Abstract

Cuphea PSR23, a semi-domesticated, high-capric-acid hybrid from Cuphea viscosissima × Cuphea lanceolata, is being developed as a potential commercial alternative source of medium-chain fatty acids. The present study evaluated the effects of initial seed moisture and final moisture contents of cooked flaked seed on Cuphea’s pressing characteristics and the quality of the extracted oil. Seeds with 9 and 12% initial moisture contents (MC) were flaked and cooked at different residence times to produce cooked seeds with MC of 3.0–5.5%. Cooked seeds were pressed using a laboratory screw press. Eighty and 84% oil were extracted from cooked seeds with 5.5 and 3.0% MC, respectively. The seeds with 9% initial MC exhibited lower pressing load increase (9.1 per 1% decrease in MC) than the seeds with 12% initial MC (16.4 per 1% decrease in MC). The pressing rate decreased by 3% as the cooked flaked seed MC decreased. The amount of foots in the oil increased from 3 to 6.6% and chlorophyll content increased from 200 to 260 ppm as cooked flaked seed MC decreased from 5.5 to 3.0%. FFA contents were 2.5% for all treatments MC studied. The phosphatide content increased as the cooked flaked seed MC decreased but the amounts were still within the levels of water-degummed oil.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cuphea, of the family Lythraceae, is a large genus of over 200 species of herbs and shrubs growing in the tropics and subtropics of the Americas. Several Cuphea species contain saturated medium-chain fatty acids (MCFAs) [1–3]. MCFAs (C8:0–C12:0) are used in soaps, detergents, cosmetics, lubricants, and food applications. One-half of the MCFAs used by the US soap and detergent industry is obtained from coconut and palm kernel oils, while the other half is from petroleum [4].

Efforts to domesticate Cuphea have progressed over the past three decades. Seed shattering and seed dormancy have been the main hurdles to successful commercialization [5, 6]. A semi-domesticated, high-capric-acid variety with partial seed retention (PSR) was reported by Knapp in 1993 [7]. Cuphea PSR23 is a hybrid between Cuphea viscosissima (a species native to the United States) and Cuphea lanceolata (a species native to Mexico). The seeds weigh 538 g/l (3.3 g/1,000 seeds) and contain up to 35% oil. The oil typically contains around 70% capric, 9% oleic, 6% palmitic, 5% linoleic, 4% myristic, and 3% lauric acids [8]. Cuphea PSR23 has been the subject of field studies for the past 6 years in west central Minnesota and central Illinois to establish the best agronomic management practices in preparation for commercial production [9–13].

Recent seed increases in Cuphea provided sufficient amounts of seed to conduct oil extraction studies, and at the same time, produce much needed oil for product development and applications testing. The first report on oil extraction from Cuphea seeds was for prepressing cooked whole seeds followed by solvent extraction of the press cake [14]. The objective of the present study was to evaluate the effects of initial seed and final moisture contents (MC) of cooked flaked seeds on continuous screw pressing characteristics of the seed and quality of crude press oil.

Materials and Methods

Cuphea seed was obtained from the 2004 harvest in central Illinois. To obtain a homogeneous seed lot, clean seeds from different plots were mixed by using a GT grain dryer (Model 345XL, GT Manufacturing, Inc., Clay Center, KS, USA). The mixed seeds were then stored in covered 0.8 m3 polyethylene bins. The seeds were used either as is (about 9% MC) or adjusted to 12% MC as follows: 45-kg batches of 12% MC seeds were prepared by spraying the seeds with distilled water as the seed was loaded into a baffled 200-l stainless-steel drum; the seed in the drum were tumbled for 5 min and allowed to stand overnight; the seeds were tumbled again and allowed to equilibrate for at least 24 h; and the seeds were flaked by using a pair of smooth roller mills (Model SP900-12 Roller Mill, Roskamp Champiom, Waterloo, IA, USA) set for a 0.25-mm gap.

Cooking Conditions

The seeds were cooked and dried by using a 3-deck seed cooker (Laboratory Seed Cooker/Conditioner Model 324, French Oil Mill Machinery Company, Piqua, OH, USA). Each deck held up to 0.08 m3 (59 cm in diameter × 29.2 cm high) of material. The cooker was preheated using 0.34 MPa steam for about an hour before seed cooking. The flaked seed was loaded immediately into the seed cooker. The sweeper arm on each deck (mounted to a common vertical shaft) guided the seed to the chute leading to the next deck below. The 45-kg (0.094-m3) flaked seed filled the bottom deck and about 5 cm deep in the middle deck. To insure uniform cooking, the flaked seeds in the cooker were recirculated by running the discharge screw and returning the seeds to the top of the cooker. The seed temperature in each deck was monitored and controlled to not exceed 110 °C thereby preventing overcooking or scorching. Cooking residence times were varied to obtain cooked seeds with different moisture contents. The cooked flaked seeds were unloaded into covered 120-l polyethylene containers and immediately screw pressed. Samples of seed before and after cooking were analyzed for moisture and oil contents.

Screw Pressing

The cooked flaked seeds were screw pressed using a Heavy Duty Laboratory Screw Press (Model L 250, French Oil Mill Machinery Company). The cored main barrel (or cage) had a diameter of 8.9 cm (Fig. 1). The barrel’s length/diameter (L/D) ratio was 8.3. The cage had four drainage sections (14.0 cm/section). Each section of screen bars (feed to discharge) was spaced using 0.51-, 0.38-, 0.25-, and 0.18-mm shims. The screw consisted of alternating worms and collars (Fig. 2). The compression ratio for this arrangement was 2.7. The main drive was powered by a 14.9-kW (20-hp) electric motor and the main shaft rotational speed was 23 rpm, which was at the lower end of the 20–30 rpm recommended by the manufacturer for full pressing. The cage was preheated to 82 °C using tempered water. A cone gap of 4.1 cm, measured between cone bracket and cone mounting plate, was used (Fig. 3). The cone gap was adjusted by using the 3-position directional valves and the hand pump of the hydraulic cone cylinder (not shown).

Cooked seeds were introduced slowly, while monitoring the press load so as not to exceed 100%. The feed rate was controlled by a variable-speed screw conveyor. As soon as the feedworm was fully covered, water to cool the shaft was started. The shaft cooling outlet water temperature was maintained at 60 °C. The press load reading was allowed to stabilize (about 10 min) before sampling. Pressing or feed rate was determined by adding the weights of crude oil and press cake collected over 5 min. Three samples of crude oil and press cake were also collected in the last 20 min of each run. The press cake was analyzed for moisture and oil contents. The oil was analyzed for solids (foots), free fatty acid, chlorophyll, phosphorus, magnesium, and calcium contents. Starting seeds (uncooked), oven-cooked whole seeds, and cooked flaked seeds were also analyzed for protein solubility.

Analytical Methods

Moisture and oil contents of the seed and press cake samples were obtained by following AOCS official methods Ba 2a–38 and Ba 3–38 [15], respectively. The solids in the crude oil were quantified using AOCS official method Ca 3a–46 [15]. The free fatty acid (expressed as capric acid) in the crude oil was determined using a Methrohm 702 SM Titrino (Methrohm, Ltd., Herisau, Switzerland) following AOCS official method Ca 5a–40 [15]. The chlorophyll content (as pheophytin) was determined following the AOCS official method Cc Ba–55 [15]. Phosphorus (for total phosphatide content) was determined by inductive coupled plasma (ICP) optical emission spectroscopy (Perkin Elmer Optima 4300DV, Perkin Elmer, Wellesley, MA, USA) by following AOCS official method Ca 20–99 [15]. Calcium and magnesium (a measure of nonhydratable phosphatide content [16]) were also determined by ICP following AOCS official method Ca 17–01 [15].

For determining protein solubility, uncooked whole seeds and press cake were ground in a coffee grinder and then defatted using hexane. For a negative control, 10 g of whole seeds was adjusted to 20% MC and placed in a covered aluminum dish. The seed in the covered aluminum dish was cooked in a 110 °C oven for 45 min. The oven-cooked seeds were defatted as described above. Protein was extracted from 0.2 g of the defatted sample with 20 ml sodium bicarbonate–carbonate buffer (pH 10). The maximum solubility of Cuphea proteins is at pH 10 [17]. Nitrogen content in the extract was analyzed by the Kjeldahl method and crude protein was calculated (%N × 6.25).

Statistical Analyses

Linear regression and analysis of variance were performed by using the SigmaStat for Windows version 3.5 (Systat Software, Inc., San Jose, CA, USA).

Results and Discussion

Because of the indeterminate growth habit of Cuphea, the harvested seeds were of varying maturities. The seed was cleaned by screening and aspirating. The clean seed was density-graded by using a gravity table to obtain a heavy fraction (for planting) and lighter fractions (for oil extraction). Typical clean Cuphea seed contains 28–30% oil, while the lighter seeds used in the present study contained of 26.5% oil (db).

Because Cuphea seeds are small, the seed was directly flaked without dehulling. The flaked seed was flattened and round, about 3 mm in diameter. Most of the kernels were still contained inside the split hulls. Some seeds appeared to be intact, but upon closer inspection, they turned out to be unfilled seeds that were not removed during cleaning. Minimal fines were generated even though the seed was not preheated before flaking.

Cooking is another major factor affecting oil expression by rupturing oil cells, reducing oil viscosity, coagulating meal protein, and reducing MC to increase friction [18]. As shown in Table 1, the temperature of the flaked seed with 9% initial MC increased to 65.6 °C after 33 min in the cooker. At this time, the MC of the cooked flaked seeds was reduced by about 47%. The MC in the cooked flaked seed was 3.1% after 54 min of cooking and the temperature was 99 °C. There appeared to be minimal protein denaturation even after 54 min of cooking, as indicated by the small differences in protein contents in the extracts from uncooked seed and cooked flaked seeds (Table 1), which we attributed to the limited amount of moisture in the flaked seed (4.4%) by the time the temperature was high enough to cause protein denaturation. Flaked seed with 12% initial MC dried to 5.5% MC after 35 min of cooking. Cooking time of 72 min was needed to reduce the MC to 3.1%. The final cooked flaked seed temperatures were also higher than that of the cooked flaked seed with 9% initial MC (Table 1). Proteins in the flaked seeds with 12% initial MC and cooked for 72 min also had protein solubility approaching that of the fully cooked seed. This was attributed to the higher moisture in the seed, the higher temperature, and the longer cooking time that the flaked seed was subjected to.

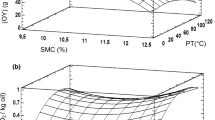

The residual oil contents in the press cake significantly decreased as the moisture content of the cooked flaked seeds decreased (Fig. 4a; Table 2). A similar trend has been reported for canola [19], crambe [20], and flaxseed [21]. No difference in residual oil contents was observed between seeds with 9 and 12% initial MC. The residual oil in the press cake decreased by about 0.4 percentage points per 1% point decrease in MC of cooked seeds. A minimum residual oil of 5.6% was achieved at 3.1% MC cooked seed. Oil recovery was calculated based on 26.5% (db) oil content of the seed and the residual oil in the press cake. Oil recovery ranged from 79.4 to 83.6% as the cooked seed MC decreased from 5.5 to 3.1% (Fig. 4b). In their study on prepressing Cuphea, Carlson et al. [14] reported residual oil contents as low as 8.5% in press cakes produced from whole seeds (initial seed MC was 8%) that were cooked at 102 °C for 90 min (final cooked seed MC of 3%).

The MC of cooked Cuphea seed did not affect the pressing rate of seeds with 9% initial moisture (Fig. 4c; Table 2). On the other hand, cooked seed MC significantly affected the pressing rate (P < 0.05) for Cuphea seed with 12% initial MC. The pressing rate decreased by 3.8% (from 79 to 76 kg/h) as cooked flaked seed MC decreased from 5.7 to 3.1%.

The press load was measured as a percentage of the full-load current (24.8 A) drawn by the 20-hp motor driving the main screw. The load on the press increased significantly as the cooked seed MC decreased (Fig. 4d; Table 2). Singh et al. [20] and Reuber [22] explained that at higher MC, water acts as a lubricant during pressing and lower moisture-containing seed produce more frictional resistance. Cuphea seed with 9% initial MC produced lower motor load increases (9.1 per 1% MC decrease) than the seed with 12% initial MC (16.4 per 1% decrease in MC). Since the seed with 9 and 12% initial MC had similar cooked seed MC going into the press and similar residual oil contents in press cake, the higher press load on cooked seeds with 12% initial MC could be due to the increased frictional resistance caused by texture changes in the cooked Cuphea seeds as the proteins were denatured (Table 1). The amount of foots in the oil increased by 1.0–1.3% per 1% decrease in cooked seed MC (Fig. 5a; Table 2). No difference was observed between the amounts of foots in the crude oil from the 9 and 12% initial MC seed. The foots in the crude oil was around 6% at cooked seed MC of 3.1%. Tighter lining bar spacing than what was used in this study may be needed to reduce the amount of foots.

Initial seed MC and cooking conditions employed did not affect the FFA content of the crude oil (Fig. 5b; Table 2), which remained around 2.5%. This value was higher than what has been reported for other oilseed crops. Typical FFA contents of crude soybean and rapeseed oils are 0.5–1.5 and 0.75%, respectively [23, 24]. We attributed the high FFA level in the Cuphea seed used in the present study to the wide range of seed maturities in the bulk seed due to the indeterminate growth habit.

Chlorophyll contents in the crude oils increased significantly as the MC of the cooked seed decreased (Fig. 5c; Table 2). No difference was observed between seeds with 9 and 12% initial MC. The chlorophyll contents of the crude oils increased by 25–29 ppm per 1% decrease in cooked seed moisture. The amounts ranged from about 200 to 260 ppm at 5.5 and 3.1% cooked seed MC, respectively (Fig. 5c). This high chlorophyll level was about ten times the usual amount (26 ppm) found in crude rapeseed oil [24]. Crude soybean oil typically contains <1 ppm chlorophyll.

Phosphorus (P) in the crude oil is a measure of the total phosphatides content. Magnesium (Mg) and calcium (Ca) are associated with the nonhydratable phosphatides (NHP). P, Mg, and Ca contents increased as the cooked seed MC decreased from 5.5 to 3.1% (Table 3). Similar results were reported by Clark and Snyder [25] for solvent-extracted soybean oil. Increased P in canola press oils from heat-treated seed has also been reported by Prior et al. [26]. On average, the P, Mg and Ca contents in Cuphea oil were 171, 74, and 47 ppm, respectively. It must be noted that the amount of Mg contributed by chlorophyll needs to be taken into account when estimating NHP. In comparison, crude soybean oil typically contains 311–940 ppm of P, 50–150 ppm of Mg and 70–200 ppm of Ca.

The present study showed that oil extraction by full pressing Cuphea seed can be easily accomplished with little seed preparation. Cuphea seed is usually stored at MC <10%, hence drying is unnecessary. Although cooked flaked Cuphea seeds dried to 3% resulted in the highest oil recovery, the longer cooking time and higher press loads increased energy consumption. In addition, the 25% increase in the already high amounts of chlorophyll will substantially increase bleaching requirements. The phosphatide contents of Cuphea oil are low and should not be a major concern. The 2.5% FFA is much higher than for most other crude vegetable oils. Cooking and drying the seed to 4–5% appears to be the optimum for pressing Cuphea seed. Press settings must be optimized for reasonable oil recovery and the amount of foots in the oil.

References

Miller RW, Earle FR, Wolff LA (1964) Search for new industrial oils. IX. Cuphea, a versatile source of fatty acids. J Am Oil Chem Soc 41:279–280

Graham SA, Hirsinger F, Röbbelen G (1981) Fatty acids of Cuphea (Lythraceae) seed lipids and their systematic significance. Am J Bot 68:908–917

Wolf RB, Graham SA, Kleiman R (1983) Fatty acid composition of Cuphea seed oils. J Am Oil Chem Soc 60:103–104

Hardin B (1991) Cuphea––plants with beautiful future––industrial applications of Cuphea: agricultural research, September, pp 16–17

Hirsinger F (1985) Agronomic potential and seed composition of Cuphea, an annual crop for lauric and capric seed oil. J Am Oil Chem Soc 62:76–80

Knapp SJ (1990) New temperate oilseed crops. In: Janick J, Simon JE (eds) Advances in new crops. Timber, Portland, pp 203–210

Knapp SJ (1993) Breakthrough towards the domestication of Cuphea. In: Janick J, Simon JE (eds) New crops. Wiley, New York, pp 372–379

Evangelista RL, Manthey LK (2004) Protein and oil contents and fatty acid compositions of Cuphea PSR23 seeds. In: The American Chemical Society 36th annual Great Lakes regional meeting program and abstracts, Peoria, IL 17–20 October, p 188

Gesch RW, Forcella F, Barbour NW, Phillips B, Voorhees WB (2002) Yield and growth response of Cuphea to sowing date. Crop Sci 42:1959–1965

Sharratt BS, Gesch RW (2004) Water use and root length density of Cuphea spp. Influenced by row spacing and sowing date. Agron J 96:1475–1480

Gesch RW, Cermak SC, Isbell TA, Forcella F (2005) Seed yield and oil content of Cuphea as affected by harvest date. Agron J 97:817–822

Forcella F, Amundson GB, Gesch RW, Papiernik SK, Davis VM, Phippen WB (2005) Herbicides tolerated by Cuphea (Cuphea viscosissima x lanceolata). Weed Technol 19:861–865

Behle R, Isbell TA (2005) Evaluation of Cuphea as a rotation crop for control of western corn rootworm (Coleoptera chrysomelidae). J Econ Entomol 98:1984–1991

Carlson KD, Kleiman R, Pavlik RP (1993) Prepress solvent extraction of Cuphea seeds. J Am Oil Chem Soc 70:1269–1272

American Oil Chemists’ Society (1997) Official methods and recommended practices of the AOCS, 5th edn. AOCS, Champaign

Hvolby A (1971) Removal of nonhydratable phospholipids from soybean oil. J Am Chem Soc 48:503–509

Evangelista RL, Wu YV, Hojilla-Evangelista MP (2006) Characterization of proteins in Cuphea (PSR23) seeds. J Am Chem Soc 83:785–790

Khan LM, Hanna MA (1983) Expression of oil from oilseeds––a review. J Agric Eng Res 28:495–503

Vadke VS, Sosulski FW (1988) Mechanics of oil expression from Canola. J Am Chem Soc 65:1169–1176

Singh KK, Wiesenborn DP, Tostenson K, Kangas N (2002) Influence of moisture content and cooking on screw pressing of crambe seed. J Am Oil Chem Soc 79:165–170

Zhang F, Koseoglu SS, Rhee KC (1994) Effects of expander process on the phospholipids in soybean oil. J Am Chem Soc 71:1145–1148

Reuber M (1992) New technologies for processing Crambe abyssinica, M.S. thesis, Iowa State University, Ames

Sipos EF, Szuhaj BF (1996) Soybean oil. In: Hui YH (eds) Bailey’s industrial oil and fat products, vol 2, edible oil and fat products: oils and oilseeds, 5th edn, Wiley, New York, pp 497–601

Niewiadomski H (1990) Rapeseed-chemistry and technology. Elsevier, Amsterdam, p 170

Clark PK, Snyder HE (1991) Effect of moisture and temperature on the phosphorus content of crude soybean oil extracted from fine flour. J Am Chem Soc 68:814–817

Prior EM, Vadke VS, Sosulski FW (1991) Effect of heat treatments on Canola press oils. I. Non-triglyceride components. J Am Chem Soc 68:401–406

Acknowledgments

The authors thank Billy Deadmond, Jeff Forrester, and Linda Manthey, all of NCAUR, for their technical assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper may contain brand names that are necessary to report factually on available data; however, the USDA neither guarantees nor warrants the standard of the product, and the use of the name by USDA implies no approval of the product to the exclusion of others that may also be suitable.

About this article

Cite this article

Evangelista, R.L., Cermak, S.C. Full-Press Oil Extraction of Cuphea (PSR23) Seeds. J Am Oil Chem Soc 84, 1169–1175 (2007). https://doi.org/10.1007/s11746-007-1142-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-007-1142-5