Abstract

Erythritol is a four-carbon sugar alcohol produced by microorganisms and is used as a natural sweetener in food industry. The present study aimed to examine the impact of various surfactants, including betaine, Tween 20, Tween 80, Span 20, and Triton X-100, on the production of erythritol by Trichosporonoides oedocephalis ATCC 16958. Finally, after 120 h culture via agitation, the supplementation with 0.5 g/L betaine increased the erythritol production by 50.38%, which was best among the five surfactants. Therefore, betaine was chosen for further research. Subsequently, the activity of erythrose reductase (ER) with the addition of 0.5 g/L betaine (0.211 U/mg protein) was slightly higher than that of the culture without betaine (0.192 U/mg protein) at 48 h of culture. However, no significant changes were observed in the ER activity with betaine addition during the fermentation stages. Interestingly, further observation with scanning electron microscope indicated that the disruption of cell was found in the culture without betaine, while that of the culture with 0.5 g/L betaine addition remained intact at 120 h post-cultivation. The enhanced erythritol production with betaine addition affected the cellular morphology that could be regulated effectively by zwitterionic surfactant betaine. Finally, the scale-up fermentation in 5-L bioreactor, erythritol production with initial 0.5 g/L betaine and 30 mg/L CuSO4·5H2O addition was up to 59.34 g/L, which was 19.59% higher than the control with only 30 mg/L CuSO4·5H2O supplementation (49.62 g/L). Thus, the present study demonstrated the mechanisms underlying the betaine-affected erythritol production and provided a feasible approach for improving the erythritol production by T. oedocephalis.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Erythritol is a natural four-carbon sugar alcohol with the smallest molecular weight among all sugar alcohols in nature (Guo et al. 2016). The sweetness of erythritol, about 70–80% arises from sucrose (Liu et al. 2017; Mirończuk et al. 2017); however, the caloric value is only 0.2 cal/g (Jovanović et al. 2014; Hashino et al. 2013). Therefore, erythritol plays a pivotal role as a functional sugar substitute in special diets for diabetics. In addition, because the erythritol is unfermentable for bacteria, it can be used to prevent dental caries effectively (Runnel et al. 2013). Currently, erythritol has been widely used as a food additive in the food industry in many countries (Rzechonek et al. 2018).

Owing to the properties of low-calorie and high sweetness, the demand of erythritol is gradually increasing. Presently, erythritol was commercially produced from glucose (Savergave et al. 2011), which primarily uses Moniliella pollinis (Sarkar et al. 1986), Trichosporonoides megachiliensis (Sawada et al. 2009), and Yarrowia lipolytica (Nicaud. 2012) as the production strains. Moreover, technologies, such as metal ion supplement, genetic engineering, or addition of surfactant, are being explored to stimulate the erythritol production during microbial fermentation (Lee et al. 2000; Janek et al. 2017; Rakicka et al. 2016). For example, when cultured with Torula spp., the yield of erythritol was 48.9% higher than that of the control after addition of 10 mg/L MnSO4·4H2O and 2 mg/L CuSO4·5H2O to the fermentation medium (Lee et al. 2000). Additional studies also revealed that Mn2+ alters the cell permeability, such that erythritol can be transported to the cell membrane; whereas Cu2+ increases the activity of ER and promotes erythritol biosynthesis. On the other hand, a recent study demonstrated the overexpression of the ER gene by sequence analysis, plasmid construction, cloning, and transformation in Yarrowia lipolytica. Consequently, the overexpression ER increased the production of erythritol by 20% as compared to the original strain (Janek et al. 2017). Especially, the addition of different surfactants in microbial fermentation demonstrated significant differences regarding the increasing product yield (Elisashvili et al. 2017). Usually, the surfactants introduced to culture media may increase the permeability of cellular membranes, thereby affecting the abundance of metabolites excreted by cells. Moreover, the influence of the surfactants on enzyme and protein profiles has also been reported (Koziróg et al. 2018). Another study indicated that non-ionic surfactant sorbitan monododecanoate (Span 20) might be applied as an effective stimulating agent for the erythritol production by Y. lipolytica yeast (Rakicka et al. 2016). Although several studies have investigated the effects of microbial fermentation by various surfactants, only a few have focused on the effects of zwitterionic surfactant on erythritol production.

Trichosporonoide oedocephalis is a potential erythritol-producing strain, and our previous studies found that the production of erythritol could be increased by optimizing the culture conditions or deleting the HOG1 gene (Li et al. 2016, 2018). To the best of our knowledge, the zwitterionic surfactant, betaine can combine with erythritol and induce the dissolution of Streptococcus mutans exopolysaccharide and reduce the adhesion of biofilms (Lim et al. 2017). Moreover, in the fed-batch fermentation, addition of betaine was validated to be a feasible and efficacious approach to improve l-threonine production by Escherichia coli (Su et al. 2018). Thus, in this study, we explored the effects of addition of different surfactants, including zwitterionic surfactant betaine, on polyol production and the key enzyme activities of the metabolic pathways during the fermentation process of T. oedocephalis. Simultaneously, the morphological change in the cells was observed by scanning electron microscopy (SEM), which revealed the influence of zwitterionic surfactant betaine on the cultivation of T. oedocephalis. Finally, the erythritol production by T. oedocephalis in the presence of optimal betaine supplement was verified in a 5-L fermenter.

Experimental

Microorganisms and media

Trichosporonoide oedocephalis ATCC 16958 was obtained from the American Type Culture Collection (USA). The fermentation medium for shake-flask culture consisted of 10 g/L yeast extract, 300 g/L glucose, 0.5 g/L KH2PO4, 0.5 g/L MgSO4, and 0.5 g/L NaCl. Moreover, the effects of surfactants on polyols production by T. oedocephalis were examined in shake-flask cultures, consisting of betaine, Tween 20, Tween 80, Span 20, and Triton X-100 with different addition concentrations (i.e., 0.25, 0.5, 1.0, 1.5, 2.0, and 2.5 g/L).

The scaled-up cultivation in 5-L fermenter contained 10 g/L yeast extract, 300 g/L glucose, 0.5 g/L KH2PO4, 0.5 g/L MgSO4, 0.5 g/L NaCl, 30 mg/L CuSO4·5H2O, and 0.5 g/L betaine.

Culture conditions

The seed medium was incubated for 48 h at 30 °C and 200 rpm on a shaker. Then, 10% (v/v) of the seed liquor was transferred into the fermentation medium and incubated at 30 °C and 200 rpm for 120 h.

Then, batch-fermentation was performed in a 5-L bioreactor consisting of a volume of 2-L incubated at 30 °C for 5 days. The aeration rate was 0.3 vvm, and the stirrer speed was adjusted to 350 rpm, while the pH was maintained at 4.5. During the whole fermentation process, samples were collected at 12-h intervals. All cultures were conducted in triplicate, and the results were presented as average values.

Statistical analysis

Results from independent replicate experiments are expressed as mean ± SE. The results were evaluated using One-sample t test (Originpro 8.0, USA), the level of significance was set at P < 0.05. Significant differences relative to corresponding controls are denoted by asterisks in the figures.

Analytical methods

The method used for detecting erythritol, glycerol, residual glucose, total protein concentration, and ER activities were the same as described previously (Li et al. 2018). Specifically, ER activities were measured by the reaction mixture (1 mL) containing 12 mM d-erythrose, 0.2 mM NADPH, 50 mM PB buffer (pH 6.5) and 0.1 mL cell extract. One unit of enzyme activity was defined as 1 μmol NADPH consumed per minute at 37 °C; enzyme activity was expressed as U per milligram of protein (U/mg protein). In this study, triplicate measurements were performed.

SEM

The cell morphology of T. oedocephalis was visualized by SEM (Qunata400F, FEI, USA). The sample processing was similar to that described previously with slight modifications (Deng et al. 2012; Signoretti et al. 2011). Briefly, at 96 h and 120 h, 2 mL of fermentation broth was withdrawn from the bioreactor, centrifuged, and the supernatant discarded. Subsequently, the cells were washed two times with phosphate buffer saline (PBS, pH 7.0) and fixed with 2.5% glutaraldehyde solution for 3 h. Then, the cell pellets were washed three times (pH 7.0) and dehydrated with ethanol (30%, 50%, 70%, 90%), followed by freeze-drying and treatment with ion-sputtering gold before the acquisition of SEM images.

Results and discussion

Effect of surfactants on polyol production

A previous study has shown that the surfactant Span 20 improves the production of polyols (Rakicka et al. 2016). However, the role of surfactants in erythritol synthesis by T. oedocephalis is not yet understand, and simultaneously, only a few zwitterionic surfactants have been applied in the microbial fermentation. To explore the effects of several surfactants on polyols accumulation and cell growth, a series of shake-flask cultures with glucose as the sole carbon source were investigated in this study. As shown in Fig. 1, after 120 h of culture, the yield of erythritol and glycerol was 24.71 and 11.76 g/L in the control group, respectively. The addition of surfactants visibly altered the production of polyols.

Effect of betaine on polyol production

First, when the concentration of betaine increased from 0.5 to 2.5 g/L, the level of erythritol decreased from 37.16 to 16.25 g/L after 120 h of fermentation (P < 0.05). Interestingly, the addition of 0.5 g/L betaine into fermentation medium yielded 37.16 g/L erythritol (P < 0.05), which was 50.38% higher than that of the control. The dry weight of the cell reached 35.1 g/L when betaine concentration was 0.5 g/L; this yield was maximal in the experimental group and much higher than the control group (26.5 g/L). This result indicated that 0.5 g/L of betaine promotes cell growth and facilitates erythritol accumulation. Previous reports indicated that betaine combined with erythritol forms a complex mixture and alters the cell membrane surface properties (Lim et al. 2017). Thus, the change of cellular morphology might be attributed to 0.5 g/L betaine addition in the fermentation culture. Furthermore, the large amount of glycerol generated as the main byproduct during the production of erythritol by T. oedocephalis (Li et al. 2016). Therefore, we also measured the production of glycerol. In this study, with increasing concentration of betaine, the production of glycerol increased initially and then decreased. At 2 g/L betaine concentration, the yield of glycerol was maximal at 16.21 g/L. Notably, the yields of byproduct glycerol were higher in the experimental group than the control group after the addition of zwitterionic surfactant betaine during the process of fermentation. Consequently, betaine not only improved the production of erythritol but also contributed to the synthesis of glycerol in T. oedocephalis. The results in Fig. 1 showed that 0.5 g/L betaine is beneficial to cell growth and erythritol accumulation. Strikingly, compared to the control, the yield of glycerol did not increase dramatically upon betaine addition. Thus, an appropriate addition of betaine was beneficial to erythritol biosynthesis.

Effect of Tween 20 on polyol production

On the other hand, Fig. 1 also showed that erythritol production was increased with the increasing concentration of Tween 20 from 0.5 to 1.5 g/L; as a result, the yield of erythritol increased from 19.28 to 27.89 g/L (P < 0.05). Furthermore, the erythritol production was significantly decreased when the Tween 20 concentration elevated from 1.5 g/L to 2.5 g/L. Moreover, the yield of erythritol was 27.89 g/L with the addition of 1.5 g/L Tween 20 (P < 0.05), which was 12.87% higher than that of the control. Nonetheless, a significant increase was observed in the cell dry weight in the presence of 1.5 g/L Tween 20. In addition, the glycerol production increased significantly with the addition of Tween 20, and that in the control group was high at each experimental concentration.

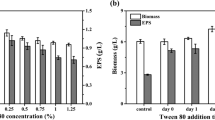

Effect of Tween 80 on polyol production

Third, at 0.5, 1.0, and 1.5 g/L Tween 80, the yield of erythritol was 29.91, 31.81, and 29.17 g/L (P < 0.05), respectively, which was higher than the control group. Conversely, the production levels of erythritol in the presence of 2.0 and 2.5 g/L Tween 80 were lower than the control. Interestingly, at all the five tested concentrations, except for 1.5 g/L Tween 80, when glycerol production was higher than the control, the others produced less glycerol than the control. Therefore, a suitable concentration of Tween 80 will reduce the production of byproduct glycerol and facilitates its downstream purification and separation.

Effect of Span 20 on polyol production

Although the addition of Span 20 to the fermentation medium inhibited the production of erythritol, the yield of glycerol was improved. Specifically, of the increase in Span 20 concentration from 0.5 to 2.5 g/L, decreased the erythritol production from 24.22 to 18.05 g/L (P < 0.05), and the level of glycerol increased from 12.13 to 15.17 g/L (P < 0.05). A previous study showed that Span 20 significantly increased the production of beta-carotene from 0.15 to 2.16 g/L in Blakeslea trispora that might be attributed to altered cell permeability, which increased the uptake of the substrate (Kim et al. 1997). Notably, the addition of 0.75 g/L Span 20 to a medium containing 30 g/L of fatty acid increased the production of oxalic acid in Aspergillus niger (Musial et al. 2006). However, the concentration of surfactants must be selected carefully as some are toxic to microorganisms and inhibit the product formation (Liu et al. 1995). Therefore, different microorganisms have different tolerance to the same substance.

Effect of Triton X-100 on polyol production

Finally, in all our experiments the addition of Triton X-100 provided a consistent yield of erythritol between 16.12 and 17.73 g/L that was relatively lower among the five tested surfactants. The other four surfactants at the same concentration, in the presence of Triton X-100, produced excessive glycerol in the fermentation system. Furthermore, at a concentration of 0.5% (v/w), Triton X-100 has a negative impact on the phytase activity and phytic acid production of Aspergillus niger A-98 (Elbatal and Karem, 2001).

The summary

Thus, neither Span 20 nor Triton X-100 was advantageous to the production of erythritol by T. oedocephalis. Nonetheless, some studies reported the effect of surfactants on the growth and metabolism of other yeasts. Surfactants, such as Tween 80 and Span 20, increased the yield of some fermentation products by destroying the plasma membrane of microorganisms. In addition, Triton X-100 not only detected the activity of enzymes in cells but also determined the amount of protein and metabolites released by cells (Sheng et al. 2013).

In general, in T. oedocephalis, the appropriate concentrations of betaine, Tween 20, or Tween 80 increased the production of erythritol, while Span 20 and Triton X-100 severely inhibited the production of erythritol. The results showed that 0.5 g/L betaine promoted the erythritol production obviously. Hence, 0.5 g/L betaine was selected as the relatively better concentration for downstream experiments to elucidate the underlying mechanism.

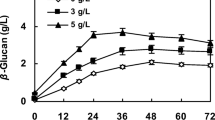

Comparative study with and without 0.5 g/L betaine

To evaluate the effect and the mechanism of zwitterionic surfactant on erythritol production by T. oedocephalis at different stages of fermentation, 0.5 g/L betaine was added to the fermentation medium, and the related fermentation parameters of the substance sampled at 24 h intervals were measured (Fig. 2). Figure 2 provides detailed fermentation process parameters. After 120 h of culture, the yields of erythritol and glycerol without 0.5 g/L betaine were 25.31 and 11.12 g/L (Fig. 2a), respectively. During fermentation, the yields of erythritol with and without 0.5 g/L betaine addition have a similar predisposition. Similarly, the cell dry weight increased rapidly in the first 24 h of culture, followed by a gradual increase. Moreover, the cell dry weight in the presence of 0.5 g/L betaine was significantly higher than that of the control after 48 h of culture. Interestingly, after 120 h of culture, the final cell dry weight with 0.5 g/L betaine reached 35.30 g/L that was a 43.22% increase compared with control (26.30 g/L).

In particular, the distinct difference in erythritol production with and without 0.5 g/L betaine increased with prolonged fermentation after 72 h (Fig. 2b). After 120 h, the addition of 0.5 g/L betaine resulted in 37.03 g/L erythritol, indicating an increase of 46.36% as compared to the control group. Moreover, glycerol yield with 0.5 g/L betaine in the fermentation medium was 12.36 g/L, which was only 11.15% higher than that of the control culture (Fig. 2b).

Erythritol biosynthesis in yeast strain is a complicated process involved multi-steps metabolic pathway, which proceeds mainly via the pentose phosphate pathway and ER catalyzes the final reaction for converting erythrose to erythritol with the utilization of one molecule of NADPH (Lee et al. 2010). Therefore, ER is hypothesized as a rate-limiting enzyme in erythritol production. At present, reports on the production of erythritol by T. oedocephalis in the medium containing zwitterionic surfactant were lacking. ER plays a critical role in the erythritol biosynthesis; thus, we carefully determined the ER activity and also explored the potential reason underlying the raised erythritol productivity induced by 0.5 g/L betaine in T. oedocephalis (Fig. 3). Consequently, the activity of ER with 0.5 g/L betaine was slightly higher than the control since 48 h. The ER activities of both groups were maximum at 48 h of culture: 0.192 U/mg proteins in the control group and 0.211 U/mg proteins in the betaine-containing group, respectively. Therefore, the addition of betaine could alter the ER activity slightly, although it might not be the main reason for a large increase in erythritol production. Another previous study showed that the enzymatic activity could be affected by surfactant supplement. For example, the activity of curdlan synthetase was greatly improved by the addition of Tween-80 (Liang et al. 2018).

To explain the possible reasons for the betaine-enhanced production of erythritol produced by T. oedocephalis, the effects of betaine on the cellular morphology of T. oedocephalis were evaluated. The samples were selected at 96 h and 120 h of culture, respectively. Figure 4a–d showed a different cellular morphology of T. oedocephalis with betaine addition as compared to that of T. oedocephalis without betaine addition. At 96 h of culture, the surface of most cells was rough and partially damaged in the control group, while the cells in the 0.5 g/L betaine-containing group were intact with a smooth surface. Subsequently, we selected yeast cells that fermented for 120 h (Fig. 4c, d). Consecutively, the cells in the control group were partially lysed and the cell surface severely damaged, while the cells with betaine addition were intact. From 96 to 120 h, the cell morphology of the control varied greatly and was damaged, and some lost the ability of polyol biosynthesis. However, in the presence of betaine, no significant changes were observed in the cell morphology at the above-mentioned time points, and the growth and metabolism might be stable. The results indicated that betaine might affect the cell growth and erythritol production by altering the surface structure of the cells. In 2017, Lim et al. demonstrated that the combination of erythritol and betaine altered the structure of the cell membrane (Lim et al. 2017). Furthermore, the addition of surfactants has been reported to change the composition of the cell membrane (Wei et al. 2016).

Scaled-up fermentation in a bioreactor with 0.5 g/L betaine addition

According to the above results, the addition of betaine (0.5 g/L) effectively stimulated the production of erythritol. Furthermore, our previous study found that the Cu2+ addition could also greatly increase the yield of erythritol in T. oedocephalis (Li et al. 2018). Fermentations were carried out in a 5-L bioreactor in the presence of 0.5 g/L betaine and the supplementation of 30 mg/L CuSO4·5H2 O. As shown in Fig. 5b, after 120 h of culture, the yield of glycerol and erythritol in the 5-L fermenter reached 30.87 g/L and 59.34 g/L, respectively. Moreover, the concentration of residual glucose presented in Fig. 5b was only 5 g/L after 120 h of fermentation. Importantly, the initial addition of 0.5 g/L betaine and CuSO4·5H2O in the fermenter increased the biosynthesis of erythritol, and after 120 h of fermentation, the yield was up to 59.34 g/L (Fig. 5b), which was better than that obtained by adding CuSO4·5H2O (49.62 g/L, Fig. 5a) alone (Li et al. 2018). After 120 h, according to previous research (Li et al. 2012), not only the glucose was exhausted but also the polyol was consumed, which leads to a decrease in the yield of erythritol. And that is why we measured the culture before 120 h. Therefore, the synergistic effect of Cu2+ and betaine could increase the yield of erythritol. Taken together, the changes in the production of polyols with betaine addition by strain T. oedocephalis suggested a simple but effective method to improve erythritol production.

Conclusions

In summary, this study investigated the effects of different surfactants on the production of erythritol by T. oedocephalis. In the few surfactants studied (betaine, Tween 20, Tween 80, Span 20 and Triton X-100), erythritol production was relatively high in the presence of 0.5 g/L betaine and reached 37.16 g/L, which was 50.38% higher than that of the control group. The further analysis of the fermentation process revealed that betaine affected the surface structure of the cells, but did not have a significant effect on the activity of erythrose reductase. Finally, with a combination of 30 mg/L CuSO4·5H2O and 0.5 g/L betaine, the erythritol concentration reached 59.34 g/L, which was relatively the largest in this study. This paper revealed the changes in the production of polyols with betaine added by T. oedocephalis, and suggesting a simple but effective method to improve erythritol production.

References

Deng H, Han Y, Liu Y, Jia W, Zhou Z (2012) Identification of a newly isolated erythritol-producing yeast and cloning of its erythritol reductase genes. J Ind Microbiol Biotechnol 39(11):1663–1672. https://doi.org/10.1007/s10295-012-1162-5

Elbatal A, Karem H (2001) Phytase production and phytic acid reduction in rapeseed meal by Aspergillus niger during solid state fermentation. Food Res Int 34:715–720. https://doi.org/10.1016/S0963-9969(01)00093-X

Elisashvili V, Kachlishvili E, Asatiani M, Darlington R, Kucharzyk K (2017) Physiological peculiarities of lignin-modifying enzyme production by the white-rot basidiomycete Coriolopsis gallica strain BCC 142. Microorganisms 5:73. https://doi.org/10.3390/Microorganisms5040073

Guo J, Li J, Chen Y, Guo X, Xiao D (2016) Improving erythritol production of Aureobasidium pullulans from xylose by mutagenesis and medium optimization. Appl Biochem Biotechnol 180:717–727. https://doi.org/10.1007/s12010-016-2127-3

Hashino E, Kuboniwa M, Alghamdi S, Yamaguchi M, Yamamoto R, Cho H, Amano A (2013) Erythritol alters microstructure and metabolomic profiles of biofilm composed of Streptococcus gordonii and Porphyromonas gingivalis. Mol Oral Microbiol 28:435–451. https://doi.org/10.1111/omi.12037

Janek T, Dobrowolski A, Biegalska A, Mirończuk A (2017) Characterization of erythrose reductase from Yarrowia lipolytica and its influence on erythritol synthesis. Microb Cell Fact 16:118. https://doi.org/10.1186/s12934-017-0733-6

Jovanović B, Mach R, Mach-Aigner A (2014) Erythritol production on wheat straw using Trichoderma reesei. AMB Express 4:34. https://doi.org/10.1186/s13568-014-0034-y

Kim S, Seo W, Park Y (1997) Enhanced synthesis of trisporic acid and β-carotene production in Blakeslea trispora by addition of a non-ionic surfactant, Span 20. J Ferment Bioeng 84:330–332. https://doi.org/10.1016/S0922-338X(97)89253-7

Koziróg A, Otlewska A, Brycki B (2018) Viability, enzymatic and protein profiles of Pseudomonas aeruginosa biofilm and planktonic cells after monomeric/gemini surfactant treatment. Molecules 23:1294. https://doi.org/10.3390/molecules23061294

Lee J, Ha S, Kim S, Oh D (2000) Increased erythritol production in Torula sp. by Mn2+ and Cu2+. Biotechnol Lett 22:983–986. https://doi.org/10.1023/a:1005672801826

Lee D, Lee Y, Ryu Y, Seo J (2010) Molecular cloning and biochemical characterization of a novel erythrose reductase from Candida magnoliae JH110. Microb Cell Fact 9:43. https://doi.org/10.1186/1475-2859-9-43

Li L, Zhang H, Fu J, Hu C, Zheng Y, Qiu Y (2012) Enhancement of ribitol production during fermentation of Trichosporonoides oedocephalis ATCC 16958 by optimizing the medium and altering agitation strategies. Biotechnol Bioprocess Eng 17:236–241. https://doi.org/10.1007/s12257-011-0359-1

Li L, Yang T, Guo W, Ju X, Hu C, Tang B, Fu J, Gu J, Zhang H (2016) Construction of an efficient mutant strain of Trichosporonoides oedocephalis with HOG1 gene deletion for production of erythritol. J Microbiol Biotechnol 26:700–709. https://doi.org/10.4014/jmb

Li L, Kang P, Ju X, Chen J, Zou H, Hu C, Yan L (2018) Enhancement of erythritol production by Trichosporonoides oedocephalis ATCC 16958 through regulating key enzyme activity and the NADPH/NADP ratio with metal ion supplementation. Prep Biochem Biotechnol 48:257–263. https://doi.org/10.1080/10826068

Liang Y, Zhu L, Gao M, Zheng Z, Wu J, Zhan X (2018) Influence of Tween-80 on the production and structure of water-insoluble curdlan from Agrobacterium sp. Int J Biol Macromol 106: 611–619. https://doi.org/10.1016/j.ijbiomac.2017.08.052

Lim J, Song S, Park H, Lee J, Lee S (2017) Spontaneous detachment of Streptococcus mutans biofilm by synergistic effect between zwitterion and sugar alcohol. Sci Rep 7:8107. https://doi.org/10.1038/s41598-017-08558-x

Liu Z, Jacobson A, Luthy R (1995) Biodegradation of naphthalene in aqueous nonionic surfactant systems. Appl Environ Microbiol 61:145–151. https://doi.org/10.1007/s00431-013-2006-7

Liu X, Lv J, Xu J, Xia J, Dai B, Xu X, Xu J (2017) Erythritol production by Yarrowia lipolytica mutant strain M53 generated through atmospheric and room temperature plasma mutagenesis. Food Sci Biotechnol 26:1–8. https://doi.org/10.1007/s10068-017-0116-0

Mirończuk A, Biegalska A, Dobrowolski A (2017) Functional overexpression of genes involved in erythritol synthesis in the yeast Yarrowia lipolytica. Biotechnol Biofuels 10:77. https://doi.org/10.1186/s13068-017-0772-6

Musial I, Rymowicz W, Witkowska D (2006) Effect of span 20 concentration on oxalic acid production from post-refining fatty acids by Aspergillus niger XP. Chem Pap 60:388–390. https://doi.org/10.2478/s11696-006-0070-4

Nicaud J (2012) Yarrowia lipolytica. Yeast 29:409–418. https://doi.org/10.1002/yea.2921

Rakicka M, Rywińska A, Cybulski K, Rymowicz W (2016) Enhanced production of erythritol and mannitol by Yarrowia lipolytica in media containing surfactants. Braz J Microbiol 47:417–423. https://doi.org/10.1016/j.bjm.2016.01.011

Runnel R, Mäkinen K, Honkala S, Olak J, Mäkinen PL, Nõmmela R, Vahlberg T, Honkala E, Saag M (2013) Effect of three-year consumption of erythritol, xylitol and sorbitol candies on various plaque and salivary caries-related variables. J Dent 41:1236–1244. https://doi.org/10.1016/j.jdent.2013.09.007

Rzechonek D, Dobrowolski A, Rymowicz W, Mirończuk A (2018) Recent advances in biological production of erythritol. Crit Rev Biotechnol 38:620–633. https://doi.org/10.1080/07388551.2017.1380598

Sarkar J, Hennebert G, Mayaudon J (1986) Optimization and characterization of an extracellular polysaccharide produced by Moniliella pollinis. Biotechnol Lett 8:319–322. https://doi.org/10.1007/BF01040857

Savergave L, Gadre R, Vaidya B, Narayanan K (2011) Strain improvement and statistical media optimization for enhanced erythritol production with minimal by-products from Candida magnoliae mutant R23. Biochem Eng J 55:92–100. https://doi.org/10.1016/j.bej.2011.03.0

Sawada K, Taki A, Yamakawa T, Seki M (2009) Key role for transketolase activity in erythritol production by Trichosporonoides megachiliensis SN-G42. J Biosci Bioeng 108:385–390. https://doi.org/10.1016/j.jbiosc.2009.05.008

Sheng L, Zhu G, Tong Q (2013) Mechanism study of Tween 80 enhancing the pullulan production by Aureobasidium pullulans. Carbohydr Polym 97:121–123. https://doi.org/10.1016/j.carbpol.2013.084

Signoretti FG, Endo MS, Gomes BP, Montagner F, Tosello FB, Jacinto RC (2011) Persistent extraradicularinfection in root-filled asymptomatic human tooth: scanning electron microscopic analysis and microbialinvestigation after apical microsurgery. J Endod 37:1696–1700. https://doi.org/10.1016/j.joen.2011

Su Y, Guo Q, Wang S, Zhang X, Wang J (2018) Effects of betaine supplementation on l-threonine fed-batch fermentation by Escherichia coli. Bioprocess Biosyst Eng 41:1509–1518. https://doi.org/10.1007/s00449-018-1978-0

Wei M, Ren Y, Liu C, Liu R, Zhang Wei Y, Xu T, Wang F, Tan T, Liu C (2016) Fermentation scale up for α-arbutin production by Xanthomonas BT-112. J Biotechnol 233:1–5. https://doi.org/10.1016/j.jbiotec.2016.05.022

Acknowledgements

The authors are grateful for the financial support from the National Natural Science Foundation of China (Grant No: 21376156, Grant No: 21676173). This study was also supported by Qing Lan Project of Jiangsu Education department. The authors are grateful for the financial support from the agricultural infrastructure project of Suzhou science and technology development plan (SNG2018046).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethical approval

This article does not contain any studies with human or animal subjects performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kang, P., Li, L., Yan, L. et al. Enhancement of erythritol production in Trichosporonoides oedocephalis by regulating cellular morphology with betaine. Chem. Pap. 73, 2065–2072 (2019). https://doi.org/10.1007/s11696-019-00766-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-019-00766-1