Abstract

The aim of this article is an empirical investigation of the MWCNT and ZnO (30:70)/10W40 HNF against SR, SVF, and T. In this study, the nanoparticles (NPs) are examined with SVF = 0.05%-1% and T = 5–55 °C. After adding NPs to 10W40 engine oil, non-Newtonian behavior is observed. Optimizing the viscosity behavior of NF is another goal of this study, which has been achieved with the special combination of NPs and adding them to the base fluid. The present introduced NF has given a more controlled viscosity and a cheaper price in competition with the other three reviewed NFs available in the literature. To predict the viscosity, RSM is used, which is based on the experimental results. The margin of deviation (MOD) is less than ±5%. Also, the sensitivity analysis in different SVFs and temperatures is analyzed separately.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nanotechnology is the use of scientific knowledge in the manipulation and control of matter, often in the nanoscale to exploit phenomena and properties dependent on structure and size. These distinct properties are the properties of individual atoms and molecules and cannot be inferred from the mass form of the same substance [1,2,3,4,5,6,7]. In recent years, it is necessary to manage energy and use new resources because of increasing demand and energy cost [8,9,10,11,12,13,14,15,16]. On the other hand, cooling and heating the energy systems are an integral part of this process [17,18,19,20,21,22,23,24]. Thus, the HT and these systems efficiency could be increased by choosing an appropriate method [25,26,27,28,29,30,31,32,33,34,35,36]. Common liquids such as water, EG, or oil are used to cool and lubrication in conventional systems. However, regarding their low thermal performance, the researchers have suggested adding the nano-sized solid particles known as nanoparticles [37,38,39,40,41,42,43,44] like metals, nitrides, carbon nanotubes and metal oxides to the based liquids like water, EG, or oils that cause better and faster heat transfer than the systems [45,46,47,48,49,50,51,52,53,54,55]. The name of the prepared suspension is NF [56,57,58,59,60,61,62,63,64,65,66] and the preparation process is shown in Fig. 1.

Main function in oil is preventing of friction, but it also has other functions such as sealing, preventing corrosion and cleaning the engine. In addition, the oils are also used to cool the internal parts of the engine [67,68,69,70,71,72,73,74,75,76]. Some other applications of NFs have been displayed in Fig. 2. Thermophysical properties of NF are different from the base fluid [77,78,79,80,81,82,83,84,85,86]. Among the important thermophysical properties, viscosity [87,88,89,90,91,92,93,94], thermal conductivity [95,96,97,98,99,100,101], density [102,103,104] and specific heat capacity [105,106,107,108,109,110] can be mentioned. Knowing the properties of nanofluid will make it used in the right place and it will be planned according to the need and application. Viscosity is defined as the resistance of a fluid to flow. Viscosity is an important parameter for oil pumping. Many scientists examined the adding NPs effect to based fluid. They found that the factors affect the viscosity [111,112,113,114,115,116,117,118,119,120,121,122].

Specifying rheological behavior of the NF causes to prevent possible damages to the systems such as the car engine [123]. For example, if the NF reveals a non-Newtonian behavior [124,125,126,127,128], the NF has much yield stress because a large amount of yield stress causes to damage the engine parts at the start. The studies about the behavior of the NF can be observed in Table 1.

Nevertheless, the cost of producing and testing the NFs is relatively high. To reduce costs, modeling can be used to determine the properties of the NFs [133,134,135,136]. In this regard, some scientists like Einstein [137] gave a theoretical model for of relative viscosity prediction of NFs: Einstein’s model is applied for SVF < 0.02 and the sphericity hypothesis of suspended solid particles in based fluid.

Wang et al. [138] proposed relative viscosity model that is used according to physical state phases:

Moreover, Bruijn [139] proposed a model to predict \(\mu_{r}\):

But these models are not able for of new generation of the NFs i.e., the hybrid NFs [140,141,142]. In recent years, some scientists presented models for predicting hybrid NFs viscosity to solve this problem [143,144,145,146,147,148,149,150]. Hemmat Esfe et al. [151, 152] have performed many experiments and modeling in this field. According to the importance of NF viscosity in the industry, Asadi and Asadi [153] studied ZnO/MWCNT NF properties of engine oil in based fluid. Their results showed a decrease of 58% in viscosity with rise in T and an increase of 45% with an increase in the SVF. They also found that the increment of the SVF at low temperatures causes a further increase the viscosity. In this study, rheological behavior of MWCNT and ZnO (30:70) with10W40 hybrid NF has been investigated. First, n index of NF was measured and it was determined that NF is a non-Newtonian and pseudo-plastic type of fluid. Relative viscosity and optimal viscosity at different temperatures and SVFs were investigated and compared with other NFs in terms of preparation costs and quality of viscosity. With the help of RSM, a model was presented to predict NF relative viscosity based on SR, SVF and T. Then, the MOD and sensitivity analysis were measured at T = 55 °C, SVF = 1%. The use of RSM improves the accuracy and speed of achieving the result and avoids the costs of preparation of NFs.

Experimentation

Nanofluid Preparation

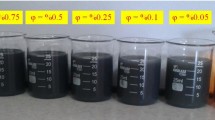

MWCNT-ZnO NF was prepared with a volume ratio (30:70) in based fluid 10W40 with the SVF = 0.05%, 0.1%, 0.25%, 0.5%, 0.75% and 1%. The used NPs are visible in Fig. 3. Then, of NPs volumetric concentrations were computed using Eq. 4 and suspended by a 2-step method in based fluid 10W40. The prepared NFs are displayed in Fig. 3.

Results and Discussion

NF Behavior

Rheological behavior of HNF MWCNT-ZnO (30:70) based on 10W40 was researched at T = 5–55 °C and SVF = 0.05–1%. Non-Newtonian properties could be represented by processing the data and using Eq. 5 [154]:

Figure 4 shows n index in SVF and T. NF behavior is similar to non-Newtonian by increasing T.

Figure 5 shows viscosity versus SR at different SVFs in comparison with the SR. The measurements indicate the dependence of the NF viscosity on SR. The increment of SS is associated with a decrease in viscosity. Given that a rise in the temperature causes to accelerate the movement of the NF particles and reduces the intermolecular force. Figure 6 shows reduction of NF viscosity with T rise. T and SVF effects on relative viscosity are displayed in Fig. 7. At higher SVF, maximum amount happens. The relative viscosity changed a little by increasing T because base fluid viscosity also increased proportionally.

Figure 8 shows NF viscosity percentage increment in comparison with SVF at various temperatures. The NF viscosity is decreased slightly by adding small amounts of the NPs to the base fluid. The small amounts of NPs cause the NF layers to displace on each other easily, but the increment of the NP amount causes to increase in the number of collisions, hence the layers move hard. Ultimately, the increment of the collisions causes to increase in the NF viscosity.

Compare With Other NF

Presence of four types of NPs has been investigated in the same base fluid 10W40. In this section, the experiment results of MWCNT (30%)-ZnO(70%)/10W40 have been compared with the results of other researches of Hemmat Esfe et al., MWCNT-SiO2(10:90)/10W40 NF [151], MWCNT-CuO(15:85)/10W40 NF [152] and MWCNT-TiO2(55:45%)/10W40 NF [155] at Ts and SVFs. The compared results in Fig. 9 display that NF MWCNT (% 15) -CuO (85%)/10W40 has a lower viscosity than three other NFs at lower SVFs. Moreover, the MWCNT-ZnO (30:70)/10W40 has the lowest viscosity at higher SVFs than other NFs. The optimal NF can be selected according to the use of the NF in Fig. 9 different parts.

In this section, viscosity increment percentage and the cost of using the NF MWCNT (30%)-ZnO (70%)/10W40 have been compared with other studies results of Hemmat Esfe et al., MWCNT-SiO2 (10:90)/10W40 NF [151], MWCNT-CuO(15:85)/10W40 NF [152] and MWCNT-TiO2 (55:45)/10W40 NF [155]. Figure 10 shows the lowest cost for preparing the MWCNT-SiO2 (10:90)/10W40 NF. It can be said that it is the best choice according to the approximately equal increment rate of the studied NFs.

Correlation

Considering the inability for predicting of MWCNT(30%)-ZnO(70%)/10W40 NF viscosity by using available theoretical models and also the expensiveness of conducting experimental tests, nanofluid viscosity modeling could be suitable way for reducing of costs, high accuracy and increase the speed of obtaining the answer. In this section by RSM, a model has been presented that can predict the relative viscosity at the temperature range and the studied SVF. In the modeling, stepwise method has been selected for the regression analysis. The independent parameters have been added to equation one by one. If an independent parameters doesn’t have a tangible effect on dependent variable during calculations, it will be eliminated from analysis and will not be included in equation. Regression coefficient (Eq. 6) is 0.9529 and model has good accuracy.

The validity and reliability of regression models have been researched using Analysis of Variance (ANOVA). Table 2 displays each parameter in Eq. 6. Table 2 shows the importance of each parameter in Eq. 6. Regression model significance is displayed by high F (172.0563). Prob > F-values less than 0.05 indicate statistical significance of model parameters. Extra model parameters effects are shown greater than 0.05 with Prob > F-values. All irrelevant parameters of model are removed.

Presented model results comparison with experimental results is shown in Fig. 11. There is an appropriate match between experimental results and prediction, which indicates high accuracy of the model. Thus, we can rely on the results obtained from the model. The MOD versus the SVF at different temperatures and for the two SRs is presented in Fig. 12. The maximum error of 5% indicates high accuracy. Equation 7 is used to get a MOD (%),

Sensitivity Analysis

To examine the independent parameters of the temperature and the SVF of the NPs, sensitivity analysis has been used to determine each parameter effect separately. The sensitivity percentage of each parameter on the temperature range and the SVF was obtained by varying ± 5%, ± 10% ± 15%, and ± 20% separately. Equation 8 is used to get the sensitivity percentage.

Figure 13 shows that SVF effect on NF relative viscosity is higher than T effect according to sensitivity analysis results.

Conclusion

MWCNT -ZnO(30:70)/10W40 NF was investigated with the SVF = 0.05% to 1% and at T = 5–55 °C. The NF behavior was specified as pseudo-plastic type and a non-Newtonian. The following results were obtained by further reviews:

-

At higher (SVFs), NF relative viscosity is much higher because the collisions are increased at higher SVFs of the NPs.

-

The NF viscosity is decreased slightly with small amount adding of NPs to based fluid because low amount of the NPs causes NF layers to displace on each other easily. However, the increment of the NPs causes the layers to move hard; hence, the NF viscosity is increased.

-

The results of the comparison between the different NFs show that the MWCNT-CuO (15:85)/10W40 NF has lower viscosity at lower SVFs than the other three NFs. Moreover, the MWCNT (%30)-ZnO (% 70)/10W40 NF has the lowest viscosity at higher SVFs than other NFs. The optimal NF can be selected according to the use of the NF in different parts.

-

Regarding the comparison of the costs for preparing the different NFs, we concluded that the minimum cost of the preparation is related to the MWCNT(10%)-SiO2 (90%)/10W40 NF. It can be said that it is the best choice according to the approximately equal increment rate of the studied NFs.

-

A model with a maximum error of 5% was presented by Response surface methodology; this shows the high accuracy of the proposed model.

-

NF sensitivity analysis indicated that SVF effect on relative viscosity is higher than of T effect.

Data Availability

Data sharing not applicable to this article as no datasets were generated or analyzed during the current study.

Abbreviations

- APS:

-

Average particle size

- Eq.:

-

Equation.

- FSR:

-

Full scale range

- MOD:

-

Margin of deviation

- MWCNT:

-

Multi-walled carbon nanotubes

- n:

-

Power law index

- NF:

-

Nanofluid

- NPs:

-

Nanoparticles

- RSM:

-

Response surface methodology

- SR:

-

Shear rates

- SSA:

-

Specific surface area

- SVF:

-

Solid volume fraction

- \(\dot{{\varvec{\upgamma}}}({\mathbf{s}}^{-1})\) :

-

Shear rate

- \(\mathbf{\varphi }\) :

-

Solid volume fraction

- μ(N.s/m2):

-

Dynamic viscosity

- \({{\varvec{\upmu}}}_{\mathbf{n}\mathbf{f}}\)(N.s/m2):

-

Dynamic viscosity of nanofluid

- ρ (kg/m3):

-

Density

- D(m):

-

Diameter

- T(°C):

-

Temperature

- m(kg):

-

Mass

- W (kg/mol):

-

Molecular mass

- P (Pa):

-

Pressure drop

- R2 :

-

Coefficient of determination

References

L. Sun, G. Wang, C. Zhang, Q. Jin, Y. Song, On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid. Nanotechnol. Rev. (Berlin) 10(1), 1339–1348 (2021)

J. Huo, H. Wei, L. Fu, C. Zhao, C. He, Highly active Fe36Co44 bimetallic nanoclusters catalysts for hydrolysis of ammonia borane: the first-principles study. Chin. Chem. Lett. 34(2), 107261 (2023)

H. Suhad, H. Neihaya, A. Raghad, Evaluating the biological activities of biosynthesized ZnO nanoparticles using Escherichia coli. Casp. J. Environ. Sci. 19(5), 809–815 (2021)

Y. Sun, C. Li, C. Yang, G. Dai, L. Li, Z. Hu, J. Zhu, Novel Li3VO4 nanostructures grown in highly efficient microwave irradiation strategy and their in-situ lithium storage mechanism. Adv. Sci. 9(3), 2103 (2022)

M. Issa, Rapid enzymatically reduction of zincum gluconicum for the biomanufacturing of zinc oxide nanoparticles by mycoextracellular filtrate of Penicillium Digitatum (Pdig-B3) as a soft green technique. Arch. Razi Inst. 77(1), 101–110 (2022)

S. Alidoust, M. Zamani, M. Jabbari, Sol-gel synthesis of nanoporous γ-alumina using TX-100 or gelatin/TX-100 mixture as effective catalysts for dehydration of alcohols. Iran. J. Catal. 10(4), 295–305 (2020)

Y. Niu, S. Gong, X. Liu, C. Xu, M. Xu, S.G. Sun, Z. Chen, Engineering iron-group bimetallic nanotubes as efficient bifunctional oxygen electrocatalysts for flexible Zn–air batteries. Escience 2(5), 546–556 (2022)

A. Komeilibirjandi, A.H. Raffiee, A. Maleki, M.A. Nazari, M.S. Shadloo, Thermal conductivity prediction of nanofluids containing CuO nanoparticles by using correlation and artificial neural network. J. Therm. Anal. Calorim. 139(4), 2679–2689 (2020)

M.H. Esfe, M.H. Hajmohammad, P. Razi, M.R.H. Ahangar, A.A.A. Arani, The optimization of viscosity and thermal conductivity in hybrid nanofluids prepared with magnetic nanocomposite of nanodiamond cobalt-oxide (ND-Co3O4) using NSGA-II and RSM. Int. Commun. Heat Mass Transfer 79, 128–134 (2016)

Y. Peng, A. Parsian, H. Khodadadi, M. Akbari, K. Ghani, M. Goodarzi, Q.V. Bach, Develop optimal network topology of artificial neural network (AONN) to predict the hybrid nanofluids thermal conductivity according to the empirical data of Al2O3–Cu nanoparticles dispersed in ethylene glycol. Physica A 549, 124015 (2020)

F. Soltani, D. Toghraie, A. Karimipour, Experimental measurements of thermal conductivity of engine oil-based hybrid and mono nanofluids with tungsten oxide (WO3) and MWCNTs inclusions. Powder Technol. 371, 37–44 (2020)

S. Fuxi, S. Hamedi, M. Hajian, D. Toghraie, A.A. Alizadeh, M. Hekmatifar, N. Sina, Addition of MWCNT-Al2O3 nanopowders to water-ethylene glycol (EG) base fluid for enhancing the thermal characteristics: design an optimum feed-forward neural network. Case Stud. Thermal Eng. 27, 101293 (2021)

M. Jamei, I.A. Olumegbon, M. Karbasi, I. Ahmadianfar, A. Asadi, M. Mosharaf-Dehkordi, On the thermal conductivity assessment of oil-based hybrid nanofluids using extended Kalman filter integrated with feed-forward neural network. Int. J. Heat Mass Transf. 172, 121159 (2021)

S.S.A. Toosi, H.R. Goshayeshi, I. Zahmatkesh, V. Nejati, Experimental assessment of new designed stepped solar still with Fe3O4+ graphene oxide+ paraffin as nanofluid under constant magnetic field. J. Energy Storage 62, 106795 (2023)

B. Jalili, A. Rezaeian, P. Jalili, F. Ommi, D.D. Ganji, Numerical modeling of magnetic field impact on the thermal behavior of a microchannel heat sink. Case Stud. Thermal Eng. 45, 102944 (2023)

S. Parand, M. Ziaei-Rad, S. Asghari, Thermal performance analysis of a trapezoid-shape grooved heat pipe with different working fluids for zero gravity applications. Thermal Sci. Eng. Progr. 40, 101802 (2023)

X.X. Tian, R. Kalbasi, C. Qi, A. Karimipour, H.L. Huang, Efficacy of hybrid nano-powder presence on the thermal conductivity of the engine oil: an experimental study. Powder Technol. 369, 261–269 (2020)

M.H. Esfe, Designing a neural network for predicting the heat transfer and pressure drop characteristics of Ag/water nanofluids in a heat exchanger. Appl. Therm. Eng. 126, 559–565 (2017)

N. Wang, A. Maleki, M. Alhuyi Nazari, I. Tlili, M. Safdari Shadloo, Thermal conductivity modeling of nanofluids contain MgO particles by employing different approaches. Symmetry 12(2), 206 (2020)

S. Ebrahimi, Thermal conductivity of water base Ni-np@ MWCNT magnetic nanofluid. Mater. Res. Bull. 150, 111781 (2022)

A. Dastnaei, M. Behbahani, R. Pourrajab, A. Noghrehabadi, Evaluation and optimization of the thermal conductivity enhancement of a water-based GO nanosheets/Au NPs hybrid nanofluid: Box-Behnken design. New J. Chem. 46(41), 20010–20021 (2022)

N. Nayebpashaee, S.M.M. Hadavi, Thermal conductivity and surface tension of graphene–Al2O3/ethylene glycol–water hybrid nanofluid at sub-zero temperatures: an experimental study. J. Thermal Anal. Calorim. (2022). https://doi.org/10.1007/s10973-022-11587-y

H. Dorrani, A. Mohebbi, Molecular dynamics insight into the best governing mechanism for thermophysical properties changes in nanofluids. J. Therm. Anal. Calorim. 148(10), 4359–4375 (2023)

M. Nemati, S.D. Farahani, H.M. Sani, Assessment of effectiveness amount of heat absorption/production and magnetic field on entropy generation during conjugate heat transfer of hybrid nanofluid. J. Inst. Eng. (India) 104(2), 231–252 (2023)

Z. Zhu, Y. Sun, C. Li, C. Yang, L. Li, J. Zhu, Y. Li, Mini-review: progress on micro/nanoscale MnMoO 4 as an electrode material for advanced supercapacitor applications. Mater. Chem. Front. 5(20), 7403–7418 (2021)

H. Li, Y. Zhang, C. Li, Z. Zhou, X. Nie, Y. Chen, S. Sharma, Extreme pressure and antiwear additives for lubricant: academic insights and perspectives. Int. J. Adv. Manuf. Technol. 120(1–2), 1–27 (2022)

H. Li, Y. Zhang, C. Li, Z. Zhou, X. Nie, Y. Chen, S. Sharma, Cutting fluid corrosion inhibitors from inorganic to organic: progress and applications. Korean J. Chem. Eng. 39(5), 1107–1134 (2022)

J. Song, D. Yu, X. Wu, D. Xie, Y. Sun, P. Vishniakov, S. Peng, Interfacial coupling porous cobalt nitride nanosheets array with N-doped carbon as robust trifunctional electrocatalysts for water splitting and Zn-air battery. Chem. Eng. J. 437, 135281 (2022)

J. Zhu, C. Li, Y. Sun, C. Yang, Y. Zhao, Z. Zhu, Y. Li, Enhanced photoluminescence of hollow CaWO 4 microspheres: the fast fabrication, structural manipulation, and exploration of the growth mechanism. Mater. Chem. Front. 6(8), 1046–1055 (2022)

L. Tang, Y. Zhang, C. Li, Z. Zhou, X. Nie, Y. Chen, H. Cao, B. Liu, N. Zhang, Z. Said, S. Debnath, M. Jamil, H.M. Ali, S. Sharma, Biological stability of water-based cutting fluids: progress and application. Chin. J. Mech. Eng. 35(1), 1–24 (2022)

W. Cui, X. Li, X. Li, T. Si, L. Lu, T. Ma, Q. Wang, Thermal performance of modified melamine foam/graphene/paraffin wax composite phase change materials for solar-thermal energy conversion and storage. J. Clean. Prod. 367, 133031 (2022)

A. Barkhordar, R. Ghasemiasl, T. Armaghani, Statistical study and a complete overview of nanofluid viscosity correlations: a new look. J. Therm. Anal. Calorim. 147(13), 7099–7132 (2022)

M.H. Esfe, M. Bahiraei, H. Hajbarati, M. Valadkhani, A comprehensive review on convective heat transfer of nanofluids in porous media: energy-related and thermohydraulic characteristics. Appl. Therm. Eng. 178, 115487 (2020)

A. Heydari, M. Goharimanesh, M.R. Gharib, Dynamic viscosity analysis of hybrid nanofluid MWCNT-Al2O3/engine oil using statistical models with evaluating its performance in a double tube heat exchanger. J. Thermal Anal. Calorim. 5, 1–15 (2022)

M. Mokarian, E. Ameri, The effect of Mg (OH) 2 nanoparticles on the rheological behavior of base engine oil SN500 HVI and providing a predictive new correlation of nanofluid viscosity. Arab. J. Chem. 15(6), 103767 (2022)

S. Dinarvand, H. Berrehal, H. Tamim, G. Sowmya, S. Noeiaghdam, M. Abdollahzadeh, Squeezing flow of aqueous CNTs-Fe3O4 hybrid nanofluid through mass-based approach: effect of heat source/sink, nanoparticle shape, and an oblique magnetic field. Results Eng. 17, 100976 (2023)

M.H. Esfe, H. Rostamian, Non-Newtonian power-law behavior of TiO2/SAE 50 nano-lubricant: an experimental report and new correlation. J. Mol. Liq. 232, 219–225 (2017)

N. Alipour, B. Jafari, K. Hosseinzadeh, Optimization of wavy trapezoidal porous cavity containing mixture hybrid nanofluid (water/ethylene glycol Go–Al2O3) by response surface method. Sci. Rep. 13(1), 1635 (2023)

Y. Azizi, M. Bahramkhoo, A. Kazemi, Influence of non-uniform magnetic field on the thermal efficiency hydrodynamic characteristics of nanofluid in double pipe heat exchanger. Sci. Rep. 13(1), 407 (2023)

M. Izadi, B. Alshuraiaan, A. Hajjar, M.A. Sheremet, M.B.B. Hamida, Free convection of nanofluids in a porous sensible heat storage unit: Combined effect of time periodic heating and external magnetic field. Int. J. Therm. Sci. 192, 108404 (2023)

E. Golab, B. Vahedi, A. Jain, R.A. Taylor, K. Vafai, Laminar forced convection in a tube with a nano-encapsulated phase change materials: Minimizing exergy losses and maximizing the heat transfer rate. J. Energy Storage 65, 107233 (2023)

F. Mehrabi, M. Ghaedi, E.A. Dil, Magnetic nanofluid based on hydrophobic deep eutectic solvent for efficient and rapid enrichment and subsequent determination of cinnamic acid in juice samples: Vortex-assisted liquid-phase microextraction. Talanta 260, 124581 (2023)

F. Seifikar, S. Azizian, A. Nasri, B. Jaleh, Comparative study on photo-thermal conversion properties of vanadium nanofluids prepared by laser ablation in H2O and polyethylene glycol. J. Ind. Eng. Chem. 123, 72–80 (2023)

M.H. Esfe, A.A. Nadooshan, A. Arshi, A. Alirezaie, Convective heat transfer and pressure drop of aqua based TiO2 nanofluids at different diameters of nanoparticles: data analysis and modeling with artificial neural network. Physica E 97, 155–161 (2018)

M. Wang, C. Li, Y. Sun, C. Yang, L. Li, Z. Zhu, S. Chou, A Li 3 VO 4 micro/nanoscale anode with fast ion transportation for advanced lithium-ion batteries: a mini-review. J. Mater. Chem. C 9(42), 14981–14996 (2021)

A. Abderrahmane, N.A. Qasem, O. Younis, R. Marzouki, A. Mourad, N.A. Shah, J.D. Chung, MHD hybrid nanofluid mixed convection heat transfer and entropy generation in a 3-D triangular porous cavity with zigzag wall and rotating cylinder. Mathematics 10(5), 769 (2022)

M. Dhlamini, H. Mondal, P. Sibanda, S. Motsa, Activation energy and entropy generation in viscous nanofluid with higher order chemically reacting species. Int. J. Ambient Energy 43(1), 1495–1507 (2022)

M.I. Asjad, M. Zahid, F. Jarad, A.M. Alsharif, Bioconvection flow of MHD viscous nanofluid in the presence of chemical reaction and activation energy. Math. Probl. Eng. (2022). https://doi.org/10.1155/2022/1707894

A.Y. Bhat, A. Qayoum, Viscosity of CuO nanofluids: experimental investigation and modelling with FFBP-ANN. Thermochim. Acta 714, 179267 (2022)

M. Yasir, A. Hafeez, M. Khan, Thermal conductivity performance in hybrid (SWCNTs-CuO/Ehylene glycol) nanofluid flow: dual solutions. Ain Shams Eng. J. 13(5), 101703 (2022)

H. Narimani, Research on synthesis of heterocyclic structures using ZnO NPs as catalyst. J. Synth. Chem. 1(2), 62–83 (2022)

T. Zolfaghari, Z. Rafiee, Preparation and study of surface modified ZnO nanoparticles in copoly (amid-imide) nanocomposite films containing triptycene. J. Synth. Chem. 1(2), 108–115 (2022)

R. Zahmatkesh, H. Mohammadiun, M. Mohammadiun, M. Dibaei Bonab, M. Sadi, Theoretical investigation of entropy generation in axisymmetric stagnation point flow of nanofluid impinging on the cylinder axes with constant wall heat flux and uniform transpiration. Iran. J. Chem. Chem. Eng. (IJCCE) 40(6), 1893–1908 (2021). https://doi.org/10.30492/ijcce.2020.43346

A. Bilal, F. Mabood, Numerical investigation of mixed convection flow of viscoelastic nanofluid with convective conditions over an exponentially stretching surface. Iran. J. Chem. Chem. Eng. (IJCCE) 40(6), 1931–1942 (2021)

X. Wang, C. Li, Y. Zhang, Z. Said, S. Debnath, S. Sharma, T. Gao, Influence of texture shape and arrangement on nanofluid minimum quantity lubrication turning. Int. J. Adv. Manuf. Technol. 119(12), 631–646 (2022)

M.H. Esfe, S. Saedodin, M. Biglari, H. Rostamian, An experimental study on thermophysical properties and heat transfer characteristics of low volume concentrations of Ag-water nanofluid. Int. Commun. Heat Mass Transfer 74, 91–97 (2016)

M. Sepehrnia, K. Mohammadzadeh, M.M. Veyseh, E. Agah, M. Amani, Rheological behavior of engine oil based hybrid nanofluid containing MWCNTs and ZnO nanopowders: experimental analysis, developing a novel correlation, and neural network modeling. Powder Technol. 404, 117492 (2022)

P. Kanti, K.V. Sharma, K.M. Yashawantha, M. Jamei, Z. Said, Properties of water-based fly ash-copper hybrid nanofluid for solar energy applications: application of RBF model. Sol. Energy Mater. Sol. Cells 234, 111423 (2022)

R. Bardool, A. Bakhtyari, F. Esmaeilzadeh, X. Wang, Developing free-volume models for nanofluid viscosity modeling. J. Thermal Anal. Calorim. (2022). https://doi.org/10.1007/s10973-020-10373-y

M. Rejvani, A. Heidari, S. Seadodin, Simultaneous effects of MWCNT and SiO2 on the rheological behavior of cooling oil and sensitivity analysis. Heliyon 9, e12942 (2023)

M.H. Ahmadi, B. Mohseni-Gharyehsafa, M. Ghazvini, M. Goodarzi, R.D. Jilte, R. Kumar, Comparing various machine learning approaches in modeling the dynamic viscosity of CuO/water nanofluid. J. Therm. Anal. Calorim. 139(4), 2585–2599 (2020)

S.R. Yan, R. Kalbasi, Q. Nguyen, A. Karimipour, Rheological behavior of hybrid MWCNTs-TiO2/EG nanofluid: a comprehensive modeling and experimental study. J. Mol. Liq. 308, 113058 (2020)

M. Salarnia, D. Toghraie, M.A. Fazilati, B. Mehmandoust, M. Pirmoradian, The effects of different nanoparticles on physical and thermal properties of water in a copper oscillating heat pipe via molecular dynamics simulation. J. Taiwan Inst. Chem. Eng. 143, 104721 (2023)

H. Naghizadeh, R. Nosouhi, S.A. Badiezadegan, M. Soleymani, A.M. Azadi, N. Azimy, H. Azimy, Effect of using CuO-oil nanofluid on surface roughness and thermal performance during superfinishing process. Adv. Eng. Mater. (2023). https://doi.org/10.1002/adem.202201918

M. Ghassemi, A. Shahidian, G. Ahmadi, S. Hamian, A new effective thermal conductivity model for a bio-nanofluid (blood with nanoparticle Al2O3). Int. Commun. Heat Mass Transfer 37(7), 929–934 (2010)

A. Kakavandi, M. Akbari, Experimental investigation of thermal conductivity of nanofluids containing of hybrid nanoparticles suspended in binary base fluids and propose a new correlation. Int. J. Heat Mass Transf. 124, 742–751 (2018)

H.F. Asl, G. Zargar, A.K. Manshad, M.A. Takassi, J.A. Ali, A. Keshavarz, Effect of SiO2 nanoparticles on the performance of L-Arg and L-Cys surfactants for enhanced oil recovery in carbonate porous media. J. Mol. Liq. 300, 112290 (2020)

A. Keykhosravi, M.B. Vanani, C. Aghayari, TiO2 nanoparticle-induced Xanthan Gum Polymer for EOR: Assessing the underlying mechanisms in oil-wet carbonates. J. Petrol. Sci. Eng. 204, 108756 (2021)

R. Khoramian, R. Kharrat, S. Golshokooh, The development of novel nanofluid for enhanced oil recovery application. Fuel 311, 122558 (2022)

M. Sepehrnia, M. Lotfalipour, M. Malekiyan, M. Karimi, S.D. Farahani, Rheological behavior of SAE50 Oil–SnO2–CeO2 hybrid nanofluid: experimental investigation and modeling utilizing response surface method and machine learning techniques. Nanoscale Res. Lett. 17(1), 117 (2022)

M. Farbod, N. Bahmani, Fabrication of AlN nanoparticles by arc discharge method and investigation of thermal conductivity of AlN transformer oil-based nanofluid. J. Austral. Ceram. Soc. (2022). https://doi.org/10.1007/s41779-022-00791-6

H. Pourpasha, S.Z. Heris, M. Mohammadpourfard, The effect of TiO2 doped multi-walled carbon nanotubes synthesis on the thermophysical and heat transfer properties of transformer oil: a comprehensive experimental study. Case Stud. Thermal Eng. 41, 102607 (2023)

H. Cheng, A.M. Abed, A.A. Alizadeh, A.A. Ghabra, F.M. Altalbawy, R. Sabetvand, Y. Riadi, The effect of temperature and external force on the thermal behavior of oil-based refrigerant inside a nanochannel using molecular dynamics simulation. J. Mol. Liq. 369, 120893 (2023)

S. Aberoumand, A. Jafarimoghaddam, Tungsten (III) oxide (WO3)–Silver/transformer oil hybrid nanofluid: Preparation, stability, thermal conductivity and dielectric strength. Alex. Eng. J. 57(1), 169–174 (2018)

M.A. Akhavan-Behabadi, F. Hekmatipour, S.M. Mirhabibi, B. Sajadi, Experimental investigation of thermal–rheological properties and heat transfer behavior of the heat transfer oil–copper oxide (HTO–CuO) nanofluid in smooth tubes. Exp. Thermal Fluid Sci. 68, 681–688 (2015)

M. Asadi, A. Asadi, S. Aberoumand, An experimental and theoretical investigation on the effects of adding hybrid nanoparticles on heat transfer efficiency and pumping power of an oil-based nanofluid as a coolant fluid. Int. J. Refrig. 89, 83–92 (2018)

A.S. Dogonchi, M. Waqas, S.M. Seyyedi, M. Hashemi-Tilehnoee, D.D. Ganji, A modified Fourier approach for analysis of nanofluid heat generation within a semi-circular enclosure subjected to MFD viscosity. Int. Commun. Heat Mass Transfer 111, 104430 (2020)

M. Molana, A.S. Dogonchi, T. Armaghani, A.J. Chamkha, D.D. Ganji, I. Tlili, Investigation of hydrothermal behavior of Fe3O4-H2O nanofluid natural convection in a novel shape of porous cavity subjected to magnetic field dependent (MFD) viscosity. J. Energy Storage 30, 101395 (2020)

Z. Li, S. Asadi, A. Karimipour, A. Abdollahi, I. Tlili, Experimental study of temperature and mass fraction effects on thermal conductivity and dynamic viscosity of SiO2-oleic acid/liquid paraffin nanofluid. Int. Commun. Heat Mass Transfer 110, 104436 (2020)

H. Yu, B. Duan, L. Feng, R. Kalbasi, Thermophysical properties improvement of a common liquid by adding reduced graphene oxide: an experimental study. Powder Technol. 384, 466–478 (2021)

M. Ghanbari, G. Rezazadeh, A MEMS-based methodology for measurement of effective density and viscosity of nanofluids. Eur. J. Mech. B/Fluids 86, 67–77 (2021)

N. Nayebpashaee, S.M.M. Hadavi, Thermal conductivity and rheological studies for graphene-Al2O3/ethylene glycol-water hybrid nanofluid at low temperatures. J. Nano Res. 73, 139–160 (2022)

A. Nasiri, M. Shariaty-Niasar, A.M. Rashidi, R. Khodafarin, Effect of CNT structures on thermal conductivity and stability of nanofluid. Int. J. Heat Mass Transf. 55(5–6), 1529–1535 (2012)

M. Hadadian, E.K. Goharshadi, A. Youssefi, Electrical conductivity, thermal conductivity, and rheological properties of graphene oxide-based nanofluids. J. Nanopart. Res. 16, 1–17 (2014)

M. Ramezanizadeh, M. Alhuyi Nazari, Modeling thermal conductivity of Ag/water nanofluid by applying a mathematical correlation and artificial neural network. Int. J. Low-Carbon Technol. 14(4), 468–474 (2019)

M.H. Esfe, The investigation of effects of temperature and nanoparticles volume fraction on the viscosity of copper oxide-ethylene glycol nanofluids. Period. Polytech. Chem. Eng. 62(1), 43–50 (2018). https://doi.org/10.3311/PPch.9741

Z. Yao, M. Derikvand, M.S. Solari, J. Zhang, F.M. Altalbawy, A.H.D. Al-Khafaji, I.M. Mohammed, Numerical assessment of the impacts of non-Newtonian nanofluid and hydrophobic surfaces on conjugate heat transfer and irreversibility in a silicon microchannel heat-sink. J. Taiwan Inst. Chem. Eng. 142, 104642 (2023)

R. Sarlak, A.M. Abed, O.A. Akbari, A. Marzban, S. Baghaei, M. Bayat, Numerical investigation of natural convection heat transfer of water/SWCNT nanofluid flow in a triangular cavity with cold fluid injection. Prog. Nucl. Energy 155, 104513 (2023)

S. Zahmatkesh, M.K. Amiri, S.P.G. Zaferani, M.R.S. Emami, M. Hajiaghaei-Keshteli, M.D. Albaqami, N. Han, Machine learning modeling of polycarbonate ultrafiltration membranes at different temperatures, Al2O3 nanoparticle volumes, and water ratios. Chemosphere 313, 137424 (2023)

M.H. Esfe, M.H. Kamyab, M. Afrand, M.K. Amiri, Using artificial neural network for investigating of concurrent effects of multi-walled carbon nanotubes and alumina nanoparticles on the viscosity of 10W–40 engine oil. Physica A 510, 610–624 (2018)

M. Izadi, M. Javanahram, S.M.H. Zadeh, D. Jing, Hydrodynamic and heat transfer properties of magnetic fluid in porous medium considering nanoparticle shapes and magnetic field-dependent viscosity. Chin. J. Chem. Eng. 28(2), 329–339 (2020)

S.M. Mousavi, B. Ehteshami, A.A.R. Darzi, Two-and-three-dimensional analysis of Joule and viscous heating effects on MHD nanofluid forced convection in microchannels. Thermal Sci. Eng. Progr. 25, 100983 (2021)

R. Ranjbarzadeh, A. Akhgar, S. Musivand, M. Afrand, Effects of graphene oxide-silicon oxide hybrid nanomaterials on rheological behavior of water at various time durations and temperatures: Synthesis, preparation and stability. Powder Technol. 335, 375–387 (2018)

F. Jabbari, A. Rajabpour, S. Saedodin, Viscosity of carbon nanotube/water nanofluid: equilibrium molecular dynamics. J. Therm. Anal. Calorim. 135, 1787–1796 (2019)

F. Iachachene, Z. Haddad, M. Arıcı, M. Jamei, A. Mataoui, Turbulent forced convective flow in a conical diffuser: hybrid and single nanofluids. Eng. Anal. Boundary Elem. 148, 205–219 (2023)

M.X. Wang, B. Almasi, H.S. Majdi, F.M. Altalbawy, D. Toghraie, I. Waleed, Y.X. Zhang, A comprehensive laboratory measurement on the thermal characteristics of Ag–CuO–tungsten oxide/water nanofluid in mono, hybrid and ternary cases and presenting a new correlation. J. Taiwan Inst. Chem. Eng. 143, 104682 (2023)

N. Kalhori, M. Mousavi-Kamazani, F. Hormozi, Effect of CeVO4/Al2O3/rGO nanocomposite on rheological properties and thermal conductivity of water-based drilling fluid. Geoenergy Sci. Eng. 221, 111312 (2023)

M.M. Rashidi, M. Alhuyi Nazari, I. Mahariq, N. Ali, Modeling and sensitivity analysis of thermal conductivity of ethylene glycol-water based nanofluids with alumina nanoparticles. Exp. Tech. 5, 1–8 (2022)

P.K. Kanti, K.V. Sharma, Z. Said, M. Jamei, K.M. Yashawantha, Experimental investigation on thermal conductivity of fly ash nanofluid and fly ash-Cu hybrid nanofluid: prediction and optimization via ANN and MGGP model. Part. Sci. Technol. 40(2), 182–195 (2022)

S.M. Mousavi, M. Yousefi, M.N. Rostami, H. Tamim, M. Alimohammadian, S. Dinarvand, Zinc oxide–silver/water hybrid nanofluid flow toward an off-centered rotating disk using temperature-dependent experimental-based thermal conductivity. Heat Transfer 51(5), 4169–4186 (2022)

M. Alishiri, A. Akbari, M.H. Saidi, Thermal performance of a pulsating heat pipe charged with F e 3 O 4-MWCNTs/DI water hybrid nanofluid: Experimental study and optimization. J. Thermal Anal. Calorim. (2022). https://doi.org/10.1007/s10973-022-11517-y

M.G. Moldoveanu, T.M. Simionescu, A.A. Minea, A. Dima, Analytical technique for estimating the termophysical properties of hybrid nanofluids. Adv. Mater. Res. 1143, 207–213 (2017)

R.S. Vajjha, D.K. Das, B.M. Mahagaonkar, Density measurement of different nanofluids and their comparison with theory. Pet. Sci. Technol. 27(6), 612–624 (2009)

H. Yarmand, S. Gharehkhani, S.F.S. Shirazi, M. Goodarzi, A. Amiri, W.S. Sarsam, S.N. Kazi, Study of synthesis, stability and thermo-physical properties of graphene nanoplatelet/platinum hybrid nanofluid. Int. Commun. Heat Mass Transfer 77, 15–21 (2016)

B. Barbés, R. Páramo, E. Blanco, C. Casanova, Thermal conductivity and specific heat capacity measurements of CuO nanofluids. J. Therm. Anal. Calorim. 115, 1883–1891 (2014)

H. O’Hanley, J. Buongiorno, T. McKrell, L.W. Hu, Measurement and model validation of nanofluid specific heat capacity with differential scanning calorimetry. Adv. Mech. Eng. 4, 181079 (2012)

Y. Gao, Y. Xi, Y. Zhenzhong, A.P. Sasmito, A.S. Mujumdar, L. Wang, Experimental investigation of specific heat of aqueous graphene oxide Al2O3 hybrid nanofluid. Thermal Sci. 25(1), 515–525 (2021)

B. Barbés, R. Páramo, E. Blanco, M.J. Pastoriza-Gallego, M.M. Pineiro, J.L. Legido, C. Casanova, Thermal conductivity and specific heat capacity measurements of Al 2 O 3 nanofluids. J. Therm. Anal. Calorim. 111, 1615–1625 (2013)

M.E.H. Assad, I. Mahariq, R. Ghandour, M.A. Nazari, T. Abdeljawad, Utilization of machine learning methods in modeling specific heat capacity of nanofluids. Comput. Mater. Continua 70(1), 361–374 (2022)

K. Ramachandran, K. Kadirgama, D. Ramasamy, M. Samykano, L. Samylingam, F. Tarlochan, G. Najafi, Evaluation of specific heat capacity and density for cellulose nanocrystal-based nanofluid. J. Adv. Res. Fluid Mech. Thermal Sci. 51(2), 169–186 (2018)

K. Irshad, N. Islam, M.H. Zahir, A.A. Pasha, A.F. AbdelGawad, Thermal performance investigation of Therminol55/MWCNT+ CuO nanofluid flow in a heat exchanger from an exergy and entropy approach. Case Stud. Thermal Eng. 34, 102010 (2022)

G.M. Chen, C.P. Tso, Viscous dissipation effect on CuO-Water nanofluid-cooled microchannel heat sinks. Case Stud. Thermal Eng. 26, 101159 (2021)

S. Alidoust, F. AmoozadKhalili, S. Hamedi, Investigation of effective parameters on relative thermal conductivity of SWCNT (15%)-Fe3O4 (85%)/water hybrid ferro-nanofluid and presenting a new correlation with response surface methodology. Colloids Surf. A 645, 128625 (2022)

A. Dezfulizadeh, A. Aghaei, A.H. Joshaghani, M.M. Najafizadeh, An experimental study on dynamic viscosity and thermal conductivity of water-Cu-SiO2-MWCNT ternary hybrid nanofluid and the development of practical correlations. Powder Technol. 389, 215–234 (2021)

S.M.S. Hosseini, M.S. Dehaj, An experimental study on energetic performance evaluation of a parabolic trough solar collector operating with Al2O3/water and GO/water nanofluids. Energy 234, 121317 (2021)

A. Shahsavar, M. Jamei, M. Karbasi, Experimental evaluation and development of predictive models for rheological behavior of aqueous Fe3O4 ferrofluid in the presence of an external magnetic field by introducing a novel grid optimization based-Kernel ridge regression supported by sensitivity analysis. Powder Technol. 393, 1–11 (2021)

A. Banisharif, P. Estellé, A. Rashidi, S. Van Vaerenbergh, M. Aghajani, Heat transfer properties of metal, metal oxides, and carbon water-based nanofluids in the ethanol condensation process. Colloids Surf. A 622, 126720 (2021)

Y. Zhu, M. Zamani, G. Xu, D. Toghraie, M. Hashemian, A.A. Alizadeh, A comprehensive experimental investigation of dynamic viscosity of MWCNT-WO3/water-ethylene glycol antifreeze hybrid nanofluid. J. Mol. Liq. 333, 115986 (2021)

S.B. Mousavi, S.Z. Heris, P. Estellé, Viscosity, tribological and physicochemical features of ZnO and MoS2 diesel oil-based nanofluids: an experimental study. Fuel 293, 120481 (2021)

M. Mahmoodi, S. Kandelousi, Semi-analytical investigation of kerosene-alumina nanofluid between two parallel plates. J. Aerosp. Eng. 29(4), 04016001 (2016)

K.A. Hamid, W.H. Azmi, R. Mamat, N.A. Usri, G. Najafi, Investigation of Al2O3 nanofluid viscosity for different water/EG mixture based. Energy Procedia 79, 354–359 (2015)

A. Malekzadeh, A.R. Pouranfard, N. Hatami, A. Kazemnejad Banari, M.R. Rahimi, Experimental investigations on the viscosity of magnetic nanofluids under the influence of temperature, volume fractions of nanoparticles and external magnetic field. J. Appl. Fluid Mech. 9(2), 693–697 (2016)

Hemmat Esfe, M., Rostamian, H., Afrand, M., & Somchai, W. (2016). Examination of effects of multi-walled carbon nanotubes on rheological behavior of engine oil (10W40).

H. Khodadadi, D. Toghraie, A. Karimipour, Effects of nanoparticles to present a statistical model for the viscosity of MgO-Water nanofluid. Powder Technol. 342, 166–180 (2019)

M.H. Esfe, S. Esfandeh, Investigation of rheological behavior of hybrid oil based nanolubricant-coolant applied in car engines and cooling equipments. Appl. Therm. Eng. 131, 1026–1033 (2018)

M. Afrand, D. Toghraie, B. Ruhani, Effects of temperature and nanoparticles concentration on rheological behavior of Fe3O4–Ag/EG hybrid nanofluid: an experimental study. Exp. Thermal Fluid Sci. 77, 38–44 (2016)

P.M. Nafchi, A. Karimipour, M. Afrand, The evaluation on a new non-Newtonian hybrid mixture composed of TiO2/ZnO/EG to present a statistical approach of power law for its rheological and thermal properties. Physica A 516, 1–18 (2019)

S. Mohsenian, A. Ramiar, A.A. Ranjbar, Numerical study of laminar non-Newtonian nanofluid flow in a T-Junction: Investigation of viscous dissipation and temperature dependent properties. Appl. Therm. Eng. 108, 221–232 (2016)

V.V. Wanatasanappan, P.K. Kanti, P. Sharma, N. Husna, M.Z. Abdullah, Viscosity and rheological behavior of Al2O3-Fe2O3/water-EG based hybrid nanofluid: a new correlation based on mixture ratio. J. Mol. Liq. 375, 12165 (2023)

A. Asadi, M. Asadi, M. Rezaei, M. Siahmargoi, F. Asadi, The effect of temperature and solid concentration on dynamic viscosity of MWCNT/MgO (20–80)–SAE50 hybrid nano-lubricant and proposing a new correlation: an experimental study. Int. Commun. Heat Mass Transfer 78, 48–53 (2016)

R. Sadri, G. Ahmadi, H. Togun, M. Dahari, S.N. Kazi, E. Sadeghinezhad, N. Zubir, An experimental study on thermal conductivity and viscosity of nanofluids containing carbon nanotubes. Nanoscale Res. Lett. 9(1), 1–16 (2014)

S. Abbasi, S.M. Zebarjad, S.H.N. Baghban, A. Youssefi, M.S. Ekrami-Kakhki, Experimental investigation of the rheological behavior and viscosity of decorated multi-walled carbon nanotubes with TiO 2 nanoparticles/water nanofluids. J. Therm. Anal. Calorim. 123, 81–89 (2016)

M.H. Esfe, O. Mahian, M.H. Hajmohammad, S. Wongwises, Design of a heat exchanger working with organic nanofluids using multi-objective particle swarm optimization algorithm and response surface method. Int. J. Heat Mass Transf. 119, 922–930 (2018)

M. Yahyaei, M. Vakili, B. Paknezhad, Artificial brain structure-based modeling to predict the photo-thermal conversion performance of graphene nanoplatelets nanofluid using experimental data. J. Therm. Anal. Calorim. 147, 109–121 (2022)

A.R. Rahmati, S.H. Mousavi, A novel lattice boltzmann simulation of natural convection in nanofluids using different viscosity and thermal conductivity models. Nanosci. Technol. 4(1), 55 (2013)

M. Vakili, S. Khosrojerdi, P. Aghajannezhad, M. Yahyaei, A hybrid artificial neural network-genetic algorithm modeling approach for viscosity estimation of graphene nanoplatelets nanofluid using experimental data. Int. Commun. Heat Mass Transfer 82, 40–48 (2017)

Einstein, A. (1905). Eine neue bestimmung der moleküldimensionen (Doctoral dissertation, ETH Zurich).

X. Wang, X. Xu, S.U. Choi, Thermal conductivity of nanoparticle-fluid mixture. J. Thermophys. Heat Transfer 13(4), 474–480 (1999)

H. De Bruijn, The viscosity of suspensions of spherical particles. The fundamental η-c and φ relations. Recl. Trav. Chim. Pays-Bas 61(12), 863–874 (1942)

S. Javadipour, A. Shokuhfar, K. Homayouni, Z. Heidary, F. Rezaei, Investigation into the size distribution of Al2O3-ZnO nanoparticles dispersed in DI water and following the impact of CNTs on the stability, heat transfer, and electricity transfer of Al2O3-ZnO-CNT hybrid nanofluid. Defect Diffus. Forum 420, 172–192 (2022)

S. Ghahremanian, A. Abbassi, Z. Mansoori, D. Toghraie, Effect of copper nanoparticles on thermal behavior of two-phase argon-copper nanofluid flow in rough nanochannels with focusing on the interface properties and heat transfer using molecular dynamics simulation. Chin. J. Chem. Eng. 42, 344–350 (2022)

O. Khaledi, S. Saedodin, S.H. Rostamian, Experimental investigation of thermal efficiency and thermal performance improvement of compound parabolic collector utilizing SiO2/ethylene glycol–water nanofluid. Environ. Sci. Pollut. Res. (2022). https://doi.org/10.1007/s11356-022-22848-6

M.A. Moghaddam, K. Motahari, Experimental investigation, sensitivity analysis and modeling of rheological behavior of MWCNT-CuO (30–70)/SAE40 hybrid nano-lubricant. Appl. Therm. Eng. 123, 1419–1433 (2017)

K.A. Hamid, W.H. Azmi, M.F. Nabil, R. Mamat, K.V. Sharma, Experimental investigation of thermal conductivity and dynamic viscosity on nanoparticle mixture ratios of TiO2-SiO2 nanofluids. Int. J. Heat Mass Transf. 116, 1143–1152 (2018)

M.H. Esfe, S. Esfandeh, A.A.A. Arani, Proposing a modified engine oil to reduce cold engine start damages and increase safety in high temperature operating conditions. Powder Technol. 355, 251–263 (2019)

Y.M. Chu, M. Ibrahim, T. Saeed, A.S. Berrouk, E.A. Algehyne, R. Kalbasi, Examining rheological behavior of MWCNT-TiO2/5W40 hybrid nanofluid based on experiments and RSM/ANN modeling. J. Mol. Liq. 333, 115969 (2021)

Y. Cao, A. Khan, A. Abdi, M. Ghadiri, Combination of RSM and NSGA-II algorithm for optimization and prediction of thermal conductivity and viscosity of bioglycol/water mixture containing SiO2 nanoparticles. Arab. J. Chem. 14(7), 103204 (2021)

W. Ji, L. Yang, Z. Chen, M. Mao, J.N. Huang, Experimental studies and ANN predictions on the thermal properties of TiO2-Ag hybrid nanofluids: Consideration of temperature, particle loading, ultrasonication and storage time. Powder Technol. 388, 212–232 (2021)

X. Yang, A. Boroomandpour, S. Wen, D. Toghraie, F. Soltani, Applying Artificial Neural Networks (ANNs) for prediction of the thermal characteristics of water/ethylene glycol-based mono, binary and ternary nanofluids containing MWCNTs, titania, and zinc oxide. Powder Technol. 388, 418–424 (2021)

S. Tian, N.I. Arshad, D. Toghraie, S.A. Eftekhari, M. Hekmatifar, Using perceptron feed-forward Artificial Neural Network (ANN) for predicting the thermal conductivity of graphene oxide-Al2O3/water-ethylene glycol hybrid nanofluid. Case Stud. Thermal Eng. 26, 101055 (2021)

A.A. Nadooshan, M.H. Esfe, M. Afrand, Evaluation of rheological behavior of 10W40 lubricant containing hybrid nano-material by measuring dynamic viscosity. Physica E 92, 47–54 (2017)

M.H. Esfe, M.R. Sarlak, Experimental investigation of switchable behavior of CuO-MWCNT (85%–15%)/10W-40 hybrid nano-lubricants for applications in internal combustion engines. J. Mol. Liq. 242, 326–335 (2017)

M. Asadi, A. Asadi, Dynamic viscosity of MWCNT/ZnO–engine oil hybrid nanofluid: an experimental investigation and new correlation in different temperatures and solid concentrations. Int. Commun. Heat Mass Transfer 76, 41–45 (2016)

W.H. Herschel, R. Bulkley, Konsistenzmessungen von gummi-benzollösungen. Colloid Polym. Sci. 39(4), 291–300 (1926)

M.H. Esfe, H. Rostamian, M.R. Sarlak, M. Rejvani, A. Alirezaie, Rheological behavior characteristics of TiO2-MWCNT/10w40 hybrid nano-oil affected by temperature, concentration and shear rate: an experimental study and a neural network simulating. Physica E 94, 231–240 (2017)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hemmat Esfe, M., Motallebi, S., Esfandeh, S. et al. Study of Rheological Behavior, Economic Performance and Development of a Model for MWCNT-ZnO (30:70)/10W40 Hybrid Nanofluid Using Response Surface Methodology. Korean J. Chem. Eng. 41, 909–921 (2024). https://doi.org/10.1007/s11814-024-00062-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-024-00062-z