the germination of spores of C. perfringens type A strains was recently obtained by Paredes-Sabja and Torres (2010). Mathematical functions based on the Weibull model for the optical density (OD) decrease, S(t), reflecting the overall loss in spore refractivity during germination can be used to describe the germination process (Rode and Foster 1962; Vary and Halvorson 1965; Collado et al. 2006):

where, OD i , OD f , and OD t are the initial, final and time t OD values while α and β are the Weibull rate index and behavior index model parameters, respectively. Estimations of model accuracy (A f ) and bias (B f ) showed an excellent fit to this model when describing the germination of C. perfringens type A food poisoning isolates in buffer solutions as affected by pH (5.8 to 8), germinant concentration (10–100 mM KCl), and spore germination temperature (TSG, 30–50 °C) (Paredes-Sabja and Torres 2010). A constant behavior index β can be used to predict the effect of T SG on germination (Fernández García et al. 2002; Mafart et al. 2002) but improved results are obtained when using the following expression:

where, a i (i = 1 to n) are model parameters obtained experimentally.

The effect of T SG on the rate index α can be assumed to follow an Arrhenius behavior:

where, α ref is the scale parameter (min), E a is the activation energy (kJ/mol), and R is the ideal gas constant (8.31 J mol−1 K−1). Combining these expressions yields the following equation to predict the effect of T SG on the germination of C. perfringens type A food poisoning isolates (Paredes-Sabja and Torres 2010):

This model was reported to fail only once by over-predicting germination for one isolate. This may reflect the need to obtain the experimental data needed to construct the germination prediction expression using as samples the product of interest instead of buffer solutions and other simple model systems. This is important as the bioavailability of the germinants is likely to affect the germination response (Paredes-Sabja and Torres 2010).

The strategy of inducing bacterial spore germination by the addition of l-asparagine and KCl as a more effective PATP spore inactivation process was investigated by Akhtar et al. (2009). The FDA authorizes the use of l-asparagine as a nutrient or dietary supplement for which a regulation of use must be issued, while KCl is a generally recognized as safe additive. The following processing strategy achieved at least 4 DR of C. perfringens spores. The first step was heating the meat at 80 °C for 10 min to pasteurize and denature meat proteins for palatability. This will also activate C. perfringens spore germination. The product was cooled in about 20 min to 55 °C and incubated 15 min at this temperature for spore germination. Inactivation of germinated spores was then achieved by a PATP treatment (586 MPa at 73 °C for 10 min).

Novel strategies achieving higher inactivation levels of bacterial spores at temperatures below 100 °C such as the one previously described will require substantial additional research. Immediately available to commercialize PATP technology, is alternative (c) in Table 2, i.e., temperatures above 100 °C to inactivate bacterial spores in a reasonably short time. The limitation of this alternative is the need for research on reaction kinetics in the pressure and temperature range required for this alternative, a severe limitation at this time (Ramírez and Torres 2009; Torres et al. 2009b; Martínez Monteagudo et al. 2011; Valdez-Fragoso et al. 2010) when compared to the large availability of data on the inactivation of bacterial spores (Reddy et al. 2003; Margosch et al. 2004, 2006a, b; Rajan et al. 2006; Ahn and Balasubramaniam 2007; Ahn et al. 2007a,b; Paredes-Sabja et al. 2007; Naim et al. 2008; Zhu et al. 2008; Juliano et al. 2009; Ratphitagsanti et al. 2009).

Nonlinear Microbial Inactivation Kinetics Models

Since pressure-treated foods first appeared on the market, significant advances in the modeling of microbial inactivation have been accomplished (e.g., McMeekin et al. 1993; Baranyi and Roberts 1995; Peleg and Cole 1998; Xiong et al. 1999a; Ahn et al. 2007b; Corradini and Peleg 2007; Klotz et al. 2007; Koseki and Yamamoto 2007b; Black and Davidson 2008; Pérez Lamela and Torres 2008b). Many authors have reported that in thermal processes, the survival curves for microorganisms deviate from the expected linear behavior (Kamau et al. 1990; Bhaduri et al. 1991; Linton et al. 1995, 1996; Anderson et al. 1996; Buzrul 2007). Models proposed to describe this non-linear behavior include the Buchanan (Xiong et al. 1999), log-logistic (Peleg et al. 2002), Gompertz (Bhaduri et al. 1991; Patterson and Kilpatrick 1998), and Weibull (Corradini and Peleg 2007) models. Experimental data obtained for microorganisms subjected to pressure treatments have been analyzed using linear (Chen 2007), Weibull (Dilek Avsaroglu et al. 2006; Koseki and Yamamoto 2007a, b), biphasic (Panagou et al. 2007), fuzzy (Ganzle et al. 2007), and other mathematical models. Some authors have described modifications of the linear model considering multi-component kinetics.

The Weibull model considers that the microbial death probability depends on the biological variation or heterogeneity within the population of a microorganism. This assumption leads to the following expression (Buzrul and Alpas 2004):

where, b and n are the scale and shape factors, respectively, which are temperature- and pressure-dependent. The coefficient b can be considered as a “rate parameter” while the exponent n is a measure of the shape of the isothermal and of the isobaric semi-logarithmic survival curve (Doona et al. 2007). While simple, this model can describe downward concave survival curves (n > 1) when damage accumulating in the survivors sensitizes them to further injury or inactivation. Upward concave curves (n < 1) suggests that the sensitive members of the population die quickly, leaving progressively more resistant survivors, a behavior previously described as “tailing”. Finally, the Weibull model includes the survival curve for the conventional first order model (n = 1; Mafart et al. 2002; Buzrul et al. 2005). Several authors have reported that the Weibull model performs much better than the classical linear inactivation model (Chen and Hoover 2003; Chen 2007; Pina Perez et al. 2007; van Boekel 2008). Another non-linear model, the log-logistic model can be described by the following mathematical expression (Cole et al. 1993; Pina Perez et al. 2007):

where, α = upper asymptote (log CFU/ml), ω = lower asymptote (log CFU/ml), σ = the maximum rate of inactivation (log (CFU/ml)/log min), and z = the log time to the maximum rate of inactivation (log min). This model is adequate to describe thermal inactivation (Little et al. 1994) but few applications to pressure processing have been reported (Guan et al. 2005). Another alternative is the modified Gompertz equation (Pina Perez et al. 2007):

where, C is the difference in value of the upper and lower asymptotes and B is the relative death rate at its maximum M. The Baranyi equation can be used in its modified form to describe microbial inactivation using the following expressions (Pina Perez et al. 2007):

where N min is the microbial population remaining in the tail phase so that if N min = 0 there is no tailing, k max is the maximum relative death rate and r is a model parameter. In conclusion, several models are available to model microbial inactivation but the general limitation is the lack of experimental values for all the model parameters. Also missing are comprehensive comparisons of the different models.

Consumer Acceptance of HPP Foods

The reasons that processors consider when investing in HPP technology include the increasing importance of eliminating microbial risks because new analytical techniques facilitate the tracking of pathogens to the processor responsible for a food poisoning outbreak. For example, when slicing meat, its handling by production workers and contact with a variety of processing and packaging equipment, introduce high product contamination risks. Another example is the treatment of cold- and hot-smoked meats, because these processes do not eliminate pathogens naturally present in these products such as Listeria monocytogenes (Tanzi et al. 2004; Rubio et al. 2010). In a survey conducted by the National Cattlemen’s Beef Association (McCarty 2008), 67% of beef consumers had seen, heard or read recently about the presence of E. coli in food. Since 83% of them acknowledged not using a thermometer to ensure safe cooking, food processors must reduce the incidence of pathogens in food, particularly in minimally processed products. In 2003, the FSIS issued a letter-of-no-objection (LNO) for the use of HPP as an effective post-packaged intervention method in controlling L. monocytogenes in ready-to-eat meat and poultry products. Health Canada issued similar LNOs for the control of L. monocytogenes in cured and uncured ready-to-eat pork products, RTE meals, and fruit preparations. Companies in the USA and Canada such as Hormel Foods, Perdue Farms, Tyson Foods, Santa Maria Foods, and Fresherized Foods are using HPP technology to meet their strict food safety programs and government regulations to deliver safer and higher quality products to the market with natural claims and clean labels (Raghubeer 2007). Other reasons to consider the implementation of HPP technology are the growing consumer demand for minimally processed products, or treated by invisible technologies because they leave no evidence of their application to foods. Also important is the need to develop high-quality functional foods with a high content of bioactive compounds for demanding niche markets such as infants and the elderly (Torres et al. 2010). A HPP colostrum beverage, developed by Fonterra in New Zealand is a good example (Halliday 2007; Hembry 2008). Another motivation for using HPP technology is the possibility of achieving longer shelf-life for export and quality superiority over products obtained by conventional technologies.

An important issue to the food industry is the low consumer confidence in processed food which has decreased in recent years, falling from 82% in 2006 to 66% in 2007 (Hollingsworth 2008). New technologies could help reverse this trend but their success is highly dependent on consumers’ acceptance and knowledge of the benefits delivered. On the other hand, novel food technologies create also high levels of consumer concern because consumers are often unaware of the processes applied to foods, and because once applied, these processes cannot be reversed. Many consumers perceive food processing as having unknown, delayed, or potentially fatal health effects (Cardello et al. 2007). However, improved taste and nutritional value are seen as the greatest potential benefits of new technologies (Deliza et al. 2003; Bruhn 2007; Cruz et al. 2010). HPP products have an excellent consumer acceptance due to a superior quality when compared to thermally processed counterparts (Wright et al. 2007). In addition to recognizing the importance of sensory properties, nutritional quality, microbial safety, and the content of bioactive compounds, studies examining consumer attitudes towards new food technologies show an increasing interest in other food qualities (Deliza et al. 2005; Mishra and Sinija 2008). Within this context, HPP technology reduces the need for preservatives and thus may contribute to positive perceptions increasing product preference and satisfaction.

In the USA, Cardello (2003) studied the attitudes towards conventional and novel food technologies of consumers and the employees of an R&D laboratory. The ones evoking the greatest concern were “genetic engineering”, “addition of bacteriocins” and “irradiation” while HPP ranked 14th among the 20 technologies surveyed. Conventional options such as “thermal energy” and “heat pasteurization” ranked 19th and 20th, respectively. Deliza et al. (2003) reported that one of the four groups studied (supermarket shoppers, housewives, female employees, and university students) lacked the knowledge of what “high pressure processing” meant. This group had the lowest product acceptance and purchase intent for novel technologies. In another study of the attitudes of military and civilian consumers of foods processed by innovative and emerging food technologies, Cardello et al. (2007) concluded that the perception of potential risk was the most important factor their interest in these processed foods regardless of the actual risks of the technology. Among the technologies assessed, irradiation and genetic engineering resulted in the greatest negative opinions while HPP yielded the most positive response of all emerging technologies. Finally, Nielsen et al. (2009) studied in six European countries the consumers’ perceptions of pulsed electric field (PEF) and HPP technologies when used to process juice and baby food. These consumers perceived as main advantages of these novel technologies the preservation of the “natural” character, improved taste and high nutritional value, whereas the main disadvantage was the lack of information about these new processes. Again, HPP showed a higher consumer acceptance when compared to PEF because it was perceived as a more “natural” technology.

The consumer studies previously described show that the lack of knowledge among consumers regarding innovative and emerging food technologies can be a major impediment to their acceptance. Thus, effective communication regarding details of processing technologies and their benefits is essential for the successful marketing of novel and conventional technology processed foods.

Conclusion

HPP was first used in the USA in the late nineteenth century. Without applying heat, treating milk at 670 MPa for 10 min achieved five to six microbial logarithmic reductions (Hite 1899). The commercialization of this discovery took almost a century due to the lack of commercial equipment capable of operating with minimal disruptions for repairs and maintenance (Torres and Velazquez 2005; Velazquez et al. 2005a,b). This limitation was overcome in the 1980s which brought the first HPP product to the market, a fruit jam in Japan. Commercial applications use 300–700 MPa for less than 3–5 min at room, or preferably refrigerated temperature for an enhanced microbial inactivation and quality retention (Torres et al. 2009a). With regards to product type and size of the companies that have adopted HPP, there are no preferences, as it has been used for meats, vegetables, fruits, purees, juices, seafood, fish, dairy, and many other product categories by transnational corporations or by small and medium size companies interested in a specialized niche market (Torres and Rios 2006; Ulloa-Fuentes et al. 2008a,b; Martínez Monteagudo et al. 2011; Torres et al. 2010).

The future of pressure processing technologies will increasingly depend on food industry support of research centers specialized in the development and commercial implementation of new technologies. On the other hand, these centers must support those entrepreneurs willing to use new technologies to improve product quality, or to develop products than are not possible with conventional technologies. A specific task is the need to accelerate the development of technologies for products that do not require low temperature during distribution and storage. Products currently obtained by HPP require refrigeration, pH <4.5 or reduced water activity to prevent the germination of bacterial spores.

References

Ahn, J., & Balasubramaniam, V. M. (2007). Effects of inoculum level and pressure pulse on the inactivation of Clostridium sporogenes spores by pressure-assisted thermal processing. Journal of Microbiology and Biotechnology, 17(4), 616–623.

Ahn, J., Balasubramaniam, V. M., & Yousef, A. E. (2007). Inactivation kinetics of selected aerobic and anaerobic bacterial spores by pressure-assisted thermal processing. International Journal of Food Microbiology, 113(3), 321–329.

Akhtar, S., Paredes-Sabja, D., Torres, J. A., & Sarker, M. R. (2009). Strategy to inactivate Clostridium perfringens spores in meat products. Food Microbiology, 26, 272–277.

Anderson, W. A., McClure, P. J., Baird Parker, A. C., & Cole, M. B. (1996). The application of a log-logistic model to describe the thermal inactivation of Clostridium botulinum 213B at temperatures below 121.1 °C. The Journal of Applied Bacteriology, 80(3), 283–290.

Baranyi, J., & Roberts, T. A. (1995). Mathematics of predictive food microbiology. International Journal of Food Microbiology, 26, 199–218.

Bhaduri, S., Smith, P. W., Palumbo, S. A., Turner Jones, C. O., Smith, J. L., Marmer, B. S., et al. (1991). Thermal destruction of Listeria monocytogenes in liver sausage slurry. Food Microbiology, 8(1), 75–78.

Black, G., & Davidson, M. (2008). Use of modelling to enhance the microbiological safety of the food system. Comprehensive Reviews in Food Science and Food Safety, 7, 159–167.

Bruhn, C. M. (2007). Enhancing consumer acceptance of new processing technologies. Innovative Food and Emerging Technologies, 8, 555–558.

Burt, S. (2004). Essential oils: their antibacterial properties and potential applications in foods—A review. International Journal of Food Microbiology, 94, 223–253.

Buzrul, S. (2007). A suitable model of microbial survival curves for beer pasteurization. Lebensmittel-Wissenschaft und Technologie, 40(8), 1330–1336.

Buzrul, S., Alpas, H., & Bozoglu, F. (2005). Use of Weibull frequency distribution model to describe the inactivation of Alicyclobacillus acidoterrestris by high pressure at different temperatures. Food Research International, 38, 151–157.

Buzrul, S., & Alpas, S. (2004). Modeling the synergistic effect of high pressure and heat on inactivation kinetics of Listeria innocua: a preliminary study. FEMS Microbiology Letters, 238, 29–36.

Cardello, A. V. (2003). Consumer concerns and expectations about novel food processing technologies: Effects on product liking. Appetite, 40(3), 217–233.

Cardello, A. V., Schutz, H. G., & Lesher, L. L. (2007). Consumer perceptions of foods processed by innovative and emerging technologies: A conjoint analytic study. Innovative Food and Emerging Technologies, 8, 73–83.

Casadei, M. A., Manas, P., Niven, G., Needs, E., & Mackey, B. M. (2002). Role of membrane fluidity in pressure resistance of Escherichia coli NCTC 8164. Applied and Environmental Microbiology, 68(12), 5965–5972.

Cassin, M. H., Paoli, G. M., & Lammerding, A. M. (1998). Simulation modeling for microbial risk assessment. Journal of Food Protection, 61(11), 1560–1566.

Chen, H. (2007). Use of linear, Weibull, and log-logistic functions to model pressure inactivation of seven foodborne pathogens in milk. Food Microbiology, 24(3), 197–204.

Chen, H., & Hoover, D. G. (2003). Pressure inactivation kinetics of Yersinia enterocolitica ATCC 35669. International Journal of Food Microbiology, 87(1–2), 161–171.

Chéret, R., Delbarre-Ladrat, C., de Lamballerie-Anton, M., & Verrez-Bagnis, V. J. (2005). High-pressure effects on the proteolytic enzymes of sea bass (Dicentrarchus labrax L.) fillets. Journal of Agricultural and Food Chemistry, 53(10), 3969–3973.

Chotyakul, N., Perez Lamela, C., & Torres, J. A. (2010). Effect of model parameter variability on the uncertainty of refrigerated microbial shelf-life estimates. Journal of Food Process Engineering. doi:10.1111/j.1745-4530.2010.00631.x.

Chotyakul, N., Velazquez, G., & Torres, J. A. (2010). Assessment of the uncertainty in thermal food processing decisions based on microbial safety objectives. Journal of Food Engineering. doi:10.1016/j.jfoodeng.2010.08.027.

Claeys, W. L., Indrawati, van Loey, A. M., & Hendrickx, M. E. (2003). Review: Are intrinsic TTIs for thermally processed milk applicable for high-pressure processing assessment? Innovative Food Science and Emerging Technologies, 4(1), 1–14.

Cole, M. B., Davies, K. W., Munro, G., Holyoak, C. D., & Kilsby, D. C. (1993). A vitalistic model to describe thermal inactivation of L. monocytogenes. Journal of Industrial Microbiology, 12, 232.

Collado, J., Fernandez, A., Rodrigo, M., & Martinez, A. (2006). Modelling the effect of a heat shock and germinant concentration on spore germination of a wild strain of Bacillus cereus. International Journal of Food Microbiology, 106(1), 85–89.

Corbo, M. R., Bevilacqua, A., Campaniello, D., D’Amato, D., Speranza, B., & Sinigaglia, M. (2009). Prolonging microbial shelf life of foods through the use of natural compounds and non-thermal approaches - a review. International Journal of Food Science & Technology, 44, 223–241.

Corradini, M. G., & Peleg, M. (2007). A Weibullian model for microbial injury and mortality. International Journal of Food Microbiology, 119(3), 319–328.

Cruz, R. M. S., Rubilar, J. F., Ulloa, P. A., Torres, J. A., & Vieira, M. C. (2010). New food processing technologies: development and impact on the consumer acceptability. In F. Columbus (Ed.), Food quality: Control, analysis and consumer concerns, pp yy. New York, NY: Nova Science Publishers.

Deliza, R., Rosenthal, A., Abadio, F. B. D., Silva, C. H. O., & Castillo, C. (2005). Application of high pressure technology in the fruit juice processing: Benefits perceived by consumers. Journal of Food Engineering, 67, 241–246.

Deliza, R., Rosenthal, A., & Silva, A. L. S. (2003). Consumer attitude towards information on non-conventional technology. Trends in Food Science and Technology, 14, 43–49.

Denys, S., Ludikhuyze, L. R., van Loey, A. M., & Hendrickx, M. E. (2000). Modeling conductive heat transfer and process uniformity during batch high-pressure processing of foods. Biotechnology Progress, 16(1), 92–101.

Denys, S., van Loey, A. M., & Hendrickx, M. E. (2000). A modeling approach for evaluating process uniformity during batch high hydrostatic pressure processing: combination of a numerical heat transfer model and enzyme inactivation kinetics. Innovative Food Science & Emerging Technologies, 1, 5–19.

Dilek Avsaroglu, M., Buzrul, S., Alpas, H., Akcelik, M., & Bozoglu, F. (2006). Use of the Weibull model for lactococcal bacteriophage inactivation by high hydrostatic pressure. International Journal of Food Microbiology, 108(1), 78–83.

Doona, C. J., Feeherry, F. E., Ross, E. W., Corradini, M., & Peleg, M. (2007). The quasi-chemical and Weibull distribution models of nonlinear inactivation kinetics of Escherichia coli ATCC 11229 by high pressure processing. In C. J. Doona & F. E. Feeherry (Eds.), High pressure processing of foods (pp. 115–144). Ames, Iowa, USA: Blackwell Publishing.

El’Yanov, B. S., & Hamann, S. D. (1975). Some quantitative relationships for ionization reactions at high pressure. Australian Journal of Chemistry, 28, 945–954.

Farnaud, S., & Evans, R. W. (2003). Lactoferrin—A multifunctional protein with antimicrobial properties. Molecular Immunology, 40(7), 395–405.

Farnaud, S., Spiller, C., Moriarty, L. C., Patel, A., Gant, V., Odell, E. W., et al. (2004). Interactions of lactoferricin-derived peptides with LPS and antimicrobial activity. FEMS Microbiology Letters, 233, 193–199.

Fernández García, A., Collado, J., Cunha, L. M., Ocio, M. J., & Martinez, A. (2002). Empirical model building based on Weibull distribution to describe the joint effect of pH and temperature on the thermal resistance of Bacillus cereus in vegetable substrate. International Journal of Food Microbiology, 77(1–2), 147–153.

Floschet, F., Geeraerd, A. H., Scheerlinck, N., Nicolai, B. M., & van Impe, J. F. (2003). Monte Carlo analysis as a tool to incorporate variation on experimental data in predictive microbiology. Food Microbiology, 20, 285–295.

Ganzle, M. G., Kilimann, K. V., Hartmann, C., Vogel, R., & Delgado, A. (2007). Data mining and fuzzy modelling of high pressure inactivation pathways of Lactococcus lactis. Innovative Food Science & Emerging Technologies, 8, 461–468.

Grauwet, T., van der Plancken, I., Vervoort, L., Hendrickx, M. E., & van Loey, A. (2009). Investigating the potential of Bacillus subtilis a-amylase as a pressure-temperature-time indicator for high hydrostatic pressure pasteurization processes. Biotechnology Progress, 25(4), 1184–1193.

Grauwet, T., van der Plancken, I., Vervoort, L., Hendrickx, M. E., & van Loey, A. (2010). Solvent engineering as a tool in enzymatic indicator development for mild high pressure pasteurization processing. Journal of Food Engineering, 97, 301–310.

Guan, D., Chen, H., & Hoover, D. (2005). Inactivation of Salmonella typhimurium DT 104 in UHT whole milk by high hydrostatic pressure. International Journal of Food Microbiology, 104, 145–153.

Halliday J (2007) Fonterra innovation takes colostrum into functional beverages. Available from: http://www.ap-foodtechnology.com/content/view/print/26182. Accessed on 6 Nov 2010.

Hartmann, C., & Delgado, A. (2002). Numerical simulation of convective and diffusive transport effects on a high-pressure-induced inactivation process. Biotechnology and Bioengineering, 79(1), 94–104.

Hayakawa, I., Kanno, T., Tomita, M., & Fujio, Y. (1994). Application of high pressure for spore inactivation and protein denaturation. Journal of Food Science, 59, 159–163.

Hembry O (2008) Fonterra health drink thrives under pressure. Available from: http://www.nzherald.co.nz/business/news/article.cfm?c_id=3&objectid=10521364. Accessed on: 6 Nov 2010.

Hendrickx, M. E., Ludikhuyze, L. R., van den Broeck, I., & Weemaes, C. A. (1998). Effects of high-pressure on enzymes related to food quality. Trends in Food Science and Technology, 9, 197–203.

Hernando Saiz, A., Tarrago Mingo, S., Purroy Balda, F., & Tonello Samson, C. (2008). Advances in design for successful commercial high pressure food processing. Food Australia, 60(4), 154–156.

Hite, B. H. (1899). The effects of pressure in the preservation of milk. Bulletin West Virginia University Agricultural Experiment Station, Morgantown, 58, 15–35.

Hollingsworth J (2008) Retailer perspective: AMI-NMA E. coli O157:H7 surveillance and prevention briefing. American Meat Institute. http://www.meatami.com/ht/a/GetDocumentAction/i/11125. Accessed on 19 Aug 2010.

Hurtado, J. L., Montero, P., Borderías, A. J., & An, H. (2002). Properties of proteolytic enzymes from muscle of octopus (Octopus vulgaris) and effects of high hydrostatic pressure. Journal of Food Science, 67(7), 2555–2564.

Iucci, L., Lanciotti, R., Kelly, A. L., & Huppertz, T. (2008). Plasmin activity in high-pressure-homogenised bovine milk. Milchwissenschaft, 63(1), 68–70.

Juliano, P., Knoerzer, K., Fryer, P. J., & Versteeg, C. (2009). C. botulinum inactivation kinetics implemented in a computational model of a high-pressure sterilization process. Biotechnology Progress, 25(1), 163–175.

Kamau, D. N., Doores, S., & Pruitt, K. M. (1990). Antibacterial activity of the lactoperoxidase system against Listeria monocytogenes and Staphylococcus aureus in milk. Journal of Food Protection, 53(12), 1010–1014.

Khurana, M., & Karwe, M. V. (2009). Numerical prediction of temperature distribution and measurement of temperature in a high hydrostatic pressure food processor. Food and Bioprocess Technology, 2, 279–290.

Klotz, B., Pyle, D. L., & Mackey, B. M. (2007). New mathematical modeling approach for predicting microbial inactivation by high hydrostatic pressure. Applied and Environmental Microbiology, 73(8), 2468–2478.

Koseki, S., & Yamamoto, K. (2007a). Modelling the bacterial survival/death interface induced by high pressure processing. International Journal of Food Microbiology, 116(1), 136–143.

Koseki, S., & Yamamoto, K. (2007b). A novel approach to predicting microbial inactivation kinetics during high pressure processing. International Journal of Food Microbiology, 116(2), 275–282.

Kouassi, G. K., Anantheswaran, R. C., Knabel, S. J., & Floros, J. D. (2007). Effect of high-pressure processing on activity and structure of alkaline phosphatase and lactate dehydrogenase in buffer and milk. Journal of Agricultural and Food Chemistry, 55, 9520–9529.

Lado, B. H., & Yousef, A. E. (2002). Alternative food-preservation technologies: Efficacy and mechanisms. Microbes and Infection, 4, 433–440.

Lakshmanan, R., Patterson, M. F., & Piggott, J. R. (2005). Effects of high-pressure processing on proteolytic enzymes and proteins in cold-smoked salmon during refrigerated storage. Food Chemistry, 90, 541–548.

Linton, R. H., Carter, W. H., Pierson, M. D., & Hackney, C. R. (1995). Use of a modified Gompertz equation to model nonlinear survival curves for Listeria monocytogenes Scott A. Journal of Food Protection, 58(9), 946–954.

Linton, R. H., Carter, W. H., Pierson, M. D., Hackney, C. R., & Eifert, J. D. (1996). Use of a modified Gompertz equation to predict the effects of temperature, pH, and NaCl on the inactivation of Listeria monocytogenes Scott A heated in infant formula. Journal of Food Protection, 59(1), 16–23.

Little, C. L., Adams, M. R., Anderson, W. A., & Cole, M. B. (1994). Application of a log-logistic model to describe the survival of Yersinia enterocolitica at sub-optimal pH and temperature. International Journal of Food Microbiology, 22(1), 63–71.

Lopez-Malo, A., Palou, E., Barbosa-Cánovas, G. V., Welti-Chanes, J., & Swanson, B. G. (1999). Polyphenoloxidase activity and color changes during storage of high hydrostatic pressure treated avocado puree. Food Research International, 31(8), 549–556.

Ludikhuyze L, van den Broeck I, Indrawati & Hendrickx ME (2002) High pressure processing of fruits and vegetables. In: Jongen W (ed) Fruits and vegetable processing: improving quality. CRC Press Inc.: New York, NY.

Mafart, P., Couvert, O., Gaillard, S., & Leguerinel, I. (2002). On calculating sterility in thermal preservation methods: Application of the Weibull frequency distribution model. International Journal of Food Microbiology, 72(1–2), 107–113.

Margosch, D., Ehrmann, M. A., Buckow, R., Heinz, V., Vogel, R. F., & Ganzle, G. (2006a). High-pressure-mediated survival of Clostridium botulinum and Bacillus amyloliquefaciens endospores at high temperature. Applied and Environmental Microbiology, 72(5), 3476–3481.

Margosch, D., Ehrmann, M. A., Buckow, R., Heinz, V., Vogel, R. F., & Gänzle, M. G. (2006b). High-pressure-mediated survival of Clostridium botulinum and Bacillus amyloliquefaciens endospores at high temperature. Applied and Environment Microbiology, 72(5), 3476–3481.

Margosch, D., Ehrmann, M. A., Gaenzle, M. G., & Vogel, R. F. (2004). Comparison of pressure and heat resistance of Clostridium botulinum and other endospores in mashed carrots. Journal of Food Protection, 67(11), 2530–2537.

Martínez Monteagudo SI, Leal Dávila M, Saldaña MDA, Torres JA & Welti Chanes J (2011) Nuevas tecnologías para la industria de alimentos en México utilizando la alta presión hidrostática. Industria Alimentaria, 32 (in press).

Mathys, A., Kallmeyer, R., Heinz, V., & Knorr, D. (2008). Impact of dissociation equilibrium shift on bacterial spore inactivation by heat and pressure. Food Control, 19(12), 1165–1173.

McCarty R (2008) Consumer perceptions of beef safety and E. coli O157:H7. American Meat Institute. http://www.meatami.com/index.php?display=GeneralSearch&action=AddSearchTermAction&searchstring=mccarty. Accessed on 19 Aug 2010.

McMeekin, T. A., Olley, J. N., Ross, T., & Ratkowsky, D. A. (1993). Predictive microbiology: Theory and application. LTD, Somerset, England: Research Studies Press.

Mills, G., Earnshaw, R., & Patterson, M. F. (1998). Effect of high hydrostatic pressure on Clostridium sporogenes spores. Letters in Applied Microbiology, 26, 227–230.

Mishra, H. N., & Sinija, V. R. (2008). Food technology to meet the changing needs of urban consumers. Comprehensive Reviews in Food Science and Food Safety, 7, 358–368.

Moermann, F. (2005). High hydrostatic pressure inactivation of vegetative microorganisms, aerobic and anaerobic spores in pork Marengo, a low acidic particulate food product. Meat Science, 69, 225–232.

Morales-Blancas EF & Torres JA (2003a) Activation energy in thermal process calculations. Encyclopedia of Agricultural, Food, and Biological Engineering. Marcel Dekker, Inc: New York. pp 1–4.

Morales-Blancas EF & Torres JA (2003b) Thermal resistance constant. Encyclopedia of Agricultural, Food, and Biological Engineering. Marcel Dekker, Inc: New York. pp 1030–1037.

Morales-Blancas EF & Torres JA (2003c) Thermal resistance parameters, determination of. Encyclopedia of Agricultural, Food, and Biological Engineering. Marcel Dekker, Inc: New York. pp 1038–1043.

Mozhaev, V. V., Heremans, K., Frank, J., Masson, P., & Balny, C. (1996). High-pressure effects on protein structure and function. Proteins: Structure, Function, and Genetics, 24, 81–91.

Mozhaev, V. V., Lange, R., Kudryashova, E. V., & Balny, C. (1996). Application of high hydrostatic pressure for increasing activity and stability of enzymes. Biotechnology and Bioengineering, 52, 320–331.

Naim, F., Zareifard, M. R., Zhu, S., Huizing, R. H., Grabowski, S., & Marcotte, M. (2008). Combined effects of heat, nisin and acidification on the inactivation of Clostridium sporogenes spores in carrot-alginate particles: from kinetics to process validation. Food Microbiology, 25(7), 936–941.

Nakayama, A., Yano, Y., Kobayashi, S., Ishikawa, M., & Sakai, K. (1996). Comparison of pressure resistances of spores of six Bacillus strains with their heat resistance. Applied and Environmental Microbiology, 62, 3897–3900.

Neuman, R. C., Kauzmann, W., & Zipp, A. (1973). Pressure dependence of weak acid ionization in aqueous buffers. The Journal of Physical Chemistry, 77(22), 2687–2691.

Nielsen, H. B., Sonne, A., Grunert, K., Banati, D., Pollák-Tóth, A., Lakner, Z., et al. (2009). Consumer perception of the use of high-pressure processing and pulsed electric field technologies in food production. Appetite, 52, 115–126.

Norton, T., & Sun, D.-W. (2008). Recent advances in the use of high pressure as an effective processing technique in the food industry. Food Bioprocess Technology, 1(1), 2–34.

Otero, L., Molina-García, A. D., & Sanz, P. D. (2002). Some interrelated thermophysical properties of liquid water and ice I: A user-friendly modelling review for high-pressure processing (www.if.csic.es/programs/ifiform.htm). Critical Reviews in Food Science and Nutrition, 42, 339–352.

Otero, L., Ousegui, A., Guignon, B., le Bail, A., & Sanz, P. D. (2006). Evaluation of the thermophysical properties of tylose gel under pressure in the phase change domain. Food Hydrocolloids, 20(4), 449–460.

Otero, L., Ramos, A. M., de Elvira, C., & Sanz, P. D. (2007). A model to design high-pressure processes towards a uniform temperature distribution. Journal of Food Engineering, 78, 1463–1470.

Otero, L., & Sanz, P. D. (2003). Modelling heat transfer in high pressure food processing: A review. Innovative Food Science & Emerging Technologies, 4, 121–134.

Palou, E., Hernandez-Salgado, C., Lopez-Malo, A., Barbosa-Cánovas, G. V., Swanson, B. G., & Welti, J. (2000). High pressure-processed guacamole. Innovative Food Science & Emerging Technologies, 1, 69–75.

Palou, E., Lopez-Malo, A., Barbosa-Cánovas, G. V., Welti-Chanes, J., & Swanson, B. G. (1999). Polyphenoloxidase activity and color of blanched and high hydrostatic pressure treated banana purée. Journal of Food Science, 64, 42–45.

Panagou, E. Z., Tassou, C. C., Manitsa, C., & Mallidis, C. (2007). Modelling the effect of high pressure on the inactivation kinetics of a pressure-resistant strain of Pediococcus damnosus in phosphate buffer and gilt-head seabream (Sparus aurata). Journal of Applied Microbiology, 102(6), 1499–1507.

Paredes-Sabja, D., Gonzalez, M., Sarker, M. R., & Torres, J. A. (2007). Combined effects of hydrostatic pressure, temperature, and pH on the inactivation of spores of Clostridium perfringens type A and Clostridium sporogenes in buffer solutions. Journal of Food Science, 72(6), M202–M206.

Paredes-Sabja, D., Sarker, N., Setlow, B., Setlow, P., & Sarker, M. R. (2008). Roles of DacB and Spm proteins in Clostridium perfringens spore resistance to moist heat, chemicals, and UV radiation. Applied and Environmental Microbiology, 74(12), 3730–3738.

Paredes-Sabja, D., Setlow, B., Setlow, P., & Sarker, M. R. (2008). Characterization of Clostridium perfringens spores that lack SpoVA proteins and dipicolinic acid. Journal of Bacteriology, 190(13), 4648–4659.

Paredes-Sabja, D., & Torres, J. A. (2010). Modeling of the germination of spores from Clostridium perfringens food poisoning isolates. Journal of Food Process Engineering, 33, 150–167.

Paredes-Sabja, D., Torres, J. A., Setlow, P., & Sarker, M. R. (2008). Clostridium perfringens spore germination: characterization of germinants and their receptors. Journal of Bacteriology, 190(4), 1190–1201.

Patterson, M. F., & Kilpatrick, D. J. (1998). The combined effect of high hydrostatic pressure and mild heat on inactivation of pathogens in milk and poultry. Journal of Food Protection, 61(4), 432–436.

Peleg, M., & Cole, M. B. (1998). Reinterpretation of microbial survival curves. Critical Reviews in Food Science and Nutrition, 38(5), 353–380.

Peleg, M., Engel, R., Gonzalez Martinez, C., & Corradini, M. G. (2002). Non-Arrhenius and non-WLF kinetics in food systems. Journal of the Science of Food and Agriculture, 82(12), 1346–1355.

Pérez Lamela, C., & Torres, J. A. (2008a). Pressure-assisted thermal processing: A promising future for high flavour quality and health-enhancing foods—Part 1. AgroFOOD Industry Hi-tech, 19(3), 60–62.

Pérez Lamela, C., & Torres, J. A. (2008b). Pressure processing of foods: Microbial inactivation and chemical changes in pressure-assisted thermal processing (PATP)-part 2. AgroFOOD Industry Hi-tech, 19(4), 34–36.

Pina Perez, M. C., Rodrigo Aliaga, D., Saucedo Reyes, D., & Martinez Lopez, A. (2007). Pressure inactivation kinetics of Enterobacter sakazakii in infant formula milk. Journal of Food Protection, 70(10), 2281–2289.

Rademacher, B., & Hinrichs, J. (2006). Effects of high pressure treatment on indigenous enzymes in bovine milk: Reaction kinetics, inactivation and potential application. International Dairy Journal, 16(6), 655–661.

Raghubeer EV (2007) The effects of high hydrostatic pressure on meats. In: White Paper, Avure Technologies, Inc., Kent, WA.

Rajan, S., Ahn, J., Balasubramanian, V. M., & Yousef, A. E. (2006). Combined pressure–thermal inactivation kinetics of Bacillus amyloliquefaciens spores in egg patty mince. Journal of Food Protection, 69, 853–860.

Raju, D., & Sarker, M. R. (2005). Comparison of the heat sensitivities of vegetative cells and spores of wild-type, cpe knock-out and cpe plasmid-cured Clostridium perfringens. Applied and Environmental Microbiology, 71, 7618–7620.

Raju, D., Waters, M., Setlow, P., & Sarker, M. R. (2006). Investigating the role of small, acid-soluble spore proteins (SASPs) in the resistance of Clostridium perfringens spores to heat. BMC Microbiology, 6, 50.

Ramirez, R., Saraiva, J. A., Perez Lamela, C., & Torres, J. A. (2009). Reaction kinetics analysis of chemical changes in pressure-assisted thermal processing, PATP. Food Engineering Reviews, 1(1), 16–30.

Ramírez, R., & Torres, J. A. (2009). Chemical and quality changes when seeking fuller utilization of seafood resources by pressure processing technologies. Fish Processing byproducts. A Sustainable Future. Fairbanks, AK: Alaska Sea Grant, University of Alaska, 189–206.

Ratphitagsanti, W., Ahn, J., Balasubramaniam, V. M., & Yousef, A. E. (2009). Influence of pressurization rate and pressure pulsing on the inactivation of Bacillus amyloliquefaciens spores during pressure-assisted thermal processing. Journal of Food Protection, 72(4), 775–782.

Reddy, N. R., Solomon, H. M., Tetzloff, R. C., & Rhodehamel, E. J. (2003). Inactivation of Clostridium botulinum type A spores by high-pressure processing at elevated temperature. Journal of Food Protection, 66, 1402–1407.

Reyns, K. M. F. A., Soontjens, C. C. F., Cornelis, K., Weemaes, C. A., Hendrickx, M. E., & Michiels, C. W. (2000). Kinetic analysis and modelling of combined high-pressure-temperature inactivation of the yeast Zygosaccharomyces bailii. International Journal of Food Microbiology, 56(2/3), 199–210.

Rode, L. J., & Foster, J. W. (1962). Ionic germination of spores of Bacillus megaterium QM B 1551. Archiv für Mikrobiologie, 43, 183–200.

Rubio, B., Martinez, B., Garcia-Cachan, M. D., Rovira, J., & Jaime, I. (2010). The effects of HPP treatment on Listeria monocytogenes inoculated in dry-cured meat products. Fleischwirtschaft, 90(4), 188–192.

San Martin-Gonzalez, M. F., Welti-Chanes, J., & Barbosa-Canovas, G. V. (2006). Cheese manufacture assisted by high pressure. Food Reviews International, 22(3), 275–289.

San Martin, M. F., Barbosa-Cánovas, G. V., & Swanson, B. G. (2002). Food processing by high hydrostatic pressure. Critical Reviews in Food Science and Nutrition, 42(6), 627–645.

Sarker, M. R., Shivers, R. P., Sparks, S. G., Juneja, V. K., & McClane, B. A. (2000). Comparative experiments to examine the effects of heating on vegetative cells and spores of Clostridium perfringens isolates carrying plasmid genes versus chromosomal enterotoxin genes. Applied and Environmental Microbiology, 66, 3234–3240.

Schmidheiny K (2008) Monte Carlo experiments. In Short Guides to Microeconometrics, Universitat Pompeu Fabra, Barcelona, Spain. http://kurt.schmidheiny.name/teaching/montecarlo2up.pdf. Accessed on 15 Nov 2009.

Shimada, S., Andou, M., Naito, N., Yamada, N., Osumi, M., & Hayashi, R. (1993). Effects of hydrostatic pressure on the ultrastructure and leakage of internal substances in the yeast Saccharomyces cerevisiae. Applied Microbiology and Biotechnology, 40, 123–131.

Smelt, J. P. P. M., Hellemons, J. C., Wouters, P. C., & van Gerwen, S. J. C. (2002). Physiological and mathematical aspects in setting criteria for decontamination of foods by physical means. International Journal of Food Microbiology, 78, 57–77.

Stewart, C. M., Dunne, C. P., Sikes, A., & Hoover, D. G. (2000). Sensitivity of spores of Bacillus subtilis and Clostridium sporogenes PA 3679 to combinations of high hydrostatic pressure and other processing parameters. Innovative Food Science & Emerging Technologies, 1(1), 49–56.

Tanzi, E., Saccani, G., Barbuti, S., Grisenti, M. S., Lori, D., Bolzoni, S., et al. (2004). High pressure treatment of raw ham, sanitation and impact on quality. Industria Conserve, 79(1), 37–50.

Torres, J. A., Chotyakul, N., Velazquez, G., Saraiva, J. A., & Perez Lamela, C. (2010). Integration of statistics and food process engineering: Assessing the uncertainty of thermal processing and shelf-life estimations. Logroño, La Rioja, España: VI Congreso Español de Ingeniería de Alimentos.

Torres, J. A., & Rios, R. A. (2006). Alta presión hidrostática: Una tecnología que irrumpirá en Chile (pp. 40–43). Febrero: Agro Economico.

Torres, J. A., Sanz, P. D., Otero, L., Pérez Lamela, C., & Saldaña, M. D. A. (2009a). Engineering principles to improve food quality and safety by high pressure processing. In E. Ortega-Rivas (Ed.), Processing effects on safety and quality of foods (pp. 379–414). Boca Raton, FL: CRC Taylor & Francis, Inc.

Torres, J. A., Sanz, P. D., Otero, L., Pérez Lamela, C., & Saldaña, M. D. A. (2009b). Temperature distribution and chemical reactions in foods treated by pressure-assisted thermal processing. In E. Ortega-Rivas (Ed.), Processing effects on safety and quality of foods (pp. 415–440). Boca Raton, FL: CRC Taylor & Francis, Inc.

Torres, J. A., & Velazquez, G. (2005). Commercial opportunities and research challenges in the high pressure processing of foods. Journal of Food Engineering, 67(1–2), 95–112.

Torres, J. A., & Velazquez, G. (2008). Hydrostatic pressure processing of foods. In S. Jun & J. Irudayaraj (Eds.), Food processing operations modeling: design and analysis (pp. 173–212). Boca Ratón, FL: CRC Press Inc.

Ulloa-Fuentes, P. A., Galotto, M. J., & Torres, J. A. (2008a). Procesos térmicos asistidos por presión (PTAP), el futuro de una nueva tecnología ya instalada en México - Part II. Industria Alimentaria (México), 30(3), 19–23.

Ulloa-Fuentes PA, Galotto MJ & Torres JA (2008b) Procesos térmicos asistidos por presión (PTAP), el futuro de una nueva tecnología ya instalada en México—Parte I. Industria Alimentaria (México), 30(2), 20, 22, 24, 26, 28, 29.