Abstract

This review focused on the progress catalysts, redox couples, mediators and oxidants have made in the power generation of direct biomass redox flow fuel cell (DBRFFC), identifying the challenges associated with them, and the approach toward resolving the issues to improve the power output of the direct biomass redox flow fuel cell. Ferric chloride and polyoxometalates currently used as catalysts with some redox couples, mediators, and oxidants provide less than 10% of the total harvestable electrons from the biomass degradation for power generation in DBRFFC. They are also inorganic toxic non-renewable catalysts that do not selectively break down the biomasses completely into simple reducing sugars for further oxidation into carbon dioxide and water only during electricity generation in the cell. By-products are produced which trap more electrons that would have been released for improved power generation if complete biomass oxidation were achieved. This challenge can be addressed by developing and combining organic catalyst with less quantity of the inorganic ones for more efficient biomass hydrolysis and oxidation. This review discussed biomass degradation in DBRFFC by thermo-chemical and photo-chemical means and the performances that have been achieved with the catalysts, redox couples, mediators and oxidants that were applied. Drawing from the knowledge will shape the future research direction toward reducing the usage of the non-renewable catalysts by designing and developing efficient renewable catalysts that can act in synergy with the inorganic ones for the biomass hydrolysis and oxidation for improved power generation of the DBRFFC.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fuel cells are electrochemical power generation devices that combine hydrogen or hydrogen-rich fuels with oxygen from air, to produce electricity, with water and heat as the only by-products. Fuel cells typically consist of two electrocatalysts—the anode (negative electrode) and the cathode (positive electrode) each dipped in an electrolyte (diffusion medium). A fuel, like hydrogen or hydrogen-containing compounds like methanol, formic acid, glucose, raw lignocellulosic biomass (LCB) is supplied to the anode, while air is supplied to the cathode, and the two electrodes are separated by an appropriate membrane material. The arrangement of the anode and the cathode electrodes with the membrane material sandwiched between them is referred to as membrane-electrode assembly (MEA). It is the heart of the fuel cell where the electrochemical activities that generate electricity take place. Fuel cells utilize catalysts to aid the oxidation of their various fuels at the anode and hydrogen reduction reaction at the cathode [58].

However, in direct biomass redox flow fuel cell (DBRFFC), the cell arrangement and the oxidation of fuel is quite different from that of the conventional ones, such as hydrogen and direct methanol fuel cells. While the oxidation of the fuel takes place at the anode in the membrane electrode assembly of these cells, it takes place in the anolyte tank (tank containing a mixture of catalyst solution and biomass), which is external to the membrane electrode assembly of the DBRFFC. The oxidation of lignocellulosic materials can be by thermos-chemical or photo-chemical process. When the biomass is oxidized, the hydrolysate is pumped into the MEA where charges are separated into anions (electrons) and cations (hydrogen ions) at the graphite anode electrode for electricity generation with the aid of redox couples. The hydrogen ion passes through the membrane material, usually polymer electrolyte membrane (PEM) to the cathode where it is reduced to hydrogen by accepting electron from the cathode. At the cathode side, there is also a catholyte tank (tank containing a solution of catalyst and an oxidant) where oxidant (air) is mixed with the same or different catalyst, the same way as that of the anolyte tank. Transportation of the charges to the anode of the DBRFFC is aided by redox couples and mediators. A potential difference is set up between the anolyte tank and the graphite anode electrode at the anode side, and the catholyte tank and the cathode graphite electrode at the cathode side of the DBRFFC, which establishes a flow of electron from the anode electrode to the cathode electrode through external circuit. In this way, electricity is generated.

Due to this special feature of DBRFFC, the oxidation of biomass in the external anolyte tank offers some flexibility in utilizing different catalysts over which biomass can be oxidized. Lignocellulosic biomass is a hydrogen-rich resource [30, 31] that is utilized directly as fuel in DBRFFC by oxidizing it with ferric chloride or polyoxometalates as catalyst in the anolyte tank of the fuel cell. While in solution, the catalyst dissociates into ions (cations and anions). The cation becomes an oxidant for the biomass oxidation, and after the oxidation, it is reduced to become an electron carrier. For instance, when biomass is introduced into the solution of ferric chloride (catalyst) in the anolyte tank of the DBRFFC, the ferric chloride becomes dissociated into Fe3+ and 3Cl−. The Fe3+ being the biomass oxidant oxidizes the biomass to release electrons and protons and by accepting an electron become reduced to Fe2+ ion. In this context, Fe3+ is the biomass oxidant and the reduced form, Fe2+, the electron carrier, while the Fe3+/Fe2+ is the redox couple. Mediators are sometimes employed in DBRFFC to facilitate charge shuttles between the anolyte tank and the anode. Mediators are inorganic or organic substances which improve the charge kinetics in redox flow fuel cells. Mediators often work with redox couples in DBRFFC and are usually introduced into the anolyte tank to improve the charge transport mechanism between the anode electrode and the anolyte. The external oxidation of biomass in the anolyte tank of DBRFFC, presents the researchers with various possibilities of designing and applying different catalysts, redox couples, mediators and oxidants for efficient biomass oxidation and electricity generation in the cell. Moreover, the rate of catalyst poisoning is greatly reduced in DBRFFC than in the conventional fuel cells. It also has catalyst regenerating ability, which makes the fuel cell attractive to researchers.

Fuel cells converts chemical energy of fuels directly into electrical energy in single-step process. It is efficient and pollutes less. In internal combustion engines (IC heat engines), the process of generating electricity is quite different from that of the conventional fuel cells. It involves a multiple-step conversions from chemical energy into thermal (heat), into mechanical, and ultimately into electrical energy. The multiple-step energy transformations involve significant energy degradation and dissipation, with pronounced adverse environmental impacts, hence the reported lower energy efficiency of heat engines compared to fuel cells [35, 39].

Fuel cells are usually classified based on fuel type, operating temperature, membrane type, mode of feeding fuel, and the properties of the electrolytes employed. Other less popular but equally important classifications are based on the nature of the catalysts (as in liquid catalyst flow fuel cell (LCFFC) [32] as well as the type of charge mediators used (for mediated fuel cell (Med-FC) [53]. Direct biomass redox flow fuel cells low-temperature fuel cell and belongs to the class of LCFFC. It utilizes shredded lignocellulosic biomasses, either in dry or wet form, directly as fuel. Even though biomass is a huge resource for energy generation, finding an efficient biomass degradation process has been an age-long challenge to researchers in biorefinery and direct biomass redox flow fuel cell researchers due to its recalcitrant nature. Biomasses are typically comprised of long-chain hydrocarbons and are thus excellent sources of hydrogen fuel for energy production. Traditionally, biomass conversion to electricity is often achieved in special biomass-fired power plants, which are also plagued with inefficiencies and significant energy losses associated with thermal conversion processes, in addition to the associated carbon emissions from biomass combustion [8]. Interestingly, electrochemical technologies provide a leeway for benign and more efficient utilization of biomass for electricity production, through biomass electrolysis to extract hydrogen from biomass, and biomass flow fuel cells that convert biomass directly to electricity [12, 28, 29, 34, 70]. Indeed, since biomass is renewable organic materials, with stored chemical energy produced naturally via photosynthesis, direct electrochemical conversion of biomass to electricity can be considered as a renewable energy technology.

Attempts have been made to develop an efficient DBRFFC, in which several kinds of fuels; lignocellulosic biomasses, coal and sewage sludge, etc., have been investigated and the performances tested over different catalysts [12, 26, 28, 29, 34, 58]. Some Reviews based on research works have also been published in this regard. For example, Liu et al. [30, 31] published a review on direct electricity generation and hydrogen production from biomass. They discussed traditional technologies for electricity and hydrogen generation from biomass and exposed the recent application of direct biomass fuel cell for the same purpose as a promising technology. In a similar review, Wang et al. [52, 55] focused on the research progress made in the deployment of LCB in energy production and storage, with emphasis on the chemistry of the processes. There are also available reviews on LCB valorization that have been also published on green oxidative processes [4, 8], however, the application of such oxidation catalysts and their performances in DBRFFC are yet to be discussed.

DBRFFC research is still a current research area with the first work published by [32] in 2014. In view of this, there is still scarcity of reviews on different areas of DBRFFC that point out some research gaps. One of such areas is the advances that have been made in the applications of catalysts, redox couples, mediators and oxidants, the problems associated with them and the possible research areas for improving the performance of DBRFFC. Incomplete biomass oxidation has plagued DBRFFC, with less than 10% of the total harvestable electrons available for power generation, while the rest is trapped in the biomass oxidation products [69]. Moreover, even with ferric chloride having good charge transfer kinetics in DBRFFC, is toxic [46], while POMs are not easy to synthesize, expensive, have large molecular masses with low kinetics, toxic [58] and harmful to the environment [36].

To address this, the review exposes the potential of combining catalysts, redox couples, mediators and oxidants, points out the challenges and make recommendations toward improving the power output of DBRFFC by incorporating the direct or indirect formic acid fuel cell concept into that of the DBRFFC configuration. We are currently developing a renewable catalyst from LCB for LCB degradation into simple sugars with high selectivity and yield using computational and experimental approach. The catalyst will be applied for biomass hydrolysis to produce a higher yield of simple sugars as rate of glucose oxidation affects the performance of the DBRFFC [69]. We hope to combine the catalyst with just 40% instead of the 100% of ferric chloride that has been conventionally used in DBRFFC. By design, this is expected to selectively oxidize glucose derived from LCB hydrolysis into formic acid instead of multiple by-products. The formic acid can be further oxidized into CO2 and water in the membrane electrode assembly of the DBRFFC through direct/indirect formic acid oxidation pathway. This configuration is expected to release more electrons for power generation. This approach is evident in the work done by Yang et al., on the enhancement of catalytic oxidation of formic acid over PdFe/C in direct formic acid fuel cell [64]. The power performance of dye-sensitized solar which have also been improved by combining chenodeoxycholic acid (CDCA) into the dye solution of Schiff base metal complexes [64]. Available works on DBRFFC have not reported the combination of organic heterogeneous and inorganic homogeneous catalysts for biomass degradation, even when sulfonated carbon-based heterogeneous acid catalyst has been reported to perform efficiently in biomass hydrolysis [10]. There exist also the possibility of doping the inorganic catalyst in the organic one. Such approach, though not on biomass degradation, was carried out by Wang and co-workers on enhanced adsorption and reduction performance of nitrate by Fe-Pd-Fe3O4 embedded multi-walled carbon nanotube [52, 55]. Graphitic nitride-dopped with Sulfur has been reported to improve the photocatalytic degradation of refractory contaminants [67]. These reported works lend support to the approach we have chosen for developing the organic catalyst. The application of the catalyst can also be extended to electrode membrane assembly (MEA) development for biomass fuel cells, where metal catalysts can be supported on the same catalyst [22] for the further oxidation of the by-products of glucose oxidation. This capability can lead to a complete oxidation of biomass, resulting in improved power performance.

Fuel cells powered by biomass can be grouped into two; indirect biomass fuel cell (IDBFC) and direct biomass fuel cell (DBFC). The former (IDBFC), converts biomass to various carbon-based fuel sources, including sugars like glucose and xylose, as well as biogas and syngas, which have been used as fuel sources in fuel cells for electricity production. These fuels are more expensive compared to the raw biomass used directly in DBRFFC, as they require external processing facility outside of the fuel cell. In the case of the solid oxide fuel cell, the major limitation of IDBFU has to do with the high temperature requirements for biomass gasification, typically in the range 500–1000 °C [60]. Indeed, an ideal biomass fuel cell has to operate at ambient conditions and the DBRFFC has this feature besides the raw biomass it directly converts to power using cheaper catalysts. As a result, DBRFFC holds a great potential as a fuel cell for all, especially the rural dwellers, thus the researchers delight.

Biomass Fuel

Biomass is a material derived from plant and animal origin. It is a huge resource, next to coal, petroleum, and natural gas for the production of energy, fuels, and chemicals. It consists of biodegradable food materials, agro-wastes, forest residues, etc. Li et al. [25] reported that about 220 billion tons of dry biomass were generated globally every year of which about 70–95% is LCB. In Nigeria, the potential to produce about 47.97 million tonnes of oil equivalent (MTOE) from biomass was reported [11]. However, emphasis placed on the utilization of biomasses that do not compete with food has made lignocellulosic biomasses (LCBs) the most cherished green resource for the production of energy, fuels and chemicals. In addition, finite nature of fossil fuel, coupled with environmental issues, such as emission of greenhouse gases and pollutants into the atmosphere, which are associated with the utilization of fossil fuels has been the motivation for researchers to develop different processes to efficiently valorize LCBs into value-added products. It has been established that a typical LCB contains (35–50%), hemicelluloses (25–35%) and lignin (15–20%) [25]. Lignocellulosic materials for the production of fuels and chemicals have recalcitrant structures that should be overcome by subjecting it to pre-treatments. Efficient valorization of LCB has been an age-long challenge to researchers, for which different process routes have been developed. Such pre-treatment processes are necessary to release the cellulose for further degradation into the desired products; be it fuels or chemicals. Some of the established pre-treatment processes, include; physical, thermo-chemical, chemical, physico-chemical and biological methods [8, 52, 55]. In this review, catalytic hydrolysis and oxidation as a chemical method of LCB degradation as applied in DBRFFC has been discussed.

Lignocellulosic Biomass Oxidation

Catalysts play a very key role in inorganic and organic chemical transformation processes. It makes processes to be realized in efficient and cost-effective way, such that high selectivity and yield of desired products can be attained. Catalysts also play a key role play in lowering the energy barrier (activation energy) required for a given process to occur. Energy is key to materials transformation and lowering the energy requirement indirectly lowers the cost of the process by reducing the energy requirement, and sometimes, enhances the selectivity of the desired product.

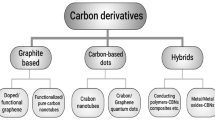

Oxidation is the removal of electron(s) from a substance or reduction in the oxidation number (state) of the reducing agent. Oxidation reaction and reduction reaction are complementary and they occur simultaneously. The reactions are referred to as redox reaction and have been applied in many chemical and biological transformation processes [16, 24, 28, 29, 34]. Well-known oxidation processes are; thermal, thermo-chemical, photo, photo-chemical and biological catalysis. These processes drive LCB oxidation in DBRFFC and microbial fuel cells. LCB valorization through thermal-chemical, and photo-chemical catalytic oxidation yields various kinds of by-products and its derivatives, as shown in Fig. 1.

Simplified scheme for LCB oxidation [4]

For instance, lignocellulosic biomass oxidation in direct biomass redox flow fuel cell (DBRFFC) over Polyoxometalates [28, 29, 34] or ferric chloride [69] produces, mainly, glucose, levulinic acid, 5-hydroxymethal furfural (5-HMF) and furfural. Production of these side products during biomass oxidation in DBRFFC has its drawbacks. The by-products are hydrocarbons which trap more electrons which can provide more electrons for power generation on further oxidation. Depending on the reaction condition, sometimes, a combination of these major products with traces of their derivatives, as indicated in Fig. 1 and other smaller molecules, such as formic acid, acetic acid, gluconic acid are formed, depending on process conditions. More formic acid production from biomass oxidation can be investigated further by altering the process conditions, such that it can be selectively produced for DBRFFC application. In most cases, the electro-oxidation catalysts have also the capability to hydrolyze LCBs. Hydrolysis and oxidation are sometimes, inseparable and occur concurrently. For example POMs and ferric chlorides possess these characteristic properties and have been studied [50, 63, 65]. For instance, the relationship between hydrolysis and oxidation of cellulose over NaVO3–H2SO4 in aqueous solution with O2 was studied [40]. They observed that the hydrolysis-oxidation pathway gives a higher yield of formic acid and suppressed the formation of by-products. This is a good approach to the understanding of biomass degradation in DBRFFC for power generation, where catalysts for hydrolysis and oxidation can be studied differently. With the approach, better catalysts for hydrolysis and oxidation can be design and developed.

Generally, catalysts are classified and applied, basically, in two forms, namely; homogeneous and heterogeneous. A homogeneous catalyst is a catalyst that exists in the same phase as the reactant. The phase may be, liquid–liquid, solid–solid or gas–gas. For example, in the transesterification of vegetable oil with methanol, catalyzed by aqueous potassium hydroxide solution (KOHaq) to produce biodiesel, the catalyst (KOHaq) is in liquid state and the reactant (vegetable oil) is also in liquid phase [18]. Under homogeneous catalysis, organic acids and sulfuric acid have been used to catalyze the hydrolysis of lignocellulosic material [23]. Unlike homogeneous catalysts, heterogeneous catalysts exist in different states from that of the reactant. In this case, the states of the reactant and the catalyst may be; liquid–gas, liquid–solid, or solid–gas. This kind of system of catalysis can be seen in lignocellulosic biomass hydrolysis over carbon-based solid acid catalyst [57] and has been reported to have some comparative advantages over homogeneous ones like sulfuric acid [44]. Electrochemical oxidation of glucose over platinum-on-carbon (Pt/C) catalyst for power generation has also been reported [33] and an example of a heterogeneous system. Some kinds of heterogeneous catalysts are developed by doping the catalyst in a material support or coated on a material [52, 55]. Different kinds of biomass fuel cells, such as methanol, formic, microbial, biomass hybrid biomass, etc., use various forms of oxidation catalysts, such as platinum (Pt), palladium (Pd), iridium (Ir). gold, POMs, ferric chloride, etc., depending on the purpose, desired product(s) and the suitability of the catalyst for biomass oxidation for power generation. Interestingly, POMs are catalysts for biomass oxidation and can be doped on porous materials, such as carbon nanotubes for enhanced catalytic activities (Chen 2020). Albert [1] investigated the selective oxidation of LCB to formic acid using tailor-made Lindqvist-type Polyoxymetalate (K5V3W3O19), while Madrid et al. [38] generated electricity from formic acid by deploying palladium and palladium alloy catalyst in formic acid fuel cell. Application of oxidation catalysts in flow fuel cells is still current but promising, especially as expensive precious metal catalysts are being replaced by cheaper, non-precious ones or made cheaper by supporting the precious metal catalysts on carbon materials. Moreover, electricity has been generated from agricultural biomass waste using ferric (FeCl3) as catalyst in the oxidation of biomass in direct biomass redox flow fuel cell [70]. Therefore, applications of oxidation catalysts in biomass transformations are very vast and have been publish in a review [8]. In DBRFFC, the biomass degradation is somewhat different, such that the hydrolysis and the oxidation of the LCB take place simultaneously, and it is necessary to describe its operation for clearer understanding.

Direct Biomass Redox Flow Fuel Cell (DBRFFC)

Direct biomass redox flow fuel cells are low-temperature proton-exchange membrane fuel cells (PEMFCs) that convert biomass directly into electricity over some catalysts in the presence of oxidant(s). In most cases, the catalysts and oxidants are in liquid states, and because of this, some authors/researchers refer to the fuel cells as liquid catalyst flow fuel cells (LCFFCs) [32] or mediated flow fuel cells (Med-FCs) [66]. The major difference between DBRFFC and the other fuels cells is that the oxidation of biomass fuel over catalysts takes place in an electrolyte tank outside of the electrochemical compartment (MEA) of the fuel cell. Another distinct feature of DBRFFC is that there is a catholyte tank where oxidants and electrolytes are mixed before pumping the mixture into the cell. The name “direct biomass redox biomass flow fuel cell” can be said to be derived from the capability of the cell to generate electricity directly from dry or wet biomass fuels using liquid catalysts (redox couples) that can be reduced, re-oxidized and re-generated in the fuel cell system by electrochemical means. A simple operation representation of DBRFFC is depicted in Fig. 2 can illustrate the concept [69].

Operation of DBRFFC [69]

DBRFFC is characterized by three major parts, namely; the anolyte tank, which contains the liquid electrolyte and the biomass (fuel); the main cell, comprising the anode and cathode graphite carbon electrodes sandwiched with proton exchange membrane (Nafion membrane), an arrangement commonly referred to as MEA; and the catholyte tank, containing the second electrolyte and an oxidant. Referring to Fig. 2, the aqueous solution of ferric chloride (FeCl3) is the anolyte because it is the electrolyte on the anode side of the fuel cell. On the cathode side, aqueous solutions of vanadium (IV) sulfate ((VO2)SO4), the main cathode electrolyte and oxygen-nitric acid (O2-(HNO3) as oxidant are contained in the catholyte tank. The main cell is the assembly of the electrodes and Nafion membrane, similar to that of a bi-cell arrangement. An electromotive force is set up as a result of the electrode potential difference between the anode and the cathode, which drives current from the anode through the external circuit to cathode of the DBRFFC. It is also likely to be a cheaper fuel cell because transition-metal catalysts that are used are relatively cheaper compared with the precious group metal catalysts used in the other fuel cells, such as hydrogen, formic and methanol fuel cells. However, DBRFFC is yet to be commercialized due to low power performance which has been attributed to the inefficient catalysts being used [58]. This challenge can be addressed by developing better and cheaper catalysts. There is also a type of DBRFFC that generates both electricity and hydrogen fuel at the same time using shared cell. In their work, Li and co-workers developed the shared cell by integrating DBRFFC with the PEMFC, such that the DBRFFC component is responsible for electricity generation from glucose while the PEMFC part, generated hydrogen [26]. The DBRFFC part used POM as the anolyte and ferric chloride as the catholyte. For the hydrogen generation part, the catholyte of the DBRFFC became the anode of PEMFC and phosphoric acid as the catholyte. The cells were connected in such a way that they share the ferric chloride electrolyte, and part of the electricity generated from the DBRFFC was used to power the PEMFC that produced the hydrogen. Because of this feature, the authors named the cell SHAREDCELL. At present, polyoxometalates (POMS) and ferric chloride are the popular oxidation catalysts for electricity generation in DBRFFC that have been studied to some extent. They have been applied as catalysts and their solutions as electrolytes in DBRFFC for the conversion of lignocellulosic biomasses, such as wheat and rice straws, sugarcane bagasse, switch grass into electricity [12, 13, 70]. Some of these works have reported the combination of catalyst with acids without explicitly indicating the role of the acid in power generation of DBRFFC, but have been stated to enhance biomass hydrolysis. In sewage treatment, DBRFFC has been integrated into wastewater treatment plant for the degradation of sewage sludge and electricity generation, in which POM was used as the oxidation catalyst and electrolyte [63, 65]. Carbohydrates and starch have also been investigated for electricity generation in DBRFFC [58]. The application of POMs in DBRFFC research has also been reported on works done by [13, 32, 63, 65]. Introduction of ferric chloride into biomass oxidation in DBRFFC emerged to address some of the challenges, such as low kinetics, toxicity and cost associated with the use of POMs [36] in DBRFFC. Zu et al. [69, 70] investigated the direct conversion of some biomass into electricity over ferric chloride as a oxidation catalyst in the anolyte tank. In another study, a combination of POM, as the main catalyst to oxidize glucose, and ferric chloride, as a charge mediator to transport electrons to the carbon anode electrode was carried out to enhance the power output of the DBRFFC [36]. Despite their performances in DBRFFC power generation, they have some drawbacks, such as incomplete biomass oxidation, high cost, and non-eco friendliness. Currently, there is scarcity of published report on a commercialized DBRFFC due to performance and durability, a reason many researchers are finding the solution through researches on efficient catalyst/electrolyte development and redesigning and engineering of the cell components. Another aspect a good progress can be made is by reviewing the activities of catalysts, redox couples, mediators and oxidants in DBRFFC and developing an efficient approach for their application.

The Chemistry of Biomass Oxidation in DBRFFC

The understanding of redox reaction and redox couples and the roles they play in biomass oxidation in DBRFFC is necessary. Oxidation occurs when the reacting chemical specie donates electron(s) to another chemical specie involved in the reaction. In other words, the chemical specie that donated electron is referred to as the reducing agent, while the one that accepted electron is the oxidizing agent. Another way of interpreting a redox reaction is to determine the change in the oxidation state of the participating chemical species based on the oxidation number. An increment in the oxidation number of a chemical specie indicates that the specie has been oxidized, while a reduction in oxidation number means that the specie has been reduced. The Table of the electrochemical series has helped in the understanding of redox reactions. Molecules of chemical compounds or species are formed based on the electronegativity or positivity of the constituents elements as depicted in Fig. 3 based on standard hydrogen reducing (SHE) potential and reflects oxidation–reduction reactions involved in the compound formation.

From Fig. 3, fluorine has the greatest oxidation strength and lithium, the least while the reverse becomes the case in order of increasing reducing strength. For biomass oxidation with ferric chloride, it has been established that the oxidizing agent is ferric ion (Fe+3), obtained from the dissociation of ferric chloride in aqueous solution of biomass and the ferric chloride, as expressed in Eq. 1

During biomass oxidation over ferric chloride catalyst, oxidation number of ferric ion becomes reduced from + 3 to + 2, that is, ferrous ion. In this context, ferric ion is the oxidizing agent while biomass is the reducing agent. For ferric ion to oxidize biomass, the ferric ion oxidation potential must be greater than that of the biomass. Even though there has not been a scientific procedure for determining biomass reducing potential, it has been speculated by scientists that the oxidation potential of ferric ion should be greater than that of the biomass for a biomass oxidation to happen. Research efforts should be directed to this aspect to enhance the knowledge and improve catalyst design for efficient biomass oxidation. In most of the research publications on biomass oxidation by ferric chloride with hydrochloric acid, scientists have been silent on the role of the acid and the chloride ion in biomass oxidation. In the biorefinery context, addition of HCl to LCB at a higher acid-solid biomass ratio and 40 °C increases the yield of simple sugars up to 65% due to the cleavage of glycosidic bonds [68]. Cheng et al. [6] reported that a combination of ferric chloride and HCl at 110 °C also enhance the yield of crystalline nanocellulose from LCBs [6]. However, the role of chloride functional group (–Cl) from chlorides compounds has been reported by some authors to enhance the cleavage of glycosidic bonds in LCB hydrolysis [44, 47, 61]. However, the detailed mechanism of glucosidic bond cleavage by –Cl has not yet been fully understood. POMs (Keggin type) have also been studied for biomass oxidation, in which POM was the oxidizing agent and biomass, the reducing agent [66]. In a similar way, the role of the Keggin POM anion was played down. So, further research should be carried out on the roles of anions of the oxidation catalysts in order to deepen the understanding of the researchers toward designing efficient oxidation catalysts for biomass degradation.

The Role of Redox Couples

There are two notable reactions that take place in the anode side of DBRFFC. The first is the oxidation–reduction reaction between the biomass and the oxidation catalyst. The second is the re-generation of the catalyst at the anode graphite electrode of the fuel cell. Electron abstraction from biomass fuel leads to biomass oxidation and degradation. Referring to Fig. 2, charges (hydrogen ion and electrons) generated, with electrons captured by ferric ions to become reduced to ferrous ions for charge (electron) storage, transportation and regeneration at the anode involves a pair of Fe ions (Fe3+/Fe2+), referred to as redox couple. In this instance, ferric ion and ferrous ion (Fe3+/Fe2+) is a redox couple. Redox couples of the same type or different types can be applied in anode and cathode sides of DBRFFC at the same time. Sometimes it may operate on one side of the fuel cell. At times, two different redox couples can be applied in DBRFFC, one playing the role of a catalyst and the other, the role of charge mediator. Other examples of metal redox couples are; Cu+2/Cu+1, Co+3/Co+2, Mn+2/Mn+1, Br−/Br2, etc. Redox couples play very important roles in the performance of electrochemical energy conversion and storage devices, such as redox batteries and redox fuel cells. The effects of combining these redox couples with other catalysts on power output of DBRFFC can be further studied. These redox couples are usually generated from aqueous solutions of some metallic salts, such as chlorides, nitrates, sulfates, etc., which when dissolved in solution become electrolytes. Such electrolytes have been applied in redox flow batteries [37] and redox flow fuel cells. In fact, the concept of redox couple originated from redox flow batteries and was imported into DBRFFC application [2]. For example, the development of all vanadium redox flow batteries (VRFB) and their operation makes use of two redox couples of vanadium, namely; negative V(II)/V(III) and V(IV)/V(V) positive redox couples [51]. Lloyd et al. [37] also made use of Cu+2/Cu+1 redox couples in studying the performance of copper chloride dissolved in deep eutectic liquid. Sometimes, two redox couples are applied in flow fuel cells; one acting as the catalysts, and the other as charge mediators. Tamirat et al. [48] published a review on mediators applied in lithium ion batteries, the mechanisms and kinetics.

Ferric-Ferrous Ion (Fe+3/Fe+2) Redox Couple

Drawing from the work done by Zu et al. [69] as depicted in Fig. 2, the chemistry of biomass oxidation by ferric chloride and the role of ferric-ferrous ions as redox couple can be fully appreciated. If we take glucose as our model biomass fuel, the complete oxidation of glucose over ferric chloride catalyst at the anolyte tank can be expressed by Eq. (2)

In terms of electrolyte containing Fe+3/Fe+2 redox couple, the half anodic redox reaction is expressed in Eq. (3)

Equation (2) shows that it is the ferric ion (Fe+3) that oxidizes the glucose, while the ferrous ion (Fe+2) is responsible for storing both the electrons and also transports them to the anode graphite electrode. In DBRFFC, the electron is discharged at the anode and through external circuits, flows to the cathode where an oxidizing agent becomes reduced by accepting the electron from the anode. The proton (H+) will then flow through the Nafion membrane where it is reduced to hydrogen by accepting electron from the cathode and then subsequently oxidized by an oxidant (oxygen) to form water. It explains further that the rate of ferrous ion generation as a result of biomass oxidation by ferric ion will affect the power output of the DBRFFC. Equation (3) relates the discharging of electrons by ferrous ion at the graphite anode electrode. It also shows that ferric ion is regenerated at the anode of the fuel cell. So, the rate of discharge of electrons at the anode could also affect the power output of the fuel cell. The ferric ion re-generated at the anode graphite electrode is recycled into the anolyte tanks. Here also, the role of chloride ion (Cl−) that is generated during the FeCl3 dissolution in water has not been fully explained, even though we know that there is bond breaking in biomass and bond formation to yield small-molecule by-products during biomass oxidation. The question that should arise is whether it is ferric ion only that initiates the bond breaking in glucose or are there any other agents, besides thermal energy (heat) that is usually applied during biomass oxidation. Hopefully, future research may take this direction for clarification. The tendency that biomass may not be completely oxidized into CO2 by ferric ion, as Eq. (3) portrays is possible. Of course, Zu et al. [70] reported that it was only 8.3% of 24e out of 24 mol of oxidized glucose molecules that was captured for electricity generation in the DBRFFC, since complete oxidation of glucose into CO2 and water that would have released 24e was not possible due to by-products production. That is to say, that the other electrons that would have been extracted from the biomass were still stored in the chemical energy of the gluconic acid, formic acid and the other by-products. This problem can be solved by designing and developing product-specific catalysts. For instance, the catalyst can be designed to degrade LCB into glucose to formic acid, such that the formic acid will subsequently be oxidized into hydrogen and CO2 which have already established process [62]. This is the possibility our current work is looking into. We are currently working on mimetic carbon catalyst development for an effective biomass hydrolysis. The focus is to know the products that will be generated during hydrolysis to determine the catalyst and process for that can efficiently oxidize the products into CO2 and H2O in DBRFFC.

For the cathodic half-cell reaction, Eq. (4) expresses the reaction, thus

In Eq. (4), electrons from the anode combine with the protons (H+) that passed through the Nafion membrane to form hydrogen which is subsequently oxidized into water on the right hand side of Eq. (4).

At the cathode also, the ferric ions accept the electrons from the anode through the graphite cathode electrode to become reduced to ferrous ion according to Eq. (5)

The re-generated ferric ion is recycled into the catholyte tank and the cycle continues. On the whole, the overall glucose/biomass oxidation reaction taking place in the DBRFFC is captured by Eq. (6).

Equations (2) and (6) are similar, however, while Eq. (1) expresses the ideal complete biomass oxidation, Eq. (6) expresses the real biomass oxidation reaction in which there are by-products formation and an electron captured by ferric ion during the oxidation. So, any redox couple that can drive biomass oxidation to near completion or complete should be the desire of the researchers to develop. In this regard a combination of catalysts is required and our project has it as one of the focus, to develop a renewable mimetic catalyst that can be effectively combined with ferric chloride to achieve a complete biomass oxidation. It is quite an interesting research because the mimetic catalyst can degrade biomass selectively to glucose while the redox couple from the ferric chloride will drive the glucose oxidation to completion through the direct/indirect formic acid oxidation pathway.

Polyoxometalates Redox Couples

Polyoxometalates (POMs) have been widely used in various applications, such as catalysis, nanotechnology, medicine, electrochemistry, materials sciences, macromolecular crystallography, magnetism, etc., due to their redox properties [14]. There are over 200 kinds of POMs with notable classifications into types, ranging from Keggin, Anderson, Waugh, Lindqvist, Silverton, to Dawson [7]. Among these types, the Keggin type has been widely studied and applied in electrocatalysis of redox flow batteries and redox flow fuel cells. DBRFFC is one of such areas POMs have been applied as biomass oxidation catalysts and/or charge mediators. For example, POMs have been applied as photocatalyst for oxidation for glucose and glycerol, and as charge mediator in DBRFFC [56]. In the study, PMo12 was used as the anolyte (anode electrolyte) to oxidize (photo and electro-oxidation) glucose and glycerol in the anolyte tank, and high-vanadium POM (H12P3Mo18V7O85) was used as catholyte (cathode electrolyte) in the catholyte tank. They reported that spectroscopy method was used to determine the reduction degree of PMo12 after the oxidation of glucose and glycerol. At the anode, PMo12 became reduced to PMo12red, after biomass oxidation and transport the charges to the graphite anode electrode, where it was re-oxidized by discharging the electron to become PMo12ox. At the cathode, H12P3Mo18V7O85 picked up the electrons from the anode and become reduced to H12P3Mo18V7O85red.. It was re-generated by supplying oxygen as oxidant to the catholyte tank to re-oxidize the H12P3Mo18V7O85red. to H12P3Mo18V7O85ox.. The regenerated POMs were recycled into their respective thanks after regeneration. In a related work, Liu et al. [30, 31] reported the application of POMs as biomass oxidation catalyst and charge mediator in DBRFFC for electricity generation. The authors undertook a fundamental study on the performance of the POMs in terms of over potentials, kinetics and charging and discharging of Keggi-type POMs at the anode and cathode electrodes. Their findings indicated that POM discharging at the cathode of the fuel cell affected the power output of the DBRFFC due its slow charge kinetics. The slow charge kinetics is due to the high molecular weight and viscosity of the POM. During biomass oxidation for power generation by DBRFFC, POMs can function as oxidizing agents and mediators. POMs used in the anolyte tank of DBRFFC is usually designated as POM I, while the ones in the catholyte tank is POM II (Antolini [3]. DBRFFC utilizing POMs in electro-oxidation of biomass to generate electricity takes the same features as is depicted in Fig. 1. Taking POM I to be PMo12 or H3PW11MoO40, and POM II as H12P3V7Mo18O85, Eq. (7) expresses the biomass oxidation with POM I in anolyte tank accordingly.

The Mo6+ become reduced to Mo5+, which carries the electrons and the proton in to the cell compartment. The anode carbon electrode re-oxidizes the Mo5+ to Mo6+ and is recycled into the anolyte tank with the aid of a peristaltic pump as expressed in Eq. (8)

On the cathode side of the fuel cell, POM II is reduced by taking up the elctron from the cathode as expressed in Eq. (9),

while the proton that passed through the Nafion membrane is oxidized to water according to Eq. (10).

Combining the anodic (Eqs. 7 and 8) and cathodic (Eqs. 9 and 10) half-cell reactions, the overall biomass oxidation reaction in the DBRFFC is expressed in Eq. (11) thus;

POMs, especially Keggin type are good catalysts, electrolytes and source of charge mediators that have been applied in DBRFFCs. However, their large molecular masses, toxicity and cost have been identified as some of the drawbacks associated with their utilization in electrochemical energy conversion systems, such as DBRFFCs. Another problem of POMs is its slow kinetics, and this affects the rate of charging and discharging of charges (charge exchange) at the anode and cathodes of the DBRFFC. Moreover, the slow re-oxidation of POM II at the cathode by oxygen is a very slow process because it not easily re-oxidized by oxygen. However, this can be resolved by combining two oxidants, oxygen and the one in which it is very soluble in, such as nitric acid.

Redox Mediators

Oxidation of organic materials by electrochemical means for the production of biochemicals and fuels, commonly referred to as electro-organic synthesis or organic electrosynthesis, usually makes use of mediators. Mediators are organic (natural) or inorganic (synthetic) chemical compounds with electrochemical activity. They have been widely studied and applied in dye-sensitized solar cells [21, 43], and electrochemical energy conversion and storage (EECS) devices, such as batteries [48], fuel cells [2, 28, 29, 34] and capacitors. Moreover, they have been also widely studied in the degradation of organic pollutants [45]. A stable aminoxyl radical, TEMPO (2,2,6,6-tetramethylpiperidine N-oxyl) has been reported as an effective organic mediator for the electrochemical oxidation of alcohol [53]. Mediators play significant roles in product selectivity by preventing over oxidation of the substrate, and to enhance the power output of the EECS devices by acting as charge shuttles. In fact, they make redox reactions to undergo continuous cyclic process by engaging the redox couples at the electrodes of fuel cells and to followed the reaction pathway of interest [27]. In this way, continuous power is generated from the DBRFFC. They, sometimes, perform the function of catalysts in multi-component systems and as a result, their function may not be clearly defined. Mediators are in most cases are usually found in the aqueous electrolyte solutions as redox couples in which the ionic (cations and anions) have dissociated. This a very interesting area redox mediators have been applied in direct biomass redox flow fuel cells (DBRFFC), and as a result, some authors refer to the cell as mediated flow fuel cell (Med-FFCs). These mediators also reduce fouling of electrodes by fuel impurities. For a better understanding of the operation of DBRFFC and application of redox mediators, it is necessary to refer to Fig. 1 in this review. It should be noted that in this illustration, ferric chlorided acted as biomass oxidation catalyst, its solution, electrolyte and the ferric/ferrous ions as redox mediator. Chen et al., studied the effect of combining FeCl3 amd methylene blue (MB) as the charge mediator [5]. They found out MB facilitated the decomposition of wheat straw in acid and alkaline media, and enhanced electron transfer from the biomass to the carbon anode of the DBRFFC, resulting in power output of 12.3 and 41.8 mW/cm2, respectively. In a similar manner, POMs have been used in DBRFFC as biomass oxidation catalyst; its solution, electrolyte and its redox mediators as ions of transition metal depending of the composition of the POM. For example, in the work by Zhao et al. [66] the combined POM and ferric chloride to enhance the electricity generating efficiency of the DBRFFC. In this case the POM was the biomass oxidation catalyst, while ferric chloride furnished the ferric/ferrous ions for charge shuttles. Some researchers have been able to use different mediators at the anode and the cathode. For example, Gong and co-researchers have been able to used two redox pairs, Fe+3/Fe+2 and VO2+/VO2+ as catalysts and charge carriers in the anolyte and catholyte tanks of the DBRFFC to generate electricity from wheat straw [12]. A summary of some research works done on DBRFFC with some catalysts, redox couples, mediators and oxidants is shown in Table 1

A knowledge of the roles and the effects of these various catalysts, redox couples, mediators and oxidants in power generation of DBRFFC that have been reported can lead to a better design and development of DBRFFC with higher power output. Moreover, understanding the mode and mechanism of operation in biomass flow fuel cells will help researchers also to know how to choose and apply suitable mediators for elecrtosynthesis of materials. According to Little and Barbara [27], the mode of operation of mediators could be “in-cell” and “ex-cell”. In the in-cell process, the oxidation and electron mediation by the mediators take place in the electrolytic cell compartment. In addition, the mediators are generated from the catalyst used for organic matter oxidation and should be applied in amounts as the catalyst such that they can be re-generated at the electrodes. For example, siting the ferric chloride used as biomass oxidation catalyst in DBRFFC of Fig. 1, the concentration of ferric ion is directly related to the concentration of ferric chloride used as a catalyst. On the contrary, ex-cell process happens separately in a substrate (biomass) tank, separate from the electrolytic cell compartment. The interesting thing about ex-cell process is that the operation of the mediators can be optimized independently of each other, that is, that of the cell and that in the electrolyte tank. This is the mode of operation in DBRFFC, where the biomass oxidation in anolyte tank takes place outside the anode electrodes where mediators are re-generated. On the mechanism of mediators between the biomass and the electrode, there are basically two of them, namely; the out-sphere and the inner-sphere. Between the two, it is out-sphere mechanism that is in operation in DBRFFC in oxidizing and transferring electrons to the anode of the fuel cell for electricity generation, as denote Fig. 4.

There are some critical conditions that should be met in the choice of redox mediators. The researcher should ensure that it is only the mediators that can under redox reaction with the substrate (biomass) and the electrode. In other words, the redox potential of the mediators should be as close as possible to that of the biomass. Moreover, redox mediators should be electrochemically stable all through the operation of the cell. To enhance the stability of some mediators, complex ligands have been employed. For example, the stability of Cu(II)/Cu(I) ion mediators applied in dye-sensitized solar cell were improve by using ligand complexes [21, 64]. Very importantly, the redox mediators should be very soluble in the electrolyte and also have good kinetics for electron transfers from the biomass to the anode electrode, so as to reduce over potential that results in slow kinetics [2].

Oxidants Applied in DBRFFC

An oxidant or oxidizing agent is a substance that accepts or gains electron(s) from an electron donor(s), usually termed as a reducing agent or reductant. In terms of a chemical specie, it is an oxidizing agent that undergoes a chemical reaction in which it gains electron(s) from another chemical specie involved in the reaction, herein, referred to as a reducing agent. As earlier mentioned, a chemical reaction in which an oxidant and a reductant are involved is also referred to as oxidation–reduction reaction or simply, redox reaction. In every redox reaction, the oxidizing and reducing agents participate simultaneously, and each can be determined based on the changes in their oxidation states, which is reflected in changes in their oxidation numbers. There are common oxidizing agents, such as oxygen (O2), Ozone (O3), and halogens (Cl2, F2, Br2 and I2) etc., and chemical species, such as hydrogen peroxide (H2O2), nitric acid, (HNO3), iron nitrate (Fe(NO3), potassium permanganate (KMnO4), etc., that are commonly used. There oxidants for biomass degradation and also others for facilitating the mixing of oxidants at the cathode of the DBRFFC. Going by the definition of an oxidizing agent as an electron(s) acceptor and making reference to Fig. 2, it is extended to some metal ions, such as Li+, Fe+3, Cu+2, Al+3, Pb+2, Zn+2, etc., as oxidizing agents. In some instances, some chemical compounds in their aqueous solutions act as oxidizing agents and catalysts, maybe, partly due to their dissociated metal ions. Such examples are ferric chloride and some Keggin-type polyoxometalates (POMs) and have been applied in biomass degradation in DBRFFC because of their characteristic oxidizing powers [28, 29, 34, 70]. Some of these oxidants mentioned have been applied in DBRFFC to enhance the performance of the fuel cell, either by facilitating biomass degradation in the anolyte tank or reducing oxygen evolution reaction in the catholyte tank during re-generation of oxidants in the tank. Notable oxidants applied in DBRFFC include, oxygen (O2), hydrogen peroxide (H2O2), nitric acid (HNO3), phosphoric acid (H3PO4) potassium permanganate (KMnO4), ferric chloride, copper chloride and Keggin-type POMs, etc. Some of these oxidizing agents are very strong and caution should be exercized in their selection for application, in terms of explosion, fire, and toxicity. Interestingly, some of these oxidants have been applied in the development of DBRFFC.

O2/HNO3

The major source of oxygen (O2) is atmospheric air, and constitutes the second largest pecentage of 21% by volume and 23.3% by mass, next to nitrogen (N2), which is 79 and 76.7 by volume and mass, respectively, of air. It is a very strong oxidizing agent after chlorine and has been applied as oxidant in biological and chemical processes. On its application in biological systems. Kanner et al. [20], published a review on initiation of lipid peroxidation in biological systems in which oxygen has been identified as an initiator. Oxygen has also been investigated for eco-friendly de-sulfurization of petroleum fractions over some catalysts [9]. In a related work, a biomass (beech wood) was oxidized by oxygen to formic acid (FA) with a yield of 61% in the presence of POM [17, 42].

Oxygen is among the few oxidants that have been applied, mostly in the catholyte tank of DBRFFC to drive the regeneration of redox mediators [28, 28, 29, 29, 34, 34, 58]. In POMs-catalyzed DBRFFCs, it has been identified that the rate of charging and dicharging in the catholyte thank is very slow due to slow dissolubility of oxygen in POMs. For this reason, oxygen has also been conbined with nitric acid (HNO3), another oxidizing agent to facilitate the dissolubiliy of O2 [12, 69, 70]. It was reported that the synegistic effect of combining O2 and HNO3 resulted in immedaite oxidation of Fe+2 to Fe+3, which facilitated the catalyst re-generation process. However, its effect on the power output of DBRFFC was not reported. Therefore, it is recommended that further research should be carried out to establish the effect of combining O2 and HNO3 in the anolyte thank on the power output of the DBRFFC.

H2O2/H3PO4/KMnO4

Hydrogen peroxide is a good oxidizing agent that has found wide applications in health as an anthiseptic; industry, as bleaching agent and in biomass pretreatment as an oxidizer. In biomass upgrading to chemicals, it has been employed as an oxidant, an alternative to gaseous oxygen, and as a green liquid for biomass deconstruction [49]. For instance, the effect of alkaline hydrogen peroxide on reducing the lignin content of coffee pulp waste was studied by Pudjiastuti et al., [41] in order to exposed the cellulose content of the pulp for ezymatic hydrolysis. They reported that the highest lignin removal was achieved at 7.5% H2O2 which resulted in decrease in lignin from 16.85 to 8.5%. Wang et al., [54] carrried out their study on the combined effect of using H2O2 and H3PO4 in the pre-treatment of linocellulosic biomass. In their study, they also considered different particle sizes of the biomass to be treated and reported that when concentrations of 1.77% H2O2 and 80% H3PO4 was used on hard wood, soft wood, bambo, and garden waste mixture, that 71–96% of lignin and 95% of hemicellulose were removed, which gave over 90% glucose conversion during enzymatic fermentation. H3PO4-impregnated wood sawdust has been directly utilized as fuel to an intermediate-temperature biomass fuel cell to generate power above 10 mW/cm2 within 75–250 °C [15]. The H3PO4 was used as a solvent to aid the breaking down of the sawdust at temperatures above 100 °C. Hydrogen peroxide’s role in biomass upgrading into formic acid has also been discussed in a review by [17].

On fuel cells, direct methanol-hydrogen peroxide fuel cell was studied in which acidified hydrogen peroxide was deployed as the electrolyte on the cathode side of the cell with carbon nanotube (CNT)-supported prussian blue as the cathode [59]. It was reported that a power density of 125mW/cm2 was achieved at a temperature of 60 °C. Zhao et al., [66] demonstrated the applicability of H2O2 in polyoxometalate-mediated flow cell for direct conversion of lignin to electricity. In their study, they compared different oxidants, ferric chloride, copper chloride, potassium permanganate and hydrogen peroxide and the effects they have on the discharging of POM at the cathode. Potassium permanganate has not been widely used as an oxidant in DBRFFC the way in which oxygen, nitic acid or hydrgen peroxide have been reported. However, it was reported that it has been used in microbial fue cell as cathloyte in a study carried out to determine the effects of cathode electron acceptors, electrode configuration and electrode spacing on chemical oxygen demand (COD) removal and output current of the fuel cell [19]. Again, the authors were silent on the role of KMnO4 as an oxidizing agent in the fuel cell.

Conclusion and Outlook

Energy production from biomass and its deconstruction into chemicals and fuels in order to replace fossil resources and mitigate climate change due to emissions from their utilization has been a serious challenge to researchers. Biomass oxidation by thermo-chemical and photo-chemical means over some catalysts which are applicable to direct biomass redox flow fuel cell (DBRFFC) has been reviewed. The roles of catalysts were highlighted in terms of the oxidation of biomass fuels in DBRFFC and their roles as oxidizing agents and sources of redox mediators. Ferric chloride and polyoxometalates are the few catalysts that have been reported to have been applied for both thermal and photo electro-oxidation of biomasses in DBRFFC. Their shortcomings, such as incomplete oxidation of biomass into CO2 and heat during electricity generation were exhaustively discussed with equations to illustrate the biomass oxidation in anode electrolyte tank (anodic half-cell reaction), and the catholyte and the redox mediators (cathode half-cell reaction). Ferric chloride, even though has good charge kinetics, is non-renewable and should be minimally used due to its toxicity. Polyoxometalates is also non-renewable and has large molecular masses with low charge kinetics. To address some of the setbacks, new renewable catalyst design using molecular modeling and simulation tools was suggested. Such catalysts can work in synergy with less of the non-renewable ones in carrying out both LCB hydrolysis and oxidation, while improving the power output. Mechanisms for the electrochemical oxidation and electron mediators were also discussed, noting the mechanisms that are relevant to the operation of DBRFFC. Drawing from the mechanism, emphasis on electron transportation was placed on the charging and discharging of electrons by the redox couples as they affect, to a large extent, the power output of DBRFFC. Efficient electron transportation by the redox mediators could address this challenge by the selection and combination of the best redox couples and charge mediators that can guarantee a better power performance. Some factors, such as ionic stability, solubility in aqueous solution and the electrochemical conductivity should be considered as guide to researchers in the selection of suitable mediators for application in DBRFFC. Oxidants that have facilitated the oxidation of biomass in the DBRFFC were also discussed. Some of these oxidants such as hydrogen peroxide have been combined with POMs for biomass oxidation in the anolyte tank. In the catholyte tank, both nitric acid and oxygen have been used and their merits and demerits discussed. In summary, new catalyst design, mediator and oxidant selection and improvement in DBRFFC design are the aspects researchers should focus on for an improved DBRFFC.

Change history

18 March 2024

A Correction to this paper has been published: https://doi.org/10.1007/s11814-024-00151-z

References

J. Albert, Selective oxidation of lignocellulosic biomass to formic acid and high-grade cellulose using tailor-made polyoxometalate catalysts. Faraday Discuss. 202, 99–109 (2017). https://doi.org/10.1039/c7fd00047b

C.W. Anson, S.S. Stahl, Mediated fuel cells: soluble redox mediators and their applications to electrochemical reduction of O2 and oxidation of H2, alcohols, biomass, and complex fuels. Chem. Rev. 120(8), 3749–3786 (2021). https://doi.org/10.1021/acs.chemrev.9b00717.Mediated

A. Ermete, Lignocellulose, cellulose and lignin as renewable alternative fuels for direct biomass fuel cells. ChemSusChem 14(1), 189–207 (2021). https://doi.org/10.1002/cssc.202001807

P.L. Arias, J.A. Cecilia, I. Gandarias, J. Iglesias, M. López Granados, R. Mariscal, G. Morales, R. Moreno-Tost, P. Maireles-Torres, Oxidation of lignocellulosic platform molecules to value-added chemicals using heterogeneous catalytic technologies. Catal. Sci. Technol. 10(9), 2721–2757 (2020). https://doi.org/10.1039/d0cy00240b

Y.A. Chen, H. Yang, D. Ouyang, T. Liu, D. Liu, X. Zhao, Construction of electron transfer chains with methylene blue and ferric ions for direct conversion of lignocellulosic biomass to electricity in a wide pH range. Appl. Catal. B Environ. 265(December 2019), 118578 (2020). https://doi.org/10.1016/j.apcatb.2019.118578

M. Cheng, Z. Qin, Y. Chen, S. Hu, Z. Ren, M. Zhu, Efficient extraction of cellulose nanocrystals through hydrochloric acid hydrolysis catalyzed by inorganic chlorides under hydrothermal conditions. ACS Sustain. Chem. Eng. 5(6), 4656–4664 (2017). https://doi.org/10.1021/acssuschemeng.6b03194

D. Wang, L. Liu, J. Jiang, L. Chen, J. Zhao, Polyoxometalate-based composite materials in electrochemistry: state-of-the-art progress and future outlook. Nanoscale (2020). https://doi.org/10.1039/C9NR10573E

W. Den, V.K. Sharma, M. Lee, G. Nadadur, R.S. Varma, Lignocellulosic biomass transformations via greener oxidative pretreatment processes: access to energy and value added chemicals. Front. Chem. 6(APR), 1–23 (2018). https://doi.org/10.3389/fchem.2018.00141

E.A. Eseva, A.V. Akopyan, A.V. Anisimov, A.L. Maksimov, Oxidative Desulfurization of hydrocarbon feedstock using oxygen as oxidizing agent (a review). Pet. Chem. 60(9), 979–990 (2020). https://doi.org/10.1134/S0965544120090091

G.S. Foo, A.H. Van Pelt, D. Krötschel, B.F. Sauk, A.K. Rogers, C.R. Jolly, M.M. Yung, C. Sievers, Hydrolysis of cellobiose over selective and stable sulfonated activated carbon catalysts. ACS Sustain. Chem. Eng. 3(9), 1934–1942 (2015). https://doi.org/10.1021/acssuschemeng.5b00530

A. Giwa, A. Alabi, A. Yusuf, T. Olukan, A comprehensive review on biomass and solar energy for sustainable energy generation in Nigeria. Renew. Sustain. Energy Rev. 69(September 2015), 620–641 (2017). https://doi.org/10.1016/j.rser.2016.11.160

J. Gong, W. Liu, X. Du, C. Liu, Z. Zhang, F. Sun, L. Yang, D. Xu, H. Guo, Y. Deng, Direct conversion of wheat straw into electricity with a biomass flow fuel cell mediated by two redox ion pairs. ChemSusChem 10(3), 506–513 (2017). https://doi.org/10.1002/cssc.201601441

X. Gong, M. Ruan, P. Song, H. Li, J. Cao, P. Yao, W. Xu, A cost-effective and highly efficientdissymmetric membrane electrode assembly designed for fuel cells. J Power Sources (2021). https://doi.org/10.1016/j.jpowsour.2021.229485

N.I. Gumerova, A. Rompel, Synthesis, structures and applications of electron-rich polyoxometalates. Nat. Rev. Chem. (2018). https://doi.org/10.1038/s41570-018-0112

T. Hibino, K. Kobayashi, P. Lv, M. Nagao, S. Teranishi, T. Mori, An intermediate-temperature biomass fuel cell using wood sawdust and pulp directly as fuel. J. Electrochem. Soc. 164(6), F557–F563 (2017). https://doi.org/10.1149/2.0511706jes

Du. Hongbo, F. Deng, R.R. Kommalapati, A.S. Amarasekara, Iron based catalysts in biomass processing. Renew. Sustain. Energy Rev. 134(41), 110292 (2020). https://doi.org/10.1016/j.rser.2020.110292

Y. Hou, M. Niu, W. Wu, Catalytic oxidation of biomass to formic acid using O2 as an Oxidant. Ind. Eng. Chem. Res. 59(39), 16899–16910 (2020). https://doi.org/10.1021/acs.iecr.0c01088

L.W. Hui, Z. Yaakob, S.R.S. Abdullah, Artificial neural network modeling and performance optimization on biodiesel production process. J. Appl. Sci. Res. 8(10), 4854–4864 (2012)

S. Jayashree, S.T. Ramesh, A. Lavanya, R. Gandhimathi, P.V. Nidheesh, Wastewater treatment by microbial fuel cell coupled with peroxicoagulation process. Clean Technol. Environ. Policy 21(10), 2033–2045 (2019). https://doi.org/10.1007/s10098-019-01759-0

J. Kanner, J.B. German, J.E. Kinsella, Initiation of lipid peroxidation in biological systems. C R C Crit. Rev. Food Sci. Nutr. 25(4), 317–364 (1987). https://doi.org/10.1080/10408398709527457

L. Kavan, Y. Saygili, M. Freitag, S.M. Zakeeruddin, A. Hagfeldt, M. Grätzel, Electrochemical properties of Cu(II/I)-based redox mediators for dye-sensitized solar cells. Electrochim. Acta 227, 194–202 (2017). https://doi.org/10.1016/j.electacta.2016.12.185

P. Khomein, W. Ketelaars, T. Lap, G. Liu, Sulfonated aromatic polymer as a future proton exchange membrane: a review of sulfonation and crosslinking methods. Renew. Sustain. Energy Rev. 137, 110471 (2020). https://doi.org/10.1016/j.rser.2020.110471

J.W. Lee, T.W. Jeffries, Efficiencies of acid catalysts in the hydrolysis of lignocellulosic biomass over a range of combined severity factors. Biores. Technol. 102(10), 5884–5890 (2011). https://doi.org/10.1016/j.biortech.2011.02.048

J. Li, D.J. Ding, L. Deng, Q.X. Guo, Y. Fu, Catalytic air oxidation of biomass-derived carbohydrates to formic acid. ChemSusChem 5, 1–7 (2012). https://doi.org/10.1002/cssc.201100466

J. Li, W. Zhang, S. Xu, C. Hu, The roles of H2O/tetrahydrofuran system in lignocellulose valorization. Front. Chem. 8(February), 70 (2020). https://doi.org/10.3389/fchem.2020.00070

Y. Li, W. Liu, Z. Zhang, X. Du, L. Yu, Y. Deng, A self-powered electrolytic process for glucose to hydrogen conversion. Commun. Chem. 2(1), 1–9 (2019). https://doi.org/10.1038/s42004-019-0169-5

D. Little, S. Barbara, ChemInform Abstract: redox catalysis in organic electrosynthesis: basic principles and recent developments. Chem. Soc. Rev. (2014). https://doi.org/10.1039/c3cs60464k

C. Liu, Z. Zhang, W. Liu, D. Xu, H. Guo, G. He, X. Li, Y. Deng, Flow fuel cell powered by combustible agricultural waste. Clean Energy 2(1), 20–28 (2018). https://doi.org/10.1093/ce/zky001

W. Liu, Y.T. Gong, W.B. Wu, W.S. Yang, C.M. Liu, Y.L. Deng, Z.S. Chao, Efficient biomass fuel cell powered by sugar with photo- and thermal-catalysis by solar irradiation. ChemSusChem 11(13), 2229–2238 (2018). https://doi.org/10.1002/cssc.201800719

W. Liu, Y. Gong, A. Tricker, G. Wu, C. Liu, Z.S. Chao, Y. Deng, Fundamental study toward improving the performance of a high-moisture biomass-fueled redox flow fuel cell. Ind. Eng. Chem. Res. 59(10), 4817–4828 (2020). https://doi.org/10.1021/acs.iecr.9b06982

W. Liu, C. Liu, P. Gogoi, Y. Deng, Overview of biomass conversion to electricity and hydrogen and recent developments in low-temperature electrochemical approaches. Engineering 6(12), 1351–1363 (2020). https://doi.org/10.1016/j.eng.2020.02.021

W. Liu, W. Mu, Y. Deng, High-performance liquid-catalyst fuel cell for direct biomass-into-electricity conversion. Angew. Chem. 126(49), 13776–13780 (2014). https://doi.org/10.1002/ange.201408226

X. Liu, M. Hao, M. Feng, L. Zhang, Y. Zhao, X. Du, G. Wang, A one-compartment direct glucose alkaline fuel cell with methyl viologen as electron mediator. Appl. Energy 106, 176–183 (2013). https://doi.org/10.1016/j.apenergy.2013.01.073

X. Liu, L. Shi, J. Gu, Microbial electrocatalysis: redox mediators responsible for extracellular electron transfer. Biotechnol. Adv. (2018). https://doi.org/10.1016/j.biotechadv.2018.07.001

X. Liu, K. Reddi, A. Elgowainy, H. Lohse-busch, M. Wang, N. Rustagi, Comparison of well-to-wheels energy use and emissions of a hydrogen fuel cell electric vehicle relative to a conventional gasoline-powered internal combustion engine vehicle. Int. J. Hydrogen Energy (2019). https://doi.org/10.1016/j.ijhydene.2019.10.192

Y. Liu, H. Li, Enhancing conversion from glucose to electricity by ferric chloride in a redox flow fuel cell. Energy 189, 116171 (2019). https://doi.org/10.1016/j.energy.2019.116171

D. Lloyd, T. Vainikka, K. Kontturi, The development of an all copper hybrid redox flow battery using deep eutectic solvents. Electrochim. Acta 100, 18–23 (2013). https://doi.org/10.1016/j.electacta.2013.03.130

E. Madrid, C. Harabajiu, R.S. Hill, K. Black, L. Torrente-murciano, Indirect formic acid fuel cell based on a palladium or palladium-alloy film separating the fuel reaction and electricity generation. ChemElectroChem (2021). https://doi.org/10.1002/celc.202001570

S. Mekhilef, R. Saidur, A. Safari, Comparative study of different fuel cell technologies. Renew. Sustain. Energy Rev. 16(1), 981–989 (2012). https://doi.org/10.1016/j.rser.2011.09.020

M. Niu, Y. Hou, S. Ren, W. Wang, The relationship between oxidation and hydrolysis in the conversion of cellulose in NaVO3–H2SO4 aqueous solution with O2. Green Chem. (2014). https://doi.org/10.1039/c4gc00970c

L. Pudjiastuti, T. Iswanto, A. Altway, E.O. Ningrum, T. Widjaja, Lignocellulosic properties of coffee pulp waste after alkaline hydrogen peroxide treatment. IOP Conf. Ser. Mater. Sci. Eng. (2019). https://doi.org/10.1088/1757-899X/543/1/012081

J. Reichert, B. Brunner, A. Jess, P. Wasserscheid, J. Albert, Biomass oxidation to formic acid in aqueous media using polyoxometalate catalysts—boosting FA selectivity by in-situ extraction. Energy Environ. Sci. 8(10), 2985–2990 (2015). https://doi.org/10.1039/c5ee01706h

Y. Saygili, M. Stojanovic, N. Flores-d, S.M. Zakeeruddin, N. Vlachopoulos, M. Grätzel, A. Hagfeldt, Metal coordination complexes as redox mediators in regenerative dye-sensitized solar cells. Inorganics (2019). https://doi.org/10.3390/inorganics7030030

F. Shen, T. Guo, C. Bai, M. Qiu, X. Qi, Hydrolysis of cellulose with one-pot synthesized sulfonated carbonaceous solid acid. Fuel Process. Technol. 169(October 2017), 244–247 (2018). https://doi.org/10.1016/j.fuproc.2017.10.015

Y. Song, J. Jiang, W. Qin, J. Li, Y. Zhou, Y. Gao, Enhanced transformation of organic pollutants by mild oxidants in the presence of synthetic or natural redox mediators: a review. Water Res. 189, 116667 (2021). https://doi.org/10.1016/j.watres.2020.116667

R.B. Sotero-santos, Toxicity of ferric chloride sludge to aquatic organisms. Chemosphere 68, 628–636 (2007). https://doi.org/10.1016/j.chemosphere.2007.02.049

C. Sun, Q. Liao, A. Xia, C. Chen, Q. Fu, Y. Huang, X. Zhu, F. Sun, Hydrolysis of disaccharides via carbon-based solid acids with binding and catalytic domains: glycosidic bond fracture properties and reaction kinetics. Fuel 300(May), 120978 (2021). https://doi.org/10.1016/j.fuel.2021.120978

A.G. Tamirat, X. Guan, J. Liu, J. Luo, Y. Xia, Redox mediators as charge agents for changing electrochemical reactions. Chem. Soc. Rev. 49(20), 7454–7478 (2020). https://doi.org/10.1039/d0cs00489h

S.P. Teong, X. Li, Y. Zhang, Hydrogen peroxide as an oxidant in biomass-to-chemical processes of industrial interest. Green Chem. 21(21), 5753–5780 (2019). https://doi.org/10.1039/c9gc02445j

J. Tian, C. Fang, M. Cheng, X. Wang, Hydrolysis of cellulose over CsxH3-xPW12O40 (X = 1–3) heteropoly acid catalysts. Chem. Eng. Technol. 34(3), 482–486 (2011). https://doi.org/10.1002/ceat.201000409

C.T.C. Wan, D. López Barreiro, A. Forner-Cuenca, J.W. Barotta, M.J. Hawker, G. Han, H.C. Loh, A. Masic, D.L. Kaplan, Y.M. Chiang, F.R. Brushett, F.J. Martin-Martinez, M.J. Buehler, Exploration of biomass-derived activated carbons for use in vanadium redox flow batteries. ACS Sustain. Chem. Eng. 8(25), 9472–9482 (2020). https://doi.org/10.1021/acssuschemeng.0c02427

F. Wang, D. Ouyang, Z. Zhou, S.J. Page, D. Liu, X. Zhao, Lignocellulosic biomass as sustainable feedstock and materials for power generation and energy storage. J. Energy Chem. 57, 247–280 (2021). https://doi.org/10.1016/j.jechem.2020.08.060

F. Wang, S.S. Stahl, Electrochemical oxidation of organic molecules at lower overpotential: accessing broader functional group compatibility with electron-proton transfer mediators. Acc. Chem. Res. 53(3), 561–574 (2020). https://doi.org/10.1021/acs.accounts.9b00544

Q. Wang, Z. Wang, F. Shen, J. Hu, F. Sun, L. Lin, G. Yang, Y. Zhang, S. Deng, Pretreating lignocellulosic biomass by the concentrated phosphoric acid plus hydrogen peroxide (PHP) for enzymatic hydrolysis: evaluating the pretreatment flexibility on feedstocks and particle sizes. Biores. Technol. 166, 420–428 (2014). https://doi.org/10.1016/j.biortech.2014.05.088

Z. Wang, L. Dai, J. Yao, T. Guo, D. Hrynsphan, S. Tatsiana, J. Chen, Chemosphere Enhanced adsorption and reduction performance of nitrate by Fe–Pd–Fe3O4 embedded multi-walled carbon nanotubes. Chemosphere 281(May), 130718 (2021). https://doi.org/10.1016/j.chemosphere.2021.130718

W. Wu, W. Liu, W. Mu, Y. Deng, Polyoxymetalate liquid-catalyzed polyol fuel cell and the related photoelectrochemical reaction mechanism study. J. Power Sources 318, 86–92 (2016). https://doi.org/10.1016/j.jpowsour.2016.03.074

X. Xiong, I.K.M. Yu, S.S. Chen, D.C.W. Tsang, L. Cao, H. Song, E.E. Kwon, Y.S. Ok, S. Zhang, C.S. Poon, Sulfonated biochar as acid catalyst for sugar hydrolysis and dehydration. Catal. Today 314(October 2017), 52–61 (2018). https://doi.org/10.1016/j.cattod.2018.02.034

F. Xu, H. Li, Y. Liu, Q. Jing, Advanced redox flow fuel cell using ferric chloride as main catalyst for complete conversion from carbohydrates to electricity. Sci. Rep. 7(1), 1–9 (2017). https://doi.org/10.1038/s41598-017-05535-2

X.H. Yan, T.S. Zhao, L. An, G. Zhao, L. Shi, A direct methanol-hydrogen peroxide fuel cell with a Prussian Blue cathode. Int. J. Hydrogen Energy 41(9), 5135–5140 (2016). https://doi.org/10.1016/j.ijhydene.2016.01.066

C. Yang, R. Guo, X. Jing, P. Li, J. Yuan, Degradation mechanism and modeling study on reversible solid oxide cell in dual-mode—a review. Int. J. Hydrogen Energy 47, 37895 (2022)

G. Yang, X. Luo, L. Shuai, Bioinspired cellulase-mimetic solid acid catalysts for cellulose hydrolysis. Front. Bioeng. Biotechnol. 9(November), 1–10 (2021). https://doi.org/10.3389/fbioe.2021.770027

S. Yang, Y. Chung, K. Lee, Y. Kwon, Enhancements in catalytic activity and duration of PdFe bimetallic catalysts and their use in direct formic acid fuel cells. J. Ind. Eng. Chem. 90, 351–357 (2020). https://doi.org/10.1016/j.jiec.2020.07.034

H. Zhang, N. Li, X. Pan, S. Wu, J. Xie, Direct transformation of cellulose to gluconic acid in a concentrated Iron(III) chloride solution under mild conditions. ACS Sustain. Chem. Eng. 5(5), 4066–4072 (2017). https://doi.org/10.1021/acssuschemeng.7b00060

J. Zhang, A. Zhong, G. Huang, M. Yang, D. Li, M. Teng, D. Han, Enhanced efficiency with CDCA co-adsorption for dye-sensitized solar cells based on metallosalophen complexes. Sol. Energy 209(August), 316–324 (2020). https://doi.org/10.1016/j.solener.2020.08.096

Z. Zhang, C. Liu, W. Liu, X. Du, Y. Cui, J. Gong, H. Guo, Y. Deng, Direct conversion of sewage sludge to electricity using polyoxomatelate catalyzed flow fuel cell. Energy 141, 1019–1026 (2017). https://doi.org/10.1016/j.energy.2017.09.143

X. Zhao, Y. Ding, B. Du, J.Y. Zhu, D. Liu, Polyoxometalate-mediated lignin oxidation for efficient enzymatic production of sugars and generation of electricity from lignocellulosic biomass. Energy Technol. 5(8), 1179–1185 (2017). https://doi.org/10.1002/ente.201600662

Y. Zheng, Y. Liu, X. Guo, Z. Chen, W. Zhang, Y. Wang, X. Tang, Y. Zhang, Y. Zhao, Sulfur-doped g-C3N4/rGO porous nanosheets for highly efficient photocatalytic degradation of refractory contaminants Yanmei. J. Mater. Sci. Technol. (2019). https://doi.org/10.1016/j.jmst.2019.09.018

Z. Zhou, D. Liu, X. Zhao, Conversion of lignocellulose to biofuels and chemicals via sugar platform: An updated review on chemistry and mechanisms of acid hydrolysis of lignocellulose. Renew. Sustain. Energy Rev. 146(December), 111169 (2021). https://doi.org/10.1016/j.rser.2021.111169

X. Zu, L. Sun, J. Gong, X. Liu, Y. Liu, X. Du, W. Liu, L. Chen, G. Yi, W. Zhang, W. Lin, W. Li, Y. Deng, Ferric ion pair mediated biomass redox flow fuel cell and related chemical reaction kinetics study. Chem. Eng. J. 348, 476–484 (2018). https://doi.org/10.1016/j.cej.2018.03.190

X. Zu, Z. Yang, L. Sun, W. Lin, G. Yi, X. Zheng, W. Li, Ferric–ferrous redox couple mediated low temperature symmetric flow fuel cell for direct conversion of biomass residues into electricity. J. Power Sources (2019). https://doi.org/10.1016/j.jpowsour.2019.227441

Acknowledgements

The authors gratefully acknowledge financial support from the World Bank-funded Second Africa Higher Education Centres of Excellence for Development Impact (ACE Impact) Project—P169064, IDA No 6510-NG. The Nigerian Communications Commission (NCC) is acknowledged for the HY4TEL project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised due to mistakenly published a graphical abstract and highlights.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ugwu, B.I., Akalezi, C., Ike, I.S. et al. Biomass Oxidation in Direct Biomass Redox Flow Fuel Cell: The Roles of Catalysts, Redox Couples, Mediators and Oxidants. Korean J. Chem. Eng. 41, 1257–1272 (2024). https://doi.org/10.1007/s11814-024-00131-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-024-00131-3