Abstract

Human milk fat substitutes (HMFSs) with triacylglycerol profiles highly similar to those of human milk fat (HMF) were prepared from lard by physical blending followed by enzymatic interesterification. Based on the fatty acid profiles of HMF, different vegetable and single-cell oils were selected and added to the lard. Blend ratios were calculated based on established physical blending models. The blended oils were then enzymatically interesterified using a 1,3-regiospecific lipase, Lipozyme RM IM (RML from Rhizomucor miehei immobilized on Duolite ES562; Novozymes A/S, Bagsværd, Denmark), to approximate HMF triacylglycerol (TAG) profiles, particularly with respect to the distribution of palmitic acid in the sn−2 position. The optimized blending ratios were determined to be: lard:sunflower oil:canola oil:palm kernel oil:palm oil:algal oil:microbial oil = 1.00:0.10:0.50:0.13:0.12:0.02:0.02. The optimized reaction conditions were determined to be: enzyme load of 11 wt%, temperature of 60 °C, water content of 3.5 wt%, and reaction time of 3 hours. The resulting product was evaluated for total and sn−2 fatty acids, polyunsaturated fatty acids, and TAG composition. A high degree of similarity was obtained, indicating the great potential of the product as a fat alternative for use in infant formulas.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Human milk is the best food for newborn infants, as it contains almost all essential nutrients, including protein, fat, carbohydrates, minerals, vitamins, and other bioactive substances. The fat in human milk accounts for 3–5 % of its composition, providing more than 50 % of its energy content [1]. Human milk fat (HMF) is primarily composed of triacylglycerols (TAGs) (>98 %), and its chemical composition varies due to such factors as lactation stage, dietary habits, season, genetics, and individual conditions. Structurally, HMF has most of its saturated fatty acids (palmitic acid) at the sn−2 position and most of its unsaturated fatty acids at sn−1 and sn−3 positions of the glycerol backbone [2]. This special fatty acid composition and positional distribution leads to the formation of a number of TAG species in the form of USU, such as 1,3-dioleoyl-2-palmitoylglycerol (OPO) and 1-oleoyl-2-palmitoyl-3-linoleoylglycerol (OPL). These TAGs, when ingested by infants, are hydrolyzed by gastric lipase (an sn−3-preferred lipase) in the stomach and pancreatic lipase (an sn−1,3-specific lipase) in the small intestine to form sn−2 monoacylglycerols (MAGs) and free fatty acids. As the sn−2 MAGs are absorbed directly by the intestine [3], saturated fatty acids at the sn−2 position can improve their absorption and avoid the formation of calcium soaps. Furthermore, as more than 70 % of the sn−2 fatty acids remain at their original position after absorption, this special structure also affects TAG metabolism and distribution in the infant’s body [4].

HMF also contains some medium-chain fatty acids (MCFAs), such as caproic and caprylic acids, and long-chain polyunsaturated fatty acids (LC-PUFAs), such as docosahexaenoic acid (DHA, n-3), arachidonic acid (AA, n-6), docosapentaenoic acid (DPA, n-3), and eicosapentaenoic acid (EPA, n-3) [5, 6]. MCFAs are located primarily at the sn−3 position of human milk TAGs, and the preduodenal lipases possess a high degree of activity toward these MCFAs at this position [4]. The hydrolyzed MCFAs are absorbed through the portal vein, providing instant energy for infants. The sn−1,2 DAGs facilitate fat digestion in the duodenum by increasing the solubility of TAGs. The LC-PUFAs DHA and AA are very important for infant development, even though they account for a very small percentage of HMF (less than 1 %, individually) [7]. DHA and AA are highly concentrated in the human retina and brain, and are important for visual and central nervous system functions [8]. However, the synthesis of DHA and AA from their precursors (linolenic acid, n-3, and linoleic acid, n-6, respectively) appears to be limited in at least some human infants due to low desaturase activity [9]. Therefore, based on the special functions of MCFAs and LC-PUFAs in HMF, the supplementation of these fatty acids in the form of human milk fat substitutes (HMFSs) should be considered for development of a more nutritionally complete infant formula.

Of the fats found in nature, lard has a chemical composition and molecular structure most similar to that of HMF. Lard has more than 65 % of its palmitic acid at the sn−2 position, and thus has a high concentration of OPO [10]. However, compared with HMF, lard has lower levels of linoleic and linolenic acids, and is free of MCFAs and LC-PUFAs. In efforts to improve the similarity of lard to HMF, some studies have reported different methods for preparing HMFSs. Yang et al. [10] and Wang et al. [11] utilized lipase-catalyzed acidolysis of lard with fatty acids from vegetable oils for preparation of HMFSs. Da Silva et al. [12] reported HMFS preparation using the interesterification of lard with soybean oils. All of these studies focused on preparation methods that resulted in HMFSs with a high degree of similarity to HMF from the perspective of fatty acid profiles. In newborns, however, HMF is ingested in the form of TAGs, and whether TAG species affect the digestion and metabolism of fat in infants remains unknown. Based on the principle that the chemical composition of HMF is the “golden rule” for HMFS preparation, TAG profiles should be the ultimate indicator in the preparation and evaluation of HMFS. In our lab, we have established two models with regard to HMFS preparation. Model I [13] is a physical blending model for obtaining blended oils with specific fatty acid composition and distribution, with precise calculations to ensure the highest possible yield. Model II [14] is an HMFS similarity evaluation model that is able to digitize the difference between HMFSs and HMF from the perspective of TAG profiles. The objective of this study, therefore, was to produce HMFSs with fatty acid profiles similar to that of HMF by blending lard with selected oils, optimized as per model I, and to increase the degree of similarity with respect to TAG profiles of the obtained HMFSs through the use of enzymatic interesterification, per model II. The conditions for enzymatic interesterification reactions were optimized based on the distribution of palmitic acid at the sn−2 position relative to all three acylglycerol positions (%sn−2 PA), degrees of similarity of sn−2 FA, and TAG composition of the products.

Experimental Procedures

Materials

Pancreatin (porcine pancreas) powder was purchased from Sigma-Aldrich Co., LLC (St. Louis, MO, USA). Lipozyme RM IM (RML from Rhizomucor miehei immobilized on Duolite ES-562) was purchased from Novozymes A/S (Bagsværd, Denmark). The esterification activity of Lipozyme RM IM was 13,746 units, where one unit is defined as the nanomoles of oleic acid produced from the hydrolysis of triolein in one minute per gram of enzyme. Sunflower oil (SFO), canola oil (CO), palm kernel oil (PKO), and palm oil (PO) were provided by Yihai Kerry Oils & Grains Industries Co., Ltd. (Shanghai, China). Microbial oil (MO) rich in AA from Mortierella alpina and algal oil (AO) rich in DHA from Schizochytrium sp. were provided by Hubei Fuxing Biotechnology Co., Ltd. (Wuhai, Hubei). The fatty acid profiles of lard and the different vegetable and single-cell oils are reported in Table 1. Silicic acid 60G TLC plates (10 × 20 cm) were purchased from Shanghai Shangbang Industrial Co., Ltd. (Shanghai, China). TAG standards, including OPO (1,3-dioleoyl-2-palmitoylglycerol), OOP (1,2-dioleoyl-3-palmitoylglycerol), PPO (1,2-dipalmitoyl-3-oleoylglycerol), POP (1,3-dipalmitoyl-2-oleoylglycerol), OOO (triolein), OOS (1,2-dioleoyl-3-stearoylglycerol), SOS (1,3-stearoyl-2-oleoylglycerol), SSO (1,3-stearoyl-2-oleoylglycerol), PPP (tripalmitin), and POS (1-palmitoyl-2-oleoyl-3-stearoylglycerol) were purchased from Larodan Fine Chemicals AB (Malmö, Sweden). Supelco 37-component fatty acid methyl ester mixture was purchased from Sigma-Aldrich China (Shanghai, China). Hexane, isopropanol, acetonitrile, and methanol were of high-performance liquid chromatograph (HPLC) purity. Glacial acetic acid, ethyl ether, and hydrochloric acid were of analytical grade.

Determination of Blending Ratios

Lard was blended with SFO, CO, PKO, MO, and AO at different ratios according to the fatty acid composition and distribution of HMF [15]. The fatty acid profiles of the blended oils were calculated using our previously established physical blending model [13].

where Y 1 and Y i are the percentages of a fatty acid species among the three acylglycerol positions in the lard and selected oils, Y 1(sn−2) and Y i(sn−2) are the percentages of a fatty acid species among sn−2 fatty acids in the lard and selected oils, and X i is the molar ratio between the selected oils and lard, in which lard is set to be 1; n is the oil species.

The final amount of the product can be described as follows:

where M is the final amount of the product, X 1 is the moles of lard and M 1 is its molecular weight, and M i is the molecular weight of the selected oil.

To guarantee the quality and maximum yield of the final product, MATLAB R2010a (MathWorks, Natick, MA, USA) was used to optimize the entire blending process.

Enzymatic Interesterification

The blended oils (10 g) were added to a 50-mL round-bottomed flask, flushed with nitrogen, and incubated in a water bath with magnetic agitation (φ 8 mm × 20 mm stirrer; Jintan Jiamei Instrument Co., Ltd., Jintan, China) speed of 500 rpm. The lipase (6–10 wt%, by weight of substrate), with water content ranging between 3.5 and 17 wt% (by weight of enzyme), was added to initiate the reaction, and samples were withdrawn from the system periodically for chemical compositional analysis. Samples were prepared in duplicate, and average values of the results were used.

Fatty Acid Composition Analysis

A 50-μL aliquot of the reaction product was removed from the reaction system and separated using thin-layer chromatography (TLC), with hexane/diethyl ether/acetic acid (80:20:1, vol/vol/vol) as the developing solvent. The plates were then sprayed with 0.2 % 2,7-dichlorofluorescein in methanol and visualized under UV light. The TAG band was scraped off and methylated with 3 mL of 4 % H2SO4 in methanol at 90 °C for 20 min under nitrogen. The fatty acid methyl esters were extracted twice with 2 mL hexane, dried with anhydrous sodium sulfate, and concentrated using nitrogen.

The analysis of fatty acid composition was carried out on a GC-14B gas chromatograph equipped with a flame ionization detector (Shimadzu Corp., Tokyo, Japan) and a fused silica capillary column (PEG-20 M, 30 m × 0.32 mm × 0.5 μm). The column was initially held at 100 °C for 4 min, followed by temperature programming to 180 °C at a rate of 10 °C/min, held at 180 °C for 4 min, and then increased to 215 °C at a rate of 4 °C/min. The injection port and detector temperatures were both set at 250 °C. The separated fatty acid methyl esters were identified by comparison of their retention times with standards, and the relative content expressed as mol %.

Sn−2 Fatty Acid Composition Analysis

TAGs were isolated by TLC, as described above, and the TAG band was scraped off and extracted twice with 2 mL of ethyl ether. After evaporation of the solvent with nitrogen, TAGs were hydrolyzed according to the method described by Luddy et al. [16], and 1 mL of 1 M Tris-HCl buffer (pH 8.0), 0.25 mL of 0.05 % bile salts, 0.1 mL of 2.2 % CaCl2, and 10 mg of pancreatic lipase were added to the TAGs. The mixture was incubated in a water bath at 40 °C for 3 min, with vigorous shaking, and then 1 mL of 6 M HCl and 2 mL of diethyl ether were added and centrifuged. Diethyl ether was then removed and dried with anhydrous sodium sulfate and evaporated under nitrogen to 200 μL. The hydrolytic products were separated on silica gel G TLC plates, and a developing solvent system of hexane/diethyl ether/acetic acid (50:50:1, v/v/v) was used. The band corresponding to sn−2 MAGs was scraped off, methylated, and analyzed, as described above.

TAG Composition Analysis

The separation and identification of TAG species was carried out according to our previously reported studies [13, 14]. The separation was performed on a LiChrospher C18 column (5 µm, 4.6 × 250 mm; Jiangsu Hanbon Science & Technology Co., Ltd., Jiangsu, China), and eluted with a binary gradient of acetonitrile (A) and isopropanol (B) at a flow rate of 0.8 mL/min, with a linear gradient of solvent A from 70 % to 60 % in the first 30 min, then to 55 % in 40 min, staying at 55 % for 20 min, and then to 70 % in 5 min. The identification was carried out on an HPLC/atmospheric pressure chemical ionization mass spectrometer (HPLC/APCI-MS). The MS conditions were as follows: APCI source block and probe temperatures, 100 °C and 400 °C, respectively; MS multiplier voltage, 700 V; and measurement range, m/z 250–1200. The sample concentration was 20 mg/mL and the injection volume was 10 µL.

Evaluation of HMFSs Based on TAG profiles

The degree of similarity of the HMFSs to HMF with respect to TAG profiles was evaluated using our established model, with the employment of four indicators that included total (C10:0, C12:0, C14:0, C16:0, C16:1, C18:0, C18:1, and C18:2) and sn−2 fatty acid (C12:0, C14:0, C16:0, C16:1, C18:0, C18:1, and C18:2) composition, and PUFA (C18:3, C20:2, C20:3, C20:4, C20:5, C22:2, C22:4, C22:5, C22:5, and C22:6) and TAG (OLaLa, MMLa, LLaO, MOLa, PMLa, LaOO, POLa, MPL, SMM, POL, PPL, PPM, OOO, POO, PPO, and POS) composition (obtained from RP-HPLC) [14]. The results from these four aspects of HMFSs were able to precisely reflect their degree of similarity in chemical composition to HMF. The model was given as follows:

where G FA/sn−2FA/PUFA/TAG is the degree of similarity of HMFSs to HMF with respect to total fatty acid composition, the percentage of fatty acids in the sn−2 position relative to the three acylglycerol positions, and PUFA or TAG composition for the n different fatty acyl species; E i(FA/sn−2FA/PUFA/TAG)is the deduced degree of similarity in the content of fatty acyl species i, the percentage of fatty acyl species i in the sn−2 position relative to its three acylglycerol positions, and the content of polyunsaturated fatty acyl species i or triacylglycerol i of HMFSs that is outside the range of that of HMF; \( {{D_{{i({\text{FA}}/{\text{sn}}{\text{--}}2{\text{FA/PUFA/TAG}})}} } \mathord{\left/ {\vphantom {{D_{{i({\text{FA}}/{\text{sn}}{\text{--}}2{\text{FA/PUFA/TAG}})}} } {\sum\nolimits_{i = 1}^{n} {D_{{i({\text{FA}}/{\text{sn}}{\text{--}}2{\text{FA/PUFA/TAG}})}} } }}} \right. \kern-0pt} {\sum\nolimits_{i = 1}^{n} {D_{{i({\text{FA}}/{\text{sn}}{\text{--}}2{\text{FA/PUFA/TAG}})}} } }} \) is the weight of the fatty acyl species i, sn−2 fatty acyl species i, polyunsaturated fatty acyl species i, or triacylglycerol i of HMF relative to its total amount; C i(FA/sn−2FA/PUFA/TAG) is the floating coefficient that is dependent on the content of fatty acyl species i, the percentage of fatty acyl species i in the sn−2 position relative to its three acylglycerol positions, and the content of polyunsaturated fatty acyl species i or triacylglycerol i of HMFSs; B i(FA/sn−2FA/PUFA/TAG) is the content of fatty acyl species i, the percentage of fatty acyl species i in the sn−2 position relative to its three acylglycerol positions, and the content of polyunsaturated fatty acyl species i or triacylglycerol i of HMFSs; and A i(FA/sn−2FA/PUFA/TAG) is the upper or lower limit of corresponding indicator i in HMF. When B is higher than the upper limit of the corresponding indicator in HMF, A is selected as the upper limit, and vice versa. If B is within the range, C is set to zero.

Results and Discussion

Determination of Blending Ratios

Human milk fat is unique in its fatty acid composition and distribution as well as its TAG profiles, and these characteristics are closely related to the healthy development of infants. As such, the evaluation of the quality of HMFSs should be based not only on their fatty acid profiles but also on their TAG profiles. HMF fatty acid and TAG profiles in different stages of lactation were reported in our previous studies [14, 15].

A high degree of similarity in fatty acid composition can be easily achieved by the physical blending of selected oils and fats. However, in terms of positional fatty acid distribution, a high level of similarity is quite difficulty to attain due to the unique PA distribution found in HMF. The blending of lard, which has a high PA content at the sn−2 position, with selected vegetable oils results in a product that is able to meet the requirements in both fatty acid composition and positional distribution in order to achieve a high degree of similarity to those in HMF. In this study, sunflower oil (SFO), canola oil (CO), palm kernel oil (PKO), microbial oil (MO), and algal oil (AO) were selected based on the difference in fatty acid profiles between lard and HMF, and their ratio to lard was determined using the physical blending model [13]. The equations derived from the model based on the fatty acid profiles of human milk fat were given as follows:

where X 1, X 2, X 3, X 4, X 5, and X 6 were the respective molar ratios of SFO, CO, PKO, PO, AO, and MO to lard; S was %sn−2 PA, determined to be 60 %, 65 %, 70 %, and 75 %; and M was the final maximum quality of the blending oils, which was optimized by the MATLAB R2010a (MathWorks, Natick, MA, USA). In Eqs. 9 and 10, 49.0 was the content of C12:0 in PKO, and 3.1 and 10.1 were the respective lower and upper limits of C12:0 in HMF. In Eqs. 11 and 12, 16.2 and 10.5 were the C14:0 content in PKO and AO, respectively, and 5.7 and 14.8 were the respective lower and upper limits of C14:0 in HMF. In Eqs. 13 and 14, 25.2, 6.2, 4.2, 8.2 and 42.3 were the C16:0 content in lard, SFO, CO, PKO, and PO, respectively; and 19.6 and 29.0 were the respective lower and upper limits of C16:0 in HMF. In Eqs. 15 and 16, 10.8, 56.4, 18.0, 2.1, and 9.7 were the C18:2 content in lard, SFO, CO, PKO, and PO, respectively; and 7.1 and 20.2 were the respective lower and upper limits of C18:2 in HMF. In Eq. 17, 25.2, 6.2, 4.2, 8.2, and 42.3 were the C16:0 content in lard, SFO, CO, PKO, and PO, respectively; and 70.3, 4.0, and 14.6 were the respective percentages of palmitic acid in the sn−2 position of lard, PKO, and PO. In Eq. 18, 39.1 and 0.5 were the C20:4 content in MO and HMF, respectively; and in Eq. 19, 34.0, and 0.3 were the C22:6 content in AO and HMF, respectively.

The ratios for the blended oils with %sn−2 PA of 60 %, 65 %, 70 %, and 75 % are shown in Table 2. The fatty acid composition and distribution in the blended oils as calculated by the model and their actual values determined by the GC are presented in Table 3.

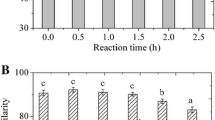

Effect of Blending Ratios

The products with fatty acid composition and distribution similar to human milk fat were obtained by physically blending lard with other vegetable oils, whereas the TAG composition of the blended oils was a mixture of TAGs of selected oils, which was different from that of HMF. Therefore, to obtain HMFSs with TAG profiles that mimic those of HMF, Lipozyme RM IM, a 1,3-specific lipase, was chosen as the catalyst for interesterification of the blended oils, and the degree of similarity in TAG composition was chosen as the reaction indicator. However, because of the existence of TAG isomers and the occurrence of acyl migration [10], two assistant indicators reflecting the variation in acyl migration and TAG isomers were chosen as %sn−2 PA and degree of similarity in sn−2 fatty acid composition. Based on the attributes of HMF, HMFSs should have %sn−2 PA greater than 60 % and a high degree of similarity in sn−2 fatty acid and TAG composition. The %sn−2 PA and degrees of similarity in sn−2 fatty acid and TAG composition at different blending ratios as a function of reaction time are shown in Fig. 1.

Effect of blending ratios on %sn−2 PA (a) and degrees of similarity in sn−2 FA (b) and TAG (c) composition as a function of reaction time. Reaction conditions: temperature, 60 °C; enzyme load, 8 wt%; water content, 3.5 wt%. 60 %, 65 %, 70 %, and 75 % refer to %sn−2 PA obtained by blending lard with sunflower oil, canola oil, palm kernel oil, palm oil, algal oil, and microbial oil, respectively, the ratios of which were determined using the physical blending model (Eqs. 1–5). %sn−2 PA refers to the distribution of palmitic acid in the sn−2 position relative to the three acylglycerol positions, and sn−2 FA refers to fatty acid in the sn−2 position

Four different oils blended with lard with different %sn−2 PA obtained from model calculations had high concentrations of palmitic acid in the sn−2 position (sn−2 PA). As reaction times increased, the content of sn−2 PA decreased, leading to a decrease in %sn−2 PA. The blended oil with %sn−2 PA of 65 % decreased to 60 % after 2.5 hours of reaction time; however, the blended oils with %sn−2 PA of 70 % and 75 % remained at more than 60 % after 6 hours of reaction time. The levels of sn−2 fatty acid composition were compared with that of HMF, and their degrees of similarity were calculated using the evaluation model (Eqs. 6–8). The sn−2 fatty acid composition was affected by acyl migration. The degrees of similarity in sn−2 fatty acid composition among the four types of the blended oils initially increased, but then decreased. However, degrees of similarity in TAG composition first increased and then flattened. As seen in Fig. 1, the degrees of similarity for the blended oils with %sn−2 PA of 70 % and 75 % were similar in sn−2 fatty acid and TAG composition, which were obviously higher than those for %sn−2 PA of 60 % and 65 %. Meanwhile, after the interesterification reaction, their %sn−2 PA were both higher than 60 %, within the range of that of HMF. However, the blended oil with %sn−2 PA of 70 % had a higher yield than that with %sn−2 PA of 75 % when the same amount of lard was used. Therefore, the blended oil with %sn−2 PA of 70 %—i.e., with a blending ratio of lard:SFO:CO:PKO:PO:AO:MO = 1.00:0.10:0.50:0.13:0.12:0.02:0.02—was chosen for the subsequent experiments.

Effect of Enzyme Load

Increasing the enzyme load in the system has the effect of accelerating the reaction rate, and thus shortens the time to reaction equilibrium [10]. However, the major reaction indicator is the degree of similarity in TAG composition, which may predict its maximum point prior to equilibrium. There is equilibrium in the enzymatic reactions, namely, hydrolysis and re-esterification [17]. A large amount of enzyme existing in the system may lead to more DAGs, and the immobilization carriers may cause increased acyl migration. Therefore, considering the enzyme cost and other side reactions, it is reasonable to optimize the enzyme load in the reaction system in order to obtain products of the highest quality. According to Fig. 2, %sn−2 PA decreased with the increase in enzyme load, and in terms of degrees of similarity of sn−2 fatty acid composition, maximum peaks occurred when the enzyme load was in the range of 5–11 wt%. However, when the enzyme load was 14 wt%, the degree of similarity decreased with the increase in reaction time. The degrees of similarity of TAG composition at enzyme loads of 11 wt % and 14 wt % had maximum points at a reaction time of 4 hours and 3 hours, respectively, whereas their values at enzyme loads of 5 wt% and 8 wt% both reflected an increasing–flattening trend, and they were lower than those of 11 wt% and 14 wt%, largely due to the differences in reaction rates. Therefore, the enzyme load of 11 wt% was selected for subsequent reactions, and the optimal reaction time for this enzyme load was determined to be 3 hours.

Effect of enzyme load on %sn−2 PA (a) and degrees of similarity in sn−2 FA (b) and TAG (c) composition as a function of reaction time. Reaction conditions: blending ratio, lard:SFO:CO:PKO:PO:AO:MO = 1.00:0.10:0.50:0.13:0.12:0.02:0.02; temperature, 60 °C; water content, 3.5 wt%. The original %sn−2 PA was 70 % under the blending ratio. For abbreviations, see Fig. 1.

Effect of Temperature

Temperature affects both the reaction rate and acyl migration in the enzymatic reaction system [18]. An increase in temperature accelerates the movement of reaction molecules, thus enhancing the frequency of their effective collision. However, higher temperatures may lead to a higher acyl migration rate of DAGs, and thus a decrease in %sn−2 PA, and may also cause irreversible inactivation of the enzyme [19]. According to Fig. 3, %sn−2 PA related to acyl migration decreased with increasing reaction temperature. The degrees of similarity of fatty acid composition reflect an increasing–decreasing trend at reaction temperatures of 40 °C, 50 °C, and 60 °C as a function of reaction time. However, for reactions at 70 °C, a maximum point was not found, and this may occur prior to 0.5 hours due to the higher reaction rate. The degree of similarity of TAG composition for reactions at 40 °C did not reach significant levels until the reaction time exceeded 4 hours. However, for reactions at 50 °C, 60 °C, and 70 °C, high degrees of similarity in TAG composition were able to be achieved within 3 hours. The degrees of similarity for reactions at 60 °C and 70 °C were similar, and both were higher than those of reactions at 50 °C. Therefore, 60 °C was selected as the reaction temperature for subsequent reactions, and the optimal reaction time for reactions at this temperature was determined to be 3 hours.

Effect of Water Content

Water content in the reaction system affects enzyme activity and the formation of partial glycerides (DAGs and MAGs) [20], and thus influences reaction rate and acyl migration. Higher water content leads to increased formation of partial glycerides and free fatty acids, and when water content reaches a certain level, the major reaction changes from esterification to hydrolysis. Therefore, in order to obtain products with high yield and of high quality, the water content in the system must be optimized. As shown in Fig. 4, the %sn−2 PA and degree of similarity in fatty acid composition decreased with increasing water content. However, with respect to similarity of TAG composition, their patterns were complex, largely resulting in differences in the content of partial glycerides at various levels of water content. With the exception of 3.5 wt%, as the content of water increased, reactions reflected an increasing–decreasing trend, while higher water content was associated with lower degrees of similarity in TAG composition. For reactions at 3.5 wt% water content, the product obtained had the highest %sn−2 PA, degree of similarity in sn−2 fatty acids, and TAG composition.

In reactions at conditions of 3.5 wt% water content, temperature of 60 °C, and enzyme load of 11 wt%, %sn−2 PA and degree of similarity in fatty acid composition decreased with increasing reaction time. After 3 hours of reaction time, the %sn−2 PA was 63.0 % (higher than the required value of 60 %), the degree of similarity in fatty acid composition was 89.8 %, and, most importantly, the degree of similarity in TAG composition reached a high value of 71.9 %. Given these observations, a reaction time of 3 hours was selected.

After optimization, the conditions selected for enzymatic preparation of HMFSs from lard, based on their TAG composition, were as follows: blending ratios, lard:SFO:CO:PKO:PO:AO:MO = 1.00:0.10:0.50:0.13:0.12:0.02:0.02; enzyme load, 11 wt%; temperature, 60 °C; water content, 3.5 wt%; and reaction time, 3 hours.

Characterization and Similarity Evaluation of the Final Product

The fatty acid composition and distribution of the product under optimized conditions are presented in Table 4, and TAG composition is shown in Table 5. Compared with the products prior to enzymatic interesterification, the content of sn−2 PA decreased from 42.5 to 38.2 % and the content of sn−2 oleic acid increased from 26.1 % to 28.6 %. Their fatty acid composition, however, obviously varied. In terms of TAG composition, the blended product contained more TAGs with unsaturated fatty acids such as LLL, OLLn, OLL, OOL, and OOO, compared with those of lard, which resulted from the added vegetable oils. After enzymatic interesterification, there was signification variation among the products with regard to TAG composition. The TAG content of OLL, OOO, PPP, and POS decreased from 5.1 %, 14.8 %, 1.4 %, and 10.5 % to 3.4 %, 10.2 %, 0.4 %, and 4.7 %, respectively, and the content of PLL, POLn, POL, and SOO increased from 2.7 %, 0.1 %, 11.9 %, and 1.6 % to 5.2 %, 2.3 %, 17.6 %, and 2.8 %, respectively.

The similarity of the products to HMF before and after enzymatic interesterification was evaluated using the established model and employing four indexes—the composition and distribution of fatty acids and the composition of PUFA and TAG—which are shown in Table 6. The degrees of similarity in total and sn−2 fatty acid and PUFA composition were slightly lower after enzymatic interesterification, whereas the similarity in TAG composition was greatly increased, from 59.7 % to 71.9 %, thus increasing the overall similarity of the product to HMF.

Conclusions

The preparation of HMFSs based on TAG profiles was achieved with a two-step method: physical blending of different oils with lard to adjust the fatty acid profiles, followed by enzymatic interesterification to increase their degree of similarity in TAG composition. The optimized conditions obtained for both steps were as follows: blending ratios of lard:sunflower oil:canola oil:palm kernel oil:palm oil:algal oil:microbial oil = 1.00:0.10:0.50:0.13:0.12:0.02:0.02, enzyme load of 11 wt%, temperature of 60 °C, water content of 3.5 wt%, and reaction time of 3 hours. The final product had high degrees of similarity in total and sn−2 fatty acid as well as PUFA and TAG composition, with values of 92.5 %, 90.3 %, 61.5 %, and 71.9 %, respectively. The preparation of HMFS utilizing this technique has the advantage of low cost and high yield, resulting in a product with a TAG profile that is highly similarity to that of HMF, suggesting the potential for industrialization.

References

Jensen RG (1999) Lipids in human milk. Lipids 34:1243–1271

Martin J-C, Bougnoux P, Antoine J-M, Lanson M, Couet C (1993) Triacylglycerol structure of human colostrum and mature milk. Lipids 28:637–643

Phan CT, Tso P (2001) Intestinal lipid absorption and transport. Frontier Biosci 6:D299–D319

Mu H, Høy C-E (2004) The digestion of dietary triacylglycerols. Prog Lipid Res 43:105–133

Bokor S, Koletzko B, Decsi T (2008) Systematic review of fatty acid composition of human milk from mothers of preterm compared to full-term infants. Ann Nutr Metab 51:550–556

Boersma ER, Offringa PJ, Muskiet F, Chase WM, Simmons IJ (1991) Vitamin E, lipid fractions, and fatty acid composition of colostrum, transitional milk, and mature milk: an international comparative study. Am J Clin Nutr 53:1197–1204

Koletzko B, Rodriguez-Palmero M (1999) Polyunsaturated fatty acids in human milk and their role in early infant development. J Mammary Gland Biol 4:269–284

Carlson SE (2001) Docosahexaenoic acid and arachidonic acid in infant development. Semin Neonatol 6:437–449

Hayat L, al-Sughayer M, Afzal M (1999) A comparative study of fatty acids in human breast milk and breast milk substitutes in Kuwait. Nutr Res 19:827–841

Yang T, Xu X, He C, Li L (2003) Lipase-catalyzed modification of lard to produce human milk fat substitutes. Food Chem 80:473–481

Wang YH, Qin XL, Zhu QS, Zhou R, Yang B, Li L (2010) Lipase-catalyzed acidolysis of lard for the production of human milk fat substitute. Eur Food Res Technol 230:769–777

da Silva RC, Soares FASDM, Fernandes TG, Castells ALD, da Silva KCG, Gonçalves MIA, Ming CC, Gonçalves LAG, Gioielli LA (2011) Interesterification of lard and soybean oil blends catalyzed by immobilized lipase in a continuous packed bed reactor. J Am Oil Chem Soc 88:1925–1933

Zou X-Q, Huang J-H, Jin Q-Z, Liu Y-F, Tao G-J, Cheong L-Z, Wang X-G (2012) Preparation of human milk fat substitutes from palm stearin with arachidonic and docosahexaenoic acid: combination of enzymatic and physical methods. J Agric Food Chem 60:9415–9423

Zou X-Q, Huang J-H, Jin Q-Z, Guo Z, Liu Y-F, Cheong L-Z, Xu X-B, Wang X-G (2012) Model for human milk fat substitute evaluation based on triacylglycerol composition profile. J Agric Food Chem 61:167–175

Zou X-Q, Guo Z, Huang J-H, Jin Q-Z, Cheong L-Z, Wang X-G, Xu X-B (2012) Human milk fat globules from different stages of lactation: a lipid composition analysis and microstructure characterization. J Agric Food Chem 60:7158–7167

Luddy F, Barford R, Herb S, Magidman P, Riemenschneider R (1964) Pancreatic lipase hydrolysis of triglycerides by a semimicro technique. J Am Oil Chem Soc 41:693–696

Miller DA, Prausnitz JM, Blanch HW (1991) Kinetics of lipase-catalysed interesterification of triglycerides in cyclohexane. Enzyme Microb Tech 13:98–103

Xu X, Skands ARH, Høy C-E, Mu H, Balchen S, Adler-Nissen J (1998) Production of specific-structured lipids by enzymatic interesterification: elucidation of acyl migration by response surface design. J Am Oil Chem Soc 75:1179–1186

Jung H, Lee Y, Kim D, Han SO, Kim SW, Lee J, Kim YH, Park C (2012) Enzymatic production of glycerol carbonate from by-product after biodiesel manufacturing process. Enzyme Microb Tech 51:143–147

Xu X, Balchen S, Høy C-E, Adler-Nissen J (1998) Pilot batch production of specific-structured lipids by lipase-catalyzed interesterification: preliminary study on incorporation and acyl migration. J Am Oil Chem Soc 75:301–308

Acknowledgments

This work was supported by the National Science & Technology Pillar Program during the Twelfth Five-Year Plan Period (No. 2011BAD02B04) and Fundamental Research Funds for the Central Universities (JUSRP11439).

Author information

Authors and Affiliations

Corresponding authors

About this article

Cite this article

Zou, X., Huang, J., Jin, Q. et al. Preparation of Human Milk Fat Substitutes from Lard by Lipase-Catalyzed Interesterification Based on Triacylglycerol profiles. J Am Oil Chem Soc 91, 1987–1998 (2014). https://doi.org/10.1007/s11746-014-2533-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-014-2533-z