Abstract

The aim of this study was to selectively enrich t10,c12-conjugated linoleic acid (t10,c12-CLA) and c9,t11-CLA in commercial CLA mixtures using a combination of urea crystallization and lipase-catalyzed esterification. The objective of the urea fractionation is to remove saturated and monounsaturated fatty acids (FA) from the CLA mixtures. CLA-enriched free FA (FFA) mixtures containing 53.8 wt% t10,c12-CLA and 39.1 wt% c9,t11-CLA were produced from the CLA mixtures containing ~34 wt% each of the two CLA isomers by a urea crystallization using methanol and the urea-to-FA weight ratio of 2.5:1. The CLA-enriched FFA mixtures were partially esterified with dodecan-1-ol in a recirculating packed-bed reactor using an immobilized lipase from Candida rugosa to further enrich the t10,c12-CLA and c9,t11-CLA in an FFA fraction and an FA dodecyl ester fraction, respectively, under the optimal conditions, i.e., temperature, 20 °C; FA-to-dodecan-1-ol molar ratio, 1:1; water content, 2 wt% of total substrates; residence time, 5 min; and reaction time, 24 h (for t10,c12-CLA enrichment) and 12 h (for c9,t11-CLA enrichment). After the reaction, an FFA fraction with 72.6 wt% t10,c12-CLA was obtained. Another FFA fraction with 62.0 wt% c9,t11-CLA was recovered after the saponification of the FA dodecyl ester fraction. The yields of t10,c12-CLA and c9,t11-CLA in the FFA fractions were 43.6 and 21.5 wt%, respectively, based on their initial weights in the CLA mixtures.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

“Conjugated linoleic acid” (CLA) means to a polyunsaturated fatty acids containing 18 carbons and two double bonds that are conjugated at positions Δ6/Δ8, Δ7/Δ9, Δ8/Δ10, Δ9/Δ11, Δ10/Δ12, Δ11/Δ13, or Δ12/Δ14 and can be in either the cis or the trans configuration [1]. Because four possible diastereomers (i.e., cis–cis, cis–trans, trans–cis, trans–trans) exist for each of the seven regioisomers, there are 28 isomers of CLA [2]. CLA is commercially produced by the alkali-catalyzed conjugation of edible oils (e.g., safflower oil) rich in linoleic acid (18:2n-6) containing two cis double bonds at positions Δ9 and Δ12 in propylene glycol [3]. cis-9,trans-11 (c9,t11)-CLA and trans-10,cis-12 (t10,c12)-CLA are the two predominant isomers found in commercial CLA products [4]. They are present at a ~1:1 ratio and constitute ~2/3 of the total fatty acids. Several animal studies and clinical trials on the biological activity of CLA have revealed that t10,c12-CLA is mainly responsible for the antiobesity properties of CLA, whereas the anticancer activity of CLA is primarily associated with c9,t11-CLA [5].

The utility of commercial CLA mixtures may be enhanced via selective enrichment of t10,c12-CLA or c9,t11-CLA in the mixtures [3]. In several published studies, researchers have attempted to selectively enrich a targeted CLA isomer via lipase-catalyzed esterification of the CLA mixtures with an alcohol compound such as l-menthol [6] and dodecan-1-ol [7, 8]. In the published studies, Candida rugosa lipase has been employed as an effective biocatalyst for the esterification because this lipase selectively esterifies c9,t11-CLA containing a cis-9 double bond but shows no selectivity toward t10,c12-CLA without the cis-9 double bond. The reaction results in the enrichment of t10,c12-CLA in the free fatty acid (FFA) fraction and enrichment of c9,t11-CLA in the form of esters. The studies mentioned above involved stirred-batch reactor systems. Notably, the presence of considerable amounts of water (20–25 wt% based on the total substrates) is needed for the reaction to take place.

A packed-bed reactor (PBR) is the most commonly used reactor for immobilized lipase-catalyzed reactions because of the greater potential for reutilization of immobilized enzymes and higher reaction efficiency as compared to a stirred-batch reactor during reactions [9]. A recirculating PBR (RPBR) is a type of the reactor in which reaction mixtures eluted from the enzyme bed move back to the starting point repeatedly. A major advantage of an RPBR in a lipase-catalyzed reaction is that the reaction is allowed to have more time to proceed as compared to any conventional type of PBR.

Recently, we demonstrated that an RPBR system can be used for immobilized C. rugosa lipase-catalyzed esterification of commercial CLA mixtures with dodecan-1-ol for the selective enrichment of a targeted CLA isomer in the mixtures containing ~33 wt% each of the t10,c12-CLA and c9,t11-CLA [2]. We were able to obtain an FFA fraction containing ~55 wt% t10,c12-CLA after a reaction time of 36 h. The yield of t10,c12-CLA in the fraction was ~22 wt% based on its weight in the CLA mixtures. Nonetheless, enrichment of c9,t11-CLA has not been performed in the study.

Urea crystallization is a process for extraction of linear n-alkane from other hydrocarbons by including the n-alkane in the channels of the crystallized urea, thereby forming urea-n-alkane clathrates. The process can also be applied to separation of linear FA from FA that are less linear. Saturated FA or monounsaturated FA are more likely to form a complex with urea than polyunsaturated FA containing more cis double bonds than the former [10].

In the present study, our purpose was to enrich t10,c12-CLA and c9,t11-CLA, separately from the same reaction products. We also considered a new approach to further increase the concentration of CLA isomers in their concentrates. We utilized a combination of urea crystallization and lipase-catalyzed esterification for the enrichment process. Before the C. rugosa lipase-catalyzed esterification, urea crystallization of the CLA mixtures was performed to obtain CLA-enriched FFA mixtures where most of oleic acid (18:1n-9) was removed because C. rugosa lipase shows selectivity toward the FA containing a cis-9 double bond. Then, a t10,c12-CLA-enriched FFA fraction and a c9,t11-CLA-enriched FFA fraction were prepared, respectively, from the CLA-enriched FFA mixtures via selective esterification of CLA isomers with dodecan-1-ol in the presence or absence of water using immobilized C. rugosa lipase, which preferentially esterifies c9,t11-CLA over t10,c12-CLA as the biocatalyst and an RPBR. The effects of water content and residence time on the concentration and yield of each CLA isomer in each FFA fraction were investigated.

Materials and Methods

Materials

Commercial CLA mixtures containing 34.2 wt% t10,c12-CLA, 33.5 wt% c9,t11-CLA, and 5.3 wt% other CLA isomers were acquired from HK Biotech Co. (Chinju, Korea). Urea (purity >99%) and dodecan-1-ol (purity >98%) were purchased from Samchun Pure Chemical Co. (Pyeongtaek, Korea). Immobilized C. rugosa lipase on Immobead 150 was acquired from Sigma Chemical Co. (St. Louis, MO, USA). The FA methyl ester (FAME) standards were purchased from Nu-Chek Prep, Inc. (Elysian, MN, USA) or Supelco (Bellefonte, PA, USA). All other reagents were of analytical grade.

Urea Crystallization

The commercial CLA mixtures (50 g) were dissolved in methanol (500 mL) with the desired amount of urea (in urea-to-CLA mixture weight ratios of 1:1, 1.5:1, 2:1, 2.5:1, 3:1, and 3.5:1, respectively), and the resulting mixture was refluxed at 250 °C until urea was dissolved completely. The solution was cooled to ordinary temperature at a rate of approximately 2.5 °C/min and held at this temperature for 30 min. The solution was then incubated at 4 °C for 16 h to allow the urea–FFA complex to crystallize. The crystals were simply discarded by filtration through a Whatman No. 1 filter paper in a Buchner funnel. Methanol was then removed from the filtrate using a rotary vacuum evaporator at 40 °C, and the remaining filtrate was acidified by adding 300 mL of hot 0.1 N HCl. An uncrystallized portion of the CLA mixtures was recovered by extracting the acidified solution with 500 mL of n-hexane in a separatory funnel twice. The n-hexane layer was washed with 100 mL of water twice and dried over anhydrous sodium sulfate. The n-hexane was removed using a rotary vacuum evaporator at 40 °C to obtain the CLA-enriched FFA mixtures, which were then stored at −80 °C until use.

C. rugosa Lipase-Catalyzed Esterification

The esterification of the CLA-enriched FFA mixtures with dodecan-1-ol was conducted in an RPBR consisting of a glass column (300 mm × 10 mm i.d.) equipped with a water jacket for temperature control. Immobilized C. rugosa lipase was used as the biocatalyst. The lipase (2 g) was manually packed into the column and was fixed in place using a stainless-steel sieve (50 mesh). The substrates contained CLA-enriched FFA mixtures and dodecan-1-ol in a molar ratio of 1:1. The substrates (80 g) were kept in a reservoir with a defined amount of added water (0, 2, 5, 10, 20, 40, and 60 wt% based on the total substrates). The reservoir consisted of a flat-bottom glass vessel (270 mm × 120 mm i.d.) with a water jacket for temperature control, and the substrates were agitated at 600 rpm using a magnetic stirrer during the reaction. The residence time of the substrates in the RPBR was 3, 5, 10, or 15 min. The RPBR and reservoir were maintained at 20 °C using a water circulator (model RW-0252G, Jeio Tech, Seoul, Korea). The substrates were pumped into the column by a metering pump (model QG 150, Syosset, NY, USA). All trials were performed in duplicate.

Separation of FFA from Reaction Products

A t10,c12-CLA-enriched FFA fraction and a c9,t11-CLA-enriched FFA fraction were separated, respectively, from the products obtained after the C. rugosa lipase-catalyzed esterification according to the method of Nagao et al. [7] with a slight modification, as depicted in Fig. 1. The reaction products (5 g) containing FFA (mainly, t10,c12-CLA), FA dodecyl esters (mainly, c9,t11-CLA dodecyl esters), and dodecan-1-ol were neutralized with 35 mL of 0.5 N KOH in 30 vol% ethanol at 35 °C for 30 min. The neutralized products were transferred into a 1-L separatory funnel and washed with 75 mL of n-hexane to extract FA dodecyl esters and dodecan-1-ol. The bottom aqueous layer was collected and stirred with 25 mL of 2 N HCl to convert the potassium salts into their acid forms. Then, the layer was transferred in another 1-L separatory funnel and washed with 75 mL of n-hexane to extract a t10,c12-CLA-enriched FFA fraction. The FFA fraction was dried in a rotary vacuum evaporator and subsequently under a nitrogen flush.

To recover a c9,t11-CLA-enriched FFA fraction, the mixtures of FA dodecyl esters and dodecan-1-ol, which were extracted from the neutralized products mentioned above using 75 mL of n-hexane were saponified with 60 mL of 0.625 N NaOH in 95 vol% ethanol at 50 °C for 30 min. The saponified products were placed into a 1-L separatory funnel and was added with 140 mL of water to dissolve the FA sodium salts. Then, 75 mL of n-hexane was added to extract the dodecan-1-ol. The bottom aqueous layer was collected and stirred with 25 mL of 2 N HCl to convert the sodium salts into their acid forms. The layer was then placed in another 1-L separatory funnel and washed with 75 mL of n-hexane to extract a c9,t11-CLA-enriched FFA fraction. The FFA fraction was dried in a rotary vacuum evaporator and subsequently under a nitrogen flush.

Analysis of Products

The relative amounts of FFA, FA dodecyl esters, and dodecan-1-ol in the FFA fractions were analyzed by gas chromatography (GC) by the method of Kang et al. [2]. An Agilent Technologies 7890A gas chromatograph (Palo Alto, CA, USA), equipped with a flame ionization detector (FID) and a fused silica capillary column (DB-17HT, 15 m × 0.25 mm i.d. × 0.15 μm film thickness, J&W Scientific, Folsom, CA, USA) was used for the analysis. Aliquots of the samples (25 mg) were dissolved in 1 mL of n-hexane, and 1 mL of the solution was injected in split mode with a split ratio of 50:1. The carrier gas was He, at a flow rate of 2.0 mL/min. The injector and detector temperatures were both 360 °C. The column was initially held at 120 °C for 1 min and was programmed to increase to 360 °C at a rate of 3 °C/min; it was then held at that temperature for 5 min.

The total FA compositions of CLA-enriched FFA mixtures, and FFA fractions were determined by the method of Kang et al. [11]. FFA samples (20 mg) were saponified with 3 mL of 0.5 N NaOH in methanol at 85 °C for 10 min, cooled to ordinary temperature, and then methylated with 3 mL of 14% BF3 in methanol at 85 °C for 10 min. After cooling to ordinary temperature, 3 mL of isooctane and 5 mL of a saturated NaCl solution were added, and the mixture was vortexed. The upper isooctane layer containing FA methyl esters (FAME) was collected and passed through an anhydrous Na2SO4 column. The FAME were analyzed by GC. An Agilent Technologies 7890A gas chromatograph, equipped with an FID and a fused silica capillary column (SP-2560, 100 m × 0.25 mm i.d. × 0.2 µm film thickness, Supelco) was used for the analysis. The sample (1 µL) was injected in split mode with a split ratio of 200:1. Helium gas served as the carrier gas at a flow rate of 1.0 mL/min. The injector and detector temperatures were set at 225 and 285 °C, respectively. The column was initially held at 100 °C for 4 min and was programmed to increase next to 240 °C at a rate of 3 °C/min; it was then held at that temperature for 17 min. The FAME were identified by comparing their retention time values with those of the standards, and their relative contents were calculated as wt%.

Statistical Analysis

The differences in the FFA samples obtained by urea crystallization or C. rugosa lipase-catalyzed esterification were examined by one-way analysis of variance (ANOVA) followed by Duncan’s multiple-range test. A value of p < 0.05 was taken to denote statistical significance.

Results and Discussion

Urea Crystallization of CLA Mixtures

Table 1 shows the FA composition of commercial CLA mixtures used as a starting material for the enrichment of targeted CLA isomers. They are mainly composed of two CLA isomers, c9,t11-CLA (33.5 wt%) and t10,c12-CLA (34.2 wt%), which constitute ~68 wt% of total FA. A considerable amount of oleic acid (14.6 wt%) was also found in the CLA mixtures. The FA profile of the CLA mixtures revealed that if the CLA mixtures are directly esterified with dodecan-1-ol using C. rugosa lipase as the biocatalyst, the alcohol will be esterified with oleic acid as well as c9,t11-CLA, thereby resulting in the enrichment of both FA in the form of dodecyl esters. Eventually, this process can lead to a reduction in the relative content of c9,t11-CLA in the FFA fraction recovered from the FA dodecyl esters.

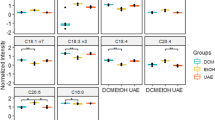

Urea crystallization can be applied to separation of oleic acid from c9,t11-CLA or t10,c12-CLA because oleic acid is more linear and more saturated than the two CLA isomers. Accordingly, before the C. rugosa lipase-catalyzed esterification, urea crystallization of commercial CLA mixtures was performed to obtain an FFA fraction from which oleic acid as well as saturated FA such as palmitic (16:0) and stearic acids (18:0) were removed. Urea-to-CLA mixture weight ratios of 1:1–3.5:1 were tested in the present study, with methanol serving as the solvent. Figure 2 shows variations in the oleic acid, c9,t11-CLA, and t10,c12-CLA content and the yield of the two CLA isomers. As the urea-to-CLA mixture weight ratios increased from 1:1 to 3.5:1, the oleic acid content decreased and t10,c12-CLA content increased in the CLA-enriched FFA mixtures. Unlike t10,c12-CLA, c9,t11-CLA showed a maximal content value at a ratio of 2:1 or 2.5:1. The yield of both CLA isomers steadily decreased with the increase in the ratio. These results are in agreement with our expectations that the three FA are removed in the order of oleic acid, c9,t11-CLA, and t10,c12-CLA, by forming a complex with urea. This result arises from the fact that the length of the linear hydrocarbon chain is greater in c9,t11-CLA than in t10,c12-CLA—i.e., c9,t11-CLA contains the cis double bond between carbons 9 and 10, when counted from the methyl end of the hydrocarbon chain, whereas t10,c12-CLA has the double bond between carbons 6 and 7. Thus, the urea-to-CLA mixture weight ratio of 2.5:1 was found to be the best for minimizing the level of remaining oleic acid while maximizing c9,t11-CLA, and t10,c12-CLA content. The FA composition of CLA-enriched FFA mixtures at the ratio of 2.5:1 is also given in Table 1. In the CLA-enriched FFA mixtures, the oleic acid content decreased from 14.6 wt% (in the commercial CLA mixtures) to 3.0 wt%. The table shows that the urea crystallization process afforded CLA-enriched FFA mixtures containing 39.1 wt% c9,t11-CLA and 53.8 wt% t10,c12-CLA with a yield of 42.2 wt% for c9,t11-CLA and 57.2 wt% for t10,c12-CLA. The CLA-enriched FFA mixtures did not contain any saturated FA such as palmitic, stearic, or arachidic acids (20:0), which were originally present in the commercial CLA mixtures.

Effects of the amount of urea on the content and the yield of t10,c12-CLA and c9,t11-CLA in the CLA-enriched FFA mixtures obtained by urea crystallization of the commercial CLA mixtures. Means with different letters for a given FFA type are significantly different (p < 0.05). The CLA mixtures contained 14.6 wt% oleic acid, 33.5 wt% c9,t11-CLA, and 34.2 wt% t10,c12-CLA

C. rugosa Lipase-Catalyzed Esterification

After the urea crystallization, the CLA-enriched FFA mixtures were esterified with dodecan-1-ol using immobilized C. rugosa lipase as the biocatalyst. This reaction enables enrichment of t10,c12-CLA and c9,t11-CLA in an FFA fraction and an FA dodecyl ester fraction, respectively, because this lipase selectivity esterifies c9,t11-CLA with dodecan-1-ol. An RPBR system was used for the reaction. We evaluated the effects of two key reaction parameters, namely, water content and residence time, on the enrichment of t10,c12-CLA and c9,t11-CLA. Because several published studies including ours [2, 7, 8] revealed that the optimal temperature and FFA-to-dodecan-1-ol molar ratio for the C. rugosa lipase-catalyzed esterification with dodecan-1-ol are near the ordinary temperature (i.e., 20–30 °C) and 1:1, respectively, the effects of temperature and substrate molar ratio were not assessed in the present study.

Effects of Water Content

The proportion of water in the substrates is one of the crucial factors affecting the lipase activity and stability during lipase-catalyzed esterification [12]. A minimal amount of water is required to maintain the specific three-dimensional structure of lipase, whereas addition of a large quantity of water to the reaction system can decrease lipase activity or shift the reaction toward hydrolysis [13]. Nevertheless, Kobayashi et al. [6] and Nagao et al. [7, 8] reported that the selective esterification of CLA isomers catalyzed by C. rugosa lipase takes place efficiently in the presence of a relatively large amount of water (20–25 wt% of the total substrates). A recent finding by No et al. [14]—who used the C. rugosa lipase-catalyzed esterification for the selective enrichment of pinolenic acid in pine nut oil—support these previous results. They also utilized a stirred-batch reactor system to carry out the reaction and reported that the optimal level of added water is 10 wt% of the total substrates in the reaction system, whereas the reaction does not proceed without added water. In contrast, according to our previous study [2], which involved the same type of reactor and enzyme as that used in the current study, little or no added water (e.g., 2 wt% of the total substrates) was needed for the esterification reaction, although a small amount of water is also formed during the reaction and is likely to accumulate in the reaction mixtures. These conflicting results show the necessity of independent studies on the effects of the amount of added water on the esterification reaction in our RPBR system.

Figure 3a shows the effects of water content of the substrates on the t10,c12-CLA content of the FFA fraction as a function of reaction time. Water content varied from 0 to 60 wt%. For these trials, the temperature, molar ratio of CLA-enriched FFA mixtures to dodecan-1-ol, and residence time of the substrates in the RPBR were maintained at 20 °C, 1:1, and 5 min, respectively. t10,c12-CLA content in all trials increased with reaction time but tended to reach a plateau (at approximately 72–75 wt%) after 36 h. There was no significant difference in t10,c12-CLA content among all the trials throughout the entire reaction period, except for two time points: 12 and 60 h—e.g., at 60 h, the t10,c12-CLA content in the trial with water content of 2 wt% was significantly greater than that of the trial with water content at 60 wt%. These results suggest that in our reaction system based on an RPBR, the C. rugosa lipase-catalyzed esterification can efficiently proceed regardless of the amount of added water. Just as in our previous study [2], these results contradict other studies [6–8, 14]. The reason for the conflicting results is still unclear; however, one thing which is clearly different from other studies is that our reaction system involves a PBR in contrast to their use of a stirred-batch reactor system. To select optimal water content for preparing t10,c12-CLA-enriched FFA fractions, a correlation between t10,c12-CLA content and the yield of t10,c12-CLA at different water content values is presented in Fig. 3b. The curve closer to the upper-right corner of the graph suggests that greater t10,c12-CLA content can be achieved at a given yield of t10,c12-CLA or a greater yield of t10,c12-CLA can be obtained at a desired t10,c12-CLA content. The curve obtained from the trial with water content of 40 wt% was closer to the upper-right corner of the graph than the others at t10,c12-CLA content of less than ~70 wt%. Nevertheless, with t10,c12-CLA content greater than ~70 wt%, the curve obtained from the trial with water content of 2 wt% was closer to the upper-right corner of the graph as compared to that obtained from the trial with water content of 40 wt%. Consequently, water content of 2 wt% was the most desirable for the t10,c12-CLA enrichment.

Effects of water content on the t10,c12-CLA content (a) and the correlation between the t10,c12-CLA content and the yield of t10,c12-CLA (b) in the free fatty acid fraction produced by C. rugosa lipase (immobilized on Immobead 150)-catalyzed esterification of the CLA-enriched FFA mixtures with dodecan-1-ol as a function of reaction time (0, 2, 4, 6, 12, 24, 36, 48, and 60 h). The yield of t10,c12-CLA was calculated based on the initial weight of the t10,c12-CLA in the commercial CLA mixtures. The reaction was performed at 20 °C, a substrate molar ratio of 1:1 (CLA-enriched FFA mixtures to dodecan-1-ol), and a residence time of 5 min in a recirculating packed bed reactor. The weights of the total substrates and the enzyme loading were 80 and 2 g, respectively

Figure 4a illustrates the effects of water content of the substrates on c9,t11-CLA content of the FFA fraction as a function of reaction time. All conditions were the same as those listed in Fig. 3. Unlike the t10,c12-CLA content reaching a plateau after a certain period of reaction time, c9,t11-CLA content in all trials increased to a maximal value of ~58 to 62 wt% with longer reaction time during the first 12 h of the reaction, but decreased with reaction time after 12 h. These results arise from the fact that C. rugosa lipase also esterifies other FA without a cis-9 double bond (including t10,c12-CLA) with dodecan-1-ol as c9,t11-CLA is gradually depleted. After c9,t11-CLA content reached a maximal value at 12 h, no significant difference was observed in c9,t11-CLA content among all trials. These results also clearly show that water content of the substrates does not markedly affect the efficiency of the C. rugosa lipase-catalyzed esterification for c9,t11-CLA enrichment. Figure 4b depicts a correlation between c9,t11-CLA content and the yield of c9,t11-CLA at different water content values. With a c9,t11-CLA content below ~60 wt%, the curve acquired from the trial with water content of 40 wt% was closer to the upper-right corner of the graph than the others, whereas the curve obtained from the trial with water content of 2 wt% was closer to the upper-right corner of the graph as compared to that obtained from the trial with water content of 40 wt% when the c9,t11-CLA content was greater than ~60 wt%. Therefore, the optimal water content of the substrates for the c9,t11-CLA enrichment was found to be 2 wt% of total substrates, same as that for the t10,c12-CLA enrichment.

Effects of water content on the c9,t11-CLA content (a) and the correlation between the c9,t11-CLA content and the yield of c9,t11-CLA (b) in the free fatty acid fraction obtained from the fatty acid dodecyl ester fraction produced by C. rugosa lipase (immobilized on Immobead 150)-catalyzed esterification of the CLA-enriched FFA mixtures with dodecan-1-ol as a function of reaction time. The yield of c9,t11-CLA was calculated based on the initial weight of the c9,t11-CLA in the commercial CLA mixtures. The reaction was performed under the conditions given in Fig. 3

Effects of Residence Time

The enzyme-to-substrate ratio greatly affects the efficiency of an enzyme-catalyzed reaction [15]. In a PBR system, because the amount of the enzyme used in the system is fixed, the enzyme-to-substrate ratio can be adjusted only by controlling the residence time, which is the time that substrates spend in the enzyme bed. Residence time is calculated by means of the following equation: residence time (min) = void volume of enzyme bed (mL)/flow rate of substrates (mL/min). In our RPBR system, the residence time can be controlled by adjusting the flow rate of the substrates fed into the immobilized C. rugosa lipase-packed bed column.

Figure 5a shows the effects of residence time on t10,c12-CLA content of the FFA fraction as a function of reaction time. The residence time tested ranged from 3 to 15 min. In these trials, the temperature, molar ratio of CLA-enriched FFA mixtures to dodecan-1-ol, and water content of the substrates in the RPBR were kept constant at 20 °C, 1:1, and 2 wt%, respectively. No remarkable difference was observed in t10,c12-CLA content among all trials during the first 24 h of the reaction. By contrast, after 36 h, the t10,c12-CLA content tended to be greater in the trial with residence time of 5 min than in the others although the difference did not reach statistical significance in some comparisons. A correlation between t10,c12-CLA content and the yield of t10,c12-CLA at different residence time values is presented in Fig. 5b. The curve obtained from the trial with residence time at 5 min was closer to the upper-right corner of the graph than the others, indicating that the optimal residence time for the t10,c12-CLA enrichment is 5 min. These results are in agreement with the findings by others. For instance, Watanabe et al. [16] found that shorter residence time is more desirable for the lipase-catalyzed direct esterification of glycerol and FA for the diacylglycerol production in an RPBR. Zhao et al. [17] also reported that relatively short residence time of 3 min is optimal for lipase-catalyzed ethanolysis of pine nut oil to obtain a pinolenic acid concentrate in the FA ethyl ester form when an RPBR is employed.

Effects of residence time on the t10,c12-CLA content (a) and the correlation between the t10,c12-CLA content and the yield of t10,c12-CLA (b) in the free fatty acid fraction produced by C. rugosa lipase (immobilized on Immobead 150)-catalyzed esterification of the CLA-enriched FFA mixtures with dodecan-1-ol as a function of reaction time. The yield of t10,c12-CLA was calculated based on the initial weight of the t10,c12-CLA in the commercial CLA mixtures. The reaction was performed at 20 °C, a substrate molar ratio of 1:1 (CLA-enriched FFA mixtures to dodecan-1-ol), and a water content of 2 wt% of total substrates in a recirculating packed bed reactor. The weights of the total substrates and the enzyme loading were 80 and 2 g, respectively

Figure 6a presents the effects of residence time on c9,t11-CLA content of the FFA fraction as a function of reaction time. All conditions were the same as those given in Fig. 5. After 12 h, c9,t11-CLA content tended to be greater in the trial with residence time of 5 min than in the others although the difference did not reach statistical significance in some comparisons. Figure 6b (illustrating a correlation between c9,t11-CLA content and the yield of c9,t11-CLA at different residence time values) also indicates that the optimal residence time for the c9,t11-CLA enrichment is 5 min, same as that for the t10,c12-CLA enrichment.

Effects of residence time on the c9,t11-CLA content (a) and the correlation between the c9,t11-CLA content and the yield of c9,t11-CLA (b) in the free fatty acid fraction obtained from the fatty acid dodecyl ester fraction produced by C. rugosa lipase (immobilized on Immobead 150)-catalyzed esterification of the CLA-enriched FFA mixtures with dodecan-1-ol as a function of reaction time. The yield of c9,t11-CLA was calculated based on the initial weight of the c9,t11-CLA in the commercial CLA mixtures. The reaction was performed under the conditions given in Fig. 5

Enrichment of CLA Isomers Under Optimal Conditions

In Figs. 3b and 5b, the points closest to the upper-right corner of the graph were obtained at 24 h, indicating that the optimal reaction time is 24 h for the t10,c12-CLA enrichment. Using the same method, the optimal reaction time was found to be 12 h for the c9,t11-CLA enrichment (Figs. 4b, 6b). Accordingly, the optimal conditions include a temperature of 20 °C, FA-to-dodecan-1-ol molar ratio of 1:1, water content of 2 wt% of total substrates, residence time of 5 min, and reaction time of 24 h (for t10,c12-CLA enrichment) and 12 h (for c9,t11-CLA enrichment). From the reaction products obtained under the optimal conditions for the t10,c12-CLA enrichment, an FFA fraction with 72.6 wt% t10,c12-CLA can be obtained. Another FFA fraction with 59.4 wt% c9,t11-CLA can also be recovered from the same reaction products. The yield of t10,c12-CLA and c9,t11-CLA was 43.6 and 28.2 wt% of their initial weights, respectively, in the commercial CLA mixtures.

An FFA fraction with 62.0 wt% c9,t11-CLA can be recovered from the reaction products obtained under the optimal conditions for the c9,t11-CLA enrichment. Another FFA fraction with 64.4 wt% t10,c12-CLA can also be obtained from the same reaction products. The yield of c9,t11-CLA and t10,c12-CLA was 21.5 and 44.9 wt% of their initial weights, respectively, in the commercial CLA mixtures.

Conclusion

Selective enrichment of t10,c12-CLA and c9,t11-CLA from commercial CLA mixtures was successfully achieved using a combination of urea crystallization and C. rugosa lipase-catalyzed esterification under the optimal conditions that we identified. We prepared CLA-enriched FFA mixtures with a reduced concentration of oleic acid (3.0 wt%) from the commercial CLA mixtures containing 14.6 wt% oleic acid using a urea crystallization method. Because C. rugosa lipase is selective toward the FA containing a cis-9 double bond, the CLA-enriched FFA mixtures can serve as good substrates for the C. rugosa lipase-catalyzed selective esterification of CLA isomers. The esterification was carried out in an RPBR. The optimal conditions were the following: temperature, 20 °C; FA-to-dodecan-1-ol molar ratio, 1:1, water content, 2 wt% of total substrates; residence time, 5 min; and reaction time, 24 h (for t10,c12-CLA enrichment) and 12 h (for c9,t11-CLA enrichment). Under these conditions, we obtained an FFA fraction containing 72.6 wt% t10,c12-CLA and another FFA fraction with c9,t11-CLA content of 62.0 wt%. The yield of t10,c12-CLA and c9,t11-CLA in the FFA fractions were 43.6 and 21.5 wt% of their initial weights, respectively, in the commercial CLA mixtures.

References

Banni S (2002) Conjugated linoleic acid metabolism. Curr Opin Lipidol 13:261–266

Kang I, Bang HJ, Kim IH, Choi HD, Kim BH (2015) Synthesis of trans-10, cis-12 conjugated linoleic acid-enriched triacylglycerols via two-step lipase-catalyzed esterification. LWT Food Sci Technol 62:249–256

Kapoor R, Reaney M, Westcott ND (2005) Conjugated linoleic acid oils, Edible oil and fat products: Specialty oils and oil products, vol. 3. In: Shahidi F (ed) Bailey’s industrial oil and fat products, 6th edn. Wiley, Hoboken, pp. 1–35

Poirier H, Shapiro JS, Kim RJ, Lazar MA (2006) Nutritional supplementation with trans-10, cis-12-conjugated linoleic acid induces inflammation of white adipose tissue. Diabetes 55:1634–1641

Belury MA, Mahon A, Banni S (2003) The conjugated linoleic acid (CLA) isomer, t10c12-CLA, is inversely associated with changes in body weight and serum leptin in subjects with type 2 diabetes mellitus. J Nutr 133:257–260

Kobayashi T, Nagao T, Watanabe Y, Yamauchi-Sato Y, Negishi S, Shimada Y (2006) Enrichment of CLA isomers by selective esterification with l-menthol using Candida rugosa lipase. J Am Oil Chem Soc 83:93–99

Nagao T, Shimada Y, Yamauchi-Sato Y, Yamamoto T, Kasai M, Tsutsumi K, Sugihara A, Tominaga Y (2002) Fractionation and enrichment of CLA isomers by selective esterification with Candida rugosa lipase. J Am Oil Chem Soc 79:303–308

Nagao T, Yamauchi-Sato Y, Sugihara A, Iwata T, Nagao K, Yanagita T, Adachi S, Shimada Y (2003) Purification of conjugated linoleic acid isomers through a process including lipase-catalyzed selective esterification. Biosci Biotechnol Biochem 67:1429–1433

Xu X, Balchen S, Høy CE, Adler-Nissen J (1998) Production of specific-structured lipids by enzymatic interesterification in a pilot continuous enzyme bed reactor. J Am Oil Chem Soc 75:1573–1579

Hayes D, Bengtsson Y, Alstine J, Setterwall F (1998) Urea complexation for the rapid, ecologically responsible fractionation of fatty acids from seed oil. J Am Oil Chem Soc 75:1403–1409

Kang KK, Kim S, Kim IH, Lee C, Kim BH (2013) Selective enrichment of symmetric monounsaturated triacylglycerols from palm stearin by double solvent fractionation. LWT Food Sci Technol 51:242–252

Stergiou PY, Foukis A, Filippou M, Koukouritaki M, Parapouli M, Theodorou LG, Hatziloukas E, Afendra A, Pandey A, Papamichael EM (2013) Advances in lipase-catalyzed esterification reactions. Biotechnol Adv 31:1846–1859

Zhao H, Lu Z, Bie X, Lu F, Liu Z (2007) Lipase catalyzed acidolysis of lard with capric acid in organic solvent. J Food Eng 78:41–46

No DS, Zhao TT, Kim BH, Choi HD, Kim IH (2013) Enrichment of erucic acid from crambe oil in a recirculated packed bed reactor via lipase-catalyzed ethanolysis. J Mol Catal B Enzym 87:6–10

Yang T, Rebsdorf M, Engelrud U, Xu X (2005) Enzymatic production of monoacylglycerols containing polyunsaturated fatty acids through an efficient glycerolysis system. J Agric Food Chem 53:1475–1481

Watanabe T, Sugiura M, Sato M (2005) Diacylglycerol production in a packed bed bioreactor. Process Biochem 40:637–643

Zhao T, Kim BH, Hong SI, Yoon SW, Kim CT, Kim Y, Kim IH (2012) Lipase-catalyzed production of pinolenic acid concentrate from pine nut oil using a recirculating packed bed reactor. J Food Sci 77:267–271

Acknowledgements

This research was supported by Main Research Program (E0124200-04) of the Korea Food Research Institute (KFRI) funded by the Ministry of Science, ICT & Future Planning and was also supported by the Sookmyung Women’s University Research Grants (1-1603-2044).

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Kim, J., Chung, MY., Choi, HD. et al. Selective Enrichment of Conjugated Linoleic Acid Isomers in Their Mixtures Using Combined Chemical and Enzymatic Methods. J Am Oil Chem Soc 94, 577–585 (2017). https://doi.org/10.1007/s11746-017-2970-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-017-2970-6