Abstract

Structuring of semi-crystalline networks in water systems is significant for a variety of industrial applications. In the present work, we investigated the coagel formation from aqueous octyl β -d-galactoside (C8-β-Gal) solutions and characterized the crystal structure and crystallite network in the prepared coagel. Differential scanning calorimetry (DSC) confirmed that the Krafft boundary temperature (T K) is 32–35 °C for C8-β-Gal concentrations below 30 wt% and a knee of the Krafft boundary exists around 2.5 wt% C8-β-Gal concentrations. The addition of NaCl increased T K slightly because of the salting-out effect. Powder X-ray diffraction (PXRD) analysis, field-emission scanning electron microscopy (FE-SEM) and atomic force microscopy (AFM) observations revealed that the coagel is comprised of the three dimensional bundled semi-crystalline network consisting of a “ribbon crystal phase” of hemihydrate crystals. Moreover, the excellent ability of C8-β-Gal to form a macroscopically homogeneous coagel was demonstrated by the comparison with other representative mono-alkylated glycoside’ systems containing octyl a -d-glucoside or dodecyl β -d-glucoside. Persistence of the liquid phase without liquid–liquid phase separation prior to and during the coagel formation was a key factor for the preparation. A novel coagel was obtained from a principal synthetic galactoside.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The solubility line of surfactants in the temperature–concentration phase diagram is called the “Krafft boundary” [1, 2]. Below the boundary, the surfactant molecule precipitates as macroscopically opaque solids or the so-called coagel [1–12].

The coagel consists of entangled three-dimensional crystalline networks with enormous surface area covered with water [3, 4]. Such structuring of crystalline architectures in a water system or a water/oil dispersion system confers a progressive increase in hardness or modifies rheological properties [5–8]. Therefore, the coagel matrices can be potentially used for various applications in the food, pharmaceutical, or cosmetic industries. For instance, the structuring of oil-based products as an alternative to the traditional manufactured solid fats [9], the pearlescent optical effect [10], and promotion of the skin permeation and distribution of drugs [5, 11] by using coagel formulations were recently reported.

The formation of the coagel phase has been widely studied for both ionic and nonionic surfactants including fatty acid salts, phospholipids, sodium dodecyl sulfate (SDS), monoglycerides (MG), and ascorbic acid derivatives [1–12].

Although the sophisticated gelation properties of synthetic glycosides containing modified lipophilic groups have been reported [13, 14], by contrast, coagel formation by n-alkyl glycosides consisting simply of sugar and normal alkyl chain units have been less explored. Because of their simple constituents, n-alkyl glycosides are readily received as renewable, biodegradable [15], and environmentally friendly surfactants and are used in a variety of applications in the food, cosmetics, and pharmaceutical industries [16–18].

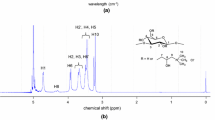

Octyl β -d-galactoside (C8-β-Gal) is a representative mono-tailed glycoside (Fig. 1a) and is commercially available. It is readily synthesized by a bio-catalyzed procedure [19], and therefore it can be categorized as a green-sustainable material. It forms micellar aggregates at concentrations above 16 mM (0.46 wt%) in aqueous solution [15]. The phase behavior in water has been studied for the high glycosides’ concentration range of between 60 and 100 wt% [20, 21] and a high Krafft boundary temperature (T K) was found in water system that starts around 42 °C for the hexagonal (H1) and the cubic (Q1) phases and forms a lamellar gel phase (L β ) below the T K.

We note that the other commercially available glycoside compound, n-octyl β-d-glucoside (C8-β-Glu), which is the structural isomer of C8-β-Gal, does not precipitate above 0 °C because of its low T K [22], whereas the surface active property of C8-β-Glu is well comparable to that of C8-β-Gal in the solution state [15]. This means that the tiny difference in structural arrangement leads to great differences in the crystal structure and solubility in water [23] regardless of the similarity of surface active properties.

Although structural analysis of single-crystal n-alkyl β -d-glycosides has not been performed yet [24], recently grazing-incident wide angle X-ray diffraction (GI-WAXD) analysis of a highly aligned C8-β-Gal crystalline film revealed the formation of a unique C8-β-Gal hemihydrate crystal structure with a high number of formula units in the unit cell (Z) [25]. The lattice constants a, b, and c were found to be twice the bilayer length, nearly bilayer length, related to the interdigitated alkyl chain packing, respectively, and the crystal structure was assumed to be a “ribbon-crystal phase” formed by modulated lamellar structure. On the other hand, the molecular assembled structure and the structuring behaviors of crystalline networks of the precipitate from an aqueous C8-β-Gal solution system had not been investigated yet. Here, we report on the formation of a coagel from aqueous C8-β-Gal micelle solutions (sol) and its structured characteristics.

Materials and Methods

Materials

n-Octyl a -d-glucoside (C8-a-Glu) (Anatrace Inc., USA) and n-dodecyl β -d-glucoside (C12-β-Glu) (Sigma-Aldrich, Germany) were purchased and used as received. n-Octyl β -d-galactoside (C8-β-Gal) was prepared following a procedure similar to the procedure applied for the synthesis of octyl β -d-glucoside in our previous research [22]. In this study, 1, 2, 3, 4, 6-penta-O-acetyl-β -d-galactopyranose was used as the starting material instead of the corresponding glucopyranoside. The total yield was 52.9%. The structure and purity of final product were confirmed by 1H-NMR, 13C-NMR (300-MHz and 75-MHz MVX-300, respectively, VARIAN Inc.), thin layer chromatography (TLC) and elemental analysis. 1H-NMR, CD3OD; d/ppm = 4.19 (d, 1H, H-1), 3.89 (dt, 1H, H-αa), 3.82 (dd, 1H, H-4), 3.74 (dd, 1H, H-6a), 3.72 (dd, 1H, H-6b), 3.42–3.56 (m, 4H, H-αb, H-2, H-3, H-5), 1.60 (m, 2H, β-CH2), 1.20–1.41 (m, 10H, –CH2–), 0.95 (t, 3H, –CH3). 13C-NMR, CD3OD; d/ppm = 104.9 (C1), 76.5, 75.0, 72.5, 70.8, 70.2, 62.4, 33.0, 30.8, 30.5, 30.4, 27.1, 23.7, 14.4. R f value; 0.51 (acetone/chloroform/methanol/water = 4:9:4:1 by vol.). Found: C, 57.24; H, 9.66. C14H28O6 requires C, 57.51; H, 9.65%. Phase transition temperature from crystalline to liquid crystalline phases of anhydrous solid (Melting point): 100 °C (96 °C [20], 98 °C [21] and 100 °C [25]).

Sample Preparation and Expression of Sample Concentration

Samples containing various weight percentages of mono-alkylated glycoside were prepared in a glass vial by dissolving in distilled water at 50 °C. The solution was transferred to the experimental container before the start of the coagel formation. The concentrations of glycosides and electrolyte were expressed in the form of weight percentage (wt%) for glycoside (e.g., glycoside in g/(glycoside + H2O) in g) and weight molar percentage (mol/kg) for the electrolyte (e.g., electrolyte in molar/H2O in kg), respectively.

Characterizations of C8-β-Gal Coagel

Coagel was prepared by storing at 4 °C for time periods with durations ranging from several minutes to days. Images of coagel were taken using a digital camera. The Krafft boundary temperature (T K) and phase transition enthalpy (∆H K) were determined by a calorimetric analysis using a model DSC 60 (Shimadzu Co. Ltd., Japan) connected to a cooling unit. A hermetically sealed aluminum container was used throughout the measurement. The coagel and the corresponding dried solid at room temperature were analyzed using a D8 ADVANCE (Bruker AXS Corp., Japan) under atmospheric conditions over an angular range of 3°–40° (2θ/ω) using Cu Kα radiation (1.542 Å, 40 kV and 40 mA). A field-emission scanning electron microscope (FE-SEM, Sirion, FEI Company, Japan) and atomic force microscopy (AFM, SPM-9600, Shimadzu Co. Ltd., Japan) were used for the observation of morphology of the coagel after drying.

Results and Discussion

Coagel Formation from Aqueous C8-β-Gal Solution

As shown in Fig. 1b, an aqueous 10 wt% C8-β-Gal solution formed the opaque solid (coagel) from the liquid state (sol) at room temperature. This then transformed into the sol state upon warming. Below 30 wt% C8-β-Gal concentration, no viscous phase was observed during the dissolving process, indicating the phase transition between the coagel and sol (micelle) state without transition via the intermediate region such as a lyotropic liquid crystalline phase.

The coagel-sol phase transition was studied by means of differential scanning calorimetry (DSC). In the thermograms of the C8-β-Gal–water mixture at various concentrations, a single and sharp endothermic peak appeared in the temperature range from 30 to 35 °C (Fig. 2). In order to confirm whether the coagel formation went through the intermediated state between sol and coagel states, time dependence of the coagel formation was evaluated by the calculation of the endothermic enthalpy, ∆H K, obtained in the DSC thermograms. It was found that ∆H K reached a constant value of 28.4 kJ/mol for the samples stored at 4 °C for 3 min, indicating that a time period of 3 min was sufficient for the completion of the coagel formation from the aqueous 10 wt% C8-β-Gal solution (Fig. 3). No intermediate phase formation was ascertained under the experiment in this study.

The diagram depicting the Krafft boundary as these transition temperatures is presented in Fig. 4, which was prepared based on DSC analysis. The T K values decrease slightly with decreasing concentrations, and the knee of Krafft boundary was presumed to present around 2.5 wt%. For the concentrations below the 2.5 wt% region, it is predicted that the T K boundary line decreases rapidly with decreased concentration since no clear endothermic peak was identified in the corresponding DSC thermogram. On the other hand, the addition of NaCl increased T K slightly (inset of Fig. 2 and Table 1), but no apparent change in ∆H K was observed (Table 1). This indicates that there are no significant electrostatic interactions between the galactose unit and NaCl. The increase of T K must be due to the influence of the salting-out effect [26].

Characterizations of Molecular Assembly and Crystallites Network in C8-β-Gal Coagel

To analyze the aggregation structure of C8-β-Gal in the solid state, powder X-ray diffraction (PXRD) measurement was carried out. PXRD profiles obtained for the opaque solid prepared from an aqueous 10 wt% C8-β-Gal solution and the dried coagel are presented in Fig. 5.

In the PXRD profile of the opaque solid [Fig. 5 (above)], the broad peak ranging from 20° to 30° implies the existence of water and the sharp diffraction peaks around 20° reflects the hydrocarbon chain ordering, implying that the opaque solid should be assigned as a coagel consisting of C8-β-Gal crystalline and water. With the exception of the broad peak of PXRD profile (above), the diffraction peaks are observed at positions very similar to those obtained in the PXRD profile of the corresponding dried solid [Fig. 5 (below)].

This means that the crystal structures of the two states are identical and the contact with excess water does not affect the dispersed crystal structure. In addition, the PXRD profile of the dried sample was similar to that of the previously reported hemihydrate crystal [25]. That is, the coagel consisted of “ribbon-crystal phase” of hemihydrate crystallites with the spacings of a = 47.9 Å, b = 25.4 Å and c = 4.73 Å (α = β = γ = 90.0°) [25]. The existence of the (210) and (310) orderings indicated at 4.7° and 6.3° in the coagel’ PXRD profile and the appearance of a single and sharp endothermic peak in DSC thermogram provide evidence that a single-type of hemihydrate crystal was formed as the precipitate.

Because the correspondence of crystal structures between the coagel and dried samples imply that the morphologies of the two samples can be similar, FE-SEM and AFM observations were performed on the dried sample. The FE-SEM and AFM study showed that the dried coagel sample consists of bundled entangled networks (Fig. 6a, b). The constituents were identified as fibrous architectures with high aspect ratios. The typical fiber thicknesses were on the micrometer scale, consistent with the insight that the coagel is formed by agglomeration of crystallites.

Macroscopic Homogenies of Coagel Prepared from Aqueous C8-β-Gal Solution

Finally, the macroscopic homogeneity of the coagel prepared from aqueous C8-β-Gal solution was compared to those for the coagels prepared from aqueous C8-a-Glu or C12-β-Glu solutions; C8-a-Glu and C12-β-Glu solutions were reported to exhibit T K above room temperature [27, 28].

When 2.5 wt% aqueous solutions of C8-a-Glu, C12-β-Glu or C8-β-Gal were stored overnight at 4 °C, the coagels formed. However, C8-a-Glu and C12-β-Glu showed distinct phase separation. It could be deduced from the difference in the height of the horizontal line before and after the inversion (Fig. 7a, b). Liquid–rich portion in the mixture did not prevent it from falling down, while a tiny amount of coagel portion were able to remain. On the other hand, C8-β-Gal coagel showed excellent homogeneity without macroscopic phase separation, and also showed stiffness that enabled it to maintain its shape under the force of gravity (Fig. 7c).

Images of coagel matrices prepared from aqueous 2.5 wt% (a) C8-a-Glu, (b) C12-β-Glu, and (c) C8-β-Gal solutions. The contents are (left) normal and (right) inverted state, respectively. Horizontal dotted lines show the level attached to the tip of contents. Vertical black lines are the standards that show the height level at normal state

These observations indicate that the formation of macroscopically homogeneous coagel is not always obtained from aqueous mono-alkylated glycosides solution even below the corresponding T K. Typically, higher T K values are obtained with increasing alkyl chain length for an analogues series of mono-tailed glycoside–water systems [28, 29]. At the same time, the aqueous solutions of mono-tailed glycosides with longer alkyl chain length are likely to form a phase separated state comprising two different liquid compositions [28, 29]. For these systems, construction of a macroscopically homogeneous crystalline network should become difficult. That is, the process of coagel formation can highly dependent on the initial aqueous solution state.

Additionally, it is expected that “ribbon crystal phase” can confer the unique surface properties of the hemihydrate crystalline. In fact, high alignment perpendicular to the Si substrate without the formation of large crystalline size was obtained for the hemihydrate crystal in thin films [25]. Therefore, it is expected that the unique crystalline structure and the resultant surface also rely on the formation ability of homogeneous distributed crystalline networks without macroscopically phase separation.

Abbreviations

- AFM:

-

Atomic force microscopy

- DSC:

-

Differential scanning calorimetry

- T K :

-

Krafft boundary temperature

- Z:

-

Number of formula units in the unit cell

- C8-β-Gal:

-

Octyl β -d-galactoside

- PXRD:

-

Powder X-ray diffraction

- FE-SEM:

-

Field-emission scanning electron microscopy

References

Luzzati V, Husson F. The structure of the liquid-crystalline phases of lipid-water systems. J Cell Biol. 1962;12:207–219. doi:10.1083/jcb.12.2.207.

Laughlin RG. The aqueous phase behavior of surfactants, chapter 5. London: Academic; 1994. p. 102–154.

Sperline RP. Infrared spectroscopic study of the crystalline phases of sodium dodecyl sulfate. Langmuir. 1997;13:3715–3726. doi:10.1021/la9702087.

Cassin G, de Costa C, van Duynhoven JPM, Agterof WGM. Investigation of the gel to coagel phase transition in monoglyceride-water systems. Langmuir. 1998;14:5757–5763. doi:10.1021/la980340m.

Palma S, Manzo R, Lo Nostro P, Allemandi D. Nanostructures from alky vitamin C derivatives (ASCn): properties and potential platform for drug delivery. Int J Pharm. 2007;345:26–34. doi:10.1016/j.ijpharm.2007.09.014.

Batte HD, Wright AJ, Rush JW, Idziak SHJ, Marangoni AG. Phase behavior, stability, and mesomorphism of monostearin–oil–water gels. Food Biophys. 2007;2:29–37. doi:10.1007/s11483-007-9026-7.

Thareja P. Rheology and microstructure of pastes with crystal network. Rheol Acta. 2013;52:515–527. doi:10.1007/s00397-013-0716-4.

Thareja P, Golematis A, Street CB, Wagner NJ, Vethamuthu MS, Hermanson KD, Ananthapadmanabhan KP. Influence of surfactants on the rheology and stability of crystallizing fatty acid pastes. J Am Oil Chem Soc. 2013;90:273–283. doi:10.1007/s11746-012-2161-4.

Marangoni AG, Idziak SHJ, Vega C, Batte H, Ollivon M, Jantzi PS, Rush JWE. Encapsulation-structuring of edible oil attenuates acute elevation of blood lipids and insulin in humans. Soft Matter. 2007;3:183–187. doi:10.1039/b611985a.

Alberola C, Blümich B, Emeis D, Wittern K-P. Phase transitions of monoglyceride emulsifier systems and pearlescent effects in cosmetic creams studied by 13C NMR spectroscopy and DSC. Colloids Surf A Physicochem Eng Asp. 2006;290:247–255. doi:10.1016/j.colsurfa.2006.05.030.

Saino V, Monti D, Burgalassi S, Tampucci S, Palma S, Allemandi D, Chetoni P. Optimization of skin permeation and distribution of ibuprofen by using nanostructures (coagels) based on alkyl vitamin C derivatives. Eur J Pharm Biopharm. 2010;76:443–449. doi:10.1016/j.ejpb.2010.08.004.

Palma S, Manzo RH, Allemandi D, Fratoni L, Lo Nostro P. Coagels from ascorbic acid derivatives. Langmuir. 2002;18:9219–9224. doi:10.1021/la026042d.

Jung JH, John G, Masuda M, Yoshida K, Shinkai S, Shimizu T. Self-assembly of a sugar-based gelator in water: its remarkable diversity in gelation ability and aggregate structure. Langmuir. 2001;17:7229–7232. doi:10.1021/la0109516.

Jung JH, Rim JA, Han WS, Lee SJ, Lee YJ, Cho EJ, Kim JS, Ji Q, Shimizu T. Hydrogel behavior of a sugar-based gelator by introduction of an unsaturated moiety as a hydrophobic group. Org Biomol Chem. 2006;4:2033–2038. doi:10.1039/B602279K.

Matsumura S, Imai K, Yoshikawa S, Kawada K, Uchibori T. Surface activities, biodegradability and antimicrobial properties of n-alkyl glucosides, mannosides and galactosides. J Am Oil Chem Soc. 1996;67:996–1001. doi:10.1007/BF02541865.

von Rybinski W, Hill K. Alkyl polyglycosides–properties and applications of a new class of surfactants. Angew Chem Int Ed. 1998;37:1328–1345. doi:10.1002/(SICI)1521-3773(19980605)37:10<1328.

Schöberl P, Scholz N. Ecology. In: Balzer D, Lüders H, editors. Nonionic surfactants: alkyl polyglucosides. Surfactant science series, vol. 91, Chapter 7. New York: Marcel Dekker; 2000. p. 331–363.

Kocher K, Wiegand H-J. Toxicology and dermatology. In: Balzer D, Lüders H, editors. Nonionic surfactants: alkyl polyglucosides. Surfactant science series, vol 91, Chapter 8. New York: Marcel Dekker; 2000. p. 365–383.

Bae J, Choi EH, Pan J-G. Efficient synthesis of octyl-β -d-galactopyranoside by Bacillus spore-displayed β-galactosidase using an amphiphilic 1,2-dimethoxyethane co-solvent. Enzyme Microb Technol. 2011;48:232–238. doi:10.1016/j.enzmictec.2010.11.002.

Sakya P, Seddon JM. Thermotropic and lyotropic phase behaviour of monoalkyl glycosides. Liq Cryst. 1997;23:409–424. doi:10.1080/026782997208334.

Misran O, Timimi BA, Heidelberg T, Sugimura A, Hashim R. Deuterium NMR investigation of the lyotropic phases of alkyl β-glycoside/D2O systems. J Phys Chem B. 2013;117:7335–7344. doi:10.1021/jp401787b.

Ogawa S, Asakura K, Osanai S. Freezing and melting behavior of an octyl β -d-glucoside–water binary system—inhibitory effect of octyl β -d-glucoside on ice crystal formation. Phys Chem Chem Phys. 2012;14:16312–16320. doi:10.1039/c2cp41439b.

Abe Y, Harata K. Crystal structures of glycolipids. In: Dumitriu S, editor. Polysaccharides: structural diversity and functional versatility, 2nd edn, Chapter 32. New York: CRC; 2004. p. 743–772.

Ahmadi S, Manicham Achari V, Nguan H, Hashim R. Atomistic simulation studies of the α/β-glucoside and galactoside in anhydrous bilayers: effect of the anomeric and epimeric configurations. J Mol Model. 2014;20:2165. doi:10.1007/s00894-014-2165-0.

Ogawa S, Ozaki Y, Takahashi I. Structural insights into solid-to-solid phase transition and modulated crystal formation in octyl-β -d-galactoside crystals. ChemPhysChem. 2016;17:2808–2812. doi:10.1002/cphc.201600400.

Ericsson CA, Ericsson LC, Kocherbitov V, Söderman O, Ulvenlund S. Thermotropic phase behavior of long-chain alkylmaltosides. Phys Chem Chem Phys. 2005;7:2970–2977. doi:10.1039/B502922H.

Kocherbitov V, Söderman O. Phase diagram and physicochemical properties of the n-octyl a -d-glucoside/water system. Phys Chem Chem Phys. 2003;5:5262–5270. doi:10.1039/B306350J.

Boyd BJ, Drummond CJ, Krodkiewska I, Grieser F. How chain length, headgroup polymerization, and anomeric configuration govern the thermotropic and lyotropic liquid crystalline phase behavior and the air-water interfacial adsorption of glucose-based surfactants. Langmuir. 2000;16:7359–7367. doi:10.1021/la991573w.

Nilsson F, Söderman O, Hansson P. Physical-chemical properties of C9G1 and C10G1 β-alkylglucosides. Phase diagrams and aggregate size/structure. Langmuir. 1998;14:4050–4058. doi:10.1021/la980261a.

Acknowledgements

The authors gratefully acknowledge the financial support by the MEXT-Supported Program for the Strategic Research Foundation at Private Universities (S1201027) 2012–2016.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interests.

About this article

Cite this article

Ogawa, S., Koga, M., Asakura, K. et al. Coagel Prepared from Aqueous Octyl β -d-Galactoside Solution. J Surfact Deterg 20, 255–261 (2017). https://doi.org/10.1007/s11743-016-1894-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11743-016-1894-8