Abstract

This study aimed to prepare and characterize oleogels and emulgels with glycerol monooleate (GMO): cholesterol gelator system. Oleogels, including 5 and 10% of each gelator were prepared. Emulgels with the same organogelator mixture concentrations, and 10 and 20% water phase were also prepared successfully. The gelation time decreased as the added gelator mixture and water concentrations increased. All samples had significant oil binding capacity and creamish-white colors. The oleogels melted just below body temperature, while emulgels melted around body temperature as determined by differential scanning calorimetry. The samples’ crystalline networks were observed with the X-ray diffraction analysis and displayed β and β′ polymorphic type crystals. Rheological measurements revealed that as gelator mixture concentration increased, gel strength enhanced, but in the emulgels, the gel strength decreased significantly as added water content increased. All oleogels and emulgels showed time-dependent thixotropic recovery ability. Temperature ramp tests indicated that the oleogels were stable up to 28 °C, but the emulgels kept their gelled consistency up to 70 °C. Overall, the common properties of these new oleogel and emulgels were provided. Future studies for some applications are foreseen.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Gels are very exciting materials, which behave like solid, although they are internally liquid. Generally, gels were defined as colloidal systems, in which the colloidal particles constitute a coherent structure and the liquid or continuous phase is permanent on the time scale and hence solid-like in its rheological behavior. Briefly, gels are unflowing or solid-like liquid systems. Gels were classified according to the nature of the liquid phase as hydrogels, emulgels, and organogels. If an aqueous solution is gelled, it is called a hydrogel (table jelly, gummy bear); if a biphasic mixture is gelled, it is called an emulgel (cheese curds); and if an organic solvent is gelled, it is called an organogel (benzene gel or oil gel). To differentiate an edible liquid oil gel, the term of oleogel was preferred within the organogel category (Co and Marangoni 2012; Martins et al. 2018; Marangoni et al. 2020).

The oleogels are gelled edible liquid oils by different gelator molecules with different gelling mechanisms. There are various classifications based on the mechanisms of gelation (self-assembly, crystallization, emulsification, nanoparticle agglomeration), type of the gelator molecules (low molecular weight gelators, polymeric gelators, inorganic gelators), and the number of gelator components (single gelators like waxes, multi-component gelators like sitosterol + oryzanol). Furthermore, the approaches implemented to prepare the oleogels could yield classification as direct dispersion (wax, ethyl cellulose oleogels), indirect method (emulsion templates), structured biphasic system (structured emulsion, oil bulking gel-filled emulsion), and oil sorption (foam, carbohydrate polymer fibers) (Co and Marangoni, 2012; Sing et al. 2017; Martins et al. 2018; Sagiri et al. 2018; Marangoni et al. 2020).

Finding new gelators and/or new ways of oleogel formation is a current research challenge. For edible purposes, the gel-forming molecules or the organogelators must be food grade (permitted by the governments and acceptable by the consumers), while for non-food applications (pharmaceutical, cosmetic, material, industrial, etc.), other pre-requirements may arise.

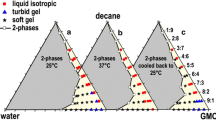

Oleogels prepared with saturated long-chain esters of mono- and di-glycerides (commonly mono- and di-stearates) have been studied (Patel 2018; Martins et al. 2018; Marangoni et al. 2020). These oleogels were quite stable, but enhances the saturated fatty acid contents of the products. Current dietary guidelines usually suggest reduction of saturated and trans fatty acid intake (Kris-Etherson and Krauss 2020). While glycerol monooleate (GMO) forms fascinating and diverse types of self-assembled structures in aqueous systems, it has usually not been used in oleogel preparations. The GMO is an amphiphile, and it can self-assemble into different liquid crystalline structures due to variation in solvent composition and temperature. These forms are known as lyotropic phases. If the concentration is above the critical micellar concentration, and the temperature is higher than Kraft temperature, various micellar forms could be prepared. Usually, GMO self-assembles in the presence of water into corresponding phases of lamellar, hexagonal, and bicontinuous phases (Amar-Yuli et al. 2009; Kulkarni et al. 2011). In one study (Cegla-Nemirovski et al. 2015), reverse lyotropic liquid crystals of GMOs were used in ternary mixtures with decane, water, and glycerol, and an organogel with reverse hexagonal structure was developed. It was discussed that GMO had been used to prepare liquid crystalline phases for drug delivery purposes (Milak and Zimmer 2015). Since GMO is a non-toxic, biodegradable, and biocompatible material, it could be investigated as an organogelator or co-gelator together with other molecules for oleogel preparation.

Cholesterol (3β-cholest-5-en-3-ol) is a common steroid synthesized by all animal cells (Li and Parish 1997). Cholesterol alone could not create lipid oleogel at concentrations up to 10% by weight, but phytosterols could create oleogels with γ-oryzanol as mixtures of appropriate ratios (Co and Marangoni 2012; Pakseresht and Tehrani 2020). There are limited numbers of studies regarding the cholesterol-based molecules forming organic or aqueous gels. Laboratory synthesized cholesterol orotate (Fan et al. 2013), synthesized chiral biphenyl-cholesterol compounds (Geiger et al. 2013), and synthesized molecules with two cholesteryl moieties and a carboxylic group (Yang et al. 2019) have been shown to provide some organogels of various non-polar solvents.

Since neither cholesterol/phytosterols nor GMO could create oleogels by themselves up to 10% of concentrations, phytosterols-monoglyceride mixtures were investigated to prepare oleogels. Glyceryl monostearate and phytosterol mixtures (8:2 ratio) at a 10% addition level yielded stable and proper oleogels (Sintang et al. 2017). In a similar study, glyceryl monostearate and native phytosterol mixtures were used to prepare oleogel foams (Truong et al. 2019). This study aimed to prepare sunflower oil oleogels and emulgels with cholesterol and GMO combinations as the organogelator and characterize the prepared gels with various physico-chemical, structural, morphological, and rheological analyses to light upon possible food and non-food applications.

Experimental

Materials

Refined-winterized sunflower oil was purchased from Trakya Birlik Oil Co., (Tekirdağ, Turkey) and used as the stock oil to prepare the oleogels. Glycerol monooleate (GMO, 1-oleoyl-rac-glycerol, 40% by TLC) from Aldrich Chemie GmbH (St. Louis, USA), and cholesterol (95%, stabilized) from Acros Organics Inc. (Geel, Belgium) were purchased. Analytical grade chemicals and solvents were used, and purchased from Sigma Chem. Co. (St. Louis, MO, USA) or Merck (Darmstadt, Germany).

Preparation of the oleogels

First, the cholesterol and GMO were separately tested for oleogel formation ability at 10% (w/w) concentration. The appropriate proportions of sunflower oil (SO) and each of the cholesterol (Cho) and GMOs were prepared in separate tubes, heated at 80 °C water bath until full dissolution, and then taken out to room temperature. The next day, the tubes were tested for flow, and it was observed that there was no oleogel, but a viscous solution was present. Then, GMO: cholesterol mixtures were used to prepare the oleogels, and added water was used to prepare the emulgels. The formulations used to prepare the two oleogels and the two emulgels with the GMO: cholesterol mixtures as the gelators are presented in Table 1.

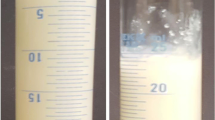

Briefly, once the given formula components were weighed, the beakers were placed in a water bath set to 80 °C and mixed at 150 rpm until all ingredients were dissolved and a clear solution was obtained. To prepare the emulgels, after dissolving the components following the same approach, the appropriate amount of pure water was slowly added while the mixture was homogenized at 3000 rpm. Once the emulsion was formed, the homogenizer was stopped. Since the 5% GMO + 5% Cho sample (GMC-OJ1) could not yield emulgels with added water (10 and 20%), they were not included in the study. Both prepared oleogels and emulgels were kept overnight at room temperature (20 ± 3 °C). The temperature of the laboratory was controlled with an air conditioner. The next day, the tubes were examined by tilting 180° to observe the flow. Tubes without flow were regarded as stable oleogels and emulgels. The prepared oleogels and emulgels could be observed in Fig. 1.

The Oleogels and Emulgels Prepared (Cho: cholesterol, GMO: glycerol monooleate, GMC-OJ1: glycerol monooleate + cholesterol oleogel one, GMC-OJ2: glycerol monooleate + cholesterol oleogel two, GMC-EJ1: glycerol monooleate + cholesterol emulgel one, GMC-EJ2: glycerol monooleate + cholesterol emulgel two, at 20 ± 3 °C)

Physical properties of the oleogels

The gelation time (GT) specifies the time required for an oleogel to solidify at given conditions (melting temperature, ambient temperature, and cooling rate, if cooled). First, the prepared oleogels were fully melted in a water bath at 80 °C for 30 min. Then, they were taken to room temperature (20 ± 3 °C), and the chronometer was started. The time elapsed until full gelation was recorded in minutes. To observe the full gelation, the tubes were tilted 180° to observe flow (Yilmaz et al. 2015). For the emulgels, the chronometer was started after the completion of the homogenization for full emulsification. Since most oleogel studies report the GT at room temperature, the same temperature was preferred in this study.

Oil binding capacity (OBC) indicates the percent of liquid oil trapped inside the oleogel structure after specific centrifugal force application. The oleogel samples were melted (80 °C for 30 min), and 1 ml of melted sample was placed into tared Eppendorf tubes. The tubes were stored in the refrigerator for 60 min for quick re-gelation, before centrifugation at 10,000 rpm for 15 min. Then, the tubes were reversed on paper clothes to drain the released liquid oil. Finally, the remaining amount was weighed again, and the OBC was calculated gravimetrically (Yilmaz et al. 2015). The emulgels were not melted but directly weighed into the tared Eppendorf tubes and centrifuged in the same way to find out the amount of released oil.

The color of the samples was assessed with a Minolta CR-400 colorimeter (Konica Minolta Sensing, Osaka, Japan), and the values of L, a*, and b* were recorded (Yilmaz et al. 2015).

Microstructural properties of the oleogels

The polarized light microscopy (PLM) images of the oleogels were taken with an Olympus BX51 polarized light microscope (Olympus Optical Co., Ltd., Japan) equipped with a CCD color video camera (Canon) at room temperature with 20-fold magnification (Yilmaz et al. 2015).

The crystalline polymorphs of the oleogel and emulgel samples were determined with a PANalytical Empyrean model (The Netherlands) X-ray diffractometer by following Cj 2–95 method (AOCS, 2012). The samples were loaded at room temperature (20 ± 3 °C) to the sample holder of the instrument. The angular scans (2θ) were performed from 2.0° to 50o at2o/min scan rate under a Cu source X-ray tube (λ = 1.54056 Å, 40 kV, and 40 mA). Data were analyzed with X’PertHighScore Plus software (Malvern Panalytical Ltd., Royston, UK) (Yilmaz et al. 2015).

Rheological properties of the oleogels

A DHR 2 rheometer (TA Instruments, USA) with a Peltier system (± 0.1 °C) under the lower plate equipped with cross-hatched parallel plate geometry (ϕ = 40 mm, gap 0.9 ± 0.1 mm) probe was used in rheological analyses. Except for the temperature ramp test, all measurements were completed at 10 °C, since at that temperature, all samples were sufficiently well solid, and the comparison of samples was easier. An amplitude sweep test with 0.01–100% strain and 1 Hz frequency was completed at first to determine the linear viscoelastic region (LVR) for each sample. The LVR is defined as the region in which a plateau of both storage (G′) and loss (G″) moduli prevail. All successful rheological measurements must be carried out within the LVR, by definition (Mezger 2014).

The frequency strain tests were conducted at the selected strain ranges of 0.038–0.103% and frequencies from 0.1 to 100 Hz at 10 °C. A time sweep test was applied for all samples to assess the structural recovery ability of the samples under specific stresses applied. Three strain gradient regions were selected and applied to the samples at 10 °C with 1 Hz frequency. In the first time region, strain at LVR strain value was applied for 180 s to simulate standard force condition. Then, strains well above each LVR strains were applied for another 180 s to simulate the structural breakdown (higher force region) conditions. Finally, strains much lower than those of the LVR strains were applied for another 900 s to simulate the structural recovery region. The samples’ structural recovery abilities exposed to stress and released from the stress were determined by this test.

To determine the effects of temperature on the rheological properties of the samples, a temperature ramp test was applied. The samples were heated from 0 °C to 80 °C at 1 °C/min rate at 1 Hz frequency within the LVR with 120 s soak time. All rheological analyses were repeated.

Statistical analysis

The oleogel and emulgel samples were prepared at two different times as two replicates of preparation, and each replicate samples were analyzed for at least in duplicate and for some analyses in triplicate. The collected data were calculated as mean values with standard deviations. The Analysis of Variance (ANOVA) and Tukey’s test were completed. The level of confidence was at least 95%. Statistical analysis was performed with Minitab v.16.1 software (Minitab 2010).

Results and discussion

Physical properties

Gelation time (GT), oil binding capacity (OBC), and instrumental color values (L, a*, b*) of the oleogel and emulgel samples are presented in Table 2. As clearly be observed, once the concentrations of GMO and cholesterol enhanced from 5 to 10%, the gelation time reduced almost by half from 95.01 to 46.21 min. This is an expected result, and many previous studies reported that as organogelator addition level increases, the GT decreases (Yilmaz et al. 2015; Patel 2018). This result is technologically advantageous and time-saving, but there must be an upper limit for the organogelator addition level. Generally, a maximum of 10% (w/w) organogelator concentration is suggested by many authors (Co and Marangoni 2012; Martins et al. 2018; Sagiri et al. 2018; Marangoni et al. 2020). At higher organogelator concentrations, taste and aroma defects, health concerns, technological unfeasibility, and other problems may arise. Even in this study, 10% of cholesterol concentration may create some health concern in food applications, but this study aimed to prepare and evaluate these new oleogels and emulgels. Furthermore, in the food products, oleogels were used as part of the formulation, and their proportion decreases, which may decrease cholesterol concentrations to acceptable low levels. In addition, these new oleogels and emulgels could be investigated in non-food (cosmetics, pharmacology, delivery, etc.) areas.

The OBC is an indicator of oil loss under harsh conditions. The samples were centrifuged to drain the un-trapped liquid oil. The OBC indicates the percentages of immobilized or trapped oil after the centrifugation and might indicate the gels’ strength and capacity. All samples presented OBC values above 99%, proving quite stable gels (Table 2). These oleogels and emulgels could reasonably be stable under mechanical food processing conditions and during transportation. Almost all successful oleogels reported in the current literature had similar OBC values (Martins et al. 2018; Sagiri et al. 2018; Marangoni et al. 2020). Extended evaluations of mechanical and thermal stability were assessed by the rheological analyses below.

The color values of both the gel samples and the organogelator molecules (cholesterol and GMO) were also measured (Table 2). The L value indicates the level of brightness and ranges from 0 (dark) to 100 (full bright). As the organogelator concentration enhanced, the L value improved, but in emulgels, it was reversed, and as the added water level increased, the L value decreased slightly. The a* values indicate the redness–greenness level of the samples from positive to negative number directions. The samples had some little levels of green tones, and as organogelator and water addition levels increased, the green tones enhanced, respectively. The b* values indicate the yellowness–blueness of samples, and all samples had some yellow tones. While higher organogelator concentrations caused yellowness to decrease, higher added water in the emulgels caused yellowness to enhance (Table 2). The color and appearance of the samples could be observed in Fig. 1. Color tones and lightness of an oleogel are mainly governed by the color of stock liquid oil and the organogelators used. Since all samples were creamy-white colored, there could be no problem during actual food or non-food applications of the prepared gels.

Microstructural properties

The samples’ PLM images are provided in Fig. 2. In Fig. 2a, and b, the images of 10% GMO and cholesterol solutions are shown. The solutions were viscous liquids (Fig. 1), but no gel was present. Likewise, in the PLM images, there were no detectable amounts of crystals or aggregates. Figure 2c, and d shows the oleogel samples formed with oil: GMO: cholesterol = 90:5:5 and oil: GMO: cholesterol = 80:10:10(w/w) systems, respectively. These samples were pure oleogels without a water phase. The rectangular-shaped crystals could be observed in both samples. As organogelator (GMO: cholesterol) concentration increased (10%) in Fig. 2d, the amount of observed lipid crystalline matrices enhanced compared to Fig. 2c with 5% of the organogelator mixture (Table 1). The rectangular-shaped crystals must provide the structural framework that supports the gel networks to entrap the liquid oil. Interestingly, neither cholesterol nor GMO alone at 10% concentration produced gel, but they together resulted in a gel state even at their 5% concentrations when added together. Once the gelator concentration increased to 10%, the gel strength enhanced and the observed crystals become more crowded and inter-contacted. This two-component gel system could work in a similar mechanism explained for the sterols + monoglycerides system (Patel 2017). Accordingly, the cholesterols might have provided the rectangular-shaped crystals, and the GMO, which is an amphiphile, might have provided some structural modifications that formed the space-filling network. There should be a synergistic effect between the cholesterol and GMO, resulting in an increase of the crystalline mass and the mass’s spatial distribution. This situation could be observed from Fig. 2a–d. Clearly, there are some tiny crystals and/or aggregates in Fig. 2a, b, which are the images of 10% of cholesterol and GMO solutions alone. Since cholesterol and GMO alone would not yield stable gel, it could be said that the crystals formed by them were not enough to support the gel structure. The two components together form their own crystals, and then they self-sort to form their independent characteristic structuring units (most probably the cholesterol crystals and GMO micelles) that contribute to each other to yield a stable gel. It was also stated that (Buerkle and Rowan 2012) the ability of two-component gelators to undergo self-sorting during the molecular assembly can be conceptually achieved by using size, shape, chirality or binding motif mismatches. This type of two-component gelation was also called the self-sorting multi-component supramolecular gels (Buerkle and Rowan 2012). Similarly, rectangular-shaped sterol crystals were shown in the study of Sintang et al. (2017), in which some phytosterols (not cholesterol) and monostearate were used as the gelators. In their samples, the clusters of monostearate were quite visible, since it is a saturated monoglyceride. In this study, the observed rectangular crystals were most probably formed by the cholesterol, but the GMO could provide some sort of amphiphile micelles or could be loaded on the surfaces of cholesterol crystals to yield the space-filling network. The networks formed by the dense and cohesive crystals were quite able to entrap the liquid oil to result in an oleogel.

In the emulgel samples, water was added at 20% (Fig. 2e) and at 10% (Fig. 2f) addition levels. The water droplets encapsulated by the GMOs could be observed from the figures. In these emulgels, organogelators (GMO: cholesterol) concentration was 10% by weight (Table 1), and the structures were truly gelled. As water content increased from 10 (Fig. 2f) to 20% (Fig. 2e), the water droplet shapes became more disorderly but still in the emulsion state. Since no external emulgator added, the emulsions must be formed with the GMO as the amphiphile molecule. In these emulgels, the individual water droplets and the rectangular-shaped cholesterol crystals must have self-sorted and then created some junction zones to provide enough structuring units to contribute a strong enough network, which yielded the gel. Dense crystals, among the crystal entanglement, and the water droplets could provide enough network structure to immobilize the liquid oil. The study of Cegla-Nemirovski et al. (2015) showed the reverse lyotropic liquid crystals of GMOs in ternary mixtures with decane, water, and glycerol, which have formed an organogel. Although they have gelled decane, it was proved that the reverse lyotropic crystals were able to provide enough structuring units to gel the decane solvent. In this study, a similar system composed of sunflower oil: water: GMO might have produced the reverse lyotropic liquid crystals to support oil gelling. Besides, there were cholesterol crystals to support the network forming units to entangle to develop the stable gel.

The polymorphic types of crystals present in oleogels were determined by X-ray diffraction patterns (Fig. 3). The wide-angle peaks corresponding to the relevant short spacing are provided in Fig. 3. It was reported that the diffraction pattern obtained from a sample is the combination of all molecules found in the sample (Stahl et al. 2017; Anonymous 2019).

The official AOCS method Cj 2–95 (AOCS 2012) defines the main peaks to identify the fat crystal polymorphs. If a sample shows a single peak at around 4.2 Å, its polymorphic form is α, if a sample contains 3.8 and 4.2 Å peaks, it must be β′ polymorph, and if the peak appears at 4.6 Å position, then it should be β polymorphic form. The GMC-OJ1 sample contains a major peak at around 4.58 Å, and it must be β polymorphic form. Much smaller peaks at around 3.36, 4.80, 5.59, and 6.24 Å appears in the GMC-OJ2 sample. It could most probably contain mixtures of both β and β′ polymorphs together. These two samples differ only for the amount of added organogelator level (Table 1). The two emulgel samples (GMC-EJ1 and GMC-EJ2) contained very similar peaks at around 2.13 (2.12) Å, 3.79 (3.77) Å, 4.87 (4.84) Å, and 5.69 (5.64) Å, respectively. The GMC-EJ1 sample contained higher amounts of water, and clearly, the peaks were less intense in that sample. In both samples, the crystal polymorphs must be mixed, and both β and β′ polymorphs must be present. The number and location of the peaks in these samples seem somewhat different from single gelator oleogels and not exactly matching with the method provided locations for pure triglyceride polymorphs (Patel 2018; Martins et al. 2018; Sagiri et al. 2018). The X-ray diffraction data provided for GMO: cholesterol oleogels and emulgels could add up to the literature.

Rheological properties

The linear viscoelastic region (LVR) for each sample was determined at 0.01–100% strain range with 1 Hz frequency, 0 min soak time at 10 °C by applying an oscillatory amplitude sweep test. The LVR describes the non-destructive deformation range and the upper limit of this range. The determined LVR strain values were 0.102, 0.038, 0.103, and 0.102% for the GMC-OJ1, GMC-OJ2, GMC-EJ1, and GMC-EJ2, respectively. Afterward, the other rheological measurements were made within their determined LVR strain values. Furthermore, the sinusoidal response signals were followed at phase shift values between 45° and 90° for all samples to ensure the viscoelastic behavior.

The frequency sweep test results of the samples are presented in Fig. 4. The tests were completed at the LVR strain ranges with 0.1–100 Hz frequency and 10 °C constant temperatures. The storage modulus (G′), loss modulus (G″), and complex viscosity (η*) were determined against applied angular frequencies. The G′ represents the elastic portion of the viscoelastic behavior and describes the solid-like properties of the sample, while G″ characterizes the viscous piece and describes the liquid-like features of the sample. The stored deformation energy for G′ and the deformation energy dissipated through the internal flowing of the sample for G″ were measured. As the main rheological rule, the gelled state of a sample is always verified with G′ > G″ condition (Mezger 2014). The complex viscosity (η*) values were obtained by the software of the instrument by dividing the complex shear modulus to the angular frequency at each point and presented in the same graphics. The storage (around 900–1100 Pa) and loss (around 700–1200 Pa) moduli of the GMC-OJ1 samples were lower than those of the GMC-OJ2 (around 1400–1900 Pa and 1150–1800 Pa) sample within the applied angular frequency measurement range, respectively. This indicates that GMC-OJ2 sample is a much stronger gel than GMC-OJ1 sample.

In fact, the added organogelator level was higher in the GMC-OJ2 sample (Table 1) to provide a more strong structure. Furthermore, even the GMC-OJ2 sample was stable through the entire measuring region; the GMC-OJ1 sample lost its gelled consistency at around 100 rad/s applied angular frequency value (Fig. 4), since at that point, the loss modulus became higher than that of the storage modulus. This indicates that the GMC-OJ1 sample produced by adding 5% of each organogelator was not strong enough to stay gelled at higher frequencies applied. Since the oleogel samples’ complex viscosity decreases as applied force enhances, all display shear thinning behavior, as observed in many other waxes and ethyl cellulose oleogels (Patel 2016; Mattice and Marangoni 2018; Patel 2018). The rheological behavior of the emulgel samples was quite different. The GMC-EJ1 sample, which contains 20% water, had storage and loss moduli values closer to each other until the applied angular velocities up to 200 rad/s. Once the angular frequency was passed 200 rad/s, the storage modulus of the GMC-EJ1 sample was enhanced, just like the true gels, and hence, it seems that the GMC-EJ1 sample had a shear thickening behavior. The storage modulus of the GMC-EJ1 sample was ranged between 1 and 10 Pa until 100 rad/s angular velocity, but after that, it increased to around 800 Pa, while the loss modulus was between 1 and 10 Pa (Fig. 4). The other emulgel containing only 10% water (GMC-EJ2) had much higher storage and loss moduli values than those of the GMC-EJ1 sample, indicating a stronger gel structure. The G′ value of GMC-EJ1 sample was ranged between 1100 and 1900 Pa, and the G″ was ranged between 1050 and 1300 Pa, respectively. As the water content of the emulgel increased from 10 to 20%, the emulgel became less strong. Clearly, the GMC-OJ2 sample and the GMC-EJ2 sample are very similar and stronger enough as gels. None of the samples satisfies the G″/G′ ≤ 0.1 condition, which defines the ‘strong gel’ classification. This ratio is also called ‘loss factor’ (tan δ), and indicates resistance to syneresis if it takes a value between 0.2 and 0.3 (Mezger 2014). Hence, the samples are not in the strong gel category, and syneresis could develop over time due to the weak crystalline entanglements, as evidenced by the measured storage and loss moduli values.

Time sweep tests were completed for the samples at 10 °C constant temperature and 1 Hz frequency with strain values below and above the strain values determined at the LVR for each sample (Fig. 5). This test provides information about the stress-related recovery ability of the gel samples. To simulate the rest condition, in the first time range (180 s), the strain at LVR values were applied; in the second region (180 s), stronger shear (LVRstrain ≤ Strain) was applied to simulate structural breakdown; and in the last region (900 s), very low shear (LVRstrain ≥ Strain) was applied to simulate structural regeneration (recovery) after the crossover point. In the GMC-OJ1 and GMC-OJ2 oleogel samples, in the first region (simulating resting behavior), the storage modulus (G′) was higher than the loss modulus (G″), indicating the presence of proper gel structure. In the second time region, strong shear was applied to simulate structural breakdown, and G′ values decreased significantly, as expected. Clearly, enough deformations occurred. Finally, in the third region, the structural recovery was observed by enhancement of the storage modulus (G′) again to above the loss modulus (G″). Clearly, a structural reformation or regeneration was very obvious in the GMC-OJ2 sample, and partly present in the GMC-OJ1 sample. This type of complete time-dependent recovery of the initial state upon reducing the load is called thixotropic behavior. This behavior was observed for many plant waxes, fatty acid, and other common oleogels in previous studies (Patel 2016; Mattice and Marangoni 2018). In the emulgel samples (GMC-EJ1 and GMC-EJ2), the same situation was observed. The gels deformed by the applied higher strains in the second time region, but recovered in the third region, once the strains were reduced to under LVR strain values. The structural recovery was evident in all samples, but some noise was also present in the third region during the measurements. There must be new complex interactions within the entanglement regions of the organogelator molecules and triglycerides crystallizing upon them. The thixotropic recovery behavior proved by the time sweep tests was usually credited as an essential and desired property in food product applications, where mixing, whipping, or other mechanical breakdown operations were common in practice. Since solid fat like properties of oleogels are expected to be present in certain food products, these oleogel and emulgel samples could be used in food products where mechanical unit operations could be applied (Patel 2016; Patel and Dewettinck 2016). Furthermore, the presence of the thixotropic recovery ability could aid in other non-food applications as well.

To observe the temperature-dependent flow behavior of the samples, a temperature ramp test was completed under constant amplitude and frequency (Fig. 6). In this test, during gradual heat application, the G′ and G″ values were followed simultaneously. At the crossover point (G′ = G″), the gelled state was lost. The crossover point was reached at around 15 °C for GMC-OJ1 and 28 °C for the GMC-OJ2 sample. Clearly, as the added organogelator level increased, the thermal stability of the oleogel was increased, expectedly.

The situation in the emulgel samples was quite interesting. The GMC-EJ1 kept its gelled consistency up to 54 °C, and GMC-EJ2 was gelled until around 70 °C (Fig. 6). As observed from Fig. 6, both the G′ and G″ values of the emulgels decrease as temperature increases, but the crossover point reached relatively higher temperatures than those measured for the oleogels. Clearly, the molten material still behaves like gel until around 54 and 70 °C, possibly due to still present junction zones of the organogelator molecules. Since emulsion is a complex system, the molten mixture could be in a viscous liquid or loose gel state.

Also, after heating, the emulsion could be broken down. Furthermore, the emulgel containing a lesser amount of water (GMC-EJ2) seems more heat stable. Overall, the GMO: cholesterol gelator system oleogels were not very heat stable and must be used in products where higher heat will not be applied.

Conclusions

The oleogel forming ability of the GMO: cholesterol gelator system was proved in this study. Neither GMO nor cholesterol could create oleogel by themselves until up to 10% (w/w) concentration. However, the GMO: cholesterol (5:5, w/w) gelator system could create an oleogel. If concentration of the organogelators increase to 10% by weight, the oleogel became stronger. Furthermore, the 10% of GMO and cholesterol organogelator added system could form emulgels with 10% added to water by weight. If the water content increases to 20% by weight, the emulgel still forms but became loose and less stable. Since this study provides a new gelator system, the data provided could be essential to start further studies and investigations with this gelator system. In conclusion, this study proves the oleogelation ability of this new gelator system to be further investigated and applied.

References

Amar-Yuli I, Libster D, Aserin A, Garti N (2009) Solubilization of food bioactives within lyotropic liquid crystalline mesophases. Curr OpCollInter Sci 14:21–32. https://doi.org/10.1016/j.cocis.2008.02.001

Anonymous (2019) X-Ray Powder Diffractometry. https://lipidlibrary.aocs.org. Accessed 15 November 2019

AOCS (1998) Official methods and recommended practices Vol I and II. American Oil Chemists’ Society (4h ed.)

AOCS (2012) AOCS Official Method Cj 2-95. X-ray diffraction analysis of fats. Official Methods and Recommended Practices of the AOCS, 6th Ed. 2011–2012 Methods and Additions and Revisions

Buerkle LE, Rowan SJ (2012) Supramolecular gels formed from multi-component low molecular weight species. ChemSoc Rev 41:6089–6102. https://doi.org/10.1039/c2cs35106d

Cegla-Nemirovsky Y, Aserin A, Garti N (2015) Oleogels from glycerol-based lyotropic liquid crystals: phase diagrams and structural characterization. J Amer Oil Chem Soc 92:439–447. https://doi.org/10.1007/s11746-015-2594-7

Co ED, Marangoni AG (2012) Organogels: an alternative edible oil-structuring method. J Amer Oil Chem Soc 89:749–780. https://doi.org/10.1007/s11746-012-2049-3

Fan Y, Yang Z, Zhang X, Cao X (2013) New cholesterol-based gelator with orotate unit. SupramolChem 25(7):441–445. https://doi.org/10.1080/10610278.2013.792343

Geiger HC, Lamson M, Galka DJ (2013) Synthesis and spectroscopic characterization of chiral biphenyl-cholesterol gels. Langmuir 30:13979–13986. https://doi.org/10.1021/la503954b

Kris-Etherton PM, Krauss RM (2020) Public health guidelines should recommend reducing saturated fat consumption as much as possible: YES. Am J Clin Nutr 112:13–18. https://doi.org/10.1093/ajcn/nqaa110

Kulkarni CV, Wachter W, Iglesias-salto G, Engelskirchen S, Ahualli S (2011) Monoolein: a magic lipid? Phys ChemChem Phys 13:3004–3021. https://doi.org/10.1039/c0cp01539c

Li S, Parish EJ (1997) The chemistry of waxes and sterols. In: Akoh CC, Min DB (eds) Food lipids: chemistry, nutrition, and biotechnology. Marcel Dekker, New York, pp 89–114

Marangoni AG, van Duynhoven JPM, Acevedo NC, Nicholson RA, Patel AR (2020) Advances in our understanding of the structure and functionality of edible fats and fat mimetics. Soft Matt 16:289–306. https://doi.org/10.1039/c9sm01704f

Martins AJ, Vicente AA, Cunha RL, Cerqueira MA (2018) Edible oleogels: an opportunity for fat replacement in foods. Food Func 9:758–773. https://doi.org/10.1039/c7fo01641g

Mezger TG (2014) Applied rheology. Anton Paar GmbH, Austria

Milak S, Zimmer A (2015) Glycerol monooleate liquid crystalline phases used in drug delivery systems. Int J Pharm 478:569–587. https://doi.org/10.1016/j.ijpharm.2014.11.072

Minitab (2010) Minitab Statistical Software (Version 16.1). Minitab, Inc., State College, Pennsylvania, US

Pakseresht S, Tehrani MM (2020) Advances in multi-component supramolecular oleogels- a review. Food Rev Intdoi. https://doi.org/10.1080/87559129.2020.1742153

Patel AR (2016) Understanding the oil-gelling properties of natural waxes. INFORM 27(5):17–20. https://doi.org/10.21748/inform.06.2016.17

Patel AR (2017) A colloidal gel perspective for understanding oleogelation. Curr Op Food Sci 15:1–7. https://doi.org/10.1016/j.cofs.2017.02.013

Patel AR (2018) Oil structuring: concepts, overview and future perspectives. In: Patel AR (ed) Edible oil structuring: concept, methods and applications. Royal SocChem, Chambridge, pp 3–21

Patel AR, Dewettinck K (2016) Edible oil structuring: an overview and recent updates. Food Func 7:20–29. https://doi.org/10.1039/C5FO01006C

Sagiri SS, Samateh M, John G (2018) Biobased molecular structuring agents. In: Patel AR (ed) Edible oil structuring: concept, methods and applications. Royal SocChem, Chambridge, pp 25–52

Singh A, Auzanneau FI, Rogers MA (2017) Advances in edible oleogel technology—a decade in review. Food Res Int 97:307–317. https://doi.org/10.1016/j.foodres.2017.04.022

Sintang MDB, Rimaux T, Van de Walle D, Dewettinck K, Patel AR (2017) Oil structuring properties of monoglycerides and phytosterols mixtures. Eur J Lipid Sci Technol 119:1500517. https://doi.org/10.1002/ejlt.201500517

Stahl MA, Buscato MHM, Grimaldi R (2017) Low sat-structured fats enriched in α-linolenic acid: physicochemical properties and crystallization characteristics. J Food Sci Technol 54:3391–3403. https://doi.org/10.1007/s13197-017-2780-8

Truong T, Prakash S, Bhandari B (2019) Effects of crystallisation of native phytosterols and monoacylglycerols on foaming properties of whipped oleogels. Food Chem 285:86–93. https://doi.org/10.1016/j.foodchem.2019.01.134

Yang H-K, Wang X-M, Liu L-L, Shi H-X (2019) Design and gelation behaviors of cholesterolbased derivatives as organogelators: an investigation of the correlation between molecular structures and gelation behaviors. New J Chem 43:3366–3373. https://doi.org/10.1039/c8nj02899k

Yılmaz E, Öğütcü M, Güneser O (2015) Influence of storage on physico-chemical and volatile features of enriched and aromatized wax organogels. J Amer Oil Chem Soc 92:1429–1443. https://doi.org/10.1007/s11746-015-2719-z

Acknowledgements

This research is funded by the Scientific and Technological Council of Turkey (TÜBİTAK) with the research Project No: 217O094. We gratefully thank for the support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Keskin Uslu, E., Yılmaz, E. Preparation and characterization of oleogels and emulgels with glycerol monooleate–cholesterol mixtures. Chem. Pap. 75, 2075–2085 (2021). https://doi.org/10.1007/s11696-020-01468-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-020-01468-9