Abstract

Three hundred and fifty novel lipases and esterases discovered from environmental DNA samples were characterized for their fatty acid profile using GC-analysis. Enzymes were selected for further study based on activity and fatty acid chain length specificity. Additional characterization was based on enzyme activity towards tributyrin and 4-methylumbelliferyl butyrate, and enzyme heat stability. Several lipases were identified, which show high specificity towards short-chain fatty acids similar to pregastric lipases from kid and calf and a lipase from Mucor javanicus. Additionally, the metagenome-derived enzymes were thermostable. Selected metagenomic lipases were immobilized on Celite and used for the synthesis of structured triglycerides.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lipases (EC 3.1.1.3) are widely distributed in Nature and are found in plants, mammals and microorganisms. Their natural function is the hydrolysis of triglycerides, and they are classified according to their specificity towards the position of a fatty acid along the glycerol backbone (e.g., sn1,3-specific lipases), fatty acid chain-length or degree of fatty-acid saturation [1]. They are widely used in lipid modification, but have also found numerous applications in other areas, such as the detergent industry and in organic synthesis [2].

A decade ago, only a handful of lipases from a specific class were readily available. These enzymes had been identified using classical screening technology i.e. isolation of lipase-producing microorganisms, purification of the active proteins, reverse genetics to clone the corresponding gene, and expression in a heterologous host. As only a fraction (estimated to less than 1%) of the microorganisms in an environmental sample can be grown using standard cultivation technology, the vast majority of nature’s reservoir of diversity escaped discovery until recently. With the advent of the metagenome approach [3, 4] this diversity is now more readily accessible, resulting in an exponential increase in the number of potentially biocatalysts. For example, more than 130 novel nitrilases were found by screening environmental DNA libraries [5], significantly expanding the number and diversity from the pool of 20 nitrilases described previously. Similarly, metagenomic lipases and esterases have been characterized as biocatalysts on a variety of substrates [6, 7] and shown to possess unique and novel properties.

In a further effort to explore the diversity of the metagenome contained in environmental libraries, more than 350 unique lipase (and esterase) genes were cloned and the enzymes produced recombinantly. Having access to such a large number of biocatalysts necessitates having an efficient, fast and reliable screen to enable biochemical characterization. In the case of lipase substrate specificity, profiling on triglyceride mixtures containing a broad range of fatty acids would meet this need. Milk fat triglycerides contain all even numbered saturated fatty acids from C4 to C18, as well as oleic acid (C18:1) [8], and so milk fat is a suitable substrate for this screen (Table 1). Furthermore, screening on this substrate opens up the possibility of discovering a metagenomic lipase that could be used in cheese making as an alternative to the mammalian lipases currently in use.

In this work, 350 novel metagenomic lipases and esterases were characterized with respect to their fatty acid selectivities and their potential application in lipid modification.

Experimental Procedures

Lipases and Chemicals

All 350 metagenomic enzymes were supplied by Verenium Corporation as lyophilized samples. Pregastric lipases from kid and calf, and a lipase from Mucor javanicus were from commercial suppliers. Immobilized lipase from Rhizomucor miehei (RMIM) was from Novozymes (Bagsvaerd, Denmark). Full-fat ultra-high temperature treated milk (UHT milk, 3.5% fat) was bought at a local grocery. The heat treatment ensures that endogenous lipases are destroyed. All chemicals were analytical grade and supplied by Fluka, Roth and Sigma-Aldrich.

Experimental Conditions, Extraction and Methylation of Free Fatty Acids

10 mg enzyme preparation was dissolved in 800 μl full fat UHT milk (pH 6.4) and incubated overnight at 40 °C at 1100 rpm in an Eppendorf thermoshaker. Released fatty acids (including mono-, di-, and triglycerides) were extracted according to Folch et al. [9]. Thus, 100 μl samples were extracted twice with 1 ml CHCl3:MeOH:4 N HCl (2:1:0.075 v/v) solution. Pentanoic and pentadecanoic acid (5 mM) served as internal standards and were added to the extraction solvent prior to further treatment. Excess solvent was evaporated in a nitrogen stream, the residue was redissolved in 500 μl n-hexane and 100 μl freshly prepared HCl solution (20% in MeOH), then transferred to glass vials with Teflon-sealed lids. The mixture was incubated with vigorous shaking at 85 °C for 15 min to obtain the fatty acid methyl esters (FAME). Next, distilled water (200 μl) was added and well mixed to remove water-soluble substances that would otherwise interfere with gas chromatographic analyses. The upper phase was removed and dried over anhydrous sodium sulfate prior to gas chromatographic analysis. Milk untreated with enzyme served as a control, and it was found that no transesterification occurred.

Gas Chromatographic Analyses

FAME were analyzed on a Hewlett-Packard 5890 Series II Plus gas chromatograph using a FFAP column (fused silica, FFAP-crosslinked, 25 m × 0.2 mm). The gas chromatograph was programmed as follows: injector 225 °C, detector 250 °C, start temperature 60 °C (1 min), then heating at 16 °C/min until 215 °C, the final temperature was held for 2 min. The injected sample volume was 0.1 μl. The quantification of the fatty acids was performed by comparison of the peak area of each methyl ester peak with that of the internal standards.

Determination of Enzyme Activity on Triglycerides

The activity of lipases (1–10 mg, depending on specific activity) was measured by hydrolysis of triglycerides using a pH-stat titration. The assay solution consisted of 5% tributyrin (v/v) and 2% gum arabic (w/v) dispersed in distilled water. The solution was emulsified with an Ultra Turrax for 5 min at high speed. The titration point was set to pH 5.8, and fatty acids released were titrated automatically with 0.01 mM NaOH. One unit of lipase activity was defined as the amount of enzyme releasing 1 μmol fatty acid per min under assay conditions. Activity values were corrected for autohydrolysis (<0.01 U/mg), which was determined in the absence of enzyme. All measurements were performed in triplicate.

Umbelliferyl Assay

The temperature optimum of lipases was determined using 4-methylumbelliferyl butyrate (4-MUB) in a microtiterplate (MTP) assay. Lipase hydrolysis yields the fluorescent compound 4-methylumbelliferone (4-MU), which was quantified using an excitation wavelength of 355 nm and an emission wavelength of 460 nm. Enzyme samples were incubated in an Eppendorf thermoshaker at 65 °C for 90 s or at 85 °C for 30 s and then stored on ice prior to fluorimetric measurement. 150 μl of these treated enzyme solutions (10 mg dissolved in 1 ml milk) were transferred to the wells of an MTP and mixed with 150 μl substrate (final concentration 90 μM 4-MUB in phosphate buffer pH 5.7, 50 mM) using the pump in the fluorimeter (Galaxy-Fluostar, BMG, Offenburg, Germany). The pH of this milk-buffer solution was adjusted to pH 6.0, the temperature was set to 37 °C, and the plate was shaken between the measurement cycles.

Alcoholysis of Triolein and Synthesis of 1,3-Diolein

The reaction was performed according to the method of Soumanou and Bornscheuer [10]. Triolein (20 mmol), ethanol (20 mmol) and 10% (w/w) immobilized RMIM were mixed in a 50-ml glass flask. The reaction mixture was incubated in a water bath at 40 °C and agitated with a magnetic stirrer at 200 rpm. After 5 and 10 h, 20 mmol ethanol were added. Reaction progress was monitored using thin layer chromatography (TLC) and Iatroscan analysis. After 24 h, the reaction was terminated by removal of immobilized lipase. The desired ethyloleate was separated on preparative scale by silica gel column chromatography (petrolether:diethylether, 7:1, v/v) yielding 80% product. The purity was checked using TLC (n-hexane:diethylether:acetic acid 87:13:0.2 v/v/v) and Iatroscan (benzene:chloroform:acetic acid, 50:30:0.5, v/v/v).

The 1,3-diolein was produced according to a published procedure [11]. Glycerol (12 mmol) was mixed with 1 g silica gel in a 50 ml glass flask until the mixture became dry. The purified ethyloleate (24 mmol), 20 ml tert-butyl-methyl-ether (MTBE) and 0.5 g immobilized RMIM were then added. The ethanol produced was removed from the reaction mixture by activated molecular sieve (4 Å). All reaction compounds were adjusted to a defined water activity (a w = 0.11) using saturated salt solutions overnight prior to the reaction [12]. The reaction progress was monitored by TLC and Iatroscan analysis. The purification of the regioisomerically pure 1,3-diolein was carried out using silica gel column chromatography. In the first separation step, an n-hexane:diethylether gradient system (5:1-1:1 v/v) was used, followed by a chloroform:acetone (96:4 v/v) eluent mixture. The identification of the desired 1,3-diolein was performed by TLC (chloroform:acetone 96:4 v/v), Iatroscan (conditions see above) and NMR-spectroscopy (1H-NMR (300 MHz, CHCl3), δ 0.88 (t, 6 H, J = 7.0 Hz, CH3), δ 1.26–1.30 (m, 40 H, CH2 group of fatty acid chain length), δ 1.63 (t, 4 H, J = 7.3 Hz, COOCH2CH2), δ 2.02 (m, 8 H, CHCH2), δ 2.34 (t, 4H, J = 7.7 Hz, COOCH2), δ 4.07–4.20 (5 H, glycerol backbone), δ 5.34 (m, 4 H, CH)).

Lipase Immobilization

Selected Verenium enzymes were immobilized by adsorption on Celite 545. For this, 50 mg lipase were dissolved in 1.5 ml sodium phosphate buffer (pH 7.5, 50 mM) and afterwards mixed with 500 mg support. The solution was stirred for 15 min. Chilled acetone was added in small portions and the preparation was collected by filtration. After several washing steps with acetone, the filtrate was dried overnight under vacuum.

Synthesis of 1,3-Dioleyl-2-palmitoyl-sn-glycerol

For this, purified 1,3-diolein (54 μmol) and vinylpalmitate (80 μmol) were dissolved in 1 ml n-hexane in 1.5 ml glass vials. All reaction components were adjusted before the reaction to a fixed water activity (a w = 0.11) using saturated salt solution [12]. Then activated molecular sieves (3 Å) and 20 mg immobilized enzyme were added and the reaction mixture was incubated at 40 °C and 1,000 rpm. The reaction progress was monitored by TLC (n-hexane:diethylether:acetic acid, 70:30:1, v/v/v) and Iatroscan (benzene:chloroform:acetic acid, 50:30:0.5, v/v/v) analysis.

HPLC Separation of Triacylglycerols

The composition of the structured triglycerides was determined by HPLC on a Chromspher 5 Lipids column (250 × 4.6 mm, Varian, Darmstadt, Germany) with an evaporative light-scattering detector (65 °C, 1.5 ml/min nitrogen) at a column temperature of 40 °C and a flow rate of 1 ml/min using 0.5% acetonitrile in n-hexane as solvents [13].

Results and Discussion

Preparation of FAME and Gas Chromatographic Analysis

The chosen method to monitor lipase selectivity was conversion of released FA to FAME, followed by quantitation of the FAME by gas chromatography. However, using complex triglyceride mixtures as lipase substrates presents certain challenges. First, the released FA must be transferred from the oil–enzyme-aqueous emulsion to organic solvent without bias. In the case of milk fat as substrate, this is particularly critical due to the high solubility of short-chain fatty acids in aqueous solution. For instance, Anderson et al. reported about 95% loss of caprylic acid and 75% loss of capric acid at pH 6.6 [14]. By lowering the pH to below the pKa of the FA carboxylates, efficient and unbiased extraction of all milk fat FA could be achieved (Fig. 1).

Effect of the addition of HCl solution ([4N] in 800 μl extraction solvent) on the extraction of milk fatty acids from samples treated with pregastric kid lipase. Fatty acids from C4:0 to C18:1 (see Table 1 for types of fatty acids, stearic acid is not included in the figure) are shown from left to right. No additional benefit was obtained above addition of 40 μL 4 N HCl

The second challenge of this method is to ensure that FA are quantitatively converted to FAME without methanolysis of triglycerides that are unreacted with lipase or mono- and diglycerides formed by lipase action. This goal was achieved by applying acid catalysis to the methylation reaction [15]. FA released by lipase action were quantified (as FAME) by comparison to internal standards (C5 and C15 fatty acids). Use of a negative control reaction, to which no enzyme was added, allowed subtraction of background free FA from the data. The kid lipase was used as a benchmark enzyme to compare lipase performance.

In order to classify the 350 metagenomic enzymes with respect to their fatty acid chain-length profile, the peak areas were calculated using Eq. 1. Enzymes which have a value of X ≥ 0.8 preferentially hydrolyze short chain fatty acids. For instance, the kid and calf lipases yielded values of X = 1.3 and 1.0, respectively. A value of Y ≥ 30,000 indicates a lipase with sufficiently high specific activity to be potentially useful. The kid and calf lipases have activity equivalent to Y = 66,932 and 100,955 per unit, respectively.

Calculation of selectivity (X) and activity (Y) parameters from peak areas of each fatty acid as determined by GC analysis.

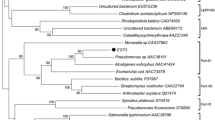

About 25% of the metagenomic enzymes showed good activity on milk fat, as determined by their Y-values, but the great majority of these enzymes did not have the desired FA specificities towards short chain fatty acids, since their X-values were less than 0.8. However, more than ten lipases were identified by their X–Y-pair to show a similar FA specificity to kid and calf lipases (Fig. 2) and had good activity. It is worth noting that many of the metagenomic lipases are derived from DNA sampled from extreme environments. Thus the observed low activities for some enzymes on milk fat may be attributable to the ambient temperature of the assays described here, and under different reaction conditions these enzymes may display useful biocatalytic properties. The observed low activities may also be due to preferences for other substrates.

Plot of X–Y (selectivity-activity) pairs for each enzyme calculated using Eq. 1. The box marks enzymes with desired properties. The value for kid enzyme is indicated with a triangle, the calf lipase is marked by a square

It has previously been suggested that animal lipases release mainly short chain fatty acids and microbial lipases prefer long-chain fatty acids [16]. Several of the microbial lipases tested here had similar short-chain FA release profiles to the benchmark mammalian lipases (Fig. 3), suggesting that microbial lipases can also show short-chain FA activity. However, these enzymes generally release greater relative quantities of C18 FA than either the kid or calf enzymes. Indeed, the overall profile of the metagenomic enzymes most closely resembled the FA release profile of the Mucor javanicus lipase.

Activity Determination using pH-stat

Ten enzymes with good activity on short-chain fatty acids in the milk-fat assays, were further characterized on tributyrin using a pH-stat assay to follow the reaction. Enzyme specific activity (U/mg lyophilized enzyme sample) was measured at 40 °C and pH 5.8 to compare the enzymes to the kid lipase operating at close to optimum conditions (37 °C, pH 5.5–6.2) [17]. Under these conditions the pregastric lipases from kid and calf had low specific activities slightly above the detection limit, and >100 mg of each enzyme was required in the assay (Table 2). Of the metagenomic lipases tested, three also had low specific activities (<1), whereas four had moderate specific activities (1–10), and lipase #10 had very high activity (87.2 U/mg) on tributyrin. Furthermore, the specific activity of this lipase on tributyrin was found to increase to >100 U/mg when the reaction temperature was increased to 90 °C. Thus although these microbial lipases did not show the same short-chain FA preference on milk-fats as the mammalian lipases, they are potentially much more active.

Thermostability Assay

The data showing that lipase #10 is thermostable and may even be thermophilic prompted examination of the thermotolerance of other metagenomic lipases. Response to temperature of lipases active on short-chain FA is also of interest in cheese making since elevated temperatures are often used for the formation and extrusion of curd. A convenient substrate to examine the influence of the heat treatment on enzyme activity is 4-MUB [18], as the released fluorophore 4-UM can be easily quantified in a fluorimeter and the reaction can be performed in microtiterplates. The residual activities of selected enzymes were first determined after incubation for 90 s at 65 °C followed by heating for 30 s at 85 °C (Fig. 4). Under these conditions the kid and calf lipases retained greater than 75% of their activity after heating at 65 °C, and less than 50% of activity after heating at 85 °C. In contrast, all the metagenomic lipases tested retained greater than 60% activity after heating at 85 °C, and several retained greater than 80% activity after this treatment.

In summary, characterization of a large number of the metagenomic lipases on milk triglycerides identified several enzymes that showed high activities on short-chain FA, and may have utility in cheese making.

Synthesis of 1,2-Oleoyl-3-palmitoyl-sn-glycerol (OOP) and 1,3-Oleoyl-2-palmitoyl-sn-glycerol (OPO)

Further examination of the profile of fatty acids released from milk triglycerides by the metagenomic lipases suggested an additional application for these enzymes. Structured triglycerides such as OPO have application in the food industry and can be synthesized by lipases that exhibit FA specificity. The method used for synthesis of OOP and OPO was transesterification of 1,3-diolein with vinylpalmitate [19, 20[t1]]. The metagenomic lipases #1, #8 and #10 were immobilized on Celite 545 and reacted with substrates for 36 h. Lipase #1 showed only low activity, whereas lipases #8 and #10 had good activity under the reaction conditions. Lipase #10 yielded a mixture of different triglycerides (Fig. 5) with PPP as the major species. In contrast, #8 yielded mainly OOP and OPO (approx. 10:1), with very low background of other triglycerides. Thus the latter metagenomic enzyme exhibits tight and potentially useful FA specificity.

The environmental metagenome contains enormous and largely untapped functional diversity of enzymes. In this work, 350 metagenomic lipases were screened with respect to their fatty acid profile using milk fat as substrate. Further characterization of selected enzymes revealed interesting and novel properties that may have potential application in a variety of fields. Accessing the metagenomic pool of lipases and esterases can be an immediate source of novel biocatalysts, or yield enzymes that can be further specialized by directed evolution.

References

Bornscheuer UT (ed) (2000) Enzymes in lipid modification. Wiley-VCH, Weinheim

Bornscheuer UT, Kazlauskas RJ (2006) Hydrolases in organic synthesis—regio- and stereoselective biotransformations, 2nd edn. Wiley-VCH, Weinheim

Handelsman J (2005) Sorting out metagenomes. Nat Biotechnol 23:38–39

Short JM (1997) Recombinant approaches for accessing biodiversity. Nat Biotechnol 15:1322–1323

Robertson DE, Chaplin JA, DeSantis G, Podar M, Madden M, Chi E, Richardson T, Milan A, Miller M, Weiner DP, Wong K, McQuaid J, Farwell B, Preston LA, Tan X, Snead MA, Keller M, Mathur E, Kretz PL, Burk MJ, Short JM (2004) Exploring nitrilase sequence space for enantioselective catalysis. Appl Environ Microbiol 70:2429–2436

Kourist R, Krishna H, Weiner DP, Bornscheuer UT (2007) Identification of a metagenome-derived esterase with high enantioselectivity in the kinetic resolution of arylaliphatic tertiary alcohols. Org Biomol Chem 5:3310–3313

Baumann M, Hauer BH, Bornscheuer UT (2000) Rapid screening of hydrolases for the enantioselective conversion of “difficult-to-resolve” substrates. Tetrahedron Asymmetry 11:4781–4790

Gresti J, Bugaut M, Maniongui C, Bezard J (1993) Composition of molecular species of triacylglycerols in bovine milk fat. J Dairy Sci 76:1850–1869

Folch J, Lees M, Stanley GHS (1956) A simple method for the isolation and purification of total lipids from animal tissues. J Biol Chem 226:497–509

Soumanou MM, Bornscheuer UT (2003) Improvement in lipase catalyzed synthesis of fatty acid methyl esters from sunflower oil. Enzyme Microb Technol 33:97–103

Berger M, Laumen K, Schneider MP (1992) Enzymatic esterification of glycerol I. Lipase-catalyzed synthesis of regioisomerically pure 1,3-sn-diacylglycerols. J Am Oil Chem Soc 69:955–960

Goderis HL, Ampe G, Feyten MP, Fouwe BL, Guffens WM, Cauwenbergh SMV, Tobback PP (1987) Lipase-catalyzed ester exchange reactions in organic media with controlled humidity. Biotechnol Bioeng 30:258–266

Adlof R (1995) Analysis of triacylglycerol positional isomers by silver ion High Performance Liquid Chromatography. J High Res Chromatogr 18:105–107

Anderson M, Heeschen W, Jellema A, Kuzdzal-Savoie S, Needs EC, Suhren G, van Reusel A (1991) Determination of free fatty acids in milk & milk products. Bulletin of the International Dairy Federation 265

Christie WW (2003) Lipid Analysis. 3rd edn, vol 15. PJ Barnes & Association, Bridgwater, England

Kwak HS (1989) Statistical patterns of lipase activities in the release of short-chain fatty acid in cheddar cheese slurries. J Food Sci 54:1559–1564

Lai DT, Mackenzie AD, O´Connor CJ, Turner KW (1997) Hydrolysis characteristics of bovine milk fat and monoacid triglycerides mediated by pregastric lipase from goats and kids. J Dairy Sci 80:2249–2257

Prim N, Sanchez M, Ruiz C, Pastor FIJ, Diaz P (2003) Use of methylumbelliferyl-derivative substrates for lipase activity characterization. J Mol Catal B Enzym 22:339–346

Schmid U, Bornscheuer UT, Soumanou MM, McNeill GP, Schmid RD (1999) Highly-selective synthesis of 1,3-oleyl-2-palmitoyl-glycerol by lipase catalysis. Biotechnol Bioeng 64:678–684

Bornscheuer UT, Soumanou MM, Schmid RD, Schmid U (1998) Preparation of symmetrical triglycerides ABA. Eur Pat EP 88:27–9

Breckenridge WC, Kuksis A (1967) Molecular weight distribution of milk fat triglycerides from seven species. J Lipid Res 8:473–478

Pitas RE, Sampugna J, Jensen RG (1967) Triglyceride structure of cows’ milk fat. I. Preliminary observations on fatty acid composition of positions 1, 2, and 3. J Dairy Sci 50:1332–1336

Author information

Authors and Affiliations

Corresponding authors

About this article

Cite this article

Bertram, M., Hildebrandt, P., Weiner, D.P. et al. Characterization of Lipases and Esterases from Metagenomes for Lipid Modification. J Am Oil Chem Soc 85, 47–53 (2008). https://doi.org/10.1007/s11746-007-1161-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-007-1161-2