Abstract

The current study represents the isolation and characterization of cellulose producing bacteria from rotten grape fruit. The best Bacterial Cellulose producer isolated from rotten grape fruit was identified as Komagataeibacter saccharivorans BC-G1 upon biochemical and molecular characterization. Bacterial Cellulose production was done in Hestrin and Schramm (HS) medium under static condition. Studies showed that BC was produced as a thick layer on the surface of medium and yield of BC was 14 g/L after 96 h of fermentation period. BC films were characterized by Scanning Electron Microscopy, Fourier Transform Infrared Spectroscopy and X-ray Diffraction. SEM analysis revealed the presence of highly extended interwoven cellulose fibrils. Characteristics of FTIR spectrum depicted the presence of characteristic absorption bands and less crystalline behavior of BC. XRD patterns demonstrated three major characteristic diffraction peaks corresponding to (110), (100) and (002) indicating presence of less crystalline behavior of BC produced in this study. Results confirmed the produced biopolymer by K. saccharivorans BC-G1 is BC.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Bacterial Cellulose (BC) is a homo-biopolymer produced by different bacterial strain in a sugar rich medium. Although the molecular formula of BC resembles to that of plant cellulose but the former has more unique and refined three-dimensional porous net like structures. Acetic acid bacteria belong to the family Acetobacteraceae and are known to produce acetic acid by oxidizing ethanol (Jose et al. 2020; Saichana et al. 2015). Most common genera which belongs to classification of the AAB (acetic acid producing bacteria) includes Acetobacter, Acidomonas, Asaia, Gluconacetobacter, Kozakia, Swaminathania and Saccharibacter. Some species like Komagataeibacter, Aerobacter, Agrobacterium, Acetobacter, Rhizobium, Sarine, Achromobacter, Alcaligenes, Azotobacter and many other bacterial strains are known for producing cellulose but the major reported producer of cellulose is Komagataeibacter xylinus (Yamada 2016).

The Komagataeibacter genus typically relates to the family Acetobacteraceae. Based on analysis of their gene sequences, members of this genus were divided into two groups: the Komagataeibacter xylinus group (includes K. xylinus, K. sucrofermentans, K. hansenii, K. europaeus, K. entanii, K. saccharivorans, K. swingsii, K. rhaeticus, K. nataicola, K. oboediens, and K. intermedius) and Komagataeibacter liquefaciens group (includes K. liquefaciens, K. sacchari, K. diazotrophicus, K. johannae, and K. azotocaptans) (Revin et al. 2020; Brandão et al. 2022 reported several types of strains form an independent genomic group from those of other Komagataeibacter, reclassified as K. hansenii, K.cocois, K.maltaceti and K. pomaceti as novel members of the genus Novacetimonas. The Novacetimonas hansenii species are the proposed representative of the novel genus (Brandão et al. 2022).

The production of BC involves the conversion of cellulose monomers into the cellulose chain using biosynthetic pathways like HMP (Hexose monophosphate pathway) and TCA (Tricarboxylic acid) with the network of several important enzymes (Ross et al. 1991). Some of the key enzymes are glucokinases, UDPG- pyrophosphorylase and cellulose synthases, which are involved in phosphorylation of glucose units, isomerization and polymerization of monomers to cellulose chains. The glucose monomers formed from biosynthetic pathways are phosphorylated to UDPG and isomerized by UDPG-pyrophosphorylase. The isomerized forms are then further polymerized to precursor of cellulose by cellulose synthase enzyme (Römling and Galperin 2015).

Various natural sources such as agro-waste, rotten vegetables and fruits, soil as well as waste water are natural reservoirs of these cellulose producing bacteria. With the complex chemical structure, BC evinces many physico-chemical properties such as high extent of polymerization (up to 7000), high crystallinity level (of 70–80%) as well as capacity of water holding/ water retention capacity (up to 95%), advance mechanical stability, great elasticity, ultrafine nano-structure, which distinguishes it from plant cellulose (Revin et al. 2020; Costa et al. 2017).

Microorganisms as well as the production method are important parameters which regulate the enhanced yield of cellulose. Commonly, BC is produced either static fermentation condition or by agitation. Though agitation enhances the oxygen diffusion rate, it causes the formation of cellulose less mutants, thus lowering the yield most of the time (Srivastava and Mathur 2021; Rastogi et al. 2018).

Recently, several researcher studies are focused on isolating the new strain for high-end production of BC. BC producers which able to synthesize thick cellulosic mat in the air liquid region mainly are Gram negative (-) with rod shape, non- disease causing aerobic bacteria (Ross et al. 1991). This biopolymer is known to exist in free form without any presence of polysaccharides like hemicellulose and lignin. The improved physicochemical properties have gathered great interest from both researchers as well as industrialists, making it an excellent choice of material in food industry, tissue engineering, biosensors, pharmaceutical and textile industries, packaging, protective coatings and flexible electronics (Molina-Ramírez et al. 2018). Extensive research reports are available on BC production from Acetobacter and Gluconacetobacter strains. Till date, there are limited studies available on production of BC from Komagataeibacter saccharivorans (Gopu and Govindan 2018). Hence the objective of this study was to screen and isolate bacteria cellulose producer with high yield from rotten fruits. The isolated BC producer K. saccharivorans BC-G1 was investigated for BC production under static culture condition. Physicochemical characterization of BC was done using SEM, FTIR and XRD. To the best of our knowledge, this is one of the few reports representing the characterization and production of BC from Komagataeibacter saccharivorans under static conditions.

Materials and methods

Screening and isolation of cellulose producing bacteria

Isolation of BC producing bacteria was done using different samples of rotten fruits namely- apple, grapes, banana and coconut were collected. A one grams of fruit samples was added to 100 mL modified Hestrin-Schramm (HS) medium containing 2.0% D-glucose (carbon source) (w/v), 0.5% peptone (nitrogen source) (w/v), 0.5% yeast extract (w/v), 0.27% Na2HPO4 (w/v), 0.12% citric acid (w/v), 0.2% acetic acid (v/v), 0.5% alcohol (ethanol) (v/v), pH 6.5 (Hestrin and Schramm 1954). The inoculated media was incubated at 30 °C for 5–7 days under static conditions to obtain stable BC layer on the top. The produced BC layer was obtained in the form of white mat on the surface of culture media which was further serially diluted to 1 × 10 − 6 times with 0.9% NaCl (saline water) (Powers and Latt et al. 1977). Serially diluted samples were further spread on acetic acid bacteria medium (Sharafi et al. 2010) (2.0% D-glucose (w/v), 1.0% yeast extract (w/v), 5% ethanol (w/v), 0.3% CaCO3 (w/v) (mix CaCO3 by shaking the medium before pouring) and 2% agar with 0.2mL of inoculum size. The plates were incubated further at 30 °C for 48 h to 72 h to obtain clear colonies of bacteria. The bacterial growth was accompanied with the development of clear zones due to CO2 production. The eleven bacterial isolates were selected for the further screening and production of cellulose.

Identification of cellulose producing bacterial isolates

Identification of selected BC producer was done using biochemical tests, carbohydrate fermentation test, morphology and gram staining analysis (Singh et al. 2017; Rangaswamy et al. 2015). Further, the isolate bacterial strain (BC- G1) from rotten grape fruit was evaluated for gene analysis using 16 S rRNA sequencing at NCIM, CSIR-NCL, India. The sequencing analysis was performed by following Sanger method using ABI 3500xL genetic analyzer (Life Technologies, USA). Two 16 S rRNA gene primer sequence used for sequencing (forward primer 704F_GTAGCGGTGAAATGCGTAGA and reverse primer- 907R_CCGTCAATTCTTTTGAGTTT were used. Once the sequencing has been done, the files obtained were edited using CHROMASLITE (version 1.5) (https://technelysium.com.au). The obtained nucleotide sequences were compared with available sequences on the National Center for Biotechnology Information GenBank (NCBI GenBank) database using BLASTn through Basic Local Alignment Search Tool (BLAST) (Zhang et al. 2000b). Moreover, the phylogenetic tree was constructed to obtain the evolutionary relationship of identified strain with other closely related species. Phylogenetic tree was constructed by Neighbor- joining method using MEGA 10.2.6 (Molecular Evolutionary Genetic Analysis) (Kumar et al. 2018) with bootstrap value of 1000 (Thongwai et el. 2022) and CLUSTAL W to align gene sequences for finding gene similarities (Thompson et al. 1994). The obtained nucleotide sequence deposited to NCBI database using GenBank submission portal (https://submit.ncbi.nlm.nih.gov/subs/genbank/).

Cellulose production from prepared fermentation media using BC-G1 isolate

To examine the capability of producing cellulose from isolated BC-G1 isolate, the fermentation media (HS medium) was prepared using glucose (20 g/L), yeast extract (5 g/L), peptone (5 g/L), citric acid (2.7 g/L), disodium hydrogen phosphate (Na2HPO4) (1.17 g/L). This media (100mL) was additionally supplemented with acetic acid, which was used to maintain final pH up to 6.5. The prepared fermentative media was further autoclaved at 121 °C for 20 min, followed by inoculation using 1% inoculum of isolated BC-G1.

Growth kinetics specific growth rate

The sampling from the culture flask was done at regular intervals to determine cell growth. Growth kinetics was estimated by measuring the optical density at 600 nm (A600) after cellulase treatment of culture broth and bacterial growth was estimated as specific growth rate (h− 1) using Eq. 1(Kovárová-Kovar and Egli 1998).

Where, Nt and N0 represent the number of bacterial cells/mL at time t2 and t1, respectively during the exponential growth phase whereas µ represents the specific growth rate of bacterial cells. Doubling time of bacteria was calculated by Eq. 2.

Production and purification of cellulose from BC-G1 isolate

The produced white mat like layer on the surface of fermentative media was collected and further purified by treating with 1% NaOH (w/v). The harvested cellulose layer was treated for 90 min (thrice) in order to remove the existing impurities from cellulose matrix, present in the form of dead cells. In addition to this, the purified cellulose was neutralized by sterile water (Vasconcelos et al. 2020). The recovered BC sheets were dried using oven drying method at 40 °C for around 1–2 h until its weight was constant (Bodea et al. 2021; Gopu and Govindan 2018).

Effect of carbon sources in BC production

Different carbon sources namely Glucose, Glycerol, Sucrose and Fructose were chosen to evaluate the effect on cellulose production using the isolated BC-G1 strain. The selected carbon sources were added into the growth media (HS media) at 2% (w/v) concentration (Mikkelsen et al. 2009; Molina-Ramírez et al. 2017).

Physicochemical characterization

Fourier transform infrared spectroscopy (FTIR)

The produced and purified BC was characterized in comparison with commercial cellulose (Himedia) using FTIR spectroscopy using Spectrum BX-II Spectrophotometer at material characterization laboratory, Jaypee Institute of Information Technology, India. For FTIR analysis, the transmission mode was selected to collect the spectra over the range of 4000–400 cm− 1 with the resolution of 4 cm− 1. In addition to this, the crystallinity was calculated by obtaining ratio using the absorption ratio method. In this method, the transmission absorbance from 1372 cm− 1 (A1372) and 2900 cm− 1(A2900) was used to obtain Cr. R1 values whereas transmission absorbance ratio from 1430 cm− 1 (A1430) and 893 cm− 1 (A893) was used to obtain Cr. R2 value. The values obtained in terms of Cr. R1 and Cr. R2 were further used to calculate crystallinity ratio (Ciolacu et al. 2011).

X-ray diffraction (XRD)

The obtained BC was also characterized along with commercial cellulose using X-ray diffraction technique using X-ray diffractometer (Shimadzu 6000 XRD, Japan) at material characterization laboratory, Department of Physics and Materials Science and Engineering, Jaypee Institute of Information Technology, India. This technique is used to examine the crystallinity of samples using patterns formed by Cu-Kα radiations. During the analysis, patterns were collected in scan range of 2θ= 5–70° with speed of 2o/min in order to distinguish several changes within the crystal structures of the cellulose samples. By XRD analysis, the crystallinity index (Cr. I) and crystallinity (Cr%) calculated using Segal’s equation (Eq. 3) (Segal et al. 1991; Ioelovich and Veveris 1987).

Where I am is the minimum intensity which represents the amorphous material. I (002) is the maximum intensity of major crystalline corresponding to the (002) plane at 2θ angle.

Scanning electron microscopy (SEM)

To investigate the structural properties of the cellulose produced by BC-G1 isolate, an electron microscope Zeiss EVO®40 (Germany) at an accelerating voltage of 5 kV was used. The morphology of the samples was studied from the surface as well as the cross-sections. Samples were sputter coated with gold before examination and were photographed at Advanced Instrumentation Research Facility (AIRF) (JNU, India).

Results and discussion

Isolation and screening of cellulose producing BC-G1 bacterial isolate

Rotten fruits were used for isolation of BC producing bacteria in modified HS media. Flask inoculated with rotten grapes was reported positive for BC production as formation of creamy, white mat like structure on the surface of modified HS media after 7 days of incubation. The isolates were then purified using serial dilution method and were tested for BC production on GEY agar plates containing 0.3% (w/v) CaCO3. Since all strains of Komagataeibacter sp. are known an acid-producers, the development of clear zone around the bacterial colonies is due to dissolution of CaCO3 in GEY agar plates supplemented with 0.3% (w/v) CaCO3. The similar findings have also been reported by Mangayil et al. 2021. The isolate was named as BC-G1 strain, which was further identified using morphological, biochemical and molecular characterization methods (Buchanan and Gibbons 1975; Rangaswamy et al. 2015). Physiological and biochemical test characteristics further demonstrated that the isolated strain belongs to the family of Acetobacter sp. as showed in Table 1 (Vos et al. 2011).

16 S rRNA gene serves as a genetic marker and used in study of bacterial taxonomy and phylogenetic analysis. The gene sequence data was aligned using CLUSTAL for finding gene similarities. The sequence analysis studies confirmed isolated BC-G1 strain as Komagataeibacter saccharivorans (Accession No. ON514605.1)( http://www.ncbi.nlm.nih.gov/genbank/ ).

Phylogenetic tree provides information related to evolutionary relationship of new strain to their ancestors. 16 S rRNA partial sequence analysis of the isolated strain BC-G1 revealed that our strain is closely related to Komagataeibacter saccharivorans (LMG 1582) with 100% identity score (Fig. 1) (Zhang et al. 2000b). The tree was constructed using Neighbor Joining method using MEGA 10.2.6 (Fig. 1) (Kumar et al. 2018).

Production of cellulose using BC-G1 isolate

The strain BC-G1 was examined for BC production under static condition at 30oC for 6 days. The BC was recovered as the floating films on the liquid medium surface after 4th day of incubation. The maximum amount of BC was obtained on day 4 of incubation (14 g/L), after which the amount of BC started decreasing (Fig. 2). Studies have shown that maximum BC from different strains of genus Komagataeibacter has been reported during 4-5th days of incubation under static condition after which the BC production was decreased subsequently (Vigentini et al. 2019). Increase in incubation time results in formation of disrupted and irregular BC membrane and slight acidity of media, as previously reported (Bodea et al. 2021; Lahiri et al. 2021).

BC yield obtained from Komagataeibacter saccharivorans BC-G1 in this study is in well agreement with the reported literature (Gopu and Govindan 2018; Mohite and Patil 2014), supporting the fact that cellulose production is dependent on number of incubation days, choice of bacteria, growth medium as well as the culture conditions. To study the effect of agitation on production of cellulose, BC-G1 strain was inoculated in HS media and incubated at 30o C, 120 rpm for 5 days (Aydin and Aksoy 2014). Results showed that upon agitation, the production of cellulose was observed to be 0.3 g/ 100 mL, dry weight. Shaking/ agitation is known to produce several non- cellulosic producing mutants which negatively affect the production of desirable cellulose in culture media, hence producing less cellulose in agitation conditions than static conditions (Kadier et al. 2021).

Growth studies of BC-G1 isolate in HS medium

The isolated BC-G1 strain was further used for evaluating the cell growth. The bacteria were inoculated in HS medium and incubated for 120 h under static and agitated conditionsSharma et al. 2016a, b; Singh et al. 2016).

The specific growth rate and doubling time variations were observed in both culture conditions using Eqs. 1 and 2 (Table 2) (Fig. 3) (Sharma et al. 2016a, b; Singh et al. 2016).

Results demonstrated that the specific growth rate of BC-G1 in HS media under static condition (0.49 h− 1) was lower than that of agitation condition (0.56 h− 1) (Table 2). Since under agitation condition, the bacteria receive more oxygen due to aeration hence the specific growth rate of bacteria is more when compared to static condition (Mathur et al. 2015). Agitation is also known to cause shear stress to the bacterial cell and may result in reduction of BC productivity. (Wang et al. 2019).

Table 2 Effect of culture conditions on specific growth rate (µ) and doubling time of Komagataeibacter saccharivorans BC-G1 isolate in HS medium.

Effect of different carbon sources on BC production

The dynamics of different carbon sources on BC production was evaluated and it was observed that the production of BC is greatly affected by the type of carbon source used. Our results demonstrate that the maximum BC production (13.65 g/L) was observed when the media was supplemented with Glucose. In addition to this, BC production was observed to be 11.9, 8.45 and 11.75 g/L for Glycerol, Sucrose and Fructose respectively (Fig. 4) (Molina-Ramírez et al. 2017).

Maximum BC production was observed till 96 h under static condition with all carbon sources as a floating gelatinous mat-like structure which became irregular and distorted upon further incubation due to depletion of growth factors in the media. When the pellicle growth slows down and all the bacteria are entrapped, the synthesis of BC reaches its threshold and bacteria starts consuming the already formed BC films for survival apart from growth media (Molina-Ramírez et al. 2017). In addition to this, the change in pH was also observed which states that the decrease of pH during cellulose production is directly linked to decrease in the synthesis of the polymer. Our results are also in compliance with the studies of Molina and others, 2017 (Molina-Ramírez et al. 2017) who have indicated the BC production using three different carbon sources namely glucose, sucrose and fructose. The results from their study also showed the maximum production using glucose as carbon source. It is considered that the glucose being the source of ultimate energy as well as the precursor of cellulose polymerization, resulted in maximum yield of BC as compared to other carbon sources.

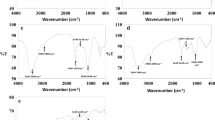

FTIR spectra of commercial cellulose and BC

The FTIR spectra analysis comprises two regions namely- functional group region as well as the fingerprint region. It is known that functional group region contains the absorption peaks having wave numbers exceeding the value of 1450 cm− 1 providing the information regarding functional groups present in the sample whereas the fingerprints region contains the absorption peaks lying in range lesser than 1450 cm− 1, providing the information regarding vibrational characteristics in the sample (Fig. 5) (Ciolacu et al. 2011). Our results showed that the first spectra region of produced BC was observed at wave number 3284 cm− 1, 3033 cm− 1,2971 cm− 1, hence indicating the presence of functional groups having hydrogen as the main element. The common vibrational pattern was observed to be C-H, N-H, and O-H with stretching vibrational patterns present in the samples. In addition to this, the second spectra region was observed from wave number 2000 cm− 1 to 2500 cm− 1 indicating the presence of functional groups with two major triple bonds vibrational stretching patterns as \({\rm{C}} \equiv {\rm{C}}\) and \({\rm{C}} \equiv {\rm{N}}\), hence showing very less peak shift in this second spectral region. The third region in our FTIR spectra was observed from wavenumber 1350 cm− 1 to 2000 cm− 1 having absorption peaks at 1367 cm− 1,1541 cm− 1,1646 cm− 1,1735 cm− 1 exhibiting the general double bond stretching with functional groups like C = N, C = O and C = C. The presence of CH functional groups with absorption peaks included in alkanes (2800–3000 cm− 1), alkenes (3000–3100 cm− 1), alkynes (3300 cm− 1) as well as other aromatic compounds was noted in spectra region above 2500 cm− 1. Moreover, it was observed that aldehyde composed of two distinct absorption peaks at 2700–2900 cm− 1 due to O = C-H stretching vibrations and O-H stretching vibrations and carboxylic acids (2400–3300 cm− 1) (Fig. 5) (Ciolacu et al. 2011). Figure 5 shows the presence of carbonyl stretching due to aldehyde group (1720–1740 cm− 1), ketones group (1705–1725 cm− 1), carboxylic acids (1700–1725 cm− 1) (Yao et al. 2015). The double bond stretching vibration region contains the absorption peaks produced by C = C stretching vibrations (1640–1670 cm− 1), aromatic ring C-C absorption peaks (1450–1600 cm− 1) (Oh et al. 2005). In addition, the FTIR absorption at 1450 cm− 1 of CH2 bending vibration refers to crystallinity band, indicating that a decrease in its intensity reflects reduction in the degree of crystallinity of the samples (Ioelovich 2021). The FTIR absorption at 893 cm− 1 of C–O–C stretching at beta glycoside linkages, is designed as an amorphous absorption band, an increase in its intensity occurring in the amorphous samples (Ciolacu et al. 2011; Nelson and O’Connor et al. 1964). The ratios of crystallinity (Cr.R) of commercial cellulose using Eq. 3 (Cr. R1 (A1372/ A2900) = 2.33, Cr. R2 A1430/ A893 = 0.60) and BC produced by BC-G1(Cr. R1 (A1372/ A2900) = 0.96, Cr. R2 A1430/ A893 = 0.92) obtained using FTIR spectra.

X-ray analysis of commercial cellulose and BC

The X- ray diffraction analysis of produced cellulose from BC-G1 and commercial cellulose was conducted. The X ray diffractograms depicted that the peaks were observed in case of cellulose produced from BC-G1 at 14.08°, 16.72o and 22.48° (Fig. 6). These peaks are known to correspond to defined crystallographic planes of (100), (010) and (002) respectively, hence revealing the presence of amorphous nature of the BC samples. In compliance to this result, the commercial cellulose was also observed to have less amorphous nature when compared to BC sample (Nelson and O’Connor et al. 1964). Less crystalline cellulose is characterized by increased hydrophilicity, reactivity, and enzymatic digestibility. Due to its amorphous structure, it can be used as a promising substrate for enzymatic hydrolysis to produce glucose, which can be applied in biotechnology for growing various microorganisms (Ieolovich,2021).

The crystallinity index (Cr. I) is calculated as %Cr using Segal’s equation (Eq. 3) (peak intensity method) (Table 3 (Poletto et al. 2014; Segal et al. 1991).

SEM micrographs of produced BC

Figure 7 shows the morphological structure of BC produced by Komagataeibacter saccharivorans BC-G1 at 5kx and 2kx magnifications. The micrographs obtained from SEM analysis revealed that the BC retained its network structure and twisting ribbons without any specific orientation, the fine microfibril structure in an interconnected network form, arranged in crossed random orientation with superimposed layers which ensured good behavior of BC in water-holding and permeability (Zhang et al. 2018a). The cellulose molecules were interconnected by hydrogen bonds, forming nanoscale crimped winding microfibrils, with a large number of micro-fibrils connected by hydrogen bonds, forming a network structure led to have property such as mechanical property, crystallinity and water holdup rate. These structures were then connected to each other with hydrogen bonds in a multi-layered network, giving the formation of a unique layered three-dimensional network structure (Poletto et al. 2014).

Conclusion

From this study, we have concluded that BC producing bacterial strain has been isolated from rotten grape fruit and was identified as Komagataeibacter saccharivorans. The culture was explored for cellulose production under static culture condition in HS medium. BC yield was high compared to other strains reported so far. Physicochemical and structural characterization of BC allowed the detailed analysis of produced biopolymer for various applications. The FTIR spectra confirmed the purity of BC and less crystalline behavior of BC-G1. X-ray diffraction pattern revealed three characteristic diffraction peaks indicating the presence of less crystalline behavior of the cellulose produced by BC-G1 isolate. SEM studies showed the reticulated fibrillar structure of BC produced by BC-G1 isolate. The study can be further extended to utilize agro-industrial raw materials as an alternative cheap and cost-effective substrate for BC production. Komagataeibacter saccharivorans BC- G1 reported in this study may be a potential candidate for large scale, cost effective production of BC with improved physicochemical properties for widespread applications.

Abbreviations

- BC:

-

Bacterial Cellulose

- HMP:

-

Hexose monophosphate pathway

- TCA:

-

Tricarboxylic acid

- UDPG:

-

Uridine diphosphate glucose

- SEM:

-

Scanning electron microscope

- FTIR:

-

Fourier-transform infrared spectroscopy

- XRD:

-

X-ray diffraction

- HS:

-

Hestrin-Schramm

- BLAST:

-

Basic Local Alignment Search Tool

- MEGA:

-

Molecular Evolutionary Genetic Analysis

- CR:

-

Crystallinity Ratio

- RPM:

-

Rotation per minute

References

Aydın YA, Aksoy ND (2014) Isolation and characterization of an efficient bacterial cellulose producer strain in agitated culture: Gluconacetobacter hansenii P2A. Appl Microbiol Biotechnol 98:1065–1075. https://doi.org/10.1007/s00253-013-5296-9

Bodea IM, Beteg FI, Pop CR, David AP, Dudescu MC, Vilău C, Stănilă A, Rotar AM, Cătunescu GM (2021) Optimization of moist and oven-dried bacterial cellulose production for functional properties. Polymers 13:2088. https://doi.org/10.3390/polym13132088

Brandão PR, Crespo MT, Nascimento FX (2022) Phylogenomic and comparative analyses support the reclassification of several Komagataeibacter species as novel members of the Novacetimonas gen. nov. and bring new insights into the evolution of cellulose synthase genes. Int J Syst Evo Microbiol 72:005252. https://doi.org/10.1099/ijsem.0.005252

Buchanan ER, Gibbons NE (1975) Bergey’s Manual of Determinative Bacteriology. Williams & Wilkins

Ciolacu D, Ciolacu F, Popa VI (2011) Amorphous cellulose-structure and characterization. Cell Chem Technol 45:13

Costa AFS, Rocha MAV, Sarubbo LA (2017) Bacterial cellulose: an ecofriendly biotextile. Int J Text Fashion Technol 7:11–26

Gopu G, Govindan S (2018) Production of bacterial cellulose from Komagataeibacter saccharivorans strain BC1 isolated from rotten green grapes. Prep Biochem Biotech 48:842–852. https://doi.org/10.1080/10826068.2018.1513032

Hestrin S, Schramm M (1954) Synthesis of cellulose by Acetobacter xylinum. 2. Preparation of freeze-dried cells capable of polymerizing glucose to cellulose. Biochem J 58:345. https://doi.org/10.1042/bj0580345

Ioelovich M (2021) Preparation, characterization and application of amorphized cellulose-a review. Polym (Basel) 13:4313. https://doi.org/10.3390/polym13244313

Ioelovich MY, Veveris GP (1987) Determination of cellulose crystallinity by X-ray diffraction method. J Wood Chem 5:72–80

Jose G, Shalumon KT, Chen JP (2020) Natural polymers-based hydrogels for cell culture applications. Curr Med Chem 27:2734–2776. https://doi.org/10.2174/0929867326666190903113004

Kadier A, Ilyas RA, Huzaifah MRM, Harihastuti N, Sapuan SM, Harussani MM, Ishak MR (2021) Use of industrial wastes as sustainable nutrient sources for bacterial cellulose (BC) production: mechanism, advances, and future perspectives. Polymers 13:3365. https://doi.org/10.3390/polym13193365

Kovárová-Kovar K, Egli T (1998) Growth kinetics of suspended microbial cells: from single-substrate-controlled growth to mixed-substrate kinetics. Microbiol Mol Biol Rev 62:646–666. https://doi.org/10.1128/MMBR.62.3.646-666.1998

Kumar S, Stecher GLi M, Knyaz C, Tamura K (2018) MEGA X: Molecular Evolutionary Genetics Analysis across computing platforms. Mol Biol Evol 35:1547–1549. https://doi.org/10.1093/molbev/msy096

Lahiri D, Nag M, Dutta B, Dey A, Sarkar T, Pati S, Edinur HA, Abdul Kari Z, Mohd Noor NH, Ray RR (2021) Bacterial cellulose: production, characterization, and application as antimicrobial agent. Int J Mol Sci 22:12984. https://doi.org/10.3390/ijms222312984

Mangayil R, Rissanen AJ, Pammo A et al (2021) Characterization of a novel bacterial cellulose producer for the production of eco-friendly piezoelectric-responsive films from a minimal medium containing waste carbon. Cellulose 28:671–689. https://doi.org/10.1007/s10570-020-03551-6

Mathur G, Dua A, Das AR, Kaur H, Kukal S, Sharma P, Mathur A (2015) Bacteria cellulose: biopolymer from Gluconacetobacter xylinus. Macromol Symp 347:27–31. https://doi.org/10.1002/masy.201400041

Mikkelsen D, Flanagan BM, Dykes GA, Gidley MJ (2009) Influence of different carbon sources on bacterial cellulose production by Gluconacetobacter xylinus strain ATCC 53524. J Appl Microbiol 107:576–583. https://doi.org/10.1111/j.1365-2672.200904226.x

Mohite BV, Patil SV (2014) Physical, structural, mechanical and thermal characterization of bacterial cellulose by G. hansenii NCIM 2529. Carbohyd Polym 106:132–141. https://doi.org/10.1016/j.carbpol.2014.02.012

Molina-Ramírez C, Castro C, Zuluaga R, Gañán P (2018) Physical characterization of bacterial cellulose produced by Komagataeibacter medellinensis using food supply chain waste and agricultural by-products as alternative low-cost feedstocks. J Polym Environ 26:830–837. https://doi.org/10.1007/s10924-017-0993-6

Molina-Ramírez C, Castro M, Osorio M, Torres-Taborda M, Gómez B, Zuluaga R, Gómez C, Gañán P, Rojas OJ, Castro C (2017) Effect of different carbon sources on bacterial nanocellulose production and structure using the low pH resistant strain Komagataeibacter medellinensis. Mater (Basel Switzerland) 10:639. https://doi.org/10.3390/ma10060639

Nelson ML, O’Connor RT (1964) Relation of certain infrared bands to cellulose crystallinity and crystal latticed type. Part I. Spectra of lattice types I, II, III and of amorphous cellulose. J Appl Polym Sci 8:1311–1324. https://doi.org/10.1002/app.1964.070080322

Oh SY, Yoo DI, Shin Y, Seo G (2005) FTIR analysis of cellulose treated with sodium hydroxide and carbon dioxide. Carbohyd Res 340:417–428. https://doi.org/10.1016/j.carres.2004.11.027

Poletto M, Ornaghi HL, Zattera AJ (2014) Native cellulose: structure, characterization and thermal properties. Materials7:6105–6119. https://doi.org/10.3390/ma7096105

Powers EM, Latt TG (1977) Simplified 48-hour IMVIC test: an agar plate method. Appl Enviro Microb 34:274–279. https://doi.org/10.1128/aem.34.3.274-279.1977

Rangaswamy BE, Vanitha KP, Hungund BS (2015) Microbial cellulose production from bacteria isolated from rotten fruit. Int J Poly Sci Article ID 280784:8pages. https://doi.org/10.1155/2015/280784

Rastogi A, Singh J, Das M, Kundu D, Banerjee R (2018) An understanding of bacterial cellulose and its potential impact on industrial applications. In: Kuila A, Sharma V (eds) Principles and applications of fermentation technology. Wiley, Hoboken. https://doi.org/10.1002/9781119460381.ch20

Revin VV, Liyas’kina EV, Sapunova NB (2020) Isolation and characterization of the strains producing bacterial cellulose. Microbiology 89:86–95. https://doi.org/10.1134/S0026261720010130

Römling U, Galperin MY (2015) Bacterial cellulose biosynthesis: diversity of operons, subunits, products and functions. Trends Microbiol 23:545–557. https://doi.org/10.1016/j.tim.2015.05.005

Ross P, Mayer R, Benziman M (1991) Cellulose biosynthesis and function in bacteria. Microbiol Rev 55:35–58. https://doi.org/10.1128/mr.55.1.35-58.1991

Saichana N, Matsushita K, Adachi O, Frébort I, Frebortova J (2015) Acetic acid bacteria: A group of bacteria with versatile biotechnological applications. BiotechnoL Adv 33:1260–1271. https://doi.org/10.1016/j.biotechadv.2014.12.001

Segal G (1991) The geometry of the KdV equation. Int J Mod Phys A 6:2859–2869. https://doi.org/10.1142/S0217751X91001416

Sharafi S, Rasool I, Beheshti-Maal K (2010) Isolation, characterization and optimization of indigenous acetic acid bacteria and evaluation of their preservation methods. Iran J Microbiol 2:38–45

Sharma P, Mathur G, Dhakate SR, Chand S, Goswami N, Sharma SK, Mathur A (2016a) Evaluation of physicochemical and biological properties of chitosan/poly (vinyl alcohol) polymer blend membranes and their correlation for vero cell growth. Carbohyd Polym 137:576–583. https://doi.org/10.1016/j.carbpol.2015.10.096

Singh O, Panesar PS, Chopra HK (2017) Isolation and characterization of cellulose producing bacterial isolate from rotten grapes. Biosci Biotech Res Asia 14:373–380. https://doi.org/10.13005/bbra/2455

Sharma R, Mathur A, Goswami N, Mathur G (2016b) Effect of carbon sources on physicochemical properties of bacterial cellulose produced from Gluconacetobacter xylinus MTCC 7795. e-Polymers 16:331–336. https://doi.org/10.1515/epoly-2016b-0047

Srivastava S, Mathur G (2021) Bacterial Cellulose: A Versatile Biopolymer. In. P. Gauba, R. Gabrani & G. Mathur (Eds.), Recent Trends in Biosciences and Biotechnology, Delhi pp.76–96

Thompson JD, Higgins DG, Gibson TJ (1994) CLUSTAL W: improving the sensitivity of progressive multiple sequence alignment through sequence weighting, position-specific gap penalties and weight matrix choice. Nucleic Acids Res 22:4673–4678. https://doi.org/10.1093/nar/22.22.4673

Thongwai N, Futui W, Ladpala N, Sirichai B, Weechan A, Kanklai J, Rungsirivanich P (2022) Characterization of bacterial cellulose produced by Komagataeibacter maltaceti P285 isolated from contaminated honey wine. Microorganisms 10:528. https://doi.org/10.3390/microorganisms10030528

Vasconcelos NF, Andrade FK, Vieira L, D A P, Vieira RS, Vaz JM, Chevallier P, de Freitas Rosa M (2020) Oxidized bacterial cellulose membrane as support for enzyme immobilization: properties and morphological features. Cellulose 27:3055–3083. https://doi.org/10.1007/s10570-020-02966-5

Vigentini I, Vincenzo F, Federico D, Sergio R, Isabella A, Cristiano M, Maurizio B, Roberto F (2019) Set-up of bacterial cellulose production from the genus Komagataeibacter and its use in a gluten-free bakery product as a case study. Front Microbiol 10: 1953. https://doi.org/10.3389/fmicb.2019.01953

Vos P, Garrity G, Jones D, Krieg NR, Ludwig W, Rainey FA, Whitman WB (eds) (2011) Bergey’s manual of systematic bacteriology: Volume 3: The Firmicutes, vol 3. Springer Science & Business Media. https://doi.org/10.1007/978-0-387-68489-5

Wang J, Tavakoli J, Tang Y (2019) Bacterial cellulose production, properties and applications with different culture methods-A review. Carbohyd Polym 219:63–76. https://doi.org/10.1016/j.carbpol.2019.05.008

Yamada Y (2016) Systematics of acetic acid bacteria. In: Matsushita K, Toyama H, Tonouchi N, Okamoto-Kainuma A (eds) Acetic Acid Bacteria. Springer, Tokyo. https://doi.org/10.1007/978-4-431-55933-7_1

Yao H, Dai Q, You Z (2015) Fourier Transform Infrared Spectroscopy characterization of aging-related properties of original and nano-modified asphalt binders. Constr Build Mater 101:1078–1087. https://doi.org/10.1016/j.conbuildmat.2015.10.085

Zhang W, Wang X, Qi X, Ren L, Qiang T (2018a) Isolation and identification of a bacterial cellulose synthesizing strain from kombucha in different conditions: Gluconacetobacter xylinus ZHCJ618. Food Sci Biotechnol 27:705–713. https://doi.org/10.1007/s10068-018-0303-7

Zhang Z, Schwartz S, Wagner L, Miller W (2000b) A greedy algorithm for aligning DNA sequences. J Comput Biol 7:203–214. https://doi.org/10.1089/10665270050081478

Acknowledgements

The authors are grateful to the Department of Biotechnology and Department of Physics and Materials Science and Engineering, Jaypee Institute of Information Technology, Noida, Uttar Pradesh, India for providing necessary facilities to execute this work.

Funding

The authors did not receive support from any organization for the submitted work.

Author information

Authors and Affiliations

Contributions

The authors listed above have equal contributions. The submitted work is part of the doctoral research of Mr. Samriddh Srivastava, done under the guidance of Dr. Garima Mathur. The authors acknowledge AIRF, Jawahar Lal Nehru University, New Delhi, for SEM facilities, and Material Characterization Lab, PMSE department, JIIT Noida for FTIR and XRD facilities.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest in the publication.

Competing interests

The authors have no financial and nonfinancial competing interests to declare that are relevant to the content of this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Srivastava, S., Mathur, G. Komagataeibacter saccharivorans strain BC-G1: an alternative strain for production of bacterial cellulose. Biologia 77, 3657–3668 (2022). https://doi.org/10.1007/s11756-022-01222-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11756-022-01222-4