Abstract

This study shows that ceramic beads, which are often used as adsorbents in wastewater treatment, can adsorb a wide range of organic micropollutants in both ionic and non-ionic forms, and the adsorption properties can be characterized through experimental studies and theoretical modeling. Actually, since there is a myriad type of chemicals, there is a limit to experimentally investigating the adsorption properties of ceramic beads. Therefore, it is necessary to estimate the adsorption properties experimentally, while a prediction model for the adsorption relationship between ceramic beads and chemicals is developed. In this study, the adsorption properties of ceramic beads, as estimated by performing isotherms and fitting Langmuir and Freundlich models, were predicted using linear free energy relationship descriptors comprising in silico calculated descriptors. In addition, the Langmuir model derives maximum uptake (qm) and adsorption affinity (b), and the Freundlich model estimates equilibrium constant (KF), meaning maximum uptake, and Freundlich exponent (n), as an indicator of adsorption compatibility. The results demonstrated that ceramic beads can be considered a suitable type of adsorbent and have heterogeneous adsorptions, as confirmed by Freundlich fitting. In the modeling study, it was checked that the employed linear free energy relationship (LFER) model could not be used to predict the heterogeneous adsorption properties estimated by the Freundlich model, while it could predict the homogeneous properties estimated by the Langmuir model. The developed model could predict the qm in R2 of 0.70 with a standard error of 0.22 log units and the adsorption affinity (log b) in R2 of 0.71 with a standard error of 0.38 log units. These results will help predict the adsorption properties of unstudied micropollutants on ceramic beads.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The development of micropollutant removal techniques is one of the most significant research topics in environmental engineering because organic micropollutants are a growing global issue related to water pollution [1]. Organic micropollutants, commonly referred to as emerging contaminants, are a class of chemicals that are present in the environment at low concentrations. Examples of micropollutants include pesticides [2], pharmaceutical and personal care products [3], steroid hormones [2], and detergents [4]. As reported, micropollutants may have a range of negative consequences for both human health and the environment over a long period of time due to their persistence [5]. Therefore, short- or long-term exposure can cause chronic illness, endocrine disruption, or unpredictable effects from combinative interactions among the contaminants [6]. Therefore, it is necessary to develop effective removal techniques for organic micropollutants.

Micropollutants have previously been removed using a number of techniques, including ozonation [7], precipitation or coagulation [8], biodegradation [9], adsorption [10,11,12,13,14], and continuous membrane processes [15]. Among them, adsorption, which is economical, eco-friendly, and effective in removing low concentrations of organic micropollutants from wastewater [16], might be regarded as one of these approaches. In the adsorption process, high removal efficiency can be achieved by choosing an efficient adsorbent, which must have a large surface area and powerful adsorption capacity [17].

The most important step in the adsorption process is selecting the appropriate adsorbent for wastewater treatment. Due to a number of factors, ceramic beads can be used as an adsorbent in this case. First, because of their large surface area, ceramic beads have a high adsorption capability. [18]. Second, it has strong chemical and thermal stabilities, so it is resistant to corrosion, degradation, and high temperatures, so it can be used even in harsh conditions [19]. Third, ceramic beads may be utilized for continuous and protracted removal processes since they are strong and long lasting. Fourth, since it is constructed of natural materials and does not emit toxic by-products, it is also recyclable and ecologically beneficial [20]. Additionally, components of the ceramic beads can be modified to filter [21] or glass forms [22]. Previously, ceramic beads could be used to remove the antibiotic tetracycline using diatomite- and wood-based ceramics [17] and to remove heavy metals using ceramic beads produced by mixing zeolite and activated carbon [23]. However, ceramic-based materials have not been applied to a wide range of organic pollutants and so their adsorption properties have not been sufficiently studied.

Because the adsorption property of ceramic beads depends on the types of micropollutants, and there are a number of types of micropollutants, experimental estimation of the adsorption properties of numerous micropollutants is highly labor intensive and material consuming. In order to cope with the problem of the number of micropollutants, it is necessary to propose a more efficient method, namely, predictive method. Therefore, this study aimed to characterize the adsorption properties of ceramic beads for various micropollutants and develop a predictive model. To achieve this research aim, an experimental study was performed by conducting adsorption experiments on 14 cations, 10 neutral compounds, and 4 anions, which are structurally diverse. In addition, the adsorption study on the ceramic beads to remove organic micropollutants has not been sufficiently performed so far; therefore, the experimental dataset was not enough for modeling. The adsorption property should be estimated under consistent conditions since the adsorption can be different according to the experiment environment. Therefore, in this study, we estimated the adsorption properties of ceramic beads at the same conditions, and their adsorption properties were estimated from Langmuir [24] and Freundlich models [25]. Subsequently, quantitative structure–adsorption relationship (QSAR) modeling was performed on the basis of the linear free energy relationship (LFER) concept [26] and in silico calculated LFER descriptors [27], and the model was further internally and externally validated. Moreover, adsorptive interactions between organic micropollutants and ceramic beads were analyzed by checking the contribution of structural properties, using molecular parameters in the modeling and the adsorption properties.

Materials and Methods

Materials Preparation

The ceramic beads, made up of activated carbon, zeolite, and clay minerals, with around 3 mm of diameter, were purchased from KOREACERAMIC (Bucheon, South Korea). Before use, it was washed several times with tertiary distilled water to remove impurities and then dried using a freeze dryer (Cool Safe, Scanvac, Denmark). To keep the adsorbent dry, it was stored in a desiccator.

Chemicals

A total of 28 chemicals, including 14 cations, 10 non-ion compounds, and 4 anions, were studied as target micropollutants. All chemicals were purchased from Sigma-Aldrich Korea Ltd. (St. Louis, USA). The chemical stock solutions were dissolved in the distilled water, and they were stored at a dark temperature of 4 °C to prevent decomposition by light.

Adsorption experiments

In the isotherm experiment, 30 mL of stock solution was filled with tertiary distilled water and chemical stock solution and 0.1 g of an adsorbent were incubated for about 24 h at 70 rpm at 25 °C. The pH was maintained at 6.5 (± 0.2) because 6.5 pH is similar to the condition of actual wastewater and acidic or basic compounds are completely ionized to anion and cation, respectively. The pH was adjusted using 0.1-M HCl and NaOH. After reaching equilibrium, the mixture that consisted of the adsorbent and stock solution was taken and centrifuged. Then, the chemical concentration in the solution was analyzed using high-performance liquid chromatography (HPLC). The adsorption amount (qe) is obtained using Eq. (1) [28].

where qe means the amount of adsorbent (μmol/g) per gram of material, Ci and Cf mean initial and final concentrations (μM), respectively. Vsol represents the volume of the solution (L), and m means the weight of the adsorption material (g). Vsol was 30 mL.

Langmuir isotherm fitting [24] was carried out to measure the maximum adsorption (qm) and adsorption affinity (b). Langmuir isotherm equation is Eq. (2) [29]. qm and b are estimated by Langmuir equation of the final concentration Cf (μM) in an experimental batch in x-axis and adsorbed concentration per g of adsorbent qe (μmol/g [by Eq. 1]) in y-axis.

Freundlich model [25] as Eq. (3) was applied to estimate the adsorption properties.

where KF [L/μmol] is the Freundlich equilibrium constant and n [dimensionless] means the Freundlich exponent.

Instrumental Analysis

Brunauer–Emmett–Teller analysis (BET) using Belsorp Mini II (BEL, Japan) was performed to measure the specific surface area, pore size, and distribution of ceramic beads. A field emission-scanning electron microscope (FE-SEM, SUPRA40VP) (Jena, Germany) was used to examine morphological features. Energy-dispersive X-ray spectroscopy (EDS) was also utilized to analyze elemental analysis or chemical characterization. High-performance liquid chromatography (HPLC) was employed to determine chemical concentrations taken from the isotherm experiment, in which a C-18 column with a particle size of 3 μm and dimensions of 4.5 × 150 mm (YMC-Triart) (Kyoto, Japan) was used as the stationary phase and a methanol and formic acid-buffered solution was used as the mobile phase. The analytical methods are given in Table S1 of the supplementary information.

The Concepts of Modeling

The QSAR modeling was used by the LFER model. The LFER model is one of the quantitative structure–activity relationship (QSAR) concepts. It has been often applied to predict numerous properties of chemicals, especially the properties of solute in solutions [12,13,14, 30, 31]. The model provides high prediction accuracy and chemical meanings of how the molecular interactive potentials correspond to the properties. The LFER equation [32] is showed at Eq. (4).

SP refers to the solute properties, such as log qm, log b, KF, and n, which was determined by Langmuir isotherm equation. E is the excess molar refraction (cm3/10 mol); S is the dipolarity and polarizability (dimensionless); A and B are the hydrogen bonding acidity and basicity, respectively (dimensionless); V is the McGowan characteristic volume (cm3/100 mol); and J+ and J− are the Coulomb interactions of the anions and cations, respectively (dimensionless; J+ is zero for an anion, J− is zero for a cation, and both J+ and J− are zero for a non-ionic compound); and c is a constant. The corresponding regression coefficients (e, s, a, b, v, j+, and j−, respectively) can be used to describe the molecular interactions in the system, which can be determined by multiple linear regression using statistical analysis (SPSS 12.0 K for Window). Furthermore, the LFER descriptors was in silico calculated [33]. The calculation methods based on several literatures [27, 34,35,36,37] are explained in the supplementary information. Table 1 presents the in silico descriptors for each molecule.

For LFER modeling, the obtained results were divided into a training set and a test set by a random function in Microsoft Excel (version 2016). Here, the probability (p), indicating the importance of the selected parameter, was considered in the section of reasonably contributing descriptors to the adsorption property. If the p-value is lower than 0.05, reliability is within the 95% confidence level. The developed model had a reliability of more than 95%.

For the internal validations, leave-one-out cross-validation (LOOCV) [38] and Y-randomization (scrambling) [39] were conducted. In LOOCV analysis, we excluded one piece of data from the training set and did modeling with the rest of the training set. Compare the excluded data with the calculated value by the model built based on the rest of the training set data. Repeated this operation for the total number of training sets. If the Q2LOOCV range is higher than 0.5, it can be determined that the model is internally robust [40]. As another internal validation, Y-randomization was performed. In this step, dependent variables were randomly mixed and applied to the prediction. This process was repeated ten times. Then, the average of the R2 values was checked to see whether the value was reasonably low. If the accuracy of Y-randomization was very low, then the developed model composed of the training set has high reasonability. To externally validate the model, the developed model was validated by the test set as an external validation set, which was not included in the modeling.

Results and Discussion

To identify the surface properties of the ceramic beads, instrumental analyses such as BET, FE-SEM, and EDS were performed. Then, the isotherm experiments were carried out to measure the adsorption properties such as maximum uptake (qm) and adsorption affinity (b) by Langmuir model and adsorption equilibrium constant (KF) and adsorption coefficient (n) by Freundlich model. Subsequently, predictive modeling was developed using LFER model, Eq. (4).

Surface Characterization Results for the Ceramic Beads

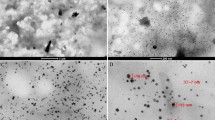

A surface area (as, BET) of 76.06 m2/g, a total volume of 0.0581 cm3/g at relative pressure p/p0 = 0.990, and a mean pore diameter of 3.05 nm were obtained. FE-SEM analysis showed ceramic beads’ morphological features at various magnifications (Fig. 1). Ceramic beads have a rough surface and a lower porosity. The contents of the ceramic beads’ elements were revealed by EDS analysis. The results are showed in Fig. 2. The analyzed elements were C, O, Na, Al, and Si.

Isotherm Results

In the isotherm experiments, it was confirmed that ceramic beads adsorb a variety of organic micropollutants. In Langmuir fitting, maximum uptake (qm) of ceramic beads for micropollutants and adsorption affinity (b) could be determined. In the Freundlich fitting, Freundlich adsorption capacity (KF) and heterogeneity of the system (n) were determined. The estimated values are given in Table 1. The estimated isotherm fittings of organic micropollutants are shown in Fig. S1. The estimated range of qm is from 2.64 to 130.63 μmol/g and that of b is from 0.0019 to 0.5041 in the Langmuir model, while KF [L/μmol] is ranged from 0.7 to 4.98, and the value of n is from 1.68 to 3.91 in the Freundlich model. In addition, although qm and KF have similar meanings, they have no reasonable correlation (R2), which is 0.1. When fitting using two isotherm models, i.e., Langmuir and Freundlich, the Freundlich model has slightly higher fitting accuracy than Langmuir, meaning that the Freundlich model can explain adsorption trends more accurately. This indicates that ceramic beads mainly have multilayer adsorption on a heterogeneous surface [41]. When considering the n value, it showed that ceramic beads have favorable adsorption since the determined 1/n is higher than 0 and lower than 1 for all chemicals [42]. In addition, when 1/n > 1, it is unfavorable adsorption. When comparing the adsorption of ceramic beads according to the types of chemicals, Fig. 3 shows that the average of qm indicates that ceramic beads have the highest adsorption for neutral compounds, while the average of KF implies that cations have the highest adsorption. Actually, isotherm curves of cations have better fittings by the Freundlich model than the Langmuir model. In addition, anions have lower adsorption in both cases.

A Correlation Between the Maximum Adsorption and Octanol–Water Partitioning Coefficients of the Organic Micropollutants

To find relevant environmental properties, lop P (the partitioning ratio of a compound in water and octanol binary phases as a measurement of lipophilicity) was correlated with the measured qm and KF values in Table 1, as shown in Figs. 4A and B. Since the log P values of most of the studied chemicals were not estimated, based on Eq. (S1) [43], the values were calculated. In the correlation of qm with log P, it was found that log P values were positively correlated with qm and KF; however, the relationship shows a poor correlation, with an R2 of 0.42. Also, the correlation of KF with the calculated log P shows no significant correlations. This implies that the calculated log P value could not solely explain the adsorption property of ceramic beads.

Modeling Using In Silico LFER Descriptors

To efficiently investigate the adsorption property, i.e., maximum uptake, it is necessary to develop a predictive model. Since the maximum uptake of an adsorbent was determined by the Langmuir model in this study, the calculated values were applied as a dependent variable for the prediction using Eq. (4). Although the Freundlich model has a higher correlation than the Langmuir model, the difference is slight, as shown by the R2 values in Table 1. In the prediction, to overcome the limitations of empirical descriptors of chemicals, that is, the limitations that can be predicted only when the descriptors exist when applying the empirical descriptor, an in silico calculated LFER descriptor was used. Before the modeling, all measured log qm data were randomly divided into two groups: the training set and the test set, as indicated in Table 1. Using the training set, a prediction model was developed, and then, using the test set, the model was externally validated. Initially, we attempted to predict all of the adsorption properties estimated by the Langmuir and Freundlich models. However, it was found that the LFER concept had a limitation in predicting adsorption parameters by the Freundlich model, i.e., KF and n.

In the prediction of qm value by Langmuir model, reliable LFER descriptors were selected by considering probability (p) values estimated by multiple linear regression in SPSS. The developed model is shown in Eq. (5).

where the superscript ‘o’ means an in silico calculated value. Surprisingly, a single descriptor of So could be used to predict log qm with an R2 of 0.70 and a standard error (SE) of 0.22 log units, which shows reasonable predictability. Eq. (5) is externally validated by a test set (10 data points), which were not included in the development of Eq. (5). The results (R2 and SE) were 0.88 and 0.19 log units, which are superior results to those of the training set. The fitted measured and calculated log qm values by Eq. (5) are shown in Fig. 5A. For further internal validation of Eq. (5), Leave-one-out cross-validation (LOOCV) was performed. The estimated Q2LOOCV value is 0.65, which is higher than 0.5, which is acceptable criteria in the LOOCV estimation. The fitting is given in Figure S2.

Similarly, adsorption affinity (b) was predicted using the LFER concept. Here, to reduce the magnitude of the range of b values, the logarithmic unit was applied, thus expressed as log b as an independent variable. Using the same steps, we developed a prediction model in Eq. (6).

where three descriptors such as So, Bo, and J+,o were selected as reasonably contributing descriptors to log b. The estimated R2 is 0.71 with a SE of 0.38. As it was observed that the estimated adjusted R2 (R2adj) is 0.65, which is similar to the R2 value (0.71), it was checked that the selection of the descriptors was reasonably done. The external validation using the test set showed that R2 and SE were 0.77 and 0.39 log units, respectively, which is reasonably acceptable. The fitting is given in Fig. 5B. Internal validation by LOOCV showed that the estimated R2LOOCV was 0.586, which is within the acceptable criteria. The result of Y-randomization analysis demonstrated that the average R2, which was calculated using ten repetitions, was 0.083, which is extremely lower than the R2 value (0.71). This means that Eq. (6) is not developed by chance.

The signs of the system coefficients of the selected descriptors in Eq. (6) revealed that increasing the dipolarity/polarizability of a molecule increases the adsorption affinity of ceramic beads, while increasing the hydrogen-bond basicity and Coulombic interaction of cations decreases it. However, the coefficient of the H-bond basicity term is actually positively correlated. This might be due to the fact that the So and Bo terms act complementarily in the modeling. In fact, the determination of system parameters in multiple linear regression might be auto-scaled.

This study revealed that ceramic beads can be used to remove organic micropollutants in ionic or non-ionic forms. The adsorption capacity was not remarkably high; however, ceramic beads can adsorb ionic and non-ionic micropollutants. The isotherm results of micropollutants on ceramic beads were generally better fitted by the Freundlich model than the Langmuir model, indicating that heterogeneous adsorption occurred on the surfaces. Nevertheless, the adsorption can be explained by the Langmuir model with good accuracy. In the modeling, the LFER concept could not be applied to predict adsorption parameters by the Freundlich model, while it could be applied to those by the Langmuir model. However, there are several tasks to be elucidated. First, further isotherm studies in various environments, for example, real wastewater and salt conditions, should be done since the adsorption properties can be differentiated according to the environments. Secondly, other prediction concepts should be applied because LFER descriptors could not correlate the Freundlich parameters. Third, more datasets should be determined to validate the predictive models. Since there are too many micropollutants, more chemicals should be tested to explain the chemical spectrum.

In addition, from the practical standpoint, it is necessary to improve the adsorption capacity of ceramic beads. Previous researchers reported cases of removing pharmaceutical-based micropollutants, which have similar types of structures investigated in this study, using activated charcoal [32]. As a result, the maximum uptake of activated carbon ranged from 305 to 2137 μmol/g, which is significantly higher than that of ceramic balls (2.64 ~ 130.63 μmol/g). Although ceramic balls have high durability and chemical stability and have a wide range of industrial applications, their adsorption capacity must be increased to be used efficiently in the adsorption process. There are several ways to do this: Examples include functionalizing and coating surfaces, controlling pore structures and beads, and selecting composite components with higher affinity.

Conclusion

Adsorption using ceramic beads was applied to remove various micropollutants. The isotherm results clearly showed that the adsorbent efficiently adsorbed organic micropollutants in ionic or non-ionic forms. The fittings of the Freundlich model verified that ceramic beads have favorable adsorption for micropollutants. In the comparison of two fitting methods, such as Langmuir and Freundlich models, it was confirmed that Freundlich models were slightly more suitable for fitting the isotherm than Langmuir models. In our modeling study, we found that LFER modeling could not be applied to heterogeneous adsorption, but homogeneous adsorption was predictable. In the modeling, the adsorption parameters such as maximum uptake and adsorption affinity in log units by the Langmuir model were predicted, and the predictive results were around an R2 of 0.70. The developed model indicated that the log qm is strongly correlated with the dipolarity and polarizability properties of a molecule. In the case of log b, it has reasonably correlated with dipolarity/polarizablity, H-bond basicity, and cationic interaction terms of micropollutants. The developed model will be useful for predicting the maximum adsorption of ceramic beads for any organic micropollutant.

Data availability

The authors confirm that the data supporting the findings of this study are available within the article and its supplementary materials.

References

M. Shakya, T. Nakamura, S. Shrestha, S. Pathak, K. Nishida, R. Malla, Water Air Soil Pollut. (2022). https://doi.org/10.1007/s11270-021-05483-8

B. Buning, D. Rechtenbach, J. Behrendt, R. Otterpohl, Environ. Prog. Sustain. Energy (2021). https://doi.org/10.1002/ep.13587

X. Ma, Z. Wang, Processes (2022). https://doi.org/10.3390/pr10010124

D.S. Kwon, S.Y. Tak, J.E. Lee, M.K. Kim, Y.H. Lee, D.W. Han, S. Kang, K.D. Zoh, Environ. Sci. Pollut. Res. Int. 24, 17606 (2017)

A. Macías-García, J. García-Sanz-Calcedo, J.P. Carrasco-Amador, R. Segura-Cruz, Sustainability 11, 2672 (2019)

A. Musolff, S. Leschik, F. Reinstorf, G. Strauch, M. Schirmer, Environ. Sci. Technol. 44, 4877 (2010)

Y. Lee, L. Kovalova, C.S. McArdell, U. von Gunten, Water Res. 64, 134 (2014)

D. Reif, L. Weisz, K. Kobsik, H. Schaar, E. Saracevic, J. Krampe, N. Kreuzinger, J. Environ. Chem. Eng. 11, 110117 (2023)

C.-W. Cho, T.P.T. Pham, S. Kim, M.-H. Song, Y.-J. Chung, Y.-S. Yun, Water Res. 90, 294 (2016)

B.-G. Cho, S.-B. Mun, C.-R. Lim, S.B. Kang, C.-W. Cho, Y.-S. Yun, J. Hazard. Mater. 426, 128087 (2022)

B.G. Cho, J.H. Lee, H.I. Kim, S.R. Jin, D.G. Kim, C.W. Cho, Y.S. Yun, Environ. Res. (2023). https://doi.org/10.1016/j.envres.2023.115593

C.-W. Cho, Y. Zhao, J.-W. Choi, J.-A. Kim, J.K. Bediako, S. Lin, M.-H. Song, Y.-S. Yun, Environ. Res. 192, 110271 (2021)

C.W. Cho, C.R. Lim, B.G. Cho, S.B. Mun, J.W. Choi, Y. Zhao, S. Kim, Y.S. Yun, Chem. Eng. J. (2021). https://doi.org/10.1016/j.cej.2021.131341

C.W. Cho, Y.F. Zhao, J.W. Choi, J.A. Kim, J.K. Bediako, S. Lin, M.H. Song, Y.S. Yun, Environ. Res. (2021). https://doi.org/10.1016/j.envres.2020.110271

H. Wang, L. Sun, K. Yan, J. Wang, C. Wang, G. Yu, Y. Wang, Chemosphere 266, 129230 (2021)

M. Karnib, A. Kabbani, H. Holail, Z. Olama, Energy Procedia 50, 113 (2014)

R. Gao, D. Liu, Y. Huang, G. Li, Ceram. Int. 46, 19799 (2020)

B. Rao, E.S. Rubin, Environ. Sci. Technol. 36, 4467 (2002)

P.H. Cong, X.Y. Wu, H. Nanao, S. Mori, Tribol. Lett. 15, 65 (2003)

G. Crini, Bioresour. Technol. 97, 1061 (2006)

J.H. Kim, S.Y. Lee, S. Rha, Y.J. Lee, H.Y. Jo, S. Lee, Water Air Soil Pollut. (2021). https://doi.org/10.1007/s11270-021-05425-4

V.S. Kumawat, A. Vyas, S. Bandyopadhyay-Ghosh, S.B. Ghosh, J. Non-Cryst. Solids (2020). https://doi.org/10.1016/j.jnoncrysol.2020.120303

S. M. Tine Aprianti, Selpiana, Ria Komala and Surya Hatina, INTERNATIONAL CONFERENCE ON SCIENCE AND APPLIED SCIENCE (ICSAS), 2014 (2018).

Y. Liu, Colloids Surf., A 274, 34 (2006)

H. Freundlich, Z. Phys. Chem. 57U, 385 (1907)

M.H. Abraham, R.P. Austin, Eur. J. Med. Chem. 47, 202 (2012)

C.W. Cho, S. Stolte, Y.S. Yun, I. Krossing, J. Thoming, RSC Adv. 5, 80634 (2015)

K. Kuroki, Ayaka) ; Hiroto, M (Hiroto, Megumi) ; Urushihara, Y (Urushihara, Yoshitomo) ; Horikawa, T (Horikawa, Toshihide) ; Sotowa, KI (Sotowa, Ken-Ichiro) ; Avila, JRA (Avila, Jesus Rafael Alcantara), SPRINGERONE NEW YORK PLAZA, SUITE 4600 , NEW YORK, NY 10004, UNITED STATESSpringer, 25, 1251 (2018)

C. Faur, H. Metivier-Pignon, P. Le Cloirec, Adsorpt.-J. Int. Adsorp. Soc. 11, 479 (2005)

J.W. Choi, C.W. Cho, Y.S. Yun, J. Hazard. Mater. (2022). https://doi.org/10.1016/j.jhazmat.2021.127214

S.R. Jin, B.G. Cho, S.B. Mun, S.J. Kim, C.W. Cho, Environ. Res. (2023). https://doi.org/10.1016/j.envres.2023.116349

Y. Zhao, S. Lin, J.-W. Choi, J.K. Bediako, M.-H. Song, J.-A. Kim, C.-W. Cho, Y.-S. Yun, Chem. Eng. J. 362, 199 (2019)

W.C. Tengyi Zhu, Y. Rajendra Prasad Singh, J. Hazard. Mater. (2020). https://doi.org/10.1016/j.jhazmat.2020.122957

F. Eckert, "Cosmotherm reference manual, version c3.0, release 15.01", Leverkusen, (1999–2014).

N.M. O’Boyle, M. Banck, C.A. James, C. Morley, T. Vandermeersch, G.R. Hutchison, J. Chem. (2011). https://doi.org/10.1186/1758-2946-3-33

S. Klamt, J. Chem. Soc. Perkin Trans 2, 799 (1993)

A. Schäfer, H. Horn, R. Ahlrichs, Chem. Phys. 100, 5829 (1994)

Z.F. Shao, M.J. Er, Neurocomputing 194, 260 (2016)

P. Gramatica, QSAR Comb. Sci. 26, 694 (2007)

M. Jalali-Heravi, M. Asadollahi-Baboli, QSAR Comb. Sci. 27, 750 (2008)

S. Kalam, S.A. Abu-Khamsin, M.S. Kamal, S. Patil, ACS Omega 6, 32342 (2021)

K.Y. Foo, B.H. Hameed, Chem. Eng. J. 156, 2 (2010)

M.H. Abraham, W.E. Acree, Phys. Chem. Chem. Phys. 12, 13182 (2010)

Acknowledgements

This research was supported by the Korean Government through NRF (RS-2023-00278351) grants and Chonnam National University (Grant number: 2021-2123).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jin, SR., Lee, KY., Cho, BG. et al. Characterization of Ceramic Beads for the Removal of Organic Micropollutants from Wastewater and Prediction of Their Adsorption Properties by In Silico Quantitative Structure–Adsorption Relationship Modeling. Korean J. Chem. Eng. 41, 1757–1765 (2024). https://doi.org/10.1007/s11814-023-00002-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-023-00002-3