Abstract

Novel analytic modeling and design method is proposed for the analysis of geothermal-integrated energy systems which provide space heating and cooling. Rather than building a complex optimization framework, an analytic design procedure is developed to determine hourly and monthly distribution of renewable-sourced energy and its sizing in a systematic manner by considering renewable characteristics and energy storage. The new design method also allows to fully realize the advantage of geothermal energy through the seasonal supply of heating and cooling and to accommodate variable generation of other renewables. The benefit of this short-cut design method has been fully illustrated with two case studies in which geothermal energy is used for the provision of combined heat and cooling in domestic and commercial applications. Case studies also demonstrate the impact of time-dependent generation of renewable energy on the sizing of energy suppliers and its seasonal or hourly allocation of working loads.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Clean generation of renewable energy and its sustainable use is one of the key measures to achieve Net Zero by 2050. Significant efforts have been made for the last few decades to develop various technologies which support the cost-effective production of carbon-free energy from renewable sources. These technical developments allow considerable reduction in the production cost of energy from renewable sources which strengthens the competitiveness of renewables over fossil fuel-based energy in the power and energy industries [1, 2]. Also, growing awareness of the important role of renewable energy for building sustainable society allows to accelerate the implementation of renewable energy in the residential, commercial and industrial sectors.

50% of worldwide final energy is consumed for the supply of heating and cooling and its demand is forecasted to be growing [3]. Although the strong growth of renewable electricity, especially for solar PV (photovoltaics) and wind power, has been observed, considerable increase in renewable heat consumption is not expected, due to its cost disadvantage over fossil fuel-based technologies [2]. Compared to other renewable sources, geothermal energy is regarded as an effective renewable source to provide a large amount of heating and cooling which utilizes the energy stored in underground wells or rocks. Also, the unique capability of season-dependent energy storage between heating and cooling provides both electricity and heat together [4]. This bidirectional feature of geothermal energy storage also allows to effectively deal with seasonal imbalance or difference between heating and cooling demands [5].

A wide range of technologies are available for the utilization of geothermal energy, and the geothermal energy is typically used for either the generation of electricity, or the supply of space or industrial heating and cooling [6]. The focus in this work is the heating and cooling systems integrated with geothermal energy, as full attention has not been made to the area of renewable heating, compared to renewable electricity, and the potential for the direct use of geothermal heating is not fully realized [3]. Furthermore, heating and cooling systems for domestic or commercial applications is highlighted in this work, as 30% of global final energy is consumed for the operations of buildings, including homes and businesses [7] and, therefore, sustainability in building sectors can be significantly benefited from the integration of renewable energy. This is also related to practical issues for the integration of renewable energy in industrial sectors, as the implementation of heat recovery for the industrial plants is not straightforward because of existing plant layout [8], and the transmission of heat over long distance is not economically attractive due to considerable energy loss [9].

The effectiveness of geothermal energy for domestic or commercial applications is closely linked to a seasonal energy storage, typically, Aquifer Thermal Energy Storage (ATES) or Borehole Thermal Energy Storage (BTES), which is used for balancing the seasonal gap between summer and winter. Combining heat pumps with geothermal energy is also common to upgrade the heat to be sufficiently high enough for space heating. The technical benefits of ATES [10] and BTES [11] had been well demonstrated with a wide range of successful applications.

The time-dependent mismatch between energy demands and renewable energy suppliers also occurred on a short-term, for example, hourly basis. Therefore, the design problem of geothermal-integrated energy systems should accommodate both seasonal and hourly characteristics of energy demand and generation. The detailed and thorough consideration of non-constant energy demands and fluctuation in variable generation from renewables would be favored for realizing the full potential of geothermal energy. Fiorentini et al. [12] developed the optimization model for the design of a BTES-integrated heating and cooling system. Their optimization is formulated with the day-averaged values of demands and operating parameters, which is then applied to determine the cost-effective decision variables over a whole year. Similar day-averaged approach for the long-term evaluation was also observed for the design method for the ATES system [13]. This multi-period approach was typically formulated as a MILP (Mixed Integer Linear Programming), which has been widely applied for the design and operation of renewable energy systems, for example, the operational optimization of domestic solar-based heating systems [14], the cost-effective sizing of thermal energy storage unit [15] and the energy management of renewable-sourced microgrids and buildings [16].

However, such a detailed design approach requires highly complex mathematical models with a large number of variables and parameters to be solved, which requires considerable computational effort and often relies on the system designer’s expertise. Also, design methods often required the use of commercial software, for example, the use of an optimization solver for the BTES-based district energy networks [17] and the application of simulation and CFD (Computational Fluid Dynamics) tools for the detailed operational analysis of ATES-based systems [18]. It is often observed in the research and industrial community as the computer-based design tools and the requirement of software-specific programming skills may not be readily applicable.

This work aims to develop a novel analytic design method which can be used to determine sizing (or capacity) of renewable energy suppliers and their monthly and hourly working loads, subject to constraints. The method is intended to be generic and simple, which can be effectively used for the top-level analysis of geothermal-energy integrated systems, without relying on optimization solvers or complex mathematical modeling of units or systems. The design method is also capable of allocating both heating and cooling of geothermal energy to the consumer, for which conventional fossil fuel-based technologies as well other renewable energy sources are simultaneously considered. The integration of energy storage is also accommodated for the design method, which allows both the sizing of an energy storage unit and energy suppliers. The analytic design and analysis method developed in this work is, first, presented in the next section. This is then followed by the case study which illustrates the application of the proposed method for the energy management of geothermal-integrated space heating and cooling systems.

Process Design of Geothermal-Integrated Energy Systems

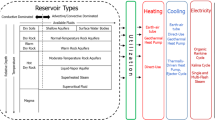

Heating and cooling management for residential areas or commercial buildings can be made with the integration of conventional energy-suppliers with technologies based on renewable sources, as shown in Fig. 1. Heating is traditionally made with heat generated from a combustion-based unit or a district heating network, while the implementation of renewable-based heating can be regarded as an additional option these days. The most common method for cooling in residential or commercial buildings is electricity-based cooling, although absorption-based chillers may be employed. The cooling management in Fig. 1 is schematically illustrated with the supply of electricity from a renewable-based unit, a CHP (Combined Heat and Power) unit or a power grid. Energy storage for energy systems is required to accommodate variation in energy demand of a consumer as well as non-continuous production patterns in renewable-sourced energy generation. Geothermal energy can provide heating and cooling to the consumer and it is typical to implement heat pumping for upgrading the quality of heat supplied geothermal storage.

The operating characteristics of energy suppliers are different. Continuous energy supply can be expected from combustion-based heat generators, while availability in renewable energy sources is non-continuous and, in some cases, unpredictable. Energy supply between different suppliers and its utilization through energy storage is strongly interacted. Hence, the analysis of renewable-integrated energy systems becomes highly complex and the determination of operating strategies is not a straightforward task.

The design method developed in this work is based on an analytic procedure for the heating and cooling management for the energy systems shown in Fig. 1, which can be used for the identification of optimal sizing of energy suppliers as well as to determine the effective allocation of heating and cooling loads for each supplier. The use of geothermal energy for the combined supply of heating and cooling is focused on this work, in which its impact on the equipment sizing and load allocation would be systematically considered. As discussed earlier, the detailed modeling and design at the levels of individual equipment or unit operations is not highlighted in the development of design method, as it is aimed to develop a decision-support framework for obtaining strategic design variables at a system level by system-wide interactions between energy suppliers and consumers. The modeling approach in this work is, therefore, to set up heating and cooling balances of a consumer in a multi-period manner and to allocate monthly and hourly loads of heating in Eqs. (1) and (3), and cooling in Eqs. (2) and (4), respectively, subject to energy demand profiles. It should be noted that only one energy supply from renewable sources is expressed in these equations, but in principle, multiple supplies can be considered.

where HMi represents for monthly heating duty for time period i, CMi for monthly cooling duty for time period i, HHi for hourly heating duty for time period i, CHi for hourly cooling duty for time period i, while subscripts BO for boiler, GE for geothermal energy, RE for renewable energy, DH for district heating, DEM for demand energy, SUR for surplus energy, and CHP for combined heat and power.

This load-based approach for the modeling of energy exchange is based on the steady-state energy demand, generation and its use which are expressed in a multi-period formulation using the representative values of energy load for each period. As discussed in the introduction, simplicity in the mathematical expression is maintained by excluding detailed modeling issues of transport phenomena, for example, hydraulic impacts on energy exchange are assumed to be negligible.

The overall design procedure developed in this work is decomposed into two sub-procedures as given in Fig. 2. The first part of the design method, referred as Design Step 1, is to distribute the monthly overall loads for each energy supplier, subject to any design constraints or characteristics to be imposed. The second part, referred to as Design Step 2, is to allocate the hourly load of energy to be supplied and to quantify energy accumulation and its utilization through the energy storage. Key assumptions and design basis related to the design method developed are as follows:

-

1.

When multiple suppliers are considered, the most systematic way of selecting the energy supplier to be used and their working load would be to formulate the optimization problem and to determine the optimal working load through rigorous economic trade-offs. Rather than the application of mathematical model and its optimization, as an analytic procedure is to be developed in this study, the order of technologies to be employed are ranked, based on technical priority set by designer or techno-economic performance indicator, for example, LCOH (levelized cost of heat) and LCOE (levelized cost of electricity). When sustainability via the integration of renewable energy is prioritized over economics, heating and cooling through fossil fuels-based units is not considered until renewable energy is fully utilized.

-

2.

Geothermal energy is assumed to be available for both heating and cooling, but the operating mode for the use of geothermal energy can be either cooling or heating only, not both at the same time. Also, the ratio of total amount of heating energy to cooling one from the geothermal source (FLES) is also specified, to reflect the difference in the relative availability of cooling and heating, subject to the design and configuration of geothermal storage, as given in Eq. 5.

$${\sum }_{i}{HM}_{i}^{GE}={FL}^{GE}{\sum }_{i}{CM}_{i}^{GE}.$$(5) -

3.

The variation in the time-dependent amount of energy generated from solar and wind sources is characterized with monthly and hourly intensity data, as the energy generation in each time period is proportionally scaled up by following intensity values specified for each time period, as shown in Eq. (6) for monthly load calculations and Eq. (7) for hourly load calculations.

$${HM}_{i}^{SOL}={FHM}^{SOL}{MI}_{i}^{SOL}; {CM}_{i}^{SOL}={FCM}^{SOL}{MI}_{i}^{SOL},$$(6)$${HH}_{j}^{SOL}={FHH}^{SOL}{DI}_{j}^{SOL}; {CH}_{j}^{SOL}={FCH}_{j}^{SOL}{DI}_{j}^{SOL},$$(7)where FHM represents a scale factor for considering the monthly heating intensity, FCM for scale factor for considering the monthly cooling intensity, FHH for a scale factor for considering the hourly heating intensity, FCH for a scale factor for considering the hourly cooling intensity, DI for hourly intensity data, and MI for monthly intensity data, while a superscript SOL represents solar energy.

-

4.

When a combined heat and power (CHP) unit is considered, the production rate between heat and power is technology dependent and, for example, heat-to-power ratio of CHP systems is ranged from 0.83 to 1.67 for reciprocating engines, and from 1 to 1.66 for gas turbines [19]. Equation (5) is used to correlate the heat generated from a CHP unit with the electricity produced, by specifying the heat-to-power ratio (FHPCHP).

$${HM}_{i}^{BO}={FHP}^{CHP}{CM}_{i}^{CHP}.$$(8) -

5.

The overall annual load of heating and cooling for renewable-based suppliers is allocated with the pre-specified factor, which represents the level of contribution for the renewable source selected, given in Eq. (9) as the ratio of the amount of renewable energy to be supplied to the annual energy demand. When the overall loads to be supplied from each renewable supplier is set, the monthly or hourly load of each supplier is calculated to be proportionally to the overall monthly or hourly demand. For the geothermal energy, the amount of geothermal energy in overall is specified with the overall combined load of heat and cooling as shown in Eq. (10), as the supply of heating and cooling through geothermal storage are co-dependent.

$$ \mathop \sum \limits_{i} HM_{i}^{RE} = FRH_{{}}^{RE} \mathop \sum \limits_{i} HM_{i}^{DEM} ;\quad \mathop \sum \limits_{i} CM_{i}^{RE} = FRC_{{}}^{RE} \mathop \sum \limits_{i} CM_{i}^{DEM} . $$(9)$$\sum_{i}{HM}_{i}^{GE}+\sum_{i}{CM}_{i}^{GE}={FRG}^{GE}\sum_{i}{HM}_{i}^{DEM},$$(10)where FRH represents the contribution factor of heating, FRC the contribution factor of cooling and FRG the contribution factor of combined heating and cooling.

-

6.

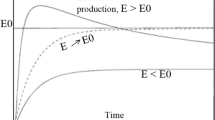

Energy balances for monthly energy load distribution given in Eqs. (1) and (2) may result in energy surplus, which is related to the application of monthly intensity in energy generation or the consideration of heat-to-power ratio for a CHP unit. Any surplus is either treated as to be lost or to be exported, subject to the availability of external energy consumers. From Eqs. (3) and (4), it is observed that hourly surplus can also occur during energy exchanges. Although this operational imbalance can be partly dealt with the part-load operation of heat or electricity generators or to be exported, the energy storage is considered in this study for accumulating and utilizing the surplus energy. The surplus energy is stored in the energy storage unit, which is then utilized in the next available timepoints, as described in Eqs. (11–14). After the renewable energy and the stored one is fully utilized, the remaining energy demand is fulfilled by conventional energy generators or energy imports (i.e. heat from district heating network or electricity from grid). This arrangement implies that no deficit in energy supply has occurred for any time period.

$${HH}_{j}^{SUR}+\left(1-{HL}^{TES}\right){HH}_{j-1}^{TES}={HH}_{j}^{TES} \quad j\in \mathrm{2,3},\dots .., 24$$(11)$${HH}_{j=1}^{SUR}+\left(1-{HL}^{TES}\right){HH}_{j=24}^{TES}={HH}_{j=1}^{TES} \quad j\in 1$$(12)$${CH}_{j}^{SUR}+\left(1-{EL}^{EES}\right){CH}_{j-1}^{EES}={CH}_{j}^{EES} \quad j\in \mathrm{2,3},\dots .., 24$$(13)$${CH}_{j=1}^{SUR}+\left(1-{EL}^{EES}\right){CH}_{j=24}^{EES}={CH}_{j=1}^{EES}\quad j\in 1$$(14)where, HL represents for heat loss, EL for electricity loss, while superscripts TES for thermal energy storage and EES for electricity energy storage.

-

7.

Energy loss during energy accumulation in the storage or transportation via the storage unit is collectively represented with a single parameter of overall heat loss per hour (HLTES), and overall electricity loss per hour (ELTES). In order to minimize the storage capacity, the level of energy accumulated in the storage unit should be positive throughout the whole day and the lowest level should be zero. The determination of minimum storage capacity required can be found by adjusting the starting energy level iteratively until the lowest level becomes zero. The details of this design procedure can be found for an analytic method in the reference of [20] and an optimization method in the reference of [21].

-

8.

The selection of a particular month is required for the determination of sizing for energy suppliers and their hourly operating profiles. The months with the biggest heating and cooling demands are selected for the design of heating and cooling systems, respectively. The overall energy load for the selected month targeted from Design Step 1 provides the basis for the average value of daily load, assuming no change in daily load throughout the month. With the averaged profile of hourly energy demand, hourly allocation of energy load for each supplier is determined with the application of either fixed working load throughout the whole day or variable working load. When the concept of variable working load is applied, the hourly load is selected to be proportionally to the overall hourly energy demand. When the fixed load is applied for characterizing the daily operation of an energy generator, the imbalance of energy surplus against deficit is regulated with the energy storage, as explained above. For solar energy, the hour-by-hour energy generation is selected by following the daily profile of solar generation.

The analytic method described above is applied to the case study in the next section. It should be noted that the proposed method is to allocate working loads of energy suppliers in a systematic way, although global optimality for achieving minimum cost required for the operation of energy systems may not be realized. Also, the design procedure is decomposed into two sub-steps, which is applied to the design problem for determining seasonal distribution and hourly allocation in sequence.

Case Study 1

Design Basis

Case study 1considered is based on the annual data of heating and cooling demands of one of hospitals located in California, US, which include hour-by-hour demand profiles of cooling and heating over the whole year as shown in Fig. 3 [22]. From this data set, the electricity use for cooling and the gas use for heating are taken as the demand of heating and cooling for the consumer, with which monthly overall demands are obtained as shown in Fig. 4a. There is no considerable difference in the monthly heating and cooling demand throughout the year, due to operational characteristics in hospital services, although large variation is widely observed for the cases of conventional residential or commercial buildings.

Hourly energy demand data for one year considered in Case Study 1 [22]

Geothermal energy is, in this study, employed by default as a main energy supplier, which is then supplemented with the conventional heat supply from a boiler or power supply from a grid, as the focus of this study is to exploit the integration of geothermal energy to fossil-fuel based energy systems. Solar energy is then selected as an additional renewable source available for the provision of heating or cooling. Such selection is made as the consideration of solar energy allows to clearly illustrate the impact of time-dependent availability on the design and operation of renewable-integrated energy systems. It should be noted that the relative cost of geothermal energy, compared to solar one is highly geographic dependent and the solar energy is preferred to be integrated with conventional energy systems. The typical data of seasonal and hourly variation for the intensity of solar energy generation given in Table 1 are used in this study for illustration purposes, although these values are highly location dependent.

For the design of heating systems, a conventional heat generator, for example, a gas-fired boiler or a CHP unit is used to supplement the remaining energy demand which is not covered by renewable-sourced heat. For the design of cooling systems, cooling is first made with the cold energy from geothermal energy, which is then followed by the use of electricity-based cooling. Electricity for operating a cooling device is supplied from renewable sources directly or from the electricity storage, before electricity export from the external grid is utilized.

When multiple energy sources are available, as explained in the previous section, candidates for energy sources are economically ranked, which can be used as a guidance for the order of utilization for renewables. However, the relative cost of generation for renewable energy is very location-specific and the degree of economic incentive for the use of renewable energy is not the same. Economic advantage from one region may not be guaranteed in a different region. Hence, the contribution of geothermal or solar energy are pre-specified in this case study, based on annual or daily energy demands, rather than being optimized through rigorous economic trade-off and screening of technology-dependent economics.

The design parameters assumed in this case study are as follows: The ratio of total amount of heating and cooling from geothermal energy is 0.8, the heat-to-power ratio for the CHP unit is 0.9. It should be noted that these values are selected or assumed from typical operating range, and different values may be taken for elaborating further details. For example, the heat-to-power ratio used in this study is a typical value for the CHP unit based on a reciprocating engine, but a large value between 3 and 10 [25] should be considered for the CHP unit based on a steam turbine. The conservative value is taken for the COP (Coefficient-of-Performance) of a ground-source heat pump to be 3.5 because it was reported in the range of or 1.9 to 7.5 [26] or 2.2 and 7.4 [27], subject to temperature difference between heating source and sink. The ratio of total amount of heating and cooling from geothermal energy, known as a heat recovery factor, is reported as 0.77 [28], with the range of 0.69–0.83 [13].

Allocation of Monthly Loads for Heating and Cooling

The first part of design methodology is to determine the monthly loads for the energy technologies considered, subject to demand data, design parameters and constraints. The month-by-month heating and cooling demands are first calculated from hour-by-hour data for the whole year. The year demand for the cooling is 3871.6 MWh and that for the heating 3127.7 MWh, in which cooling period for the use of geothermal energy is assumed to be from April to September.

The allocation of monthly loads is then carried out by following design procedures presented in Fig. 2a. The first scenario is based on 30% of combined heating and cooling loads supplied from geothermal energy, and the remaining is supplemented by the boiler for heating and the electricity grid for cooling, of which design results are given in Fig. 4a. For the months of heating from geothermal energy, additional electricity of 266.6 MWh is required to drive the heat pump for the upgrading of heat from geothermal storage. Overall heating from geothermal energy is 933.2 MWh, including 266.6 MWh of heat added through heat pumping, and overall cooling from geothermal energy is 1166.5 MWh. It can be seen in Fig. 4a that the benefit of geothermal energy for providing both heating and cooling is fully demonstrated.

Figure 4b shows the results when the solar energy is simultaneously used with geothermal one for providing 20% of heating and cooling loads, respectively, which is equivalent to 625.53 MWh for solar heating and 774.31 MWh for solar electricity. The variation of monthly intensity for solar heating and power is clearly observed, in which the profile follows a typical pattern given in Table 1. Higher than 20% of contribution from solar heating can be possible, because geothermal energy during summer months is only used for cooling. However, higher contribution of cooling driven by solar electricity is limited by the utilization of geo-energy cooling, which underlines the inherent inefficiency for the integration of solar electricity when geothermal energy is introduced.

Careful measures should be taken to integrate geothermal energy storage with a CHP unit for combined heat and cooling management, as illustrated in Fig. 4c. When a CHP unit is employed, it can be beneficial to cogenerate the electricity during winter period, as geothermal energy is not utilized for cooling. However, considerable surplus energy is inevitable during summer, which should be exported to the external consumer. When no electricity export is feasible, the CHP unit should be operated at a very small working load or the surplus energy should be disposed of, which is highly inefficient or expensive.

The Sizing and Hourly Operating Profiles of Energy Suppliers

The next step from the design methodology is to calculate the size required for energy suppliers and to determine their hourly operating profiles, with the consideration of design parameters and constraints. First, January and May are selected for the month for the design of heating and cooling systems, respectively. This is because the heating demand of January is 299.2 MWh, which is the biggest among heating months, and the heating demand of May 345.1 MWh, which is the biggest among cooling months. The maximum heating demand from this dataset is observed between 6 and 7 AM, as it is typical that additional heating in the early morning is provided according to people’s morning activities.|.

The average hourly profile for January and May is shown with bullet points connected with a straight line, as shown in Fig. 5a and b. Two scenarios are considered for the case study. Scenario A is based on the result of Fig. 4a, in which 30% of overall load is supplied from geothermal energy and the remaining from the boiler for heating and the electricity grid for cooling. The next scenario, Scenario B, is to consider 20% contribution for both solar heating and cooling, in addition to the utilization of geothermal energy for covering 30% of overall daily energy demands.

For Scenario A, The design problem for heating in January is the energy management of providing overall 166.27 MWh of geothermal heating and 132.91 MWh of heat from a boiler, which is equivalent to 5.36 MWh and 4.29 MWh for the day in average, respectively. For the design of cooling system, 213.7 MWh of overall cooling demand for May are satisfied with 213.7 MWh of geothermal cooling, together with 131.5 MWh of electricity import from the grid, which is equivalent to 6.89 MWh and 4.24 MWh for the day in average, respectively.

Two design options are employed for illustrating purposes. One is to use thermal energy storage as shown in Fig. 5c and d and the other is without thermal energy storage as given in Fig. 5a and b. The hourly load of geothermal energy presented in Fig. 5a and b follows the hourly variation in overall energy demand and, correspondingly, the same pattern is observed for that of energy generated from a boiler in Fig. 5a and that of electricity imported from the grid in Fig. 5b. No energy surplus and deficit for any period of the day occurs for this option. The maximum capacity for the heat generator is 279.7 kWh and that for geothermal heating is 349.9 kWh, which occurs at 6 AM. For the operation of the heat generator, the minimum part load operation is observed with 48.6% of full capacity at 16 PM. Compared to hourly change of heating demand in January, variation in that of cooling demand in May is relatively smooth without a sudden increase or decrease, and the difference between maximum and minimum loads for geothermal cooling is relatively small.

When thermal energy storage is introduced, the working load of an energy generation unit can be flexible to accommodate fluctuation in the amount of renewable energy generation or to proactively deal with any gaps between demand and generation. Figure 5c is obtained by following the hourly variation of geothermal energy supply with overall energy demand and fixing the working load of a boiler throughout the whole day. When the hourly profile given in Fig. 5c is designed, it is assumed that 5% of thermal energy stored in the energy storage unit is lost per every hour, which results in 187.25 kWh of fixed working capacity for a boiler and 316.4 kWh of maximum storage capacity required for thermal energy storage. The variation in the working load of a boiler and the heat stored in the thermal energy storage is compared in Fig. 5d and with the introduction of the heat storage unit, the capacity of a boiler is reduced by 33%. It should be noted that there exists economic trade-off between an energy generator and an energy storage unit, and the optimization framework can be applied if their design interactions and its impact on economics should be examined in detail. The systematic optimization framework which allows rigorous evaluation of CAPEX and OPEX for energy systems and determines hour-by-hour optimal loads for energy suppliers is available in the literature, including Kim et al. [21].

Design results of Scenario B are given in Fig. 6 for heating and Fig. 7 for cooling. Cases with and without the energy storage unit are considered for both heating and cooling. When no heat storage unit is applied, the working load of a heat generator is correspondingly adjusted for covering the remaining demand and the maximum capacity required for the heat generator is identified to be 279.7 kWh occurred at 6 AM, as shown in Fig. 6a. As solar heating is additionally used in this scenario and the contribution from solar energy is relatively large during the daytime, the minimum load for the heat generator is identified as 32.2 kWh at 13 PM and such wide variation in working load may not be accepted in practice. Figure 6b and c shows the hourly profiles for heating management with the application of fixed capacity for a heat generator and the use of TES (thermal energy storage) having 5% of energy loss per hour. The size of the heat generator is identified as 163.1 kWh and the maximum capacity of TES required for this case is 749.2 kWh.

The design of hourly cooling loads for each supplier is given in Fig. 7, in which an electricity energy storage unit is considered. The electricity imported for cooling can be adjusted for balancing between surplus and deficit when the energy storage unit is employed, which would be a straightforward option. Rather than following the hour-by-hour profile of overall cooling demand with electricity import, the role of solar energy is investigated. As the generation profile of solar energy cannot be manipulated, the daily working capacity of solar energy for cooling is to be identified. With 5% of electricity loss per hour for the storage unit, 4.33 MWh of cooling should be contributed for one day from solar energy, which is given in Fig. 7a. This amount of solar energy is much larger than the one identified from Design Step 1, which was calculated as 2.92 MWh. This big increase in production capacity for solar energy is mainly related to energy loss occurring during storage and very limited flexibility in the generation capacity throughout the day.

Case Study 2

Case Study 2 is intended to demonstrate the applicability of the analytic design method proposed. The data of cooling and heating demand for Case Study 2 is based on monthly energy needs of the apartment located in Seville, Spain [29], with the assumption of 1000 m2 required for space heating and cooling in this study. Contrary to Case Study 1, cooling is only demanded for summer periods, while heating is only required for winter, as shown in Fig. 8. As the original data is only available for monthly data, the application of Design Step 1 shown in Fig. 2 is only applied for illustration purposes. When heating and cooling is fulfilled by geothermal energy, the assumption of 0.8 for the ratio of the overall heating energy and overall cooling energy is taken. A monthly profile given in Table 1 is also used to characterize month-dependent characteristics in solar energy generation.

Figure 8a shows the distribution of the geothermal energy supply over a year and the requirement of additional energy for heat pumping during heating months, when 50% of overall heating and cooling is satisfied with geothermal sources. Figure 8b represents the monthly allocation of geothermal energy when the maximum contribution from geothermal energy is considered. For this particular case, the maximum use of geothermal energy is identified as 82% of overall energy demand and its further use is limited by heating demand as shown in Fig. 8b.

Integration of solar energy, together with geothermal one is considered in Fig. 8c, in which 10% of cooling demands is provided with electricity generated from solar energy and 50% of heating and cooling demand from geothermal energy. The contribution of geothermal and solar energy is increased to the maximum allowable level, of which results is shown in Fig. 8d, as the contribution of geothermal energy is increased to 50–82% and that of solar is from 10 to 17.6%.

The level of contribution for geothermal energy is determined when all the heat demand for heating months is fully covered by geothermal sources as illustrated in Fig. 8b and d. However, the additional solar contribution beyond 17.6% for this case study is not feasible due to small cooling demand in June, although additional supply from solar energy can be made for other summer months as shown in Fig. 8d. This feature illustrates the impact of different characteristics of renewable energy generation on the sizing and working loads of energy systems.

Conclusions and Future Work

The new design method based on analytic procedure has been developed, which is used for systematic decision on capacity and working loads of geothermal energy when geothermal energy is applied for seasonal heating and cooling, subject to other renewable as well as fossil fuel-based energy sources. The analytic design is based on energy load balances between demands and energy suppliers, with which the allocation of loads for each energy technology is made. The development of the design framework is intended to avoid the use of complicated mathematical models or the application of complex optimization techniques. The simplicity in the model allows the design procedure to be rather straightforward, which can be readily applicable for the design of building and commercial energy systems in practice.

Two case studies have been presented on how the proposed method can be applied for the design of geothermal-integrated energy systems. Through case studies, the benefit of geothermal energy is clearly demonstrated for accommodating both cooling and heating over different working periods. The energy systems integrated with geothermal energy can be further advantageous to domestic or commercial buildings located in geographic regions in which heating and cooling are not needed at the same season. However, it should be noted that careful consideration should be made for the integration of another renewable energy, together with geothermal one, as such integration may lead to very large increase in working capacity or inefficient operation associated with part-load operation over a longer period.

As simplicity in the design procedure is maintained, it would be beneficial to include the unit-level modeling and simulation of energy generators, which is then strategically linked to the current design method. This allows us to examine part-load performance of energy units and its techno-economic impact in more detail, which can be seen as one of the main future work.

Abbreviations

- ATES:

-

Aquifer thermal energy storage

- BTES:

-

Borehole thermal energy storage

- CAPEX:

-

Capital cost

- CFD:

-

Computational fluid dynamics

- CHP:

-

Combined heat and power

- COP:

-

Coefficient of performance

- DH:

-

District heat

- EC:

-

Electric cooler

- EES:

-

Electricity energy storage

- GTE:

-

Geothermal energy

- HP:

-

Heat pump

- LCOE:

-

Levelized cost of electricity

- LCOH:

-

Levelized cost of heat

- MILP:

-

Mixed integer linear programming

- OPEX:

-

Operating cost

- PG:

-

Power grid

- PV:

-

Photovoltaics

- RE:

-

Renewable energy

- TES:

-

Thermal energy storage

- CH:

-

Hourly cooling duty [kWh or MWh]

- CM:

-

Monthly cooling duty [kWh or MWh]

- DI:

-

Hourly intensity data for solar energy [W]

- EL:

-

Electricity loss [kWh or MWh]

- FCH:

-

Scale factor for considering the hourly intensity of solar cooling energy [–]

- FCM:

-

Scale factor for considering the monthly intensity of solar cooling energy [–]

- FHH:

-

Scale factor for considering the hourly intensity of solar heating energy [–]

- FHM:

-

Scale factor for considering the monthly intensity of solar heating energy [–]

- FHP:

-

The ratio of heat-to-power for a CHP unit [–]

- FRC:

-

Contribution factor for cooling from renewable energy [–]

- FRH:

-

Contribution factor for heating from renewable energy [–]

- FRG:

-

Contribution factor for heating and cooling from geothermal energy [–]

- FL:

-

The ratio of total amount of heating energy to cooling one from the geothermal source [–]

- GTE:

-

Geothermal energy [–]

- HH:

-

Hourly heating duty [kWh or MWh]

- HL:

-

Heat loss [kWh or MWh]

- HM:

-

Monthly heating duty [kWh or MWh]

- MI:

-

Monthly intensity data for solar energy [kWh/(m2month)

- BO:

-

Boiler

- CHP:

-

Combined heat and power

- DEM:

-

Demand energy

- DH:

-

District heating

- EES:

-

Electricity energy storage

- GE:

-

Geothermal energy

- GR:

-

Electricity grid

- RE:

-

Renewable energy

- SOL:

-

Solar energy

- SUR:

-

Surplus energy

- TES:

-

Thermal energy storage

- i :

-

Month

- j :

-

Hour

- GE:

-

Geothermal energy

- GR:

-

Electricity grid

- RE:

-

Renewable energy

- SUR:

-

Surplus energy

References

IEA, Renewables 2021—analysis and forecast to 2026 (IEA, Paris, 2021)

IRENA, Renewable power generation costs in 2021 (International Renewable Energy Agency, Abu Dhabi, 2022)

IRENA, IEA and REN21, Renewable energy policies in a time of transition: heating and cooling (IRENA, OECD/IEA and REN21, 2020)

IRENA and IGA, Global geothermal market and technology assessment (International Renewable Energy Agency Abu Dhabi; International Geothermal Association, The Hague, 2023)

M. Pellegrini, M. Bloemendal, N. Hoekstra, G. Spaak, A. Andreu-Gallego, J. Rodriguez-Comins, T. Crotenhuis, S. Picone, A.J. Murrell, H.J. Steeman, Sci. Total. Environ. 665, 1–10 (2019)

T. Sharmin, N.R. Khan, M.S. Akram, M.M. Ehsan, Int. J. Thermofluids 18, 100323 (2023)

IEA, Buildings, Paris, https://www.iea.org/energy-system/buildings. Accessed on 21 Aug 2023 (2023)

J.K. Kim, Renew. Sustain. Energy Rev. 167, 112718 (2022)

K.C. Kavvadias, S. Quoilin, Appl. Energy 216, 452 (2018)

P. Fleuchaus, B. Godschalk, I. Stober, P. Blum, Renew. Sustain. Energy Rev. 94, 861 (2018)

S.K. Shah, L. Aye, B. Rismanchi, Renew. Sustain. Energy Rev. 97, 38 (2018)

M. Fiorentini, P. Heer, L. Baldini, Energy 262, 125464 (2023)

O. Todorov, K. Alanne, M. Virtanen, R. Kosonen, Sustain. Cities Soc. 53, 101977 (2020)

A. Omu, S. Hsieh, K. Orehounig, Appl. Energy 180, 313 (2016)

P. Benalcazar, Energy Convers. Manag. 242, 114255 (2021)

D. Steen, M. Stadler, G. Cardoso, M. Groissbock, N. DeForest, C. Marnay, Appl. Energy 137, 782 (2015)

M. Fiorentini, J. Vivian, P. Heer, L. Baldini, REHVA 14th HVAC World Congress, Rotterdam, The Netherlands https://doi.org/10.34641/clima.2022.64 (2022)

B. Bozkaya, R. Li, W. Zeiler, Appl. Therm. Eng. 144, 681 (2018)

U.S. Doe, Combined heat and power technology fact sheet series: overview of CHP technologies (US DOE, Washington, 2017)

J. Kim, M. Kim, M. Binns, J. Lee, H. Cho, S.C. Yi, J. Ceram. Process. Res. 22, 722 (2021)

J. Kim, H. Park, S. Kim, J. Lee, Y. Song, S.C. Yi, Renew. Sustain. Energy Rev. 183, 113429 (2023)

NREL, Commercial and Residential Hourly Load Profiles for all TMY3 Locations in the United States, https://doi.org/10.25984/1788456 Accessed on 21 Aug 2023 (2014)

EC, Photovoltaic Geographical Information System, Brussels, https://re.jrc.ec.europa.eu/pvg_tools/en/#PVP. Accessed on 21 Aug 2023 (2023)

IEA, Example of daily load profile for solar PV production relative to electricity demand in 2050, Paris, https://www.iea.org/data-and-statistics/charts/example-of-daily-load-profile-for-solar-pv-production-relative-to-electricity-demand-in-2050. Accessed on 21 Aug 2023 (2022)

UK Beis, Combined heat and power technologies: a detailed guide for CHP developers—part 2 (UK BEIS, London, 2021)

D. Fischer, T. Wolf, J. Wapler, R. Hollinger, H. Madani, Energy 118, 853 (2017)

O. Ruhnau, L. Hirth, A. Praktiknjo, Sci. Data 6, 189 (2019)

S. Schuppler, P. Fleuchaus, P. Blum, Geotherm. Energy 7, 11 (2019)

P. Zangheri, R. Armani, M. Pietrobon, L. Pagliano, M.F. Boneta, A. Muller A (2014) Heating and cooling energy demand and loads for building types in different countries of the EU. Report of ENTRANZE project. https://www.entranze.eu/files/downloads/D2_3/Heating_and_cooling_energy_demand_and_loads_for_building_types_in_different_countries_of_the_EU.pdf Accessed on 21 Aug 2023 (2014)

Acknowledgements

This work is conducted with the support of the Korea Institute of Energy Technology Evaluation and Planning with the government (Ministry of Trade, Industry and Energy) in 2019 (20192010106970, Development of the integrated and decentralized smart hub thermal storage system for heat trading).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kim, JK., Kim, S.H., Lee, S. et al. Analytic Method for the Design and Analysis of Geothermal Energy-Integrated Space Heating and Cooling Systems. Korean J. Chem. Eng. 41, 103–116 (2024). https://doi.org/10.1007/s11814-024-00016-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-024-00016-5