Abstract

Density and viscosity data as a function of temperature (5–100 °C) were collected for oils (normal and high-oleic) from nine cultivars of peanut. Density decreased linearly (R 2 ≥ 0.99) with increasing temperature for all oils, whereas viscosity (dynamic or kinematic) decreased exponentially with increasing temperature. At any particular temperature, dynamic viscosity increased linearly (R 2 ≥ 0.95) with decreasing oil density among the various oils. Slopes of the linear fits (with units of kinematic viscosity) for dynamic viscosity versus density plots decreased in an exponential fashion as the measurement temperature decreased. High-oleic oils had both the lowest densities and highest viscosities, with viscosity differences being most apparent at cooler temperatures. Increasing contents of oleic acid, decreasing contents of linoleic acid, and decreasing contents of palmitic acid were each associated with decreased density and increased viscosity among the oils. Two of the three high-oleic oils had the significantly (p < 0.05) highest content of total tocopherols, while the other high-oleic oil was statistically grouped with the oils having the 2nd highest total tocopherol content. This suggests a link between increased total tocopherols and high-oleic peanut oils; however, no obvious linear correlations were observed in tocopherol content and oil physical properties (density or viscosity).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Peanut (Arachis hypogaea L.) is an important crop valued worldwide as an edible seed, and this seed typically contains 40–50% oil by mass. The quantity and chemistry of this oil depends on the specific cultivar, seed maturity and growing conditions among other factors [1]. New cultivars of this species are continuously being released with a range of advantageous traits, one of which being an oil with enriched levels of oleic acid. Oleic acid percentages in traditional peanut oils range from approximately 41 to 67%, whereas in high-oleic peanut oils, this fatty acid content is nearer 80% [2]. Oleic acid enrichment has been achieved through classical breeding techniques [3]. A primary functional benefit of high-oleic oils is an extended shelf life in food applications, as these oils are less susceptible to lipid oxidation due to the reduction in the total number of double bonds compared to traditional oils [2, 4].

Density and viscosity are fundamental physical parameters that are critical to numerous process engineering equations common in the edible oil industry. Accordingly, there have been multiple reports pertaining to measurements and/or means of estimating these properties for edible oils [5–9]. From these and other studies [10], there has been a limited amount of density and viscosity data reported for peanut oils, but the origins, processing history, and/or chemistry of these oils have not always been fully reported. Furthermore, the ongoing release of new cultivars dictates the need for data specific to these varieties.

Technological advancements in instrumentation allow for more accurate and precise data acquisition. Two relatively new methods, one for oil density determination and another for oil viscosity determination, were utilized in this work. Density was measured based on the oscillating tube principle, which is a relatively recent but well-established means of accurately determining liquid density [11]. The increased accuracy and precision associated with oscillating tube density meters, coupled with the ease of measurement at various temperatures, are key improvements over previous methods of density measurement, including hydrometers and/or pycnometers. The viscometer used in this study is generally referred to as Stabinger-type viscometer, and this instrument utilizes a unique measuring principle in which a small, rapidly rotating tube is filled with an oil of interest, and within the oil, another, smaller tube is suspended and held in place via magnetic and buoyancy forces. The rotation of the outer tube induces rotation of the inner tube, and this rotation is a function of the temperature and oil viscosity, which is ultimately calculated by the instrument [12]. In sequence with the viscosity measurements, density is also measured, ultimately allowing for the simultaneous determination of dynamic viscosity, kinematic viscosity and density.

The objective of the current work was to describe density, dynamic viscosity and kinematic viscosity as a function of temperature for the oil from nine different cultivars of peanut. Oil chemical analyses were conducted to support the physical observations. Data from this study are important from a food science perspective, in terms of optimizing oil refining and handling processes, as well as predicting the quality and stability of products containing these oils. These data are also important from a biodiesel perspective, as these physical and chemical characteristics should also correlate to the physical and chemical properties of the methyl esters prepared from these same oils.

Materials and Methods

Materials

Peanut pods from eight cultivars were collected from fields located near Dawson, GA, during the 2005 crop season. A single peanut cultivar (Flavorunner-458) was sampled from Seminole, TX, during the same cropping season. The cultivars were AgraTech 201, Georgia-02C, Flavorunner-458, Georgia-01R, DP-1, C-99R, AP-3, Georgia Green, C11-239, and these are abbreviated as AT-201, GA-02C, FR-458, GA-01R, DP-1, C-99R, AP-3, GA-Green, and C11-239, respectively. Cultivars, sampling location, and basic seed characteristics are listed in Table 1. The eight Georgia cultivars were grown in close proximity and were subjected to similar cultural practices, such as irrigation and pest and nutrient management. The 2005 crop season near Dawson, GA, could be described as an average year for precipitation (596 mm rainfall). The cultivar from Texas represents a much more arid set of growing conditions, but is representative of a significant portion of the total US peanut production area. The peanuts tested included both medium and late-maturing cultivars, which were dug and windrowed individually when 50% of sampled pods were matured to the brown or black color classes [13]. Peanuts were air-dried to between 15 and 20% moisture and mechanically threshed. All peanut cultivars were further dried upon harvest to 10.5% moisture content on forced-air dryers to standardize moisture content.

Peanut shells were removed from each sample using a Hattaway (Cordele, GA) Model No. 4 lab sheller-separator. Medium-sized seed (those seed that will ride a 0.72-cm slotted screen but not a 0.84-cm screen) were kept separate for oil analysis. Peanut seed of each variety were processed in a Hander (Osaka, Japan) New 52 screw-type oil expeller. Prior to expelling, peanut seed were pre-heated between 95 and 100 °C to improve efficiency of oil expression [14]. Oil was collected in 9.5-l plastic containers and allowed to settle for 48 h in a seed conditioning room at 30 ± 3 °C. Vacuum filtration was applied to the bilayer of oil in preparation for further testing to remove any unsettled particulates. Peanut meal was collected also and placed in a −10 °C freezer for further oil evaluations.

Density Determination

Oil density was measured as a function of temperature from 10 to 90 °C using an Anton-Paar (Graz, Austria) DMA 5000 oscillating tube density meter. The specified accuracy of the instrument is ±5 × 10−6 g/ml and ± 0.01 °C. The specified reproducibility of the instrument is ±1 × 10−6 g/ml and ± 0.001 °C. A minimum of three independent replications were collected for each oil. More information regarding the measuring principles of this type of instrument is available [11].

Viscosity Measurment

Dynamic and kinematic viscosities were determined using an Anton-Paar (Graz, Austria) SVM3000 Stabinger-type dual viscometer/density meter [12]. While the viscosities of most vegetable oils typically display shear rate dependence at relatively low shear rates, i.e. ≤60 l/s [15–17]; for the current method, dynamic and kinematic viscosities are determined at relatively rapid shear rates such that viscosity measurements are independent of shear rate. Dynamic viscosity has SI units of mPa s, whereas kinematic viscosity is the dynamic viscosity divided by liquid density and has SI units of mm2/s [18, 19]. Density is simultaneously measured in the Stabinger-type viscometer to allow for the automatic calculation of kinematic viscosity; that is, the sample is introduced into both the dynamic viscometer and density measuring cells during operation of this instrument. The specified accuracy of the density meter portion of this instrument is 0.0005 g/ml. Dynamic viscosity, density and kinematic viscosity were measured from 100 to 5 °C at 5 °C increments. Temperature control was internal to the instrument and automatically programmed to change after a stable measurement was obtained at the previous temperature.

Fatty Acid Profile Analyses

Samples of oil were methylated according to the method of Bannon et al. [20]. Briefly, oil was hydrolyzed using methanolic potassium hydroxide and resulting fatty acids were converted to their methyl esters using boron trifluoride as a catalyst. The methyl esters were extracted into hexane and analyzed by gas chromatography (GC) using a Perkin Elmer Autosampler XL GC (Perkin Elmer Instruments, Norwalk, CN) with a flame ionization detector (FID) and a capillary column containing 70% cyanopropyl polysilphenylene-siloxane as the stationary phase (30 m length 0.25 mm i.d., 0.25 μm film thickness). Helium was used as the carrier gas at 1.85 ml/min. A temperature program was used with an initial temperature of 60 °C held for 2 min. The temperature was increased to 180 °C at 10 °C/min, then to a final temperature of 235 °C at 4 °C/min. The injector was heated to 265 °C and the split flow was 76.9 ml/min. The detector temperature was 265 °C. Fatty acids were identified by comparison with fatty acid methyl ester standards purchased from Matreya (Matreya, Pleasant Gap, PA). Fatty acids were quantified according to AOCS Official Method Ce 1-62 where each fatty acid was expressed by using the peak area percent as a ratio to the total area of all methyl esters present [21].

Tocopherol Analyses

Samples of oil were diluted with hexane according to the method of Hashim et al. [22]. The samples were accurately weighed and density was used to factor the final volume for content calculation. Tocopherols were analyzed using a Luna 5-μm Silica column, 250 mm length, 4.60 mm i.d. (Phenomenex, Torrance, CA, Cat No. 00G-4274-EO) with a mobile phase of 1% isopropanol in hexane at a flow rate of 1.4 ml/min. The injection volume was 20 μl. The detector was a Waters 2487 Dual Wavelength Absorbance Detector set to 294 nm. The tocopherols were identified by comparison with standards purchased from Sigma (Sigma Chemical, St. Louis, MO). Standards of α, β, δ and γ tocopherol were diluted with hexane. Their concentration was determined by the absorbance maximums of the solutions using UV spectroscopy according to Beer’s Law. Extinction coefficients were taken from the Merck Index. Calculations of the unknown were done by comparison of peak areas and the calculated concentrations of the standard solutions. Standard curves of each isomer covered five orders of magnitude and bracketed all sample concentrations.

Statistical Analyses

All measurements, excluding the viscosity measurements, were independently replicated a minimum of three times. All viscosity measurements were independently replicated a minimum of two times. Random sample were replicated three or more times for viscosity measurements and all coefficients of variation were less than 0.5%. Statistical Analysis Software ver. 9.1 was used for data analysis. Means were differentiated using PROC GLM and the Tukey multiple adjustment (p < 0.05–0.001). PROC NLIN was used to fit viscosity/temperature data for the various peanut oils.

Results and Discussion

Fatty acid profile data for the various oils is presented in Table 2. The predominant fatty acid was oleic, C18:1, which accounted for greater than 50% of the fatty acids present in all oils. Three of the peanut oils, FR-458, AT-201 and GA-02C are considered high-oleic, as this fatty acid is enriched in these oils to levels near 80%, with a concomitant reduction primarily in the linoleic species, C18:2. Oleic acid content was significantly (p < 0.001) higher in the three high-oleic oils as compared to the other samples.

Density as a function of temperature (10–90 °C) was well described by a straight line (R 2 ≥ 0.99) for all peanut oils (Fig. 1a), with density decreasing linearly with increasing temperature. Similar slopes for the fitted lines were observed for all oils (mean = −6.688 × 10−4 g/ml °C; coefficient of variation <0.1%) (Table 3). Density as a function of temperature (24–110 °C) for various vegetable oils (no peanut) were reported by other authors and the density/temperature slopes were calculated, including those of soy, rapeseed and corn with values of −6.674, −6.550 and −6.650 × 10−4 g/ml °C respectively [8]; values that are similar to density/temperature slopes for the current peanut oils. Average oil density at 20 °C is presented in Fig. 1b to better illustrate variation in this parameter among oils. The density difference between oils with the highest (GA-Green) and lowest (GA-02C) densities was approximately 3.0 mg/ml at 20 °C. There was a slight trend toward density convergence at higher temperatures in the current data, which is illustrated in a plot of density difference between GA-Green and GA-02C across the tested temperature range of 10–90 °C (Fig. 2). At 10 °C, the density difference in these samples was ∼3.0 mg/ml, whereas at 90 °C the difference in these samples was ∼2.9 mg/ml, and this data was well described by a straight line (R 2 = 0.99).

Average density at 10 and 90 °C is presented in Table 3 to allow statistical comparisons among oils, and numerous significant differences (p < 0.001) were observed at either temperature tested. This reflects both the homogenous nature of these oils, which allows for consistent sampling, and the high accuracy and precision of the density meter.

Fatty acids in the form of triacylglycerols (TAGs) make up the majority of peanut oil, accounting for greater than 95% of peanut oil from fully mature peanuts [1]. While the percentages of the specific TAGs in the peanut oils are unknown, a molecular weight for the various oils can be defined as:

where xi is the mole fraction of each fatty acid and MWi is the molecular weight of each fatty acid [6]. Liquid density is established to be a function of molecular size, and in a comparison of 14 different vegetable oils taken from various literature sources, density was stated to decrease with increases in oil MW; however, calculated values for the MW’s of the various oils were not presented [9]. A poor linear correlation (R 2 = 0.08) was calculated in a plot of MWoil versus density at 20 °C for the current peanut oils (data not shown), suggesting density variation in these samples is primarily attributable to other factors.

The iodine value (IV), which is a measure of total oil unsaturation, was calculated from fatty acid compositional data by AOCS Official Method Cd 1c-85 [23] and plotted against oil density at 20 °C (Fig. 3a). Density linearly increased (R 2 = 0.99) with increasing IV, i.e. increasing total number of double bounds. This is in agreement with earlier vegetable oil density data [9]. High-oleic acid oils were found to have the lowest density at any temperature tested (Fig. 1, Table 3). Comparisons of the primary unsaturated fatty acid contents with oil density found a negative linear correlation (R 2 = 0.95) for oleic acid and a positive linear correlation (R 2 = 0.96) with linoleic acid as density increased (Fig. 3b). For the primary saturated fatty acids present in these oils, a positive linear correlation (R 2 = 0.92) was observed with palmitic acid content and increasing density (Fig. 3c). A poor linear fit (R 2 = 0.17) was observed in the plot of stearic acid content and density at 20 °C (Fig. 3c).

Iodine value, % unsaturated and % saturated fatty acids of oils versus density at 20 °C. Data points are means, error bars are standard deviations. Straight lines are best linear fits. a Iodine value versus oil density at 20 °C. Symbols appear on the graph. b Percentage of unsaturated fatty acids versus oil density at 20 °C. c Percentage of saturated fatty acids versus oil density at 20 °C

Data in Fig. 3 were also analyzed for linear correlations in the absence of the three high oleic oils as these oils had substantially lower densities which may skew the fitted lines. A similar linear correlation (R 2 = 0.98) was determined in the plot of iodine value versus density at 20 °C (data not shown). For plots of C18:1, C18:2, C16:0 and C18:0 versus density at 20 °C, R 2 values were 0.77, 0.93, 0.62 and 0.82 respectively (data not shown). Poorer fits were noted for C18:1, C18:2, C16:0 versus density at 20 °C in the absence of high oleic oils. However, the fit for C18:0 improved substantially from an R 2 of 0.17–0.82. Clearly, the high oleic oils substantially affect linear correlations of individual fatty acids versus density at 20 °C. However, the fit of the iodine value, which takes into account both saturated and unsaturated species is more robust.

Molecular structure is an established factor affecting liquid density [9]. The exact stereospecific structures of the various TAGs present in these peanut oils are unknown. However, the incorporation of fatty acids into TAGs is restricted to a fairly homologous series for vegetable oils [9]. For example, previous work with peanut oil (non high-oleic) found that the species OLL, OOL, POL and PLL accounted for 26.1, 21.5, 13.4 and 8.4% of the TAGs present, with O, L and P being oleic, linoleic and palmitic acids respectively [24]. Other data support the nonrandom distribution of fatty acids on TAGs in peanut oils (and other vegetable oils); for example, unsaturated species predominate at the sn-2 position, whereas saturated species occur most frequently at the sn-1 or sn-3 positions [1]. This non-random occurrence of fatty acids in TAGs, coupled with the predominance of TAGs in vegetable oils, allows extrapolations between fatty acid profile data and oil physical properties. Unsaturation within fatty acid hydrocarbon chains induces nonlinearity in the structure [25], which in turn limits packing of TAGs containing unsaturated species due to steric hindrance effects. This leads to a decrease in density as observed for the high-oleic oils (Fig. 1). Additionally, the two cis double bonds within linoleic acid result in a molecular structure that is more compact than oleic acid [26], allowing this moiety to pack more effectively with neighboring molecules. This further explains the decreased density of the high-oleic oils, as linoleic acid content is concomitantly reduced in these oils as mentioned previously. Palmitic acid accounted for no more than 10% of the fatty acids present in these oils; therefore, the positive linear correlation with this fatty acid and increasing oil density is hypothesized to be primarily a function of the inverse correlation between palmitic acid and oleic acid content. That is, cultivars that contained high levels of oleic acid also contained lower levels of palmitic acid.

Both dynamic viscosity (Fig. 4a) and kinematic viscosity (Fig. 4b) of the individual oils decreased in a curvilinear fashion with increasing temperature, in agreement with data for other vegetable oils [5, 7, 16, 27]. Viscosity measurements were began at 100 °C and subsequent measurements were made as the temperature was decreased in 5 °C increments. The precision for dynamic viscosity measurements was set to allow for not more than a 0.14% (instrument preset) change in dynamic viscosity per min beginning immediately after the measuring temperature had stabilized. Stable measurements of dynamic viscosity were obtained down to the lowest temperature tested, 5 °C, for all oils excluding GA-01R.

Differences in dynamic viscosity became more obvious as the temperature decreased, with the three high-oleic oils having both the highest dynamic and/or kinematic viscosity (Fig. 4). Like density, viscosity is a function of molecular size and structure with increases typically occurring for larger and/or more extended types of molecules [19]. Viscosity is also a function of intermolecular attractions between molecules, with stronger attractions characteristic of liquids with higher viscosities [28]. Comparison of methyl esters of the same chain length (18 carbons) but with differing degrees of unsaturation, found dynamic viscosity to follow the order methyl oleate (1 double bond) > methyl stearate (saturate) > methyl linoleate (2 double bonds) > methyl linolenate (3 double bonds) [28]. These authors attribute this observation to increased intermolecular interactions between π electrons of double bonds among the methyl esters, and the hypothesis that these interactions are geometrically favored in oleates as compared to linoleates or linolenates. Alternatively, the increased nonlinearity of the methyl oleates as compared to the saturated and/or multiple double bond species, as discussed previously for the current oil density observations, could also contribute to the data trend of Rodrigues et al. [28]. Similar hypotheses are proposed to explain the increased viscosities of the high-oleic oils for the current data; that is, the molecular conformation of the triglycerides present in the high-oleic peanut promote higher viscosities as a result of the increased content of oleic acid coupled with the concurrent decrease in linoleic acid. At higher temperatures, viscosity measurements were more similar among the various oils, meaning the increased thermal energy effectively minimized both structural differences and differences in intermolecular interactions among the oil molecules, which ultimately normalizes viscosity data. Numerous statistical differences in dynamic viscosity were observed at 10 and 90 °C (Table 3), which reflects both the homogenous nature of these oils, and the high accuracy and precision of the viscosity meter used for these measurements.

Viscosity–temperature data for vegetable oils are well established to follow variants of an Arrhenius type relationship [5, 9, 19]. Recently, Fasina et al compared three different models, the Arrhenius equation, the power law equation and the modified Williams–Lanel–Ferry (WLF) equation to describe the effects of temperature on the viscosities of 12 different vegetable oils [5]. Of the three models, the modified WLF equation gave the best fit. Accordingly, this equation was used to model the dynamic viscosity/temperature data for the current peanut oils. The modified WLF equation is found below:

where η is the dynamic viscosity, T is the absolute temperature in Kelvin and “a” and “b” are constants derived from the model. Data for the constants “a” and “b” are summarized in Table 4. Constants derived for the cultivar, GA-01R, were unevenly skewed as compared to other samples as there was no viscosity data available for this oil at 5 °C. Note that removing viscosity data for 5 °C from the model fitting exercise shifted the values of constants “a” and “b” for all cultivars to values more similar to that of GA-01R (data not shown). Excluding GA-01R, values of “a” ranged from 0.842 to 0.859 and values of “b” ranged from −236.8 to −233.7. Fasina et al. previously reported values of 0.986 and −226.3 for “a” and “b” respectively for peanut oil [5]. R 2 values were greater than 0.99 (data not shown) for all cultivars of peanut oil, suggesting the overall goodness of fit for the model was acceptable in each case. Viscosity data covered temperatures from 100 to 5 °C, a temperature range that was comparable to the range of 95 to 5 °C that was measured by Fassina et al. [5], meaning it is appropriate to compare mean square error values, or the measure of variation not explained by the model, between the two studies. MSE values for the current work range from 0.020 to 0.029 (Table 4), values which are equivalent to the data of [5].

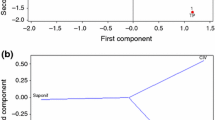

Dynamic viscosity of individual oils increased in a positive, curvilinear manner with increasing density, with these changes being a function of the decreasing temperature (Fig. 5a). Note the temperature axis on Fig. 5a is not perfectly to scale and is added to aid data interpretation. A negative, linear relationship (R 2 ≥ 0.95, all temperatures tested) for dynamic viscosity as a function of increasing oil density was observed among the various oils at any specific temperature. This relationship is seen in its totality in Fig. 5a and at 100 °C and 10 °C in Fig. 5b and c, respectively. As the temperature decreased, the slope of the dynamic viscosity/density data among oils became steeper (Figs. 5a, 6a). The slopes of these lines have units of kinematic viscosity, and this calculated kinematic slope decreased exponentially with decreasing temperature (Fig. 6a). Furthermore, as the temperature decreased, the calculated y-intercept of the dynamic viscosity/density data increased exponentially (Fig. 6b).

Dynamic viscosity data as a function of temperature. a Dynamic viscosity versus density for the various peanut oils from 90 to 10 °C. Temperature axis is not perfectly to scale, added to aid data interpretation. b Dynamic viscosity versus density of the various peanut oils at 100 °C. Straight line is best linear fit. c Dynamic viscosity versus density of the various peanut oils at 10 °C. Straight line is best linear fit. All symbols appear on the graph

Linear model parameters for dynamic viscosity versus density data of peanut oils calculated at different measuring temperatures. a Slope of best linear fit for dynamic viscosity versus density graphs at different measuring temperatures. b Y-intercept of best linear fit for dynamic viscosity versus density graphs at different measuring temperatures

No obvious linear correlations were observed with total tocopherols and oil physical properties, although the three high-oleic oils did have significantly (p < 0.05) higher levels of total tocopherols as compared to most of the other samples (Fig. 7). GA-02C and AT-201 had the highest content total tocopherols of all oils, whereas FR-458 had a total tocopherol content that was significantly (p < 0.05) greater than 3 of the oils and significantly similar to 2 non high-oleic oils (C11-239 and GA-Green). Furthermore, no obvious correlations were observed in plots of the individual tocopherols, α, β, δ and γ and oil physical properties (data not shown). Viscosity is established to increase with increasing levels of oxidation, and this is attributed to the formation of polymeric structures within the oil as well as increased levels of saturation [16]. Therefore, the increased content of tocopherols in the high-oleic oils may minimize viscosity changes in these samples under conditions that promote oxidative deterioration, i.e. frying. Others have seen an increase in α tocopherol with increasing levels of linoleic acid across a range of vegetable oils [29], but this was not observed in the current data (data not shown).

References

Sanders TH (2002) Groundnut (peanut) oil. In: Gunstone FD (ed) Vegetable oils in food technology: composition, properties and uses. CRC, Boca Raton, pp 231–243

Okeefe SF, Wiley VA, Knauft DA (1993) Comparison of oxidative stability of high-oleic and normal-oleic peanut oils. J Am Oil Chem Soc 70:489–492

Pattee HE, Isleib TG, Moore KM, Gorbet DW, Giesbrecht FG (2002) Effect of high-oleic trait and paste storage variables on sensory attribute stability of roasted peanuts. J Agric Food Chem 50:7366–7370

Bolton GE, Sanders TH (2002) Effect of roasting oil composition on the stability of roasted high-oleic peanuts. J Am Oil Chem Soc 79:129–132

Fasina OO, Hallman H, Craig-Schmidt M, Clements C (2006) Predicting temperature-dependence viscosity of vegetable oils from fatty acid composition. J Am Oil Chem Soc 83:899–903

Halvorsen JD, Mammel WC, Clements LD (1993) Density-estimation for fatty-acids and vegetable-oils based on their fatty-acid composition. J Am Oil Chem Soc 70:875–880

Noureddini H, Teoh BC, Clements LD (1992) Viscosities of vegetable-oils and fatty-acids. J Am Oil Chem Soc 69:1189–1191

Noureddini H, Teoh BC, Clements LD (1992) Densities of vegetable-oils and fatty-acids. J Am Oil Chem Soc 69:1184–1188

Rodenbush CM, Hsieh FH, Viswanath DS (1999) Density and viscosity of vegetable oils. J Am Oil Chem Soc 76:1415–1419

Magne FC, Wakeham H (1944) Viscosities and densities of hydrogenated peanut oils. Oil and Soap 21:347–349

ASTM d 4052–96 (2002) e1 Standard test method for density and relative density of liquids by digital density meter

ASTM d 7042–04 Standard test method for dynamic viscosity and density of liquids by stabinger viscometer (and the calculation of kinematic viscosity)

Williams EJ, Drexler JS (1981) A non-destructive method for determining peanut pod maturity. Peanut Sci 8:134–141

Sivakumaran K, Goodrum JW, Bradley RA (1985) Expeller optimization for peanut oil production. Trans ASAE 28:316–320

Geller DP, Goodrum JW (2000) Rheology of vegetable oil analogs and triglycerides. J Am Oil Chem Soc 77:111–114

Santos JCO, Santos IMG, Souza AG (2005) Effect of heating and cooling on rheological parameters of edible vegetable oils. J Food Eng 67:401–405

Nik WBW, Ani FN, Masjuki HH, Giap SGE (2005) Rheology of bio-edible oils according to several rheological models and its potential as hydraulic fluid. Ind Crop Prod 22:249–255

Steffe JF (1996) Rheological methods in food process engineering, 2nd edn. Freeman, East Lansing

Teeter HM, Cowan JC (1956) Viscometric properties of higher fatty acids and their derivatives. J Am Oil Chem Soc 33:163–169

Bannon CD, Craske JD, Hai NT, Harper NL, Orourke KL (1982) Analysis of fatty-acid methyl-esters with high-accuracy and reliability II. Methylation of fats and oils with boron trifluoride-methanol. J Chromatogr 247:63–69

AOCS Ce 1-62 (2004) Fatty acid composition by gas chromatography. In: Official methods and recommended practices of the AOCS, edited by American Oil Chemists’ Society, Champaign

Hashim IB, Koehler PE, Eitenmiller RR, Kvien CK (1993) Fatty acid content and tocopherol content of drought stressed florunner peanuts. Peanut Sci 20:21–24

AOCS Cd 1c-85 (2004) Calculated iodine value. In: Official methods and recommended practices of the AOCS, edited by American Oil Chemists’ Society, Champaign

Singleton JA, Pattee HE (1987) Characterization of peanut oil triacylglycerols by HPLC, GLC and EIMS. J Am Oil Chem Soc 64:534–538

deMan JM (1990) Principles of food chemistry, 2nd edn. Van Nostrand Reinhold, New York

Oda M, Ueno T, Kasai N, Takahashi H, Yoshida H, Sugawara F, Sakaguchi K, Hayashi H, Mizushina Y (2002) Inhibition of telomerase by linear-chain fatty acids: a structural analysis. Biochem J 367:329–334

Rabelo J, Batista E, Cavaleri FW, Meirelles AJA (2000) Viscosity prediction for fatty systems. J Am Oil Chem Soc 77:1255–1261

Rodrigues JD, Cardoso FD, Lachter ER, Estevao LRM, Lima E, Nascimento RSV (2006) Correlating chemical structure and physical properties of vegetable oil esters. J Am Oil Chem Soc 83:353–357

Kamal-Eldin A, Andersson R (1997) A multivariate study of the correlation between tocopherol content and fatty acid composition in vegetable oils. J Am Oil Chem Soc 74:375–380

Author information

Authors and Affiliations

Corresponding author

Additional information

The use of trade names in this publication does not imply endorsement by the United States Department of Agriculture-Agricultural Research Service.

About this article

Cite this article

Davis, J.P., Dean, L.O., Faircloth, W.H. et al. Physical and Chemical Characterizations of Normal and High-Oleic Oils from Nine Commercial Cultivars of Peanut. J Am Oil Chem Soc 85, 235–243 (2008). https://doi.org/10.1007/s11746-007-1190-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-007-1190-x