Abstract

Phosphate surfactants containing ether and hydroxyl groups were prepared by a simple reaction between the corresponding epoxide and the diethyl phosphate. The relationships between the structure and colloidal properties were evaluated in terms of the critical micelle concentration (CMC), γCMC, foaming ability, and water absorbing and holding abilities. Based on these results, it was concluded that the ether and hydroxy groups synergistically worked together to decrease the CMC and increase the foaming ability. The degree of neutralization remarkably affected the colloidal properties. The highly neutralized states showed a more positive effect on water holding power but an opposite effect on the foaming ability.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Over the past few decades, the phosphate ester-type anionic surfactants have been attracting attention in the surfactant industry [1, 2] because they have been extensively applied in various industrial fields, such as rust and corrosion inhibition [3, 4], antistatic agents [5, 6], lubricants [7], emulsifiers [8, 9], etc. In addition to the monophosphate-type detergents [10, 11], Gemini-type phosphates have also been prepared and their amphiphilic properties studied [12]. Specifically, monoalkyl phosphate (MAP) has been playing a key role in the toiletry industry in personal-care products. Because of their compatibility with skin and inherent low-irritation characteristics, they have been significantly used in toiletry applications, such as cleansers, body and hair shampoos, and oral care formulations [2, 13–15].

In this paper, we introduce a new preparation method for the phosphate that possesses a free hydroxy group and an ether linkage in the molecule. At the same time, homologues containing several oxyethylene groups were prepared by a reaction between the corresponding oxirane derivative and diethyl phosphate, which is a key step in this process.

We also studied the colloidal properties of the prepared amphiphilic phosphates. Studies on the various physicochemical properties and effects of these functional groups, such as free hydroxyl and oxyethylene groups would provide useful information when novel surfactants and detergents are designed. Furthermore, the relationships between the structure and properties of the aqueous solution were also discussed for various neutralization degrees of the surfactant dibasic phosphate groups.

Experimental Procedures

General Measurements

Melting points were recorded by an MP-J3 melting point apparatus (Yanagimoto Co.) and were uncorrected. The identification of the structure was confirmed from the NMR spectra and elemental analysis. The 1H-NMR spectra were recorded using a JNM-LA300 (300 MHz for 1H) instrument. Chemical shifts are reported in ppm downfield (δ) from an internal standard (TMS in CDCl3 and CD3OD).

Preparation of Raw Materials

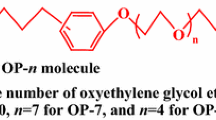

In this study, we prepared two kinds of oxirane derivatives, 1m and 4m,n, as raw materials. As Scheme 1 shows, one is a normal α-olefin oxide, 1,2-epoxyalkane 1m, where, m is the number of carbons of the corresponding olefin. These epoxy compounds, α-olefin oxide 1m, [dodecene, tetradecene, hexadecene and octadecene oxide] were obtained from the ADEKA Co., Ltd., and were used without further purification. Another homologue 4m,n contains an ether group and oxyethylene group in addition to the epoxide group, where m and n indicate the number of carbon atoms in the alkyl group and the number of oxyethylene groups, respectively. We solely synthesized these raw materials 4m,n. The synthetic procedure is described in the next section. The phosphorylating agent composed of a mixture of diethyl phosphate 48 mol%, ethyl phosphate 49 mol%, and H3PO4 3 mol% was also obtained from the ADEKA Co., Ltd.

Preparation of epoxide derivatives (4m,n)

Scheme 1 illustrates an outline of the preparation procedure. n-Alkyl glycidyl ether was prepared according to the published method [16]. The synthesis of n-octyl glycidyl ether 4 8,0 is described here as an example. To a solution of 70.1 g (0.54 mol) of n-octanol and 0.85 g of SnCl4 was slowly added 54.9 g (0.60 mol) of epichlorohydrin. The mixture was well stirred and maintained at 80 °C during the addition, and then the contents were heated at 110 °C for 2 h. The epoxide was produced by the dehydrochlorination of the crude chlorohydrin 3m,n, which was not isolated, in a strong alkaline solution (45 g of 48% NaOH aqueous solution) as described by Sandler and Karo [16]. The crude epoxide ether was purified by distillation under reduced pressure to yield n-octyl glycidyl ether 4 8,0 as a colorless liquid, b.p. 94–97 °C/6 mmHg. 75.9 g yield 74%. The other homologues containing the oxyethylene group were obtained in a similar manner from the corresponding alkyl polyoxyethylene glycol ether 2m,n.

Their b.p. and yield were as follows: 4 10,0 : 104–110 °C/3 mmHg, 67%. 4 12,0 : 110–115 °C/1.5 mmHg, 85%. 4 12,2 : 198–205 °C/1.5 mmHg. 82%, 4 12,3 : 226–232 °C/2 mmHg, 71%. 4 12,4 : 220–226 °C/1 mmHg, 60%, and the representative 1H-NMR spectra are summarized in Table 1. The spectra of other homologues containing various alkyl chain lengths and oxyethylene groups were also in fair agreement with their δ values and integration with the theoretical values.

Synthesis of Phosphate Surfactants (6m, 7m,n)

Scheme 2 summarizes the preparation of the phosphate surfactants 6m and 7m,n. The preparation of the 2-hydroxy tetradecyl phosphate homologue 6 14 is described here as an example. 1,2-Epoxytetradecane (6.37 g, 30 mmol, 1 14 ) was reacted with phosphorylation agent (48 mol% diethyl phosphate (DEP), 4.58 g, 33 mmol) at 60–70 °C. After a 2-h reaction, 5.4 ml (0.3 mol) of water was added with stirring in order to hydrolyze the diethyl phosphate ester 5 14 , which was not isolated. The solution was diluted with toluene, and the toluene layer was washed with water. After drying and evaporation of the toluene, the crude product was purified by recrystallization from ethyl acetate and hexane 1:1 [v/v] as a white solid powder, 3.92 g, yield 42%, m.p. of 6 14 was 88–92 °C. The m.p. of the other homologues were as follows: 6 12 68–74 °C, 6 16 99–101 °C, 6 18 101–104 °C. The structure of the product was determined by 1H NMR. The representative 1H-NMR data are summarized in Table 1. The other phosphate surfactant homologues of 7m,n were also prepared from the corresponding epoxides 4m,n in a similar manner as already described. Due to the ether linkage, all of these phosphates 7m,n were very viscous, therefore, they did not exhibit a clear melting points.

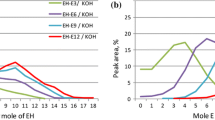

In order to prepare some specimens with different neutralization degree, the product was neutralized with the prescribed amount of 0.5 M NaOH aqueous solution in accordance with the neutralization curve. The pH change with respect to the neutralization of the polybasic phosphate is graphically illustrated in Fig. 1.

Surface Tension Measurement

The surface tension was measured by Wilhelmy’s vertical plate method using a Model A-3 tensiometer (Kyowa Kagaku Co., Ltd.). Samples were prepared by diluting each phosphate with ultra pure water to specific concentrations. The purity of the water was ascertained by its conductivity and surface tension. It was confirmed to be less than 1 μS/cm and more than 71.0 mN/m, respectively. By adding the calculated amount of 1 M aq. NaOH in accordance with Fig. 1, the neutralization degree of the phosphate was controlled. The solution was maintained at 25 °C and measured at the same temperature. The measurements were taken after the surface tension was kept constant for a period of 20–30 min. For the lower surfactant concentrations, it usually took longer to reach equilibrium. Reproducibility of the surface tension measurements was maintained at less than 0.5 mN/m. Figure 2 shows the results of 6 12 for a free phosphate and disodium salt, and Fig. 3 shows the results for the monosodium salt of 6 12 , 7 8,0 and 7 12,0 , respectively. Other representative data of the CMC and γ CMC are shown in Table 2.

Moisturizing Ability

The moisturizing characteristics of the surfactant, that is, the water-absorption and water-holding capacity were evaluated as follows. The dried surfactants were kept in a desiccator whose humidity was adjusted to 80% at 25 °C for the prescribed time, and the amount of absorbed water was calculated from the weight increase. The sample in the desiccator was transferred to another desiccator whose humidity was 45%, and the weight loss was measured again to evaluate the ability of retaining the water. In this study, 6 12 , 7 8,0 , 7 12,0 and 7 12,2 were evaluated. The influence of the neutralization degree of these surfactants was also discussed.

The water content was calculated by the following equation.

Water content (%) = 100 × (WW – WD)/WD where WW is weight of the wet sample, and WD is weight of the dry sample. Results are summarized in Figs. 4, 5.

Foaming Test

In the foaming test studies of the phosphate-type surfactants, the improved semi-micro TK-method was used. Bubbling a certain quantity (250 mL) of air through a 2-mm inside diameter glass tube for a fixed time (60 s) generated foams. The details of the equipment set up were described in a previous paper [17]. The volume of the foams was immediately measured after the bubbling (V 0) and 5 min later (V 5). These results are summarized in Table 3. In this study, we evaluated the foaming stability of the surfactant foams by a new parameter, that is, the specific foaming ability (SFA), that was defined as the ratio of V 0 to V 5. Based on these three parameters, the SFA in addition to the V 0 and V 5, we could obtain some information about their foaming characteristics especially on their foaming ability. Representative results of the three kinds disodium phosphates are depicted in Fig. 6. The SFA increased in the order of 7 12,2 , 7 12,0 and 6 12 , that is, 7 12,2 showed the highest foam persistence over a wide range of concentrations.

Results and Discussion

Preparation of the Surfactants

As shown in Schemes 1 and 2, a nucleophilic reaction between the epoxides, 1m, 4m,n, and phosphorylation agent, diethyl phosphate (DEP), is an important key reaction for the preparation of the surfactants. In this reaction, we need to consider the generation of by-products, the secondary phosphate, which is an isomer of the primary phosphate. According to the NMR spectrum, the crude products were mixture of two isomers. It was confirmed that the primary isomer was obtained as the major product. This result was in agreement with our expectation based on the structure of the epoxide. DEP reacted with the less-hindered epoxide carbon. The secondary phosphate in the crude product was easily removed by recrystallization as the carbon number increases. Each phosphate, 6 10 –6 16 , obtained from the corresponding alkane-epoxide was readily available in the pure form of the primary phosphate after recrystallization. On the other hand, the phosphate homologues containing ether and the oxyethylene groups, 7m,n, were viscous or greasy compounds, which were difficult to purify by recrystallization or preparative chromatography. The ratio between the primary and secondary phosphates was estimated at 8/2 by comparing the integral values of –CH(OH)CH 2 OPO3H and –CH2CH(OPO3H)CH2OH in the 1H-NMR spectrum. These compounds were used for measurement of the colloidal properties with no further purification. Neutralization curves of the three kinds of phosphate surfactants, 6 9 , 7 6,0 , 7 12,2 , are shown in Fig. 1. Two highly clear pH jumps were recognized at the mono- and di-equivalent points in each curve. This indicates that each phosphate obtained here is a dibasic acid, that is, they were mono-alkylated phosphate as we expected.

Surface Tension and CMC

It is widely understood that HLB is the predominant factor that determines the CMC. In particular, the chain length of the carbon atoms in a surfactant, which leads an increased hydrophobicity, is believed to be the main cause of the CMC decrease. However, comparative studies of hydrophobic groups with different structures suggested that the presence of functional groups that create hydrogen bonds among the amphiphilic compounds had a greater influence on the CMC than HLB. The present study attempted to examine the various structural characteristics of hydrophobic groups in surfactants in order to identify the primary determinants of the CMC. First, the influence of neutralization on the surface tension was examined. Second, three hydrophobic groups with different structures were compared with respect to the CMC. Finally, two hydrophobic groups with similar structures except for the presence of a hydroxyl group were compared in relation to the CMC. The basic findings in terms of the surface activities, surface tension and CMC are summarized in Figs. 2, 3 and Table 2.

Figure 2 shows the influence of the neutralization on the surface tension. Phosphate 6 12 was prepared from a simple dodecene oxide and then examined in both the neutralized and non-neutralized states, i.e., free acid and disodium salt. The result, as predicted, showed a greater CMC in a highly neutralized state than in the less neutralized state. This was due to the fact that the concentration of the phosphate anion increases as the neutralization proceeds. As a consequence, the hydrophilicity of the surfactant increased, and at the same time, the negatively charged state of the phosphate head group was almost completely in favor of the phosphate anion. Based on these findings, it was assumed that the actual increase in hydrophilicity and the repulsion of the negatively charged head groups led to the increase in the CMC.

Figure 3 summarizes the comparison of the three hydrophobic groups with respect to the CMC. It attempted to examine the general understanding that the structure of a hydrophobic group in amphiphiles markedly affected the CMC in aqueous solutions. When two kinds of phosphates, 6 12 and 7 8,0 , were compared, a significant difference in the CMC was observed. The CMC of 6 12 was approximately 10 times greater than that of 7 8,0 , which suggests that the latter, 7 8,0 , has a tendency to aggregate and form a micelle in a less concentrated solution. However, a close examination of the structures of these phosphates reveals a contradiction between this result and the widely accepted notion that in aqueous media, the CMC decreases as the hydrophobic character of the surfactant increases. In these two phosphates, the hydrophobic group is different at the ω-8 position, that is, in 6 12 , there is a methylene group, whereas in 7 8,0 , there is an ether oxygen atom. In other words, in 7 8,0 , the dodecyl group is divided into two parts, an octyl group and a trimethylene group by a single ether oxygen atom. Since the hydrophobicity is related to the chain length, the phosphate 6 12 should have a stronger hydrophobic character than 7 8,0 , and therefore, in accordance with the above understanding that an increase in the hydrophobic character leads to decrease in the CMC, 6 12 should have resulted in a lower CMC than 7 8,0 .

In order to account for this unexpected result, an alternative perspective was taken. It is assumed that the CMC decrease is attributed to the hydrogen bond between the hydroxy group, the ether oxygen atom, and the phosphate group, which are present in 7 8,0 , but not in 6 12 . This may explain the results of the present study. Figure 7 describes how the phosphate surfactants containing both ether and hydroxyl groups in a single molecule have an easier aggregation due to their strong hydrogen bond.

Another comparison in favor of this argument is between 7 12,0 and 7 8,0 , as shown in Fig. 3. 7 12,0 is similar to 7 8,0 in that it contains an ether oxygen atom in its structure. However, the longer carbon chain in 7 12,0 , which is known to increase the hydrophobicity, is assumed to contribute to the lower CMC, according to the earlier discussion. The result in Fig. 3 actually showed no significant difference between the two phosphates, suggesting that the strong hydrogen bond created between the hydroxyl group and the ether oxygen atom had a greater influence on the CMC than the hydrophobicity.

The effects of oxyethylene units of the ethoxylated sodium alkyl sulfates on their CMCs have been reported [18–20]. In this study, an additional comparison between homologues with two oxyethylene groups, 7 12,0 and 7 12,2 suggested no clear systematic difference in terms of the number of oxyethylene groups, as shown in Table 3.

Based on these findings, it is concluded that when considering the influence of surfactant structures on the CMC, the presence of certain functional groups in the amphiphilic compounds that create strong hydrogen bonds, is more important than its HLB.

A final comparative study in support of the above analysis was carried out between the mono dodecyl phosphate (MAP12) and 6 12 . 6 12 possesses a hydroxyl group at the C-2 position in addition to the MAP12 structure. This experiment was to test whether the presence of a hydroxyl group on its own had any significant influence on the CMC. The result showed no appreciable difference between the two, ruling out the possibility that the hydroxyl group in the molecule independently affected the CMC level.

Overall, it is concluded that the coexistence of certain functional groups, notably the hydroxyl group and the ether oxygen atom, is thought to be the key factor influencing the colloidal property of surfactants.

Moisturizing Ability

Figure 4 shows the influence of the neutralization degree on the water absorbing and holding capability of the phosphate surfactant, in which 7 8,0 is illustrated as an example. The water holding rate was directly proportional to the neutralization degree of the samples. The water content values of the disodium salts were about three times that of the free acid, while that of the monosodium derivatives were intermediate between the two homologues. These results were similar to that of the amphiphilic amino acid derivatives, between the free acid and sodium salt, as previously reported [21].

At the same time, the influence of the surfactant’s structure on the water holding properties was discussed. Figure 6 shows the effects of three kinds of functional groups, i.e., the hydroxy, ether, and oxyethylene groups, on the water absorbing and holding properties. We expected that the introduction of the hydroxy group from the epoxide moiety of the raw material would result in an increase in the water absorbing capacity, but unfortunately, the results were contrary to our expectation. The capacity of the disodium salt of 6 12 , which contains only a hydroxy group other than phosphate, was extremely poor and its plots were located through out the bottom region of the graph.

As it was distinct from 6 12 , in the case of the coexisting ether and hydroxyl groups, a predominant synergistic effect was recognized. The water holding ability of 7 12,0 was about five times that of 6 12 . The structural difference between 6 12 and 7 12,0 is shown in Scheme 2. The increase in the hydrogen bond due to the coexistence of the ether and hydroxyl group is likely to be the main reason for this synergistic effect.

The introduction of the oxyethylene group into the surfactant significantly increased the water absorbing property, but its water retention ability was extremely weak. It showed the tendency to easily release the moisture acquired during the absorbing process. The influence of the chain length of the hydrophobic group in the phosphate was so slight that the difference was not easily recognized among the homologues, 7 8,0 , 7 10,0 , and 7 12,0 .

Foaming Ability

The absolute foaming ability of the phosphate surfactant with different neutralization degrees under various representative concentrations is summarized in Table 3. Although there was no clear systematic trend in Table 3, some relationship between their structure and the foaming ability may be deduced from this table. The neutralization state of the specimen produced some effect on the foaming. The lower the neutralization of the phosphate is, the better the foaminess and foam stability. The foaming ability was individually dependent on their structure, concentration, and neutralization. For example, 6 12 showed an excellent foaming ability at a more concentrated state than the CMC, even though a poor or no foaming was observed with a solution below the CMC. Generally speaking, the volume of foam (V 0) is found to increase according to a sigmoid shape with a strong variation close to the CMC as shown in Fig. 8.

Table 3, indicates the effect of the hydroxyl and ether groups. The phosphate 7 12,2 , showed clear synergistic effects between the hydroxy and ethylene oxide groups under a fully neutralized state. However, contrary to our hypothesis that the hydroxyl group in the 6 n series shows a positive effect on the foaming property, the result did not indicate a positive correlation. No clear difference was recognized between the foaming ability of 6 12 and MAP 12 .

References

Jungermann E, Silberman HC (1976) Phosphorous-containing anionic surfactants. In: Linfield WM (ed) Anionic surfactants Part II. Marcel Dekker, New York, pp 495–580 Chap 15

Tracy DJ, Reierson RL (2002) Commercial synthesis of monoalkyl phosphates. J Surfactants Deterg 5:169–172

Sala M, Kolar J, Strlic M, Kocevar M (2006) Synthesis of myo-inositol 1, 2, 3-tris- and 1, 2, 3, 5-tetrakis (dihydrogen phosphate)s as a tool for the inhibition of iron-gall-ink corrosion. Carbohydrate Res 341:897–902

Samui AB, Phadnis SM (2005) Polyaniline-dioctyl phosphate salt for corrosion protection of iron. Prog Org Coat 54:263–267

Park HS, Kim SJ, Rhee HW (1997) Synthesis and properties of water-soluble polyamine phosphate type durable antistatic agent. Sen-i Gakkaishi 53:249–257

Polowinska A, Szosland L, Jantas R (1987) New phosphoric derivatives of poly(ethyleneglycol)s as antistatic agents for man-made fibers. Acta Polym 38:125–131

Hellsten M, Karlsson G, Emanuelsson J (1971) Alkyl phosphates as inhibitors for metal corrosion in detergents containing chelating agents. Tenside Deterg 8:237–247

Plass J, Emeis D, Blumich B (2001) P-31 nuclear magnetic resonance studies on alkyl phosphate emulsifiers in cosmetic oil-in-water emulsions. J Surf Deterg 4:379–384

Riddle BL, Kipp EM (1991) Friction and wear properties of PEG esters in the presence of a complex phosphate ester. Lubr Eng 47:991–996

Yuan ZW, Hao JC, Hoffmann H (2006) A promising system of mixed single- and double-short-tailed PEO ether phosphate esters: phase behavior and vesicle formation. J Colloid Interface Sci 302:673–681

Nan YQ, Hao LS, Liu HL (2006) The influence of sodium phosphate on extraction phenomena of aqueous two-phase cationic/anionic surfactant systems. J Dispers Sci Technol 27:419–425

Zhu YP, Masuyama A, Okahara M (1991) J Am Oil Chem Soc 68:268–271

Imokawa G, Tsutsumi H, Kurosaki T (1978) Surface activity and cutaneous effects of monoalkyl phosphate surfactants. J Am Oil Chem Soc 55:839–843

Imokawa K (1979) Study on skin-irritating and biological properties of monoalkyl phosphate anionic surfactants. J Am Oil Chem Soc 56:604–609

Tsubone K, Uchida N, Mimura K (1990) New amphoteric surfactants containing a phosphoric acid group:1. Synthesis and physicochemical properties of sodium 2-(N-2-hydroxyalkyl-N-methylamino)ethyl hydrogen phosphate. J Am Oil Chem Soc 67:451–454

Sandler SR, KaroW (1968) In: Organic functional group preparations, Chap 5, Ethers and oxides, Academic Press, New York, p 109

Abe A, Asakura K, Osanai S (2004) Synthesis and characterization of novel amphiphiles containing amino acid and carbohydrate. J Surf Deterg 7:297–303

Dahanayake M, Cohen AW, Rosen MJ (1986) Relationship of structure to properties of surfactants13. Surface and thermodynamic properties of oxyethylenated sulfates and sulfonates. J Phys Chem 90:2413–2418

Lange H, Schwuger MJ (1980) Grenzflaecheneigenschaften von Alkylsulfaten. Colloid Polym Sci 258:1264–1270

Aratono M, Ikeda N (1997) Adsorption of surfactants at a gas–liquid interface. In Surfactant Science Series 70, Chap 2, Marcel Dekker, NY, pp 116–117

Deguchi K, Osanai S, Umezawa S (2001) Synthesis and physicochemical properties of dipeptide type surfactants I, N-dedecanoylglutamyl-glutamic acid and glutamylaspartic acid. J Oleo Sci 50:763–772

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Osanai, S., Yamada, G., Hidano, R. et al. Preparation and Properties of Phosphate Surfactants Containing Ether and Hydroxy Groups. J Surfact Deterg 13, 41–49 (2010). https://doi.org/10.1007/s11743-009-1137-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11743-009-1137-3