Abstract

In this study, optimization of ZnO/EG nanofluids was investigated to increase efficiency and reduce costs. To determine the efficiency of nanofluid, the definition of Mouromtseff number was used. The cost of nanofluid in terms of the volume fraction of nanoparticles (φ) was determined. Then, Mouromtseff functions and costs were calculated by response surface methodology (RSM) with regression up to 96%. To determine the minimum cost and maximum efficiency in terms of Mouromtseff number, a non-dominated sorting genetic algorithm (NSGA II) which is powerful in achieving optimal response was employed. In the end, the Pareto front, optimal values of Mouromtseff, and the minimum corresponding cost were obtained. Also, for achieving an optimal pattern of minimum cost in terms of maximum thermal efficiency, a suitable correlation was presented. The results show that to achieve maximum thermal efficiency, the minimum cost is $ 360 per liter and also the minimum cost to achieve the optimal efficiency coefficient is in φ = 0.5%. Nanofluid optimization can also reduce nanofluid costs by up to 10%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Optimization and control of energy consumption is one of the most important issues for human societies. The response to this concern has led to extensive research in this area [1, 2]. Khandouzi et al. [3] optimized energy in building foundation piles with better geometry design. Geothermal energy, which is one of the cleanest energies, was used in this study. ANSYS-FLUENT software was selected for numerical simulation. The results for thermal performance show that the U6 heat exchanger has the best performance at a depth of 25 m, and the spiral geometries, U and W, are in the next steps. Heat and mass transfer properties of the fluid improve with adding nano-particles to the base fluid. Due to the low heat and mass transfer of most heat transfer fluids, nanoparticles can increase heat transfer, because of adding superior properties to them. Hence, because of this important feature of nanofluids, they can be utilized to remove heat from laser applications, electronic hub chips, car radiators and heat exchangers [4,5,6,7]. Zhang et al. [8] investigated the rheological properties and lubrication performance of MoS2/CNT hybrid nanofluid in MQL grinding process with nickel-based alloy. Comparison of MoS2/CNT hybrid nanofluid performance with non-hybrid nanofluid was also investigated. The results show that hybrid nanoparticles had better performance than mono-nanoparticles. Experiments show that the mixing ratio of MoS2/CNTs (2:1) is optimal and the volume fraction of 6% is the optimal value. Ghobadi and Hassankolaei [9] numerically analyzed the effects of Joule heating and Carreau nanofluid heat radiation. Thermophoresis and Brownian motion were considered in the modeling. The results show that the local Nusselt number and the surface tension force for shear-thickening fluid are higher than shear-thinning fluid. Shahlaei and Hassankolaei [10] conducted a similar study in this field using nonlinear thermal radiation. Gholinia et al. [11] investigated the reduction of thermal peak using water cooling fluid and nanoparticles of MWCNTs and SWCNTs. ANSYS-FLUENT software was used for modeling. The heat flux applied to the electrical system is fixed. The results show that increasing a thermal peak is formed in the lower temperature range. To optimize and recover energy, Armin et al. [12] investigated the effects of angle and fuel injection time on a heavy-duty dual-burner engine. Approximately 30% of the energy entering the cylinder of an internal combustion engine is used and the rest is wasted in various ways. Ghobadi and Hassankolaei [13] investigated heat transfer on a stretching cylinder that was affected by heat generation, nonlinear thermal radiation, and nanoparticle shape coefficient. Al2O3–TiO2/H2O hybrid nanofluid was used in this study. The results show that the use of hybrid nanofluids increases the temperature and the shape of Al2O3 nanoparticles had a greater effect on the Nusselt number compared to nanoparticles in the form of hexahedron. Wang et al. [14] investigated various vegetable oils that can be used as a base fluid in nanofluids. The results show that MQL grinding in vegetable oils has lower friction factor, specific grinding energy, and grinding wheel wear than flood grinding. Zhang et al. [15] in a laboratory study analyzed the performance of various vegetable oils in the presence of MoS2 nanoparticles. The results show that the mechanism of vegetable oil film formation is better in MQL mill. Also, the lubricating properties of vegetable oils were better than liquid paraffin. Yin et al. [16] studied various vegetable oils in the minimal lubrication (MQL) method. The MQL method was further investigated for mineral oils. Research on milling force was also conducted by Duan et al. [17]. They study milling force modeling for aluminum alloys. The research process was presented by experimental method, finite element, and cutting force modeling. According to the research, suggestions were made for modeling and future work, including the study of various factors, such as lubrication conditions, deformation of the workpiece, and the study of size. According to the researches, a rise in the number of nanoparticles causes an increase in the thermal conductivity of nanofluids (\({k}_{{\text{nf}}}\)) so that the more temperature of nanofluid, the higher \({k}_{{\text{nf}}}\) [18,19,20]. So far, many experiments have been conducted to achieve different properties of nanofluids with nanoparticles. But to reduce these tests, different experimental and quasi-experimental models have been suggested to predict experimental data.

Zhang et al. [8] investigated the rheological properties and lubrication performance of MoS2/CNT hybrid nanofluid in MQL grinding process with nickel-based alloy. Comparison of MoS2/CNT hybrid nanofluid performance with non-hybrid nanofluid was also investigated. The results show that hybrid nanoparticles had better performance than mono-nanoparticles. Experiments show that the mixing ratio of MoS2/CNTs (2:1) is optimal and the volume fraction of 6% is the optimal value. Ghobadi and Hassankolaei [9] numerically analyzed the effects of Joule heating and Carreau nanofluid heat radiation. Thermophoresis and Brownian motion were considered in the modeling. The results show that the local Nusselt number and the surface tension force for shear-thickening fluid are higher than shear-thinning fluid. Shahlaei and Hassankolaei [10] conducted a similar study in this field using nonlinear thermal radiation. Gholinia et al. [11] investigated the reduction of thermal peak using water cooling fluid and nanoparticles of MWCNTs and SWCNTs. ANSYS-FLUENT software was used for modeling. The heat flux applied to the electrical system is fixed. The results show that increasing a thermal peak is formed in the lower temperature range. To optimize and recover energy, Armin et al. [12] investigated the effects of angle and fuel injection time on a heavy-duty dual-burner engine. Approximately 30% of the energy entering the cylinder of an internal combustion engine is used and the rest is wasted in various ways. Ghobadi and Hassankolaei [13] investigated heat transfer on a stretching cylinder that was affected by heat generation, nonlinear thermal radiation, and nanoparticle shape coefficient. Al2O3–TiO2/H2O hybrid nanofluid was used in this study. The results show that the use of hybrid nanofluids increases the temperature and the shape of Al2O3 nanoparticles had a greater effect on the Nusselt number compared to nanoparticles in the form of hexahedron. Wang et al. [14] investigated various vegetable oils that can be used as a base fluid in nanofluids. The results show that MQL grinding in vegetable oils has lower friction factor, specific grinding energy and grinding wheel wear than flood grinding. Zhang et al. [15] in a laboratory study analyzed the performance of various vegetable oils in the presence of MoS2 nanoparticles. The results show that the mechanism of vegetable oil film formation is better in MQL mill. Also, the lubricating properties of vegetable oils were better than liquid paraffin. Yin et al. [16] studied various vegetable oils in the minimal lubrication (MQL) method. The MQL method was further investigated for mineral oils. Research on milling force was also conducted by Duan et al. [17]. They study milling force modeling for aluminum alloys. The research process was presented by experimental method, finite element, and cutting force modeling. According to the research, suggestions were made for modeling and future work, including the study of various factors, such as lubrication conditions, deformation of the workpiece and the study of size. Gao et al. [21] modeled predictive forces and mechanical analysis in the grinding process using CNT nanoparticles. In this study, four models based on grain and fiber geometries were presented and forces modeling was performed using these models. The results show that the presence of two MQL and CNT MQL improves the grinding process and in comparison, with dry grinding reduces the force in the vertical direction by 14.81% and 20.07%, respectively, and in the horizontal direction by 27.03% and 26.81%, respectively. Artificial Intelligence (AI) can be used to predict experimental data. An AI-based neural network is a famous approach that has been proposed in the past decade and has many different algorithms. Hemmat et al. [22] in a study using several methods of artificial intelligence investigated the performance of TiO2 nanoparticles with SAE 50 base oil. GA-RBF, LS-SVM, and GEP were used to predict nanofluid viscosity. The results show that the accuracy of GA-RBF was higher than other methods.

Summary of studies in the field of heat transfer coefficient of nanofluids is listed in Table 1.

Genetic algorithms based on processes observed in natural evolution were introduced by Holland [30] in the 1970s and in fact, they belong to a higher category as evolutionary algorithms. This algorithm includes evolutionary programming, evolutionary strategies, and genetic programming and works based on Darwin’s theory. In other words, the most appropriate chromosomes generate through the random displacement of previous genes and continue to exist. The genetic algorithm uses the simulation of natural genetic processes to overcome real complex problems which cannot be solved with traditional optimization methods [31]. Hemmat et al. [32] optimized and investigated the behavior of EG-based CuO nanofluids using ANNs and genetic algorithms. At first, nanofluids with concentrations of 0.125, 0.25, 0.5, 0.75, 1, and 1.5% were prepared at different temperatures by two-step method and laboratory tests were performed. ANN results show that two hidden layers with 8 neurons in each are the best ANN. One of the most efficient algorithms is the non-dominated sorting genetic algorithm-II (NSGA-II). The first selecting criterion for the NSGA-II is the rank of the answer and the second one is the density of the answer. Whatever rank of the answer is lower and the density of the answer’s distance is greater, it is more favorable [33,34,35,36,37]. Mehrabi et al. [26] modeled the heat transfer and pressure drop characteristics of TiO2/water nanofluid using the hybrid algorithm GA- PNN. The proposed model was verified using the NSGA-II algorithm. In this algorithm, pressure drop and Nusselt number were selected as target functions. The results showed that the use of Multi-Objective Optimization (MOO) for heat transfer and pressure drop characteristics leads to the best point based on the importance of goals in the design process. Due to several controllers and unknown or complex mathematical mechanisms, many phenomena do not have a satisfying mathematical model. So the relation between the response variable with one or more independent variables (studying variables) can be determined. Hemmat et al. [38] investigated the thermal conductivity and cost evaluation for SWCNT-ZnO nanofluids based on water and EG with 70 and 30% ratio, respectively. A relation for the prediction of thermal conductivity was presented with R2 = 0.9918. The relationship was presented in terms of temperature and volume fraction. Cost analysis also shows that the addition of nanoparticles is appropriate in terms of improving thermal conductivity and cost. One of the methods to obtain the relationship between independent and dependent variables is the RSM [39,40,41,42,43]. Shanbedi et al. [44] examined the laminar flow heat transfer of MWCNT/water nanofluid in the pipe horizontal rotary using RSM. A set of 15 tests in various conditions have been conducted with the RSM method. The results showed that the RSM method matches well with the experimental results and the precision, accuracy, and response of this approach are verified.

In this study, the performance, the modeling, and the optimization of EG-ZnO nanofluid from an economic perspective and rheological properties are investigated. For this purpose, RSM and NSGA II methods were used. First, the MOO, and the features and applications of the NSGA II algorithm, and the optimization process with them are discussed. Using the RSM, relationships are provided to predict the cost of nanofluid and ANOVA is also provided. Using various diagrams, the accuracy of the presented relationships is checked. The results related to the optimization of ZnO/EG nanofluid performance, which includes the minimum cost for the highest thermal performance and the values related to the volume fraction and temperature are explained and the optimal values are compared with the non-optimal state.

MOO of Nanofluid to Decrease Cost and Increasing Thermal Efficiency Coefficient

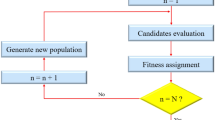

In this study, MOO was performed with the non-dominated sorting genetic algorithm II (NSGA II). The algorithm used non-dominated sorting and crowding distance functions. All points in the non-dominated sorting function were compared two by two with each other. Then, each response (points) was calculated as much as was defeated with other responses. A set of responses that weren’t defeated had Rank 1 and was put in the first front. Then this point was put away and the comparing operation was performed to front all the answers. The members of the population were taken by the software as input and took them in suitable fronts with their ranks. Crowding distance that its abbreviation is CD shown in Fig. 1 is a function that plays the role of a population distributor to prevent unbalanced density or dispersion of population. Crowding distance is shown in Fig. 1.

Procedure of NSGA II Algorithm

First, N member of initial population (Pt) is generated. Then, the values of objective functions for initial population are computed. The members are ranked and CD is determined. Then based on rank and CD, parents are selected by binary tournament selection method and mutation and combination operators are performed on them. The new population (Qt) is combined with the previous population and sorting is done once more. From the whole population which is more populated than the initial population, N top members are selected for the next generation. To select next generation, from the upper front’s id selected. If by choosing other fronts, the member of the population becomes more than N, selection of members is taken with regards to CD. Then the main procedure of the algorithm is shown in Fig. 2.

NSGA II flowchart was showed in Fig. 3. As is known in the optimization algorithm, to determine the fitness functions, the response surface method was used. Also, for creating a new population of genetic operators included cross-over and mutation were used. Finally, the optimization process with the number of iterations was ended.

To decrease cost and increase Mouromtseff number, NSGA-II algorithm was used. So, φ and temperature were set as optimizing variables. Given that NSGAII algorithm for generating initial population and next generation of using genetic algorithm cross-over and mutation was defined. In this section single point, crossover, and Gaussian mutation operators were used. The crossover percentage parameter, the mutation percentage, and the mutation rate were set 0.85, 0.3, and 0.3 respectively. Also, the random function was used to generate the initial population and random population. Equation 1 is used to determine the performance of the nanofluid in the turbulent state. From this relationship, the heat transfer of different coolers can be well investigated. This relationship states that the higher the value of the Mo number, the better the cooling and heat transfer. This relationship indicates that the viscosity of the nanofluid also has a significant effect on the performance of the nanofluid and the nanofluid with lower thermal conductivity and viscosity may be preferred to the nanofluid with higher thermal conductivity and viscosity. The values of specific heat capacity (Cp,nf) and density (ρnf) of the nanofluid are obtained using Eqs. 2 and 3. In Eqs. 2 and 3, the parameters \(\rho\),\(C\) and \(\varphi\) represent the density, the heat capacity, and the volume fraction of the nanoparticles, respectively, and the subtitles nf, f, and p represent the nanofluid, base fluid, and nanoparticles, respectively.

Objective functions in two-objective optimization were cost function and Mouromtseff number. An accurate evaluation of optimal conditions in terms of nanoparticles focus and temperature can be achieved by having the function. Cost evaluation and \({k}_{{\text{nf}}}\) can be achieved using the RSM with experimental data [45].

Approximation of Objective Functions

Response Surface Methodology (RSM)

To expand and optimize processes, there are a series of practical mathematical and statistical methods which is called RSM. By careful design of experiments, several independent variables (input variables) influence the response (output variable) which is the objective to optimize. Response surface method or in abbreviates form the RSM was used as a statistical method. Equation 4 shows the calculation of the dependent parameter y in terms of independent parameters x1 and x2 and linearly in the RSM [46]. The value of ε in this equation also indicates the degree of deviation. The coefficients \({\beta }_{0}\), \({\beta }_{1}\), and \({\beta }_{2}\) are also regression coefficients in the RSM. Equation 5 also presents the matrix state of Eq. 4, where Y is the matrix of dependent parameters and X is the matrix of independent parameters.

where the unknown parameters \({\beta }_{0}\), \({\beta }_{1}\), and \({\beta }_{2}\) are regression coefficients. To check the quality of performance of linear regression, one of the most important parameters is the sum of squares of the residual (Eq. 6).

In Eq. 6, \({{\text{SS}}}_{{\text{E}}}\) is equal to the sum of the squares of error and \({y}_{i}\) is the actual value of data i and \({\widehat{y}}_{i}\) is the predicted value for data i. \({e}_{i}\) is the vector of the next n values that is calculated from Eq. 7.

Since XTXb = XTy, the sum of the square error, SSE, can also be calculated from Eq. 8. In Eq. 8, b is related to the regression coefficient matrix.

Unbiased estimator of \({\sigma }^{2}\) is given by:

In Eq. 9, n and p are the number of observations and regression coefficients, respectively. The total sum of squares can be determined by Eq. 10:

Using two defined equations the R2 is

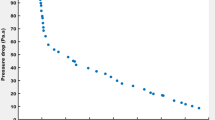

\({R}^{2}\) in Eq. 11 is called the convergence coefficient and has a value between zero and one. The closer the value of \({R}^{2}\) is to 1, the more accurate the hegemony presented by the RSM. To approximate a suitable relationship with the RSM method, an experiment was performed on the Mouromtseff number in terms of φ and temperature. Experimental data of φ and temperatures were considered in the range of (0.5–5.5) and (20–80) respectively. The amount of the cost of ZnO/EG nanoparticles in terms of φ according to the company cost definition was determined. Also, Mouromtseff number has been determined with the values of \({k}_{{\text{nf}}}\), viscosity, heat capacity, and density which were extracted from Lee et al. The trend of cost change of nanofluids with Mouromtseff number is shown in Fig. 4 for the range of 0.99–1.1. With the increase in the Mouromtseff number, the overall cost of nanofluids has increased. Increasing the Mouromtseff number from 0.99 to 1.1 has increased the cost by almost 55%, which is significant.

Analysis of Variance (ANOVA)

A cubic mathematical model is proposed for the Mouromtseff number as a combined function of Re number and φ as dependent variables. The p value is introduced as a criterion parameter to check the importance or unimportance of each correlations terms. Mathematical correlation terms with p values lower than 0.05 are important terms and terms with a p value higher than 0.05 are the unimportant ones and can be removed from the correlation. Also, a mathematical model is proposed to predict cost function in Eq. 15, according to mentioned principles for Eq. 14 and Tables 2 and 3.

Figure 5a and b shows a graph of the normal probability values of the residuals for the Mouromtseff number and the cost of nanoparticles, respectively. The normal probability diagram of the residuals should not have a regular trend because there is a possibility of error in modeling. Also, the graph should not be S-shaped. The values of the normal probability of residuals in Fig. 5a and b do not have a regular trend and are not s-shaped and are appropriate.

The predicted values of Eqs. 12 and 13 for the Mouromtseff number and cost in terms of actual and laboratory values are shown in Fig. 6, respectively. The proximity of the data to the bisector line indicates good modeling accuracy. Due to the smaller distance of the cost from the bisector line than the Mouromtseff number, the higher accuracy of the cost modeling is obvious.

Figure 7 shows the cost values in terms of volume fraction for the obtained values from the RSM. Since the presented equation to calculate the cost is based on the volume fraction parameter and temperature has no role in it, two-dimensional and three-dimensional diagrams are not different from each other. As shown in the figure, as the volume fraction of nanoparticles increases, so does the price. Figure 8 shows a graph of the changes in Mouromtseff number in terms of volume fraction and temperature in three dimensions. As it turns out, increasing the volume fraction has a significant effect on the values of the Mouromtseff number. The changes in Mouromtseff number with temperature changes were insignificant.

Results

Members of population and the number of repetition have been performed to achieve optimal results and with different values. The results determined from optimization which was proposed for 20 members and 20 repetitions as a term of orientation in Fig. 9. In the figure, to investigate convergence and achieve to Pareto front, the results in the first, the fifth, and the tenth front were presented. These results are from defeated and undefeated fronts which the effect of elimination of undefeated results in each repetition is identifiable. As it is clear in Fig. 9, optimal fronts are in progress during the optimization process. This progress shows the accuracy of the performance of the algorithm. In this figure, the curve of the Pareto front has been presented. Optimal points of Mouromtseff number and their costs can be determined by this curve. As the results of the final optimization fronts, good convergence results have been achieved. According to the obtained results, to get Mouromtseff number is 1.09 and the costs of first-generation and the last generation of Pareto front are 378 and 358, respectively. The results show MOO algorithm can reduce 6 percent the costs from the first generation to the fifteenth generation. Also, the optimal result for the Mouromtseff number is 1.025. The costs were decreased from $ 285 to 258 per liter in the first generation in the Pareto front which was showed that the optimal algorithm could reduce 10% of costs.

The two-objective optimization Pareto front of increasing Mouromtseff number and decreasing costs is displayed in Fig. 10. The last front is the Pareto front that all points are optimal and non-dominated respect each other. The results can be concluded that to achieve the number of about 1 Mouromtseff, at least to the tune of $ 235 per liter have to be spent. Also, least cost to get the highest thermal efficiency coefficient equal to 1.1 is about $ 360 per liter. Meanwhile, the cost required is equal to $ 390 per liter of oil, according to preliminary data of Fig. 4.

To get the optimal points’ algorithm Mouromtseff number, Eq. 14 was presented. It can be predicted the least cost for a specific Mouromtseff number.

In MOO, one of the Pareto points is selected as a trade point. A trade point is an equivalent between the objective function values and can select one Pareto front point according to the requirement and being valuable of the objective function. Unlike the weighting coefficients method, Pareto optimization includes a collection of optimal points achieved by changing the coefficients. Optimal results are presented for each φ and temperature variable in Table 4. For the amount of Mouromtseff number, T and φ values which have the lowest cost are presented in Table 4.

As it is clear from the results, it is possible to select according to the importance of each function. Based on the results obtained, the maximum Mouromtseff number or maximum efficiency of nanofluid at suitable cost is obtained at T = 80 °C is 4.21. Also, the minimum cost to achieve optimal thermal efficiency is spent at φ = 0.5%. According to the result, the cost is increasing by increasing the φ. However, since the coefficient of thermal efficiency depends on temperature, it is not necessarily possible to reach such a conclusion for the coefficient of thermal efficiency.

Conclusion

Modeling and optimizing ZnO/EG nanofluid performance were investigated using RSM and NSGA II methods in this study. The Mouromtseff number indicates the performance of the nanofluid in turbulent flow mode, and a higher value means that the nanofluid is more efficient, although the cost parameter must also be considered. Therefore, in this study, Mouromtseff number and costs were optimized, and the optimal state is the maximum Mouromtseff number and the minimum cost. Modeling of Mouromtseff number and cost number was also performed based on experimental data. Using the RSM, two equations were presented for the Mouromtseff number and the cost of ZnO/EG nanofluids, which are in terms of temperature and volume fraction of nanoparticles. The results show good modeling accuracy so that R2-Adjusted values or Mouromtseff number and cost were 96.67% and 99.91%, respectively. Also, the addition of nanoparticles to the base fluid increases the Mouromtseff number and costs. Based on the results of NSGA II method, the Pareto front and the optimal values related to both the parameters of the Mouromtseff number and the cost of nanofluids were obtained. Also, with the RSM, an equation was presented to calculate the minimum cost in terms of Mouromtseff number. The results show that it takes at least $ 235 per liter to reach the Mouromtseff number of about 1. For maximum thermal efficiency or efficiency of 1, the minimum cost is $ 360 per liter, while according to initial laboratory data, it is $ 390 per liter of oil. Also, the maximum Mouromtseff number or the highest nanofluid efficiency was obtained at a reasonable cost in a volume fraction of 4.21% and T = 80 °C. The minimum cost to achieve the optimal efficiency was in the volume fraction of 0.5%, which was equal to $ 236 per liter of oil. The results also show that nanofluid optimization can reduce costs by up to 10%. Despite the study of modeling and optimization of ZnO/EG nanofluids in this study, but due to the emergence of nanofluid science, there is a lot of work in this field and other basic nanoparticles and fluids should be considered in future studies. In addition, in future studies, the performance of nanofluids can be compared with each other in terms Mouromtseff number and costs, or the optimization of nanofluid performance in slow and transient flow regimes can be investigated, and also several types of nanoparticles can be used as base fluids and studied so-called hybrid nanofluids that have a special place.

Abbreviations

- C P :

-

Specific heat

- \({e}_{i}\) :

-

Vector of residual values

- k :

-

Thermal conductivity

- n :

-

Number of data

- R 2 :

-

Regression coefficient

- \(R^{2}_{\text{adj}}\) R 2 :

-

Adjusted regression coefficient

- \({{\text{SS}}}_{T}\) :

-

Sum of squares

- P t :

-

Member of initial population

- Q t :

-

New population

- T :

-

Temperature

- X :

-

Independent parameter

- Y :

-

Response

- y i :

-

Actual value

- \({\widehat{y}}_{i}\) :

-

Predicted value

- AARD:

-

Average absolute relative deviation

- AI:

-

Artificial intelligence

- ANFIS:

-

Adaptive neuron-fuzzy inference system

- ANN:

-

Artificial neural networks

- ANOVA:

-

Analysis of variance

- CD:

-

Crowding distance

- EG:

-

Ethylene glycol

- f:

-

Base fluid

- GA-PNN:

-

Genetic algorithm–polynomial neural network

- GA-RBF:

-

Genetic algorithm-radial basis function neural networks

- GEP:

-

Gene expression programming

- GMDH:

-

Group method of data handling

- LS-SVM:

-

Least square support vector machine

- MAE:

-

Mean absolute error

- MLP:

-

Multilayer perceptron

- Mo:

-

Mouromtseff number

- MOO:

-

Multi-objective optimization

- MRE:

-

Mean relative error

- MSE:

-

Mean square error

- MWCNT:

-

Multi-walled carbon nanotube

- N :

-

Member of initial population

- NF:

-

Nanofluid

- P:

-

Nanoparticle

- PRESS:

-

Predicted residual error of sum of squares

- NSGA II:

-

Non-dominated sorting genetic algorithm

- Re:

-

Reynolds number

- Rprop:

-

Resilient backpropagation algorithm

- RSME:

-

Root mean square error

- RSM:

-

Response surface methodology

- SSE :

-

Sum of squares of the residual

- STDR:

-

Standard deviation in the relative error

- \(\varepsilon\) :

-

Experimental error

- φ :

-

Solid volume fraction

- μ :

-

Viscosity

- ρ :

-

Density

References

X. Zhang, Y. Tang, F. Zhang, C.S. Lee, A novel aluminum–graphite dual-ion battery. Adv. Energy Mater. 6(11), 1502588 (2016)

M.N. Zadeh, M. Pourfallah, S. Sabet, M. Gholinia, S. Mouloodi, A.T. Ahangar, Performance assessment and optimization of a helical Savonius wind turbine by modifying the Bach’s section. SN Appl. Sci. 3(8), 1–11 (2021)

O. Khandouzi, M. Pourfallah, E. Yoosefirad, B. Shaker, M. Gholinia, S. Mouloodi, Evaluating and optimizing the geometry of thermal foundation pipes for the utilization of the geothermal energy: numerical simulation. J. Energy Storage 37, 102464 (2021)

M.M. Sarafraz, A. Arya, F. Hormozi, V. Nikkhah, On the convective thermal performance of a CPU cooler working with liquid gallium and CuO/water nanofluid: a comparative study. Appl. Therm. Eng. 112, 1373–1381 (2017)

M.H. Esfe, S.S.M. Esforjani, M. Akbari, A. Karimipour, Mixed-convection flow in a lid-driven square cavity filled with a nanofluid with variable properties: effect of the nanoparticle diameter and of the position of a hot obstacle. Heat Transf. Res. 45(6), 563–578 (2014)

M. Gholinia, S.A.H. Kiaeian Moosavi, S. Gholinia, D.D. Ganji, Numerical simulation of nanoparticle shape and thermal ray on a CuO/C2H6O2–H2O hybrid base nanofluid inside a porous enclosure using Darcy’s law. Heat Transf. Asian Res. 48(7), 3278–3294 (2019)

A.H. Ghobadi, M. Armin, S.G. Hassankolaei, M. Gholinia Hassankolaei, A new thermal conductivity model of CNTs/C2H6O2–H2O hybrid base nanoliquid between two stretchable rotating discs with Joule heating. Int. J. Ambient Energy 1, 1–52 (2020). https://doi.org/10.1080/01430750.2020.1824942

Y. Zhang, C. Li, D. Jia, D. Zhang, X. Zhang, Experimental evaluation of the lubrication performance of MoS2/CNT nanofluid for minimal quantity lubrication in Ni-based alloy grinding. Int. J. Mach. Tools Manuf 99, 19–33 (2015)

A.H. Ghobadi, M.G. Hassankolaei, Numerical treatment of magneto Carreau nanofluid over a stretching sheet considering Joule heating impact and nonlinear thermal ray. Heat Transf. Asian Res. 48(8), 4133–4151 (2019)

S. Shahlaei, M.G. Hassankolaei, MHD boundary layer of GO–H2O nanoliquid flow upon stretching plate with considering nonlinear thermal ray and Joule heating effect. Heat Transf. Asian Res. 48(8), 4152–4173 (2019)

M. Gholinia, A.A. Ranjbar, M. Javidan, A.A. Hosseinpour, Employing a new micro-spray model and (MWCNTs-SWCNTs)-H2O nanofluid on Si-IGBT power module for energy storage: a numerical simulation. Energy Rep. 7, 6844–6853 (2021)

M. Armin, M. Gholinia, M. Pourfallah, A.A. Ranjbar, Investigation of the fuel injection angle/time on combustion, energy, and emissions of a heavy-duty dual-fuel diesel engine with reactivity control compression ignition mode. Energy Rep. 7, 5239–5247 (2021)

A.H. Ghobadi, M.G. Hassankolaei, A numerical approach for MHD Al2O3–TiO2/H2O hybrid nanofluids over a stretching cylinder under the impact of shape factor. Heat Transf. Asian Res. 48(8), 4262–4282 (2019)

Y. Wang, C. Li, Y. Zhang, M. Yang, B. Li, D. Jia et al., Experimental evaluation of the lubrication properties of the wheel/workpiece interface in minimum quantity lubrication (MQL) grinding using different types of vegetable oils. J. Clean. Prod. 127, 487–499 (2016)

Y. Zhang, C. Li, D. Jia, D. Zhang, X. Zhang, Experimental evaluation of MoS2 nanoparticles in jet MQL grinding with different types of vegetable oil as base oil. J. Clean. Prod. 87, 930–940 (2015)

Q. Yin, C. Li, L. Dong, X. Bai, Y. Zhang, M. Yang et al., Effects of physicochemical properties of different base oils on friction coefficient and surface roughness in MQL milling AISI 1045. Int. J. Precis. Eng. Manuf. Green Technol. 8(6), 1629–1647 (2021)

Z. Duan, C. Li, W. Ding, Y. Zhang, M. Yang, T. Gao et al., Milling force model for aviation aluminum alloy: academic insight and perspective analysis. Chin. J. Mech. Eng. 34(1), 1–35 (2021)

M. Hadadian, E.K. Goharshadi, A. Youssefi, Electrical conductivity, thermal conductivity, and rheological properties of graphene oxide-based nanofluids. J. Nanopart. Res. 16(12), 1–17 (2014)

Z. Hajjar, A. Morad Rashidi, A. Ghozatloo, Enhanced thermal conductivities of graphene oxide nanofluids. Int. Commun. Heat Mass Transf. 57, 128–131 (2014)

A. Nasiri, M. Shariaty-Niasar, A. Rashidi, A. Amrollahi, R. Khodafarin, Effect of dispersion method on thermal conductivity and stability of nanofluid. Exp. Therm. Fluid Sci. 35(4), 717–723 (2011)

T. Gao, C. Li, M. Yang, Y. Zhang, D. Jia, W. Ding et al., Mechanics analysis and predictive force models for the single-diamond grain grinding of carbon fiber reinforced polymers using CNT nano-lubricant. J. Mater. Process. Technol. 290, 116976 (2021)

M.H. Esfe, A. Tatar, M.R.H. Ahangar, H. Rostamian, A comparison of performance of several artificial intelligence methods for predicting the dynamic viscosity of TiO2/SAE 50 nano-lubricant. Physica E 96, 85–93 (2018)

A.M. Adham, N. Mohd-Ghazali, R. Ahmad, Optimization of nanofluid-cooled microchannel heat sink. Therm. Sci. 20(1), 109–118 (2016)

M. Ziaei-Rad, M. Saeedan, E. Afshari, Simulation and prediction of MHD dissipative nanofluid flow on a permeable stretching surface using artificial neural network. Appl. Therm. Eng. 99, 373–382 (2016)

A.K. Santra, N. Chakraborty, S. Sen, Prediction of heat transfer due to presence of copper–water nanofluid using resilient-propagation neural network. Int. J. Therm. Sci. 48(7), 1311–1318 (2009)

M. Mehrabi, M. Sharifpur, J.P. Meyer, Modelling and multi-objective optimisation of the convective heat transfer characteristics and pressure drop of low concentration TiO2–water nanofluids in the turbulent flow regime. Int. J. Heat Mass Transf. 67, 646–653 (2013)

P. Valinataj-Bahnemiri, A. Ramiar, S.A. Manavi, A. Mozaffari, Heat transfer optimization of two phase modeling of nanofluid in a sinusoidal wavy channel using artificial bee colony technique. Eng. Sci. Technol. Int. J. 18(4), 727–737 (2015)

A.M. Hussein, Adaptive neuro-fuzzy inference system of friction factor and heat transfer nanofluid turbulent flow in a heated tube. Case Stud. Therm. Eng. 8, 94–104 (2016)

M. Saeedan, A.R.S. Nazar, Y. Abbasi, R. Karimi, CFD Investigation and neutral network modeling of heat transfer and pressure drop of nanofluids in double pipe helically baffled heat exchanger with a 3-D fined tube. Appl. Therm. Eng. 100, 721–729 (2016)

J.H. Holland, Genetic algorithms and the optimal allocation of trials. SIAM J. Comput. 2(2), 88–105 (1973)

A.R. Ghasemi, M.H. Hajmohammad, Minimum-weight design of stiffened shell under hydrostatic pressure by genetic algorithm. Steel Compos. Struct. 19(1), 75–92 (2015)

M.H. Esfe, M. Bahiraei, O. Mahian, Experimental study for developing an accurate model to predict viscosity of CuO–ethylene glycol nanofluid using genetic algorithm based neural network. Powder Technol. 338, 383–390 (2018)

H. Safikhani, A. Abbassi, A. Khalkhali, M. Kalteh, Multi-objective optimization of nanofluid flow in flat tubes using CFD, artificial neural networks and genetic algorithms. Adv. Powder Technol. 25(5), 1608–1617 (2014)

A. Abdollahi, M. Shams, Optimization of heat transfer enhancement of nanofluid in a channel with winglet vortex generator. Appl. Therm. Eng. 91, 1116–1126 (2015)

S. Halelfadl, A.M. Adham, N. Mohd-Ghazali, T. Maré, P. Estellé, R. Ahmad, Optimization of thermal performances and pressure drop of rectangular microchannel heat sink using aqueous carbon nanotubes based nanofluid. Appl. Therm. Eng. 62(2), 492–499 (2014)

G.M. Normah, J.T. Oh, N.B. Chien, K.I. Choi, A. Robiah, Comparison of the optimized thermal performance of square and circular ammonia-cooled microchannel heat sink with genetic algorithm. Energy Convers. Manag. 102, 59–65 (2015)

F.A. Boyaghchi, M. Chavoshi, V. Sabeti, Optimization of a novel combined cooling, heating and power cycle driven by geothermal and solar energies using the water/CuO (copper oxide) nanofluid. Energy 91, 685–699 (2015)

M.H. Esfe, A.A.A. Arani, M. Firouzi, Empirical study and model development of thermal conductivity improvement and assessment of cost and sensitivity of EG-water based SWCNT-ZnO (30%:70%) hybrid nanofluid. J. Mol. Liq. 244, 252–261 (2017)

L. Sun, C.L. Zhang, Evaluation of elliptical finned-tube heat exchanger performance using CFD and response surface methodology. Int. J. Therm. Sci. 75, 45–53 (2014)

J.S. Nam, D.H. Kim, H. Chung, S.W. Lee, Optimization of environmentally benign micro-drilling process with nanofluid minimum quantity lubrication using response surface methodology and genetic algorithm. J. Clean. Prod. 102, 428–436 (2015)

M. Rahimi-Gorji, O. Pourmehran, M. Hatami, D.D. Ganji, Statistical optimization of microchannel heat sink (MCHS) geometry cooled by different nanofluids using RSM analysis. Eur. Phys. J. Plus 130(2), 1–21 (2015)

A. Sadollah, A. Ghadimi, I.H. Metselaar, A. Bahreininejad, Prediction and optimization of stability parameters for titanium dioxide nanofluid using response surface methodology and artificial neural networks. Sci. Eng. Compos. Mater. 20(4), 319–330 (2013)

B.S. Kim, B.S. Kwak, S. Shin, S. Lee, K.M. Kim, H.I. Jung, H.H. Cho, Optimization of microscale vortex generators in a microchannel using advanced response surface method. Int. J. Heat Mass Transf. 54(1–3), 118–125 (2011)

M. Shanbedi, S. Zeinali Heris, A. Maskooki, H. Eshghi, Statistical analysis of laminar convective heat transfer of MWCNT-deionized water nanofluid using the response surface methodology. Numer. Heat Transf. Part A Appl. 68(4), 454–469 (2015)

G.J. Lee, C.K. Kim, M.K. Lee, C.K. Rhee, S. Kim, C. Kim, Thermal conductivity enhancement of ZnO nanofluid using a one-step physical method. Thermochim. Acta 542, 24–27 (2012)

R.F. Gunst, Response surface methodology: process and product optimization using designed experiments. Technometrics 38, 285 (1996)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Esfe, M.H., Hajmohammad, H., Motallebi, S.M. et al. Cost and Efficiency Optimizations of ZnO/EG Nanofluids Using Non-dominated Sorting Genetic Algorithm Coupled with a Statistical Method. Korean J. Chem. Eng. 41, 175–186 (2024). https://doi.org/10.1007/s11814-023-00003-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-023-00003-2