Abstract

Polycaprolactone (PCL) polymer has been surface modified using oxygen low-temperature plasma and melt extruded into single filaments. Oxygen plasma was generated using a radiofrequency source with power of 150 W. The PCL polymer samples were treated with plasma for various durations of 5 min, 10 min, and 20 min. Water contact angle measurements were carried out to assess the wettability, revealing that the treatments reduced the contact angle by up to 11°. Changes in the chemical bonding and surface compositions were characterized by using x-ray photoelectron spectroscopy and Fourier-transform infrared spectroscopy, revealing a high concentration of oxygen functionalities on the surface. Crystallinity changes were studied by using x-ray diffraction analysis. The surface morphology of the polymer was investigated using field-emission scanning electron microscopy. The thermal degradation and melting behavior was studied using thermogravimetric analysis and differential scanning calorimetry, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recently, plasmas have been used extensively in the design of advanced materials, particularly for adhesion and surface modifications. Although plasmas have long been known to the scientific community, good understanding of the physics and chemistry of their interaction with materials is still lacking. However, materials scientists continue to look for various avenues via which plasmas could be incorporated to enhance the end functionality of products, particularly in biomedical and green energy industries.1 Biopolymers are currently preferred materials for use in biological applications such as tissue engineering because of their easy processing flexibility, biodegradability, and biocompatibility in comparison with metallic or ceramic counterparts.2,3 Biopolymers can be broadly classified into natural and synthetic polymers. Natural polymers mainly consist of polysaccharides and proteins. In spite of their good biocompatibility, their use in medical fields is limited because of a strong immunogenic response, complex purification process, and the possibility of disease transmission.4 A good alternative is to use synthetic biopolymers such as aliphatic polyesters, polyhydroxyalkonates, or polypropylene fumarate, to name a few. Among these, aliphatic polyesters are the most popular for use in tissue engineering applications. The main advantage of aliphatic polyesters is their ability to degrade biologically in controlled physiological environments. The most commonly used aliphatic polyesters for biomedical applications are polyglycolide (PGA), polylactide (PLA), polycaprolactone (PCL), and their copolymers (copolylactones). PCL is a semicrystalline polyester and is Food and Drug Administration (FDA) approved for use in medical applications, being beneficial for tissue regeneration and drug delivery applications due to its biocompatibility, processability, degradability, and mechanical properties.5,6,–7 However, it is considered to be a hydrophobic material, which restricts its use in polymeric scaffolds for tissue engineering. The biocompatibility of a material is related to the mechanisms by which it interacts with its biological environment. Since materials interact with tissues through cell adhesion, the biocompatibility of materials is very closely related to cell adhesion.8 Hence, the surface wettability and osteoconductivity of PCL materials must be improved, given the low cell attachment and proliferation on untreated PCL scaffolds.9,10

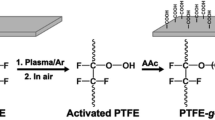

To address this issue of hydrophobicity of PCL, researchers have tried various surface modification methods based on flame treatment, corona discharge, photon, electron, and ion beams, and x- and γ-rays. Among these methods, plasma treatments are the most promising, as they are solvent free and very effective for surface modification and improving the biological properties without affecting other desired properties.11 Low-temperature plasmas (LTPs) are a unique state of matter due to the presence of neutral atoms and molecules, radicals, excited states, ions, and electrons. They contain characteristic electron energies of a few to 10 eV with ionization degrees that are typically small but can be increased to higher values, particularly in arc discharges. These energetic electrons can generate radicals, charged species, excited states, and photons. At low pressures, space-charge sheaths at the plasma boundaries can accelerate and deliver fluxes of ions to surfaces with adjustable energies ranging from a few to hundreds of eV. These ion fluxes permit surface modification by sputtering, etching, activation, and deposition, which is important for technological devices ranging from etching and deposition of materials in microelectronics to medical implants.12 The use of plasmas for surface modifications of biomaterials is considered very useful compared with other wet chemical processes, as plasmas can induce functionalities resulting in unique electronic, optical, mechanical, and biological properties.13

Experimental studies have shown that plasma treatments can change or improve the surface properties of targeted polymers. Hence, plasma treatments can be used for surface modification or thin-layer coating on the polymeric surface, while the control of both the surface chemical composition and physical topography of the polymers is possible by controlling different parameters. Specifically, plasma surface modification can introduce functional groups, surface roughness control, crosslink formation, and graft polymerization on polymeric surfaces.14 Plasma treatments have frequently been used to insert chemically reactive functional groups onto polymer substrates. Typical plasma treatments by oxygen, ammonia, or even air can generate carboxyl groups.15,16,17,–18 Such polymer treatments have been shown to increase not only the wettability and adhesion properties but also mechanical properties.19 A considerable amount of research is currently being carried out to improve the surface characteristics of PCL polymers to promote cell adhesion using plasma treatments. In particular, a focus of such research has been the use of air, oxygen, and ammonia plasmas to promote the hydrophilic nature of the polymer surface.20 The idea is to replace the weak chemical bonds on the surface of neat PCL with highly reactive amine, carboxyl, hydroxyl, and aldehyde groups.21,22,23,–24 Plasma treatments can also affect the crystallinity of the polymer, which also greatly affects the cell adhesion.25,26

Prabhakaran et al. fabricated PCL nanofibrous scaffolds using an electrospinning technique and modified the surface using plasma treatments, reporting a 17% increase in cell proliferation after plasma treatments.27 In another study, Ma et al. reported an increase in cell proliferation and spreading when using air plasma treatments on electrospun PCL nanofibers, mainly through the introduction of COOH groups.28 Fujihara et al.29 and Zander et al.30 both used air plasma treatments as a supplementary process in the fabrication of materials to improve the biocompatibility, varying the voltage and treatment time. The proliferation was improved due to oxygen-containing polar groups. In another study, Martins et al. used two types of gases (Ar and O2), two powers (20 W and 30 W), and two exposure times (5 min and 10 min) and claimed that, although the surface properties contribute substantially to the physicochemical properties and cellular performance of scaffolds, to achieve the best results various parameters must be optimized.11 Similarly, Jacobs et al.31 employed three types of gas (air, Ar, and He), three powers (1.1 W, 1.6 W, and 2.1 W) and three ranges of exposure times (0–30 s, 0–70 s, and 0–90 s). They found that the discharge atmosphere had a significant effect on the PCL surface modification, but the results obtained revealed no conclusive trend with respect to the other variables (power and time). Herrera et al.32 investigated the effect of power (10 W, 20 W, and 30 W) and exposure time (1 min, 3 min, and 5 min) for air plasma treatment on an electrospun PCL mesh. They claimed that increasing the surface energy affected the hydrophilicity of material via the generation of polar groups without affecting the morphological properties of the material. More recently, Asadian et al.33 used atmospheric plasma jets to plasma-treat PCL solution before generating nanofibers, observing a great influence of pretreatments on the morphology of the electrospun PCL nanofibers. These enhancements were attributed to increased solution conductivity, which acted as a process improvement parameter. However, the wettability of polymer nanofibers still had to be enhanced by applying a second plasma treatment to the synthesized nanofibers. In a typical plasma generation process, electrons gain energy from the applied electric energy. Upon further energy addition, electrons are accelerated until they gain sufficient energy to cause electron ejection or bond breaking, resulting in the formation of positive ions, molecular fragments, or free radicals. However, there is still a lack of basic knowledge on the processes that take place at the surface level due to plasma–surface interactions. While researchers are trying to understand these interactions, it is evident that plasma processes can be leveraged to explore various avenues of material design.

It is clear from the above-mentioned studies that further studies must be conducted to effectively take advantage of plasma modifications of polymers, particularly for biomedical applications. More information in this area will help researchers and engineers clearly establish the effect of each variable on the physicochemical and biological properties of the developed scaffolds. The purpose of the present study is thus to contribute to the scientific findings on plasma treatments of biopolymers and thereby enhance their use in tissue engineering applications. Oxygen plasma treatment results in oxygen or hydroxyl group functionalization. These functionalities can help in the formation of secondary bonding or esterification during extrusion, which can aid polymer chain organization during extrusion, affecting the crystallinity of the extruded filaments. The polymer chain conformations and crystallinity can then further influence the viscoelastic, thermal, and mechanical properties of the bulk polymer. To the best of the authors’ knowledge, there have been no studies on how plasma treatments of PCL pellets before extrusion affect the crystallinity and thermal properties of extruded PCL filaments, which can be used for making scaffolds using three-dimensional (3D) printing techniques for tissue engineering applications. Plasma treatment is affected by various parameters such as the plasma power, gas flow rate, chamber pressure, distance of the sample from the plasma discharge, and exposure time. The aim of this work is to investigate the effects of oxygen plasma treatment at 150 W for different durations (5 min, 10 min, and 20 min) on the surface modification of PCL pellets and the resulting effect on crystallinity and thermal properties of the extruded filaments. Spectroscopic studies including XPS and FTIR spectroscopy were applied to investigate the surface chemistry; Morphological changes were studied using SEM and XRD analysis. Hydrophilicity changes were monitored using water contact angle measurements. The thermal properties and crystallinity changes of the extruded filaments were studied using XRD analysis, TGA, and DSC techniques.

Experimental Procedures

Materials and Methods

Polycaprolactone polymer pellets with average molecular weight of 50,000 and average size of 3 mm were kindly provided as research samples by Perstorp UK under the trade name CAPA 6500.

Experimental Setup

PE-100 equipment from Plasma Etch was used for LTP treatments. The design of the machine was custom modified with a rotating circular drum for use as a sample holder to ensure uniform functionalization of the powder materials (Fig. 1). Pellets were plasma treated in the presence of oxygen gas at chamber pressure of 0.2 mTorr and constant flow of 30 ccm at radiofrequency (RF) power of 150 W generated at a standard frequency of 13.5 MHz for three different durations of 5 min, 10 min, and 20 min. The surface-treated pellets were later used to extrude filaments with diameter of about 1.3–1.7 mm using a Haake Minilab twin-screw extruder at heating temperature of 70°C and screw speed of 75 rotations per min.

Material Characterization

Microstructural Characterization

X-ray diffraction (XRD) analysis was carried out to study the changes in the crystallinity of the polymer due to plasma functionalization, using a Bruker D8 diffractometer with a monochromatic Cu Kα radiation source at 40 kV and 40 mA. Diffraction data were collected in the 2θ range of 10°–30° at a scan rate of 0.1°/min. The surface morphology of the plasma-treated polymer pellets was studied by FE-SEM (JOEL JSM-7200F) after sputtering with a thin layer of gold/palladium under vacuum.

Chemical Modification

Chemical analysis was performed by Fourier-transform infrared-attenuated total reflectance (FTIR-ATR) spectroscopy (Thermo Scientific Nicolet iS5) using 32 averaged scans at resolution of 4 cm−1 over the range of 4000–400 cm−1. FTIR spectroscopy was conducted to investigate the effect of oxygen treatment for various durations on the functional groups on the surface of the pellets. Background spectra were taken in the empty chamber before measurements to eliminate the influence of water moisture and CO2 in the air. XPS studies were performed on pellets to characterize the surface binding energy and attachment of oxygen functionalities using a Phi Electronics, Inc. VersaProbe 5000 equipped with a monochromatic Al x-ray source with a spot size of 100 µm at 25 W. The system offers dual charge neutralization, so no corrections were made to the peak positions. Survey scans were taken with step size of 0.8 eV and pass energy of 187.85 eV. High-resolution scans were taken with step size of 0.1 eV and pass energy of 23.5 eV.

Water Contact Angle (WCA) Measurements

Water contact angle measurements (Data Physics OCA200) were performed on the pellet samples using the sessile drop method to characterize the change in hydrophilicity of the materials. Droplets with volume of 10 nanoliters were dispensed and deposited onto the substrate. Movies were recorded for at least 15 s. SCA20 software was used to analyze the images and automatically calculate the contact angle by fitting the droplet profile.

Thermal Characterization

Differential scanning calorimetry (DSC) was carried out in nonisothermal mode at a scan rate of 10°C/min using a TA Instruments Q2000 DSC. The machine was purged with dry nitrogen at 50 mL/min. The heat–cool cycle was utilized to study the thermal behavior of the material. The material was heated from room temperature to 150°C, then cooled to − 80°C again before another heating cycle was ran up to 150°C, as shown in Fig. 2. The percentage crystallinity was calculated using the enthalpy values obtained from the first melting endotherms. To calculate the percentage crystallinity, 139.5 J/g was used as the 100% crystallinity value for PCL. The influence of the plasma treatments on the thermal stability and decomposition behavior of the material was investigated using thermogravimetric analysis (TGA), employing a TA Instruments Q-500. The equipment was purged with dry nitrogen at 90 mL/min and 10 mL/min for the furnace and sample, respectively. Samples were scanned from 30°C to 500°C at ramp rate of 10°C/min, while sample weight loss data were recorded as a function of temperature. The sample weight loss and its derivative weight loss curves were obtained from each test, and thermal stability parameters such as the onset and decomposition temperatures were recorded along with the residue for each sample. Three samples from each system were scanned, and average data are presented for comparison.

Results

The surface binding energy of the oxygen-plasma-treated PCL pellets was characterized using XPS technique, revealing that the plasma treatments were effective for increasing the oxygen-related functional groups on the surface. Such enhancement can affect the hydrophilicity of the material. The results are shown in Fig. 3. The elemental composition of oxygen and carbon and the O/C ratio obtained from the XPS results revealed that, as the duration of the treatment was increased, the carbon content decreased while the oxygen content increased. The greatest oxygen content was found in the pellets treated for 20 min, in which condition the O/C ratio was also highest. To understand the surface functional groups in more detail, high-resolution C 1s spectra were studied. The quantitative results obtained from deconvolution of the graphs (not shown here) showed that the C 1s spectra could be divided into three main regions corresponding to C-C bonds at around 285 eV, C-O bonds at around 286.5 eV, and C=O bonds at around 289 eV (Table I). It was found that, initially with treatment for 5 min and 10 min, the C-O bond concentration increased, but upon further treatment, the C=O signal increased drastically for 20 min, reducing the C-O content to almost its neat counterpart. The reason for this reduction in C-C bonds and increase in C-O and C=O bonds after 5 min and 10 min is due to the introduction of new functional groups of hydroxyl, carboxyl, and carbonyl. After 20 min of treatment, due to prolonged functionalization, an increase in the carbonyl (C=O) groups was observed, which may be due to condensation of hydroxyl and carbonyl groups during the treatment itself. This is also evident from the reduction of the C-O bond percentage on the surface; the decrease in hydroxyl (–OH) functionalities is not desirable in the current experiment, because they are expected to promote hydrogen bonding among the polymer chains during extrusion or even esterification. For this reason, no treatments beyond 20 min duration were performed.34

The FTIR results revealed that, even though there were no additional functional groups attached upon plasma treatments, the intensity of various groups was slightly altered (Fig. 4). The absorption bands at around 2940 cm−1 can be assigned to asymmetric stretching of C-H hydroxyl groups. The bands at 2860 cm−1 are assigned to symmetric stretching of C-H hydroxyl groups. The intensity of these peaks was not altered to a great extent. However, with prolongation of the treatment duration, there was an increase in the intensity at around 1720 cm−1 assigned to stretching vibrations of the -C=O of the ester carbonyl group along with the COOH group assigned to intensities at around 1710 cm−1. It was also found that, for treatments with shorter duration (5 min), the intensities of the peaks at around 1240 cm−1 and 1190 cm−1 associated with C-O-C and OC-O bonds increased slightly, but upon further treatment, they reduced and became almost similar to those observed for neat pellets. Thus, the results of the XPS and FTIR studies indicate that, with short durations (5 min and 10 min), the functional groups were mainly due to C-O bonding, but upon further treatment, the functionalities were more due to C=O.32

PCL polymer is semicrystalline, meaning that it contains both amorphous and crystalline regions, where each type of region can be used for different applications.25,26 XRD studies of oxygen-plasma-treated pellets revealed that, with an increase in the treatment duration of pellets, their surface became more amorphous (Fig. 5). It was found that, on increasing the treatment time, the peaks at 21.4° and 23.8°, representing its crystalline nature and being associated with diffraction from the (110) and (200) lattice planes, showed reduced intensity, indicating reduced surface crystallinity. However, as there were no additional peaks, it can be inferred that the plasma treatments did not significantly affect the crystallinity, which is expected as plasma treatments are only surface phenomena.35

Water contact angle measurements were carried out to quantify the change in the wettability of the surface of the PCL pellets (Fig. 6). The results for the plasma-treated pellets revealed an improvement in their hydrophilic nature with a reduction of the contact angle by up to 11°. The contact angle, which was initially around 67.8°, reduced to around 56.6° after oxygen plasma treatment for 20 min. However, there was not a very drastic change in the hydrophilicity of the pellets, particularly with water droplets.

SEM micrographs of plasma-treated pellets at multiple locations revealed no significant change in the surface of the pellets in terms of any pattern formation (Fig. 7a and b). However, in the case of samples treated for 20 min (Fig. 7c), rough surface groves were observed, which might be mainly due to a reduction in the surface crystallinity and weakening of the polymer surface during the treatments due to the rotation of the drum or even plasma-induced etching and polymer surface degradation. The primary focus of this (SEM) study is to determine whether any surface-level etching or crystallization occurred due to the plasma treatments. In case of samples treated for 5 min, no significant morphological changes were observed. However, in case of samples treated for 10 min and 20 min, surface-level morphological changes were observed, as confirmed for two samples in this study. During the tests, images were taken at multiple locations (from all available directions) only to confirm whether the changes were uniform and representative of the morphological effects due to plasma treatments. Importantly, the morphological changes provide only an indication of the surface-level reactions due to the plasma treatment. For this, the results of the more accurate technique of XPS are presented in Table I. For the end product, i.e., the extruded filaments, the morphological changes on the pellets (shown in SEM images) will not have any significance because, during the melt extrusion process, the pellets will be melt blended and only chemical changes in the form of surface energies will influence how the polymer chains arrange themselves. The main reason for performing SEM analysis on the pellets was to investigate whether the plasma treatment only altered the surface energy (as confirmed through XPS) or also caused any surface-level etching/crystallization.

From the DSC and TGA data (Table II), it can be inferred that plasma treatment of the pellets prior to extrusion of filaments did not have any significant effect on any of the crystallization values or decomposition values obtained from DSC and TGA graphs, respectively (Figs. 2 and 8). The amount of functionalization by C-O and C=O bonds formed during plasma treatment on the surface of the pellets was not very effective for forming any additional secondary bonds during the melt extrusion process. However, if the process is properly optimized by changing treatment parameters such as the power and duration, or even increasing the exposed surface area, there is scope for promoting secondary bonding during the extrusion process, which may help to improve the thermal properties of the material.

Conclusion

Although plasma treatments are primarily preferred as a surface modification tool, incorporation of plasma treatments during the manufacturing process itself has huge potential for the development of novel materials. Based on the results of the present study, it can be concluded that plasma treatments were successful in modifying the surface of the material in terms of binding energies via incorporation of oxygen functional groups with C-O and C=O bonding, as confirmed by XPS and FTIR studies. LTP treatments were also successful in altering the hydrophilicity of the material to some extent. However, material (pellet) modifications prior to extrusion could not translate into improvements of the thermal properties of the material, which may also be related to the mechanical stability, particularly for polymers. There is a need to optimize the process further in order to achieve desirable functionalities to promote secondary bonding among polymer chains. This could be achieved by a better understanding of the effect that various parameters have on the surface modification and functionalization of polymer bulk material and clarification of the physical and chemical processes involved in plasma generation to incorporate them into material design, particularly in the early stages of material development.

References

R. d’Agostino, P. Favia, C. Oehr, and M.R. Wertheimer, Plasma Process. Polym. 2, 7 (2005).

L.S. Nair and C.T. Laurencin, Prog. Polym. Sci. 32, 762 (2007).

H. Tian, Z. Tang, X. Zhuang, X. Chen, and X. Jing, Prog. Polym. Sci. 37, 237 (2012).

Yazhong Bu, Jianzhong Bei, and Shenguo Wang, Front. Bioeng. Biotechnol. 7, 98 (2019).

T.K. Dash and V.B. Konkimalla, J. Control. Release 158, 15 (2012).

M. Quiquerez, M. Peroglio, L. Gremillard, J. Chevalier, L. Chazeau, C. Gauthier, T. Hamaide, and A. Bignon, Key Eng. Mater. 361, 403–406 (2008).

A.P. Zhu, M.B. Chan-Park, and J.X. Gao, J. Biomed. Mater. Res. B Appl. Biomater. 76, 76 (2006).

M. Lotfi, M. Nejib, and M. Naceur, Adv. Biomater. Sci. Biomed. Appl. 8, 208 (2013).

Savelyeva MS, A.A. Abalymov, G.P. Lyubun, Vidyasheva IV, A.M. Yashchenok, T.E.L. Douglas, D.A. Gorin, and B.V. Parakhonskiy, J. Biomed. Mater. Res. A 105, 94 (2017).

S.N. Gorodzha, A.R. Muslimov, D.S. Syromotina, A.S. Timin, N.Y. Tcvetkov, K.V. Lepik, A.V. Petrova, M.A. Surmeneva, D.A. Gorin, G.B. Sukhorukov, and R.A. Surmenev, Colloids Surf. B Biointerfaces 160, 48 (2017).

Albino Martins, Elisabete D. Pinho, Susana Faria, Iva Pashkuleva, Alexandra P. Marques, Rui L. Reis, and Nuno M. Neves, Small 5, 1195 (2009).

I. Adamovich, S.D. Baalrud, A. Bogaerts, P.J. Bruggeman, M. Cappelli, V. Colombo, U. Czarnetzki, et al. J. Phys. D Appl. Phys. 508, 1 (2017).

P.K. Chu, J.Y. Chen, L.P. Wang, and N. Huang, Mater. Sci. Eng. R Rep. 36, 143 (2002).

Melanie Macgregor and Krasimir Vasilev, Materials 12, 191 (2019).

Kristen R. Kull, Michelle L. Steen, and Ellen R. Fisher, J. Membrane Sci. 246, 203 (2005).

M.R. Sanchis, V. Blanes, M. Blanes, D. Garcia, and R. Balart, Eur. Polym. J. 42, 1558 (2006).

Jiangnan Lai, Bob Sunderland, Jianming Xue, Sha Yan, Weijiang Zhao, Melvyn Folkard, Barry D. Michael, and Yugang Wang, Appl. Surf. Sci. 252, 3375 (2006).

S. Yoshida, K. Hagiwara, T. Hasebe, and A. Hotta, Surf. Coat. Technol. 233, 99 (2013).

Hisham Abourayana, Peter Dobbyn, and Denis Dowling, Plasma Processes Polym. 15, 3 (2018).

R.L. Reis and J.S. Román, Biodegradable Systems in Tissue Engineering and Regenerative Medicine (Boca Raton: CRC, 2004).

C. López-Santos, A. Terriza, J. Portoles, F. Yubero, and A.R. González-Elipe, J. Phys. Chem. C 119, 20446 (2015).

R. Ghobeira, N. De Geyter, and R. Morent, Biodegradable Polymers: Recent Developments and New Perspectives (Zagreb: IAPC, 2017), pp. 191–236.

E. Pakdel, J. Fang, L. Sun, and X. Wang. Nanocoatings for smart textiles, in Smart Textiles: Wearable Nanotechnology, edited by N.D. Yilmaz, (Wiley: Hoboken, 2018), p. 247.

A.A. Ivanova, D.S. Syromotina, S.N. Shkarina, R. Shkarin, A. Cecilia, V. Weinhardt, and T. Baumbach, et al., RSC Adv. 8, 39106 (2018).

Ita Junkar, Uroš Cvelbar, Alenka Vesel, Nina Hauptman, and Miran Mozetič, Plasma Processes Polym. 6, 667 (2009).

H. Cui and P.J. Sinko, Front. Mater. Sci. 6, 47 (2012).

M.P. Prabhakaran, J. Venugopal, C.K. Chan, and S. Ramakrishna, Nanotechnology 19, 455102 (2008).

Zuwei Ma, Wei He, Thomas Yong, and S. Ramakrishna, Tissue Eng. 11, 1149 (2005).

K. Fujihara, M. Kotaki, and S. Ramakrishna, Biomaterials 26, 4139 (2005).

N.E. Zander, J.A. Orlicki, A.M. Rawlett, and T.P. Beebe Jr, ACS Appl. Mater. Interfaces 4, 2074 (2012).

T. Jacobs, N. De Geyter, R. Morent, T. Desmet, P. Dubruel, and C. Leys, Surf. Coat. Technol. 205, S543 (2011).

L.A. Can-Herrera, A. Ávila-Ortega, S. de la Rosa-García, A.I. Oliva, J.V. Cauich-Rodríguez, and J.M. Cervantes-Uc, Eur. Polym. J. 84, 502 (2016).

M. Asadian, S. Grande, I. Onyshchenko, R. Morent, H. Declercq, and N. De Geyter, Appl. Surf. Sci. 481, 1554 (2019).

G. Beamson and D. Briggs, High Resolution XPS of Organic Polymers. The Scienta ESCA300 Database, Chichester, New York (1992).

K.H. Lee, H.Y. Kim, M.S. Khil, Y.M. Ra, and D.R. Lee, Polymer 44, 1287 (2003).

Acknowledgements

The authors acknowledge the financial support provided by funding agencies through Grant NSF-AL EPSCoR 16552820, GRSP AL-EPSCoR, and NSF-MRI 1531934. The authors also acknowledge Mr. Paul Simutis of DataPhysics Instruments USA Corp, Charlotte, NC for conducting water contact angle measurements.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mohammed, Z., Jeelani, S. & Rangari, V. Effect of Low-Temperature Plasma Treatment on Surface Modification of Polycaprolactone Pellets and Thermal Properties of Extruded Filaments. JOM 72, 1523–1532 (2020). https://doi.org/10.1007/s11837-020-04004-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04004-y